Abstract

This study analyses the state-of-the-art application of Life Cycle Assessment (LCA) in the production and recycling of rare earth elements (REEs), highlighting its strategic role in promoting sustainability across resource-intensive sectors. A systematic literature review (SLR) was conducted in accordance with PRISMA guidelines using the Scopus database. A total of 78 peer-reviewed studies were included, with no time restrictions applied. The review focused on studies applying LCA to REE production from both primary and secondary sources, particularly those integrating emerging digital technologies such as artificial intelligence, big data, and process simulations. Studies lacking LCA methodology or not specifically addressing REEs were excluded. The findings show that LCA, when enhanced by digital tools, serves as a key enabler for making industrial processes more sustainable by improving traceability, reducing environmental impacts, and supporting responsible decision making along the value chain. Recycling from secondary sources such as electronic waste emerges as a practical solution to reduce dependency on primary resources and to promote circular models. In particular, recycling has been shown to reduce environmental impacts by 64–96%, underscoring its effectiveness in mitigating the ecological footprint of REE production. The innovative contribution of this study lies in demonstrating how the integration of LCA and digital technologies can accelerate the transition toward more sustainable, resilient, and transparent rare earth value chains.

1. Introduction

Rare earth elements (REEs) comprise 17 elements with similar chemical properties, including scandium, yttrium, and 15 lanthanides. These elements have been identified as critical raw materials by the European Union due to their economic importance and supply risk, driven by factors such as the concentration of production in countries with weak governance, limited substitutability, and low end-of-life recycling rates [1]. In the growing global demand for advanced technology, REEs play an increasingly central role. Currently, much of their production is concentrated in China. They are used in high-tech sectors, including lighting, catalysts, permanent magnets, the automotive industry, and renewable energy sources such as wind turbines [2].

However, the increase in production has raised concerns about their environmental, economic, and social impacts, including extraction, production, reuse, recycling, and disposal [3]. In this context, identifying and promoting more sustainable practices throughout the REE lifecycle becomes crucial to mitigating these impacts. While REE production from primary sources is rising, the growing scarcity of resources makes it increasingly necessary to adopt a sustainable approach that includes secondary sources. These include mining waste, end-of-life recycling, and the management of municipal and industrial waste [4]. Electronic waste (e-waste) represents a growing challenge for the global technology industry, as the gradual phasing out of obsolete technologies has led to a significant increase in the amount of Waste Electrical and Electronic Equipment (WEEE), with harmful effects on global climate, the environment, and human health [5]. Integrating digital technologies such as artificial intelligence (AI), big data, and process simulations plays a crucial role in improving the precision and efficiency of Life Cycle Assessment (LCA) for REE production. These tools enable real-time monitoring of resource use, energy consumption, and environmental impacts throughout the REE production cycle. For instance, AI-based predictive models allow for better resource allocation and waste minimisation during extraction and processing, thereby improving production efficiency [6]. Big data technologies also facilitate monitoring emissions and waste management, leading to more comprehensive assessments of environmental performance [7]. These innovations contribute directly to sustainability by enabling cleaner, data-driven decision making that reduces environmental burdens and promotes more efficient resource use. These innovations enhance the accuracy of ecological assessments and help identify more sustainable extraction and recycling processes, optimising the entire REE production chain.

LCA is a well-established methodology used to evaluate the overall environmental impact of a product or process, considering all stages of its life cycle, from raw material extraction to disposal (cradle-to-grave). LCA is increasingly being used to evaluate REE production processes as it allows for the identification of the phases that contribute most to environmental impact, such as extraction, refining, and waste management [8]. The LCA methodology relies on specific databases and tools, such as SimaPro or GaBi, which quantify impacts in key categories, including climate change, acidification, eutrophication, and human toxicity. Additionally, recent studies have emphasised the importance of considering not only direct environmental impacts but also those related to energy consumption and the use of chemicals in production [9].

By supporting a comprehensive analysis of REE life cycles, LCA contributes significantly to the design of more sustainable and resilient supply chains. Due to the environmental impacts and growing demand for REEs, there has been a notable increase in LCA-based studies, identifying the processes most responsible for environmental impacts and suggesting more sustainable alternatives. However, LCA studies on REEs remain limited. Navarro and Zhao [6] reviewed published studies focusing exclusively on ecological aspects. With the advent of new extraction technologies and the increasing amount of research, there is now a need for an updated analysis that also considers the economic and social dimensions of REE impacts. Only one recent study [10] has addressed all three dimensions (environmental, financial, and social) using a lifecycle approach.

Finally, the review by Kossakowska and Grzesik [11] highlighted that most studies focus on primary REE sources, such as Mountain Pass (USA) and Bayan Obo (China), leaving a significant knowledge gap regarding secondary sources. Considering these gaps, the present study aims to comprehensively review LCA research in the REE sector, analysing primary and secondary sources and emerging extraction and recycling technologies.

Compared to previous studies, this article stands out for its multidisciplinary approach, addressing not only the environmental dimensions but also the economic and social aspects of REE production. Unlike past reviews, such as Navarro and Zhao [6], which focused solely on environmental elements, and Kossakowska and Grzesik [11], which focused on primary sources, this study also considers secondary sources and the crucial role of digital technologies in improving the sustainability of REE production.

Therefore, there is a significant gap in the literature concerning integrating secondary sources for REE recovery and using digital technologies in LCAs. Most studies focus on primary sources, paying little attention to the potential of emerging technologies such as AI and big data in optimising extraction and recycling processes. Additionally, there is a lack of studies considering the economic and social impacts, which are becoming increasingly relevant as REEs play a central role in sustainable technologies such as renewable energy. Filling this gap is crucial to enabling a more sustainable management of critical raw materials and supporting innovation in green technologies. This article aims to fill these gaps by adopting a holistic approach, integrating digital technologies into LCA studies to provide a more comprehensive assessment of the environmental, social, and economic impacts of REE production.

In summary, this study offers a significant contribution to sustainability in the critical raw materials sector. It addresses the lack of research on secondary sources for REE recovery, such as electronic and industrial waste, promoting circular economy models and reducing reliance on environmentally harmful primary extraction.

It also underscores the role of digital technologies (AI, big data, simulations) in enhancing LCA accuracy and enabling smarter, real-time assessments that support more sustainable decision making across the REE value chain.

By adopting a holistic approach that integrates environmental, economic, and social dimensions, this study helps redefine REE production through a sustainability lens, paving the way for more responsible and future-ready resource management.

This article is structured into several sections. Section 2, dedicated to methodology, describes the data collection process through a systematic literature review using the Scopus database, providing details on inclusion criteria and data analysis. Section 3 presents the results of the bibliometric analysis and the content of the selected articles. Section 4 discusses and interprets the results, emphasising the importance of adopting sustainable technologies and accurate assessment methodologies to reduce environmental impacts and improve the efficiency of REE supply chains. Finally, Section 5 presents the main conclusions, identifies the limitations of the research, and suggests directions for future investigations, with a particular focus on integrating emerging technologies at an industrial scale.

2. Materials and Methods

2.1. Data Collection

The authors conducted a Systematic Literature Review (SLR) to achieve the research objective, adopting a systematic and quantitative approach [12,13]. This approach allows for mapping what is known and identifying what remains unexplored [13]. Generally, a literature review focuses on synthesising existing research and empirical cases, highlighting areas that require further study [14]. A SLR is a rigorous process to minimise bias by following predefined steps and criteria for identifying, selecting, and critically evaluating studies. This approach improves the reliability and replicability of the review, providing a structured analysis of research gaps [15]. An SLR allows researchers to understand trends, confirm findings, and identify inconsistencies across multiple studies [16].

In this study, the Scopus database was used to gather material. Scopus provides access to “reliable, robust, and cross-checked data” [17,18] (p.166). It functions not only as a bibliographic database but also as a powerful search engine that indexes the contents of other major repositories, such as ACM, IEEE, Springer, AIS Electronic Library, and DBCP Computer Science Bibliography [19]. Its advanced search capabilities exceed those of many other platforms and allow for comprehensive coverage while maintaining a high level of precision. Scopus is particularly rich in content from the social sciences [20], making it especially suitable for interdisciplinary reviews. The choice of a single database, such as Scopus, ensures more precise results and greater replicability of the process, excluding the possibility of redundancies and duplications [21]. This approach has also been validated by previous research that highlights how working within a single curated database enhances methodological clarity and reduces overlap in data [22]. Moreover, Scopus is widely adopted in academic research due to its robustness and disciplinary breadth [23], and its use helps to ensure the inclusion of high-quality studies across diverse fields. Utilising a well-structured and curated database like Scopus also helps to ensure the inclusion of high-quality research from a wide range of disciplines, making it particularly suitable for interdisciplinary studies [24].

The bibliographic search was conducted using the following search string:

(TITLE-ABS-KEY) “Rare earth elements” AND “Life cycle” *

The initial inclusion criteria concerning the characteristics of scientific contributions followed the guidelines of Pickering and Byrne [12], which included the following:

- articles, conference proceedings, and book chapters;

- studies written in English;

- no time limits were set.

Additionally, applying no temporal constraints allows for including foundational and recent studies, enriching the analysis and enabling a comprehensive literature overview [25].

2.2. Data Analysis

The literature search yielded 349 records, which were collected and organised in an Excel spreadsheet [26]. For each record, the following data were systematically documented: title, authors, author affiliation, abstract, keywords, publication year, source, type of paper, research approach, purpose, and main results. Additional contextual variables such as REE source type, technological approach, and sustainability focus were also extracted to support thematic classification. This structured approach ensures that all relevant information is gathered for each study, facilitating a comprehensive and replicable analysis.

More stringent inclusion criteria were then applied to refine the selection. In line with the research objectives, the review focused on scientific contributions that employed the LCA methodology to evaluate REE production and extraction technologies from primary and secondary sources. Moreover, the methodology also considered articles discussing emerging digital technologies to improve REE production, such as adopting advanced extraction and recycling techniques through tools like artificial intelligence (AI), big data, and process simulations. Consequently, studies that discussed impacts related to rare earth elements but did not apply the LCA methodology were excluded. Similarly, articles using the LCA methodology for elements or sectors other than REE production were not considered. This filtering process significantly reduced the initial sample. Still, it ensured the inclusion of only the most relevant studies for the topic, addressing the limited number of comprehensive LCA studies in the REE sector [11].

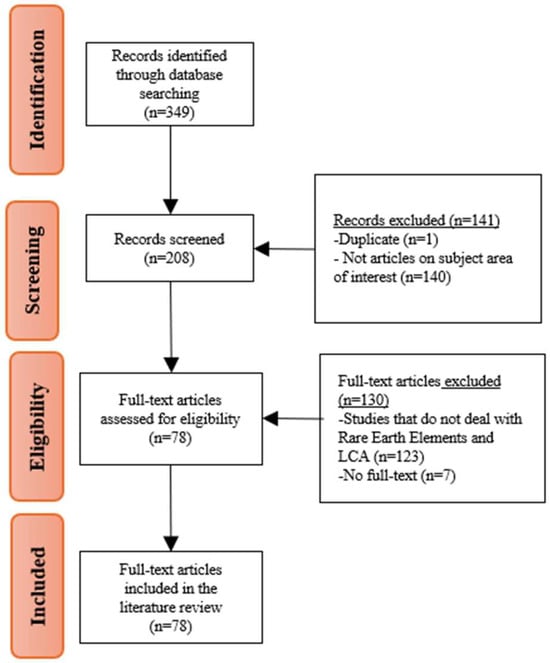

The final sample consisted of 78 records subjected to content analysis [27,28]. Content analysis involves systematically reviewing the texts to identify key findings, recurring themes, and trends in the analysed sector. This methodology allowed for a more in-depth interpretation of the data [29]. The analysis of these articles aimed to extract information regarding the environmental, economic, and social impacts of REE production and technologies, focusing on the potential of secondary sources and the integration of emerging digital technologies in production and recycling processes. No data transformations or statistical conversions were applied during the synthesis phase. Only explicitly reported data were extracted from each study. Studies with missing core methodological or outcome information were excluded during the full-text screening phase to ensure consistency and reliability in the content analysis. The findings were synthesised and organised into thematic categories through content analysis to identify recurring patterns, research gaps, and sustainability dimensions related to REE production and recycling. These themes are further developed and discussed in the Results section. This method was chosen due to the heterogeneity of the included studies in terms of the research design, objectives, and indicators used. Conceptual variation among studies was explored by grouping them thematically according to their focus on key aspects of REE production and sustainability. This approach allowed for the identification of shared patterns and differences across studies in terms of methodologies, sustainability dimensions, and technological perspectives. To ensure transparency and replicability, the review process followed the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) framework [15]. PRISMA provides a structured approach for conducting systematic reviews, offering a flowchart outlining the study identification, selection, and inclusion process. This ensures that all relevant studies are considered and the selection process is transparent and traceable. Figure 1 illustrates the PRISMA flowchart, which details the various stages of the review process, including the records identified, duplicates removed, screening results, and final study inclusion.

Figure 1.

PRISMA flow diagram (authors’ elaboration).

Following the identification and screening process illustrated in Figure 1, studies were further assessed for eligibility in the synthesis based on thematic grouping criteria (e.g., REE source type, digital technologies, sustainability dimension).

Given the heterogeneity and qualitative nature of the included studies, no formal risk of bias assessment tool was applied. However, only peer-reviewed studies with sufficient methodological detail were included. The inclusion process was conducted manually by the authors through independent screening of full texts to minimise subjectivity. No automation tools were used in this phase.

3. Results

3.1. Bibliometric Results

With the collected data, the authors developed a descriptive framework of the selected articles, highlighting three aspects relevant to the analysis: the temporal distribution, the source titles, and the co-occurrence of keywords.

Table 1 presents the temporal distribution of the selected articles for review from 2010 to 2024. Most articles were published between 2016 and 2021, with 2017 as the peak year, featuring the highest number of publications (13). This increase in research could be linked to the growing global demand for green technologies and sustainable production practices, which aligns with the interest boom in REE research during those years. Between 2010 and 2014, the number of articles was relatively low, suggesting that this research topic, related to rare earth elements and life cycle assessment, gained momentum only in recent years. Following 2017, there was a significant decline; however, the trend remained steady, with a notable number of publications continuing until 2022.

Table 1.

Temporal distribution of selected articles (authors’ elaboration).

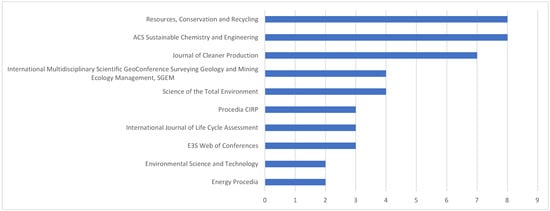

Figure 2 shows that the sources that have published the most articles are Resources, Conservation and Recycling and ACS Sustainable Chemistry & Engineering, with eight articles each, followed by the Journal of Cleaner Production, with seven.

Figure 2.

The 10 most prolific source titles.

The articles come from various sources, including scientific journals and conference proceedings. This indicates that the topic of rare earth elements and their sustainability interests diverse scientific and professional communities. Many primary sources focus on environmental sustainability, recycling, and resource management issues. This confirms the importance of these aspects in rare earth research.

Furthermore, sources such as International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, SGEM, and Science of the Total Environment indicate an interdisciplinary approach to studying rare earth elements, including environmental, economic, and social aspects.

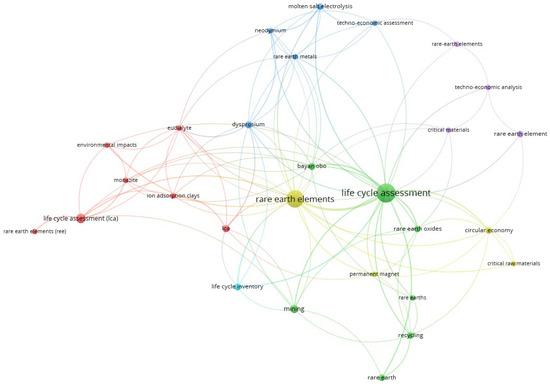

To analyse the most recurring keywords, the authors used the VOSviewer software (version 1.6.19). Figure 3 represents a co-occurrence map generated by VOSviewer, using a bibliographic dataset related to scientific production on rare earth elements LCA. The connections between the terms show the relationships between different keywords used in scientific articles, with the lines representing the strength of the links (co-occurrences) between them. Larger nodes indicate keywords with a higher frequency of use in the literature, while the colours identify thematic groups or research clusters [30]. The authors only used keywords repeated at least three times. The analysis produced 199 keywords and 53 keywords that met the inclusion criterion. The software identified six clusters.

Figure 3.

Co-occurrence network (authors’ elaboration through VOSviewer).

The Red Cluster analyses environmental impacts and applies LCA to evaluate rare earth elements. Keywords such as “life cycle assessment (LCA)”, “environmental impacts”, and “rare earth elements (ree)” indicate that this cluster explores the use of LCA to assess the ecological impacts associated with the production and processing of minerals such as “monazite” and “ion adsorption clays”. These materials are central to discussions on the environmental impacts of rare earth elements, with particular attention to the effects of extraction and processing on ecosystems and communities.

The Blue Cluster is dedicated to exploring emerging technologies for extracting and recovering rare earth elements, highlighting economic and technical aspects. Terms such as “molten salt electrolysis,” “neodymium,” “rare earth metals,” and “dysprosium” reflect interest in advanced technological solutions, such as molten salt electrolysis for rare earth separation, as well as critical elements like neodymium and dysprosium, which are essential to producing permanent magnets and other technological applications. The term “techno-economic assessment” emphasises balancing technological innovation with economic sustainability.

The Purple Cluster focuses on issues related to the economic and technical analysis of rare earth elements and critical materials. Keywords such as “rare-earth elements,” “techno-economic analysis,” and “critical materials” indicate that this cluster explores the role of rare earth elements as strategic resources and the technical and economic challenges associated with their extraction and processing. Economic evaluation becomes crucial to understanding how these materials affect not only industry but also the security of global supply chains.

The Green Cluster primarily addresses the sustainability and management of rare earth elements through LCA. Keywords such as “life cycle assessment (LCA),” “rare earth elements,” “bayan obo,” and “mining” focus on evaluating the environmental impacts throughout the entire life cycle of rare earth elements. This cluster focuses on extraction areas such as Bayan Obo, one of the largest rare earth deposits. It emphasises the importance of optimising mining practices to reduce environmental impact.

The Yellow Cluster emphasises the circular economy and recycling of rare earth elements. Keywords such as “rare earth oxides”, “circular economy”, “critical raw materials”, “rare earth”, and “recycling” highlight the importance of incorporating rare earth elements into a circular economy model to reduce dependence on primary extraction. The focus on “permanent magnet” underscores the importance of recovering permanent magnets, which are essential for many modern technologies, and recycling them to support sustainable production.

The Light Blue Cluster analyses and quantifies impacts through the Life Cycle Inventory. Keywords such as “life cycle inventory,” related to “mining,” and “rare earth oxides” indicate the importance of creating a detailed inventory that tracks the emissions and impacts of each phase of the rare earth life cycle, from extraction to production. This cluster represents the methodological foundation for accurately understanding the environmental impact of these activities, enabling informed decision making regarding sustainability.

3.2. Themes’ Analysis

The content analysis includes the title, abstract, keywords, context, purpose, main results related to the study, and future perspectives. The analysis allowed us to classify the results into four macro-categories: (1) Recycling of REEs from secondary sources; (2) Environmental, social, and economic impacts of REE production; (3) Life cycle assessment of rare earth element extraction technologies; and (4) Digital Technologies and LCA in REE production.

3.2.1. Recycling of REE from Secondary Sources

The analysis of REE recycling from secondary sources reveals a significant potential to reduce dependence on primary resources and mitigate the environmental risks of mining. In the case of e-waste, WEEE recycling represents a substantial opportunity aligned with the principles of the circular economy [31]. However, challenges emerge concerning the environmental impacts of various recovery methods. For example, electrochemical recovery (ER) processes show a lower environmental impact than pyrometallurgical and hydrometallurgical methods. However, they require rigorous control of chemical inputs, such as hydrochloric acid, to further minimise impact [32].

Additionally, using maleic acid for REE recovery contributes to mitigating environmental impacts but raises concerns regarding overall energy balance and potentially toxic waste management [32]. Hydrometallurgical extraction of precious elements from WEEE with a high concentration of rare earth elements has proven to be a viable alternative to primary resources [33]. However, high costs and technical complexities may limit widespread adoption. In the automotive industry, LCA analysis suggests that regeneration could accumulate approximately 150,000 tons of critical materials in the EU [34], though scalability may hinder such practices.

The recovery of rare earth elements from fluorescent powders has both advantages and drawbacks. On the one hand, recycling with final disposal significantly reduces direct emissions compared to processes without disposal, indicating a more efficient management of hazardous by-products [35]. On the other hand, although rare earth recovery from fluorescent powders reduces CO2 emissions up to 200 times compared to primary production, there are ecotoxic impacts that require careful assessment of risks to aquatic ecosystems [36]. Hydrometallurgical methods entail higher environmental impacts than primary production; however, these impacts can be reduced by simultaneously recovering other valuable materials [37]. This suggests that multi-material recovery could maximise environmental benefits, although technical complexities and high costs remain barriers to large-scale adoption.

The recycling of Neodymium–Iron–Boron (NdFeB) magnets is notable for its ability to reduce environmental impact by 64% to 96% compared to virgin production [38,39]. Specifically, acid-free dissolution technology reduces the global warming impact by 73% compared to traditional processes, highlighting how technological innovation can contribute to sustainability [40]. However, clean energy is crucial to optimise the environmental benefits of recycling, underscoring the need for sustainable energy policies, especially in countries with fossil fuel-based energy mixes [41].

Regarding mining waste and slag, the ENVIREE project demonstrates that mining waste can serve as a secondary source for rare earth elements while reducing the environmental impacts associated with their extraction [42]. However, ecological benefits vary significantly based on the energy sources used in the recovery process. Hydropower use, for instance, is associated with lower environmental impacts than fossil fuel energy, underscoring the importance of energy mix [43]. Regarding REE concentrates from New Kankberg waste, the most significant environmental impact is linked to the final disposal of residues; using original gold residues as input for REE production could balance the negative impact, suggesting that integrated waste management can improve overall sustainability [44].

Overall, REE recycling from secondary sources shows significant potential to reduce environmental impact and dependence on primary resources (Table 2). Still, the effectiveness of these processes depends heavily on technology, waste management, and sustainable energy use. Adopting innovative technologies, such as acid-free dissolution and using less impactful acids in hydrometallurgical processes, demonstrates the potential for improving recycling sustainability. Nonetheless, challenges related to costs, technical complexity, and energy infrastructure remain.

Table 2.

Key results from life cycle assessment studies on recycling of rare earth elements from secondary sources (source: author’s elaboration).

3.2.2. Environmental, Social, and Economic Impact of REE

The production and recycling of REEs present significant challenges and offer opportunities to improve environmental, social, and economic sustainability throughout their life cycle. The production processes for REEs generate considerable environmental impacts, including global warming, acidification, and human toxicity, particularly during the refining stages. However, these impacts vary depending on the type of mineral, the technologies used, and the reference sources in modelling. Adopting advanced technologies and making strategic choices about raw materials could reduce the overall impact. Scandium production stands out for its high impact on toxicity and global warming, highlighting the need for targeted technological innovations to manage these issues [52,53,54].

Across the different life cycle phases of REEs, the extraction and concentration of minerals such as bastnasite and monazite are less impactful than the separation and reduction phases of rare earth oxides (REO). This indicates that purification and transformation technologies require targeted improvements to make the process more sustainable. Light rare earth elements have lower environmental impacts than heavy rare earth elements, and effective chemical waste treatment is crucial for mitigating negative environmental effects [55,56].

A comparison between global producers reveals that production at Mountain Pass in the United States has the best environmental performance, primarily due to more efficient chemical management. In contrast, the production pathway in China at Bayan Obo is associated with higher impacts, especially regarding freshwater and terrestrial ecotoxicity. This discrepancy underscores the potential of advanced industrial practices and stricter environmental regulations to significantly reduce the ecological impact of REE production [56,57].

From a social perspective, REE production raises concerns about labour rights, health and safety, and human rights, especially in developing countries. Extraction processes in China and Malaysia have a higher social footprint than those in Australia and the United States, with the highest social risk observed in the Bayan Obo supply chain. This finding highlights the need for the stricter monitoring of working conditions and safety practices in contexts with weaker regulations to ensure greater equity in the REE value chain [58,59].

Economically, LCC analysis reveals that REE recycling from WEEE is generally cheaper than extraction from primary resources, providing an economically sustainable alternative under favourable market conditions. However, the economic feasibility of recycling is closely linked to material substitutability and market dynamics. Therefore, policies that incentivise recycling markets and support material substitution can strengthen the circular economy and reduce dependence on natural resources [3].

Technologically, using process simulations based on LCA in the pre-feasibility phase helps reduce environmental impacts and support informed decision making. Using clean energy sources and efficient chemical management are key factors in reducing the environmental effects of REE production and recovery. Integrating renewable energy lowers environmental impacts and represents a sustainable path for long-term production, highlighting that adopting clean energy is crucial for improving sector sustainability [60,61].

In conclusion, the analysis reveals that while significant opportunities exist to mitigate the environmental, social, and economic impacts of REE production and recycling, achieving these objectives necessitates a comprehensive approach that integrates innovative technologies, renewable energy sources, and responsible resource management practices (Table 3). The choice of energy sources, waste disposal technologies, and supply chain management policies strongly influences the overall sustainability of REEs, making coordinated progress in all these areas essential to support a transition towards more responsible and less impactful production.

Table 3.

Key impacts of rare earth element production and recycling from LCA, S-LCA, and LCC studies (source: author’s elaboration).

3.2.3. Life Cycle Assessment of Rare Earth Element Extraction Technologies

The importance of REEs for green technologies is well established; however, their extraction and production often rely on unsustainable techniques. LCA is a recognised tool for assessing these impacts [52]. Among emerging technologies, bioleaching for recovering Nd, Dy, and Pr from NIB permanent magnets shows potential, with electricity and oxalic acid as primary sources of environmental impact [76,77]. Ultrasonic-assisted bioleaching can reduce greenhouse gas emissions by up to 91% [78]. In situ leaching for REEs in ion-adsorption clays shows lower environmental impacts compared to primary minerals for some categories [53,79].

The room-temperature ionic liquid electrochemical (RTIL) process improves efficiency over molten salt electrolysis (MSE) in almost all categories except for ozone depletion [80]. MSE is the dominant method in China for neodymium and other REE metals, but it causes significant impacts in categories such as ecotoxicity and carcinogenicity [2,81]. Coal by-products rich in REEs could reduce supply risks, with biosorption emerging as a sustainable technique [82].

The liquid–liquid extraction of REEs demonstrates industrial scalability and sustainability but increases global warming potential by 67% [83]. The solvent extraction of REEs utilises reagents such as sodium hydroxide and hydrochloric acid, which significantly increase environmental impacts [78,84].

For permanent magnets, REE recycling is economically advantageous, although environmental impacts and manual disassembly allow for an almost complete recovery of magnetic material [85,86,87]. Projects like NEOHIRE reduce REE usage in wind turbines, although with considerable environmental impacts [88]. Additionally, REE recovery from phosphogypsum waste has a greater environmental impact than conventional disposal but offers potential environmental benefits from the recovered materials [89].

Finally, green technologies require REEs that are challenging to replace, with a 1% increase in green energy production resulting in a 0.18% depletion of REE reserves and a 0.90% increase in greenhouse gas emissions [90]. Table 4 summarizes the main results.

Table 4.

Environmental impacts of rare earth element extraction technologies based on life cycle assessments (source: author’s elaboration).

3.2.4. Digital Technologies and LCA in REE Production

Digital technologies, including AI, big data analysis, and process simulations, are revolutionising the precision and efficiency of LCA in the REE industry (Table 5). These tools enable a more accurate tracking of resource use, energy consumption, and environmental impacts throughout the REE production cycle. AI-driven predictive models, for instance, optimise resource allocation and minimise waste during extraction and processing, significantly enhancing production efficiency [6]. Big data technologies facilitate real-time monitoring of emissions, waste management, and resource depletion, enabling more comprehensive assessments of environmental performance [7].

Moreover, process simulation-based LCA is particularly effective when applied during the early stages of REE project development. This approach helps to reduce environmental impacts by informing decision making from the feasibility phase [59]. Such simulations, coupled with AI and big data analytics, are essential in making the REE supply chain more sustainable and transparent, allowing stakeholders to make data-driven decisions that align with sustainability goals.

One promising application of digital technologies in this field is the integration of AI with recycling processes. Digital platforms, for instance, can enhance the recovery of REEs from e-waste, thereby contributing to circular economy strategies. These platforms help optimise the recovery processes, reducing the demand for primary extraction and mitigating supply risks [95]. Simulations powered by AI can also model the environmental impacts of different recycling techniques, identifying the most sustainable practices [96].

Additionally, automated high-throughput evaluations have been used to accelerate processes like liquid–liquid extraction, enhancing the efficiency and scalability of REE production while minimising environmental impacts. These technologies allow for the development of more sustainable extraction techniques, which are critical as the global demand for REEs continues to rise [83]. Studies indicate that the use of these advanced extraction technologies can significantly reduce the greenhouse gas emissions associated with traditional methods, making them a key component in the push towards greener production processes [80].

Finally, LCI analysis highlights the role of energy and water emissions as key contributors to the environmental impacts of REE production, with the digital management of these inventories offering a more structured approach to impact reduction. Digital platforms that manage LCIs help industries adopt more sustainable practices and allow for real-time adjustments to minimise the environmental footprint of REE production [97].

Table 5.

Applications of digital technologies in REE production and life cycle assessment (source: author’s elaboration).

Table 5.

Applications of digital technologies in REE production and life cycle assessment (source: author’s elaboration).

| Digital Technology | Application in REE Production | Benefits/Outcomes | Reference(s) |

|---|---|---|---|

| Artificial Intelligence (AI) | - Predictive models to optimise resource allocation and process control; used in mineral sorting and leaching efficiency improvements. | - Minimises waste, reduces reagent use, enhances extraction precision, and increases production efficiency. | [6] |

| Big Data Analysis | - Large-scale datasets are used to enable real-time monitoring of emissions, waste treatment, and resource consumption throughout REE production chains. | - Supports comprehensive environmental assessment, enables adaptive resource management, and facilitates better sustainability oversight across production systems. | [7] |

| Process Simulation | - Applied in early stages of REE project development (feasibility phase). These AI applications are increasingly used for adaptive process control and yield prediction. | - Reduces environmental impacts and improves decision making through accurate data. This contributes to reducing environmental burden and improves economic viability of REE production. | [60] |

| AI in Recycling Processes | - Intelligent systems are used to identify, sort, and recover REEs from e-waste, leveraging algorithm-based decision making and automation within digital recycling infrastructures. | - Promotes circular economy practices, decreases reliance on primary sources, and mitigates supply chain vulnerabilities associated with rare earth materials. | [95] |

| Simulations for Recycling Techniques | - Environmental impact modelling tools are used to compare and evaluate various REE recycling methodologies to determine their ecological and economic viability. | - Identifies the most sustainable and efficient recycling pathways, guiding process improvements and encouraging environmentally responsible recovery practices. | [96] |

| Automated High-Throughput Evaluations | - Automation technologies are implemented to accelerate complex tasks such as liquid–liquid extraction by processing large numbers of experimental conditions simultaneously. | - Enhances scalability, reduces time and energy demands, and supports the development of innovative, low-impact separation and recovery technologies. | [83] |

| Life Cycle Inventory (LCI) Management | - Digital tools are deployed to manage inventories related to energy use, emissions, and water consumption during REE production and recycling stages. | - Enables structured tracking of resource flows, facilitates continuous environmental performance improvements, and supports real-time corrective measures. | [98] |

4. Discussion

The results of this analysis underscore the increasing importance of recycling REEs from secondary sources and the integration of digital technologies, such as artificial intelligence and big data, in the LCA of rare earth production. These technologies not only enhance the accuracy of environmental assessments but also facilitate more efficient resource management and mitigate the environmental impacts associated with the primary production of rare earth elements.

Recycling rare earth elements, particularly from e-waste, emerges as a promising strategy to reduce dependency on primary extraction and mitigate supply risk. The study results show that ER processes have lower environmental impacts compared to pyrometallurgical and hydrometallurgical methods [31]. However, recycling technologies are not free from negative impacts. For example, the hydrochloric acid used in the ER process and the reagents used in pyrometallurgical processes significantly contribute to environmental impacts, highlighting the need for further improvements in the selection of chemical reagents. Hydrometallurgical technologies, while useful for recovering precious metals, present higher environmental impacts due to the intensive use of water and energy. Hydrometallurgical and biosorption methods have demonstrated strong potential for the efficient and environmentally balanced recovery of REEs from electronic waste, confirming the relevance of e-waste as a sustainable secondary source [99]. Among the emerging strategies to improve the sustainability of REE recycling, microwave-assisted leaching and mechanochemical approaches are gaining traction due to their potential to reduce processing time, energy demand, and reagent use, making them viable alternatives to conventional treatments [100]. While flotation is traditionally associated with primary mineral processing, its emerging application to secondary resources remains underexplored in practice despite systematic evidence supporting its technical viability and environmental relevance in REE recovery [101].

Recycling rare earth elements from WEEE represents a significant opportunity to manage a critical waste stream according to the principles of the circular economy [30]. However, the issue of managing by-products and process residues remains open, as highlighted by the results of Ohene Opare and Mirkouei [31], which indicate that recycling must also address challenges related to toxicity and potential pollution generated by chemical separation processes. In several developing contexts, including Pakistan, the identification of industrial residues and e-waste as potential REE sources raises important considerations regarding the technical feasibility and environmental governance of recovery practices [102]. From an environmental perspective, the results indicate that rare earth element production has significant impacts in various categories, including climate change, human toxicity, and eutrophication [64]. Rare earth extraction and refining are particularly impactful stages, with high energy consumption and intensive use of chemical reagents. However, the use of recovery technologies, such as bioleaching, offers a promising solution to mitigate these impacts. Research shows that ultrasound-assisted bioleaching can reduce greenhouse gas emissions by up to 91% compared to traditional processes [78].

On the social side, rare earth production poses high risks to the health and safety of local communities, especially in developing countries where environmental and social regulations are less stringent [59]. The social impact analysis conducted by Schlör et al. [57] reveals that production processes in China, compared to those in Australia or the United States, present higher social risks, raising ethical concerns related to social justice and corporate governance in global supply chains. The analogy with conflict minerals highlights how the extraction of REEs can also be entangled with poor labour conditions and human rights violations, particularly in regions where governance is weak and oversight mechanisms are insufficient [103]. This raises serious concerns about ethical sourcing, especially as demand for rare earth elements accelerates in response to global digitalisation and energy transitions. These issues are further amplified by the uneven geography of digital production, where marginalised communities are disproportionately exposed to environmental degradation, exploitative labour, and displacement, thereby bearing the hidden costs of the global digital economy [104]. The rare earth element supply chain is particularly exposed to systemic vulnerabilities, including geopolitical tensions, market concentration, and weak labour and environmental standards in several key production regions [105]. These challenges create conditions where social risks—such as labour exploitation, regulatory non-compliance, and human rights violations—may persist unchecked, especially in opaque, multi-tiered networks. Addressing such complexity requires innovative approaches that go beyond traditional monitoring mechanisms. In this regard, digital supply chain surveillance powered by AI offers a promising direction. As highlighted by Brintrup et al. [106], AI-driven platforms can enable real-time data analysis, risk forecasting, and anomaly detection across vast supplier networks. These systems can automatically flag unethical sourcing, track material provenance, and support compliance with social and environmental standards. By embedding such technologies into REE governance frameworks, stakeholders can move toward more transparent, accountable, and socially sustainable supply chains.

The integration of digital technologies, such as AI and big data, represents a radical shift in the Life Cycle Assessment of rare earth elements. AI-driven predictive models and digital platforms enable the real-time assessment of environmental impacts while optimising resource use [6]. The ability to simulate different scenarios during the pre-feasibility phase, as illustrated by Pell et al. [60], allows for the overall reduction in a project’s environmental impacts, providing decision-making support based on accurate and up-to-date data.

Digital technologies also play a crucial role in the recycling of WEEE. AI-powered recycling process simulations enable the identification of the most sustainable methods for recovering rare earth elements from e-waste, thereby reducing the demand for primary resources and enhancing overall efficiency [96]. However, challenges remain in the large-scale implementation of these technologies, particularly concerning the energy required to power such platforms, which can contribute to environmental impacts if not optimised [76].

The results highlight that energy is a critical factor in the overall impact of rare earth production. The digital management of LCI offers a more structured approach to reducing impacts, allowing industries to monitor emissions and energy consumption in real-time [98]. However, as indicated by the study by Kossakowska and Grzesik [43], the energy used in the production of REE concentrates has variable impacts depending on the energy source, with hydropower and nuclear energy being less impactful compared to coal. This underscores the importance of selecting clean energy sources to minimise the overall environmental footprint.

5. Conclusions

This SLR provides an in-depth overview of the application of the LCA methodology in the production and recycling of REEs. It highlights that, despite the strategic importance of these materials for the global energy transition, their extraction and processing continue to generate significant environmental impacts, particularly in terms of energy consumption and material use. Recycling REEs from secondary sources, such as electronic, mining, and magnetic waste, proves to be a concrete solution to reduce dependence on primary resources and improve the overall efficiency of the REE life cycle. This supports a more circular and resource-conscious approach to managing critical raw materials, aligning with long-term sustainability objectives. At the same time, the integration of the LCA methodology with digital tools makes a significant contribution to achieving several United Nations Sustainable Development Goals (SDGs), providing a practical foundation for addressing the environmental, economic, and social challenges associated with the production and recycling of rare earth elements. Specifically, this synergy supports Goal 9 by fostering resilient infrastructure, the adoption of advanced technologies, and innovative industrial models; it reinforces Goal 12 through the optimisation of resource use and the reduction of waste across the material life cycle, promoting circular economy practices; and it contributes to Goal 13 by providing tools to quantify and reduce environmental emissions, guiding decisions toward low-impact production processes. In this way, the digitalisation of environmental assessments not only enhances the precision and transparency of analyses but also acts as a key enabler in the transition toward a more sustainable, equitable, and climate-aligned industrial system.

Emerging technologies, such as bioleaching, low-temperature electrochemical processes, and liquid–liquid extraction, show potential for reducing these impacts, although their effectiveness depends on the availability of integrated recycling policies and the use of advanced digital tools. The integration of digital technologies, including artificial intelligence, big data analytics, and process simulations, is transforming the LCA landscape by enhancing the accuracy of assessments, facilitating the real-time monitoring of consumption and emissions, and supporting informed strategic decision making for sustainability. These digital innovations not only enhance technical performance but also serve as enablers for more sustainable, adaptable, and transparent industrial systems.

Despite the methodological robustness and breadth of this analysis, the study presents some critical limitations. Firstly, there remains a lack of in-depth studies on the socio-economic impacts of REE production and recycling, which limits a comprehensive and integrated assessment of sustainability. Secondly, the quality and reliability of the data used in LCA analyses remain insufficient, with high levels of uncertainty related to waste management, data representativeness, and the lack of REE-specific characterisation factors. Finally, although promising results have emerged regarding the potential of new recycling technologies, there is still insufficient empirical evidence concerning their actual implementation in real industrial contexts, which is a crucial aspect for advancing towards more sustainable production of rare earth elements. Addressing these limitations is essential to strengthening LCA as a strategic tool for driving sustainability across REE value chains. A methodological limitation of this review is the exclusive use of the Scopus database, which may have excluded relevant studies indexed elsewhere.

Furthermore, no formal risk of bias assessment or certainty evaluation was conducted, which limits the ability to quantify the strength of the included evidence. Moreover, by focusing on studies that explicitly apply LCA methodologies, this review provides a clear and consistent framework for analysis. However, this approach may have excluded some relevant contributions related to digital optimisation and sustainability in REE production. As a result, certain aspects of the potential impact of digital technologies might be less emphasised, suggesting opportunities for future research to further explore their applicability across the full REE life cycle.

Considering the evidence and limitations identified in this analysis, future research should focus on three main areas of development (Table 6). First, it is crucial to deepen the analysis of the socio-economic impacts associated with the production and recycling of rare earth elements. Integrating LCA methodologies with economic and social assessments across the entire life cycle of REEs will enable a more comprehensive understanding of the effects on global markets and local communities, providing a complete picture of both the benefits and challenges inherent in these supply chains. This integration is fundamental to promoting inclusive and socially just sustainability transitions.

Table 6.

Future research directions (source: author’s elaboration).

Second, improving the quality and reliability of the data used in environmental assessments becomes a priority. Building more comprehensive and transparent databases, specifically dedicated to rare earth elements, combined with the adoption of advanced uncertainty management tools such as Monte Carlo analysis, will allow for more robust results and support the development of more effective, evidence-based policies. Ultimately, it will be crucial to validate the effectiveness of emerging recycling technologies in real-world industrial settings. The development of pilot studies and large-scale projects will enable the assessment of the technical feasibility, costs, and actual environmental impacts of these solutions. Such efforts will accelerate the shift toward greener, more resilient production systems based on empirical evidence. The integration of advanced digital tools, such as artificial intelligence and big data analytics, could further enhance the efficiency of production and recycling processes, making the rare earth supply chain more sustainable and resilient. Ultimately, this will help shape a future-ready REE sector that aligns industrial innovation with environmental responsibility.

Author Contributions

Conceptualization, G.C.E., R.G.M. and L.D.P.; methodology, G.C.E. and V.U.; formal analysis, G.C.E. and V.U.; writing—original draft preparation, G.C.E. and L.D.P.; writing—review and editing, R.G.M.; supervision, R.G.M. and O.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

ECS Project 0000024 Rome Technopole,—CUP [F83B22000040006], PNRR Mission 4 Component 2 Investment 1.5, funded by the European Union—NextGenerationEU.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| ER | Electrochemical Recovery |

| GHG | Greenhouse Gas |

| LCA | Life Cycle Assessment |

| HDD | Hard Disc Drive |

| LCC | Life Cycle Costing |

| LCI | Life Cycle Inventory |

| MSE | Molten Salt Electrolysis |

| NdFeB | Neodymium–Iron–Boron |

| PEGDA | Polyethylene glycol diacrylate |

| PRISMA | Preferred Reporting Items for Systematic Review and Meta-Analyses |

| REE | Rare Earth Element |

| REO | Rare Earth Oxide |

| RTIL | Room-Temperature Ionic Liquid |

| S-LCA | Social Life Cycle Assessment |

| SRL | Systematic Literature Review |

| WEEE | Waste Electrical and Electronic Equipment |

References

- Edahbi, M.; Plante, B.; Benzaazoua, M.; Cayer, A. Geoenvironmental characterization of two REE deposits: The Montviel carbonatites and Kipawa silicates. In Proceedings of the Environment and Natural Resources: Challenges and Solutions Conference, Online, 24–25 November 2021. [Google Scholar]

- Schreiber, A.; Marx, J.; Zapp, P.; Kuckshinrichs, W. Comparative life cycle assessment of neodymium oxide electrolysis in molten salt. Adv. Eng. Mater. 2020, 22, 1901206. [Google Scholar] [CrossRef]

- Filho, W.L.; Kotter, R.; Özuyar, P.G.; Abubakar, I.R.; Eustachio, J.H.P.P.; Matandirotya, N.R. Understanding rare earth elements as critical raw materials. Sustainability 2023, 15, 1919. [Google Scholar] [CrossRef]

- Viana, L.N.; Soares, A.P.S.; Guimarães, D.L.; Rojano, W.J.S.; Saint’Pierre, T.D. Fluorescent lamps: A review on environmental concerns and current recycling perspectives highlighting Hg and rare earth elements. J. Environ. Chem. Eng. 2022, 10, 108915. [Google Scholar] [CrossRef]

- Kwon, G.; Yoon, K.; Kwon, E.; Park, J.; Lee, H.; Song, H. Technical advancement in valorization of electronic waste and its contribution to establishing economic value-chain. Chem. Eng. J. 2024, 494, 153154. [Google Scholar] [CrossRef]

- Navarro, J.; Zhao, F. Life-cycle assessment of the production of rare-earth elements for energy applications: A review. Front. Energy Res. 2014, 2, 45. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Bailey, G.; Joyce, P.J.; Schrijvers, D.; Schulze, R.; Sylvestre, A.M.; Sprecher, B.; Van Acker, K. Review and new life cycle assessment for rare earth production from bastnäsite, ion adsorption clays and lateritic monazite. Resour. Conserv. Recycl. 2020, 155, 104675. [Google Scholar] [CrossRef]

- Tuncay, G.; Yuksekdag, A.; Mutlu, B.K.; Koyuncu, I. A review of greener approaches for rare earth elements recovery from mineral wastes. Environ. Pollut. 2024, 357, 124379. [Google Scholar] [CrossRef]

- Wulf, C.; Zapp, P.; Schreiber, A.; Marx, J.; Schlör, H. Lessons learned from a life cycle sustainability assessment of rare earth permanent magnets. J. Ind. Ecol. 2017, 21, 1578–1590. [Google Scholar] [CrossRef]

- Kossakowska, K.; Grzesik, K. A review of life cycle assessment studies of rare earth elements industry. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference SGEM2017, Albena, Bulgaria, 29 June–5 July 2017; Volume 17, pp. 19–25. [Google Scholar]

- Pickering, C.; Byrne, J. The benefits of publishing systematic quantitative literature reviews for PhD candidates and other early-career researchers. High. Educ. Res. Dev. 2014, 33, 534–548. [Google Scholar] [CrossRef]

- Pickering, C.; Grignon, J.; Steven, R.; Guitart, D.; Byrne, J. Publishing not perishing: How research students transition from novice to knowledgeable using systematic quantitative literature reviews. Stud. High. Educ. 2015, 40, 1756–1769. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Galvagno, M.; Dalli, D.; Galvagno, M. Theory of value co-creation: A systematic literature review. Manag. Serv. Qual. 2014, 24, 643–683. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

- Warmelink, H.; Koivisto, J.; Mayer, I.; Vesa, M.; Hamari, J. Gamification of production and logistics operations: Status quo and future directions. J. Bus. Res. 2020, 106, 331–340. [Google Scholar] [CrossRef]

- Yang, E.C.L.; Khoo-Lattimore, C.; Arcodia, C. A systematic literature review of risk and gender research in tourism. Tour. Manag. 2017, 58, 89–100. [Google Scholar] [CrossRef]

- Paré, G.; Trudel, M.C.; Jaana, M.; Kitsiou, S. Synthesizing information systems knowledge: A typology of literature reviews. Inf. Manag. 2015, 52, 183–199. [Google Scholar] [CrossRef]

- Hamari, J.; Keronen, L. Why do people play games? A meta-analysis. Int. J. Inf. Manag. 2017, 37, 125–141. [Google Scholar] [CrossRef]

- Macke, J.; Genari, D. Systematic literature review on sustainable human resource management. J. Clean. Prod. 2019, 208, 806–815. [Google Scholar] [CrossRef]

- Chadegani, A.A.; Salehi, H.; Yunus, M.M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ebrahim, N.A. A comparison between two main academic literature collections: Web of Science and Scopus databases. Asian Soc. Sci. 2013, 9, 18–26. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on conducting a systematic literature review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Følstad, A.; Kvale, K. Customer journeys: A systematic literature review. J. Serv. Theory Pract. 2018, 28, 196–227. [Google Scholar] [CrossRef]

- Pasca, M.G.; Renzi, M.F.; Di Pietro, L.; Guglielmetti Mugion, R. Gamification in tourism and hospitality research in the era of digital platforms: A systematic literature review. J. Serv. Theory Pract. 2021, 31, 691–737. [Google Scholar] [CrossRef]

- Eloranta, V.; Turunen, T. Seeking competitive advantage with service infusion: A systematic literature review. J. Serv. Manag. 2015, 26, 394–425. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analyzing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, 13–23. [Google Scholar]

- Van Eck, N.J.; Waltman, L. Manual for VOSviewer Version 1.6.11; Centre for Science and Technology Studies: Leiden, The Netherlands, 2019. [Google Scholar]

- Li, Z.; Diaz, L.A.; Yang, Z.; Jin, H.; Lister, T.E.; Vahidi, E.; Zhao, F. Comparative life cycle analysis for value recovery of precious metals and rare earth elements from electronic waste. Resour. Conserv. Recycl. 2019, 149, 20–30. [Google Scholar] [CrossRef]

- Ohene Opare, E.; Mirkouei, A. Environmental and economic assessment of a portable e-waste recycling and rare earth elements recovery process. Am. Soc. Mech. Eng. 2021, 85413, V005T05A007. [Google Scholar]

- Cesaro, A.; Gallo, M.; Moreschi, L.; Del Borghi, A. The hydrometallurgical recovery of critical and valuable elements from WEEE shredding dust: Process effectiveness in a life cycle perspective. Resour. Conserv. Recycl. 2024, 206, 107609. [Google Scholar] [CrossRef]

- Bobba, S.; Tecchio, P.; Ardente, F.; Mathieux, F.; Dos Santos, F.M.; Pekar, F. Analysing the contribution of automotive remanufacturing to the circularity of materials. In Proceedings of the 27th CIRP Life Cycle Engineering (LCE) Conference, Grenoble, France, 3–5 May 2020. [Google Scholar]

- Yang, D.; Gao, S.; Hong, J.; Ye, L.; Ma, X.; Qi, C.; Li, X. Life cycle assessment of rare earths recovery from waste fluorescent powders—A case study in China. Waste Manag. 2019, 99, 60–70. [Google Scholar] [CrossRef] [PubMed]

- Amato, A.; Becci, A.; Birloaga, I.; De Michelis, I.; Ferella, F.; Innocenzi, V.; Beolchini, F. Sustainability analysis of innovative technologies for the rare earth elements recovery. Renew. Sustain. Energy Rev. 2019, 106, 41–53. [Google Scholar] [CrossRef]

- Liu, L.; Keoleian, G.A. LCA of rare earth and critical metal recovery and replacement decisions for commercial lighting waste management. Resour. Conserv. Recycl. 2020, 159, 104846. [Google Scholar] [CrossRef]

- Jin, H.; Afiuny, P.; McIntyre, T.; Yih, Y.; Sutherland, J.W. Comparative life cycle assessment of NdFeB magnets: Virgin production versus magnet-to-magnet recycling. In Proceedings of the 23rd CIRP Life Cycle Engineering (LCE) Conference, Berlin, Germany, 8–10 June 2016. [Google Scholar]

- Jin, H.; Afiuny, P.; Dove, S.; Furlan, G.; Zakotnik, M.; Yih, Y.; Sutherland, J.W. Life cycle assessment of neodymium-iron-boron magnet-to-magnet recycling for electric vehicle motors. Environ. Sci. Technol. 2018, 52, 3796–3802. [Google Scholar] [CrossRef]

- Chowdhury, N.A.; Deng, S.; Jin, H.; Prodius, D.; Sutherland, J.W.; Nlebedim, I.C. Sustainable recycling of rare-earth elements from NdFeB magnet swarf: Techno-economic and environmental perspectives. ACS Sustain. Chem. Eng. 2021, 9, 15915–15924. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, B.; Gao, F.; Chen, W.; Nie, Z. Life cycle assessment of regeneration technology routes for sintered NdFeB magnets. Int. J. Life Cycle Assess. 2022, 27, 1044–1057. [Google Scholar] [CrossRef]

- Grzesik, K.; Kossakowska, K.; Bieda, B.; Kozakiewicz, R. Screening Life Cycle Assessment of beneficiation processes for Rare Earth Elements recovery from secondary sources. In Proceedings of the International Conference on the Sustainable Energy and Environmental Development (SEED 2017), Krakow, Poland, 14–17 November 2017. [Google Scholar]

- Kossakowska, K.; Grzesik, K. The significance of energy consumption in environmental impact of rare earth elements recovery from tailings and mining waste. In Proceedings of the Energy and Fuels 2018 Conference, Cracow, Poland, 19–21 September 2018. [Google Scholar]

- Bieda, B.; Grzesik, K. Uncertainty analysis of the life cycle inventory of rare earth elements from secondary flotation of rare earth elements in beneficiation rare earth waste from the gold processing: Case study. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference (SGEM 2017), Albena, Bulgaria, 29 June–5 July 2017; pp. 269–276. [Google Scholar]

- Agrawal, R.; Bhagia, S.; Satlewal, A.; Ragauskas, A.J. Urban mining from biomass, brine, sewage sludge, phosphogypsum and e-waste for reducing the environmental pollution: Current status of availability, potential, and technologies with a focus on LCA and TEA. Environ. Res. 2023, 224, 115523. [Google Scholar] [CrossRef]

- Hu, A.H.; Kuo, C.H.; Huang, L.H.; Su, C.C. Carbon footprint assessment of recycling technologies for rare earth elements: A case study of recycling yttrium and europium from phosphor. Waste Manag. 2017, 60, 765–774. [Google Scholar] [CrossRef]

- Jin, H.; Frost, K.; Sousa, I.; Ghaderi, H.; Bevan, A.; Zakotnik, M.; Handwerker, C. Life cycle assessment of emerging technologies on value recovery from hard disk drives. Resour. Conserv. Recycl. 2020, 157, 104781. [Google Scholar] [CrossRef]

- Karal, E.; Kucuker, M.A.; Demirel, B.; Copty, N.K.; Kuchta, K. Hydrometallurgical recovery of neodymium from spent hard disk magnets: A life cycle perspective. J. Clean. Prod. 2021, 288, 125087. [Google Scholar] [CrossRef]

- Bieda, B.; Grzesik, K.; Kozakiewicz, R.; Kossakowska, K. Life cycle environmental assessment of the production of rare earth elements from gold processing. In Proceedings of the 2017 International Conference on Energy and Environment (CIEM), Timișoara, Romania, 19–20 October 2017; pp. 134–137. [Google Scholar]

- Bieda, B.; Grzesik, K. Application of stochastic approach based on Monte Carlo (MC) simulation for life cycle inventory (LCI) of the rare earth elements (REEs) in beneficiation rare earth waste from the gold processing: Case study. In Proceedings of the International Conference on Advances in Energy Systems and Environmental Engineering (ASEE17), Wroclaw, Poland, 2–5 July 2017. [Google Scholar]

- Fritz, A.G.; Tarka, T.J.; Mauter, M.S. Technoeconomic assessment of a sequential step-leaching process for rare earth element extraction from acid mine drainage precipitates. ACS Sustain. Chem. Eng. 2021, 9, 9308–9316. [Google Scholar] [CrossRef]

- Zapp, P.; Schreiber, A.; Marx, J.; Kuckshinrichs, W. Environmental impacts of rare earth production. MRS Bull. 2022, 47, 267–275. [Google Scholar] [CrossRef]

- Deng, H.; Kendall, A. Life cycle assessment with primary data on heavy rare earth oxides from ion-adsorption clays. Int. J. Life Cycle Assess. 2019, 24, 1643–1652. [Google Scholar] [CrossRef]

- Bailey, G.; Orefice, M.; Sprecher, B.; Önal, M.A.R.; Herraiz, E.; Dewulf, W.; Van Acker, K. Life cycle inventory of samarium-cobalt permanent magnets, compared to neodymium-iron-boron as used in electric vehicles. J. Clean. Prod. 2021, 286, 125294. [Google Scholar] [CrossRef]

- Koltun, P.; Tharumarajah, A. LCA study of rare earth metals for magnesium alloy applications. In Materials Science Forum; Trans Tech Publications: Wollerau, Switzerland, 2010; Volume 654–656, pp. 803–806. [Google Scholar]

- Marx, J.; Schreiber, A.; Zapp, P.; Walachowicz, F. Comparative life cycle assessment of NdFeB permanent magnet production from different rare earth deposits. ACS Sustain. Chem. Eng. 2018, 6, 5858–5867. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P.; Hake, J.F.; Voßenkaul, D.; Friedrich, B. Environmental impacts of rare earth mining and separation based on eudialyte: A new European way. Resources 2016, 5, 32. [Google Scholar] [CrossRef]

- Schlör, H.; Zapp, P.; Marx, J.; Schreiber, A.; Hake, J.F. Non-renewable resources for the Energiewende—A social life cycle analysis. Energy Procedia 2015, 75, 2878–2883. [Google Scholar] [CrossRef][Green Version]

- Schlör, H.; Venghaus, S.; Zapp, P.; Marx, J.; Schreiber, A.; Hake, J.F. The energy-mineral-society nexus—A social LCA model. Appl. Energy 2018, 228, 999–1008. [Google Scholar] [CrossRef]

- Pell, R.; Wall, F.; Yan, X.; Li, J.; Zeng, X. Temporally explicit life cycle assessment as an environmental performance decision making tool in rare earth project development. Miner. Eng. 2019, 135, 64–73. [Google Scholar] [CrossRef]

- Zapp, P.; Marx, J.; Schreiber, A.; Friedrich, B.; Voßenkaul, D. Comparison of dysprosium production from different resources by life cycle assessment. Resour. Conserv. Recycl. 2018, 130, 248–259. [Google Scholar] [CrossRef]

- Wang, L.; Wang, P.; Chen, W.Q.; Wang, Q.Q.; Lu, H.S. Environmental impacts of scandium oxide production from rare earths tailings of Bayan Obo Mine. J. Clean. Prod. 2020, 270, 122464. [Google Scholar] [CrossRef]

- Adibi, N.; Lafhaj, Z.; Payet, J. New resource assessment characterization factors for rare earth elements: Applied in NdFeB permanent magnet case study. Int. J. Life Cycle Assess. 2019, 24, 712–724. [Google Scholar] [CrossRef]

- Weng, Z.; Haque, N.; Mudd, G.M.; Jowitt, S.M. Assessing the energy requirements and global warming potential of the production of rare earth elements. J. Clean. Prod. 2016, 139, 1282–1297. [Google Scholar] [CrossRef]

- Haque, N.; Hughes, A.; Lim, S.; Vernon, C. Rare earth elements: Overview of mining, mineralogy, uses, sustainability and environmental impact. Resources 2014, 3, 614–635. [Google Scholar] [CrossRef]

- Koltun, P.; Klymenko, V. Cradle-to-gate life cycle assessment of the production of separated mix of rare earth oxides based on Australian production route. Min. Miner. Depos. 2020, 14, 1–15. [Google Scholar] [CrossRef]

- Lima, F.M.; Lovon-Canchumani, G.A.; Sampaio, M.; Tarazona-Alvarado, L.M. Life cycle assessment of the production of rare earth oxides from a Brazilian ore. In Proceedings of the 25th CIRP Life Cycle Engineering (LCE) Conference, Copenhagen, Denmark, 30 April–2 May 2018; pp. 481–486. [Google Scholar]

- Zaimes, G.G.; Hubler, B.J.; Wang, S.; Khanna, V. Environmental life cycle perspective on rare earth oxide production. ACS Sustain. Chem. Eng. 2015, 3, 237–244. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Z.X.; Zhao, Y.; Wang, S.Q. The life cycle assessment of rare earth oxides production in Bayan Obo. J. Mech. Eng. Res. Dev. 2016, 39, 832–839. [Google Scholar]

- Schlör, H.; Zapp, P.; Marscheider-Weidemann, F.; Schuller, A.; Venghaus, S.; Hake, J.-F. The social footprint of permanent magnet production based on rare earth elements—A social life cycle assessment scenario. Energy Procedia 2017, 142, 984–990. [Google Scholar]

- Lee, J.; Choi, H.; Kim, J. Environmental and economic impacts of e-waste recycling: A systematic review. Chem. Eng. J. 2024, 494, 152917. [Google Scholar] [CrossRef]

- Sala, D.; Bieda, B. Life Cycle Inventory (LCI) Stochastic Approach Used for Rare Earth Elements (REEs), Considering Uncertainty. Inż. Miner. 2021, 1, 283–292. [Google Scholar] [CrossRef]

- Sala, D.; Bieda, B. Stochastic approach based on Monte Carlo (MC) simulation used for Life Cycle Inventory (LCI) uncertainty analysis in Rare Earth Elements (REEs) recovery. E3S Web Conf. 2022, 349, 01013. [Google Scholar] [CrossRef]

- Ratthanaphra, D.; Suwanmanee, U. Uncertainty analysis of environmental sustainability of biodiesel production using Thai domestic rare earth oxide solid catalysts. Sustain. Prod. Consum. 2019, 18, 237–249. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P. Life Cycle Assessment studies of rare earths production—Findings from a systematic review. Sci. Total Environ. 2021, 791, 148257. [Google Scholar] [CrossRef] [PubMed]

- Magrini, C.; Jagodzińska, K. Can bioleaching of NIB magnets be an answer to the criticality of rare earths? An ex-ante life cycle assessment and material flow cost accounting. J. Clean. Prod. 2022, 365, 132672. [Google Scholar] [CrossRef]

- Jin, H.; Reed, D.W.; Thompson, V.S.; Fujita, Y.; Jiao, Y.; Crain-Zamora, M.; Sutherland, J.W. Sustainable bioleaching of rare earth elements from industrial waste materials using agricultural wastes. ACS Sustain. Chem. Eng. 2019, 7, 15311–15319. [Google Scholar] [CrossRef]

- Brown, R.M.; Struhs, E.; Mirkouei, A.; Raja, K.; Reed, D. Mixed rare earth metals production from surface soil in Idaho, USA: Techno-economic analysis and greenhouse gas emission assessment. Sci. Total Environ. 2024, 944, 173945. [Google Scholar] [CrossRef]

- Vahidi, E.; Navarro, J.; Zhao, F. An initial life cycle assessment of rare earth oxides production from ion-adsorption clays. Resour. Conserv. Recycl. 2016, 113, 1–11. [Google Scholar] [CrossRef]

- Pérez-Cardona, J.R.; Huang, T.Y.; Zhao, F.; Sutherland, J.W.; Atifi, A.; Fox, R.V.; Baek, D.L. Molten salt electrolysis and room temperature ionic liquid electrochemical processes for refining rare earth metals: Environmental and economic performance comparison. Sustain. Energy Technol. Assess. 2022, 54, 102840. [Google Scholar] [CrossRef]

- Vahidi, E.; Zhao, F. Life cycle analysis for solvent extraction of rare earth elements from aqueous solutions. In Proceedings of the REWAS 2016: Towards Materials Resource Sustainability, Cancun, Mexico, 14–17 February 2016; pp. 113–120. [Google Scholar]

- Alipanah, M.; Park, D.M.; Middleton, A.; Dong, Z.; Hsu-Kim, H.; Jiao, Y.; Jin, H. Techno-economic and life cycle assessments for sustainable rare earth recovery from coal byproducts using biosorption. ACS Sustain. Chem. Eng. 2020, 8, 17914–17922. [Google Scholar] [CrossRef]

- An, L.; Yao, Y.; Hall, T.B.; Zhao, F.; Qi, L. Agile synthesis and automated, high-throughput evaluation of diglycolamides for liquid–liquid extraction of rare-earth elements. Green Chem. 2024, 26, 7188–7197. [Google Scholar] [CrossRef]

- Vahidi, E.; Zhao, F. Environmental life cycle assessment on the separation of rare earth oxides through solvent extraction. J. Environ. Manag. 2017, 203, 255–263. [Google Scholar] [CrossRef] [PubMed]

- Becci, A.; Beolchini, F.; Amato, A. Sustainable strategies for the exploitation of End-of-Life permanent magnets. Processes 2021, 9, 857. [Google Scholar] [CrossRef]

- Wall, F.; Rollat, A.; Pell, R.S. Responsible sourcing of critical metals. Elements 2017, 13, 313–318. [Google Scholar] [CrossRef]

- Sprecher, B.; Xiao, Y.; Walton, A.; Speight, J.; Harris, R.; Kleijn, R.; Kramer, G.J. Life cycle inventory of the production of rare earths and the subsequent production of NdFeB rare earth permanent magnets. Environ. Sci. Technol. 2014, 48, 3951–3958. [Google Scholar] [CrossRef]

- Berzi, L.; Dattilo, C.A.; Del Pero, F.; Delogu, M.; Gonzalez, M.I. Reduced use of rare earth elements for permanent magnet generators: Preliminary results from NEOHIRE project. In Proceedings of the AIAS 2019 International Conference on Stress Analysis, Assisi, Italy, 4–7 September 2019; pp. 961–977. [Google Scholar]

- Kulczycka, J.; Kowalski, Z.; Smol, M.; Wirth, H. Evaluation of the recovery of Rare Earth Elements (REE) from phosphogypsum waste–case study of the WIZÓW Chemical Plant (Poland). J. Clean. Prod. 2016, 113, 345–354. [Google Scholar] [CrossRef]

- Golroudbary, S.R.; Makarava, I.; Kraslawski, A.; Repo, E. Global environmental cost of using rare earth elements in green energy technologies. Sci. Total Environ. 2022, 832, 155022. [Google Scholar] [CrossRef]

- Thompson, V.S.; Gupta, M.; Jin, H.; Vahidi, E.; Yim, M.; Jindra, M.A.; Reed, D.W. Techno-economic and life cycle analysis for bioleaching rare-earth elements from waste materials. ACS Sustain. Chem. Eng. 2018, 6, 1602–1609. [Google Scholar] [CrossRef]

- Lee, J.C.; Wen, Z. Rare earths from mines to metals: Comparing environmental impacts from China’s main production pathways. J. Ind. Ecol. 2017, 21, 1277–1290. [Google Scholar] [CrossRef]

- Schulze, R.; Lartigue-Peyrou, F.; Ding, J.; Schebek, L.; Buchert, M. Developing a life cycle inventory for rare earth oxides from ion-adsorption deposits: Key impacts and further research needs. J. Sustain. Metall. 2017, 3, 753–771. [Google Scholar] [CrossRef]

- Kiran, R.; Karbalaeisaleh, F. Investigation of Life Cycle Assessment of Utilizing Waste Coal-based Feedstocks. In Proceedings of the 38th Annual International Pittsburgh Coal Conference (PCC 2021), Online, 20–23 September 2021. [Google Scholar]

- Vahidi, E.; Zhao, F. Assessing the environmental footprint of the production of rare earth metals and alloys via molten salt electrolysis. Resour. Conserv. Recycl. 2018, 139, 178–187. [Google Scholar] [CrossRef]

- Vuppaladadiyam, S.S.V.; Thomas, B.S.; Kundu, C.; Vuppaladadiyam, A.K.; Duan, H.; Bhattacharya, S. Can e-waste recycling provide a solution to the scarcity of rare earth metals? An overview of e-waste recycling methods. Sci. Total Environ. 2024, 924, 171453. [Google Scholar] [CrossRef]

- Bailey, G.; Mancheri, N.; Van Acker, K. Sustainability of permanent rare earth magnet motors in (H)EV industry. J. Sustain. Metall. 2017, 3, 611–626. [Google Scholar] [CrossRef]

- Arshi, P.S.; Vahidi, E.; Zhao, F. Behind the scenes of clean energy: The environmental footprint of rare earth products. ACS Sustain. Chem. Eng. 2018, 6, 3311–3320. [Google Scholar] [CrossRef]