Abstract

This study provides a comprehensive thermochemical characterization of common nut residues—almonds, walnuts, hazelnuts, peanuts, and pistachios shells—as potential biomass fuels, examining their chemical composition, calorific values, and emissions profiles. Their suitability as renewable energy sources was systematically assessed by verifying compliance with ISO 17225-2 standards for pellet production. The nut residues demonstrated promising energy characteristics, with higher heating values ranging from 17.75 to 19.12 MJ/kg and most samples fulfilling ISO 17225-2 classifications A1 or A2. Specifically, the walnut residues met the highest quality classification (A1), whereas the almond, hazelnut, and pistachio residues met the A2 classification, and the peanut residues were classified as B due to higher nitrogen content. A Life Cycle Assessment (LCA) was also performed to quantify the environmental impacts, focusing on CO2 emissions from energy recovery and transportation. The results showed significantly lower CO2 emissions from all the nut residues compared to fossil fuels such as coal, natural gas, fuel oil (HFO), and LPG. The almond residues exhibited the lowest total CO2 emissions at 1669.27 kg CO2 per ton, while the peanuts had the highest at 1945.93 kg CO2 per ton. Even the highest-emitting nut residues produced substantially lower emissions compared to coal, which emitted approximately 4581.12 kg CO2 per ton. These findings highlight the potential of nut residues as low-carbon, renewable energy sources, providing both environmental advantages and opportunities to support local agricultural economies.

1. Introduction

In the ongoing global pursuit of sustainable energy sources, biomass has emerged as a prominent contender. Biomass offers a renewable and environmentally friendly alternative to conventional fossil fuels. Among the diverse selection of biomass resources, nut residues, derived from peanuts, hazelnuts, walnuts, almonds, and pistachios shells, stand out as promising candidates for energetic valorization [1,2]. Their widespread abundance in various regions across the globe and structural similarities to other biomass sources, such as coconut residues, emphasize their potential for sustainable energy production [3].

Dried fruit residues represent a valuable yet often overlooked byproduct of the fruit processing industry. While these residues are typically discarded as waste, their potential as renewable energy sources remain largely untapped. Agricultural residues are excellent alternative materials as substitutes for wood because they are plentiful, widespread, and easily accessible [4,5]. By harnessing the energy-rich properties inherent in these biomasses, researchers aim to not only address waste management concerns [6] but also to contribute significantly to the transition towards a more sustainable energy landscape [7].

Thermochemical characterization forms the cornerstone of understanding the energy potential of nut residues [8]. This comprehensive analysis examines their chemical composition, heating value, combustion characteristics, and emissions profile [9,10]. Advanced techniques like pyrolysis, gasification, and combustion enable researchers to unlock the latent energy stored within these organic materials, offering profound insights into their suitability for various energy conversion processes [11,12].

Recent studies have explored innovative approaches for the energetic valorization of agricultural residues. For instance, the granulation and pyrolysis of such residues have shown strong potential to support a more circular and sustainable bioeconomy by enhancing fuel properties and facilitating handling and transport [13]. Furthermore, process conditions—particularly temperature and pressure—significantly influence the physicochemical characteristics of pyrolyzed biomass, impacting its energy efficiency and final application [14]. In addition, biochar derived from nut and fruit shells has found widespread applications across various industrial sectors, including use as a sorbent, reducing agent, and bioenergy carrier, highlighting its versatility and added value [15].

Each variety of nut residue possesses unique characteristics that influence its behavior during thermochemical conversion. Factors such as lignocellulosic content, moisture content, and elemental composition play essential roles in determining energy potential and combustion efficiency [16,17,18]. Understanding these nuances is crucial for optimizing bioenergy conversion technologies and maximizing energy yield [19,20].

Although several studies have evaluated the energetic potential of agricultural biomasses, such as walnut, almond, and hazelnut residues [1,2,3], a systematic analysis of nut residues’ compliance with ISO 17225-2 standards [21] for pellet production combined with a Life Cycle Assessment (LCA) is still limited. This study addresses this gap by conducting a comprehensive and integrated thermochemical, energetic, and environmental analysis of common nut residues in Portugal. Additionally, a preliminary LCA focusing specifically on CO2 emissions is presented, offering an initial yet realistic perspective on the potential climate benefits of using these residues as renewable energy sources.

Beyond their technical merits, the utilization of nut residues for energy production holds significant environmental and socioeconomic benefits [22]. By diverting these agricultural residues from landfills and incinerators [23], the associated greenhouse gas emissions can be mitigated, contributing substantially to climate change mitigation efforts [24,25]. Integrating nut residues into energy production systems can create new revenue streams for farmers and processors, fostering rural development and job creation while enhancing energy security and resilience [26]. Additionally, biomass plays a crucial role in current European Union (EU) strategies to mitigate climate change [27], as outlined in the green paper adopted by the Commission in 1996 [28].

Despite their underutilization, nut residues represent an accessible and homogenous biomass resource with potential for integration into existing energy systems. Their high energy content and low ash production make them suitable candidates for combustion or co-firing in small-to-medium-scale applications. However, effective integration requires addressing several challenges, including feedstock collection logistics, seasonal variability, and compatibility with current combustion technologies. The exploration of such integration pathways is particularly relevant in the context of decentralized renewable energy systems and rural bioeconomy initiatives [29].

In Portugal, the annual production of almond, walnut, hazelnut, peanut, and pistachio residues is estimated at approximately 58,000 tonnes, based on agricultural and industrial data [30,31,32,33,34,35,36]. Considering their lower heating values, this biomass corresponds to an energy potential of approximately 935 TJ per year. When compared with Portugal’s total primary energy consumption—around 863 PJ in 2023 [37]—this represents about 0.1%, entirely derived from renewable agricultural byproducts. Although modest at the national scale, this fraction could meaningfully contribute to the renewable share of the energy mix while also providing a sustainable outlet for agri-food waste. These figures underscore the potential of nut shells as a viable component in decentralized bioenergy strategies. Moreover, such residues may play a significant role in small-scale or localized applications. For example, agro-industrial operations such as nut processing and roasting facilities could reuse shell residues on-site to meet thermal demands, reducing external energy dependence and operational costs. Similarly, rural households and cooperatives could benefit from pelletized or briquetted forms of this biomass for heating purposes, particularly during the colder months. In these contexts, even a small contribution can translate into measurable energy savings and improved sustainability, aligning with circular economy principles and energy autonomy goals.

In summary, the exploration of nut residues as biomasses for energetic valorization and thermochemical characterization represents a promising possibility for advancing sustainable energy solutions and waste management practices. By examining their chemical composition, energy content, and suitability for thermochemical conversion processes, researchers can unlock new opportunities for sustainable energy production and contribute significantly to a greener, more sustainable future [38].

2. Materials and Methods

2.1. Sampling

The samples utilized in this study were sourced from the residues of the most prevalent nuts found in Portugal, including almonds, hazelnuts, walnuts, pistachios, and peanuts. These particular fruits were selected due to their widespread availability and significance within the Portuguese agricultural landscape.

Upon collection, the residues were thoroughly cleaned and dried to remove any extraneous matter and ensure uniformity across samples. Care was taken to eliminate any contaminants that could potentially affect subsequent analyses.

2.2. Proximate Analysis

Proximate analyses were conducted on all samples to determine four key properties important for biomass characterization: moisture (M), volatile matter (VM), ash (A), and fixed carbon (FC). These analyses adhered to the standards outlined in ISO 18134-1 [39], ISO 18122 [40], and ISO 18123 [41]. Each biomass yielded a representative sample, and their initial masses were recorded. These samples were subjected to a Protherm PLF 100/6 furnace set at 105 °C until reaching a stabilized weight, indicating complete moisture removal. The final mass post-drying was recorded, and moisture content in percentage was calculated based on weight variance (Equation (1)).

where is the mass, in grams, of the empty container; is the mass, in grams, of the container containing the sample before drying; and is the mass, in grams, of the container containing the sample after drying.

From the dried biomass sample used in moisture analysis, a portion was extracted and weighed. This sample was then subjected to thermal decomposition under inert atmosphere in a covered crucible in a muffle furnace at 550 °C, in accordance with ISO 18123 [40]. During this thermal treatment, volatile matter is released as a combination of gases and vapors formed by the thermal degradation of organic compounds. The percentage of volatile matter was determined by the mass loss during this step, as calculated in Equation (2).

where is the mass, in grams, of the empty container plus the lid; is the mass, in grams, of the container plus the lid containing the dried sample before thermal decomposition under inert atmosphere; and is the mass, in grams, of the container plus the lid containing the sample after thermal decomposition under inert atmosphere.

The residue from volatilization underwent ashing in a muffle furnace set at 550 °C until reaching a consistent weight, indicative of complete organic matter combustion. The ash content in percentage was then calculated using (Equation (3)).

where is the mass, in grams, of the empty container; is the mass, in grams, of the container with the sample after thermal decomposition under inert atmosphere; and is the mass, in grams, of the container with the ash.

Fixed carbon content was subsequently calculated by deducting moisture, volatile matter, and ash content from 100% (Equation (4)).

2.3. Elemental Analysis

The biomass samples underwent weighing in a tin container, and their masses were recorded. Subsequently, elemental analysis of carbon (C), hydrogen (H), nitrogen (N), and sulfur (S) contents was performed on all samples in accordance with the guidelines outlined in ISO 16948 [42], utilizing a ThermoScientific Flashsmart CHNS/O elemental analyzer. The oxygen content was determined by subtracting the contents of C, H, N, S, and ash from 100%, as expressed in Equation (5).

2.4. Calorimetry

The sample combustion was carried out using an isoperibolic calorimeter (mod. 6300, Parr Instruments Co., Moline, IL, USA) in accordance with the procedures outlined in ISO 18125 [43]. The calorimeter underwent calibration utilizing a benzoic acid standard (Benzoic Acid Parr No. 3415). The net heat value (NHV) was determined according to ISO 18125.

2.5. Biomass Evaluation System

To assess the suitability of biomass samples for energy valorization, the classification scale provided in ISO 17225-2 was used. This scale categorizes potential biomasses into three groups based on specific parameters, including ash content (A), nitrogen content (N), and moisture content (M) (Table 1). The ISO 17225 series provides precise guidelines for classifying solid biofuels, which helps facilitate efficient biofuel trading and promotes mutual understanding between buyers and sellers. Additionally, it serves as a communication tool for equipment manufacturers.

Table 1.

ISO 17225-2 standards.

2.6. Life Cycle Assessment

A Life Cycle Assessment (LCA) methodology was employed to quantify the environmental impacts associated with using nut residues (almond, walnut, hazelnut, peanut, and pistachio) as renewable energy sources. The LCA accounts for both energy recovery and transportation emissions to provide a comprehensive understanding of the CO2 emissions associated with each shell type.

In the energy recovery phase, the total energy output (in MJ) for each shell type was determined based on their respective heating values. The CO2 emissions from the samples were calculated using the results from elemental analysis, which provided data on the carbon content of each shell. By applying stoichiometric combustion equations, the total CO2 emissions per ton of shell were calculated based on the amount of carbon present in each biomass type.

Additionally, the transportation phase considered the CO2 emissions associated with transporting the residues from nut production areas to biomass energy plants. A transport distance of 400 km was assumed, which reflects the typical distances between agricultural regions and energy facilities in the country. The CO2 emissions for transportation were calculated using an emission factor of 62.1 g of CO2 per ton of biomass per kilometer, in accordance with transportation emissions data provided by the European Environment Agency [44].

To provide a comparative analysis, the emissions from fossil fuels (coal, natural gas, fuel oil, and LPG) required to generate the same energy output were calculated using standard CO2 emission factors and lower heating values (LHVs) for each fuel. For coal, the LHV was considered to be 24 MJ/kg with an associated CO2 emission factor of 0.278 kg CO2/MJ [45]. Natural gas was assigned an LHV of 50 MJ/kg with an emission factor of 0.198 kg CO2/MJ [46]. Fuel oil (HFO) was calculated using an LHV of 42.5 MJ/kg and an emission factor of 0.271 kg CO2/MJ, while LPG had an LHV of 46 MJ/kg and a CO2 emission factor of 0.228 kg CO2/MJ [45].

3. Results and Discussion

3.1. Proximate Analysis Results

The moisture content of biomass residue plays a crucial role in its suitability as fuel [47]. Higher moisture levels diminish the heating value, consequently influencing how biomass behaves during pyrolysis and the quality of the resulting products. For effective biofuel application, biomass residue should ideally maintain a moisture content below 10% [47]. Excessive moisture in biomass residue necessitates greater energy input for moisture removal, making it less efficient for pyrolysis. Consequently, the low moisture content observed in these nut residues renders them well suited for pyrolysis applications, around 7.3 to 9.3% (Table 2).

Table 2.

Results of proximate analysis.

VM and FC contents are crucial factors for assessing the ignition and subsequent gasification or oxidation characteristics of biomass, depending on its intended use as an energy source [48,49]. Biomass with higher VM content tends to be more reactive, readily volatilizing and producing less char. This makes the studied residues particularly suitable for pyrolysis processes, facilitating biofuel production [48,49]. The FC contents of the residues ranged from 20% to 29%, showing somewhat high values compared to the other biomass values [50].

Elevated ash levels in biomass can significantly diminish the fuel’s energy content. Moreover, during thermochemical conversion processes, the chemical composition of the ash can lead to operational challenges, such as slag formation during combustion at high temperatures [51]. The observed ash content levels in these samples fell comfortably within acceptable ranges, making them highly suitable for combustion and pyrolysis conversion processes [52].

The almond residues exhibited lower percentages of FC and VM compared to those reported by [18]. The results for the walnut residues indicate lower volatile matter and ash content, but a higher fixed carbon percentage, compared to the values reported in [53], which were 70%, 1.26%, and 15.895%, respectively.

The hazelnut residues, in comparison to the findings of [38], differed only in moisture and ash content, with values of 3.96% and 8.70%, respectively. The peanut residues exhibited substantial differences across all parameters in contrast with the study by [54]. Particularly noteworthy were the high VM (84.90%) and FC (13.40%) percentages on a dry basis.

Lastly, in the case of the pistachio residues, these results diverged from the analysis conducted by [55], revealing higher VM values but lower FC and moisture levels.

3.2. Elemental Analysis Results

Within the chemical composition of fuel, carbon stands as a fundamental element [56]. The quality of fuel is significantly influenced by its carbon content, as higher levels typically denote superior quality [56]. Hydrogen, the second most significant component in fuel, contributes greatly to its thermal value, manifesting in a visible flame upon combustion. Oxygen, on the other hand, diminishes the heating value of fuel [56]. From an environmental perspective, nitrogen’s presence can contribute to the elevation of greenhouse gases, rendering it an undesirable element within biomass [57,58]. Sulfur is typically found in trace amounts within biomass [59].

Comparing the composition of these almond residues to those studied by [18], only insignificant differences were observed, except for the oxygen content, which was higher at 41.6% (Table 3). Similarly, the walnut residue results showed minimal difference when compared with those of [53], with the results of this study being 5% higher.

Table 3.

Elemental analysis results.

Comparing the results of hazelnut residues to the values reported by [38], only a small difference was found. However, when contrasted with [18], more significant variations emerged, particularly in carbon content at 51.2% and oxygen content at 40%.

In the case of the peanut residues, these results closely resembled those of the study by [54], with the most notable difference being the carbon content, which stood at 46%.

Lastly, when comparing the pistachio residues to the values reported by [55], minimal differences were noted, with the primary distinction being a 4% lower carbon content and a 4% higher oxygen content.

3.3. Calorimetry Results

The higher heating values (HHVs) of the residues ranged from 13.8 to 18.45 MJ/kg, falling closely within the range typical of biomass with substantial heating values and high-quality lignite coals [60] (Table 4).

Table 4.

Calorimetry results.

Comparing these findings with those from the literature, several differences emerge. The almond residues presented a lower HHV than that reported by [18], which was 20.58 MJ/kg. Conversely, the results from the walnut residues were similar, although slightly higher, than those of [53], who reported an HHV of 17.93 MJ/kg. The HHV of the hazelnut residues exhibited minimal deviation from the results of [18], which stood at 19.09 MJ/kg.

For residues that presented higher HHV values, the peanuts demonstrated a slightly elevated HHV and LHV compared to those reported by [54], which were 18.547 MJ/kg and 17.111 MJ/kg, respectively. The results for the pistachio residues were very similar in comparison to the research by [55], with an HHV of 17.522 MJ/kg.

Table 5 and Table 6 show the compilation of the thermo-chemical composition of the studied residues and of the more commonly utilized biomasses for energy production.

Table 5.

Proximate analysis and calorimetry results of various biomasses.

Table 6.

Elemental analysis results of various biomasses.

The sample values closely align with those of common biomasses in terms of composition and characteristics, often displaying comparable or even superior results. When compared to wood, one of the oldest and most prevalent biomasses, the primary differences are higher carbon content and lower oxygen content, resulting in a noticeable variance in the O/C ratio, while the H/C ratio remains consistent. Although the higher heating value (HHV) results are slightly lower than those of wood, they remain close.

In elemental analysis, the samples exhibit satisfactory results. Compared to wood, they demonstrate lower ash percentages, indicating favorable biomass quality. However, they display lower fixed carbon percentages, consequently resulting in a reduced volatile matter to fixed carbon (VM/FC) ratio.

Assessing the suitability of the nut residue samples for energy valorization, using the classification scale provided in the ISO 17225-2 [31] standards for the studied characteristics, the samples were categorized accordingly (Table 7). Notably, the walnut shell meets all the criteria for Class A1 classification. Three of the samples (almond, hazelnut, and pistachio residues) meet all the requirements for Class A2 classification. However, the peanut shell only qualifies for Class B classification due to the high nitrogen content.

Table 7.

ISO 17225-2 evaluation.

3.4. Life Cycle Assessment Results

The Life Cycle Assessment (LCA) presented in this study primarily aims to quantify the carbon dioxide (CO2) emissions associated with the use of nut residues as a bioenergy source. The assessment is structured around two main stages: (i) emissions resulting from the energy conversion of biomass (direct combustion) and (ii) emissions associated with the transportation of biomass to the point of use. To allow a scientifically valid comparison with fossil fuels, all the results are expressed in terms of specific emissions, i.e., kilograms of CO2 per megajoule (kg CO2/MJ) of useful energy produced. Transport emissions were estimated assuming a 400 km average distance by heavy-duty diesel truck, reflecting typical national logistics in Portugal, where biomass residues are transported from production regions in the north and south to central processing facilities. This yields an emission factor of 24.84 kg CO2 per tonne of biomass transported. Although transport emissions represent a smaller proportion of the total emissions compared to production, they still constitute an important factor, particularly for products that require long-distance transportation.

Table 8 highlights the carbon footprint associated with both the energy recovery and transportation phases for various shell types. Peanuts exhibit the highest CO2 emissions at 1945.93 kg, followed by walnuts (1750.82 kg) and pistachios (1811.26 kg). Almonds and hazelnuts have slightly lower production emissions, at 1669.27 kg and 1694.74 kg, respectively.

Table 8.

Carbon footprint associated with the energy recovery and transportation of the various shell types.

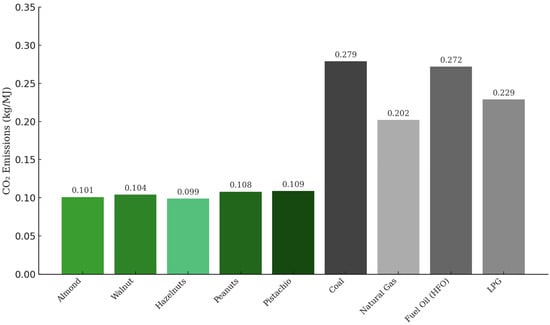

Figure 1 illustrates the specific emissions (kg CO2/MJ) of the different nut residues—almond, walnut, hazelnut, peanut, and pistachio—compared to the four most common fossil fuels: coal, natural gas, heavy fuel oil (HFO), and liquefied petroleum gas (LPG). To ensure methodological consistency, the fossil fuel values include both direct combustion emissions and transport-related emissions, based on average distribution distances reported in the literature (100 km for natural gas and HFO, 150 km for coal and LPG) [67,68,69].

Figure 1.

CO2 emissions (kg/MJ) associated with energy production from nut residues and fossil fuels.

The results show significant differences between fossil fuels and nut residues. On average, the nut residues exhibit specific emissions ranging from 0.099 to 0.109 kg CO2/MJ, with hazelnut as the lowest and pistachio as the highest emitter. In contrast, coal and HFO exceed 0.27 kg CO2/MJ, underscoring the high environmental impact of conventional fossil fuels. Natural gas is the least carbon-intensive fossil fuel (0.202 kg CO2/MJ), yet it is still notably higher than the average emissions of nut-based biomass.

Previous research supports the energy potential of nut shell residues. For instance, pyrolysis studies on pistachio, almond, and walnut shells demonstrated favorable thermal degradation behavior, with activation energies between 102 and 121 kJ/mol [70]. Other studies highlight positive carbon balances—e.g., biochar production from walnut shells offset 107.7 kg CO2-eq per tonne of feedstock [71], while almond byproduct energy systems achieved net emissions of just 0.9 kg CO2-eq/kg through energy displacement effects [72].

The findings from this study complement the existing research, reinforcing the viability of using agricultural byproducts in bioenergy systems to achieve carbon reductions and promote sustainable energy practices.

Despite the relevance of these findings, it is important to acknowledge the limitations of this assessment. The present LCA focuses solely on CO2 emissions, excluding other relevant environmental impacts such as water consumption, land use, biodiversity loss, or acidification potential. Furthermore, the assumed transport distances are average values drawn from the literature, representing a balance between geographical representativeness and methodological comparability. A more comprehensive assessment—including full environmental impact categories or multi-criteria LCA—will be essential to fully evaluate the sustainability of using these residues for bioenergy purposes.

Based on the estimated availability of 56,683 tonnes of nut residues annually and their lower heating value (LHV), the energy potential reaches approximately 259.89 GWh per year. Assuming substitution of fossil thermal fuels such as natural gas (≈41.73 EUR/MWh [73]), the avoided energy cost is estimated at ~10.85 million EUR/year, or ~191.5 EUR/tonne of biomass). The cost estimates for biomass valorization were based on typical values from the technical literature and reports: 0–20 EUR/tonne for biomass acquisition (as these are low-value agricultural residues) [74], 32 EUR/tonne for transport over 400 km, and ~64 EUR/tonne for drying and shredding operations [74]. This results in a total cost range of 50 to 116 EUR/tonne, yielding an estimated net profit margin of ~75.5 to 141.5 EUR/tonne. Overall, this simplified economic analysis supports the viability and competitiveness of using nut residues as a local renewable energy resource.

While the present study demonstrates the environmental and economic potential of using nut residues for energy production, it is important to consider the challenges associated with scaling up these practices to an industrial level. Based on national estimates, Portugal may generate approximately 56,683 tonnes of such residues annually, corresponding to an energy potential of nearly 260 GWh. Although this is a relevant contribution to the renewable energy portfolio, large-scale utilization would require the establishment of efficient logistics chains, preprocessing infrastructure (e.g., drying and grinding), and possibly the creation of regional biomass aggregation centers. These factors, combined with the seasonality and geographical dispersion of production, highlight the need for targeted policy and investment to enable scalability within the national energy system.

4. Conclusions

This study highlights the potential of common nut residues—including almonds, walnuts, hazelnuts, peanuts, and pistachios—as a renewable energy source. Through comprehensive chemical and energy analyses, the suitability of these residues for energy production was assessed. The findings reveal promising characteristics, with some samples meeting high-quality standards comparable to established biomass sources. Most residues classify well on the ISO 17225-2 scale for pellet production, reinforcing their viability for energy use. Although the energy values of these residues do not surpass those of traditional biomass sources, the results demonstrate their potential as alternative energy sources, offering both environmental benefits and the opportunity to support local agricultural economies.

The Life Cycle Assessment (LCA) further expands on this by evaluating the CO2 emissions associated with both energy recovery and transportation of these residues. The results show that using nut residues as biomass can significantly reduce carbon emissions compared to traditional fossil fuels such as coal, natural gas, fuel oil (HFO), and LPG. Among the residues studied, peanuts exhibited the highest CO2 emissions during energy recovery, at 1921.09 kg CO2 per ton, while almonds showed the lowest emissions at 1644.43 kg CO2 per ton. However, even the highest-emitting shell types produced considerably lower CO2 emissions than coal, which emits 4581.12 kg CO2 to produce the same energy as 1 ton of almond residues alone.

When considering both energy recovery and transport emissions, the total LCA results further demonstrate the environmental benefits of using biomass. Transport emissions, although smaller in comparison to energy recovery emissions, are still a significant factor, especially when large distances are involved in the supply chain. Almonds exhibited the lowest total LCA emissions, while peanuts and pistachios were the most carbon-intensive. Nonetheless, all shell types offer a significant reduction in carbon emissions when compared to fossil fuels, making them viable candidates for sustainable energy production.

Overall, this study underscores the potential for nut residues to serve as a renewable alternative to fossil fuels, contributing to both carbon footprint reduction and local economic support through agricultural byproducts. However, further research is needed to explore the full potential of nut biomass in larger-scale applications and to assess other environmental impacts, such as land use and water consumption. By leveraging this abundant and often underutilized resource, nut residues could play an important role in advancing sustainable energy solutions and supporting the global transition toward greener energy systems.

Author Contributions

Conceptualization, A.D.d.S.B.; methodology, A.D.d.S.B.; validation, A.D.d.S.B.; formal analysis, A.D.d.S.B. and M.O.; investigation, A.D.d.S.B., J.H.B. and M.O.; resources, A.D.d.S.B.; data curation, A.D.d.S.B. and M.O.; writing—original draft preparation, J.H.B.; writing—review and editing, A.D.d.S.B. and M.O.; supervision, A.D.d.S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hebda, T.; Brzychczyk, B.; Francik, S.; Pedryc, N. Evaluation of Suitability of Hazelnut Shell Energy for Production of Biofuels. In Proceedings of the Engineering for Rural Development, Jełgawa, Łotwa, 23–25 May 2018; Volume 17, pp. 1860–1865. [Google Scholar]

- Shah, M.A.; Khan, M.N.S.; Kumar, V. Biomass Residue Characterization for Their Potential Application as Biofuels. J. Therm. Anal. Calorim. 2018, 134, 2137–2145. [Google Scholar] [CrossRef]

- Garzón, E.; Arce, C.; Callejón-Ferre, A.J.; Pérez-Falcón, J.M.; Sánchez-Soto, P.J. Thermal Behaviour of the Different Parts of Almond Shells as Waste Biomass. J. Therm. Anal. Calorim. 2022, 147, 5023–5035. [Google Scholar] [CrossRef]

- Güler, C.; Şen, S. The Utilization of Hazelnut Shell (Coryllus avellana L.) Residues as Compressed Combustible Fuel. Ormancılık Dergisi 2013, 9, 111–116. [Google Scholar]

- Adhikari, S.; Nam, H.; Chakraborty, J.P. Conversion of Solid Wastes to Fuels and Chemicals through Pyrolysis. Waste Biorefinery Potential Perspect. 2018, 2018, 239–263. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Biomass Combustion Systems: A Review on the Physical and Chemical Properties of the Ashes. Renew. Sustain. Energy Rev. 2016, 53, 235–242. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Warmiński, K.; Tworkowski, J.; Szczukowski, S. Willow Biomass Energy Generation Efficiency and Greenhouse Gas Reduction Potential. Pol. J. Environ. Stud. 2015, 24, 2627–2640. [Google Scholar] [CrossRef]

- Acar, S.; Ayanoglu, A. Determination of Higher Heating Values (HHVs) of Biomass Fuels. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2012, 28, 749–758. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 2. Potential Utilisation, Technological and Ecological Advantages and Challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Açıkalın, K. Thermogravimetric Analysis of Walnut Shell as Pyrolysis Feedstock. J. Therm. Anal. Calorim. 2011, 105, 145–150. [Google Scholar] [CrossRef]

- Colpani, D.; Santos, V.O.; Araujo, R.O.; Lima, V.M.R.; Tenório, J.A.S.; Coleti, J.; Chaar, J.S.; de Souza, L.K.C. Bioenergy Potential Analysis of Brazil Nut Biomass Residues through Pyrolysis: Gas Emission, Kinetics, and Thermodynamic Parameters. Clean. Chem. Eng. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Zhylina, M.; Shishkin, A.; Miroshnichenko, D.; Sterna, V.; Ozolins, J.; Ansone-Bertina, L.; Klavins, M.; Goel, G.; Goel, S. Granulation and Pyrolysis of Agricultural Residues for an Enhanced Circular Economy. Results Eng. 2025, 26, 104919. [Google Scholar] [CrossRef]

- Miroshnichenko, D.; Malik, I.; Lebedev, V.; Solovey, L.; Gorbunov, K.; Dyakova, N. Influence of Temperature and Pressure of Renewable Energy Pyrolysis on Properties of Charcoal. IOP Conf. Ser. Earth Environ. Sci. 2024, 1376, 012030. [Google Scholar] [CrossRef]

- Miroshnichenko, D.; Zhylina, M.; Shmeltser, K. Modern Use of Biochar in Various Technologies and Industries. A Review. Chem. Chem. Technol. 2024, 18, 232–243. [Google Scholar] [CrossRef]

- Jia, G. Combustion Characteristics and Kinetic Analysis of Biomass Pellet Fuel Using Thermogravimetric Analysis. Processes 2021, 9, 868. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G.; Morgan, T.J. An Overview of the Organic and Inorganic Phase Composition of Biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Demirbas, A. Relationships Between Heating Value and Lignin, Moisture, Ash and Extractive Contents of Biomass Fuels. Energy Explor. Exploit. 2002, 20, 105–111. [Google Scholar] [CrossRef]

- Salgado-Ramos, M.; Martí-Quijal, F.J.; Huertas-Alonso, A.J.; Sánchez-Verdú, M.P.; Barba, F.J.; Moreno, A. Almond Hull Biomass: Preliminary Characterization and Development of Two Alternative Valorization Routes by Applying Innovative and Sustainable Technologies. Ind. Crops Prod. 2022, 179, 114697. [Google Scholar] [CrossRef]

- Lu, X.; Gu, X. A Review on Lignin Pyrolysis: Pyrolytic Behavior, Mechanism, and Relevant Upgrading for Improving Process Efficiency. Biotechnol. Biofuels Bioprod. 2022, 15, 106. [Google Scholar] [CrossRef]

- ISO 17225-2:2014 (E); Solid Biofuels-Fuel Specifications and Classes-Part 2: Graded Wood Pellets. ISO: Geneva, Switzerland, 2014.

- Wu, Y.; Zhao, F.; Liu, S.; Wang, L.; Qiu, L.; Alexandrov, G.; Jothiprakash, V. Bioenergy Production and Environmental Impacts. Geosci. Lett. 2018, 5, 14. [Google Scholar] [CrossRef]

- Uamusse, M.M.; Persson, K.M.; Tsamba, A.J. Gasification of Cashew Nut Shell Using Gasifier Stovein Mozambique. J. Power Energy Eng. 2014, 2, 11–18. [Google Scholar] [CrossRef]

- McKendry, P. Energy Production from Biomass (Part 1): Overview of Biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Sivabalan, K.; Hassan, S.; Ya, H.; Pasupuleti, J. A Review on the Characteristic of Biomass and Classification of Bioenergy through Direct Combustion and Gasification as an Alternative Power Supply. J. Phys.Conf. Ser. 2021, 1831, 012033. [Google Scholar] [CrossRef]

- Casau, M.; Dias, M.F.; Matias, J.C.O.; Nunes, L.J.R. Residual Biomass: A Comprehensive Review on the Importance, Uses and Potential in a Circular Bioeconomy Approach. Resources 2022, 11, 35. [Google Scholar] [CrossRef]

- Özyuğuran, A.; Yaman, S.; Küçükbayrak, S. Prediction of Calorific Value of Biomass Based on Elemental Analysis. Int. Adv. Res. Eng. J. 2018, 2, 254–260. [Google Scholar]

- Ericsson, K.; Nilsson, L.J. Assessment of the Potential Biomass Supply in Europe Using a Resource-Focused Approach. Biomass Bioenergy 2006, 30, 1–15. [Google Scholar] [CrossRef]

- Ahn, Y.; Han, J. Economic Optimization of Integrated Network for Utility Supply and Carbon Dioxide Mitigation with Multi-Site and Multi-Period Demand Uncertainties. Appl. Energy 2018, 220, 723–734. [Google Scholar] [CrossRef]

- Regato, M.; Guerreiro, I.; Regato, J.; Pereira, M.M. Pistaceira: Estado Da Produção; Instituto Politécnico de Beja: Beja, Portugal, 2017. [Google Scholar]

- Martínez, E.; Couceiro, J.F.; Cabello, M.J.; Armadoro, S.; Correia, B. Expansion of Pistachio Cultivation in the Iberian Peninsula: Keys to the Future. Acta Hortic. 2018, 1219, 281–286. [Google Scholar] [CrossRef]

- Atlas Big Produção Mundial de Amendoim Por País. Available online: https://pt.atlasbig.com/paises-pela-producao-de-amendoim (accessed on 2 June 2025).

- Razavi, S.M.A.; Rafe, A.; Mohammadi Moghaddam, T.; Mohammad Amini, A. Physical Properties of Pistachio Nut and Its Kernel as a Function of Moisture Content and Variety. Part II. Gravimetrical Properties. J. Food Eng. 2007, 81, 218–225. [Google Scholar] [CrossRef]

- Teixeira, M.M. Avaliação de Elementos Potencialmente Tóxicos Em Frutos Secos de Diferentes Origens; Universidade de Lisboa: Lisboa, Portugal, 2021. [Google Scholar]

- Rodrigues, M.Â.; Barreira, J.C.M.; Ferreira, I.C.F.R.; Bento, A. Avaliação e Sistematização de Subprodutos Frutos Secos: Uma Aproximação Quantitativa à Disponibilidade de Subprodutos; Centro Nacional de Competências dos Frutos Secos: Bragança, Portugal, 2020. [Google Scholar]

- Food and Agriculture Organization of the United Nations. FAO Website. 2025. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 2 June 2025).

- Statistics Portugal Primary Energy Consumption by Energy Source Type and Consumption Type Annual. Available online: https://www.ine.pt/xportal/xmain?xpid=INE&xpgid=ine_indicadores&indOcorrCod=0002103&xlang=pt&contexto=bd&selTab=tab2 (accessed on 2 June 2025).

- Sezer, S.; Özveren, U. Investigation of Hazelnut Husk Combustion by Using A Novel Non-Linear Kinetic Model through Thermogravimetric Analysis. Sak. Univ. J. Sci. 2021, 25, 326–338. [Google Scholar] [CrossRef]

- ISO 18134-3:2015 (E); Solid Biofuels-Determination of Moisture Content-Oven Dry Method-Part 3: Moisture in General Analysis Sample. ISO: Geneva, Switzerland, 2015.

- ISO 18122:2015 (E); Solid Biofuels-Determination of Ash Content. ISO: Geneva, Switzerland, 2015.

- ISO 18123:2015 (E); Solid Biofuels—Determination of the Content of Volatile Matter. ISO: Geneva, Switzerland, 2015.

- ISO 16948:2015 (E); Solid Biofuels-Determination of Total Content of Carbon, Hydrogen and Nitrogen. ISO: Geneva, Switzerland, 2015.

- ISO 18125:2017 (E); Solid Biofuels-Determination of Calorific Value. ISO: Geneva, Switzerland, 2017.

- ISO 14083:2023(E); Greenhouse Gases—Quantification and Reporting of Greenhouse Gas Emissions Arising from Transport Chain Operations. ISO: Geneva, Switzerland, 2023.

- IEA Full Lifecycle Emissions Intensity of Global Coal and Gas Supply for Power Generation. 2018. Available online: https://www.iea.org/data-and-statistics/charts/full-lifecycle-emissions-intensity-of-global-coal-and-gas-supply-for-power-generation-2018 (accessed on 7 October 2024).

- Comer, B.; O’Malley, J.; Osipova, L.; Pavlenko, N. Comparing the Future Demand for, Supply of, and Life-Cycle Emissions from Bio, Synthetic, and Fossil LNG Marine Fuels in the European Union; International Council on Clean Transportation: Washington, DC, USA, 2022. [Google Scholar]

- Przywara, M.; Przywara, R.; Zapała, W.; Opaliński, I. Mechanical Properties of Solid Biomass as Affected by Moisture Content. AgriEngineering 2023, 5, 1118–1135. [Google Scholar] [CrossRef]

- Jia, Y.; Li, Z.; Wang, Y.; Wang, X.; Lou, C.; Xiao, B.; Lim, M. Visualization of Combustion Phases of Biomass Particles: Effects of Fuel Properties. ACS Omega 2021, 6, 27702–27710. [Google Scholar] [CrossRef]

- Ozbayoglu, G. Energy Production From Coal. Compr. Energy Syst. 2018, 3, 788–821. [Google Scholar] [CrossRef]

- Sulaiman, S.A.; Romli, R. Combustion Performance of Cellulosic Biomass in a Gasifier-Based Cookstove. AIP Conf. Proc. 2012, 1440, 942–952. [Google Scholar]

- Han, J.; Yu, D.; Wu, J.; Yu, X.; Liu, F.; Xu, M. Effects of Torrefaction on Ash-Related Issues during Biomass Combustion and Co-Combustion with Coal. Part 3: Ash Slagging Behavior. Fuel 2023, 339, 126925. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Jovičić, N.; Antonović, A.; Matin, A.; Antolović, S.; Kalambura, S.; Krička, T. Biomass Valorization of Walnut Shell for Liquefaction Efficiency. Energies 2022, 15, 495. [Google Scholar] [CrossRef]

- Perea-Moreno, M.A.; Manzano-Agugliaro, F.; Hernandez-Escobedo, Q.; Perea-Moreno, A.J. Peanut Shell for Energy: Properties and Its Potential to Respect the Environment. Sustainability 2018, 10, 3254. [Google Scholar] [CrossRef]

- Açikalin, K.; Karaca, F.; Bolat, E. Pyrolysis of Pistachio Shell: Effects of Pyrolysis Conditions and Analysis of Products. Fuel 2012, 95, 169–177. [Google Scholar] [CrossRef]

- Tripathi, M.; Sahu, J.N.; Ganesan, P. Effect of Process Parameters on Production of Biochar from Biomass Waste through Pyrolysis: A Review. Renew. Sustain. Energy Rev. 2016, 55, 467–481. [Google Scholar] [CrossRef]

- Darvell, L.I.; Brindley, C.; Baxter, X.C.; Jones, J.M.; Williams, A. Nitrogen in Biomass Char and Its Fate during Combustion: A Model Compound Approach. Energy Fuels 2012, 26, 6482–6491. [Google Scholar] [CrossRef]

- Vorbrodt-strzałka, K.; Pikoń, K. Environmental Impacts Associated with Production and Utilization of Agricultural Biogas. Arch. Gospod. Odpad. Ochr. Środowiska 2013, 15, 1–12. [Google Scholar]

- ISO 16994:2016 (E); Solid Biofuels-Determination of Total Content of Sulfur and Chlorine. ISO: Geneva, Switzerland, 2016.

- Ranzi, E.; Cuoci, A.; Faravelli, T.; Frassoldati, A.; Migliavacca, G.; Pierucci, S.; Sommariva, S. Chemical Kinetics of Biomass Pyrolysis. Energy Fuels 2008, 22, 4292–4300. [Google Scholar] [CrossRef]

- Demirba, A. Calculation of Higher Heating Values of Biomass Fuels. Fuel 1997, 76, 431–434. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Ryu, C.; Gang, K.S.; Yang, W.; Park, Y.K.; Jung, J.; Hyun, S. Comparison of Biochar Properties from Biomass Residues Produced by Slow Pyrolysis at 500 °C. Bioresour. Technol. 2013, 148, 196–201. [Google Scholar] [CrossRef]

- Helena Da Silveira, J.; Ricardo, I.; Thomé, H.; Ii, D.; Hugo, V.; Sebben, A.; Fabiano, I.; Gasparin, P.; Lúcia, I.V.; Da, A.; et al. Characterization of Residual Biomass from the Harvest of Eucalyptus Saligna for Thermal Conversion Processes Caracterização Da Biomassa Residual Da Colheita de Eucalyptus saligna Para Processos de Conversão Térmica. Rev. Eletrônica Em Gestão Educ. Tecnol. Ambient. REGET 2020, 24, 1–26. [Google Scholar] [CrossRef]

- Pandey, D.; Daverey, A.; Dutta, K.; Yata, V.K.; Arunachalam, K. Valorization of Waste Pine Needle Biomass into Biosorbents for the Removal of Methylene Blue Dye from Water: Kinetics, Equilibrium and Thermodynamics Study. Environ. Technol. Innov. 2022, 25, 102200. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, B.; Chen, L.; Du, J.; Li, W.; Luo, Z. Pyrolysis Kinetics of Hulless Barley Straw Using the Distributed Activation Energy Model (DAEM) by the TG/DTA Technique and SEM/XRD Characterizations for Hulless Barley Straw Derived Biochar. Braz. J. Chem. Eng. 2018, 35, 1039–1050. [Google Scholar] [CrossRef]

- Channiwala, S.A.; Parikh, P.P. A Unified Correlation for Estimating HHV of Solid, Liquid and Gaseous Fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Krasenbrink, A.; Hass, H.; Rose, K.D.; Godwin, S.; Hamje, H.; Nelson, R. Well-to-Wheels Report Version 4.a—JEC Well-to-Wheels Analysis—Well-to-Wheels Analysis of Future Automotive Fuels and Powertrains in the European Context; Publications Office: Ispra, Italy, 2014. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Pereira, L.G.; Cavalett, O.; Bonomi, A.; Zhang, Y.; Warner, E.; Chum, H.L. Comparison of Biofuel Life-Cycle GHG Emissions Assessment Tools: The Case Studies of Ethanol Produced from Sugarcane, Corn, and Wheat. Renew. Sustain. Energy Rev. 2019, 110, 1–12. [Google Scholar] [CrossRef]

- Pujol Pereira, E.I.; Suddick, E.C.; Six, J. Carbon Abatement and Emissions Associated with the Gasification of Walnut Shells for Bioenergy and Biochar Production. PLoS ONE 2016, 11, e0150837. [Google Scholar] [CrossRef] [PubMed]

- Saracoglu, M.S.; Coruh, M.K. Thermal Degradation Properties, Kinetic, Thermodynamic and Reaction Mechanism of Pyrolysis of Biomass Shells: Pistachio, Almond, Walnut and Hazelnut as Bioenergy Potential. Biomass Convers. Biorefinery 2023, 14, 32427–32452. [Google Scholar] [CrossRef]

- Kendall, A.; Marvinney, E.; Brodt, S.; Zhu, W. Life Cycle–Based Assessment of Energy Use and Greenhouse Gas Emissions in Almond Production, Part I: Analytical Framework and Baseline Results. J. Ind. Ecol. 2015, 19, 1008–1018. [Google Scholar] [CrossRef]

- REN REN Data Hub. Available online: https://datahub.ren.pt/pt/gas-natural/mercado (accessed on 2 June 2025).

- Cavalleri, M. Biomassa Florestal Logística de Recolha e Valorização. Available online: https://lisboaenova.org/images/stories/PontodeEncontro/2011/BiomassaFlorestal_cavalleri.pdf (accessed on 2 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).