Abstract

Reducing carbon dioxide emissions is a key priority in the European Union, which aims to achieve carbon neutrality by 2050. Construction has a key role to play in this effort, as it is responsible for a significant proportion of greenhouse gas emissions, especially due to cement production. At the same time, waste reuse emerges as a key strategy within the circular economy, another pillar of European policies. By valuing byproducts and waste, such as construction and demolition waste (CDW), it is possible to reduce the extraction of natural resources, amount of waste sent to landfills, and emissions associated with the production of new materials. This study, with the main objective of evaluating the possibility of using CDW as supplementary cementitious materials, emerges as a possible solution to reduce these problems. Two CDW treatment methods were used: (i) mechanical grinding and (ii) calcination. The mechanical grinding method, even with the use of laboratory equipment, has shown that it is possible to obtain CDW particles with characteristics suitable for replacing cement. For the calcination process, temperatures between 600 °C and 800 °C were the most suitable. The results proved that the replacement of cement by CDW in pastes resulted in suitable behavior for the construction industry, having revealed an incorporation content of up to 25% CDW, a compressive strength and strength activity index higher than that found for pastes developed with fly ash. Regarding the calcination process, this revealed an improvement in the compressive strength of the developed pastes, resulting in an increase in strength activity index of between 7 and 10%.

1. Introduction

Currently, humanity faces several problems related to waste production and greenhouse gas emissions into the atmosphere. The construction industry makes a huge contribution to this problem, representing around 40% of the waste generated worldwide [1] and around 39% of carbon dioxide emissions into the atmosphere [2]. On the other hand, the high intensity of the construction industry has also led to an enormous consumption of natural raw materials [3], which increases the importance of circular construction and the reuse of end-of-life raw materials.

Around 10 billion tons of construction and demolition waste (CDW) are produced annually [4], which can and should be reused. Today, a large part of this waste still ends up being placed in dumps or landfills [1,5], generating major environmental and social problems. On the other hand, a great loss of resources is ensured by their lack of reuse.

CDW is made up of several materials, such as concrete, mortars, bricks, and ceramics, among others [1,6], which all have potential for several applications in the construction industry. The reuse of CDW has been addressed by several research teams, namely as substitutes for natural aggregates [7,8,9] and more recently as supplementary cementitious materials [10,11].

Research indicates that substituting up to 30% of natural coarse aggregate with recycled material in concrete does not significantly impair physical–mechanical qualities [10,12,13]. The findings have also demonstrated that the mechanical qualities of concretes incorporating CDW aggregates are inferior to those of reference concrete composed of natural aggregates. Moreover, concrete produced using recycled aggregate is less durable due to its increased porosity. Consequently, the utilization of CDW as an aggregate in concrete is inadvisable for applications in aggressive environments [14].

On the other hand, the substitution of a portion of Portland cement with CDW in cement-based materials began to arouse the interest of the scientific community, since it allows us to reduce the carbon footprint, therefore mitigating the environmental harm associated with Portland cement manufacturing [10,15,16].

The cement industry is deeply integrated into the European economy, with facilities spread throughout the European Union [17]. Around 175 million tons of cement are produced in Europe each year, mainly to produce concrete, but also other cement-based composite materials such as mortars and precast concrete products. The cement industry significantly contributes to global carbon emissions, mainly because carbon dioxide (CO2) is released during the cement manufacturing process [18]. Therefore, it is necessary to reduce the environmental impact resulting from cement production, especially CO2 emissions. In this context, the Paris Agreement aims to reduce CO2 emissions resulting from cement manufacturing by 30% by 2030 [19]. Reducing carbon emissions from cement and concrete production is essential for promoting sustainable construction and addressing climate change [18]. The use of low-carbon cement and the incorporation of supplementary cementitious materials in concrete production can significantly reduce the carbon footprint associated with concrete. By integrating materials such as fly ash, slag, silica fume, pozzolan, and others during the manufacturing process, significant savings in CO2 emissions are achieved in the cement manufacturing phase [17,20].

Tang et al. [21] and Zhang et al. [22] utilized recycled brick powder to substitute 5–30% of the cement mass in mortar samples, revealing that an optimal quantity of recycled brick powder enhanced the mechanical qualities of the mortar while exerting negligible effects on durability. Duan et al. [23] examined recycled powder derived from various CDW sources, including waste concrete, assorted waste bricks, and waste aerated brick. They discovered that materials recycled from mixed CDW and waste bricks with a fine particle size exhibited a superior strength activity index of 80% at a replacement ratio of 30%. Wu et al. [24] observed that the incorporation of recycled concrete powder reduced the dry shrinkage of mortar. They stated that recycled powder had a significant quantity of amorphous and glass phases, which facilitated the secondary hydration reaction. Li et al. [25] utilized recycled concrete powder to substitute 10–30% of cement, yielding results comparable to those obtained with recycled brick powder.

Existing research concerning CDW as cement replacement predominantly focused on the individual examination of concrete and brick waste powders. Moreover, numerous studies aimed to reduce waste factors by utilizing materials generated in laboratories or small-scale productions, allowing for the control of cement type, curing duration, and other parameters. On the other hand, the literature research [10] indicates that an activation process can enhance the application of CDW as a supplementary cementitious material. The prevailing activation methods involve thermal, mechanical, chemical, nano-silica, and biological activation [26], with mechanical and thermal activation methods being the most used.

This study aims to go further, studying the incorporation of the CDW mix without the need for prior treatment regarding its separation by material type. Thus, the main objectives of this study were as follows: (i) develop a mechanical grinding process suitable for the use of CDW as supplementary cementitious material; (ii) evaluate the influence of the CDW calcination process at 600 °C and 800 °C; (iii) evaluate the fresh and hardened behavior of pastes incorporating CDW powder.

2. Research Significance

Currently, many of the studies that address CDW use this waste as a substitute for natural aggregates. The use of CDW as a supplementary cementitious material is still recent, and much of the work developed focuses on studying specific types of waste, such as concrete or ceramic waste. These studies have shown great potential for CDW as supplementary cementitious materials. However, several challenges still exist in society and in the construction sector, since the separation of CDW by type of material is not a common practice in most countries, as is the case in Portugal. Therefore, this study aims to address this problem using mixtures of CDW, consisting of concrete, mortars, ceramics and aggregates, as potential supplementary cementitious material.

This study contributes significantly to the field compared to the existing literature, addressing innovative aspects that have been little or not at all explored. Thus, this research provides valuable insights to provide other ways of valuing CDW, avoiding its prior selection and categorization. The development of these new pastes using CDW as binder replacement and the investigation of their impact on physical and mechanical performance allows us to eliminate critical gaps in the field and pave the way for advances in sustainable construction and waste management.

3. Materials

3.1. Treatment of CDW

The CDW used in this study is characterized as mixed CDW, originating from Portuguese construction works and marketed by a Portuguese waste management company, located in the central region of Portugal. CDW was initially produced to be marketed as a substitute for natural aggregate, with a grain size between 0 and 10 mm, with quality control and composition. CDW has already been used by this research team [6], being a mixture of waste consisting of mortar, concrete, brick, ceramic, lime paste, natural stone, soil, and other minor constituents. It features a density of 2143.9 kg/m3 and water absorption of 7.82%. Several authors have successfully used mechanical grinding methods for the treatment of different materials, especially industrial waste, to obtain supplementary cementitious materials [10,27,28,29]. Thus, in this study, only the fraction between 0 and 4 mm was used, which was duly processed to obtain a fine powder which can be used as a supplementary cementitious material. A heat treatment process was also applied to the CDW after its mechanical grinding. Figure 1 shows a schematic representation of the treatment steps applied to CDW.

Figure 1.

Schematic representation of the CDW processing steps.

3.1.1. Mechanical Grinding of CDW

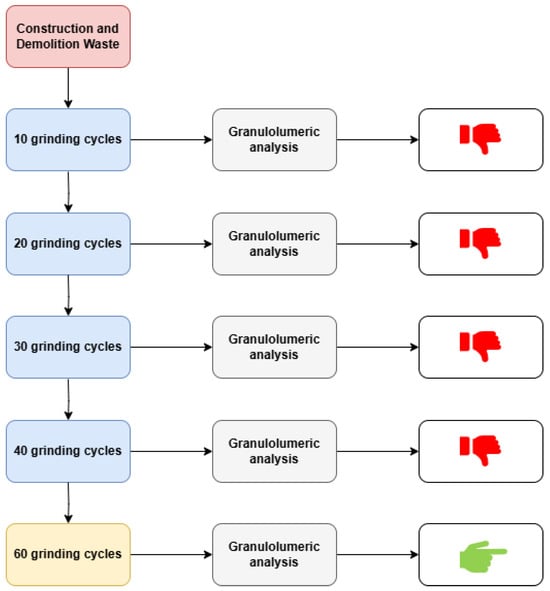

To reduce the dimensions of the CDW to form a powder with dimensions like those of cement, the CDW aggregate was subjected to a mechanical grinding process. The grinding cycles were performed using a Los Angeles mill with 20 metal balls inside. In each cycle, 5000 g of CDW aggregates were ground for 15 min. Several grinding cycles were applied (Figure 2) until the verification of the following condition (Equation (1)):

where

D50CDW ≤ D50CEM,

D50CDW—Size of 50% of the accumulated retained particles of the CDW powder;

D50CEM—Size of 50% of the accumulated retained particles of the cement.

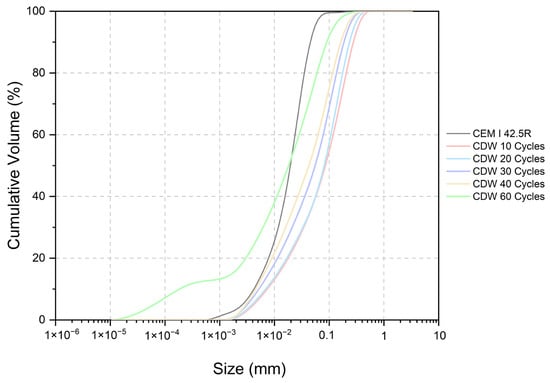

At each grinding stage, a sample of CDW powder was collected and subsequently analyzed using a laser granulometer (Malvern Instruments Limited, Worcestershire, UK). A laser particle size analysis, based on the laser diffraction method, was performed on the cement and CDW powder utilizing a Malvern Instruments Mastersizer 3000 (Malvern Instruments Limited, Worcestershire, UK), capable of measuring particle sizes ranging from 10 nm to 3.5 mm. The particle size distribution, specific surface area, D10, D50, and D90 value were determined from the measurements. In this way, it was possible to continuously control the milling process and its interference in the distribution and average particle size of the CDW. Figure 3 shows the particle size distribution of cement and CDW powder after 10, 20, 30, 40, and 60 grinding cycles. It was possible to verify that after each grinding step, the granulometric curve of the CDW powder gradually approached the granulometric distribution curve of the cement.

Figure 3.

Granulometric curve of cement and CDW after 10, 20, 30, 40, and 60 grinding cycles.

Figure 2.

Schematic representation of the CDW mechanical grinding process.

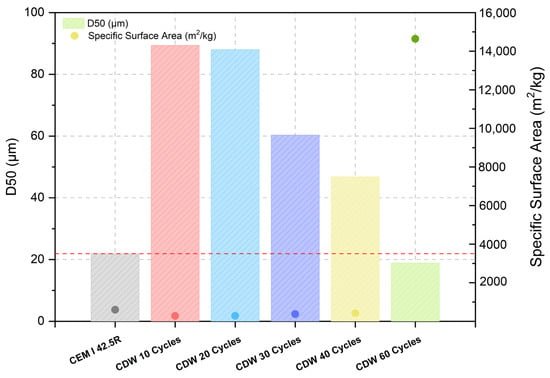

Based on Figure 4, it is possible to observe the D50 value and the specific surface area of the cement and CDW after the different grinding cycles. It was found that as the time and number of grinding cycles increased, there was simultaneously a decrease in D50 value and an increase in the specific surface area, demonstrating the effectiveness of the grinding process adopted. It was also possible to verify that carrying out 60 grinding cycles led to obtaining a CDW powder with a D50 value about 14% lower than the one verified for cement. However, the specific surface area obtained was much higher. In the literature, the relationship between the D50 value and specific surface area is well-established [30,31]. It is clear that as the average particle size of a powder decreases, its specific surface area increases. These properties support the hydration reaction by facilitating nucleation, generating new hydrated compounds, and improving material density through a filling effect [21,30,31].

Figure 4.

D50 value and specific surface area of cement and CDW after 10, 20, 30, 40, and 60 grinding cycles.

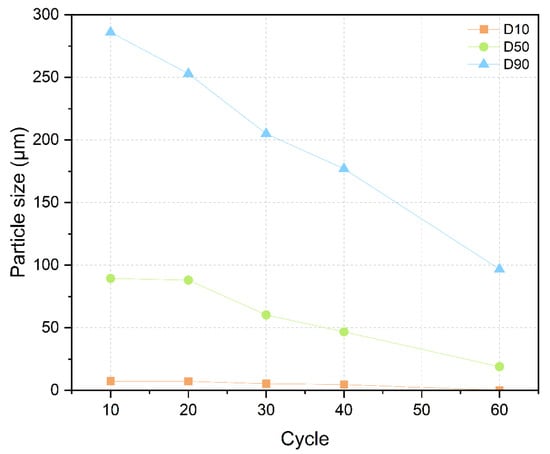

According to Figure 5, it was possible to verify that the CDW particle size, evaluated by the D10, D50, and D90 value, decreases as the number of grinding cycles increases, as reported by other authors [30,31]. It is important to highlight that the grinding process has a great influence on the D90 value in all grinding cycles, demonstrating great efficiency from the application of a small number of cycles in reducing the size of larger particles. However, only after the 20th grinding cycle was it possible to verify a greater influence on the D10 and D50 value.

Figure 5.

Grinding cycle vs. CDW particle size.

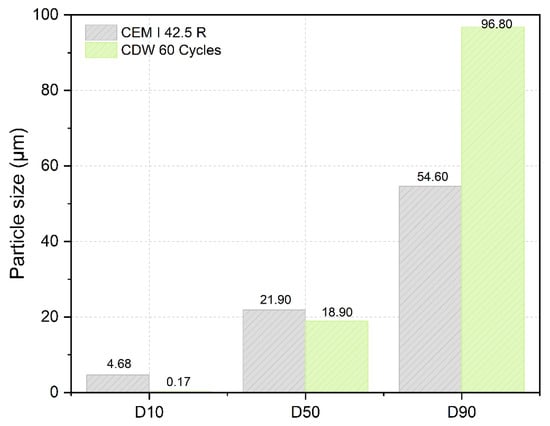

Based on the results obtained for the different grinding cycles, the condition indicated in Equation (1), and the results present in Figure 6 and Figure 7, the application of 60 cycles was selected as the CDW grinding procedure. It is important to note that supplementary cementitious materials must have diameters equal to or smaller than those found for cement in order to improve their chemical reactivity and particle packing effect [10,32]. Some authors evaluated the effect of the grinding time of supplementary cementitious materials on the mechanical behavior of mortars, having observed that as the grinding time increases, the mechanical properties obtained are improved [10,33].

Figure 6.

D10, D50, and D90 values of cement (CEM I 42.5R) and CDW after 60 grinding cycles.

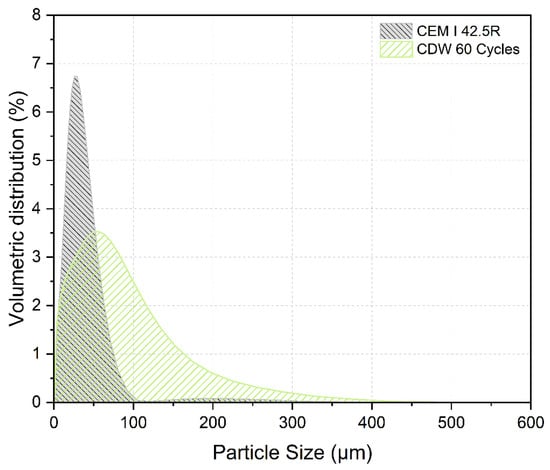

Figure 7.

Volumetric distribution of cement particles and CDW after 60 grinding cycles.

According to Figure 6, it was possible to verify that the application of 60 grinding cycles in the CDW proved to be an effective mechanical grinding procedure. In relation to the D10 and D50 values, it was found that CDW presented a decrease in its value of approximately 96% and 14% compared to cement, respectively. While for the D90 value, CDW presented a value approximately 77% higher than that of cement. This behavior is associated with the large dispersion of particle sizes in the CDW used to produce the CDW powder, which ranges from 0 to 4 mm. However, through the analysis of Figure 7, we can observe that more than 53% of the volumetric distribution of the CDW particles is between 14 µm and 120 µm, as is the case for the cement particles.

Table 1 shows the density of Portland cement and CDW powder determined according to LNEC Specification E 64 [34]. It was possible to verify that the density of CDW is approximately 14% lower than that presented by cement. Similar values were obtained by Takareva et al. [12].

Table 1.

Density of cement and CDW powder after 60 cycles of 60 grinding cycles.

3.1.2. Thermal Treatment of CDW

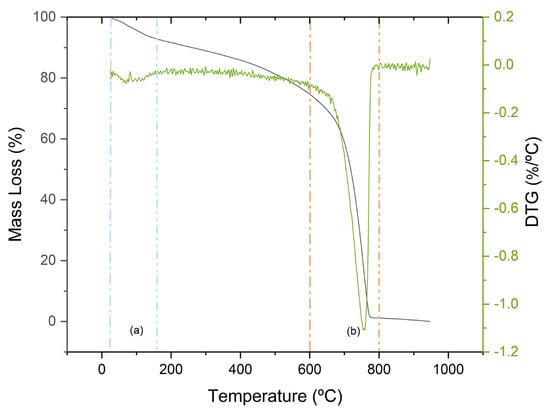

Figure 8 shows the results obtained for the thermogravimetry tests (TG), performed using a NETZSCH Thermal Analyzer (NETZSCH-Gerätebau GmbH, Selb, Germany). Approximately 20 mg of CDW powder was placed in an alumina crucible and subjected to heating from room temperature to approximately 1000 °C at a uniform rate of 10 °C/min. In this way, it was possible to evaluate the mass loss that occurred in the samples under analysis. The test was carried out on three samples. The thermogravimetric (TGA) and differential thermogravimetric (DTG) curves provide insight into the thermal stability and decomposition behavior of the samples [35]. The TGA analysis identifies several significant thermal events related to moisture loss and the decomposition of mineral phases. Based on the DTG curve, it was possible to observe the existence of two peak points, indicated in Figure 8 as zones (zone (a) and (b)). Zone (a), with loss between 30 °C and 150 °C, is attributed to the evaporation of water, as reported in other research works [12,35,36,37]. Zone (b), with loss between 600 °C and 800 °C, is related to the decarbonation of calcium carbonate (CaCO3) to form calcium oxide (CaO) and carbon dioxide (CO2) [12,37,38,39,40].

Figure 8.

TGA and DTG of CDW powder.

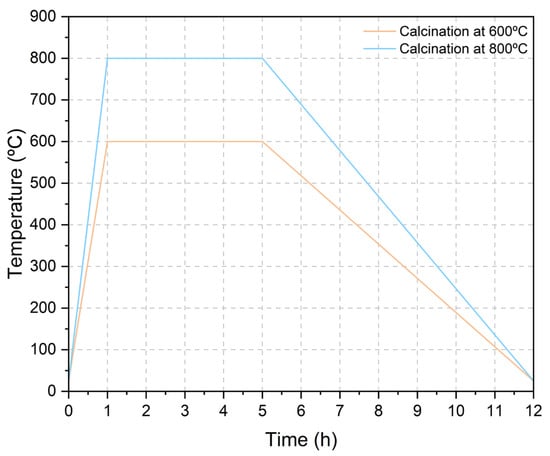

Based on the results obtained, the CDW was subjected to a calcination process for 4 h, adopting two different temperatures, 600 °C and 800 °C, as shown in Figure 9.

Figure 9.

CDW calcination process.

Figure 10 shows the density of CDW calcined at 600 °C and 800 °C. Compared to CDW without heat treatment, it was possible to verify that the density did not present significant changes, remaining practically unchanged, as already reported by Baggio et al. [10].

Figure 10.

Density of calcinated CDW.

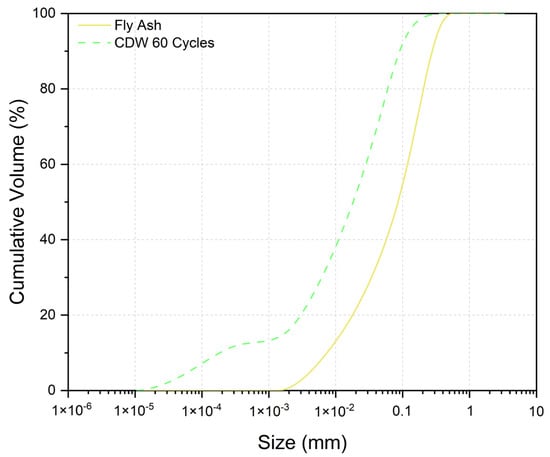

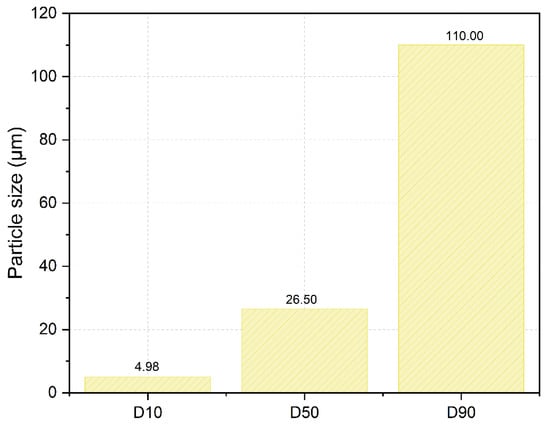

3.2. Fly Ash

The fly ash utilized was generated at the Pego thermoelectric power plant in Portugal. In the bibliography, fly ash is a supplementary cementitious material that is already well known [41,42,43,44]. Thus, comparing its performance with CDW will provide valuable insights for the study and comparison of CDW when subjected to different treatment methods. Figure 11 shows the particle size distribution of fly ash. It was possible to observe that the fly ash used has larger particles than CDW after 60 grinding cycles. In Figure 12 we can observe the D10, D50, and D90 value of fly ash.

Figure 11.

Granulometric curve of fly ash and CDW after 60 grinding cycles.

Figure 12.

D10, D50, and D90 value of fly ash.

The density of fly ash is 2364 kg/m3 and its specific surface area is 461 m2/kg.

4. Experimental Details

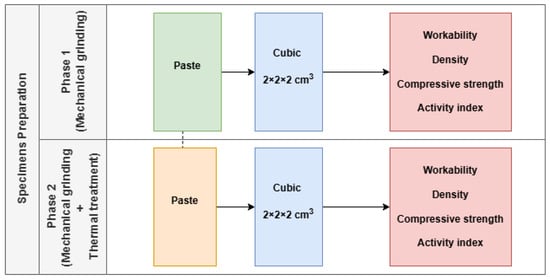

4.1. Specimen Preparation

This study was developed in two phases (Figure 13). In phase 1, the incorporation of CDW was studied only with the application of mechanical grinding. In phase 2, the incorporation of CDW into pastes was evaluated, with the CDW receiving two different treatments, mechanical grinding and thermal treatment.

Figure 13.

Schematic representation of the specimen’s preparation (phase 1 and 2).

In both phases, the incorporation of CDW powder in pastes was studied, based on the workability, density, compressive strength, and activity index. The workability was tested in the fresh state. The density, compressive strength and activity index were performed based on the development of cubic specimens with dimensions of 2 × 2 × 2 cm3. After molding, the test specimens remained in an environment with high relative humidity and were demolded after 24 h. After demolding, the specimens were stored in a water curing tank at room temperature until testing was carried out, in accordance with the specifications in the Portuguese Standard NP EN 196-1 [45]. A total of 15 specimens were performed for each composition, totaling 135 specimens. The determination of compressive strength was performed at 7, 28, and 90 days.

4.2. Mixtures Design

The proportions of the paste mixtures are in Table 2. For the development of phase 1, seven different compositions were developed. A reference composition was developed with 100% binder consisting of Portland cement (P_REF). Additionally, a composition was developed incorporating 25% fly ash to replace cement, by volume (P_FA). Five compositions were also developed with the incorporation of CDW powder as a replacement for cement, by volume, in different contents: 5% (P_CDW5), 15% (P_CDW15), 25% (P_CDW25), 50% (P_CDW50), and 75% (P_CDW75). The study of the indicated contents for CDW powder aimed to evaluate a wide range of incorporation contents. In phase 2, two different compositions were studied, keeping the CDW replacement content fixed at 25%, but testing the CDW calcined at 600 °C (P_CDW25-600 °C) and 800 °C (P_CDW25-800 °C).

Table 2.

Mix proportions of pastes.

4.3. Methods

The determination of the workability of the pastes was carried out according to the spreading table method, standardized in the European standard EN 1015-3 [46]. However, considering the absence of aggregate in the paste formulation, a cylindrical mold 25 mm in diameter and 60 mm in height was used. The cylindrical mold was filled in two approximately equal layers, each layer being compact with 10 strokes. Subsequently, the mold was removed vertically, and 15 strokes were applied on the spreading table. The workability of the pastes was determined by measuring the spreading diameter in two mutually perpendicular directions. The water–binder ratio of the mortars was determined based on different iterations until Equation (2) was verified.

where

LLow ≤ DFlow ≤ LUp,

LLow—Lower limit established for the flow test diameter, 12 cm;

DFlow—Paste flow test diameter, cm;

LUp—Upper limit established for the flow test diameter, 13 cm.

The compressive strength was determined based on the Portuguese Standard NP EN 196-1 [45] using hydraulic press Lloyd LR50K, (Ametek/Lloyd Instruments Ltd., West Sussex, UK) at a rate of 150 N/s.

The pozzolanic reactivity of the pastes was evaluated using the indirect strength activity index method. The activity index was assessed following the methodology outlined in Wu et al. [47] and in the standard EN 450-1 [48], in which pastes composed of cement and CDW powder were subjected to compressive strength testing at 28 and 90 days of curing. Thus, the strength activity index was determined based on Equation (3).

where

SAI—Strength activity index, %;

A—Average compressive strength of test mixture, MPa;

B—Average compressive strength of the reference mixture, MPa.

This method has been used by several researchers [41,49,50]. However, this relationship does not fully indicate its reactivity, as the physical filling effect and other influences of CDW powders or others supplementary cementitious materials also contribute to mechanical strength [31,47]. Thus, it is important to take this into account in the results analysis. In the bibliography there are other standards that can be used to assess the activity index [31], whose verification limits are different, and can vary between 65% [51], 70% [52], and 75% [48,53,54].

5. Results and Discussion

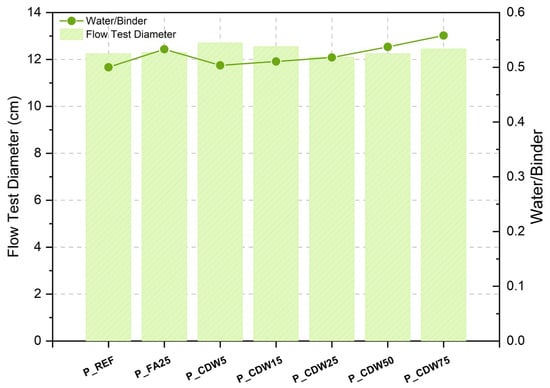

5.1. Workability

The workability of the pastes was determined to maintain the flow test diameter between 12.5 ± 0.5 cm, as mentioned in Equation (2). According to Figure 14, it was possible to verify that the water–binder ratio of the pastes with the incorporation of CDW powder varied between 0.503 and 0.558, resulting in an increase of between 0.7% and 11.6% compared to the reference composition. This increase in the amount of water in the compositions with the replacement of Portland cement by mechanically processed CDW powder, using 60 grinding cycles, is due to approximately 50% of the CDW particles having a smaller size than the cement particles (Figure 6 and Figure 7) and their higher specific surface area (Figure 4). This increase in workability was already observed by Lima et al. [55], who used higher levels of superplasticizer with the incorporation of higher CDW content in order to obtain adequate workability for their mixtures. However, a slight increase in the water–binder ratio of the paste was observed with the incorporation of 25% fly ash, approximately 6% compared to the reference composition (100% Portland cement). Considering that the D50 value of fly ash and cement are identical (Figure 6 and Figure 12), this behavior can be associated with the shape of the particles, such as a rougher surface [56].

Figure 14.

Flow test diameter and water–binder ratio of reference paste with incorporation of fly ash and CDW powder.

Maintaining consistent workability is crucial for enabling reliable comparisons among the various cement pastes produced. Nevertheless, substantial variations in the water–binder ratio can lead to significant changes in the physical and mechanical properties of the pastes, particularly in terms of water absorption and mechanical strength. In general, cement pastes with higher water–binder ratios tend to exhibit increased open porosity and reduced compressive strength.

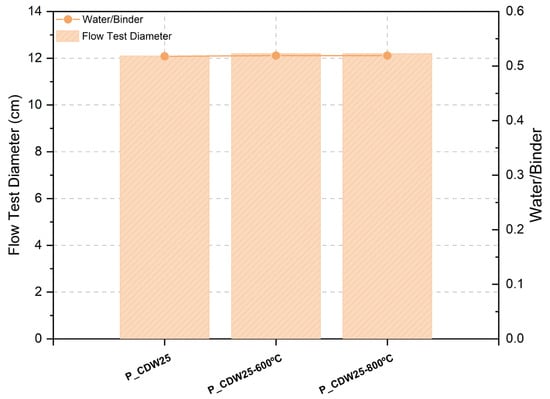

Based on the results presented in Figure 15, it was possible to verify that the calcination process of the CDW powder at 600 °C and 800 °C did not confer any change in the water–binder ratio of the pastes (P_CDW25-600 °C and P_CDW25-800 °C) compared to the paste with the incorporation of non-calcined CDW powder (P_CDW25). These results are corroborated by the practically unchanged density of the CDW powder after the calcination process (Figure 10), which did not significantly change the dosage of the mixtures studied (Table 2).

Figure 15.

Flow test diameter and water–binder ratio of pastes with incorporation of calcinated CDW powder.

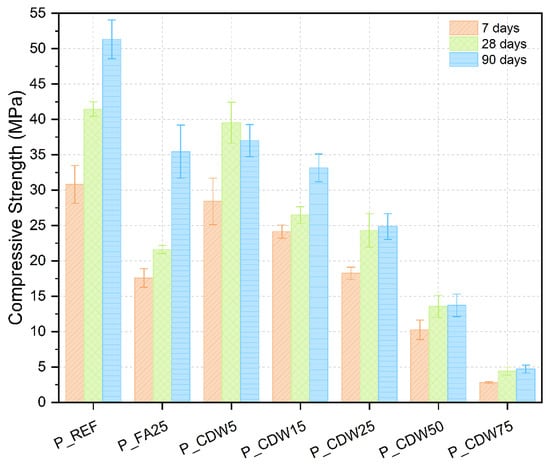

5.2. Compressive Strength

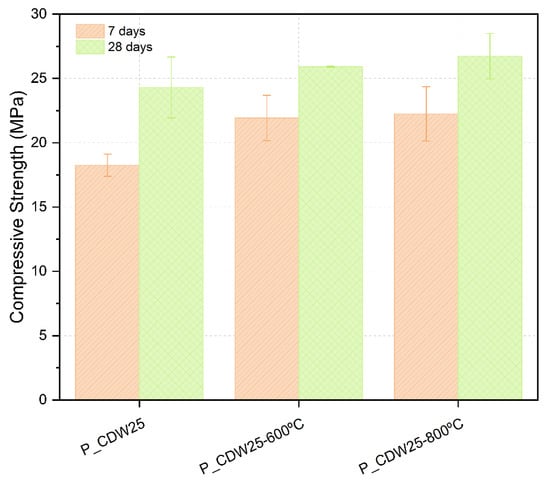

The compressive strength of the developed pastes was measured at 7, 28, and 90 days of curing, as shown in Figure 16 and Figure 17.

Figure 16.

Compressive strength of reference paste with incorporation of fly ash and CDW powder, at 7, 28, and 90 days.

Figure 17.

Compressive strength of pastes with incorporation of calcinated CDW powder at 7 and 28 days.

Regarding the pastes with the incorporation of non-calcinated CDW powder (Figure 16), it was possible to observe that the incorporation of CDW powder as a replacement for Portland cement resulted in a decrease in compressive strength for all ages studied compared to the reference composition. The incorporation of 5%, 15%, 25%, 50%, and 75% of CDW powder resulted in a decrease in compression resistance ranging from 8% to 91% at 7 days, from 5% to 89% at 28 days, and from 28% to 91% at 90 days of age. Lima et al. [55] studied the incorporation of different levels of CDW powder (5% to 20% of the cement percentage) in pastes and observed similar behavior, i.e., the incorporation of a higher level of CDW resulted in a more significant decrease in compressive strength.

However, the incorporation of a low content of CDW powder (5% CDW) did not cause a significant change in the compressive strength of the pastes, due to their lower cement replacement [12] and the small particle size of the powder [57]. Tokareva et al. [12] observed the same behavior for mortars developed with different contents of different types of CDW. The reduction in the mechanical strength of the cement pastes was anticipated, primarily due to the lower cement content (dilution effect), which led to a lower formation of hydration products as the CDW content increased [58,59,60], and also because of the higher water–binder ratio of the pastes (Figure 14), which creates a more porous and consequently more fragile structure [61,62]. Regarding CDW as supplementary cementitious material, several authors have studied the incorporation of concrete waste (recycled concrete powder) as cement replacement, also verifying a decrease in mechanical properties of cementitious materials as a result of a higher content replacement [28,29,63].

Regarding the composition incorporating 25% fly ash (P_FA25), it was possible to verify a decrease in compressive strength of approximately 43%, 48%, and 31% at 7, 28, and 90 days of curing, respectively. The decrease in compressive strength of cementitious mixtures with fly ash incorporation has already been reported by other authors [41,64,65], due to the lower pozzolanic reactivity, lower clinker content and higher paste water–binder ratio. Fly ash is a well-known supplementary cementitious material already used in the manufacture of cement [66]. This composition also serves as a standard composition to evaluate the performance of pastes produced with the incorporation of CDW powder. Accordingly, a comparative analysis between cement paste incorporating 25% of non-calcinated CDW powder (P_CDW25) and the paste with 25% of fly ash (P_FA25) revealed that the CDW-based paste exhibited comparable compressive strength at 7 days, a 12% increase at 28 days, and approximately 30% lower strength at 90 days. This effect of greater gain in compressive strength of cementitious mixtures incorporating fly ash at later ages has also been identified by other authors [41,65]. This behavior is attributed to the slower pozzolanic reaction kinetics of fly ash, which consequently delays the development of compressive strength [41].

Considering the evolution over time in general, mainly between 28 and 90 days of age, the incorporation of CDW powder does not provide a development in resistance as significant as that observed for the paste with the incorporation of fly ash, whose evolution is around 64%. However, by comparing the reference paste (P_REF) with the paste incorporating 25% CDW powder (P_CDW25), it was possible to verify that the evolution of the compressive strength between 28 and 90 days was positive and similar, with an increase of approximately 25%. This behavior supports what has already been mentioned in previous works [31,57,59]: (i) a minimal influence or slight improvement in the mechanical properties is seen if the percentages of supplementary cementitious material are lower (between 20 and 30%); (ii) CDW, mainly recycled concrete particles, participate in the pozzolanic reaction.

Figure 17 shows the behavior of the pastes with the incorporation of CDW powder calcined at 600 °C (P_CDW25-600 °C) and 800 °C (P_CDW25-800 °C), based on the results obtained in the thermogravimetry tests (Figure 8). It was possible to verify that the thermal treatment of CDW after mechanical grinding provided an improvement in compressive strength compared to untreated CDW. The exposure of CDW powder to a temperature of 600 °C resulted in an improvement in compressive strength of approximately 20% at 7 days and approximately 7% at 28 days. In turn, the exposure to a temperature of 800 °C led to an improvement in compressive strength of approximately 22% at 7 days of age and approximately 10% at 28 days compared to the paste without thermal activation (P_CDW25). Several authors have reported that the application of thermal treatment in CDW or recycled concrete waste powder has led to improved mechanical performance [10,30,67,68]. It was stated by Rocha and Toledo Filho [31] that the ideal temperature range for heat treatment is between 600 and 900 °C, since in this temperature range CH decomposition into CaO occurs, accelerating the hydration and improving mechanical behavior [69] and the CaCO3 decomposition into CaO, which may participate in a new hydration reaction [30,70]. In the bibliography it is also mentioned that heat treatment with temperatures below 600 °C and above 1000 °C are not as effective regarding the mechanical performance of cementitious materials with the incorporation of supplementary cementitious materials [30,31].

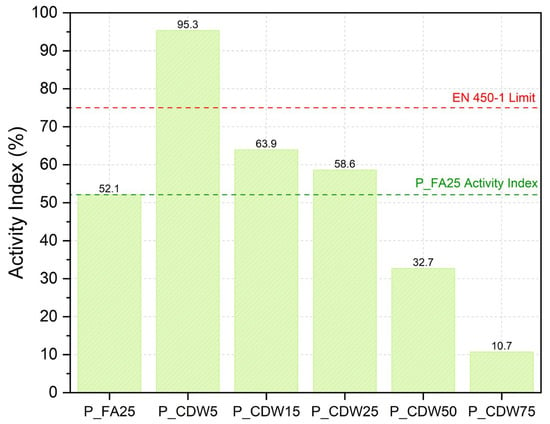

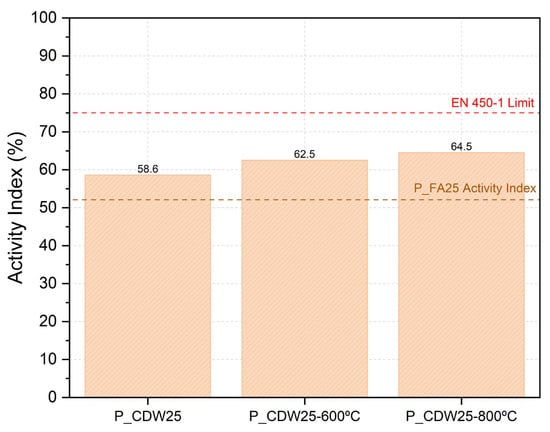

5.3. Strength Activity Index

Figure 18 and Figure 19 present the SAI results for 28 days of the pastes with the incorporation of non-calcinated CDW powder and calcinated CDW powder, respectively. As mentioned before, there is no universally accepted standard defining a specific threshold. However, researchers commonly adopt a 75% benchmark, as recommended by EN 450-1 [47] for fly ash activity index.

Figure 18.

Activity index of pastes with incorporation of fly ash and CDW powder at 28 days [48].

Figure 19.

Activity index of pastes with incorporation of calcinated CDW powder at 28 days [48].

Based on Figure 18, it was possible to verify that for the developed pastes, the activity index was only reached according to the limit established in the EN 450-1 [48] standard for the paste with the incorporation of 5% CDW. However, based on the activity index achieved with the paste incorporating 25% fly ash (P_FA25), it was possible to verify that the pastes incorporating 5%, 15%, and 25% of CDW powder presented a higher activity index at 28 days, demonstrating a better performance. By comparing the paste with the incorporation of 25% fly ash and 25% CDW powder, it was possible to verify that the paste with CDW presented a higher activity index of approximately 12%. This behavior can be explained by the smaller particle size of CDW and its larger specific surface area (Figure 4) compared to fly ash particles (Figure 12).

The activity index of the pastes incorporating calcined CDW powder can be seen in Figure 19. Once again it was possible to verify that none of the pastes incorporating 25% CDW reached the limit imposed by the EN 450-1 standard [48]. However, all of them presented a higher activity index than that presented by the pastes incorporating 25% fly ash. It was also possible to verify that exposure to calcination of CDW powder resulted in a higher activity index. Calcination at 600 °C resulted in an improvement in the activity index of approximately 7% and calcination at 800 °C resulted in an improvement of approximately 10% compared to the activity index of the paste with untreated CDW. As previously mentioned, this behavior is justified mainly by the CaCO3 decomposition into CaO, which may participate in a new hydration reaction [30,31,70].

6. Conclusions

The utilization of CDW as supplementary cementitious materials represents a field with significant research potential, particularly concerning the application of mixed CDW, which is widely available across the world. The use of mixed CDW could circumvent the need for pre-selection and separation processes, thereby enhancing its practical viability. In this study, CDW was used as a substitute for cement and its performance was compared with fly ash, a well-known supplementary cementitious material.

The following conclusions can be drawn from this study:

- Treatment of CDW: The CDW grinding process was crucial to obtain a powder with an average particle size suitable for replacing the binder. The applied grinding process led through numerous grinding cycles to an increasingly smaller average particle size, making it possible to achieve an average particle size about 14% lower than that verified for cement. However, there was a huge change in the specific surface of the CDW particles, which presented a value much higher than that of cement. However, even though a specific mill was not used to obtain very fine particles, it was possible to obtain promising results and particles with the potential to replace cement. On the other hand, the calcination process applied to CDW proved to be effective, since the selected temperatures (600 °C and 800 °C) allow the decarbonation of calcium carbonate, as can be verified in the thermogravimetry tests.

- Workability: The water–binder ratio of the pastes with the incorporation of CDW powder (non-calcined and calcined) revealed a slight increase with the incorporation of higher CDW content because of the smaller particle size and higher specific surface of CDW compared to cement particles.

- Compressive strength: The incorporation of a higher content of non-calcined CDW resulted in a decrease in the compressive strength of the studied pastes for all ages analyzed. This behavior is related to the lower cement content (dilution effect), which led to a lower formation of hydration products and a higher water–binder ratio. However, the incorporation of CDW up to an incorporation content of 25% in replacement of cement allowed us to obtain a behavior at 7 and 28 days very similar, and, in some cases (5% CDW and 15% CDW), even superior to that of the pastes produced with the incorporation of 25% of fly ash. On the other hand, the compressive strength of the pastes produced with the incorporation of 25% of CDW calcined at 600 °C and 800 °C, which proved to be a very effective treatment, since its mechanical performance was improved due to the CH decomposition into CaO and the CaCO3 decomposition into CaO, allowing the acceleration of the hydration reactions.

- Activity index: It was possible to verify that only the paste incorporating 5% of non-calcined CDW revealed an activity index higher than that specified by the EN 450-1 standard [48], that is, higher than 75%. It was possible to verify that higher CDW contents resulted in a lower activity index as a result of its lower compressive strength. However, up to an incorporation content equal to or greater than 25% CDW, the activity index observed was higher than that observed for pastes with the incorporation of 25% fly ash. On the other hand, the calcination process applied to CDW allowed us to obtain an activity index that was approximately 10% higher than the performance of non-calcined CDW because of CaCO3 decomposition into CaO, which may participate in a new hydration reaction.

Thus, this study demonstrated that non-calcined and calcinated CDW can be used as a supplementary cementitious material, being able to replace not only cement, but also fly ash, whose production has already ended in several European Union countries due to the closure of thermoelectric plants as a result of measures implemented by the European Union to achieve carbon neutrality by 2050. The use of CDW as a supplementary cementitious material also contributes to the decarbonization of buildings and the reduction in the consumption of natural raw materials, taking advantage of industrial waste that is widely available throughout the world and generated by the construction industry itself.

6.1. Research Limitations and Challenges

The use of CDW as a partial replacement for cement in concrete has gained attention for its potential to reduce environmental impacts; however, several limitations hinder its widespread application. A major challenge lies in the highly variable composition and quality of CDW, which can include a heterogeneous mix of concrete, masonry, mortar, ceramics, and sometimes contaminants such as metals, organics, or hazardous substances. This variability affects the consistency and reliability of recycled material’s performance. Moreover, most C&D-derived materials exhibit low pozzolanic activity compared to conventional supplementary cementitious materials like fly ash or slag, limiting their contribution to the mechanical and durability properties of concrete. Significant processing—such as crushing, grinding, and screening—is often required to make CDW suitable for use as a binder, which adds economic and energy costs. Additionally, high replacement levels may lead to reductions in compressive strength, increased porosity, and durability issues such as carbonation or sulfate attack. Furthermore, the absence of widely accepted technical standards and specifications for the use of CDW in cementitious applications presents regulatory and market adoption challenges. Finally, logistical constraints related to the collection, transportation, and processing of waste materials can undermine the economic feasibility of such practices. Collectively, these factors limit the practical and environmental benefits of incorporating CDW as a cement substitute in construction.

6.2. Future Directions

The future development of CDW as sustainable alternatives to cement is promising, particularly in the context of global efforts to reduce carbon emissions, minimize resource consumption, and transition to a circular economy. Advances in processing technologies, such as high efficiency grinding, thermal activation, and chemical enhancement, are expected to improve the reactivity and performance of CDW powders. The integration of digital tools such as AI-driven material characterization and lifecycle assessment models may also help optimize formulations and evaluate cost-effectiveness more accurately. Additionally, increasing regulatory pressure to reduce landfill waste and carbon emissions may incentivize the development of standardized guidelines and certifications for CDW powder production and use. Collaboration between industry, academia, and policymakers could lead to the establishment of technical standards, quality benchmarks, and financial incentives that support market adoption. On the other hand, further application developments are required in other construction materials, namely mortars and concrete, which can be widely used in the construction sector.

Author Contributions

Conceptualization, S.C., K.K. and J.A.; methodology, S.C., K.K. and J.A.; software, S.C.; validation, S.C. and J.A.; formal analysis S.C., K.K. and E.H.; investigation, S.C., K.K., E.H. and J.A.; resources, S.C. and J.A.; data curation, S.C. and E.H.; writing—original draft preparation, S.C. and K.K.; writing—review and editing, S.C., K.K. and J.A.; visualization, S.C., K.K., E.H. and J.A.; supervision, S.C., K.K. and J.A.; project administration, S.C., K.K. and J.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was also partly financed by FCT/MCTES through national funds (PIDDAC) under the R&D Unit Centre for Territory, Environment and Construction (CTAC) under reference UIDB/04047/2025 and UIDP/04047/2025.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Alwis, A.M.L.; Bazli, M.; Arashpour, M. Automated recognition of contaminated construction and demolition wood waste using deep learning. Resour. Conserv. Recycl. 2025, 219, 108278. [Google Scholar] [CrossRef]

- IEA. Global Status Report for Buildings and Construction; IEA: Paris, France, 2019. [Google Scholar]

- Khan, Z.A.; Balunaini, U.; Costa, S.; Nguyen, N. A review on sustainable use of recycled construction and demolition waste aggregates in pavement base and subbase layers. Clean. Mater. 2024, 13, 100266. [Google Scholar] [CrossRef]

- Chen, K.; Wang, J.; Yu, B.; Wu, H.; Zhang, J. Critical evaluation of construction and demolition waste and associated environmental impacts: A scientometric analysis. J. Clean. Prod. 2021, 287, 125071. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Jia, Z.; Aguiar, J.; Cunha, S.; Jesus, C. Green Thermal Aggregates: Influence of the Physical Properties of Recycled Aggregates with Phase Change Materials. Materials 2023, 16, 6267. [Google Scholar] [CrossRef]

- Li, T.; Nogueira, R.; de Brito, J.; Liu, J. A simple method to address the high water absorption of recycled aggregates in cementitious mixes. Constr. Build. Mater. 2024, 411, 134404. [Google Scholar] [CrossRef]

- Alsaif, A.S.; Alqarn, A.S. Characteristics of concrete incorporating construction and demolition waste aggregate and post-consumer tires rubber and steel fibers. Constr. Build. Mater. 2024, 435, 136820. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, X.; Kong, L. Evaluation of carbon and economic benefits of producing recycled aggregates from construction and demolition waste. J. Clean. Prod. 2023, 425, 138946. [Google Scholar] [CrossRef]

- Baggio, T.F.; Possan, E.; Andrade, J.J.O. Physical-chemical characterization of construction and demolition waste powder with thermomechanical activation for use as supplementary cementitious material. Constr. Build. Mater. 2024, 437, 136907. [Google Scholar] [CrossRef]

- Meng, T.; Dai, D.; Jia, Y.; Ying, K.; Meng, R.; Hong, Y. Comparative study of nanomaterials activated recycled powders from demolition and decoration wastes as supplementary cementitious material. Case Stud. Constr. Mater. 2023, 19, 02543. [Google Scholar] [CrossRef]

- Tokareva, A.; Kaassamani, S.; Waldmann, D. Fine demolition wastes as Supplementary cementitious materials for CO2 reduced cement production. Constr. Build. Mater. 2023, 392, 131991. [Google Scholar] [CrossRef]

- Silva, S.R.; Oliveira Andrade, J.J. Investigation of mechanical properties and carbonation of concretes with construction and demolition waste and fly ash. Constr. Build. Mater. 2017, 153, 704–715. [Google Scholar] [CrossRef]

- Oliveira Andrade, J.J.; Possan, E.; Squiavon, J.Z.; Ortolan, T.L.P. Evaluation of mechanical properties and carbonation of mortars produced with construction and demolition waste. Constr. Build. Mater. 2018, 161, 70–83. [Google Scholar] [CrossRef]

- Liu, Q.; Tong, T.; Liu, S.; Yang, D.; Yu, Q. Investigation of using hybrid recycled powder from demolished concrete solids and clay bricks as a pozzolanic supplement for cement. Constr. Build. Mater. 2014, 73, 754–763. [Google Scholar] [CrossRef]

- Zhang, B.; Feng, Y.; Xie, J.; Dai, J.; Chen, W.; Xue, Z.; Li, L.; Li, Y.; Li, J. Effects of pretreated recycled powder substitution on mechanical properties and microstructures of alkali-activated cement. Constr. Build. Mater. 2023, 406, 133360. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2023, 136, 682–697. [Google Scholar] [CrossRef] [PubMed]

- Barbhuiyaa, S.; Kanavaris, F.; Dasc, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- United Nations. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 22 April 2025).

- Kaptan, K.; Cunha, S.; Aguiar, J. A Review: Construction and Demolition Waste as a Novel Source for CO2 Reduction in Portland Cement Production for Concrete. Sustainability 2024, 16, 585. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: Acritical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, C.; He, B.; Yi, S.; Tang, L. Recycling fine powder collected from construction and demolition wastes as partial alternatives to cement: A comprehensive analysis on effects, mechanism, cost and CO2 emission. J. Build. Eng. 2023, 71, 106507. [Google Scholar] [CrossRef]

- Duan, Z.; Hou, S.; Xiao, J.; Li, B. Study on the essential properties of recycled powders from construction and demolition waste. J. Clean. Prod. 2020, 253, 119865. [Google Scholar] [CrossRef]

- Wu, H.; Wang, C.; Ma, Z. Drying shrinkage, mechanical and transport properties of sustainable mortar with both recycled aggregate and powder from concrete waste. J. Build. Eng. 2022, 49, 104048. [Google Scholar] [CrossRef]

- Li, S.; Gao, J.; Li, Q.; Zhao, X. Investigation of using recycled powder from the preparation of recycled aggregate as a supplementary cementitious material. Constr. Build. Mater. 2021, 267, 120976. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, S.; Huang, B.; Yang, Q.; Li, J. Comparison of mechanical, chemical, and thermal activation methods on the utilisation of recycled concrete powder from construction and demolition waste. J. Build. Eng. 2022, 61, 105295. [Google Scholar] [CrossRef]

- Mucsi, G.; Halyag Papné, N.; Ulsen, C.; Figueiredo, P.O.; Kristály, F. Mechanical activation of construction and demolition waste in order to improve its pozzolanic reactivity. ACS Sustain. Chem. Eng. 2021, 9, 3416–3427. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- He, Z.H.; Han, X.D.; Zhang, M.Y.; Yuan, Q.; Shi, J.Y.; Zhan, P.M. A novel development of green UHPC containing waste concrete powder derived from construction and demolition waste. Powder Technol. 2022, 398, 117075. [Google Scholar] [CrossRef]

- Kaptan, K.; Cunha, S.; Aguiar, J. A Review of the Utilization of Recycled Powder from Concrete Waste as a Cement Partial Replacement in Cement-Based Materials: Fundamental Properties and Activation Methods. Appl. Sci. 2024, 14, 9775. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; Toledo Filho, R.D. The utilization of recycled concrete powder as supplementary cementitious material in cement-based materials: A systematic literature review. J. Build. Eng. 2023, 76, 107319. [Google Scholar] [CrossRef]

- Mohammed, S. Processing, effect and reactivity assessment of artificial pozzolans obtained from clays and clay wastes: A review. Constr. Build. Mater. 2017, 140, 10–19. [Google Scholar] [CrossRef]

- Oliveira, D.R.B.; Leite, G.; Possan, E.; Marques Filho, J. Concrete powder waste as a substitution for Portland cement for environment-friendly cement production. Constr. Build. Mater. 2023, 397, 132382. [Google Scholar] [CrossRef]

- National Laboratory of Civil Engineering (LNEC). E 64. Cements—Determination of Density; National Laboratory of Civil Engineering (LNEC): Lisbon, Portugal, 1979. (In Portuguese) [Google Scholar]

- Pane, I.; Hansen, W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem. Constr. Res. 2005, 35, 1155–1164. [Google Scholar] [CrossRef]

- Singh, A.; Panghal, H.; Rath, D.K.; Kumar, R.; Chaudhhary, S. Evaluating the potential of oil seed extract ashes from niger, cotton, and flaxseed as sustainable supplementary cementitious materials. Sustain. Energy Technol. Assess. 2025, 76, 104285. [Google Scholar] [CrossRef]

- Jia, Z.; Cunha, S.; Aguiar, J.; Chen, B. Performance of concrete with demolition waste and PCM under high temperature ranges. Constr. Build. Mater. 2025, 472, 140975. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, J.; Shi, M. Quantitative analysis of the calcium hydroxide content of eva-modified cement paste based on TG-DSC in a dual atmosphere. Materials 2025, 15, 2660. [Google Scholar] [CrossRef]

- Wang, C.; Chazallon, C.; Braymand, S.; Hornych, P. Influence of self-cementing properties on the mechanical behaviour of recycled concrete aggregates under monotonic loading. Constr. Build. Mater. 2023, 367, 130259. [Google Scholar] [CrossRef]

- Cunha, S.; Silva, M.; Aguiar, J. Behavior of cementitious mortars with direct incorporation of non-encapsulated phase change material after severe temperature exposure. Constr. Build. Mater. 2020, 230, 117011. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Camões, A.; Branco, F.G. Synergetic effect of biomass fly ash on improvement of high-volume coal fly ash concrete properties. Constr. Build. Mater. 2022, 314, 125680. [Google Scholar] [CrossRef]

- Narmluk, M.; Nawa, T. Effect of fly ash on the kinetics of Portland cement hydration at different curing temperatures. Cem. Concr. Res. 2011, 41, 579–589. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Lee, H.-S.; Park, K.-B. Simulation of low-calcium fly ash blended cement hydration. ACI Mater. J. 2009, 106, 167–175. [Google Scholar]

- Termkhajornkit, P.; Nawa, T.; Kurumisawa, K. Effect of water curing conditions on the hydration degree and compressive strengths of fly ash-cement paste. Cem. Concr. Compos. 2006, 28, 781–789. [Google Scholar] [CrossRef]

- NP EN 196-1; Methods of Testing Cement. Part 1: Determination of Strength. Portuguese Institute for Quality (IPQ): Lisbon, Portugal, 2017. (In Portuguese)

- EN 1015-3; Methods of Test for Mortar for Masonry-Part 3: Determination of Consistence of Fresh Mortar (By Flow Table). European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Wu, Y.; Mehdizadeh, H.; Mo, K.H.; Ling, T.C. High-temperature CO2 for accelerating the carbonation of recycled concrete fines. J. Build. Eng. 2022, 52, 104526. [Google Scholar] [CrossRef]

- NP EN 450-1; Fly Ash Concrete, Part 1: Definition, Specifications and Conformity Criteria. Portuguese Institute for Quality (IPQ): Lisbon, Portugal, 2012. (In Portuguese)

- Malladi, R.C.; Ajayan, A.; Chandran, G.; Selvaraj, T. Upcycling of construction and demolition waste: Recovery and reuse of binder and fine aggregate in cement applications to achieve circular economy. Clean. Eng. Technol. 2025, 24, 100864. [Google Scholar] [CrossRef]

- Horsakulthai, V. Effect of recycled concrete powder on strength, electrical resistivity, and water absorption of self-compacting mortars. Case Stud. Constr. Mater. 2021, 15, 00725. [Google Scholar] [CrossRef]

- GB/T 17671–1999; Method of Testing Cements—Determination of Strength. National Stabdard of the People’s Republic of China: Beijing, China, 1999.

- GB/T 1596–2017; Fly Ash Used for Cement and Concrete. National Stabdard of the People’s Republic of China: Beijing, China, 2017.

- ASTM C311; Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- NBR 12653; Pozzolanic Materials—Requirements. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2015. (In Portuguese)

- Lima, D.O.; Lira, D.S.; Rojas, M.F.; Savastano Junior, H. Assessment of the potential use of construction and demolition waste (CDW) fines as eco-pozzolan in binary and ternary cements. Constr. Build. Mater. 2024, 411, 134320. [Google Scholar] [CrossRef]

- Liu, R.; Feng, M.; Liu, Z.; Yuan, L.; Tao, G.; Yu, Z.; Meng, X.; Chen, J. An innovative structural energy storage solution using fly ash-cement composites for net-zero energy buildings. Cem. Concr. Compos. 2025, 157, 105960. [Google Scholar] [CrossRef]

- He, X.; Zheng, Z.; Yang, J.; Su, Y.; Wang, T.; Strnadel, B. Feasibility of incorporating autoclaved aerated concrete waste for cement replacement in sustainable building materials. J. Clean. Prod. 2020, 250, 119455. [Google Scholar] [CrossRef]

- Moon, D.-J.; Moon, H.-Y.; Kim, Y.-B. Fundamental properties of mortar containing waste concrete powder. Geosyst. Eng. 2005, 8, 95–100. [Google Scholar] [CrossRef]

- Wu, H.; Liang, C.; Xiao, J.; Xu, J.; Ma, Z. Early-age behavior and mechanical properties of cement-based materials with various types and fineness of recycled powder. Struct. Concr. 2022, 23, 1253–1272. [Google Scholar] [CrossRef]

- Wu, H.; Yang, D.; Xu, J.; Liang, C.; Ma, Z. Water transport and resistance improvement for the cementitious composites with eco-friendly powder from various concrete wastes. Constr. Build. Mater. 2021, 290, 123247. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.; Ferreira, V. Mortars with Incorporation of Phase Change Materials for Thermal Rehabilitation. Int. J. Archit. Herit. 2017, 11, 339–348. [Google Scholar] [CrossRef]

- Cantero, B.; Bravo, M.; Brito, J.; del Bosque, I.S.; Medina, C. Mechanical behaviour of structural concrete with ground recycled concrete cement and mixed recycled aggregate. J. Clean. Prod. 2020, 275, 122913. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Wang, H.; Fang, Y.; Shen, W.; Chen, P.; Xu, Y. Eco-friendly treatment of recycled concrete fines as supplementary cementitious materials. Constr. Build. Mater. 2022, 322, 126491. [Google Scholar] [CrossRef]

- Kabay, N.; Tufekci, M.M.; Kizilkanat, A.B.; Oktay, D. Properties of concrete with pumice powder and fly ash as cement replacement materials. Constr. Build. Mater. 2015, 85, 1–8. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Compliance Criteria for Current Cements. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- Vashistha, P.; Oinam, Y.; Kim, H.; Pyo, S. Effect of thermo-mechanical activation of waste concrete powder (WCP) on the characteristics of cement mixtures. Constr. Build. Mater. 2023, 362, 129713. [Google Scholar] [CrossRef]

- Bogas, J.A.; Carriço, A.; Pereira, M.F.C. Mechanical characterization of thermal activated low-carbon recycled cement mortars. J. Clean. Prod. 2019, 218, 377–389. [Google Scholar] [CrossRef]

- Real, S.; Carriço, A.; Bogas, J.A.; Guedes, M. Influence of the treatment temperature on the microstructure and hydration behavior of thermoactivated recycled cement. Materials 2020, 13, 3937. [Google Scholar] [CrossRef]

- Wu, H.; Xu, J.; Yang, D.; Ma, Z. Utilizing thermal activation treatment to improve the properties of waste cementitious powder and its newmade cementitious materials. J. Clean. Prod. 2021, 322, 129074. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).