Abstract

A Life Cycle Assessment (LCA) of viticulture in the Tacoronte-Acentejo Designation of Origin was the primary goal of this research, aiming to examine and quantify the environmental impacts generated by viticulture and winemaking processes. Data for the investigation were collected through tailored questionnaires administered to viticulturists and winemakers affiliated with the Regulatory Council of the Tacoronte-Acentejo Designation of Origin. These surveys were designed to gather detailed information on the inputs used in both viticulture and winemaking processes, encompassing all stages of production. The results were classified into the following four environmental impact categories: carbon footprint, human toxicity, depletion of fossil energies, and ozone layer depletion. In viticulture, the major contributors to environmental impact included vehicle fuel consumption, pesticide application, and the use of copper sulfate. In the winery phase of production, electricity consumption and glass bottle production were the primary factors with significant environmental implications. These findings provide valuable insights for vineyard and winery managers in favor of implementing more sustainable practices, such as reducing fuel for vehicles and machinery and the use of pesticides in the vineyard phase, and reducing glass bottle usage and electricity consumption in the winery phase. Through this research, they will be able to focus their efforts on the inputs that generate the greatest environmental impacts in order to reduce them.

1. Introduction

Global wine production was estimated at 244.1 million hectoliters in 2023, a 7% decrease compared to 2022, due to extreme weather conditions and fungal diseases that developed throughout the year [1]. The European Union produced 165 million hectoliters of wine in the same year, representing 68% of the total production [1]. It is important to note that these figures exclude juices and musts. Additionally, wine is the largest agri-food sector in the European Union in terms of exports, accounting for 7.6% of the total exports in 2020 [2]. France and Italy are the top global wine producers, reaching 49.8 and 45.6 million hectoliters, respectively. Spain comes in third place with a production of 35.7 million hectoliters in 2022 [1]. Spain represents 15% of the world’s wine production, highlighting the significance of this sector on a global scale.

In Europe, the agricultural sector ranks fifth in terms of environmental pollution [3], contributing to 11% of total greenhouse gas (GHG) emissions. Spain leads in synthetic pesticide and fertilizer consumption in Europe [4]. Similarly, Canary Islands vineyards are among the areas with intensive pesticide use, although not as much in terms of fertilizer use compared to vineyards throughout the rest of Spain.

Spain is the country with the largest vineyard area in the European Union, covering 964 million hectares (mha), followed by France with 798 mha and Italy with 718 mha [5]. Despite having the largest area, Spain’s wine production is surpassed by Italy and France, with Spain producing 33 million hectoliters in 2021 [5].

Meanwhile, the Canary Islands, a Spanish volcanic archipelago of eight islands located about 100 km off the west coast of the African continent, have a significant tradition of viticulture for both commercial and self-consumption purposes. The first records of vines in the Canary Islands date back to the 15th century, and since then, it has been a very important crop for the archipelago, which is why it is the second-most widely cultivated crop in terms of surface area. However, the vineyard area in the Canary Islands has been decreasing, following the overall trend in Spain, indicating a decline in the viticultural sector [6]. This decline has led to a search for wine production with a higher added value and greater environmental sustainability [7]. Moreover, consumers increasingly value and demand products obtained through sustainable cultivation or environmentally respectful processes. The wine industry is no exception to this trend [8]. Several studies confirm that consumers are willing to pay more for sustainable or eco-certified wines [9,10].

Given this context, the European Environment Agency has proposed reduction targets for each European country to mitigate current environmental impacts, emphasizing the need for additional measures to achieve these goals by 2030, such as efficient water use, reduction in the use of environmentally harmful products, and a decrease in carbon emissions [3]. Therefore, this study focuses on the vitivinicultural sector; however, it does not analyze the specific characteristics of wines, such as visual, olfactory, or gustatory aspects. Instead, it specifically examines the environmental impacts of the sector. The scarcity of such studies emphasizes the importance of researching this area, especially considering the global significance of the vitivinicultural sector, including its impact on Spain [11].

Specifically, this article contributes to this body of literature by measuring the environmental impacts of viticulture and winemaking processes through LCA. This study is novel in being the first research to focus on measuring environmental impacts in the Canary Islands using the Life Cycle Assessment methodology. Therefore, it establishes the current environmental status of wineries in Tacoronte-Acentejo, serving as a precedent for future studies. Seven wineries and their corresponding vineyards in the Tacoronte-Acentejo region on Tenerife Island (Canary Islands, Spain) are analyzed. This sample represents more than 30% of the viticultural surface area registered under the Tacoronte-Acentejo Denomination of Origin, and the participating wineries account for around 50% of the wine production in the region. This selection is justified, as Tacoronte-Acentejo represents 40% of the vineyard area in Tenerife and 20% of the total viticultural area in the Canary Islands, making it the Denomination of Origin with the largest extent in the region.

Therefore, the aim of this study is to identify which inputs are the most harmful to the environment (carbon footprint), human health (human toxicity), ozone layer depletion, and the depletion of fossil fuels through different impact categories. To achieve this goal, the following research question is addressed: Which inputs have the greatest impact on viticulture activities and winery processes for each of the impact categories analyzed? Notably, no research of this nature has been conducted in the Canary Islands for any agricultural product, highlighting the significance of this study in setting a precedent for sustainability, particularly in the viticultural sector.

2. Materials and Methods

2.1. Study Area

The Canary Islands have a vineyard area of 6192 hectares, accounting for 2% of the total in Spain. This makes them one of the Autonomous Communities with the smallest vineyard area, mainly due to the limited available agricultural land [12]. In the Canary Islands, vineyards are the second-largest crop in terms of area, only surpassed by bananas [13]. In 2012, the sector encompassed 8727 hectares, but this progressively decreased to 5946 hectares in 2021 (−30%), mainly due to the lack of generational renewal [11]. Total grape production also decreased from 16,523 tons in 2012 to 13,560 tons in 2021 (−18%), due to adverse climatic conditions for the crop favoring the development of fungal diseases that are difficult to treat [3,14].

One of the main reasons for the abandonment of vineyards is the lack of generational succession [7]. On one hand, there is an aging population of grape growers and winemakers, and on the other hand, the harsh working conditions involved, primarily due to the difficulty in mechanizing this agricultural land, are unappealing to younger generations, leading them to choose other sectors. Wine prices also play a role; for instance, Spain is the country with the highest volume of wine exports, but it is also the cheapest, averaging EUR 1.10 per liter, while France and Italy sell their wine at EUR 5.37 and EUR 2.50 per liter on average, respectively [7]. The rugged topography of the Canary Islands is another factor contributing to the abandonment of vineyards, complicating both access to the land and its mechanization. This results in much of the fieldwork being carried out manually, with less machinery involvement compared to other regions of Spain.

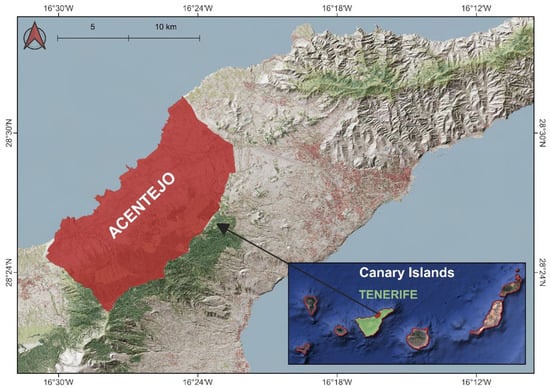

The island of Tenerife (see Figure 1) accounts for the largest vineyard area in the region, representing 45% of the total in the Canary Islands. In terms of production, this island contributes to 65% of the wine production in the Canary Islands and has five Designations of Origin. Tacoronte-Acentejo is the oldest, the one with the largest surface area, and historically, the one with the highest production. The vineyard area in Tenerife decreased from 4739.8 hectares in 2012 to 2756.6 hectares in 2021 (−41.8%) [13]. Meanwhile, grape production was 16.5 million kg in 2012, and by 2021, it had reduced to 13.5 million kg [13].

Figure 1.

Island of Tenerife, where the Acentejo Region has been specified, is the area of the island where the study has been conducted and encompasses five municipalities: Tacoronte, El Sauzal, La Matanza, La Victoria, and Santa Ursula. On the other hand, the Vitivinicultural Designation of Origin of Acentejo brings together 9 municipalities, which include, in addition to the aforementioned ones, La Laguna, Tegueste, Santa Cruz, and El Rosario.

According to the Köppen climate classification, a standardized methodology for classifying and studying climates worldwide [15], the municipalities in the Tacoronte-Acentejo area are classified as semi-arid, warm, and Oceanic-Mediterranean, with the latter being the most predominant [16]. This classification is based on different climate types, using the average monthly values of precipitation and air temperature. The vineyards in this region are situated between 100 and 1000 m above sea level, resulting in unique characteristics due to a variety of aromas, alcohol content, and phenological processes, which differ between the coastal areas and the more mountainous regions. Many of these vineyards are considered heroic viticulture due to meeting conditions set by the Center for Research, Study, Safeguarding, Coordination, and Valuation of Mountain Viticulture (CERVIM), as follows: an average altitude exceeding 500 m, slope greater than 30%, and terraced vineyards or small-sized vineyards with difficult mechanization.

2.2. Methodology

This research conducted an analysis of the environmental impacts of viticulture and winery processes for a sample of seven wineries (see Table 1) and their corresponding vineyards affiliated with the Regulatory Council of the Tacoronte-Acentejo Designation of Origin. To quantify these impacts, the Life Cycle Assessment (LCA) methodology was employed, as outlined in the ISO 14040 and 14044 standards [17,18]. These standards were established to provide a standardized methodology for assessing the environmental performance of a product throughout its life cycle stages. The aim is to generate results that indicate the impacts generated during the product’s acquisition process, facilitating efforts to reduce such impacts [19].

Table 1.

List of the studied wineries with their main characteristics.

All seven wineries participating in the study have vineyards of varying ages, including some pre-phylloxera plantings [20], planted on their own roots. The choice of trellising system depends on the grape variety planted. Although different trellising systems are used in the Canary Islands, the Tacoronte-Acentejo region predominantly employs the converted simple trellis system. Previously, the most common trellising system was the low or table trellis system, but this presents various issues for vineyard cultivation, as well as for the aeration and illumination of grape clusters. Therefore, the majority of estates have converted to the simple trellis system. Meanwhile, new plantations are established using a simple trellis system [14]. The predominant red grape varieties include ‘Listán negro’, ‘Tempranillo’, ‘Negramoll’, and, to a lesser extent, ‘Castellana negra’, ‘Baboso negra’, and ‘Vijariego tinta’, among others. Regarding white grape varieties, ‘Listán blanco’ is predominant, while ‘Albillo criollo’ and ‘Marmajuelo’ are found in smaller quantities [21].

Life Cycle Assessment (LCA) is a widely used tool for measuring the environmental impact of any viticulture or winemaking product [22]. LCA, standardized in ISO 14040, is employed to evaluate environmental impacts throughout the life cycle of a product, process, or service, considering all inputs consumed during production [19,23]. Over the past decade, the number of articles applying LCA methodology has increased significantly, covering the environmental impacts of various agricultural products such as lettuce cultivation [24], coffee [25], and olives for oil [26].

For the analysis, the corresponding functional unit was defined for each process. For viticulture, 1 kg of grapes was chosen, and for wineries, 1 bottle of wine (0.75 L), which is approximately equivalent to 1 kg of grapes, was established. These functional units are widely used in the available literature, making them suitable for comparison with results from other studies [27,28].

2.3. Evaluation of Environmental Impact

For the evaluation of environmental impacts, the Open LCA 2.0. software was utilized, designed for Life Cycle Assessment calculations. The Agribalyse 3.1 database, specifically developed for the assessment of agricultural and food products, was employed. The impact assessment method chosen was ReCiPe Midpoint (H) V1.01, because it is adapted to the European context. Specifically, the Midpoint method was used, because it has a stronger relationship with environmental flows [29,30]. Moreover, this method offers a greater number of impact categories, a total of 18, all related to the environment. Out of these 18, 4 impact categories were selected, as they are the most representative for research focused on the wine industry; these impact categories are global warming, ozone layer depletion, fossil fuel depletion, and human toxicity [19,31]. This selection of categories aims to provide greater clarity to the document [32].

2.4. Data Collection

The data from vineyards and wineries were gathered through two custom questionnaires, one focused on viticulture and the other on winemaking processes. Initially, existing questionnaires from previous research studies [19,33,34] were adapted to the specific case of Tacoronte-Acentejo. These questionnaires were completed in person by winemakers, oenologists, or managers of the wineries.

Data collection occurred from January to May 2023, and the obtained data correspond to the 2022 campaign. Utilizing the data from this campaign was possible, as all inputs and processes for both viticulture and winemaking were known. Initially, a pilot questionnaire was developed for viticulture, and another for wineries, to validate their effectiveness. After the initial testing, necessary corrections and adjustments were made to acquire the desired information. Subsequently, with the refined questionnaires, the necessary information was collected.

This method of data collection was chosen to ensure first-hand and reliable data, fostering a better working atmosphere between the interviewer and the interviewees [35].

2.5. Description and System Boundaries

For this study, system boundaries were established following the “cradle-to-grave” approach [36]. In the viticulture phase, the entire process was considered, starting from the first tasks performed in a season—typically pruning between January and March—until the grapes are harvested and transported to the winery; this process is referred to as “cradle-to-door” [18]. In the winemaking phase, the scope includes activities from grape reception to bottling and packaging, excluding the distribution of bottles to retail points. These system boundaries aim to standardize the calculation of environmental impacts, facilitating comparability across different research studies [32].

None of the seven participating wineries in this study are certified in organic production. Only one of them practices ecological methods (W1), using entirely natural products in viticulture, while in winemaking processes, some enological products of synthetic origin are used, but in low doses. This winery has not obtained organic certification due to neighboring vineyards practicing conventional viticulture, which could pose challenges in obtaining certification.

Another limitation of this study relates to the exclusion of CO2 sequestration by the vineyards. Future research should aim to quantify the amount of CO2 captured by vineyards in the Tacoronte-Acentejo region, particularly for the “Listán Negro” and “Listán Blanco” grape varieties, which are among the most widely cultivated in the Canary Islands.

2.6. Inventory Analysis

To compile the inventory of inputs, data related to the vineyards (see Table A1 and Table A2 in the Appendix A) were initially collected. The most commonly used phytosanitary products in the analyzed vineyards were sulfur, copper sulfate, and pesticides (composed of insecticides, acaricides, and fungicides, all included in the inventory). These inputs are applied to combat the main diseases that develop in the Tacoronte-Acentejo region due to the climate, downy mildew and powdery mildew, which usually occur during the vine’s growth phase, and botrytis, which, if it appears, does so in the final stage of cluster ripening [7].

Various fertilizers were used, with animal manure being the main one, as five of the participating wineries apply it to their vineyards. This is evidenced by the results obtained after conducting the LCA, which show that it has no significant impact. Its environmental impact is minimal, as it undergoes no treatment, only being applied once cured. Fertilizers with high nitrogen and potassium content were used to a lesser extent. These fertilizers are applied to the soil once the leaves have fallen in autumn, with the aim of providing nutrients to the soils where the roots are located. Additionally, the application of well-cured natural fertilizers helps to prevent the occurrence of diseases such as armillaria. In some cases, these applications can be repeated after winter pruning (February–March) [7].

Some wineries employed ecological products, such as bentonite, diatomaceous earth, cinnamon, soy lecithin, or kaolin, with a very low or negligible environmental impact compared to phytosanitary products. These natural products are used as preventive measures against vineyard diseases.

All analyzed vineyards are rainfed, so water for irrigation was not considered. However, water used for dissolving and applying products that require water was quantified at 1600 L per hectare.

Vehicle fuel corresponds to the transportation of workers to the vineyards, typically carried out in their personal cars. This was calculated based on the number of treatments applied during a season and the distance from the winery or residence to the vineyards. Machinery fuel consumption was obtained by considering the number of times machinery was used in the vineyard, with hours of operation being used as the unit of measure, and oil and lubricants accounting for 2% of the total fuel usage.

Regarding the disposal of pruning residues, the analyzed wineries destroy these residues with tractors on-site, using them as organic material. Therefore, their impact is included in machinery fuel consumption. In this regard, they differ from other places where pruning residues are incinerated [18]. Only two wineries use electricity in their vineyards, as they employ electric machinery and pumps for various treatments.

In the winemaking phase, the inputs considered included grapes, enological products, packaging materials (corks, glass bottles, capsules, and labels), electricity used, water, and the origin of these products, in order to calculate transportation from their source to the winery. The latter was measured in kg/km [18]. Caustic soda was universally used by winemakers for cellar and wine container cleaning.

3. Results

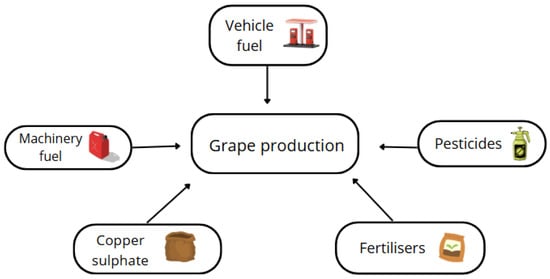

After completing the inventory, the results for the vineyard phase are obtained. The inventory compiled all the information related to the inputs used in the vineyards during one season. The collected data are distributed based on the kilograms harvested, representing the quantity of each input needed to produce 1 kg of grapes. Heterogeneity is observed in the products used in the vineyard, reflecting variations depending on the specific needs of each vineyard. However, some inputs like sulfur, vehicle fuel, tractor fuel, and pesticides become essential for grape production. Figure 2 shows the different inputs required for the production of the final product.

Figure 2.

Inputs necessary to obtain 1 kg of grapes during one season in Tacoronte-Acentejo.

In the Tacoronte-Acentejo region, the production of 1 kg of grapes requires different input amounts. On average, 101 L of vehicle fuel and 240 L of machinery fuel are needed for field operations. Regarding the products used, averages of 3.06 g of pesticides, 16.14 g of fertilizers, 3.96 g of copper, and 42.08 g of sulfur are required to produce 1 kg of grapes over a growing season.

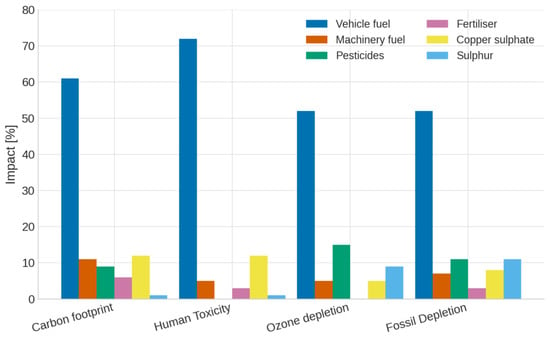

The results for the vineyard phase are categorized into the following four impact categories (see Figure 3): carbon footprint, human toxicity, depletion of fossil energy, and depletion of the ozone layer. It is important to note that only inputs representing more than 1% of the total are considered in the analysis, while the rest are deemed less relevant.

Figure 3.

Impact categories in the Tacoronte-Acentejo vineyard phase for the production of 1 kg of grapes differentiated by the inputs used.

Concerning carbon footprint, it is observed that the most impactful input is the fuel used in vehicles for transporting workers to vineyards, constituting over 61%. This input remains consistent across all impact categories, serving as the primary environmental factor. The difficulty in reducing this consumption lies in the current vehicles used for estate tasks, unless replaced by renewable energy vehicles. The necessity for travel to vineyards for various seasonal tasks is unavoidable. This input has also been identified as one of the most environmentally impactful aspects in various studies [37,38,39,40,41,42]. Additionally, beyond vehicle fuel, fuel for agricultural machinery emerges as the second-most significant input, contributing to over 11%. This machinery is employed within the estate for diverse field tasks. While challenging to replace, there is potential for substitution with clean energy vehicles or minimizing interventions with machinery using this fuel, provided that it does not adversely affect the vineyard’s proper development. It is also an input that appears repeatedly in other studies conducted on viticulture [40,42,43].

Pesticides rank as the third input for carbon footprint, comprising over 8% of the total. Notably, the software does not factor in the environmental impact of pesticide production, but does consider its impact during transportation to vineyards. The Agribalyse 3.1 database, which is used because of its affinity with the agricultural sector, does not include the production of these pesticides, but does include their transport, yet it is one of the best recognized and most widely used databases in the scientific literature for LCA. The utilization of these products is attributed to their preventive and curative application on specific occasions. Furthermore, the geographic conditions of the surveyed vineyards, characterized by high ambient humidity during much of the vineyard’s development period, necessitate an increased number of pesticide treatments due to the proliferation of fungi and diseases. As in other regions, the vineyards’ geographical location dictates the timing of applications [44,45]. The impact of pesticides in the Tacoronte-Acentejo region is lower than in other locations where similar studies have been conducted, where pesticides are the leading inputs affecting various impact categories. In this study, however, they rank third [18,42,43].

Finally, fertilizers represent the smallest share of the key inputs for vineyards, accounting for slightly over 5%. It is important to highlight that these fertilizers are not applied annually; instead, their application is alternated between years. Consequently, the annual average is computed. Various types of manures and fertilizers are utilized across the estates. Liquid manure, originating from animals and comprising urine and livestock feces, is directly applied to the soil using atomizing backpacks. In contrast, some estates employ solid animal manure, directly applying it to vine trunks and blending it with the soil. Following application, irrigation is typically carried out to safeguard the vines. Additionally, one estate utilizes natural fertilizer derived from animal feces and organic matter from other temporary crops. After processing and curing, this fertilizer is applied to the soil similarly to animal manure. Typically, these fertilizers are imported, necessitating transportation to the Canary Islands; however, this aspect is not considered by the software. Others opt for organic matter, which does not contribute to any carbon footprint. Moreover, this organic matter is often self-produced on the estate, resulting in minimal or zero transportation. In summary, the average carbon footprint for all surveyed estates amounts to 1.40 kg of CO2 equivalent per 1 kg of grapes.

The findings for Tacoronte-Acentejo show a slight reduction compared to two other studies concentrating on the Iberian Peninsula. In one of these investigations, the outcome was 1.42 kg of CO2 equivalent per 1 kg of grapes in Cangas, Galicia [18], and 1.61 kg of CO2 equivalent in Ribeiro, Galicia [40]. However, studies conducted in Italy and Cyprus presented lower and distant values of 0.39 and 0.56, respectively. Meanwhile, Portugal reported higher results with 2 kg of CO2 equivalent per 1 kg of grapes [46,47,48].

Another impact category under scrutiny is human toxicity. This category gauges the toxic effects of specific products on humans, using dichlorobenzene as the unit of measurement to evaluate the impact of chemical emissions. The leading detrimental input during the vineyard phase is vehicle fuel, contributing 72.18% to the total. Other inputs, such as copper sulfate and pesticides, are the subsequent products negatively affecting human health, constituting 12.23% and 6.57%, respectively. Additional harmful inputs encompass machinery fuel at 5.41% and fertilizers at 2.4%, with the remainder being practically negligible. The average value for all surveyed estates concerning human toxicity is 1.41 kg 1.4-DB equivalent.

The remaining analyzed impact categories, including the depletion of fossil fuels and the depletion of the ozone layer, follow a consistent pattern. Similar to previous categories, vehicle fuel continues to be the primary input, accumulating 52.06% and 52.18% of the total. Pesticides also recur as a detrimental input for these impact categories, with values of 11.05% and 15.26%, respectively. Sulfur makes its debut as an input with a certain environmental impact for these last two impact categories, exceeding 8% in both cases. This is because the sulfur used is processed with petroleum-derived products, and its transformation affects both ozone layer depletion and fossil fuel depletion. The final value for fossil fuel depletion is 0.24 kg of equivalent fuel for the production of 1 kg of grapes. Meanwhile, for the ozone layer depletion category, the average value is 1.18 × 10−7 kg CFC-11 equivalent.

Considering these findings, it raises the question of whether there is homogeneity in identifying the most environmentally harmful inputs. Various articles have compiled results from major LCA studies in vineyards or winemaking processes, facilitating comparisons [44]. Other publications have compared different production methods in viticulture, distinguishing between organic, conventional, and even biodynamic farming. For instance, Villanueva-Rey et al. [33] evaluated three different viticulture techniques—biodynamic, conventional, and uncertified biodynamic—using LCA to determine which method had the least environmental impact. The study concluded that biodynamic practices had the lowest pollution levels, while conventional viticulture had the highest, attributed to fewer phytosanitary products and fertilizers in biodynamic practices, as well as more manual labor.

Impact Assessment for Winery Phase

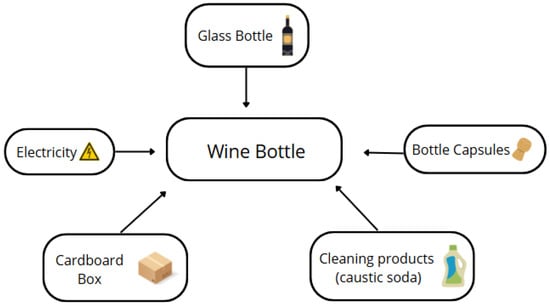

For the winery phase, an inventory is conducted to collect all the inputs consumed during a season. The weight of the inputs is distributed considering the number of bottles produced by each winery. Broadly speaking, we can observe that the inputs are quite homogeneous. This is because certain inputs such as bottles, corks, labels, or capsules are needed for wine bottling. Similarly, water is necessary for cleaning and other processes in the winery. The greatest difference is found in oenological products, as each winemaker has their own techniques for winemaking, and there are also varying needs for wines each season.

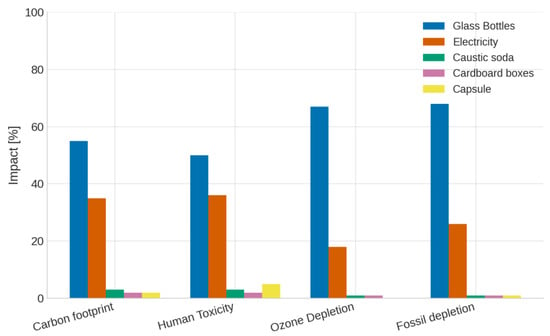

In this phase, the same impact categories as those in the vineyard phase are analyzed, and the main inputs are identified (see Figure 4). As in the vineyard phase, only inputs with a percentage higher than 1% are considered. As we can observe in the figure, the central product is the wine bottle, which is the target of the process, and for this, all the surrounding inputs are necessary.

Figure 4.

Inputs necessary to obtain a bottle of Tacoronte-Acentejo wine (75 cl.).

To produce one bottle of Tacoronte-Acentejo wine (0.75 L), the inputs shown in Figure 4 are required. On average, 492.84 g of glass (bottles), 0.72 kWh of electricity, 3.18 g of caustic soda used for cleaning and disinfection, 32.6 g of cardboard per bottle (boxes), and 0.92 g for bottle capsules are needed.

As in the vineyard phase, the following two inputs are present in all impact categories and have a significant weight in each of them: glass bottles and electricity consumed in the winery (see Figure 5). This is not a particular finding of this research; it is consistent with various studies where bottles are identified as one of the main contributors to environmental impacts due to the high electricity consumption required for their production [31,37,39,40,42,43].

Figure 5.

Impact categories in the winery phase of Tacoronte-Acentejo for the production of a bottle of wine differentiated by the inputs used (75 cl.).

Specifically, the carbon footprint of the analyzed wineries has an average value of 1.49 kg of CO2 for producing a 0.75 L wine bottle, which is approximately equivalent to 1 kg of grapes. The average carbon footprint values for a wine bottle from other studies range from 0.65 to 2.5 kg CO2 [18,27,39,40]. The primary input is the glass bottles used, representing 56.47% of the total consumption. This is due to the high energy requirements for the production of this product and its transportation to the Canary Islands. This latter factor is what causes the percentage of glass bottle use in the studied region to increase compared to other studies, where the glass bottle typically accounts for an average of 26.55%. As mentioned earlier, this input is the one that has the greatest impact in various studies, indicating a need for measures to reduce this impact, such as using lighter bottles that perform the same function or exploring alternative materials.

The other significant input is the electricity used in the winery, accounting for 35.66% of the total. This includes usage for both winemaking machinery and the proper functioning of the winery, with consumption peaks occurring during the harvest months between September and November. Other studies, such as those by Laca et al. [18] and Vasquez-Rowe et al. [40], have quantified electricity consumption, which accounts for 6% and 10%, respectively—percentages lower than those obtained for Tacoronte-Acentejo.

It should be noted that some wineries purchase bottles manufactured in the Canary Islands, but the percentage is lower compared to imported bottles. As for the electricity used by all participating wineries, it is sourced from fossil fuels, explaining its high impact. This impact would be lower if renewable energy sources were used to generate electricity.

The remaining products have a very low representation compared to those mentioned earlier. With less than 2% of the total, cardboard boxes used for the storage and subsequent distribution of bottles, caustic soda, and bottle capsules are included. This pattern is repeated in the other analyzed impact categories—human toxicity, depletion of the ozone layer, and depletion of fossil fuels—with percentages very similar to those described previously, with glass bottles and electricity being the main inputs. Bottles account for over 49% in the remaining three impact categories, and electricity accounts for over 20% in the rest of the categories. In contrast, capsules, labels, and corks have very low impacts in terms of environmental impact, being less than 5% in all analyzed categories. The water used for cleaning the winery and containers has an even lower impact. It should be noted that in the human toxicity category, the aluminum capsules of bottles contribute, due to different manufacturing processes, to a higher impact. A scientific analysis of possible alternatives to aluminum, such as wax or PVC, should be considered to achieve a lower environmental impact.

In the case of wine, Navarro et al. [34] conducted an LCA in 18 wineries across Spain and southern France to analyze the carbon footprint of viticulture and winemaking. The results showed that in the winemaking phase, the production and transportation of glass bottles and the winery’s electricity consumption were the major contributors to carbon footprint. In viticulture, fuel consumption and the use of phytosanitary products were significant, while other inputs were less relevant. A similar study on Chilean organic wine by Letamendi et al. [45] reported comparable results, emphasizing the environmental impacts of glass bottles and electricity consumption in winery processes.

In addition to being a deeply rooted crop in the Canary Islands, viticulture presents characteristics that are less harmful to the environment compared to other emerging (avocado) or established (banana) crops. One of the most notable features is its low water requirement, as the majority of vineyards are rainfed (69.9%) [13], whereas the other two crops require constant irrigation. Irrigated vineyards in the Tacoronte-Acentejo region require 2400 m3/ha per year, while avocado cultivation in Tenerife demands between 6000 and 9000 m3/ha per year and banana cultivation can reach up to 15,000 m3/ha per year [49]. Therefore, the environmental footprint of vineyards is significantly lower than that of other representative crops in this region and archipelago. These findings support the idea that the Tacoronte-Acentejo region continues to promote a crop that is environmentally beneficial, while also preserving the heritage associated with its landscape and viticultural tradition.

The results obtained in the viticulture section show a direct relationship between a lower carbon footprint and higher agricultural yield, which aligns with previous LCA studies in vitivinicultural systems. Research such as that by [40,42] has demonstrated that plots with higher yields tend to exhibit a lower environmental impact per unit of product, due to greater efficiency in the use of inputs and resources. This efficiency, also observed in the plots analyzed in the present study, is reinforced by an adequate agrochemical composition of the soil, where parameters such as the Ca/Mg ratio—identified here as one of the most relevant—were found to be within or near optimal ranges. Ref. [39], it was emphasized that the nutrient balance in the soil not only supports yield, but also contributes to a better energy efficiency and lower environmental burden throughout the cultivation cycle.

Regarding the winery phase, the differences observed in comparison to other studies may be attributed to several system-specific factors, as follows: the small size of the winery, more efficient energy management, the absence of active climate control, and a more rational use of materials during the fermentation and stabilization stages (oenological products). Additionally, the local character of wine consumption may reduce the indirect impacts associated with transport and distribution, although this phase was not considered in the present study.

These results demonstrate that even in small-scale systems such as the one analyzed, the winery phase can maintain relatively low impacts if the resources used are optimized and the technology is adapted to local conditions. They also reinforce the importance of analyzing each phase of the life cycle independently, especially when aiming to identify opportunities for environmental improvement in insular scenarios or those with structural limitations, such as those found in the Canary Islands.

4. Conclusions

In this study, the environmental impacts of viticulture and winemaking processes were assessed across several farms and wineries affiliated with the Regulatory Council of the Tacoronte-Acentejo Designation of Origin. It is noteworthy that environmental impact measurements through Life Cycle Assessment (LCA) had not been conducted in the Canary Islands for any wine-related product or process prior to this research, making this study a novel contribution and setting the groundwork for future investigations in other regions of the archipelago. Additionally, by conducting this research, the results could be used to analyze the evolution of the region in the future and to verify if the dissemination of the findings has helped to improve sustainability.

The results revealed some heterogeneity despite being located in the same region, primarily attributed to variations in the inputs used and the number of treatments and interventions employed at the different vineyards and wineries. In the winemaking phase, two major inputs with significant detrimental impacts were glass bottles and electricity. A reduction in bottle weight could lead to a 20% decrease in CO2 emissions. Substituting these inputs would not only have a positive environmental impact, but could also be economically beneficial for wineries. For instance, using lighter bottles would reduce the energy needed for production, and the implementation of solar energy could decrease electricity costs. Other inputs, such as caustic soda, bottle capsules, and cardboard boxes, had lower impacts compared to the primary inputs.

Based on these results, recommendations are proposed to reduce the environmental impact of viticulture. These include considering alternatives such as electric vehicles and machinery, transitioning to natural pesticides to reduce human toxicity (such as using horsetail, cinnamon, or nettle manure), and installing renewable energy sources in wineries, as all participating wineries in the study have the possibility to install solar panels, from which they could obtain the necessary energy to power both products. The installation of charging points, for example, for vehicles used during both the winery and vineyard phases would cost between EUR 15,000 and EUR 30,000, depending on the type of charging used (semi-fast or fast), but these charging station prices correspond to one charging point per vehicle and do not take into account the possible subsidies for which they could be eligible. Additionally, the use of lighter glass bottles and local production could contribute to a significant reduction in impacts.

These improvement measures could be effectively implemented through various policies based on the sustainability of the agricultural sector. Specific regulations could be established to mandate a reduction in bottle weight or the use of renewable energy for different processes involving electricity, both in the vineyard and in the winery. Another appealing measure could be the mandatory implementation of sustainability certifications, which would help to combat and improve current practices. These certifications generally require thorough supervision to verify the effectiveness of the adopted measures. For now, this aspect is still in an initial process and, in our particular case, the wineries analyzed do not have any obligation to improve in the environmental aspect.

In conclusion, this research provides a starting point for understanding the environmental state of the wine sector in the Tacoronte-Acentejo region, laying the foundation for sustainable long-term improvements. Furthermore, it allows for a comparative analysis in the future to assess the evolution of the wineries analyzed, as well as the region itself, and whether they have adopted sustainable resources that do not harm the environment. Future research will aim to compare different regions (Denominations of Origin), in addition to the extension of the limits within which it intends to carry out a complete LCA from cradle to grave, as well as to check whether the participants in this research have taken measures to reduce their environmental impacts.

Author Contributions

Conceptualization, I.d.M.-P.C.; methodology, S.M.B.C. and P.A.G.; formal analysis, I.d.M.-P.C. and P.A.G.; resources, J.C.S.; writing—original draft preparation, S.M.B.C. and N.C.-P.; writing—review and editing, S.M.B.C. and N.C.-P.; supervision, I.d.M.-P.C. and J.C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study due to Legal Regulations (https://www.boe.es/buscar/act.php?id=BOE-A-2007-12945, accessed on 12 July 2024).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would especially like to thank the Consejo Regulador de la Denominación de Origen Tacoronte-Acentejo for their collaboration in obtaining the data used in this research, as well as the participating wineries.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Appendix A

Table A1.

Inventory of input usage in vineyard cultivation.

Table A1.

Inventory of input usage in vineyard cultivation.

| Winery | Input | Quantity | Unit |

|---|---|---|---|

| W1 | Machinery oil | 0.5 | g |

| Water | 13.6 | kg | |

| Cinnamon | 1 | g | |

| Copper | 0.5 | g | |

| Tractor fuel | 17 | g | |

| Vehicle fuel | 13 | g | |

| Liquid manure | 4 | g | |

| Soy lecithin | 1 | g | |

| Animal manure | 4 | g | |

| Pesticides | 0.2 | g | |

| Silica | 0.6 | g | |

| W2 | Machinery oil | 1.2 | g |

| Water | 2 | kg | |

| Sulphur | 50 | g | |

| Bentonite | 20 | g | |

| Kaolin | 20 | g | |

| Copper | 2 | g | |

| Tractor fuel | 11 | g | |

| Vehicle fuel | 28 | g | |

| Pesticides | 0.5 | g | |

| Silicate | 2 | g | |

| Diatomaceous earth | 20 | g | |

| W3 | Water | 950 | L |

| Sulphur | 43 | g | |

| Tractor fuel | 10 | g | |

| Vehicle fuel | 100 | g | |

| Natural fertilizer | 37 | g | |

| Pesticides | 1.05 | g | |

| W4 | Water | 480 | g |

| Sulphur | 13.6 | g | |

| Kaolin | 1.9 | g | |

| Tractor fuel | 29 | g | |

| Vehicle fuel | 70 | g | |

| Electricity | 0.58 | kWh | |

| Soy lecithin | 0.03 | g | |

| Pesticides | 3.05 | g | |

| W5 | Machinery oil | 0.3 | g |

| Water | 1 | kg | |

| Sulfur | 86 | g | |

| Bentonite | 10 | g | |

| Tractor fuel | 7 | g | |

| Vehicle fuel | 270 | g | |

| Liquid manure | 217 | g | |

| Paraffin wax | 5 | g | |

| Pesticides | 2.1 | g | |

| Silica | 4 | g | |

| Diatomaceous earth | 10 | g | |

| W6 | Machinery oil | 0.2 | g |

| Water | 1430 | g | |

| Sulfur | 50 | g | |

| Kaolin | 0.22 | g | |

| Copper | 0.3 | g | |

| Tractor fuel | 140 | g | |

| Vehicle fuel | 160 | g | |

| Glyphosate | 0.03 | g | |

| Animal manure | 0.05 | g | |

| Pesticides | 200 | g | |

| Potassium | 0.2 | g | |

| W7 | Machinery oil | 0.15 | g |

| Water | 1625 | g | |

| Sulphur | 50 | g | |

| Copper | 9 | g | |

| Tractor fuel | 30 | g | |

| Electricity | 5.79 | kWh | |

| Animal manure | 375 | g | |

| Pesticides | 0.45 | g |

Table A2.

Inventory of use of inputs for the winery.

Table A2.

Inventory of use of inputs for the winery.

| Winery | Input | Quantity | Unit |

|---|---|---|---|

| W1 | Water | 12.6 | L |

| Glass bottles | 574.5 | g | |

| Cardboard | 32 | g | |

| Cork | 5.93 | g | |

| Capsule | 0.79 | g | |

| Electricity | 0.019 | kWh | |

| Labels | 1.93 | g | |

| Packaging film | 0.00092 | g | |

| Caustic soda | 0.93 | L | |

| Sulfurous | 500 | mL | |

| Transport of goods | 102.058 | kg*km | |

| W2 | Water | 380 | L |

| Glass bottles | 594 | g | |

| Cardboard | 53.75 | g | |

| Cork | 4 | g | |

| Capsule | 0.6 | g | |

| Electricity | 0.43 | kWh | |

| Labels | 3 | g | |

| Caustic soda | 0.05 | L | |

| Sulfurous | 504 | mL | |

| Transport of goods | 23.8 | kg*km | |

| W3 | Water | 20 | L |

| Glass bottles | 670 | g | |

| Cardboard | 32.7 | g | |

| Cork | 4.97 | g | |

| Capsule | 0.76 | g | |

| Electricity | 0.6 | kWh | |

| Envelopes | 0.02 | g | |

| Labels | 2.49 | g | |

| Packaging film | 0.0012 | g | |

| Yeast | 0.16 | g | |

| Caustic soda | 20 | l | |

| Sulphur | 550 | ml | |

| Transport of goods | 26.67 | kg*km | |

| W4 | Water | 850 | L |

| Ammonium | 0.017 | g | |

| Glass bottles | 570 | g | |

| Cardboard | 18 | g | |

| Citric acid | 0.000069 | g | |

| Cork | 6 | g | |

| Capsule | 1.2 | g | |

| Electricity | 1.4 | kWh | |

| Stabilizers | 0.8 | L | |

| Labels | 2 | g | |

| Packaging film | 0.0083 | g | |

| Yeast | 0.2 | g | |

| Nutrients | 0.053 | g | |

| Peracetic acid | 0.00017 | g | |

| Sulfurous | 0.01 | L | |

| Transport of goods | 114.31 | kg*km | |

| W5 | Water | 150 | L |

| Glass bottles | 574.5 | g | |

| Cardboard | 32.6 | g | |

| Cork | 3.6 | g | |

| Capsule | 0.8 | g | |

| Electricity | 0.38 | kWh | |

| Labels | 3 | g | |

| Packaging film | 0.0015 | g | |

| Caustic soda | 0.74 | L | |

| Caustic soda | 16 | L | |

| Sulfurous | 3 | mL | |

| W6 | Water | 740 | L |

| Glass bottles | 484.24 | g | |

| Cardboard | 26.75 | g | |

| Cork | 5.86 | g | |

| Capsule | 1 | g | |

| Electricity | 0.703 | kWh | |

| Stabilizers | 0.7 | L | |

| Labels | 2.11 | g | |

| Packaging film | 0.008 | g | |

| Yeast | 0.18 | g | |

| Nutrients | 0.033 | kg | |

| Caustic soda | 1.32 | L | |

| Sulfur | 1340 | mL | |

| Sulfur | 0.0098 | L | |

| Transport of goods | 111.23 | kg*km | |

| W7 | Water | 927,000 | L |

| Bentonite | 0.05 | g | |

| Glass bottles | 556.38 | g | |

| Cardboard | 0.00036 | kg | |

| Capsule | 1.29 | g | |

| Electricity | 1.56 | kWh | |

| Labels | 1.59 | g | |

| Packaging film | 0.00081 | g | |

| Gum Arabic | 0.6 | g | |

| Yeast | 0.18 | g | |

| Nutrients | 0.6 | g | |

| Sulphur | 0.007 | L | |

| Tannins | 0.15 | g | |

| Transport of goods | 180.36 | kg*km |

References

- OIV. Actualidad de la Coyuntura del Sector Vitivinícola Mundial en 2022; Organización Internacional de la Vid y el Vino: Dijon, France, 2023; p. 20. [Google Scholar]

- EU. Agri Dashboard Wine. Wine, 2022. Available online: https://agriculture.ec.europa.eu/document/download/9b037197-f279-4b1b-9282-d94e78bfe27a_en?filename=wine-dashboard_en.pdf (accessed on 12 July 2024).

- EEA. Trends and Drivers of EU Greenhouse Gas Emissions; EEA Report No 3/2020; European Environment Agency: Copenhagen, Denmark, 2021; Available online: https://www.eea.europa.eu/publications/trends-and-drivers-of-eu-ghg (accessed on 26 April 2024).

- Alonso González, P.; Parga-Dans, E.; Pérez Luzardo, O. Big sales, no carrots: Assessment of pesticide policy in Spain. Crop Prot. 2021, 141, 105428. [Google Scholar] [CrossRef]

- OIV. Actualidad de la Coyuntura del Sector Vitivinícola Mundial en 2021; Organización Internacional de la Vid y el Vino: Dijon, France, 2021; p. 20. [Google Scholar]

- MAPA. Superficies y Producciones Anuales de Cultivo; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2009.

- Alonso González, P.; Parga-Dans, E. Natural wine: Do consumers know what it is, and how natural it really is? J. Clean. Prod. 2020, 251, 119635. [Google Scholar] [CrossRef]

- Vecchio, R.; Annunziata, A.; Parga Dans, E.; Alonso González, P. Drivers of consumer willingness to pay for sustainable wines: Natural, biodynamic, and organic. Org. Agric. 2023, 13, 247–260. [Google Scholar] [CrossRef]

- Berghoef, N.; Dodds, R. Determinants of interest in eco-labelling in the Ontario wine industry. J. Clean. Prod. 2013, 52, 263–271. [Google Scholar] [CrossRef]

- Forbes, S.L.; Cohen, D.A.; Cullen, R.; Wratten, S.D.; Fountain, J. Consumer attitudes regarding environmentally sustainable wine: An exploratory study of the New Zealand marketplace. J. Clean. Prod. 2009, 17, 1195–1199. [Google Scholar] [CrossRef]

- Godenau, D. El cambio climático en Canarias: Implicaciones para los vinos. In Vinaletras 7o Cuaderno de Cultura y Vino Tacoronte-Acentejo; Cabildo de Tenerife: Santa Cruz de Tenerife, Spain, 2019; p. 11. [Google Scholar]

- INE. Censo Agrario 2020; Universidad Autónoma de Madrid: Madrid, Spain, 2020; p. 36. [Google Scholar]

- ISTAC. Superficie Cultivada Superficie de Producción y Árboles Diseminados Según Productos Agrícolas Permanentes y Sistemas de Cultivo. Municipios e islas de Canarias por años; Instituto Canario de Estadística: Santa Cruz de Tenerife, Spain, 2021. [Google Scholar]

- Prendes Ayala, C.; Lorenzo Bethencourt, C.D.; Alvarez de la Paz, F.J.; Cabrera Pérez, R.M.; Prendes Lorenzo, C.D. Estudio comparativo entre el sistema tradicionaly en espaldera, de las principales enfermedades fúngicas de la vid, en el municipio de Tacoronte. In XXVI Jornadas de Viticultura y Enología de la Tierra de Barros; Universidad de Extremadura: Badajoz, Spain, 2004; pp. 115–128. [Google Scholar]

- Chazarra, A.; Mestre, A.; Pires, V.; Cunha, S.; Silva, Á.; Marques, J.; Carvalho, F.; Mendes, M.; Neto, J.; Mendes, L.; et al. Atlas Climático dos Arquipélagos das Canárias, da Madeira e dos Açores; Ministerio de Agricultura, Alimentación y Medio Ambiente: Madrid, Spain, 2011; p. 80. [CrossRef]

- Abecia, J.A.; Máñez, J.; Macias, A.; Laviña, A.; Palacios, C. Climate zone influences the effect of temperature on the day of artificial insemination on fertility in two Iberian sheep breeds. J. Anim. Behav. Biometeorol. 2017, 5, 124–131. [Google Scholar] [CrossRef]

- ISO14040; Environmental Management—Life Cycle Assessment: Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006; p. 20.

- ISO14044; Environmental Management—Life Cycle Assessment: Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006; p. 46.

- Laca, A.; Gancedo, S.; Laca, A.; Díaz, M. Assessment of the environmental impacts associated with vineyards and winemaking. A case study in mountain areas. Environ. Sci. Pollut. Res. Int. 2021, 28, 1204–1223. [Google Scholar] [CrossRef] [PubMed]

- Moreira Gregori, P.; Guedes Pérez, E. Enoturismo en un destino del sol y playa: El caso de la bodega las tirajanas de Gran Canaria—España. Int. J. Sci. Manag. Tour. 2016, 2, 205–224. [Google Scholar]

- Rodríguez-Torres, I. Variedades de vid cultivadas en canarias. In Descriptores Morfológicos. Caracterización Morfológica, Molecular, Agronómica y Enológica; Instituto Canario de Investigaciones Agrarias: Santa Cruz de Tenerife, Spain, 2017; p. 197. [Google Scholar]

- Iakovou, E.; Moussiopoulos, N.; Xanthopoulos, A.; Achillas, C.; Michailidis, N.; Chatzipanagioti, M.; Koroneos, C.; Bouzakis, K.-D.; Kikis, V. A methodological framework for end-of-life management of electronic products. Resour. Conserv. Recycl. 2009, 53, 329–339. [Google Scholar] [CrossRef]

- Iannone, B. Sustainable process in wine sector: Biodynamic agriculture. The case of Emidio Pepe winery. In Proceedings of the 10th Interdisciplinary Workshop on Intangibles, Intellectual Capital And Extra Financial Information, Ferrara, Italy, 18–19 September 2024; p. 23. [Google Scholar]

- Foteinis, S.; Chatzisymeon, E. Life cycle assessment of organic versus conventional agriculture. A case study of lettuce cultivation in Greece. J. Clean. Prod. 2016, 112, 2462–2471. [Google Scholar] [CrossRef]

- Humbert, S.; Loerincik, Y.; Rossi, V.; Margni, M.; Jolliet, O. Life cycle assessment of spray dried soluble coffee and comparison with alternatives (drip filter and capsule espresso). J. Clean. Prod. 2009, 17, 1351–1358. [Google Scholar] [CrossRef]

- Tsarouhas, P.; Achillas, C.; Aidonis, D.; Folinas, D.; Maslis, V. Life Cycle Assessment of olive oil production in Greece. J. Clean. Prod. 2015, 93, 75–83. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Salomone, R.; Petti, L.; Mondello, G.; Raggi, A. Is there a simplified LCA tool suitable for the agri-food industry? An assessment of selected tools. J. Clean. Prod. 2017, 149, 406–425. [Google Scholar] [CrossRef]

- Manzardo, A.; Marson, A.; Zuliani, F.; Bacenetti, J.; Scipioni, A. Combination of product environmental footprint method and eco-design process according to ISO 14006: The case of an Italian vinery. Sci. Total Environ. 2021, 799, 149507. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Huijbregts, M.A. Introducing Life Cycle Impact Assessment; Springer: Dordrecht, The Netherlands, 2015; pp. 1–16. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; van Zelm, R. Corrección de: ReCiPe2016: Un método armonizado de evaluación del impacto del ciclo de vida a nivel de punto medio y punto final. Int. J. Life Cycle Assess. 2020, 25, 1635. [Google Scholar] [CrossRef]

- Meneses, M.; Torres, C.M.; Castells, F. Sensitivity analysis in a life cycle assessment of an aged red wine production from Catalonia, Spain. Sci. Total Environ. 2016, 562, 571–579. [Google Scholar] [CrossRef]

- Jourdaine, M.; Loubet, P.; Trebucq, S.; Sonnemann, G. Una comparación cuantitativa detallada de la evaluación del ciclo de vida de los vinos embotellados utilizando un procedimiento de armonización original. Prod. Más Limpia 2020, 250, 119472. [Google Scholar] [CrossRef]

- Villanueva-Rey, P.; Vázquez-Rowe, I.; Moreira, M.T.; Feijoo, G. Comparative life cycle assessment in the wine sector: Biodynamic vs. conventional viticulture activities in NW Spain. J. Clean. Prod. 2014, 65, 330–341. [Google Scholar] [CrossRef]

- Navarro, A.; Puig, R.; Fullana-i-Palmer, P. Product vs corporate carbon footprint: Some methodological issues. A case study and review on the wine sector. Sci. Total Environ. 2017, 581–582, 722–733. [Google Scholar] [CrossRef]

- Torres, M.A.; Paz, K.; Salazar, F.G. Métodos de Recolección de Datos Para una Investigación; Boletín Electrónico No. 03 2015, 21; Universidad Rafael Landívar: Ciudad de Guatemala, Guatemala, 2015; Available online: https://api.semanticscholar.org/CorpusID:185679539 (accessed on 12 July 2024).

- Gazulla, C.; Raugei, M.; Fullana-I-Palmer, P. Taking a life cycle look at crianza wine production in Spain: Where are the bottlenecks? Int. J. Life Cycle Assess. 2010, 15, 330–337. [Google Scholar] [CrossRef]

- Amienyo, D.; Camilleri, C.; Azapagic, A. Environmental impacts of consumption of Australian red wine in the UK. J. Clean. Prod. 2014, 72, 110–119. [Google Scholar] [CrossRef]

- Bonamente, E.; Scrucca, F.; Rinaldi, S.; Merico, M.C.; Asdrubali, F.; Lamastra, L. Environmental impact of an Italian wine bottle: Carbon and water footprint assessment. Sci. Total Environ. 2016, 560, 274–283. [Google Scholar] [CrossRef]

- Rinaldi, S.; Bonamente, E.; Scrucca, F.; Merico, M.C.; Asdrubali, F.; Cotana, F. Water and carbon footprint of wine: Methodology review and application to a case study. Sustainability 2016, 8, 621. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Mallo, J.; De la Cerda, J.J.; Moreira, M.T.; Feijoo, G. Carbon footprint of a multi-ingredient seafood product from a business-to-business perspective. J. Clean. Prod. 2013, 44, 200–210. [Google Scholar] [CrossRef]

- Fusi, A.; Guidetti, R.; Benedetto, G. Delving into the environmental aspect of a Sardinian white wine: From partial to total life cycle assessment. Sci. Total Environ. 2014, 472, 989–1000. [Google Scholar] [CrossRef] [PubMed]

- Bosco, S.; Di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Greenhouse gas emissions in the agricultural phase of wine production in the Maremma rural district (Tuscany, Italy). Ital. J. Agron. 2011, 6, 93–100. Available online: https://hdl.handle.net/11382/314652 (accessed on 12 July 2024). [CrossRef]

- Neto, R.C.; Silva, C.A. Energy supply infrastructure LCA model for electric and hydrogen transportation systems. Energy 2013, 56, 70–80. [Google Scholar] [CrossRef]

- Ferrara, C.; De Feo, G. Life cycle assessment application to the wine sector: A critical review. Sustainability 2018, 10, 395. [Google Scholar] [CrossRef]

- Pattara, C.; Russo, C.; Antrodicchia, V.; Cichelli, A. Carbon footprint as an instrument for enhancing food quality: Overview of the wine, olive oil and cereals sectors. J. Sci. Food Agric. 2017, 97, 396–410. [Google Scholar] [CrossRef]

- Bartocci, P.; Fantozzi, P.; Fantozzi, F. Environmental impact of Sagrantino and Grechetto grapes cultivation for wine and vinegar production in central Italy. J. Clean. Prod. 2017, 140, 569–580. [Google Scholar] [CrossRef]

- Litskas, V.D.; Irakleous, T.; Tzortzakis, N.; Stavrinides, M.C. Determining the carbon footprint of indigenous and introduced grape varieties through Life Cycle Assessment using the island of Cyprus as a case study. J. Clean. Prod. 2017, 156, 418–425. [Google Scholar] [CrossRef]

- Maesano, G.; Milani, M.; Nicolosi, E.; D’amico, M.; Chinnici, G. A Network Analysis for Environmental Assessment in Wine Supply Chain. Agronomy 2022, 12, 211. [Google Scholar] [CrossRef]

- Cruz Pérez, N.; Santamarta Cerezal, J.C.; Álvarez Acosta, C. La Huella Hídrica y la Huella de Carbono en la Actividad Agraria de las Islas Canarias; Universidad de La Laguna: Santa Cruz de Tenerife, Spain, 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).