Abstract

In the era of increasing climatic requirements and changing approaches towards circular economy (CE), the demand for materials designed with care for the environment is growing. This idea is especially important in the construction industry, where ordinary Portland cement (OPC) production emits a large number of greenhouse gases. The main aim of this article is to demonstrate the possibility of using industrial waste for geopolymer production according to CE goals, including closing material loops. This work is based on a critical analysis of the literature and selected case studies. The most important findings of this article allow us to confirm that the role of industrial waste in the construction industry is growing and that industrial by-products are valuable sources for geopolymer production. The development of sustainable materials allows the introduction of closed loops into production processes by making it possible to reuse materials after the end of use, which is an important issue in the context of introducing CE into practice, especially in existing systems.

1. Introduction

Geopolymers are amorphous, inorganic, synthetic aluminosilicate polymers created from the synthesis of silicon (Si) and aluminum (Al) and obtained geologically from minerals. Their composition is similar to that of zeolite, however, revealing an amorphous microstructure [1,2]. Geopolymers are most often hard, mechanically resistant, and durable bodies resembling natural stone or concrete [3]. However, they are created by a different mechanism than materials related to cement. The binding of Portland cement is simple: it occurs through the hydration of calcium silicates and the formation of a hydrated C-S-H phase with the released hydroxide levels, along with the bonding of geopolymers and the geopolymer cement, leading them through polycondensation [1]. Geopolymers can be produced based on both natural raw materials and industrial by-products, or even some waste materials [4].

These materials find a lot of application, including in medicine, water purification, and the energy industry, but still, the main area of their use is the construction industry [5,6]. In this area, they are considered an eco-friendly alternative for ordinary Portland cement (OPC) [7,8] and the most suitable materials for strengthening the sustainability of the construction industry and the revolution towards circular economy (CE) [9,10]. Firstly, the geopolymers can be used for the manufacture of different kinds of by-products and waste materials, and secondly, they have a small environmental burden (low gas emissions during manufacturing and small energy consumption) [11,12]. One of the possibilities is the usage of construction and demolition waste in the geopolymerization process [12,13]. These kinds of materials are characterized by reasonable mechanical properties and effectively close material loops in the recycling process. Furthermore, for some by-products, such as coal shells/gouges, it is possible to use them to produce insulation materials for the construction industry with high fire resistance, meaning that with appropriate design, the geopolymerization process is possible via up-cycling [14]. Their unique properties for the immobilization of hazardous elements also allow these materials to be applied as an effective solution for radioactive waste immobilization [15,16,17].

This review fills the research gap in the literature and links CE principles to multi-sector applications of geopolymers. This kind of analysis gives a new perspective on wider applications of geopolymers in practice. The main aim of this article is to demonstrate the possibility of using industrial waste for geopolymer production according to CE goals, including closing material loops. The provided review is in the form of a critical analysis and stresses the aspects connected to waste and by-product valorization. In the review, firstly, the coherence of the CE approach with geopolymers is discussed. Secondly, industrial by-products are used as raw materials for the geopolymerization process. Next, synthesis methods and their main properties are discussed in comparison to geopolymers based on natural feedstocks. Then, some information about areas of application is presented and a discussion of the challenges and limitations of the use of geopolymers based on industrial by-products is provided. Eventually, future perspectives are presented.

2. Methodology

This review is based on sources in the literature; however, it has the character of a critical analysis, not a systematic review. Because of this, the typical Preferred Reporting Items for Systematic (PRISMA) method was not applied; however, some of the elements of this approach were adopted for the presented review. They were applied for a better visualization of the problems at hand. Some approaches typical of systematic reviews were used to show the extent of the problem and the most popular directions of this research area around the world. The steps employed were as follows:

- Step 1: A research question was formulated to check the possibility of using industrial waste for geopolymer production according to CE goals, including closing material loops.

- Step 2: Relevant publications were identified using the Scopus database and appropriate keywords.

- Step 3: Using this database ensured the proper quality of the selected materials, i.e., that they had a scientific background. The keywords were selected in relation to the topic and in line with the critical character of the review to show different points of view on the analyzed problem.

- Step 4: The publications were first assessed according to abstracts and relevance for the planned topic.

- Step 5: The interpretation of the findings was made by a minimum of two co-authors working together.

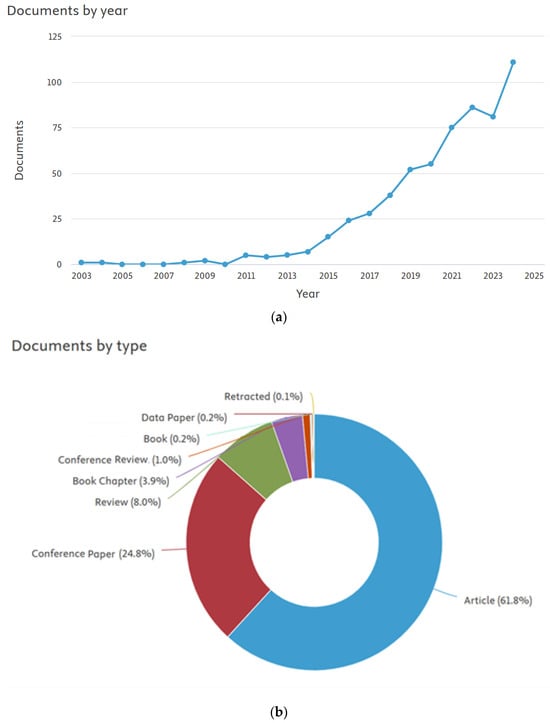

The first phase was a determination of the basic literature for the problem. The connection between the two keywords “geopolymer” and “industrial by-products” allows us to obtain 610 results in the Scopus database (Figure 1).

Figure 1.

Results of the analysis in the Scopus database: (a) published documents by year; (b) published documents by type.

The analysis of these results shows a clear trend in the last year that the interest in this topic is growing. The topic has been intensively developed since 2014, and the number of publications is increasing (Figure 1a). Taking into consideration the types of publication, the most important part, more than 60%, is original research articles, about 25% conference papers, and 8% are review publications (Figure 1b). Based on these data, it is evident that the importance of the topic is growing and new studies are being conducted in this area.

Additionally, some more in-depth and related analyses have been made on this topic, to the best of the authors’ knowledge. The replacement of the keyword “industrial by-product” with “waste” significantly increased the number of results up to 4664. These terms have different meanings, but in the literature, they are very often treated as synonyms. However, it should be noted that according to the regulations, the method of processing this kind of raw material is different and the by-products usually meet fewer restrictions. Another difference is that the source of waste is not only industrial activity. The overview of the obtained results confirms that many authors treat these two terms as equal, even though they have different meanings according to the economy. Another consequence of this difference is the various approaches to this material with respect to legal issues. In many countries, the classification as waste means that special permission to process these materials is necessary. Meanwhile, the classification as a by-product means these materials are more likely to be processed. Because of this, we decided in this review to be more precise about this terminology; however, it did not prevent us from using articles where the term “waste” was used (not always correctly).

In the second step, to narrow down the list, the previous two keywords were combined with the additional keyword “circular economy” to achieve the goals of the article more accurately. In this case, we obtained only 23 results. To expand the list, we replaced “circular economy” with “sustainability”. As a result, we obtained 95 results. These two results were the basis for this review.

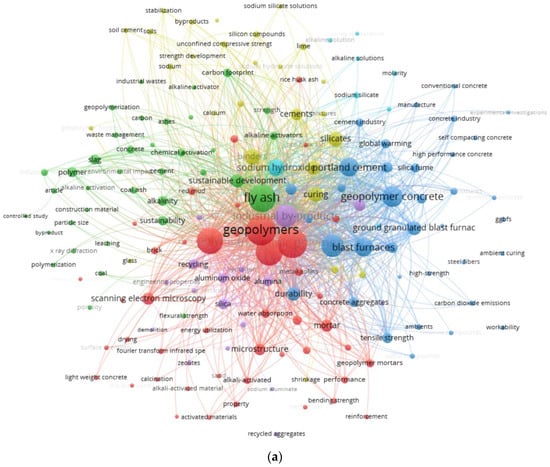

To visualize the initial research results and delve deeper into particular areas, we also created a map of connection keywords used in the 610 articles. We set a limit of 10 repetitions of selected keywords. For the visualization, we used VOSviewer version 1.6.20 (Centre for Science and Technology Studies, Leiden University, Leiden, The Netherlands) (Figure 2).

Figure 2.

Visualization of network connection based on used keywords in articles: (a) overall visualization; (b) visualization part of the network focused on the connection keyword “industrial by-products”.

The obtained results show that the main material used in this area is “fly ash” (Figure 2a), which has a strong connection with other keywords found in the literature, including “sustainability”, “carbon footprint”, and other environmentally driven terms. It is represented by a green cluster. The blue cluster in Figure 2a represents “geopolymer concrete”, and is strongly connected with slag precursors (ground granulated blast-furnace slag (GGBF) or slag). It is worth noting that these two main clusters are connected by a significant number of yellowish phrases like “cement” or “byproducts” that show a lot of common areas between them. The red cluster with the main keyword “geopolymer” shows a lot of terminology connected with material characterization. Some violet points indicate a connection with the blue cluster, connected with some base elements and terms such as “recycling”. The other possible raw materials for the geopolymerization process do not appear directly. The scheme shows some keywords are connected with the concrete and building industries, but do not directly link geopolymer with construction and demolition waste. Also, the other raw materials, such as mine tailings, are missing. The analysis of connections demonstrates that the most widely used industrial by-products as raw materials dedicated to geopolymer manufacturing are fly ash and slag.

3. Importance of Industrial By-Products Explained as a Part of the Circular Economy Approach

The CE is attracting the attention of governments, enterprises, and non-governmental organizations because it is proposed as an answer to the unsustainable, conventional linear economic model [18]. Nowadays, the CE approach, supported by innovative socio-technological concepts, articulates a future radically different from the one that exists now [19]. The origin of the term CE has been attributed to many authors. Today, the CE covers many concepts and associations, which are generally linked to the representations of cyclic closed-loop systems [20]. Currently, the most well-known definition is provided by the Ellen MacArthur Foundation [18], which defines the CE as an industrial system that is restorative or regenerative by intention and design. It replaces the concept of “end of product life” with the possibility of renewal, leans towards the use of renewable energy, eliminates the use of toxic chemicals that hinder reuse, and strives to eliminate waste through the appropriate design of materials, products, systems, and within these business models [18].

Because the CE is a concept that is in the process of being defined, it has been used to define different ways of coordinating materials, technology, and organization. For example, in China, the concept of the CE has slowly shifted from a focus on recycling of the waste to a broader focus on creating closed material loops in production, distribution, and consumption [21]. In Europe, the transition to a circular economy is encompassed in broader categories regarding required system changes related to technology, organization, society, consumer activities, financing methods, and politics [22]. Elements such as product and service systems and the collaborative economy were also taken into account [22]. For others, the pursuit of a CE is essentially a matter of economics and profit maximization that brings inventory optimization.

The concepts underlying the CE are not new; the idea of using waste as a resource in economic activity at the level of enterprises can be traced back to the 19th century [23]. Furthermore, before the industrial revolution, municipal waste management plants in Western Europe were described as material recovery facilities that used manual sorting and screening for the production of secondary raw materials [23]. This idea is also the basis for using industrial by-products in geopolymer production. Many industrial by-products, such as fly ash or mine tailings, can be used as raw materials for geopolymer synthesis. This approach also offers clear environmental benefits, such as utilizing waste materials [24,25].

The concept of a CE can be seen as another possible stage in the evolution of waste management systems. Following the need for effective resource use, many countries and governments, driven by an ambition for waste management policy, have implemented numerous initiatives in this regard. Germany was a pioneer in this field thanks to the adoption in 1994 “Act on closed circulation of substances and waste management” [26]. The purpose of this document was to protect natural resources and ensure compliance with the rules for the disposal of environmental waste. In the European Union, the discussion on CE developed in July 2014, when the European Commission published the directive “Towards a circular economy: a zero waste programme for Europe” [19,22]. In December 2014, this strategy was discontinued and the new Commission made a commitment to present by the end of 2015 a new package that would also take into account the full economic cycle and not just waste reduction [27]. This was carried out during public consultations from May to August 2015, and in December 2015, the package “Closing the loop: plan EU action on the circular economy” was officially published [27]. In December 2019, the European Commission announced the European Green Deal, i.e., a development strategy that accelerates the transition to a circular economy [28].

The main goal of the Green Deal strategy is to maintain the value of products, materials, and resources in the economy for as long as possible, with waste minimization and sustainable development, to promote a low-carbon, resource-efficient and competitive economy. It is believed that the CE will increase the competitiveness of the European Union, help to create new jobs and new business opportunities, and also offer more efficient and innovative ways of producing and consuming [19,28]. The updated directives set waste reduction targets and a long-term pathway for waste management and recycling [29]. It is worth noting that the very concept of obtaining materials with lower footprint emissions from waste is strongly associated with this idea, which gives new perspectives for geopolymer materials. This initiative can be the answer to regulatory gaps in the case of geopolymer materials, including the possibility to create a roadmap for standardizing geopolymer production.

Several attempts have been made to trace the conceptual and theoretical origins of the CE [20]. The ecological economy has been recognized as a significant precursor of the environmental economy and industrial ecology. One of the principles of the ecological economy states that economic systems should consist of as much recycling and renewable energy as possible, so as not to put future generations at a significant risk of scarcity of natural resources [30]. The idea of the economic environmental theory states that the environment provides esthetic values and a resource base for the economy, absorbs the remaining flows, and constitutes a life support system. Additional services that are undervalued or underestimated should be internalized in the economy [31].

In addition to the conceptual foundations of the green economy and the environmental economy, it is suggested that industrial ecology probably has the greatest practical impact on the CE development [31]. Industrial ecology is defined as ‘the study of material and energy flows resulting from human activity’. It provides the basis for the development of approaches to closing cycles in such a way as to minimize the impact of these activities on the environment. The fundamental problems of industrial ecology are as follows [32]: (a) improving pathways for industrial processes and the use of materials (creating circular industrial ecosystems), (b) dematerialization of industrial production, and (c) systematization of energy use schemes. In this way, the circular economy is radically shifting away from conventional modes of organization in the linear economy [32]. Taking this into consideration, we have to note that the production of geopolymers from industrial by-products is in line with the first point. It allows recirculation of the potential waste into different products dedicated in particular to building applications. Moreover, the by-products from the energy industry suit the idea of urban mining well. The green economy is seen as the path to sustainable development by solving financial problems and challenges related to climate change, as well as other environmental impacts. In this area, geopolymers are useful and considered as an environmentally friendly material for replacing OPC [33].

Several basic principles were proposed to coordinate activities in the CE. Stahel [34] identifies five principles with an emphasis on stock quality in the CE [34,35]:

- The smaller loops (in terms of activity and geographic scope) are more profitable and efficient.

- Loops should be defined as a series of logistic processes, where waste and used products have undergone recovery processes and constitute value in the form of secondary raw materials and materials; loops have no beginning or end.

- The speed of flows in the loops is crucial: inventory management efficiency in a CE increases with decreasing flow velocity.

- Continuation of ownership is cost-effective: reuse, repair, and refurbishment without changes in ownership (marketing authorization holder) save transactional costs.

- The CE needs functioning markets.

It is worth comparing these principles with the approach of the Ellen McArthur Foundation [18], where the CE is based on the following three principles that apply to both challenges related to resources as well as to the system:

- Protection and strengthening of the so-called natural capital by controlling finite resources and balancing renewable resource flows.

- Optimization of resource efficiency through the circulation of products, components, and materials with the greatest utility at any time in the technical and biological cycles.

- Supporting system efficiency through disclosure and design of negative externalities.

To effectively implement the ideas of the circular economy, research should be conducted on materials that will allow for a departure from linear economic processes, such as geopolymers made from anthropogenic raw materials, such as by-products from industrial processes and waste materials [19,36]. This approach allows for minimizing the negative impact on the environment by making materials potentially reusable and does not consume significant natural resources. Moreover, predicting and controlling the performance of materials throughout their life cycle is desirable, including designing intelligent structures allowing for self-monitoring and self-healing [37]. An important element is also to be aware of materials’ end of life and find a strategy for their recirculation. From the perspective of CE and environmental policy, industrial by-product-based geopolymers seem to be very promising materials for applications and the interest in their usage should increase.

4. Current Practices in Geopolymer Production

4.1. Industrial By-Products—Precursors for the Geopolymerization Process

The basic advantages of using industrial by-products are connected with environmental benefits. Some of them are pretty obvious, such as closing the loops and extending the circulation of materials. Others are connected with more specialistic knowledge, such as the fact that a lot of industrial by-products, including fly ashes and slags, require less of the sodium silicate (Na2SiO3) solution than metakaolin-based geopolymers during the synthesis process, which also reduces their environmental impact [38].

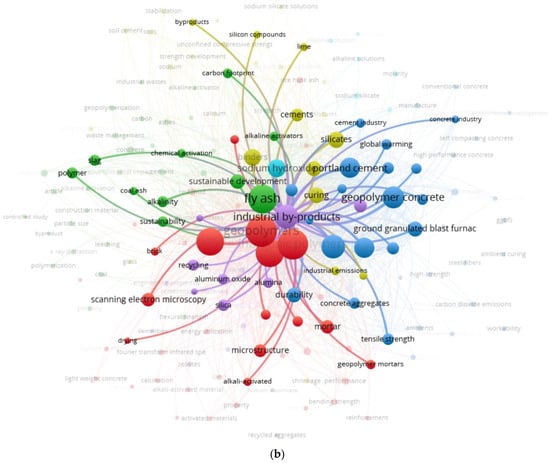

When writing about the raw materials, especially the precursors for the geopolymerization process, it should be stressed that they have to be rich in both alumina and silica [38]. A large number of industrial by-products, such as silica fume or glass waste, do not meet these requirements, and because of this, they should rather be considered as a valuable additive, not a precursor for the process. The main group of industrial by-products applied for geopolymers manufacturing is presented in Figure 3, with their placement on the graph according to chemical (oxide) composition.

Figure 3.

Ternary diagram of chemical compositions of commonly used binders [39].

Among the most important applications in the geopolymerization process are slags. These materials are usually by-products of iron production. They are obtained in a process where temperatures are about 1500 °C. According to chemical composition, they contain a large amount of calcium oxide (CaO)—about 40%—and silicon dioxide (SiO2)—30–40%. This composition is similar to that of OPC (Figure 3) [40]. However, the slags contain reactive elements like iron; these elements do not play an important role in the synthesis of geopolymers because they remain passivated during hydration and hardening. From a further application point of view, these elements could play a role in increasing self-sensing capabilities (thanks to the combination of ionic and electronic conduction) and pre-establish this material for advanced applications [41,42].

The second important group is fly ash [43]. They are usually by-products of energy production, especially from coal power plants. Their composition and quality depend on many factors, including the technology used, the coal deposit, season, etc. [44]. This group can be divided into two classes: C and F, following ASTM C618; the class requirements are connected with chemical (oxide) composition (Figure 3). The advantages of fly ashes include the possibility to use them in the delivery state, because they do not require additional activation, and they demonstrate potential as fast ionic conductors, which also allows for the application of these raw materials for some self-sensing applications [42,45].

The disadvantage of both these precursors is their application in the cement industry as an additive to replace clinker. As a consequence, the supply of both materials drastically decreased [4,46,47]. Moreover, another issue is the declining supply of fly ash in some countries, due to the transition away from coal combustion power plants. These trends are evident in the USA and EU countries, causing a shift toward more environmentally friendly energy sources. Therefore, the identification of more precursors is important [48].

The next category of industrial by-products is mine tailings, which include quite a wide range of coal gauges or coal shales that were tested as a potential materials for geopolymerization. The main area of planned application for these materials is building products [49]. The disadvantage of these precursors is the necessity for activation, usually by using the calcination process, which consumes a large amount of energy. The advantage is the abundance of material generated by the mining industry in response to the increasing demand for mineral products [50]. Also, a similar situation exists with red mud, which is a by-product of the Bayer process from aluminum production. In this case, during the production process, the alumina plant produces one to two times as much red mud as alumina [40].

Other precursors are made in lower amounts and are not so intensively investigated as by-products potentially useful in the geopolymerization process. The characteristics of the most popular precursors are presented in Table 1.

Table 1.

The exemplary composition of the most popular industrial by-products, which are precursors in geopolymer synthesis.

Except for alumina and silica, some of the precursors contain a significant amount of calcium and iron oxides. In the case of calcium, it can enhance the properties of geopolymers by generating calcium silicate hydrates and polymeric gel; however, a significant amount also accelerates the bonding process, preventing the proper geopolymer network from forming [67,68]. In the case of iron oxide, it very often reacts, creating ferro-sialates, that influence visual and structural aspects [67,68].

Based on current publications, the trend of mixing different kinds of local by-products and waste to obtain optimal composition is visible [52]. This kind of composition is always designed taking into consideration a local condition and potential application. The physical and mechanical properties should be designed according to requirements for specific construction; for example, using materials with high compressive strength for pavement could cause problems during demolition, or during the repair of underground infrastructure. Also, to fulfill the environmental requirements, it is good to employ local by-products in material design to avoid the costs of transportation [69].

4.2. Geopolymer Synthesis Methods

The high variety of industrial by-products applied to geopolymer synthesis requires different approaches and adjustments in the process to be more suitable for specific by-product composition. Various activators and process modifications are applied.

The first step is proper preparation of industrial by-products, which, for some of them, involves milling and/or activation. This step is necessary to obtain reactive ingredients of the material components, such as silica, that will create the geopolymer network during the synthesis [70]. Non-reactive components will only play the role of aggregate, such as sand in geopolymer composition. It will not effectively create a geopolymer matrix [71]. Some research suggests that reactiveness is connected with the amount of amorphous phase in the raw material and can be validated using X-ray diffraction (XRD) [70,72]. The investigation provided by Li et al. [51] shows that there is a negative correlation between the compressive strength of final materials and raw material particle size [51]. However, it is important to note that the process of milling is also energy-consuming and generates additional costs connected with material processing. Moreover, materials that are too fine can cause problems with processing due to the generation of dust. Additionally, the previous research also confirms the positive correlation between particle size and the leaching rate [51]. In this step, some materials are required to be activated. It is necessary, for example, for mine tailings [50]. The process of activation is most often provided by a temperature up to 800 °C. The differential scanning calorimetry (DSC) analysis allows for the determination of the proper temperature for the calcination of particular materials. Because calcination is a very expensive step, some investigations have determined possible alternatives such as mechanical activation, usually made by milling [50]. However, this kind of activation cannot always be applied.

The next step is the selection of a proper activator for the synthesis. In the case of activators, the most popular are alkali-based. However, some research has also been conducted on acids and salts as an auxiliary additive for alkali solutions [7,73,74]. These two mechanisms of creating geopolymers are slightly different. The activation using acids or salts is less investigated, and it has not been tested on a larger scale. Nevertheless, the provided research shows promising results for several raw materials, especially natural ones such as metakaolin and volcanic tuffs [75,76]. This research shows benefits for acid activation, such as better early age, enhanced thermal properties, resistance to efflorescence, and leaching [76]. Moreover, the activator based on acids emits a smaller carbon footprint [75,77]. In the case of alkali activation, in theory, there are a lot of possibilities, such as different alkali substances: hydroxides (derived from group 1 elements, so-called alkali metals), silicates, carbonates, or alkaline sulfates [78]. The alkaline metal hydroxides used for geopolymerization can be various, including NaOH, KOH, LiOH, RbOH, or CsOH [79,80]. Additionally, Na2SiO3 and sodium metasilicate, as well as potassium silicate, can be employed in this process. The important point is the requirement of the pH level, which should be 11.5 for proper process efficiency in case of alkali-activated geopolymers [68]. This pH allows for the proper reaction of ingredients with the activator and, as a result, creates a proper material structure. In practice, the following activators are most commonly used:

- Na2SiO3 combined with NaOH;

- NaOH alone;

- Na2CO3 combined with Na2SiO3;

- Na2SiO3 alone.

Also, the research shows the connection between the alkali concentration and the geopolymer’s mechanical strength [68]. Nevertheless, while the correlation exists, a lot of scientists try to limit the molarity of solutions because of the environmental burden and high probability of efflorescence occurrence. Additionally, at high morality (above 12 M) for some materials, a reduction in strength is observed [68]. Because alkali agents, such as Na2SiO3, are environmentally intensive, research is also being conducted to find more environmentally friendly alternatives [68,80]. It is worth noting that several studies show that the usage of a large amount of silica silicate can cause environmental indicators to be worse for the geopolymers than for OPC [81]. Promising options include various aluminosilicate precursor materials, such as rice husk ash, glass waste, silica fume, sugar cane straw ash, olive biomass, and diatomite fume [68,82].

A kind of alternative is an application of the geopolymerization process activated by acids. In this case, phosphoric acid is the most popular option [68,83]. It has been tested for many industrial by-products, including fly ash, mine tailings, and slags [83]. Despite some tests in the area of activation by acids, currently, the alkali is the most widely applied option.

The final step in the synthesis is a curing process. Also, it can be made in different ways. The two most popular ways are ambient and oven curing. Ambient curing is the most environmentally friendly option, but it does not work for all materials, because of some differences connected with mineralogical composition [68,84]. In the case of some minerals, in the geopolymerization process, it is necessary to increase the temperature. Usually, this range of temperature does not exceed 100 °C. The second component is time. The typical time of curing in the case of laboratory research is around 24 h, but in practice, this time can be significantly shortened to several hours [68,84]. The time of 24 h is very often just a result of leaving the samples in the oven overnight. Other alternative solutions for curing are water and wet curing in salt or fresh water [68,85], carbonation curing [86], steam processing [87,88], and microwave [89], electric heat [90], and sunlight curing [91]. Most of the alternatives were also successfully tested on industrial by-products [7].

4.3. Performance Characteristics

The final performance of geopolymers is strictly connected with their precursors, used additives, and method of synthesis. Because of this, it is quite hard to provide one performance characteristic of geopolymers based on natural sources and on industrial by-products. Previous works were mainly focused on comparing fly-ash-based geopolymers with metakaolin, but the results of this research were not always similar regarding the obtained performance characteristics. It is also worth noting that some investigations suggest that the best results concerning performance characteristics, especially strength, are obtained by mixing natural precursors such as metakaolin with industrial by-products such as fly ash [55]. However, other research shows that mixing can also result in opposite outcomes, reducing the compressive strength in comparison with geopolymers made from a single raw material [92]. The above research confirms that the crucial factor is the chemical and mineralogical composition of the precursors rather than their origin; especially important is the SiO2/Al2O3 ratio that has a strong correlation with the strength [84,93]. The other performance characteristics are shown in Table 2.

Table 2.

The comparison of fly-ash-based and metakaolin-based geopolymers.

The number of works comparing the usefulness of other industrial by-products with the original materials for the geopolymer synthesis is much lower. He et al. [63] compared red-mud-based geopolymers with metakaolin-based ones. This investigation shows the higher strength properties of metakaolin-based materials and a lower amount of pores compared to red-mud-based samples [63]. Despite the relatively large amount of work on geopolymers based on industrial by-products, it is not always possible to make a direct comparison with other provided works on natural materials because there is no standardization for the process of geopolymerization, which is quite often modified according to raw material specifications.

5. Areas of Application

Currently, the main area of application for geopolymers is the building industry. A relatively large amount of research is dedicated to basic construction products as pavements or bricks [98]. In this area, various industrial by-products are employed, including slags, fly ash, sewage sludge, and mine tailings [24,99]. According to the literature, there are some well-known projects connected with the use of fly ash for large manufacturing projects such as the Toowoomba Wellcamp Airport, Global Change Queensland GCI building or prefabricated elements for a special crypt system. The first project was connected with a number of different types of surfaces made from geopolymers on this airport, such as sidewalks, playing field slabs, building foundations, etc., which have been made from geopolymers [100]. For this project, the alkaline-activated geopolymer concretes were commercialized in Australia under the name E-Crete™ (company: Zeobond, Brighton, Australia). In this case, fly ash and recycled waste aggregates were used [100,101]. The second project was connected with manufacturing some parts of the Global Change Queensland GCI building, constructed in 2013, which had 3 floors made of 33 precast geopolymer concrete elements [102]. It was the first public building in the world to use geopolymer concrete structural elements designed by the HASSELL company (Jacksonville, FL, USA) in cooperation with Bligh Tanner (Fortitude Valley, Australia) and Wagners (Toowoomba, Australia) companies. It is worth mentioning that apart from geopolymer materials, other environmentally friendly technologies were used in the building [102]. Another application was made by the Rocla company. For its customers, it made 3000 prefabricated elements for a special crypt system [103]. The company used about 2.5 thousand tons of geopolymer concrete for this purpose. All manufactured elements were finished to a high standard, both in terms of surface condition and dimensional accuracy [103].

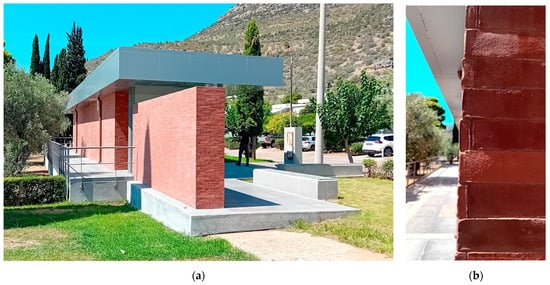

Another example of technology is the production of geopolymers from red mud, as presented in Figure 4.

Figure 4.

Products that save natural resources: (a) the pavilion made using elevation from geopolymer materials based on bauxite residue, so-called “House of Bauxite”—the environmental awareness pavilion located in Aspra Spitia, Greece; (b) the details of elevation.

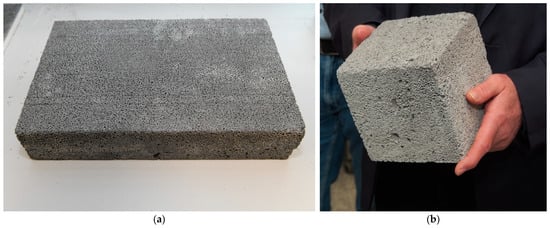

However, the application of geopolymers as a building material over the last years also brings new perspectives. One of them is the design of insulation materials using foamed geopolymers. The foaming process is usually made using hydrogen dioxide or aluminum powder. As a precursor, fly ash, slags, or mine tailings can be used [14,104]. The obtained material has not only low thermal conductivity but also reasonable mechanical properties. Additionally, the test shows that it is fire-resistant [65]. The exemplary foamed materials made from industrial by-products are presented in Figure 5.

Figure 5.

Products made from fly ash by Faculty of Materials Engineering and Physics, Cracow University of Technology, Poland: (a) foamed plate dedicated for elevation; (b) foamed cubic product.

In the case of building applications, some research has also been conducted to enhance the performance of some products for advanced applications by including different additives, especially nanomaterials [25]. The areas of investigation are connected with improving seismic resilience [105], developing sensing properties, or solar-driven self-cleaning geopolymers [106]. Wang et al. [49] pointed out that industrial by-products based on geopolymers have significant electrical response variations under different loading conditions. They may monitor changes in compression, bending, and tension strength of some elements [49]. Moreover, they monitor other factors such as temperature, moisture, and corrosion, because of the changes in conductivity [49]. It confirms the potential of this material for self-sensing applications.

Another quite obvious area of exploitation is the mine tailings and some sediments used for stabilization of the exploited mines [107]. This solution has additional advantages because the main by-products are used practically on-site, which reduces transportation costs and is beneficial from an environmental perspective. In this case, these materials have an advantage confirmed also by Life Cycle Assessment (LCA) analysis [81,108]. It can also provide additional advantages because these materials provide effective immobilization of radionuclides and heavy metals and are investigated as materials for nuclear waste storage and for hazardous waste immobilization [15,16]. This ability is also used in designing the sorption materials based on geopolymers, for example, for dyes’ photocatalytic degradation [109] or used as catalysts in biodiesel production [110].

It is worth stressing that the usage of industrial by-products also has some limitations. They are not widely investigated for medical applications, because of regulation and standardization limitations [6].

6. Challenges and Limitations

In this section, the challenges and limitations of producing geopolymers from industrial by-products are discussed. Also, the implementation of the results from several perspectives such as technical, economic, and social aspects, and environmental issues, is presented. The main issues are presented in Table 3.

Table 3.

Selected challenges and limitations in the area of implementation of geopolymers based on industrial by-products.

Despite the many challenges, the examples presented in Section 4 show the possibilities of producing geopolymers from industrial by-products. The presented technologies show the possibilities of managing various industrial waste into materials that can be used in the broadly understood construction, energy, and other industries. Materials obtained in the geopolymer synthesis are characterized not only by appropriate mechanical properties, but also by many features, such as the immobilization of heavy metal elements by binding them in the material structure and fire resistance. These properties also predispose the obtained product to be used as the so-called special materials. Examples of possible applications include the protection of landfills, where materials are often affected by corrosive factors. The fireproof properties suggest that this material may also be used in mining. It should be noted, however, that most of the research work currently being carried out is at the prototype stage [10,111]. The developed technologies require considerable investment in their development and adaptation to local conditions before they can be implemented. The potential costs associated with the technology scaling process are not always possible without appropriate support and legal regulations.

Thus, another important aspect in the development of technology is the problem that may arise at the stage of adapting solutions for the use of by-products in the geopolymerization process to local conditions. The properties of the acquired material are strongly dependent on the base raw material [84,112]. Therefore, it is important to obtain a source of raw material with a stable chemical composition or the possibility of introducing each batch of material into the measurement process and, depending on the results obtained, introducing appropriate additives into the process [113,114].

Another aspect is the selection of elements that will be produced in the geopolymerization process. If we assume that these will be typical building materials, sales opportunities on the local or regional market should be taken into account, because in this case, transport costs will play a significant role (both in financial terms and the so-called “environmental costs”) [68]. In the case of materials with special properties, the market reach may be significantly larger geographically. Even if the recycling of construction materials gives a great possibility, especially regarding the amount of waste that can be managed, it does not always provide the solution that allows for so-called up-cycling. So, for the most valuable waste, another strategy should be considered [19,115]. An example of this approach could be the production of materials for higher economic value from recycled feedstock or industrial by-products from processes in which original products have a lower value. This kind of material is mentioned in Section 4, nanomaterials, where industrial by-products are used to produce an advanced geopolymer composite with improved properties.

Another potential limitation is the current scale of application of geopolymers. Although geopolymers are considered the most environmentally friendly materials for building, the real benefits are limited by the scale of applications of these materials. Nowadays, the usage of geopolymers is limited to some experimental buildings and niche applications. If we compare the amount of used secondary raw materials in geopolymers to those in concrete, the scale of application is significantly larger for concrete. This is because nowadays, concrete is the most widely used building material [116]. As a part of concrete, different ingredients can be applied to increase the environmental friendliness of this material, such as recycled aggregates [117,118], fly ash and slag [116], waste glass [119,120], waste plastic and rubber [121], and also other waste and by-products [116,122,123]. It is worth noting that most of these additives do not worsen the concrete properties, and some of them even improve the concrete characteristics, reducing at the same time the environmental burden [124,125]. Moreover, most of the concretes with recycled additives are also recyclable, similarly to geopolymers, and thus, they allow for closing the loops in the circular economy approach [125,126]. Thus, the small scale of application of geopolymer materials is currently one of the factors that limit their positive impact on the environment.

The next challenging area is regulatory and standardization issues. The CE approach can support this process, for example, by the possibility of a design roadmap for standardizing geopolymer production connected with some initiatives like the EU’s Green Deal. However, the transition to a CE is a related challenge with multi-level management. There is currently a significant gap in knowledge about options management at the levels of the EU, member states, local authorities, the private sector, and citizens [19]. This is not a trivial matter, because the CE requires a massive transformation of the underlying conventions of economic systems [127,128]. The role of research is important in identifying appropriate forms of CE that decision-makers, businesses, and citizens might want to apply. This requires investigation to assess the ecological impacts, costs, and benefits of potential CE products and services. It is also important to find possible negative side effects caused by the transformation of the CE and identify of potential actors, who may be adversely affected by this process [18,128].

Technological innovations, such as the production of geopolymers from industrial by-products, are still needed to enhance process efficiency in recycling materials in the reuse of polluted and mixed flow. Beyond new technologies to influence effective interest in society and organizations, it is necessary to understand the issues related to prevailing trends and general feelings towards the idea of a CE to increase both demand and supply of the business models related to it [18]. In addition to implementing regulations, at the international and national levels, it is possible to undertake additional action in each country. For example, governments can support the development of various policy instruments, including taxation and additional economic incentives. Additionally, due to the significant urbanization in the world, the role of local governments, including municipal authorities, in supporting CE is significant. This means, among other things, an appropriate way of spatial planning, supporting the development of smart technologies and virtual platforms, selection of appropriate systems and other activities that enable the closing of material loops [20].

7. Future Perspectives

7.1. Material Development and Advanced Products

One of the basic innovations that should be developed for geopolymeric products, including industrial by-product-based geopolymers, is to design the materials for more advanced applications with tailored properties. Examples in this area are self-cleaning, self-sensing, or self-healing properties [37,41,106]. The unique composition of selected industrial by-products can be helpful in achieving this aim. These raw materials can enhance and tailor performance characteristics and promote circular economy principles [68]. In this area, some necessary steps could be connected to creating artificial raw materials for geopolymer synthesis using natural sources such as clays and feldspars or industrial by-products [4].

In the case of traditional, well-recognized materials that are mainly dedicated to the construction industry, further study should be connected mainly with upscaling the solution and stabilization technology [4], which is one of the challenges mentioned in Section 5. Currently, the traditional processes meet a lot of problems with implementation on a large scale. A notable example is the creation of insulation materials using the foaming process. This process is influenced by a lot of factors, such as atmospheric pressure, which causes the problems with foam growth and foam stabilization [129]. Another important trend is to make the production process more environmentally friendly by finding alternatives to more harmful components, such as Na2SiO3. However, while the research on the small scale confirms this possibility, the environmentally friendly additives are not applied on a wider scale.

7.2. Modern Production Technologies—3D Printing

Another possibility to be coherent with the CE approach in the building industry is the use of additive technology [130]. It is worth mentioning that the efficiency of this technology is strictly related to the materials [131,132]. The greatest benefits are derived from using waste materials such as construction and demolition waste; however, it is connected with some practical problems, starting from optimization of the material viscosity and ending with problems with legal regulations [131]. Currently, the main limitations of this technology are related to material issues [132]. The provided investigation shows that additive manufacturing has high potential to be used in the building industry for printing infrastructure as well as residential buildings. The provided research shows that it reduces the cost of materials and labor by up to 80% and limits the influence on the environment [69,133]. These issues are clearly in line with the CE approach, because of reduced environmental impact, including the amount of waste [134]. However, despite the fact that this technology has a lot of advantages, today, its application is quite limited and requires further research, including the following:

- Solving the materials problem connected with scaling-up technology, especially the rheological behavior of applied pastes;

- Designing proper materials for binder jetting technology: nowadays, most of the research connected with the construction industry is based on extrusion techniques [134,135];

- Designing more efficient materials, especially for 3D printing and the reinforcement construction performed in additive manufacturing technology [130,135].

Additive manufacturing, in this case, is regarded as more environmentally friendly compared to traditional technologies applied for metals, including casting [136]. This technology allows us to save energy and materials [137,138].

7.3. Data-Driven Modeling for Optimizing Process Conditions

Future trends also include using computer modeling for predicting the properties of the geopolymers and geopolymer composites. This kind of work can be especially useful in the case of using industrial by-products as raw materials, because of the changeability of this feedstock. The large number of variables that influence the process of geopolymerization is difficult to model, and because of this, the computer-aided approach is necessary for designing advanced materials with tailored properties [139,140].

Currently, some artificial neural networks, as well as systems based on artificial intelligence (AI), have been investigated in this area [114,141]. Zhang et al. [142] researched the possibility of using the artificial neural network (ANN) system for the prediction of durability for geopolymer mortar reinforced with nanoparticles and PVA fiber. The ANN was able to predict the freeze–thaw cycle for investigated materials, sulfate erosion resistance of geopolymers, and chloride ion permeability with sufficient accuracy. Moreover, it was possible to obtain some data for compressive strength, electric flux values, and the loss rate of mass, which were useful for the durability study [142]. Other research shows the possibility of calculating the effect of molar ratios on the compressive strength of fly-ash–slag geopolymer [143]. The development of such models can be a crucial point for further implementation of industrial by-product-based geopolymers on a broader scale.

7.4. Circular Economy

In the context of future trends, it is also worth highlighting some new areas of exploration for the CE. This idea, especially in the material context, also goes beyond the Earth’s problems [144]. The same new conceptions show that the basic concepts for CE should also be applied to space exploration, including the potential terraforming process for other planets [145,146]. At this moment, it may sound a little bit futuristic, but in space exploration, this could work because of economic reasons. Saving resources and materials for space travel is equal to saving money, and it seems to be one of the most important motivations for starting many activities [145]. In this case, the geopolymers can play an important role, due to experience gained from using different kinds of raw materials for their production; they seem to be the ideal material for production infrastructure on other planets [147,148]. Moreover, some research has been conducted in this direction utilizing Martian and lunar regolith simulants [146,149].

Another important trend is connected with the implementation of CE principles, especially lower input and use of natural resources, increased share of recyclable resources, and fewer material losses [150]. From an economic perspective, based on a summary by Ghisellini et al. [151], the implementation of the principles of CE is expected to bring economic benefits for companies and local government communities due to the reduction in waste management, reduction in environmental externalities (less environmental pollution), and new jobs, opportunities, and improved prosperity for low-income households. In Europe, it has been estimated that thanks to the rapid technological development, the CE could create an increase in resource productivity of up to 3% per year, and following the CE scenario would yield a growth of gross domestic product (GDP) by 7% in relation to current development, along with additional employment [18]. Benefits at the national level from the CE have been estimated for the economies of the Netherlands, Finland, France, Spain, and Sweden. The practical application of industrial by-products as a raw material well suits these scenarios. Moreover, the lower emission of greenhouse gases during the geopolymerization process compared to OPC production additionally supports this idea. It is worth noting that recent analyses and discussions on the CE, including its development, have focused mainly on the scarcity of resources and its impact on the environment in macroeconomic terms. In the literature on the subject, little attention has been given to the potential economic benefits resulting from the implementation of the circular economy for industrial entities [127,152]. Such an approach may prove unattractive to investors and other long-run decision-makers who are considering introducing closed loops to processes in the enterprise supply chain. As a result, the potential benefits from the implementation of such products as industrial by-products based on geopolymers seem to be crucial for their further adoption.

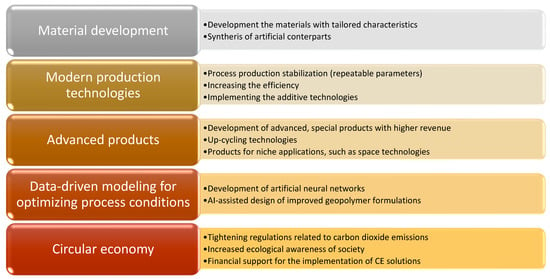

7.5. Current Trends

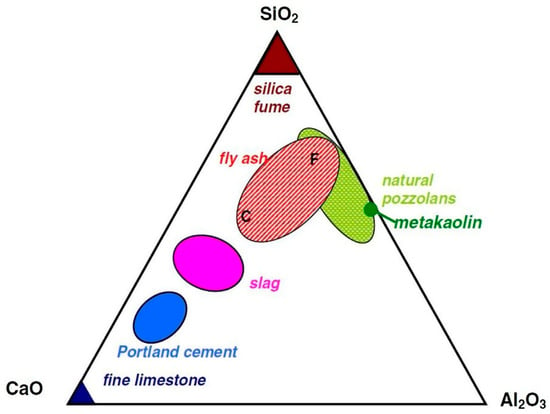

A summary of presented trends in the context of further development for industrial by-products based on geopolymers is presented in Figure 6.

Figure 6.

The predicted area of further development for industrial by-products based on geopolymers.

8. Conclusions

The current review links CE principles to multi-sector applications of geopolymers. It shows the new directions of development of sustainable materials: geopolymers that will allow the introduction of closed loops into production processes by enabling their reuse after the end of their life cycle. This is an important issue in the context of introducing the CE into existing systems. In the case of geopolymers, this change can be mainly achieved through the use of industrial by-products. Most of this technology is almost ready to be implemented on a wider scale. The provided review allows the formulation of some main conclusions in this area, which show current areas of interest, limitations, and challenges:

- Based on the literature analysis, it is obvious that the importance of the topic is growing and new research is provided in this area.

- The literature analysis also shows that the most widely used industrial by-products are fly ash and slag as raw materials dedicated to geopolymer manufacturing.

- From the perspective of CE and environmental policy, industrial by-product-based geopolymers seem to be very promising materials for applications and the interest in their usage should be increasing.

- Various raw materials were tested for geopolymerization. However, the technology is highly flexible and most of them can be created for some products, but not all of them are profitable for wider implementation and not all obtained products are of sufficient quality.

- The crucial aspect of precursor selection is a chemical and mineralogical composition of the raw materials rather than their origin.

- Currently, the most popular area of application for industrial by-product-based geopolymers is the construction industry; however, the importance of other areas is rising, especially in applications as an advanced material, including nanocomposites.

- There are still many challenges related to the practical application of industrial by-product-based geopolymers, but only a part of them are connected to technical limitations. A lot of challenges are connected with economic, environmental, and social barriers, including a lack of proper standards for geopolymer materials.

- The further implementation of technologies for geopolymers based on industrial by-products is controlled by many factors, and not all of them are technological. The CE approach can be supportive of this process.

- The most important further trends seem to be the development of materials with tailored properties, enhancement of technological solutions, usage of additive manufacturing in production, design of specialized products with higher revenue, wider application of computer-aided modeling, and support for circular economy solutions.

Innovative solutions have a crucial role in today’s economy, as well as sustainable development. The CE approach to geopolymers can combine these two trends and develop the proper technology. The article demonstrates selected solutions in the area of industrial by-product-based geopolymers that comply with the CE approach. They also show the importance of the continuation of research in this field for the development of innovative solutions.

Author Contributions

Conceptualization, K.K. and L.A.; methodology, K.K. and J.M.; validation, L.A., A.J. and L.Z.; formal analysis, L.Z.; investigation, K.K., K.B. and A.Z.; resources, A.J.; data curation, J.M. and A.J.; writing—original draft preparation, K.B. and K.K.; writing—review and editing, L.A., J.M. and A.Z.; visualization, K.K.; supervision, K.K.; project administration, A.J.; funding acquisition, A.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the project titled “Creation of a construction and technical engineering center for the provision of a full cycle of accredited services to the construction, road construction sector of the Republic of Kazakhstan” no. BR21882278, scientific adviser Jeksembayeva Assel Doctor of PhD.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank the COST Action CA21103 for COST meeting support.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| ANN | artificial neural network |

| AI | artificial intelligence |

| CE | circular economy |

| DSC | differential scanning calorimetry |

| GGBFS | ground granulated blast-furnace slag |

| LCA | Life Cycle Assessment |

| OPC | ordinary Portland cement |

| XRD | X-ray diffraction |

References

- El Alouani, M.; Saufi, H.; Aouan, B.; Bassam, R.; Alehyen, S.; Rachdi, Y.; El Hadki, H.; El Hadki, A.; Mabrouki, J.; Belaaouad, S.; et al. A Comprehensive Review of Synthesis, Characterization, and Applications of Aluminosilicate Materials-Based Geopolymers. Environ. Adv. 2024, 16, 100524. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic Polymeric New Materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Rihan, M.A.M.; Onchiri, R.O.; Gathimba, N.; Sabuni, B. Mix Design Approaches of Eco-Friendly Geopolymer Concrete: A Critical Review. Hybrid Adv. 2024, 7, 100290. [Google Scholar] [CrossRef]

- Martín-Rodríguez, P.; García-Lodeiro, I.; Fernández-Carrasco, L.; Blanco-Varela, M.T.; Palomo, A.; Fernández-Jiménez, A. Artificial Precursor for Alkaline Cements. Compos. Part B Eng. 2025, 296, 112216. [Google Scholar] [CrossRef]

- Drabczyk, A.; Kudłacik-Kramarczyk, S.; Korniejenko, K.; Figiela, B.; Furtos, G. Review of Geopolymer Nanocomposites: Novel Materials for Sustainable Development. Materials 2023, 16, 3478. [Google Scholar] [CrossRef]

- Kudłacik-Kramarczyk, S.; Drabczyk, A.; Figiela, B.; Korniejenko, K. Geopolymers: Advanced Materials in Medicine, Energy, Anticorrosion and Environmental Protection. Materials 2023, 16, 7416. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Liu, B.; Li, Q.; Zhang, Q.; An, C.; Sun, Z.; Wei, S.; Fan, J. Review of Solid Waste-Based Geopolymers: Preparation, Deterioration and Durability. Mater. Today Commun. 2025, 43, 111820. [Google Scholar] [CrossRef]

- Cong, P.; Du, R.; Gao, H.; Chen, Z. Comparison and Assessment of Carbon Dioxide Emissions between Alkali-Activated Materials and OPC Cement Concrete. J. Traffic Transp. Eng. (Engl. Ed.) 2024, 11, 918–938. [Google Scholar] [CrossRef]

- Umer, M.; Ahmad, J.; Anis Khan, H.; Khushnood, R.A. Valorization of Recycled Steel Wires from End-of-Life Tires as an Alternative Fiber Reinforcement in Geopolymer Concrete to Foster Circularity: A Review. Eur. J. Environ. Civ. Eng. 2025, 29, 715–743. [Google Scholar] [CrossRef]

- Odeh, A.; Al-Fakih, A.; Alghannam, M.; Al-Ainya, M.; Khalid, H.; Al-Shugaa, M.A.; Thomas, B.S.; Aswin, M. Recent Progress in Geopolymer Concrete Technology: A Review. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 48, 3285–3308. [Google Scholar] [CrossRef]

- Katarzyna, B.; Le, C.H.; Louda, P.; Michał, S.; Bakalova, T.; Tadeusz, P.; Prałat, K. The Fabrication of Geopolymer Foam Composites Incorporating Coke Dust Waste. Processes 2020, 8, 1052. [Google Scholar] [CrossRef]

- Şahin, O.; İlcan, H.; Ateşli, A.T.; Kul, A.; Yıldırım, G.; Şahmaran, M. Construction and Demolition Waste-Based Geopolymers Suited for Use in 3-Dimensional Additive Manufacturing. Cem. Concr. Compos. 2021, 121, 104088. [Google Scholar] [CrossRef]

- Aldemir, A.; Akduman, S.; Kocaer, O.; Aktepe, R.; Sahmaran, M.; Yildirim, G.; Almahmood, H.; Ashour, A. Shear Behaviour of Reinforced Construction and Demolition Waste-Based Geopolymer Concrete Beams. J. Build. Eng. 2022, 47, 103861. [Google Scholar] [CrossRef]

- Sitarz, M.; Figiela, B.; Łach, M.; Korniejenko, K.; Mróz, K.; Castro-Gomes, J.; Hager, I. Mechanical Response of Geopolymer Foams to Heating—Managing Coal Gangue in Fire-Resistant Materials Technology. Energies 2022, 15, 3363. [Google Scholar] [CrossRef]

- Jain, S.; Onuaguluchi, O.; Banthia, N.; Troczynski, T. Advancements in Immobilization of Cesium and Strontium Radionuclides in Cementitious Wasteforms—A Review. J. Am. Ceram. Soc. 2025, 108, e20131. [Google Scholar] [CrossRef]

- Houhou, M.; Leklou, N.; Ranaivomanana, H.; Penot, J.D.; De Barros, S. Geopolymers in Nuclear Waste Storage and Immobilization: Mechanisms, Applications, and Challenges. Discov. Appl. Sci. 2025, 7, 126. [Google Scholar] [CrossRef]

- Li, J.; Chen, L.; Wang, J. Solidification of Radioactive Wastes by Cement-Based Materials. Prog. Nucl. Energy 2021, 141, 103957. [Google Scholar] [CrossRef]

- MacArthur, E. Towards the Circular Economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Korniejenko, K.; Kozub, B.; Bąk, A.; Balamurugan, P.; Uthayakumar, M.; Furtos, G. Tackling the Circular Economy Challenges—Composites Recycling: Used Tyres, Wind Turbine Blades, and Solar Panels. J. Compos. Sci. 2021, 5, 243. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A Review of the Circular Economy in China: Moving from Rhetoric to Implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Morseletto, P. Sometimes Linear, Sometimes Circular: States of the Economy and Transitions to the Future. J. Clean. Prod. 2023, 390, 136138. [Google Scholar] [CrossRef]

- Velis, C.A.; Wilson, D.C.; Cheeseman, C.R. 19th Century London Dust-Yards: A Case Study in Closed-Loop Resource Efficiency. Waste Manag. 2009, 29, 1282–1290. [Google Scholar] [CrossRef] [PubMed]

- Azad, N.M.; Samarakoon, S.M.S.M.K. Utilization of Industrial By-Products/Waste to Manufacture Geopolymer Cement/Concrete. Sustainability 2021, 13, 873. [Google Scholar] [CrossRef]

- Jindal, B.B.; Sharma, R. The Effect of Nanomaterials on Properties of Geopolymers Derived from Industrial By-Products: A State-of-the-Art Review. Constr. Build. Mater. 2020, 252, 119028. [Google Scholar] [CrossRef]

- Federal Ministry for the Environment. The Closed Substance Cycle and Waste Management Act. Available online: https://enb.iisd.org/consume/closed.html (accessed on 30 March 2025).

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed on 2 February 2025).

- European Commission. Circular Economy Action Plan. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 2 February 2025).

- Eisenriegler, S.; Sparer, G. Social Innovation Repair—The R.U.S.Z Case: A Systemic Approach Contributing to the Unplanned Obsolescence of Capitalism. In Factor X; Lehmann, H., Ed.; Eco-Efficiency in Industry and Science; Springer International Publishing: Cham, Switzerland, 2018; Volume 32, pp. 287–295. ISBN 978-3-319-50078-2. [Google Scholar]

- Ayres, R.U. Eco-Thermodynamics: Economics and the Second Law. Ecol. Econ. 1998, 26, 189–209. [Google Scholar] [CrossRef]

- Andersen, M.S. An Introductory Note on the Environmental Economics of the Circular Economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Ehrenfeld, J.R. Industrial Ecology: A Framework for Product and Process Design. J. Clean. Prod. 1997, 5, 87–95. [Google Scholar] [CrossRef]

- Furtos, G.; Prodan, D.; Sarosi, C.; Popa, D.; Moldovan, M.; Korniejenko, K. The Precursors Used for Developing Geopolymer Composites for Circular Economy—A Review. Materials 2024, 17, 1696. [Google Scholar] [CrossRef]

- Stahel, W.R. Policy for Material Efficiency—Sustainable Taxation as a Departure from the Throwaway Society. Phil. Trans. R. Soc. A 2013, 371, 20110567. [Google Scholar] [CrossRef]

- Chrispim, M.C.; Mattsson, M.; Ulvenblad, P. The Underrepresented Key Elements of Circular Economy: A Critical Review of Assessment Tools and a Guide for Action. Sustain. Prod. Consum. 2023, 35, 539–558. [Google Scholar] [CrossRef]

- Avilés-Palacios, C.; Rodríguez-Olalla, A. The Sustainability of Waste Management Models in Circular Economies. Sustainability 2021, 13, 7105. [Google Scholar] [CrossRef]

- De Koster, S.A.L.; Mors, R.M.; Nugteren, H.W.; Jonkers, H.M.; Meesters, G.M.H.; Van Ommen, J.R. Geopolymer Coating of Bacteria-Containing Granules for Use in Self-Healing Concrete. Procedia Eng. 2015, 102, 475–484. [Google Scholar] [CrossRef]

- Habert, G.; d’Espinose De Lacaillerie, J.B.; Roussel, N. An Environmental Evaluation of Geopolymer Based Concrete Production: Reviewing Current Research Trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-Term Durability Properties of Geopolymer Concrete: An in-Depth Review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean Production and Properties of Geopolymer Concrete; A Review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Comparison of Electrical and Self-Sensing Properties of Portland Cement and Alkali-Activated Slag Mortars. Cem. Concr. Res. 2019, 118, 84–91. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Z.; Zhu, Y.; Yu, K.; Ning, C.; Jia, X.; Hui, Y.; Li, Y.; Chen, Q.; Banthia, N.; et al. Next-Generation Green Intelligent Self-Sensing Geopolymer Composites for Enhancing Construction Security and Sustainability: A Review. Compos. Part B Eng. 2025, 295, 112191. [Google Scholar] [CrossRef]

- Singaram, K.K.; Khan, M.A.; Talakokula, V. Review on Compressive Strength and Durability of Fly-Ash-Based Geopolymers Using Characterization Techniques. Arch. Civ. Mech. Eng. 2025, 25, 73. [Google Scholar] [CrossRef]

- Korniejenko, K.; Halyag, N.; Mucsi, G. Fly Ash as a Raw Material for Geopolymerisation—Chemical Composition and Physical Properties. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012002. [Google Scholar] [CrossRef]

- Cui, X.-M.; Zheng, G.-J.; Han, Y.-C.; Su, F.; Zhou, J. A Study on Electrical Conductivity of Chemosynthetic Al2O3–2SiO2 Geoploymer Materials. J. Power Sources 2008, 184, 652–656. [Google Scholar] [CrossRef]

- Bullerjahn, F.; Bolte, G. Composition of the Reactivity of Engineered Slags from Bauxite Residue and Steel Slag Smelting and Use as SCM for Portland Cement. Constr. Build. Mater. 2022, 321, 126331. [Google Scholar] [CrossRef]

- Maamoun, N.; Kennedy, R.; Jin, X.; Urpelainen, J. Identifying Coal-Fired Power Plants for Early Retirement. Renew. Sustain. Energy Rev. 2020, 126, 109833. [Google Scholar] [CrossRef]

- Xiao, R.; Prentice, D.; Collin, M.; Balonis, M.; La Plante, E.; Torabzadegan, M.; Gadt, T.; Sant, G. Calcium Nitrate Effectively Mitigates Alkali–Silica Reaction by Surface Passivation of Reactive Aggregates. J. Am. Ceram. Soc. 2024, 107, 7513–7527. [Google Scholar] [CrossRef]

- Wang, A.; Pan, Y.; Zhao, J.; Liu, P.; Wang, Y.; Chu, Y.; Liu, K.; Sun, D. Research Progress of Resourceful and Efficient Utilization of Coal Gangue in the Field of Building Materials. J. Build. Eng. 2025, 99, 111526. [Google Scholar] [CrossRef]

- Abbadi, A.; Mucsi, G. A Review on Complex Utilization of Mine Tailings: Recovery of Rare Earth Elements and Residue Valorization. J. Environ. Chem. Eng. 2024, 12, 113118. [Google Scholar] [CrossRef]

- Li, Y.; Dong, Y.; El-Naggar, M.R.; Wang, F.; Zhao, Y. The Influence of Particle Size and Calcium Content on Performance Characteristics of Metakaolin- and Fly-Ash-Based Geopolymer Gels. Gels 2024, 10, 639. [Google Scholar] [CrossRef]

- Luo, Z.; Zhi, T.; Liu, L.; Mi, J.; Zhang, M.; Tian, C.; Si, Z.; Liu, X.; Mu, Y. Solidification/Stabilization of Chromium Slag in Red Mud-Based Geopolymer. Constr. Build. Mater. 2022, 316, 125813. [Google Scholar] [CrossRef]

- Feng, X.; Yan, S.; Jiang, S.; Huang, K.; Ren, X.; Du, X.; Xing, P. Green Synthesis of the Metakaolin/Slag Based Geopolymer for the Effective Removal of Methylene Blue and Pb (II). Silicon 2022, 14, 6965–6979. [Google Scholar] [CrossRef]

- Kozub, B.; Sitarz, M.; Gądek, S.; Ziejewska, C.; Mróz, K.; Hager, I. Upscaling of Copper Slag-Based Geopolymer to 3D Printing Technology. Materials 2024, 17, 5581. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Pang, E. Strength and Microstructure of Geopolymer Based on Fly Ash and Metakaolin. Materials 2022, 15, 3732. [Google Scholar] [CrossRef] [PubMed]

- Kozub, B.; Dudek, J.; Melnychuk, M. The Effect of Oil Additives on the Properties of Fly Ash-Based Foamed Geopolymers. Materials 2024, 17, 5819. [Google Scholar] [CrossRef] [PubMed]

- Wattanasiriwech, D.; Yomthong, K.; Wattanasiriwech, S. Adsorption Efficiency and Photocatalytic Activity of Fly Ash-Based Geopolymer Foam Mortar. Ceram. Int. 2021, 47, 27361–27371. [Google Scholar] [CrossRef]

- Toobpeng, N.; Thavorniti, P.; Jiemsirilers, S. Effect of Additives on the Setting Time and Compressive Strength of Activated High-Calcium Fly Ash-Based Geopolymers. Constr. Build. Mater. 2024, 417, 135035. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, Y.; Chai, H.; Zhao, L.; Sun, H.; Zhang, H. Study on the Properties and Interfacial Transition Zone of Coal Gasification Slag Aggregate and Mineral Powder Geopolymer Mortar. Constr. Build. Mater. 2024, 414, 134864. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, F.; Zhou, F.; Lu, M.; Hou, H.; Li, J.; Liu, D.; Wang, T. Early Solidification/Stabilization Mechanism of Heavy Metals (Pb, Cr and Zn) in Shell Coal Gasification Fly Ash Based Geopolymer. Sci. Total Environ. 2022, 802, 149905. [Google Scholar] [CrossRef]

- Wan, J.; Zhang, F.; Han, Z.; Song, L.; Zhang, C.; Zhang, J. Adsorption of Cd2+ and Pb2+ by Biofuel Ash-Based Geopolymer Synthesized by One-Step Hydrothermal Method. Arab. J. Chem. 2021, 14, 103234. [Google Scholar] [CrossRef]

- Zhu, W.; Rao, X.H.; Liu, Y.; Yang, E.-H. Lightweight Aerated Metakaolin-Based Geopolymer Incorporating Municipal Solid Waste Incineration Bottom Ash as Gas-Forming Agent. J. Clean. Prod. 2018, 177, 775–781. [Google Scholar] [CrossRef]

- He, J.; Zhang, J.; Yu, Y.; Zhang, G. The Strength and Microstructure of Two Geopolymers Derived from Metakaolin and Red Mud-Fly Ash Admixture: A Comparative Study. Constr. Build. Mater. 2012, 30, 80–91. [Google Scholar] [CrossRef]

- Shoaei, P.; Musaeei, H.R.; Mirlohi, F.; Narimani Zamanabadi, S.; Ameri, F.; Bahrami, N. Waste Ceramic Powder-Based Geopolymer Mortars: Effect of Curing Temperature and Alkaline Solution-to-Binder Ratio. Constr. Build. Mater. 2019, 227, 116686. [Google Scholar] [CrossRef]

- Mróz, K.; Figiela, B.; Korniejenko, K. Fire Performance and Characterization of Geopolymer Foams Using Fly Ash and Coal Gangue. Cem. Wapno Beton. 2024, 29, 212–232. [Google Scholar] [CrossRef]

- Li, J.; Sun, Q.; Zu, Y. Influence of Steel Slag Doping on the Mechanical Properties and Microstructural Characterization of Coal Gangue Based Geopolymer. Mater. Chem. Phys. 2025, 333, 130251. [Google Scholar] [CrossRef]

- Kaze, C.R.; Lecomte-Nana, G.L.; Kamseu, E.; Camacho, P.S.; Yorkshire, A.S.; Provis, J.L.; Duttine, M.; Wattiaux, A.; Melo, U.C. Mechanical and Physical Properties of Inorganic Polymer Cement Made of Iron-Rich Laterite and Lateritic Clay: A Comparative Study. Cem. Concr. Res. 2021, 140, 106320. [Google Scholar] [CrossRef]

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical Fundamentals of Geopolymers in Sustainable Construction. Mater. Today Sustain. 2024, 27, 100842. [Google Scholar] [CrossRef]

- Munir, Q.; Kärki, T. Cost Analysis of Various Factors for Geopolymer 3D Printing of Construction Products in Factories and on Construction Sites. Recycling 2021, 6, 60. [Google Scholar] [CrossRef]

- Oh, J.E.; Jun, Y.; Jeong, Y. Characterization of Geopolymers from Compositionally and Physically Different Class F Fly Ashes. Cem. Concr. Compos. 2014, 50, 16–26. [Google Scholar] [CrossRef]

- Kaze, C.R.; Jiofack, S.B.K.; Cengiz, Ö.; Alomayri, T.S.; Adesina, A.; Rahier, H. Reactivity and Mechanical Performance of Geopolymer Binders from Metakaolin/Meta-Halloysite Blends. Constr. Build. Mater. 2022, 336, 127546. [Google Scholar] [CrossRef]

- Vogt, O.; Ukrainczyk, N.; Ballschmiede, C.; Koenders, E. Reactivity and Microstructure of Metakaolin Based Geopolymers: Effect of Fly Ash and Liquid/Solid Contents. Materials 2019, 12, 3485. [Google Scholar] [CrossRef]

- Nikolov, A.; Nugteren, H.; Rostovsky, I. Optimization of Geopolymers Based on Natural Zeolite Clinoptilolite by Calcination and Use of Aluminate Activators. Constr. Build. Mater. 2020, 243, 118257. [Google Scholar] [CrossRef]

- Lv, Q.; Wang, Z.; Gu, L.; Chen, Y.; Shan, X. Effect of Sodium Sulfate on Strength and Microstructure of Alkali-Activated Fly Ash Based Geopolymer. J. Cent. South Univ. 2020, 27, 1691–1702. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Tome, S. Insights into Alkali and Acid-Activated Volcanic Ash-Based Materials: A Review. Cem. Concr. Compos. 2024, 152, 105660. [Google Scholar] [CrossRef]

- Park, J.A.; Pimenta, M.M.; Bezerra, A.C.D.S. Acid Activation in Low-Carbon Binders: A Systematic Literature Review. Buildings 2023, 14, 83. [Google Scholar] [CrossRef]

- Dihaji, H.; Azerkane, D.; Bih, L.; Essaddek, A.; Haily, E.M. Comparative Study of Geopolymers Synthesized with Alkaline and Acid Reactants at Various Liquid-to-Solid Ratios Using Moroccan Kaolin Clay. Constr. Build. Mater. 2025, 468, 140453. [Google Scholar] [CrossRef]

- Provis, J.L. Geopolymers and Other Alkali Activated Materials: Why, How, and What? Mater. Struct. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Taki, K.; Mukherjee, S.; Patel, A.K.; Kumar, M. Reappraisal Review on Geopolymer: A New Era of Aluminosilicate Binder for Metal Immobilization. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100345. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F.; Marvila, M.; Azevedo, A.R.G.; Franco De Carvalho, J.M.; Ribeiro, J.C.L. Application of Eco-Friendly Alternative Activators in Alkali-Activated Materials: A Review. J. Build. Eng. 2021, 35, 102010. [Google Scholar] [CrossRef]

- Munir, Q.; Abdulkareem, M.; Horttanainen, M.; Kärki, T. A Comparative Cradle-to-Gate Life Cycle Assessment of Geopolymer Concrete Produced from Industrial Side Streams in Comparison with Traditional Concrete. Sci. Total Environ. 2023, 865, 161230. [Google Scholar] [CrossRef]

- Nykiel, M.; Korniejenko, K.; Setlak, K.; Melnychuk, M.; Polivoda, N.; Kozub, B.; Hebdowska-Krupa, M.; Łach, M. The Influence of Diatomite Addition on the Properties of Geopolymers Based on Fly Ash and Metakaolin. Materials 2024, 17, 2399. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Z.; Liu, X. Comprehensive Understanding of Aluminosilicate Phosphate Geopolymers: A Critical Review. Materials 2022, 15, 5961. [Google Scholar] [CrossRef]

- Tome, S.; Nana, A.; Tchakouté, H.K.; Temuujin, J.; Rüscher, C.H. Mineralogical Evolution of Raw Materials Transformed to Geopolymer Materials: A Review. Ceram. Int. 2024, 50, 35855–35868. [Google Scholar] [CrossRef]

- Giasuddin, H.M.; Sanjayan, J.G.; Ranjith, P.G. Strength of Geopolymer Cured in Saline Water in Ambient Conditions. Fuel 2013, 107, 34–39. [Google Scholar] [CrossRef]