Abstract

In the current scenario in many cities, huge quantities of biowaste solid matter are generated, making it a big challenge to keep our cities smart/clean without creating health issues. The second challenge is to mitigate solid biowastes from municipalities, and it needs systematic valorization/conversion approaches to transform/generate them into clean/least carbon-emitting fuel sources. This effort can help make smart cities with additional amounts of energy generation that can be used by each citizen for their daily energy needs. In the cities, biowastes are reported as food waste (from domestic kitchens and restaurant/hotel), green plant residues (from parks and other cleaning activities), and other miscellaneous sources. Due to the huge generation of these biowastes, the respective cities can look dirtier and also show a poor level of development. So, people from municipal authorities and some research groups have to start converting this biowaste solid matter into renewable and sustainable energy that can help reduce this biowaste accumulation through the promotion of sustainable bioenergy sources. In valorization approaches, biological (anaerobic digestion) and thermochemical (like pyrolysis) processes are common, and these can be applied to biowaste mitigation to minimize the negative impact on the environment and its components. In India, some states, like Madhya Pradesh, have put efforts into creating biogases like green hydrogen from their cities generated biowastes. In this review, we emphasize the different sources of biowaste in cities with their volumes/quantities, factors/activities for generations, and mitigation approaches for biowaste conversion into fuels with the promotion of sustainable goal achievement. Now that waste matters, effort is put into a take-home concept/message regarding the conversion/recovery, and extraction of waste into energy/other valuable products for home needs. It helps keep cities clean, smart, and rich in revenue sources.

1. Introduction

In many cities, the different nature of biowaste availability is reported, and it has become a big challenge for municipal authorities to resolve this issue in an effective and eco-friendly way. Some critical issues are found in cities that occur due to poor management of biowastes by municipal authorities [1]. And nowadays, every citizen in any city wants to live in a smart city with clean air and water quality. It is well known to everyone that the nature of municipal solid waste (MSW) matters and that it is a good source of various kinds of biowaste. However, some challenges in this regard have been reported in biowaste management efforts in effective ways [1,2]. It needs to separate the biowaste fraction (as a useful measure/effort) from different MSW matters, and this approach can help enhance biowaste management in developed and developing countries around the world [3]. Recently, some papers have discussed the comparison studies on the environmental performance of three market-ready technologies that were applied for the conversion of several types of biowaste by different treatment/conversion technologies like composting, fermentation, and incineration as waste-to-energy/value-added product concept [1,3]. This approach needs a systematic biowaste collection process that can be applied to collect residual municipal solid biowaste (RES-MSBW). Researchers in current years report the global warming potential (GWP) application as an environmental indicator. And it is also a critical burden for the application of mitigation approaches for biowastes. This is due to the lack of suitable operation facilities and sufficient credit gain that can be applied to generate different forms of products, like energy/fuel sources, from biowastes [4]. Some reports are also discussed on environmental performance in the context of waste-to-energy approaches via suitable conversion plant facilities. It needs a proper investigation task that can be performed by using a suitable model, and then it needs to implement similar approaches that can provide the marginal cost and revenues as an economic concept [5]. Some eco-friendly conversion approaches are applied to different types of biowaste, and these can provide a net negative global warming potential (GWP). A better mode of environmental performance in the context of waste-to-energy plant facilities is discussed with respect to the mode of operation and their impact on waste conversion to energy generation/yield with different types of energy [6]. In current scenarios, researchers emphasize the concept of environmental credit generation at the highest rates with the promotion/implementation of co-incineration of biowaste utilization. This (co-incineration) is a completely heat-oriented waste-to-energy conversion approach that is applied by different plants. In this context, an anaerobic digestion approach in different plants can be operated for the conversion of biowastes into value-added and fermentation products/produce with carbon credits. And many plants applied it with power delivery-based processes [1,6,7].

In metropolitan cities, a huge and high density of people is found, and these people have shown their trends toward biowaste generation. This is due to the different activities performed by more human beings. In biowaste source mitigation, the first task is to separate biowastes, which is performed by different types of people (i.e., citizens/municipal authority people/employees) [4,6]. Then it is handled by a specific stream/set of people. Normally, the biowaste collection system is reported as diverse in nature and can cover a wide range of options, such as traditional door–door or more sophisticated pneumatic underground systems to collect waste [7]. Handling streams can be completed by performing composting and also applying anaerobic digestion tasks for biowaste conversion into value-added products, including fuel source generation, which were performed by the separately collected biowaste (SEP-BIO) process [8]. A second effort for the collection of biowaste was performed from residual municipal solid (RES) wastes under the name of RES-BIO. Normally, many people have implemented a landfill task for biowastes as a standard disposal approach/also as a method for RES-wastes in developing countries. Then people can apply the incineration approach for heat energy recovery as the concept of –biowaste-to-energy concept in many countries as existing or developed waste management tasks/systems [7,8]. Some efforts were made on a comprehensive LCA (life cycle assessment) study on biowaste impacts on substrate values, with some negative impacts from its non-treated form. These LCA efforts can help divert biowaste from landfill disposal trends in many cities [9]. It can then be applied for biowaste utilization/conversion into composting and microbial fermentation processes that can result in some valuable products/fuel generation. And it can provide more environmental benefits with the reduction of greenhouse gases. Some executed results from the LCA process were found in a comparison of the environmental impacts of biogas utilization that was produced from anaerobic digestion plants with the capability to convert biowaste into an energy source [10]. It was discussed for the biowaste-to-biomethane conversion situation with biogas up-gradation processes on biomethane, and this fuel can also be used for transportation sectors with higher benefits than conventional biogas treatment plants/processes such as burning in a combined heat and power (CHP) unit with subsequent ways of energy product effort [9,10]. Researchers have performed some LCA studies on residual waste (RES) matters at the worldwide level, and then some comprehensive reviews of LCA studies were reported that can be applied to biowaste management efforts [11]. In a number of biowaste conversion techniques/approaches, anaerobic digestion (AD) was applied for biowaste matter hydrolysis. It utilizes the microbial fermentation process, and this approach is a promising technique for the conversion of biowaste into renewable energy (biogas/biomethane) with some organic compounds/fertilizers’ generation effort [10,11]. This approach can help mitigate environmental pollution in several countries, including India. Conversion approaches with twice/more credits can be achieved from waste-to-energy processes [8,11].

In context to smart city conversion efforts, it is necessary to apply the AD process for municipal solid waste management (MSWM) strategy, and it needs to collect different types of waste (inorganic, inert/neutral, or organic waste matters). In an effort to sustain the nature of the energy generation process, it needs to collect and separate the different organic waste matters with proper sorting tasks/capacities by people/municipal authorities [12]. And then these organic wastes from municipal locations can be sent to anaerobic digestion or dark fermentation processes for the production of biogas, including methane and other alcoholic or non-alcoholic fuels like hydrogen. The MSWM strategy needs to complete different stages like pre-collection, collection/transport, and systematic treatment tasks (like the conversion of waste to fuel) [13]. Normally, in the pre-collection process/stages, respective persons need to deposit the different types of waste from each citizen, and it can also be collected from surface and underground containers for waste matters via conventional approaches/systems. Normally, in this stage, pre-collection boxes in pneumatic systems can be applied [14]. The next stage in the MSWM plan is the collection/transport system, which is the intermediate stage between pre-collection and treatment of waste matters. In this stage, waste matter is collected first and then transported to recovery or disposal centers [12,13]. In waste materials, discarded material can be responsible for lasting energy, and non-renewable resources can create disposal issues responsible for air, water, and soil pollution. So, it needs to be completed for systematic treatment by the different plants that can help recover the energy without any emission of toxin gases into the air. Further, these biowaste mitigation processes can be sources of non-causative public health costs, roadway-related congestion, damages, and accidents [12,14]. The novelty/innovation of this review is discussed by exploring the different types of biowastes, their characterization, and their impact on city development. Further emphasis is shown on effective biological transformation approaches like anaerobic digestion (AD) and some other converting approaches like recycling plastic waste. These approaches helped in the transformation of waste (organic/non-organic types), and then they generated and also recovered value-added products with more marketing demands. All these conversion approaches help in the mitigation of waste that impacts environmental components like humans and others in dirty cities. Further, this review explores some characteristics of smart cities around the world, which are now demanded by every civilian in the world [11,13,14]. In current scenarios in cities, more quantities of waste generation (organic, toxic, and inorganic types) are reported due to modern lifestyles and their standards. Due to several activities at different levels (academic, hospital, commercial, and industrial), this waste generation has become a big burden and a challenge for cities to minimize their load. This mitigation impact can help some valuable products recover while improving the smartness of cities’ outlook. This requires different levels of awareness, like academic, social, and economic levels. In this regard, a number of academic and non-government organizations are involved in creating awareness for waste mitigation and generation [11,14].

Now, the authors discussed the other products, like healthcare and fabrication materials, that are synthesized in sustainable ways from waste matter conversion. To discuss the healthcare, materials, and fabrication material synthesis approaches with quality standards and compatibility, some efforts were made to analyze the ceramic-on-ceramic coupling process with some common materials [14,15]. These materials are zirconium dioxide (ZrO2), aluminum oxide (Al2O3), and silicon nitride (Si3N4), and these were tested according to the Tresca failure criterion for stress distribution investigation. Further study was performed on a two-dimensional axis-symmetric finite element-based computer model. This helped to evaluate the Tresca stress on the ceramic-on-ceramic coupling process under the gait cycle [15]. Another report in this context discussed electric discharge machines for Ti-6Al-4V-EL alloy synthesis, which are used in the biomedical industry nowadays. In this context, roughening levels of process variables were discussed. These variables are pulse current, polarity, pulse ON time, and pulse OFF time. These were reported with four tools, such as electrodes of graphite, brass, copper, and aluminum, with evaluation by two experiment phases. It has used the SiC powder-mixed dielectric process [16]. Further, this process was modeled using the adaptive neural fuzzy inference system (ANFIS). This process has produced surfaces with relatively low roughness, as confirmed [17]. An effort for surface generation via aluminum was conducted with an estimation of the minimum friction force (i.e., 25 N), and then it was compared with other surfaces. The analysis of variance was performed for electrode material (i.e., 32.65%), and it was found to have more significance for material removal rate [18]. In another report, a molybdenum disulfide (MoS2)-based nano-fluid-minimum quantity lubrication (NF-MQL) system was discussed that was applied during the helical milling process by using a FIREX-coated tool. This tool is used for breaking down any metal into small pieces [19]. This analysis helped in the evaluation of workpiece elemental transfer and tool wear mechanisms. From this published work, it was claimed that there is a 1% nanoparticle concentration in the lubricant, and it has gone to low tool wear (to 13 µm) after 10 holes [20]. Still, some efforts were made on parametric analysis, which was based on eccentricity, axial pitch, tangential feed, and spindle speeds. These were shown to be correlated with mechanical damage [21]. The lowest tool wear was shown by using eccentricity level (1), spindle speed for Ti-6Al-4V (1000 rpm), and spindle speed for carbon fiber (CFRP~7500 rpm). Further value of tangential fees (0.01 mm/tooth), axial pitch (1.5 mm), and 1% of MoS2 nanoparticles [19,21].

The authors emphasized the impact of biowaste materials on the city’s environment and health issues in direct/indirect ways. Also, it was discussed mitigation approaches for biowastes that push the city clean and smart with additional sources of revenues for local people. This advantage can occur after the conversion of biowastes into value-added products like fuel in a sustainable form. This paper explores the features of smart that need to be maintained for better health [10,12]. The novelty of the paper is based on its pioneering approach to catalyzing the integration of renewable energy sources within smart cities by leveraging municipal-based biowaste conversion strategies. The novel framework delineates a comprehensive model that optimizes the valorization of biowaste streams generated within urban ecosystems, positioning them as potent substrates for renewable energy production, which is described in the paper. Therefore, by delineating the intrinsic interplay between biowaste conversion and intelligent urban management, this paper presents a forward-looking trajectory for sustainable energy generation, resource management, and environmental resilience at both local and global scales. This review discusses mainly sustainable organic wastes from municipal locations, waste-to-energy conversion efforts, and the environmental impacts of organic/biowaste disposal in open places with public health issues, as well as city development that can be burdensome to make smart cities.

2. Waste Matters: Generation from Cities

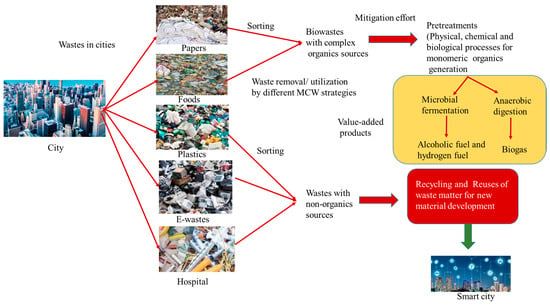

In many cities, there are a lot of challenges for municipal solid waste (MSW) management plans, and in the last few years, the total generation of MSW quantities has increased by nearly 292.4 million tons, which is nearly 23.7 million tons more than the 2017 generation quantities. This waste quantity is nearly 208 million tons more than in 1990 [22]. But in 2017, per capita MSW generation was found to generate nearly 4.5 pounds per person per day, whereas in 2018, per capita MSW generation was found to generate nearly 4.9 pounds per person per day. This waste generation was found to be higher compared to previous years (2018 to 2017). In this context, the EPA has discussed waste food management strategies that it can utilize to generate sustainable fuels [22,23]. Some waste generation sources are discussed below. Figure 1 shows the different types of waste that are generated in cities due to different activities.

Figure 1.

Generation of various wastes and their mitigation into value-added products by different approaches.

2.1. Paper and Paperboard Wastes

In MSW categories, paper and paperboard are reported as valuable wastes with organic matter sources, and in 2018, these wastes (i.e., paper and paperboard) were the largest components in MSW. Environmental protection analysis classifies paper and paperboard matter as nondurable goods, used for container and packaging tasks. Paper and paperboard can be generated from different offices and also from office papers, tissue paper, and paper plates/cups [24]. Other sources of paper waste are container and paper-based packaging tasks/products like corrugated boxes and milk cartons, and bags/snacks. Some estimation was performed by the American Forest and Paper Association (AF & PA) for post-consumer paper and paperboard generation quantity sources in 2018 [25]. In total MSW quantities, total quantities of paper and paperboard were reported at 67.4 million tons, or 23.1%, in 2018. Out of this quantity, nearly 46 million tons of paper and paperboard were recycled, achieving a 68.2% recycling rate. This rate of recycling of these wastes was found to be the highest rate when compared to other materials in MSW [24,25]. In the categories of nondurable goods, paper-made goods (excluding newspapers) showed a recycling rate of 43%, but the newspaper recycling rate was 65%. The recycling rate of this organic matter/fraction can help in the mitigation of these waste products, with the possibility of reusing material for new products [26,27]. In paper and paperboard waste categories, paper containers and packaging material (except corrugated boxes) showed a good recycling rate (21%), but corrugated boxes only showed a recycling rate of 96.5% in 2018. Finally, it was concluded that paper and paperboard waste quantities were 4.2 million tons, or 12% of the total MSW quantity, combusted in 2018 [28]. In the same year, landfills received 17.2 million tons of MSW paper and paperboard. In 2018, landfills received 17.2 million tons of MSW paper and paperboard. This was 11.8% of the total MSW landfilled. In 2018, reports for the generation of newspapers were found to decline from 87.7 million tons in 2000 to 67.4 million tons in 2018 [29,30]. Figure 2 shows the flow of waste management for the city that can be minimized with valuable product synthesis.

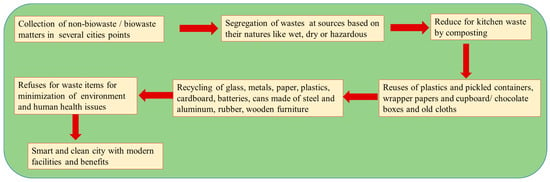

Figure 2.

Flow chart of waste matter management with the benefit of keeping the city clean.

2.2. Food Waste

In cities, due to maintaining smartness and cleanliness, there are several hostels, restaurants, big food sellers, and hostels in academic institutions that produce/generate huge quantities of food waste. There are also several shops selling fruits and vegetables that are responsible for generating food waste. To maintain a clean environment in cities, it is necessary to collect the generated waste, which is the fourth material in MSW. It was found to generate nearly 63.1 million tons, or 21.6% of total MSW, in 2018 [31]. In the world, several cities are responsible for food waste generation activities, and then this waste can be disposed of at landfill sites. Also, sometimes these can be gone for systematic treatment with the help of biological/chemical methods, reducing the environmental problems/issues [32]. Then these approaches can be utilized to generate fuel sources from food waste in cities with the best performance capabilities. Generating sustainable fuels from food waste can give smartness to cities through waste reduction. Huge quantities of food waste generation have been reported in India, China, and the U.S.A., along with Brazil, and these countries are top rankers in food waste generation activity in the world [31,32]. Normally, many people still prefer to utilize landfill and composting tasks as traditional approaches for food waste management and disposal activities. This activity of food waste management is very common in developing countries, but it is not feasible as a strategy for food waste management due to the generation of toxic gas emissions, bad odor, and environmental pollution issues associated with these tasks [33]. In recent years, stricter regulations and demand for renewable fuels/biochemicals have been generated, which has pushed advanced research on food waste utilization. From these efforts, food waste valorization was applied to different types of food waste, resulting in bioethanol, biodiesel, and biogas generation as green fuel categories [34]. Further, these food wastes can be applied for value-added chemical generation for industry needs with the help of green synthesis and with upcoming advanced research activities. In context, food waste utilization efforts were performed for first-generation fuels with proper food waste processing tasks in developing countries, including India [33,34]. Now, due to changes in existing legislation with time, people/researchers have changed the food waste disposal activity with the utilization or shifting of good food waste management from linear to circular bioeconomy as case studies. Nowadays, food waste utilization is performed with the help of green technologies for green fuel production in smart cities, and these can be applied to anaerobic digestion and chemical production routes with future directions for sustainable value-added production like fuels [35].

In the world’s population in the current period, nearly 3 billion people feed on food for their survival daily, and then huge quantities of food wastage are also reported, which is a serious issue for the world because of the big losses caused by the creation of hungry people among the several people. A number of studies are conducted by the FAO on food waste generation survey and analysis, and then huge quantities of food waste generation (1.3 billion tons) are reported every year [36]. From the FAO report, this food waste quantity is one-third of the total food production in the world, and its cost is found to be nearly 750 billion, or 47 INR lakh crores. The UN Hunger Report has discussed food waste generation in the world and also suggested that if food waste becomes zero, then there will be enough food to feed the entire global population. And this report has informed us of the total number of hungry people (811 million) every day in the world. The hunger of people in the world is found to be due to higher quantities of food waste generated from daily activity by several functions and operations [37]. FAO (Food Agriculture Organization) reports on food waste quantity (931 million tons) every year, and this quantity of food waste is nearly 17% of total food production capacity in the world [36,37]. In UNEP (the UN environment program), the food waste index report for 2021 is discussed for different sources, and nearly all food waste comes from 61% of households, 26% from food services, and 13% from retail shops [38]. Further information on wasted food in the U.S. is 59 kg/household, and in China, this food waste is 64 kg/household. Some reports on household food waste estimation have come from the U.S. (i.e., 1.9 × 107 tons/year) and China (9.1 × 107 tons/year), as well as other countries [39]. A report from the National Resources Defense Council (NRDC) discusses 40% of food eaten in the U.S., but in India, Asia, and China, the quantity of food waste is found to be 1.3 billion tons/year. Some countries in the world are struggling to feed their starving populations due to the huge quantity of food waste generated [38,39].

2.3. Parks/Yards-Based Green Wastes

In the yard, trimming plant parts is also a source of green waste material. And these were generated with an estimated quantity of 35.4 tons, or 12.1% of total MSW, in 2018. In 1990, these wastes were found to be 35 million tons or 17% of the total MSW quantity. Some of these waste generation quantities can be increased due to densely located populations in cities [40]. Due to state legislation discouraging yard trimming generation from 1990 onward, these were found to reduce/decline the quantity of green/yard waste. And it has reduced other organic disposal tasks in landfills. These are sources of waste reduction measures, and now people are utilizing backyard composting for grass-trimming residues and waste from the yard [41]. Garden waste is accumulated plant matter from gardening activities, and it can be green waste parts that come from cutting/removing vegetation like cutting the lawn, lawn weed removal, hedge trimming, or pruning (which means consisting of lawn clipping, leaf matter, wood, and soils) [40,41]. The composition and volume of the garden waste can vary from season to season, and they can also vary depending on location to location. Some studies were performed in Aarhus, Denmark, and it was found to be a varying quantity (122 kg to 155 kg/year) for average garden waste generation/person [42]. Garden waste is found to be an excellent resource for cheap feedstock, and it needs systematic shredding and processing for conversion into briquettes and pellets. This waste material can be utilized as a cheap, smokeless fuel for rural and industrial heating tasks. Efforts from city people are performed for systematic shredding processing tasks for garden waste, and then it can be converted into composting tasks for biofertilizer development that can help in soil regeneration for fast plant growth [43]. The garden waste can be utilized as bulk material for the treatment of kitchen waste. Larger branches of garden plants can be used for creating biochar, and they can be excellent sources/forms of stable carbon. This form of garden waste can enhance soil fertility via sequestering carbon [42,43]. Shredded waste and leaf waste can be used as mulching mediums for gardens and farms. The application of mulch material can reduce weed growth and labor requirements. The addition of mulch materials to soils can add nutrients to the soil and help prevent moisture losses that occur by evaporation [44]. Further benefits of mulch addition to the soil include that it can encourage the growth of beneficial soil microbes for healthy, productive growth of plants and vegetation [42,44].

Some issues are found due to garden waste dumping, which can facilitate the spreading of exotic vegetation into forest remnants. This can occur due to the introduction of seeds and propagules contained within the garden waste. Some selection criteria for home gardens by local gardeners are shown, and they can depend on the choice of plants and be based on ease of propagation, suitability to local environmental conditions, and novelty [45]. Some specific characteristics increase the chance of plant parts and seeds being introduced into forested areas by creating problems like dumping issues. Sometimes garden waste dumping tasks near nature reserves can surround an urban area, increasing the risk of fire [44,45]. In the current period for smart city development efforts, it needs to utilize the dumped garden wastes in dried conditions, and it can utilize them for creating fuel in addition to already fallen debris fuel loads with high chances of fire thriving and spreading [46]. Further, issues from gardening waste can come in the form of weeds spreading, increasing the chances of building fuel for fires. Dumped garden waste can increase the rate of erosion by smothering natural vegetation [47]. Sometimes garden waste can add high levels of sediment, which can contribute to the siltation of creeks and waterways. In Pune, India, garden waste can generate nearly 60 to 70 MT/day, and its garden waste is collected by a collection system for collecting this waste, shredding it, and transporting it to a centralized processing system to recover the fuel sources [47,48].

2.4. Plastic Wastes

In recent years, like 2018, plastic product generation has been found to account for nearly 35.7 million tons (12.2% of total MSW generation) in big cities. This plastic quantity is nearly 4.5 million more from 2010 to 2018, and it is occurring due to increased numbers of durable goods and also the containers and packaging that are made up of plastic materials [49]. If it is compared to the quantity of plastic waste/material generation from 1990 to 2018, then it is nearly 4% higher (i.e., 8.2% to 12.2%). In the last eight years, the quantity of plastic material has increased from 12.2% to 13.2%, which is due to the usage of more products that are wrapped in plastic packaging [49,50].

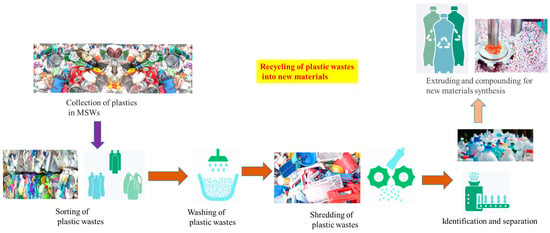

In the current period, plastic waste use has reached productive levels at local and global levels. In this effort, researchers recommended simple solutions for local communities, like recycling processes for plastic waste that can be used for developing filler materials for cement blocks, ropes, and household food like baskets/mats [51]. These materials can be utilized in most big cities for selling these products, reducing plastic waste, and generating good/strong buildings in smart cities. Plastic waste utilization at a larger scale is discussed for the recycling of plastic/textiles that can be used in clothing and furniture development, and these can be sources of revenue generation in smart cities [52,53]. The numbers of waste materials in cities are discussed for the synthesis of monetary values like clothing, shoes, and road construction. In many cities in India, society is incentivized to collect plastic, and it needs to capture its full value for other product development [54]. Such waste materials treatment needs systematic plastic waste management plans, which can normally be started at the household and individual levels, and then effective strategies like good education with high/more motivation for citizens so they can change their behavior with regard to plastic material uses for their product packaging tasks [54,55]. Figure 3 shows the recycling process for new material developments.

Figure 3.

Plastic waste in cities for the recycling process.

2.5. Other Wastes

In many cities, there are several types of non-organic waste generated. In this category, e-waste generation (including consumer electronic items/waste) with a quantity of 2.7 million tons (1% of the total MSW quantity) is found in the cities. In the e-waste category, some selected consumer electronics products are TVs, DVD players, VCRs, and video cameras [56,57]. Further, stereo systems, telephones, and computer equipment are also parts of e-waste in many cities. In India, recently increased quantities of e-waste collection and respective processing have been reported in the last four years, with four times more quantities and processing [58]. Nearly 95% of e-waste is handled in illegal modes/ways by the informal sector. In this sector, informal waste pickers are better known as Kabadiwalas, and they are not very aware of following environmental standards or burning materials [59]. These should not go for local recycling or be diverted to landfills; otherwise, they can cause severe environmental damage and health hazards. Some efforts by recyclers are performed through the use of rudimentary recycling techniques, and these can release toxic pollutants into the surrounding environment [59,60]. Some reports have talked about the many hazardous substances that come from e-waste processing. These can be found to be extremely dangerous to human health and the environment. Countries like the United States and China, including India, are also found to be the world’s largest producers of e-waste, and these quantities can be found to be 3.23 million tons/year [57,59]. In India, 2020–2021, e-waste quantities (3.4 lakh tons) have been processed, and further, the plastic waste generation/year was found to be at a high/increasing rate (of 3%), according to the report of the CPCB (Central Pollution Council Board). Further, e-waste generation at a high rate was reported with nearby quantities of 7.1 tons in 2018–2019 and 10.14 lakh tons in 2019–2020, with every year having a 31% hike rate [61]. From many published papers, nearly 468 authorized recyclers and 2808 collection points in 22 states in India are reported for e-waste generation, with some authorized processing tasks. The high number of recyclers (i.e., No. 468) is responsible for collecting and processing nearly 13 lakh tons of e-waste, but it is still insufficient to meet India’s e-waste generation and processing needs [60,61]. In India, plastics and other low-value e-waste were burned, releasing fine particles into the air. With the help of desoldering techniques, some value-added products, like some metals like gold/silver, from e-waste materials are extracted/recovered, but these are processed incorrectly and produce chemical/harmful fumes [59,61].

3. Impacts of Waste with Mitigation Efforts in Cities

In the coming years, in many cities, various types of organic and inorganic wastes will be generated from different sources like household, industrial, academic, and hospital activities, and these wastes, including e-waste in landfills, can impact surface and groundwater sources due to the presence of harmful chemicals that leach from landfills into surface water sources [62]. Further, toxic byproducts of improper e-waste recycling tasks can be reached through sewers and city drains. These products in different waste streams can be contaminated with surface water by entering local waterways. It has been discussed for plastic influences, and then systematic plastic waste management can be started at the household and individual levels [61,62]. Some case studies were conducted in Jamaica City. In this study, it was started by environmental wardens in the country by sensitizing their neighbors to community cleanliness and disposing of waste in a safe way, and eco-friendly manner [63]. People have talked about community members, and these were employed through world bank-supported projects. These projects can help spread awareness about systematic management, and then they can keep the communities clean and healthy [60,63]. Normally, communities and school people (including young students) can be found as effective parts of the projects, and these can be involved via collecting the several waste types with sorting types for separate waste like plastic bottles/e-waste. These can be utilized for several wastes, like plastic and metals, by effective recyclers. And remaining wastes can be removed from them (including litter or clogging) [64]. Based on systematic solid municipal waste strategies, people need to be involved in adequate collection and disposal systems in many places in cities, and then they need to apply the necessary steps for cities with proper insurance of all types of waste management in an eco-friendly or sound way. For smart cities, it needs to pursue sufficient interventions like the ban on certain types of plastic use/burning [58,64].

3.1. A Case Study on Plastic Waste Accumulation

In California, plastic materials are now banned, and this effort has resulted in a 72% decrease in plastic litter on local beaches from 2010 to 2017. Further, a plastic ban by itself cannot solve the issue of plastic mismanagement. In many cities, there have been many attempts to implement plastic materials ban rules without proper incentives and management structures [65]. These can struggle to achieve meaningful results due to noncompliance, black markets, and continued littering of plastics. It needs an adequate disposal system for several wastes, including plastic material. Further, efforts are required for plastic policies with proper support from an effective waste management system, and government authority capability is also needed to enforce such policies [66].

In the coming period, in many cities, plastic pollution/waste will be a major concern, and it can cause the accumulation of plastic objects like bottles and any other products in the city environment with high chances of adverse influences on wildlife habitat and human health. Due to plastic material accumulation, it has entered three-quarters (via the recycling process) of the environment, like the ocean and also our ecosystems, with more destruction and pollution [65,66]. In less developed countries or their cities, the majority of plastic waste can end up in the ocean ecosystem, affecting marine animals. In recent years, the utilization of many products made of plastic materials, like plastic bottles and food containers, has been reported, and is due to inexpensive and highly durable materials [67]. Plastic materials showed slow degradation (nearly 400 years/more for partial/complete forms). It is also due to its chemical structures, and now it has become a big challenge for many cities/also for the world. Due to huge populations and product packaging tasks, plastic waste is generated in developing countries, and it can end up in open, unregulated dump sites or be thrown directly into rivers and streams, creating a threat to aquatic life [68]. Dumping sites of plastic materials can result in the blowing of wind into water bodies like rivers, and then, with the help of river water medium, plastic materials can be carried out to sea locations. Another issue is the volume of plastic material that can be exported to developing nations from Europe, the U.S., Japan, and similar countries [67,68]. Recycling standards for developing countries and developed nations in the world are found to be different, and they can affect the environment by causing significant environmental damage [69,70,71]. Next, due to the significant quantity of plastic waste, an adequate recycling process has not yet been performed, which can result in more plastic being thrown into unregulated dump sites in landfills in the developing world. In the UK, over 5 million tons of plastic waste (due to plastic packaged consumer products each year) are sent in three parts to landfills and one part to recycling processing [72,73].

3.2. Trends in Waste Generation in Worldwide Cities

In recent years, post-consumer waste generation trends have been found to more than double quantities at the city level worldwide over the last thirty years. Due to more population growth in the MSW generation, an exponential trend was found from 1980 onwards and still continues to grow steadily in many European countries, like the North [74]. In Western Europe and North America, the average MSW rate was found to be between 1.4 and 1.8 kg/capita/day in the last decade. But, now, due to huge population growth in many large cities in the global South, it is now reaching a value between 1 and 1.4 kg/capita/day. The urban lifestyle can contribute to high quantities of waste generation from people’s homes and also from outside sources [75]. Food service industries can also thrive on disposable options with people’s increased food consumption on the streets and their habits of leaving consumable foods in disposable waste bins in public [76,77]. In 2012, urban residents at the global level generated nearly 1.2 kg/capita/day of MSW, compared to 0.6 kg/capita/day in 2002. In Brazil, the average daily MSW quantity generation/person is about 1.1 kg. But in major cities in Africa, MSW generation can be estimated at 0.3 to 1.4 kg/capita/day [78]. Differences in waste generation can be found at large ranges, with the quantity of waste generation in the range of 0.5 kg/capita/day in Bamenda and Yaoundé cities and 0.8 kg/capita/day in the city of Cameroon. Further studies on waste generation quantities are performed, and they are based on population size and growth rates of people with influences on MSW management tasks. There is a positive correlation between population size and the rate of waste production, with % of households involved in regular waste collection activity [73,77,78].

3.3. Waste Generation with City Development Trends

In the current era, industrial production of consumer goods is characterized by a reduction in product life spans, growing product variety, material component diversity, and increased packaging trends in product safety and convenience tasks. These are responsible for generating huge waste quantities and producing water, soil, and air contaminants [79]. Further, the rise in solid waste material can be linked to increased levels of urbanization and wealth. It was found that between 1997 and 2007, GDP (gross domestic product) in India increased at a rate of 7%. However, the estimation of the rise in MSW over 10 years is found to be nearly 45%, from 40 to 70 million tons [80]. And this figure for Brazil also found a similar relationship between wealth and MSW generation capacity. From 2009 to 2010, GDP rose by 7.5%, with an increase in MSW generation of 6.8%. Reports on population growth are discussed, along with increased product consumption and waste generation trends. And more affluent segments of the population consume more, leading to the generation of waste with larger impacts on the environment [79,80]. Some countries like China, Brazil, and India have added nearly 509 million new consumer items between 1990 and 2000, with an average purchasing power of 839 billion USD. Normally, new consumers can be found as people with typically four-member households with at least a purchasing power parity ~PPP of $10,000/year (USD). And these PPP dollars can be found between 1.3 and 5.3 times higher than conventional dollars in twenty countries (out of which seventeen are developing and three are transitional countries) [81]. Further, increased income can make people more able to purchase household appliances, electronics, cars, and other items, and it can indicate high lifestyles for the consumption of more packaged food items and meats [82]. In the current situation, waste generation practices are characterized by an exponential increase in volume and material diversification of discarded objects and substances [83]. And it is due to the increase in packaging, shorter product durability, programmed obsolescence, economic growth logic, consumerism, and mass consumption. All these factors can be responsible for driving the MSW generation in cities, and then in cities, there is a chance of copying large quantities of MSW [82,83].

3.4. Household Waste Composition in Cities

It has been discussed that different waste compositions can come from household locations with changes due to cultural and technological activities and can vary across different continents and regions with time. In household waste, changes can depend on many technical aspects involved in the creation of a more sustainable and equitable waste management service [84]. Different ashes come from heating and cooking tasks, and they could be found as larger components of household waste in some cities, like North America, until the middle of the last century. Urban waste in the global North in the current period can contain more recyclable goods and electronics, with a higher chance of MSW generation [85]. MSW can contain larger portions of biodegradable waste with the least portion of non-recyclable material fractions [74,86]. Among various kinds of valuable materials, it was reclaimed by households or by informal recyclers for reuse in trading tasks. In American cities, household waste can have high fractions of organic compounds/matter, and it can be found up to 70% or more [87]. Household waste compositions in Brazil are reported to have larger fractions of organic matter up to 51.4%, and these are highly recyclable type wastes (32%), like metals, papers, cardboard, plastics, or glass, with lesser/smaller proportions (i.e., 17%) of non-recyclable materials [88]. Further, the number of electronic waste items is now growing at a high rate due to increased demand for e-waste recycling trends. MSW generation is now rising from 2017 to 2018, and it is due to the EPA enhancing its food measurement methodology with a full account for waste food management throughout the food system [87,88].

4. MSW Management Strategies in Cities

Management of MSW continues to be a high priority for state and local governments. This includes the source reduction of wastes before they enter the waste stream and the recovery of products from generated wastes by recycling, composting, or other methods. It also includes environmentally sound waste management through combustion with energy recovery and conversion, as well as landfilling practices that meet current standards or newly emerging waste conversion technologies [89]. The Environmental Protection Agency (EPA) has developed techniques for the management of non-hazardous materials during MSW management, and in this context, it needs various waste management strategies for different types of waste materials in all streams and in all circumstances [90]. Common approaches to waste management are known, and they are achieved by reducing, reusing, and recycling for sustainable material management efforts [89,90].

Characteristics of MSW Strategies

In recent years, various types of MSWs have been generated worldwide, and still, their processing is performed by landfill tasks via waste disposal and waste dumping processes up to 70% of the time. Out of this quantity, only 19% of this waste goes to systematic recycling tasks or proper treatment by mechanical/biological processes [91]. Only a small percentage of this waste (11%) is going through the incineration process. In different cities in the world, landfill technologies are found in different modes, and they can proceed from open dumping to sanitary landfills with the process of methane recovery [90,91]. In some places in cities, waste can be burned as a common process, which can occur in or around informal settlements and also in rural areas. Some countries in the world are involved in upgrading their landfills to sanitary landfills, and this can occur especially in South Africa, Uganda, Ghana, and Egypt [92]. In earlier decades, some concerns/incidents were reported in Africa due to landfill tasks, and now this country has changed with ownership and operations by many people to enforce standards. During the waste management task, it needs more resources, but they are limited in their utility in the removal of waste [91,92]. Due to formal neighborhoods and little investment, there is limited infrastructure for sustainable waste management. Some cities in the global south are reported to adopt expensive waste management models like mechanized separation systems for recycling processes and high-tech energy incineration processes [93]. In these waste management tasks, a smaller number of jobs are generated with non-economic sustainability by locking government responsibility into long-term waste management contracts and preventing the use of appropriate technologies [94]. Now some policymakers are showing increased interest with respect to the social aspect of waste, and they are showing more interest in learning by experience without consideration of the social aspect of waste compromises. Further, by implementing policy goals, we can reduce the detrimental and costly social effects on vulnerable social groups [93,94].

In the formal recycling process, very little product/fuel is recovered. So, it needs positive environmental (including health) impacts with more benefits from various waste management strategies, which involve collection, separation, redirection, and recycling of waste materials. And it has to start with organized door-to-door selective collection systems, and then it can be utilized for recycling waste materials [95]. It needs some embodied opportunities for environmental education in the city community, and it can help shift attitudes and values away from current wasteful consumption patterns and habits. Next, it can utilize or push toward reuse and informed, educated consumption and disposal [95,96].

Some MSW management strategies are discussed for Brazil, and this country has generated nearly 80% of household waste, which has gone through the regular collection process and then utilized for the primary final destination as its disposal into sanitary landfills (58.1%) and controlled landfills (24.2%) [97]. The rest of the waste has gone for disposal into unprotected waste dumps (18%). In Brazil, only 927 municipalities (i.e., 17%) had an official selective waste collection system in 2016 [98]. These effective waste collection systems were performed by informal waste collectors, and they are stigmatized and denied agency [97,98]. Now, a number of researchers are involved in the investigation of shifts in the waste and recycling systems. These can affect the social perception of waste pickers through the waste picker’s own construction of themselves and their praxis [99]. These can help build an efficient and inclusive waste management system in cities. Now many cities are involved in generating sustainable energy systems through the utilization of organic fractions from MSW via anaerobic digestion. This can help provide additional energy backup with cleaning and also be involved in the process of smart cities [99,100]. Table 1 discussed the several value-added products that were generated from the different types of MSW in cities with efforts for mitigation. And Figure 4 shows the fuel sources from different wastes used by microbial fermentation.

Table 1.

Non-fuel-based value-added products from municipal waste are reported to utilize different conversion/extraction approaches with waste mitigation promotion.

Figure 4.

Different biowastes in the city are converted by effective pretreatments.

5. Anaerobic Digestion for Biogases

Several studies have conducted intersectional analysis on biowaste management tasks at the municipal level, and in this context, the application of anaerobic digestion (AD) has shown several benefits, and this approach to conversion can be applied to biowastes into biogas. Further efforts were performed on the application of material flow analyses, which has helped in the quantification of AD treatment effectiveness with regard to biowaste utility via the promotion of clean energy and biofertilizer generation [101,104]. Sometimes, biowaste mitigation from cities can help make a smart city with the promotion of clean energy and the environment with the gain of pure/good-quality water/air. In the AD process, municipal biowaste can be utilized for clean fuel development with biofertilizer development [105].

In India, various villages have applied the AD process with cow dung/manures, and crop residues. From this bioprocess, produced biogas can cover more than 50% of energy consumption (EC) for cooking tasks, with a reduction in firewood dependency. But, in the case of towns and cities, the AD process can be effectively applied to municipal biowastes and can help in the generation of biogas and organic fertilizers with further control of different pollutants [106]. AD process capability can provide the richer nutrients required for crop production and better yields. But the AD-mediated digestate can harm the environment without proper treatment before discharge back to the environment. It is found to generate the additional energy from municipal biowaste utilities via the AD process, and it can supply up to 4–6% or more of EC via the AD-mediated valorization process. This technique is a vital option, but it requires appropriate post-treatment and quality control with better farmer trust [105,106].

Figure 5 shows the AD processes for biogas generation, and this process is integrated into the composting process.

Figure 5.

Anaerobic digestion process is integrated with the composting process for complete biowaste utilization into value-added products, making cities smarter.

Researchers recommended the application of AD processes for biowastes in cities, and AD provides multiple benefits and objectives/purposes like environmental advantages and surplus potential revenue generation. It is a better approach compared to composting and landfilling tasks [107]. In some countries, unsafe solid waste management practices are being used by local-level management authorities, which can have local impacts on ecosystems and public health due to biowaste disposal without proper treatment compared to global levels. Still, there are systematic studies performed on the estimation of the potential of AD to reduce local pollution in Indian municipalities [107,108]. Some studies were conducted on materials flow analysis (MFA) of biowaste management at municipal levels, and it was applied for the quantification of AD process potential. This approach can provide a better substitute for conventional energy/fertilizer sources [109]. Next, these studies can help determine the trade-offs from water and energy input information, and then they can help estimate the reduction capabilities and potential of biowaste-related emissions in local environments [110]. In this regard, AD processes have been applied to biowaste utilization/mitigation in six municipals in Maharashtra, and then they were checked for gradients of population density from 700 to 18,000 inhabitants/km2. This result was discussed in the context of India’s laws and programs that promoted the AD process for biowaste utility [109,110,111].

European countries’ anaerobic digestion process is utilized for the valorization of biowastes, and it requires appropriate post-treatment, quality control, and trust-building efforts with farmers/gardeners. Efforts to minimize trade-offs are performed with water-saving options, and nearly 2–20% of current groundwater abstraction in municipalities is needed to treat all the types of biowaste under the category of wet-AD systems (more than 3%) with dry AD systems [112]. Biowaste management with an AD process system can help provide a contextualized solution with additional benefits to generate energy, fertilizers, and water. These can be possible via implementation—at the basic level, to conceive a valorization strategy for all AD products. Further, it can reduce environmental pollution and minimize trade-offs with water resources [112,113]. Some recent research has focused on the technical feasibility of achieving value-added products from digestates from urban/centralized AD plants (UC-AD). In this context, exhausted efforts were put into identifying and clarifying the existing processing technologies [114]. Specific issues were also found related to UC-AD digestates. Valorization tasks were performed based on final product destinations. From the UC-AD process, useful information was applied to assess the AD-mediated valorization process, and it was applied to local markets. For this reason, agricultural waste was sent to the first destination, where it was allowed to have a more direct impact on nutrients and carbon cycles [114,115].

In the AD process, several characteristics were found to be more desirable. And it can concentrate larger quantities of biowaste matter to enhance the organic matter’s stability. It can promote the production of pure and reformulated fertilizers for enhanced crop yields. In thermal conversion processes, it can be found to be under development or have full-scale demonstration capability [116,117]. In the AD process, the valorization of solid organic matter can result in the production of biofuels/biochar. In the coming year/future, there are more chances of starting a biorefinery business [118]. Some studies were performed on lithium-ion-based batteries, and they have used biomass electrodes with commercial efforts in their development. In this battery, a carbon stem of water spinach (Ipomea aquatica)-based electrode was used, which had an impact on battery performance. In this study, water spinach was processed to nanocarbon by hydrothermal/and pyrolysis approaches [119,120]. And then the size of nanocarbon particles was selected with 200 mesh pores using the grinding method. This lithium-ion-based battery type was a bag battery with a size of 8 cm × 12 cm, and it was optimized via the use of 50% LiCl and Li2SO4 electrolyte media [121]. Next, it was applied with a polyurethane/polyacrylate binder and a triethylamine/non-emulsifier. These chemical solutions have achieved the highest power (5.4 W) and energy value (4.51 W.h.) generation from carbon-based lithium-ion batteries [119,121].

Some biomass harvesting processes, like microalgae, are reported to be upscaling processes. And it can help valorize the nutrients in the AD process in the liquid phase, and then these can help produce the renewable biomass from the sunlight process. In UC-AD digestates, several value-added products can be generated in a laboratory at pilot-scale or pilot conditions, and biopesticides, composite materials, and biosurfactants can be easily produced [117,122]. In another report, the AD process has been utilized as a technological alternative to bioprocessing [123,124]. And it can help complete the management of municipal biowastes (MBWs). This approach can keep pollution under control through the generation of renewable energy like methane [123,124,125].

A few bioprocess factors, like biowaste particle sizes, can influence hydrolysis and the lag phase of microbial growth. These can be limiting factors in AD with biowaste utilization [126]. In this context, this research was evaluated at a laboratory scale for AD process capacity determination with the help of biochemical methane potential (BMP) at a temperature of 30 °C for 30 days. This AD was influenced by biowaste particle sizes [127,128]. In this process, particle sizes from the range of less than 2 mm to 12.5 mm were chosen, and a study was performed to obtain the results. Better results for methane production (i.e., 128 mL. g.VS−1) and electrical energy (2960.4 kWh/week) were found for particle sizes of less than 2 mm. These results have confirmed 19% more biofuel production from the utilization of biowaste from the AD process, and it can help make cities clean and smart with additional fuel generation [126,127]. This process can be applied as the best option for lowering costs for design and maintenance to generate fuel and mitigate biowaste from cities. It needs high quantities of organic matter to generate biogas, and currently in the world, very little biogas generated from biowastes is utilized. In the current period, due to techniques and bioprocess advances, biogas of up to 20% can be produced, fulfilling the global demands for energy/fuels [128]. In modern society, there is more demand for bioproducts, which need sustainable and renewable sources. There are huge quantities of complex organic sources like agricultural residues, food wastes, or animal wastes that can be utilized for the production of biogas and methane as clean energy [129].

This effort is sustainable development with more potential as raw carbon sources. Applications of biogas are found to be utilized as local sources of power and heat energy as well as for clean cooking fuels in households at the municipal/city level [129]. The upgrading of biomethane can provide bioenergy with multiple benefits compared to natural gas. It is reported without any/net toxic gas emissions. In this context, biogas and biomethane from AD processes can play major roles in surplus energy generation in a sustainable manner in the future, and furthermore, they can provide opportunities for waste minimization in cities by cutting toxic gas emissions [130]. Further importance of simulation studies on material flow in the AD process is found. It needs an experimental test design to validate the data that was provided to us, and it can save a lot of time to obtain the best results [129,130]. It needs local government help and suggestions for the promotion of biogas and methane production with the necessary momentum and energy to obtain them at a lower cost. This can provide transport fuel, agricultural fertilizers, and a clean environment [131,132,133]. Due to more urban/city places in every country in the world, there is a huge production of biowastes from different sources/activities, and these are good sources for biogas/biomethane production [134]. This effort in the city can make it smart and also clean, with chances of a healthy life for every citizen, and these can be found as sustainable feedstock for biogas generation promotion by 40% in the coming future. In the IEA report, an examination of biomethane resources was performed, and in the current period, biogas is still found to be a more expensive fuel compared to natural gas prices in their regions [133,134].

It requires them to minimize the cost gap between both fuels in their local regions. Further effort is needed to recognize the value of this fuel while avoiding CO2 and methane emissions in our environment. This process is still needed, with improvements in performance that can help the cost-competitiveness of biomethane. Production and use of biogas like methane can help achieve a more circular economy by making existing resources more reusable, which can fulfill the rising demand for energy services. These can further provide a wider range of environmental benefits [135]. Table 2 shows the different energy sources that are generated from biowaste and sustainable techniques.

Table 2.

Bioenergy generation sources by biowaste uses.

Recently, several studies have been performed on the examination of the diameter ratio and friction coefficient that were applied to check the influence of the equivalent plastic strain (PEEQ). These were performed during contact between two brass solids. In the study, the infinite model was applied to two hemispheres with diameter ratios (ranges of one to five) [136]. Further studies were performed on the upper hemisphere diameter, with a value of 17.5 mm in the variations. Later consideration was given to the bottom hemisphere and diameter ratios. In this study, confirmation was made on finite element results, and these were shown to agree with some previous results on analytical contact models [137]. From these studies, some findings were revealed on differences in ratio diameters and friction coefficients with PEEQ. So, an increase in the coefficient of friction can cause an expansion of the maximum PEEQ area for a diameter ratio (i.e., one), and next it shows a reduction in the PEEQ maximum area for a diameter ratio (i.e., two to five) [138]. Expansion and contraction in the PEEQ area were shown with indications of contact radius widening and contacts. It can be found as coefficients of friction and diameter ratios change. Further research is needed to investigate the effect of other parameters in the PEEQ analysis process [136,138]. This process can be found in material properties and multiple-cycle loading conditions. Some efforts are needed for the practical implications of these findings that can contribute to our proper understanding of engineering design and failure analysis [137,138].

In another study, contact mechanics behavior was reported between two brass hemispheres with differences in diameter ratios and friction coefficients, and these have become the subject of this current study. In this study, seven diameter ratios (in the range of one to seven folds) were compared with the friction coefficient (i.e., the values of 0.05, 0.1, 0.4, and 0.8). In this study, two experiments were performed with simulation tasks that helped to investigate the behavior of the contact mechanics [139,140]. Further experiments and simulation designs were performed to investigate the effect of friction coefficients and diameter ratios on von Misses. This investigation has helped determine the loading process and deformation [141]. Further results were shown on the finite element method simulation (µ = 0). And lubricated conditions experiments were shown coherently between each other. From this experiment study, it was proven that the coefficient of friction has influenced the unloading deformation and von Mises stress distribution. The next studies focused on the dome’s impact on the deformation ratio and friction coefficient (ranging from 0.05 to 0.8). And this analysis indicated no significant differences in both parameters [141,142]. The distribution of von Mises on the diameter ratio (i.e., one) showed similar results between the two specimens. Specimen 2 was reported to have a wider von Mises distribution than specimen 1 at a higher diameter ratio [143]. And from the diameter ratio (three to seven), highly localized stress at the edge of the contact area was reported. And then these regions can be caused by shear stress, which can also result from the middle material pushing the surrounding material sideways. At the increased friction coefficient, localized stress areas were shown to decrease, which indicated a reduced resultant load [140,143].

6. Characteristics of Smart Cities with Efforts to Mitigate Waste

In the current scenario, in every city in India or other countries, the respective local/central governments put efforts into making the cities clean, and beautiful/smart. In this context, the government put its efforts into acceleration exercises for waste minimization with the generation of value-added products like clean fuel sources and others like biofertilizers [144]. Value-added products are always found to provide many benefits to environmental components like health and economics. Further, it is found in sustainable types that harm the environment. This effort in the city can utilize the biowaste matter for the generation of clean energy sources, with additional sources of energy for good lighting, more appliance utilization, and clean city maintenance [145]. Apart from these facilities, smart cities have some priorities for optimal development of infrastructure that can help enhance the economy and social, cultural, and urban development [146]. In the smart city effort, it needs to improve the communication channel for various services like housing, entertainment, telecommunications, and business. These need to connect with advanced technologies via city growth and developmental activity [145,147]. And Figure 6 shows different sources of waste and their conversion into different value-added products.

Figure 6.

Different value-added products from generated wastes in the city and various pretreatment processes applied to waste conversion into valuable products.

A smart city has shown some strategic elements/components in sustainable manners and can also help improve the outlook with better facilities for precipitation drivers, better consumption habits, and better energy management. Further, it needs the utilization of renewable energies for the preservation of natural resources and environmental care tasks. Some components of a smart city are discussed in detail in later sections.

Combustion Facility for Renewable Energy Recovery

In this context, the above sections have been discussed with different types of waste that are generated in cities with an environmental burden on good health for each citizen. Numerous efforts were made for the mitigation of wastes of different types in cities, and it can keep the city smart, beautiful, and highly clean/green [147,148]. In 2018, nearly 34.6 million tons of MSW were used for the combustion process, and it has helped to recover bioenergy/fuel, especially for utilizing the biowastes. In the combustion process, rubber, leather, and textiles (all three wastes accounted for more than 16% of total MSW) were lost in an energy recovery effort [149]. And plastic (16%), paper and paper board (12%), along with food waste (22%), were lost in the combustion process. Other materials in MSW were found to be only 10% each [102,150]. The city’s landfill issue in 2018 was discussed, and it was found to be 146.1 million tons. Out of these waste quantities, food waste (~24%), plastic waste (~18%), paper/paperboard (12%), and rubber/leather/textiles (all three wastes ~11%) were reported [103,149]. Table 3 explores the characteristics of smart cities at the global level.

Table 3.

Characteristics of smart cities that need to keep up with better facilities and performance.

7. Conclusions and Future Perspectives

This review discusses the different types of waste generation in cities and how they become big challenges for maintaining clean and smart cities. This review explores the different sources of waste generation, which are found at an exponential level around the world. In recent years, every citizen has wanted to live in smart/clean cities. So, there are sustainable technologies that can help in the collection, separation/sorting processes, and better transport facilities for sending the wastes into processing centers in cities. Waste management in cities is performed by several projects and facilities. This review also discusses the potential of anaerobic digestion with some other processing like recycling and reuses for waste utilization for new products and also fuel sources. This effort can help mitigate waste through the recovery of value-added products. In the future, there will need to be advances in technologies in the MSW management plan that can help make the cities smart and fully developed. The AD process has aided in the utilization of biowastes for biogas production as well as the development of biofertilizers. In the biowaste category, there are several sources, like paper waste, food waste from hotels/restaurants, and also fruit and vegetables. These are good examples. Some biowaste, like food-left portions and fruit/vegetable waste, can be big challenges due to its fast degradation properties and is responsible for dirtiness and health-related issues. So, these wastes can be utilized in the AD process, microbial fermentation, and recovery approaches by extraction. These processes are good sustainable technologies for value-added products like biogas or alcoholic fuel/biohydrogen generation. Further, these products can help in biorefinery promotion and smart city development efforts.

Author Contributions

P.K.S., R.K.S. and A.K.S.: conceptualization; design of the study; formal; data analysis; writing original draft, review, and editing. U.K.S.: data curation; formal analysis; and typo—correction. P.P. and R.S.: review and editing of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work has received no specific funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

AD: Anaerobic digestion; AF & PA: American Forest and Paper Association; CNCs: Cellulose nanocrystals; CPCB: Central Pollution Council Board; DVD players: Digital versatile disc; EE: Energy efficiency; EPA: Environmental Protection Agency; FAO: Food Agriculture Organization; GWP: Global warming potential; ICT: Information and communication technologies; INC: incineration; ITS: Intelligent transportation systems; LCA: Life cycle assessment; LFGTE: Landfill gas to energy; MBWs: Management of municipal biowastes; MSW: Municipal solid waste; MSW: Municipal solid waste; MSWM: Municipal solid waste management; NRDC: National Resources Defense Council; PHA: Polyhydroxyalkanoates; PPL: paper-plastic laminate; RES: Residual municipal solid; SEP-BIO: Separately collected biowaste; TVs: Televisions; UC-AD: Urban/centralized AD plants; UK: United Kingdom; UNEP: UN environment programs; U.S.A.: United States of America; UWASN: Underwater acoustic sensor networks; VCRs: Video cassette recorders; WELL: Water efficiency label; WTE: Waste-to-energy.

References

- Fan, Y.V.; Klemeš, J.J.; Lee, C.T.; Perry, S. Anaerobic digestion of municipal solid waste: Energy and carbon emission footprint. J. Environ. Manag. 2018, 223, 888–897. [Google Scholar]

- Halkos, G.; Petrou, K.N. Analysing the Energy Efficiency of EU Member States: The Potential of Energy Recovery from Waste in the Circular Economy. Energies 2019, 12, 3718. [Google Scholar]

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-biomethane or biowaste-to-energy? An LCA study on anaerobic digestion of organic waste. J. Clean. Prod. 2018, 174, 462–476. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M.; Zhou, Z. Comparison of waste-to-energy technologies of gasification and incineration using life cycle assessment: Case studies in Finland, France and China. J. Clean. Prod. 2018, 203, 287–300. [Google Scholar]

- Di Maria, F.; Sisani, F.; Contini, S. Are EU waste-to-energy technologies effective for exploiting the energy in bio-waste? Appl. Energy 2018, 230, 1557–1572. [Google Scholar]

- Mehta, Y.D.; Shastri, Y.; Joseph, B. Economic analysis and life cycle impact assessment of municipal solid waste (MSW) disposal: A case study of Mumbai, India. Waste Manag. Res. 2018, 36, 1177–1189. [Google Scholar]

- Pavlas, M.; Dvořáček, J.; Pitschke, T.; Peche, R. Biowaste Treatment and Waste-to-Energy—Environmental Benefits. Energies 2020, 13, 1994. [Google Scholar] [CrossRef]

- Amiri, L.; Abdoli, M.A.; Gitipour, S.; Madadian, E. The effects of co-substrate and thermal pretreatment on anaerobic digestion performance. Environ. Tech. 2017, 38, 2352–2361. [Google Scholar] [CrossRef]

- Farré, J.A.; Mateu, C.; Teixidó, M.; Cabeza, L.F. Pneumatic Urban Waste Collection Systems: A Review. Appl. Sci. 2023, 13, 877. [Google Scholar] [CrossRef]

- Pérez, J.; Lumbreras, J.; Rodríguez, E. Life cycle assessment as a decision-making tool for the design of urban solid waste pre-collection and collection/transport systems. Resour. Conserv. Recycl. 2020, 161, 104988. [Google Scholar]

- Tiwary, A.; Williams, I.D.; Pant, D.C.; Kishore, V.V.N. Emerging perspectives on environmental burden minimisation initiatives from anaerobic digestion technologies for community scale biomass valorisation. Renew. Sustain. Energy Rev. 2015, 42, 883–901. [Google Scholar] [CrossRef]

- Chàfer, M.; Sole-Mauri, F.; Solé, A.; Boer, D.; Cabeza, L.F. Life cycle assessment (LCA) of a pneumatic municipal waste collection system compared to traditional truck collection. Sensitivity study of the influence of the energy source. J. Clean. Prod. 2019, 231, 1122–1135. [Google Scholar] [CrossRef]

- Grigoratos, T.; Fontaras, G.; Giechaskiel, B.; Zacharof, N. Real world emissions performance of heavy-duty Euro VI diesel vehicles. Atmos. Environ. 2019, 201, 348–359. [Google Scholar] [CrossRef]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Ammarullah, M.I.; Santoso, G.; Sugiharto, S.; Supriyono, T.; Wibowo, D.B.; Kurdi, O.; Tauviqirrahman, M.; Jamari, J. Minimizing Risk of Failure from Ceramic-on-Ceramic Total Hip Prosthesis by Selecting Ceramic Materials Based on Tresca Stress. Sustainability 2022, 14, 13413. [Google Scholar] [CrossRef]

- Farooq, M.U.; Anwar, S.; Bhatti, H.A.; Kumar, M.S.; Ali, M.A.; Ammarullah, M.I. Electric Discharge Machining of Ti6Al4V ELI in Biomedical Industry: Parametric Analysis of Surface Functionalization and Tribological Characterization. Materials 2023, 16, 4458. [Google Scholar] [CrossRef]

- Philip, J.T.; Kumar, D.; Mathew, J.; Kuriachen, B. Experimental Investigations on the Tribological Performance of Electric Discharge Alloyed Ti-6Al-4V at 200–600 °C. J. Tribol. 2020, 142, 061702. [Google Scholar] [CrossRef]

- Usman, M.; Ishfaq, K.; Rehan, M.; Raza, A.; Mumtaz, J. An In-Depth Evaluation of Surface Characteristics and Key Machining Responses in WEDM of Aerospace Alloy under Varying Electric Discharge Environments. Int. J. Adv. Manuf. Technol. 2023, 124, 2437–2449. [Google Scholar] [CrossRef]

- Mughal, K.; Mughal, M.P.; Farooq, M.U.; Anwar, S.; Ammarullah, M.I. Using Nano-Fluids Minimum Quantity Lubrication (NF-MQL) to Improve Tool Wear Characteristics for Efficient Machining of CFRP/Ti6Al4V Aeronautical Structural Composite. Processes 2023, 11, 1540. [Google Scholar] [CrossRef]

- Li, J.; Shi, W.; Lin, Y.; Li, J.; Liu, S.; Liu, B. Comparative Study on MQL Milling and Hole Making Processes for Laser Beam Powder Bed Fusion (L-PBF) of Ti-6Al-4V Titanium Alloy. J. Manuf. Process. 2023, 94, 20–34. [Google Scholar]

- ul Haq, M.A.; Hussain, S.; Ali, M.A.; Farooq, M.U.; Mufti, N.A.; Pruncu, C.I.; Wasim, A. Evaluating the Effects of Nano-Fluids Based MQL Milling of IN718 Associated to Sustainable Productions. J. Clean. Prod. 2021, 310, 127463. [Google Scholar]

- Sutcu, M.; Ozturk, S.; Gencel, O. Synergic effect of recycled paper sludge and expanded perlite on the engineering properties of porous clay bricks: A new mathematical modelling approach. Constr. Build. Mater. 2023, 370, 130450. [Google Scholar] [CrossRef]

- Mansikkasalo, A.; Lundmark, R.; Söderholm, P. Market behavior and policy in the recycled paper industry: A critical survey of price elasticity research. For. Policy Econ. 2014, 38, 17–29. [Google Scholar] [CrossRef]

- Tang, S.; Kant, X.; Laaksonen-Craig, S.; Asinas, E.R. Measuring the competitiveness of Canadian pulp and paper in the US market reveals needs for more research. Can. J. For. Res. 2008, 38, 2951–2964. [Google Scholar]

- Zhang, Z.; Macquarrie, D.J.; Budarin, V.L.; Hunt, A.J.; Gronnow, M.J.; Fan, J.; Shuttleworth, P.S.; Clark, J.H.; Matharu, A.S. Low-temperature microwave-assisted pyrolysis of waste office paper and the application of bio-oil as an Al adhesive. Green Chem. 2015, 17, 260–270. [Google Scholar]

- Danial, W.H.; Majid, Z.A.; Muhid, M.N.M.; Triwahyono, S.; Bakar, M.B.; Ramli, Z. The reuse of wastepaper for the extraction of cellulose nanocrystals. Carbohydr. Polym. 2015, 118, 165–169. [Google Scholar]

- Vieira, C.M.F.; Pinheiro, R.M.; Rodriguez, R.J.S.; Candido, V.S.; Monteiro, S.N. Clay bricks added with effluent sludge from paper industry: Technical, economical and environmental benefits. Appl. Clay Sci. 2016, 132, 753–759. [Google Scholar]