Abstract

Environmental pollution and energy shortages have become increasingly prominent. Building energy conservation is an important part of a low-carbon strategy. Integrating phase change material (PCM) into a building’s roof is effective in altering the space cooling load, however less effective in reducing it. To reduce the cooling load, a novel ventilation roof with shape-stabilized PCM (VRSP) is introduced. The mechanical ventilation is used at night by embedding ducts in the roof to remove the solidification heat of the PCM. To identify the best position of PCM and an optimum design, the thermal performances of three kinds of VRSPs were compared and investigated through CFD simulation: ventilation roofs with outer-layer shape-stabilized PCM (VRSPO), middle-layer shape-stabilized PCM (VRSPM) and inner-layer shape-stabilized PCM (VRSPI). The effects of PCM and ventilation parameters on the thermal performance of three roofs were analyzed on a typical design day in summer in Wuhan. The results show that for VRSPO, VRSPM and VRSPI, the proper thicknesses of PCM are 35 mm, 25 mm and 15 mm; melting temperatures are 35~37 °C, 33~35 °C and 29~31 °C, respectively; the proper ventilation speeds are 2.5~2.6 m/s; and the optimum cavity radii are all 40 mm. The best performance can be obtained by placing PCM on the outer layer. The PCM of VRSPO has the highest number of days in which the phase change process occurs (specifically, 75 days in the summer). The application of VRSP can effectively reduce the internal surface temperature of the roof, by an average of 1.77 °C. The maximum and average inner surface temperatures of VRSPO in different weather conditions can be calculated using the daily average outdoor sol-air temperature or average dry bulb temperature by fitting equations. The structure can be used as a passive and active envelope in areas with hot and long summers.

1. Introduction

Energy consumption in the building sector has shown remarkable growth in recent years [1] and is predicted to increase rapidly in the coming decades as well [2]. Due to economic development and the increasing demand for indoor thermal comfort, space cooling has become the fastest-growing section of building energy consumption, which is expected to triple from 2010 to 2050 [2,3]. Hence, energy saving in buildings, particularly in space cooling is rather important. Improving the thermal insulation performance of the building envelope can contribute to the reduction of space cooling energy requirements [4]. With the new generation of district heating and the increase in the proportion of renewable energy in the network, seasonal heat storage becomes crucial for the sustainable and stable operation of the system [5]. Therefore, it is important to consider the energy efficiency of individual seasons. Luo et al. [6] proposed a new idea to turn the building envelope into a multifunctional component that could shield the exterior heat flux while providing additional heating/cooling energy to the interior spaces.

In recent years, PCM has attracted much more attention from researchers due to its characteristics of high energy storage density and temperature variation attenuating capacity [7]. Many studies have investigated the thermal performance of the building envelopes incorporated with PCM experimentally or numerically, in different climate regions. Khedher et al. [8] studied the thermal performance of a combined three-layer PCM in a building envelope and used a program to analyze the thermal performance of a typical Tunisian city in summer. It was found that the octadecane layer with a thickness of 1 cm performed well in the test chamber. It was additionally noted that thickness is the key to the performance of PCM. Lei et al. [9] applied PCM to the exterior and interior surfaces of walls, respectively, in tropical Singapore. The numerical simulation results showed that the walls installed with PCM reduced heat gains effectively throughout the whole year in the tropical region, and the walls showed a better performance when the PCM was applied to the exterior surfaces. He et al. [10] proposed a novel wall combining PCM, micro-channel heat pipes and a radiative cooling plate, which could decrease the inner surface temperature of the wall and the cooling load of the room effectively, as indicated by the field testing results. Huakeer Wang et al. [11] applied the PCM to the wallboards of different rooms in Shanghai. The simulation results showed that the optimal melting temperatures of PCM in the different rooms were 22~26 °C, which is the comfort temperature range for human beings. The economic results showed that the PCM integrated into the southern wall had the best economic benefit. Shilei Lu et al. [12] integrated the PCM into a floor heating system to effectively reduce the mismatch between energy supply and demand and found that the system could provide a comfortable indoor thermal environment, while adjusting suitable operational strategies. Ben Khedher et al. [13] combined PCM with nanomaterials to make an evaluation of nanomaterial enhancement using numerical simulation and experimental methods. The addition of nanomaterials was able to greatly improve the melting and curing rates of PCM.

In addition, a variety of novel roofs integrated with PCM were proposed, such as a roof coupled with PCM and cool materials [11,14] and a roof with outer-layer shape-stabilized PCM [15]. These roofs showed a better thermal performance than ordinary roofs. The influencing factors were additionally investigated [15,16,17,18], such as the type of PCM, the thickness of the PCM, the phase transition temperature and so on. The economic benefit of the roof with PCM was taken into consideration by J. Xamán et al. [19]. They studied a concrete roof with a PCM layer on its interior surface, in warm Mexican weather. The result showed that the roof would have a payback period of 12.18 years, less than the ordinary building service life of 30 years in Mexico. Several studies additionally gave the optimum design of the roof parameters, according to a simulation or experiment results. Bhamare et al. [20] studied the thermal performance of a residential roof integrated with an inclined PCM layer, through the numerical model. The results indicated that the roof could maintain the ceiling temperature within a narrow range and decrease the peak heat load, and the roof showed a better thermal performance when the PCM layer was inclined at an angle of 2°. Meng et al. [21] laid a PCM layer outside the common roof and a layer of high-reflectivity film outside the PCM layer, and the experiment results demonstrated that the new type of roof performed better than the PCM roof and common roof in the reduction of indoor air temperature, inner surface temperature and inner surface heat flux. Typically, PCMs are installed on the inside of the building envelope to regulate the indoor environment. Therefore, the PCM may not be fully cured at night because the insulation prevents heat loss to the external environment, and the heat stored in the PCM is discharged to the interior, thus not resulting in appreciable energy savings or higher energy consumption for space cooling [22].

In addition to the application of PCM, ventilation is another efficient way to improve energy efficiency and reduce cooling loads. There are two main forms of ventilation, first including night ventilation, which could remove the heat gains during the daytime by introducing cool outdoor air to the room at night or enhance the cooling performance during the nighttime, including natural ventilation and mechanical ventilation [23]. The other is using the hollow part of the building envelope as a ventilation duct to improve its thermal insulation performance [24]. Regarding the former method, Ran et al. [25] combined the nighttime ventilation with green roofs and found that when the night ventilation worked, the indoor temperature under the roof decreased as the air change rate increased, and the decrease was significant at night; Ji et al. [26,27] proposed a novel wall-mounted attached ventilation system for night cooling, which could generate a downward air jet that flowed over the inner surface of the west-external wall to improve the cooling performance at night. The experimental and numerical results indicated that decreasing the supply air temperature could improve the cooling performance, and the optimal air velocity was approximately 4 m/s. Another method comprising taking ventilation as a part of building envelopes was additionally a creative attempt to reduce energy consumption in buildings. A hollow block ventilation wall whose block cavity was used as a ventilation duct was proposed, and the experimental results showed that the air velocity in the cavity had a great influence on the thermal performance [24]. In addition, hollow core slab systems were studied in the past three decades [28,29],and Benjamin Park et al. [30] studied the optimal control strategies for energy savings.

Both PCM and ventilation can effectively save energy, and the experiment results of the PCM underlined the importance of coupling the PCM with ventilation to guarantee the efficacy of the PCM in reducing room loads [16]. Therefore, the combination of PCM and ventilation came into being. Kang et al. [31] placed the phase change boards between the ceiling and roof slab and conducted mechanical ventilation for the phase change boards at night to store the cooling energy. The results of the experiment showed that the use of the phase change board could improve the cooling potential of the roof and decrease the indoor temperature distinctly. Gunay et al. [32] carried out a numerical investigation on the thermal response of the room equipped with a hollow core slab and found that the peak load of the room decreased obviously after adding the micro-capsuled PCMs into the hollow core. Faheem et al. [33] integrated the microencapsulated PCM into the prefabricated hollow core slab for ventilation. The numerical simulation results showed that in a high thermal mass building, the slab’s cooling effect is better when the phase transition temperature is 20 °C, whereas the influence of ventilation speed contributed more to a low thermal mass building. Hu et al. [34] presented a PCM-enhanced ventilated window for pre-cooling and pre-heating. The average energy savings were 0.7 MJ/day for ventilation pre-cooling and 1.6 MJ/day for ventilation pre-heating, compared to the normal ventilation window, respectively.

PCM is an economical and efficient building material. Latent heat storage in PCM is an efficient technology that can be applied to building envelopes and could effectively prevent over-heating in summer and decrease the indoor air temperature. Shape-stabilized PCM can be produced by immersing the porous materials of the envelope in melted PCM, or by adding PCMs to supporting materials directly. The advantage of shape-stabilized PCM is that there is no macroscopic change in the state of the composite before and after phase transition, and no container is required. The mass ratio of PCMs to supporting materials should be controlled to prevent PCMs from leaking the supporting materials during melting. This paper proposes a structure of a ventilation roof with shape-stabilized PCM. The prefabricated concrete hollow core slab is the roof’s main structure, which is used to bear the pressure of the roof to such an extent and needs to reach the strength required by the design; nighttime ventilation is carried out through the cavity of the slab to remove the solidification heat of PCM. Hollow core panels are commonly used in rural areas of China. They can be ventilated within their cavities to remove heat and are a common energy-saving technology for energy-saving buildings. Waterproof layer materials can be selected according to specific needs, and waterproof membranes are used in this study. The position of PCM has an important effect on the thermal insulation of the roof, because the thermal performance of the roof varies greatly when PCM is located in different positions. Existing studies usually place the PCM in the middle layer of the roof; however, few scholars have investigated the optimal location of PCM. The innovations of this study are as follows: (i) The coupling applications of PCM and ventilation to roofs are studied; (ii) the influences of different locations and the thermal properties of PCM on the VRSP are considered; and (iii) the effects of ventilation on roof thermal insulation and the improvement of the latent heat utilization ratio of PCM are investigated. The PCM placed at three positions is studied, namely, below the ventilation layer, between the screed coat and the ventilation layer and above the screed coat layer. The thermal performance of the structure, the optimum PCM layer thickness and melting temperature and the cavity’s ventilation strategy under the different positions of the PCM layer are studied by computational fluid dynamics (CFD) numerical simulation, and the best position of the PCM and the best ventilation speed are determined.

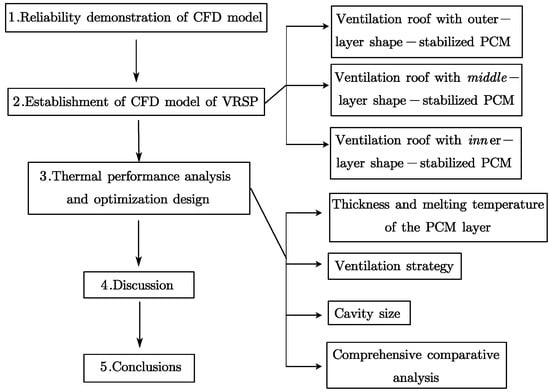

There are five sections in this study. Section One introduces the background and the literature review. Section Two presents the research methodology, theoretical basis, research content and boundary conditions. Section Three shows the results of the study and provides analysis. Section Four develops the discussion of this roof structure and related studies. Section Five concludes the whole article. Figure 1 shows the flow diagram of the study.

Figure 1.

Flow diagram of the study.

2. Methodology

In order to analyze the thermal performance of ventilation roofs with different positions of shape-stabilized PCM and obtain the optimum design of roof structure, firstly, the reliability of the CFD model in studying ventilation roofs with PCM layers must be demonstrated through the literature research. This then allows us to establish the CFD models of VRSP this paper proposes, analyze the thermal performance and optimize the design of the PCM layer thickness, melting temperature, ventilation strategy and cavity size through a CFD simulation program.

2.1. Verification of Numerical Simulation Method

The continuous development of computer technology has resulted in analyzing the heat transfer of PCMs through the CFD package of ANSYS Fluent 16.0 (https://www.ansys.com/products/fluids/ansys-fluent, accessed on 25 May 2023). The CFD simulation method is favored by more and more researchers, because of its high efficiency and adequate accuracy.

The governing mathematic equations in simulation are as follows:

Equation of mass continuity:

where ρ is density, t is time and u is speed.

Momentum equation:

where p is pressure and τ is shear stress.

Energy equation:

where e is internal energy, λ is thermal conductivity, T is temperature and q is heat source per unit volume.

Dabiri et al. [35] built up a CFD model of a penetrated concrete hollow core roof, whose holes were filled with PCM according to ref [36] and compared the experimental results of ref [36] with the simulation results obtained by the CFD package of ANSYS Fluent. There was less than a 0.2% deviation between the experimental results and the simulation results for the indoor temperature. Muhammad et al. [37] took up the validation of a CFD melting and solidification model for phase change in vertical cylinders. The results showed that the maximum discrepancy between the predicted melt fraction of PCM obtained by the CFD model and that obtained in the experiment was 7.5%. The results were in close agreement with each other. Through the literature review above, it can be concluded that the calculation results of the phase change heat transfer model of the CFD numerical simulation method were reliable.

The finite volume method is used for CFD. The basic idea of deriving discrete equations is as follows: First of all, the calculation area is divided into a series of non-repetitive control volumes; each control volume has a node as a representative; the conservation type of differential equation is sought in any control volume; and a certain time interval is used for the integration of space and time. The function to be sought and its derivatives of time and space are then used to change the type of line or interpolation to make assumptions. Finally, the integration of the first step is made according to the selected type of line and organized into a set of discrete equations about the unknown quantities at the nodes. The finite volume method focuses on the physical point of view to construct the discrete equations; each discrete equation is a representation of the conservation of some physical quantities on a finite size volume; the derivation process and the physical concepts are clear; the discrete equation coefficients have a certain physical meaning; and the method can ensure that the discrete equations have conservation properties, which is the main advantage of the finite volume method.

The CFD analysis can be used as an effective tool to solve the heat transfer problems in the ventilation process. A large number of experiments verified the accuracy of the CFD model in the ventilation study. Buratti et al. [38] investigated the thermal performance of a new ventilated brick wall, by means of experiments and CFD simulations. Three turbulent models (standard k–ε, standard k–ω and laminar) were used for the simulation within the air gap, and results showed that the standard k–ε model could obtain reliable results and was selected for the thermal performance investigation. Diarce et al. [39] used the Fluent CFD code to study the thermal behavior of a new ventilated wall with outer-layer PCM; the RNG k–ε model, which is based on the standard k–ε model, showed good agreement between the experimental and could be considered suitable for the simulation under turbulent flow conditions. In addition, many scholars used the standard k-ε model to perform a CFD numerical study on the thermal performance of a ventilated wall or roof [33,40,41]. The k-ε model was calculated as ref. [42]. From the above studies, we can conclude that the CFD method can be used to study the heat transfer of ventilation processes with reliable results. In this study, ANSYS FLUENT is used to solve all the transport equations. The standard k–ε model is used to predict the heat transfer of ventilation roofs.

2.2. Establishment of the Simulation Model

2.2.1. Physical Model

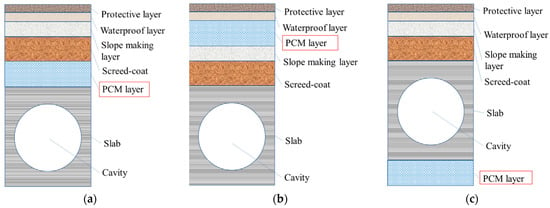

The main structures of the ventilation roofs with shape-stabilized PCM this paper studied were mainly composed of a prefabricated concrete hollow core slab and shape-stabilized PCM. The roof includes a protective layer, waterproof layer, slope-finding layer, screed-out, slab and PCM layer, mainly with the slab as a pressure-bearing structure. Existing studies usually place the PCM in the middle layer of the roof; however, few scholars have investigated the optimal location of PCM. There are three different kinds of ventilation roofs with shape-stabilized PCM: ventilation roofs with middle-layer, outer-layer and inner-layer shape-stabilized PCM (VRSPM, VRSPO and VRSPI), whose structures are shown in Figure 2. The VRSPM is shown in Figure 3. Each ventilation cavity is parallel, and night ventilation runs parallel through channels; therefore, this study selected a unit with one cavity as the object. The standard k-ε model, DTRM radiation model and solidification-melting model were used. The SIMPLE scheme for velocity–pressure coupling was applied to solve PCM momentum equations. The under-relaxation factor of 0.7 was selected to improve the convergence stability. The simulation is conducted at the unsteady-state with the energy equation convergence criteria of 1 × 10−3.

Figure 2.

The structures of three kinds of ventilation roofs with shape-stabilized PCM: (a) VRSPM; (b) VRSPO and (c) VRSPI.

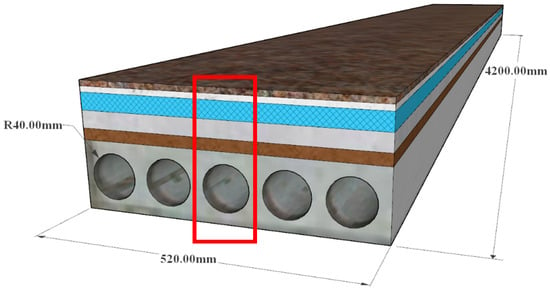

Figure 3.

Schematic diagram of VRSPM (The red frame is a VPSPM cell in this study).

The 3D model of the VRSPM, established by CFD is shown in Figure 4. The thickness of each layer is shown in Table 1, and the length of the model is 4200 mm and the width is 104 mm. All structural layers were used as the simulation calculation area. The heat transfer among the cavities of the hollow core slab was symmetric, and the heat flux at the interface between the adjacent cavities was close to 0. Therefore, a cavity in the middle of the prefabricated concrete hollow core slab was taken as the research object, and a unit of the whole roof structure was simulated and analyzed. The thickness and thermal physical properties of the material in each layer of the ventilation roof with a shape-stabilized PCM model are shown in Table 1. The shape-stabilized PCM selected was made from mixed paraffin, high-density polyethylene and expanded graphite. High-density polyethylene can ensure that the PCM is solid before and after the phase change and can maintain its shape unchanged, and expanded graphite can greatly improve the thermal conductivity of the PCM. In order to increase heat storage, the mass ratio of paraffin wax is selected as much as possible on the basis of ensuring no leakage of paraffin wax. Investigations indicated that the maximum range of the paraffin mass ratio is 80–85% [43,44]. Paraffin of RT35 is selected as the PCM; the latent heat of that selected is 189 kJ/kg [45]; the phase change temperature range is 35–37 °C; the density is 755 kg/m3 and the thermal conductivity is 0.21 W/(m.K). In order to increase the thermal conductivity of the shape-stabilized PCM, expanded graphite was added. The mass percentages of paraffin, high-density polyethylene and expanded graphite in the formalized PCM are 85%, 10% and 5%, respectively. Therefore, the latent heat of the shape-stabilized PCM is equal to the mass percentage of paraffin times the latent heat of paraffin wax, which is 161 kJ/kg. The shape-stabilized PCM has a density of 940 kg/m3 in the solid-state and 755 kg/m3 in the liquid-state, a specific heat capacity of 2210 in the solid-state and 2510 in the liquid- state and a thermal conductivity of 1.37 W/(m.K).

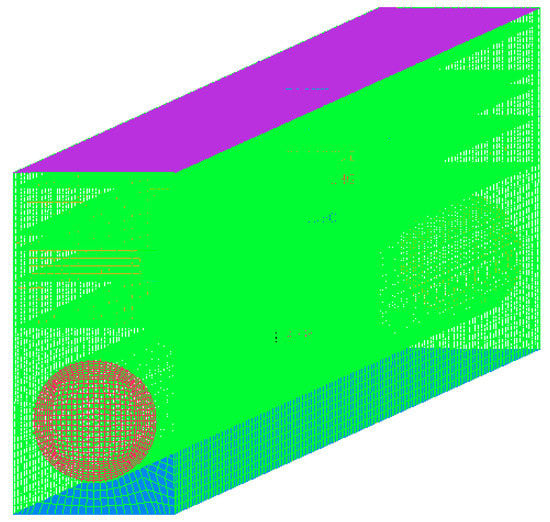

Figure 4.

The 3D models of the VRSPM established by CFD.

Table 1.

The thickness and thermal physical properties of materials in each layer of the VRSP model.

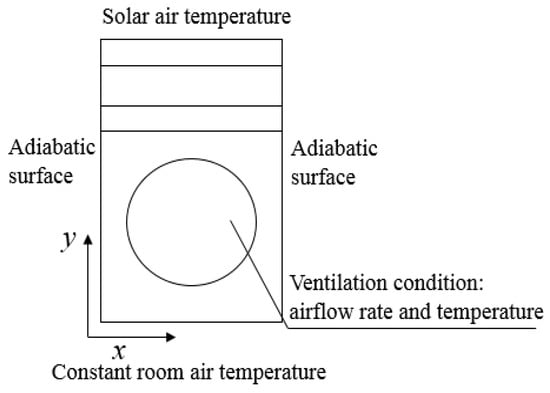

2.2.2. Boundary Conditions

The boundary conditions of one unit of VRSPs are shown in Figure 5. Due to the symmetry of the cavity heat transfer, the middle interface between two adjacent cavities was set as an adiabatic boundary; namely, the left and right sides of the models were set as adiabatic boundary conditions. The cavity entrance was set as a velocity entrance, and the speed was controlled by the UDF (User Defined Function) program. The cavity exit was free flow, and the other boundary surfaces of the entrance and exit section were set as adiabatic boundary conditions. The interior and exterior surfaces of the roof were both set to the third boundary condition. The convective heat transfer coefficient of the roof’s inner surface and indoor air was 8.7 W/(m2·K) [12], and the indoor air temperature set point was 26 °C. The convective heat transfer coefficient between the exterior surface and outdoor air was 23.3 W/(m2·K) [12]. According to the intensity of solar radiation, outdoor air temperature and the external finish of the roof (here, the absorption coefficient of the external finish was 0.75), the outdoor sol-air temperature tsol-air on a typical summer day (air-conditioning system design day) in Wuhan was calculated and used as the boundary condition of the outdoor climate. Further, tsol-air is calculated as follows:

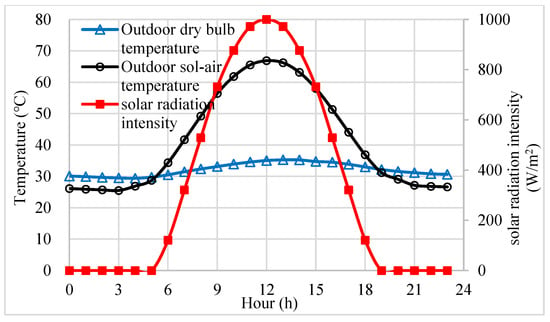

where tsol-air is the solar–air outdoor air temperature, which is a combined temperature that takes into account solar radiation, outdoor air temperature and long-wave radiation, °C; tw is the outdoor air temperature, °C; a is the absorptance of solar radiation on the exterior surface of the enclosure structure, taking 0.74; I is the solar radiation illumination, W/m2; aout is the flow heat exchange coefficient on the exterior surface of the enclosure structure, taking 23.26 W/m2·k and Qlw is the long-wave radiation heat exchange between the exterior surface of the enclosure structure and the environment. The hourly sol-air temperature and outdoor air dry-bulb temperature on a typical summer day (air-conditioning system design day specified in Chinese design code (”Design code for heating ventilation and air conditioning of civil buildings cod GB50736-2012” [46])) in Wuhan is shown as Figure 6.

Figure 5.

The boundary conditions of the one unit of VRSPs.

Figure 6.

The sol-air temperature on a typical summer day in Wuhan.

The no-slip velocity condition was imposed on the ventilated roof; it can be expressed numerically as follows:

where u is the fluid velocity field, and us is the velocity field at the solid boundary.

u(x,t) = us(x,t)

The side-by-side cavities are used for ventilation ducts. The ventilation air comes from outside. The ventilation time is automatically controlled. The control method for ventilation time is that ventilation starts when the outdoor temperature is lower than the lowest temperature of the cavity surface (selecting the bottom point on the mid-section of the cavity as the test point) and stops when the outdoor temperature is higher than that, and the ventilation time is dynamic and varies depending on the outdoor climate.

2.2.3. Mesh and Time Step Independence Analysis

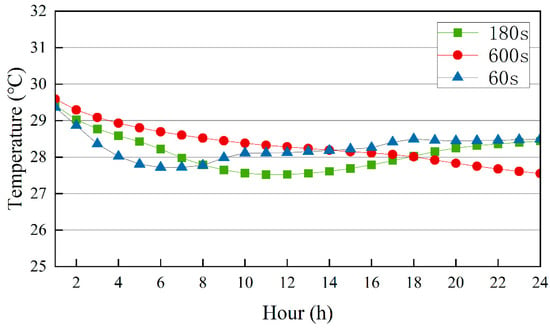

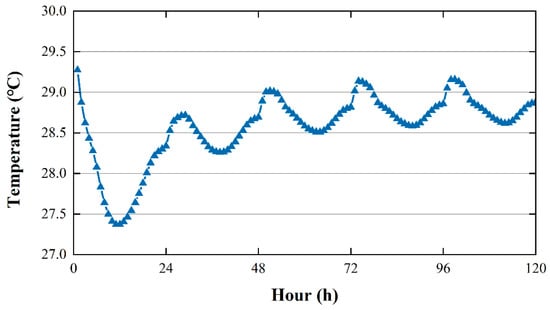

The mesh and time step independence were tested with VRSPO, and the conditions were set for simulation: a phase change temperature of 35 °C, ventilation speed of 1 m/s, cavity radius of 40 mm and phase change layer thickness of 30 mm. The ICEM CFD program was used to mesh the established roof model. A hexagonal structure grid was used in the roof construction, and an O-block grid was used in the ventilated cavity when calculating the airflows and the energy fluxes. A local mesh refinement was adopted around the cavity. The dimensions varied from 2 mm to 9 mm. As shown in Figure 7, the internal surface temperature of the roof obtained by the Fluent model 3 times with discrepancies (60 s, 180 s and 600 s) was studied. Table 2 shows the maximum absolute error and the average relative error. The trend of the roof inner surface temperature at the step length of 180 s is consistent with 60 s, whereas the deviation is larger at 600 s. The average relative error for the step size of 180 s is within the acceptable range, and 180 s was chosen as the time step for the simulation considering the efficiency of the calculation. The number of steps was set to 2400. Five days were simulated, and the results of the fourth day were selected for analysis. The results of the five-day simulation are shown in Figure 8. It can be seen that the temperature trend of the inner surface temperature of the roof tends to stabilize when the PCM is put into use from the third day. The results of the fourth and fifth days are very close. Therefore, the simulation results of the fourth day were chosen for this study.

Figure 7.

Time step test results.

Table 2.

Error in time step.

Figure 8.

VRSPM simulation results under 5 days.

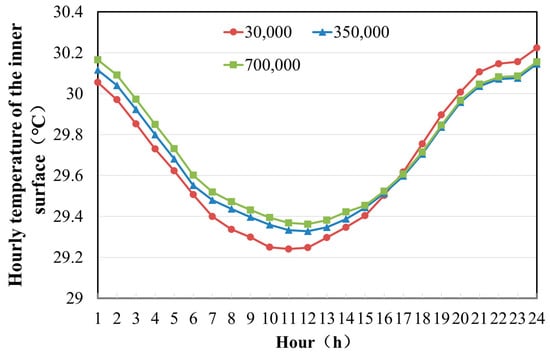

For the numerical simulation calculation with Fluent software, the grid number will affect the calculation time and precision. This study established a model of VRSPM with 3 grid numbers for grid independence analysis: 30,000, 350,000 and 700,000. The hourly temperatures of the roof’s inner surface for the models with three different grid numbers are shown in Figure 9. Table 3 shows the relative error. The results calculated by the models with 350,000 and 700,000 cells were mostly coincident, indicating that the model with 350,000 cells can obtain accurate results, whereas the calculation time of the 700,000 cells model is relatively longer. Therefore, this paper selected a model of 350,000 cells to simulate the thermal insulation performance of the VRSP.

Figure 9.

Hourly temperatures of roof inner surface for VRSPM models with different grid numbers.

Table 3.

Mesh sensitivity.

2.2.4. Model Validation

The experimental results of PCM roofs from Tianjin University were applied for verification. In this paper, the experiments on PCM roofs in the literature [47] were used as reference objects, and Fluent CFD was used to build a PCM roof model consistent with their experiments, and the simulated data were contrasted to the experimental data in the literature, so as to verify the accuracy of the phase change roof model using computational fluid dynamics (CFD) (the standard k–ε model was used). The experimental room was built on the campus of Tianjin University. The structure has a crack-resistant mortar layer, a phase change layer, a bonded mortar layer, a waterproof layer and a roof foundation layer. The PCM was encapsulated into the PE-RT pipe, and then the PE-RT pipes were arranged side by side. The simulation results and experimental results are shown in Table 4. The differences between the data obtained from the simulations and the experimental data are small, with the maximum relative error of 2.59% and the minimum relative error of 1.46%, which indicates that the accuracy of simulating the heat transfer process by phase change with CFD is high, and the simulation results obtained are more reliable.

Table 4.

Phase change roof model simulation values and experimental values.

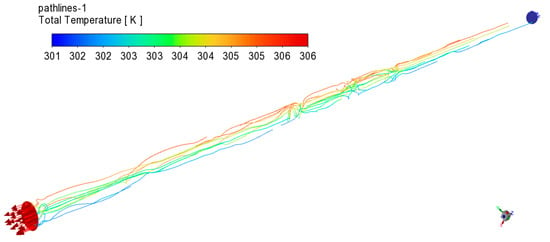

The cavity inlet air temperature is the outdoor air temperature, and the wind speed is 1 m/s. The flow diagram of the ventilation model for this study inside the hollow slab is shown in Figure 10.

Figure 10.

Ventilation streamline.

3. Results and Analysis

3.1. Thermal Performance Influencing Factors Analysis of Different VRSPs

The thermal performance of VRSP depends on the material properties and physical dimensions of each layer and the ventilation control method. The effects of the thickness and melting temperature of PCM, ventilation control method and cavity size on the thermal performance of the three kinds of VRSP were studied with the CFD simulation software, respectively. Time lag and decrement factor (the ratio of the inner surface temperature amplitude to the outer surface temperature amplitude during a day) were used for the thermal performance evaluation of VRSP.

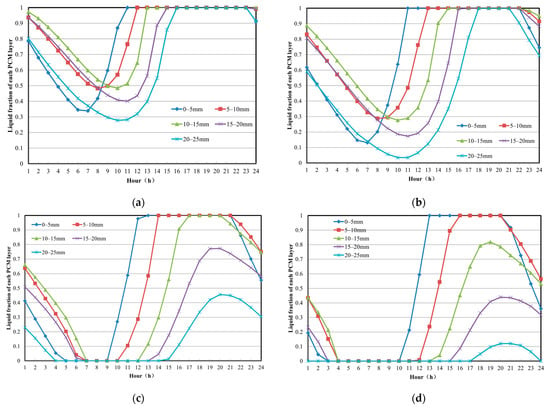

To access the suitable PCM thickness, the liquid fraction and utilization rate of latent heat are used to evaluate the PCM and determine the thickness of the PCM. The liquid fraction is defined as follows:

In this equation, and are the solid temperature and liquid temperature, respectively (K). When the temperature is between the and , the phase transition process will occur, which is defined as the phase transition temperature.

PCM was divided into several sub-layers every 5 mm to investigate the application of PCM. The utilization rate of latent heat in a certain sub-layer is the difference between the maximum liquid fraction and the minimum liquid fraction during a day. The value ranges from 0 to 1.0, where 0 means the solid state for liquid phase rate, 0–1 is the solid–liquid coexistence, i.e., melting state and 1 is the liquid state, i.e., completely melted state. The average utilization rate of latent heat in PCM is the mean value of . The maximum liquid fraction appears during the daytime. If the 1, it means that part of the PCM is not melted and is too thick. The minimum liquid fraction appears at night. If the , it means that part of the PCM is not solidified, and the temperature of the PCM is too high to solidify completely.

3.1.1. Thickness and Melting Temperature of PCM

The influence of the thickness and melting temperature of PCM on the thermal performance of the VRSPs on a typical summer day in Wuhan was simulated and analyzed. The ventilation speed in the ventilation duct is usually 0–3 m/s, considering the noise problem. In the case study on thickness and melting temperature analysis of PCM, the cavity radius of the slab is 40 mm, ventilation speed is 1.0 m/s and the ventilation time at night is automatically controlled by comparing the ambient air temperature and the bottom surface temperature in the middle cross-section of the cavity. Different types of paraffin can produce PCMs with different melting temperatures. The thermal properties with similar phase transition temperatures show little change. Here, it is assumed that the thermal properties including density, thermal conductivity and latent heat remain constant when the phase change temperature is changed, to analyze the influence of the phase change temperature on the thermal characteristics of the structure. When the PCM is located at different positions, the temperature and heat transfer of the PCM are different. The temperature of PCM is higher at the upper layer and lower at the middle layer. Therefore, in roofs with different PCM positions, there are different optimal phase change temperatures and PCM thicknesses. Therefore, different values are simulated for comparative analysis to achieve the best performance of the structure.

- (1)

- VRSPM

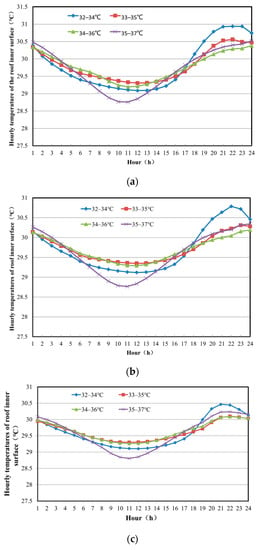

With the shape-stabilized PCM placed in the middle layer, the inner surface hourly temperature and thermal performance of the roof with different thicknesses (20 mm, 25 mm and 30 mm) and melting temperatures (32~34 °C, 33~35 °C, 34~36 °C and 35~37 °C) are shown as Figure 11 and Table 5.

Figure 11.

Hourly temperatures of roof inner surface for VRSPM with different PCM thicknesses: (a) 20 mm PCM; (b) 25 mm PCM and (c) 30 mm PCM.

Table 5.

The thermal performance of VRSPM with different thicknesses of PCM and melting temperatures.

As is shown in Figure 11 and Table 5, with the increase in PCM layer thickness, the peak temperature and temperature amplitude of the roof’s inner surface as well as the decrement factor gradually decrease, and the time lag increases, indicating that the thicker the PCM layer, the better the insulation effect. With the increase in PCM layer thickness, the average utilization rate of latent heat in PCM (UR) decreases. That is because the PCM cannot melt or solidify completely in the phase transition cycle throughout the day as the thickness grows. Consequently, when the thickness of PCM is 20 mm, the UR is up to 100%, whereas it does not happen when the thickness exceeds 20 mm. Therefore, the PCM layer thickness should be properly determined to achieve high thermal performance and a high utilization rate of latent heat at the same time.

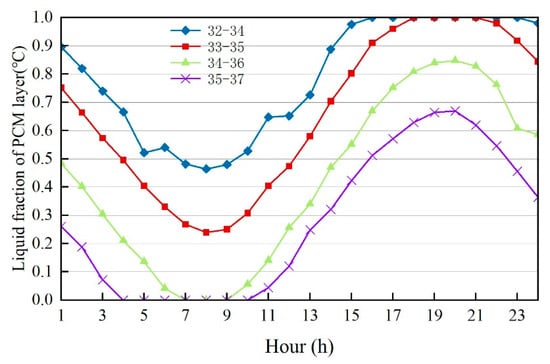

Figure 12 shows the liquid fraction of 25 mm PCM with different melting temperatures. When the phase transition temperatures are 32–34 °C, 33–35 °C, 34–36 °C and 35–37 °C, the URs are 60.3%, 81.9%, 84.6% and 64.6%, respectively. As the melting temperature increases, the UR first increases and then decreases, reaching its highest at a melting temperature range of 34–36 °C. When the phase transition temperature is 32–34 °C, the maximum liquid fraction of each layer is 100%, the minimum liquid fraction of each layer is 27.8~49.0% and the average UR of all layers is 60.31%. As the melting temperature increases (here the melting temperature is assumed to be the same as solidification temperature), the minimum liquid fractions of all layers and the maximum liquid fractions of some layers decrease; therefore, the average UR first increases and then decreases. From Figure 12a,b, it can be seen that at low melting temperatures, the liquid phase ratio of PCM sub-layers can reach 1 however not 0. That is, the phase change temperature is low; the PCM layers can be completely melted however not completely solidified. From Figure 12c,d, it can be seen that at higher melting temperatures, the liquid phase ratio of PCM sub-layers can reach 0 however not 1. That is, the PCM layers can be completely solidified however not completely melted; they can only be partially melted. We can additionally conclude that when the melting temperature is low, it is difficult to reach the solidification temperature at night, which leads to a low UR; when the melting temperature is high, the PCM cannot melt completely during the daytime, which additionally leads to a low UR. Thus, there is an optimal melting temperature range. The liquid fractions of PCM with different melting temperatures are shown in Figure 13.

Figure 12.

Liquid fraction of 25 mm PCM with different melting temperatures: (a) melting temperature of 32~34 °C; (b) melting temperature of 33~35 °C; (c) melting temperature of 34~36 °C and (d) melting temperature of 35~37 °C.

Figure 13.

Liquid fraction of 25 mm PCM with different melting temperatures.

As the melting temperature increases, the minimum temperature and average temperature of the inner surface reduce slightly, whereas the peak temperature, temperature amplitude and DF first decrease and then increase. The optimum melting temperature is 34~36 °C at different thicknesses of PCM, because the average utilization rate of latent heat is the highest, and the average temperature of the inner surface is the lowest. When the thickness of PCM is 20 mm, the average utilization rate of PCM is up to 100%; however, the thickness is too small to decrease the roof inner surface temperature effectively. However, when the thickness of PCM is 30 mm, the average utilization rate of the latent heat of PCM is only 75.32%. Consequently, a large part of PCM is not utilized effectively, leading to a poor economy. Therefore, 25 mm is the appropriate thickness.

- (2)

- The VRSPo

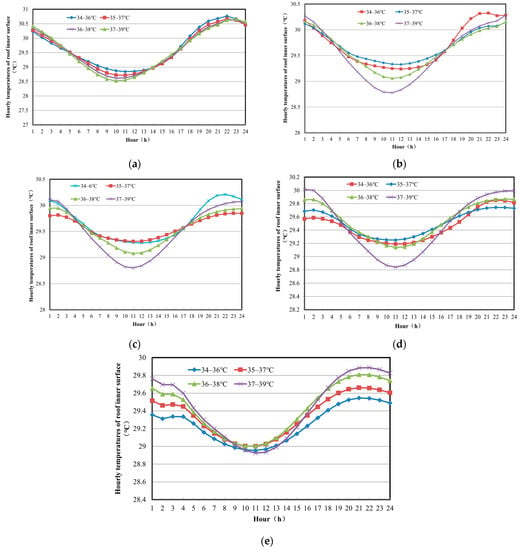

With the shape-stabilized PCM placed in the upper layer, the thermal performance of the roofs with different PCM thicknesses (20 mm, 30 mm, 35 mm, 40 mm and 50 mm) and different melting temperatures (34~36 °C, 35~37 °C, 36~38 °C and 37~39 °C) is shown in Figure 14 and Table 6.

Figure 14.

Hourly inner surface temperatures of VRSPO with different thicknesses and melting temperatures of PCM: (a) 20 mm PCM; (b) 30 mm PCM; (c) 35 mm PCM; (d) 40 mm PCM and (e) 50 mm PCM.

Table 6.

Thermal performance of VRSPO with different thicknesses and melting temperatures of PCM.

Due to space limitations, in the analysis of the thermal performance of VRSPo and VRSPI, the hourly liquid phase ratio of PCM was not depicted; however, the latent heat utilization rate was directly calculated. As Figure 14 and Table 6 show, the influences of the melting temperature and thickness on the thermal performance of VRSPO are consistent with the VRSPM. Comparing the thermal performance and latent heat utilization rate of PCM comprehensively, it can be concluded that, for the VRSPO, the optimum thickness of PCM is 35 mm, and the optimum melting temperature is 35~37 °C. At the optimum condition, the average inner surface temperature is 29.58 °C, the decrement factor is 0.019, the time lag is 10 h, and the utilization rate of latent heat in PCM is 96.05%.

- (3)

- The VRSPI

With the shape-stabilized PCM placed in the inside layer, the hourly temperatures of the inner surface and the thermal performance evaluation indexes of VRSPI with different PCM layer thicknesses (15 mm, 20 mm and 25 mm) and different melting temperatures (28~30 °C, 29~31 °C and 30~32 °C) are shown in Figure 15 and Table 7.

Figure 15.

Inner surface hourly temperatures of VRSPI under different thicknesses of PCM and melting temperatures: (a) 15 mm PCM; (b) 20 mm PCM and (c) 25 mm PCM.

Table 7.

The thermal performance of VRSPI under different thicknesses of PCM and melting temperatures.

As Figure 15 and Table 7 show, with the increase in thickness of PCM, the roof shows better heat insulation; however, the average utilization rate of latent heat decreases gradually. When the thickness of PCM is 20 mm or 25 mm, the average utilization rate of latent heat is lower than 50%. When the thickness of PCM is 15 mm, the average utilization rate of latent heat is the highest, at 61.30%. In addition, with the increase in melting temperature, the effect of thermal insulation and the utilization rate of latent heat are improved.

Therefore, to achieve better thermal performance and a higher utilization rate of latent heat, the optimum thickness of PCM is 15 mm, and the optimum melting temperature is 30~32 °C for the VRSPI.

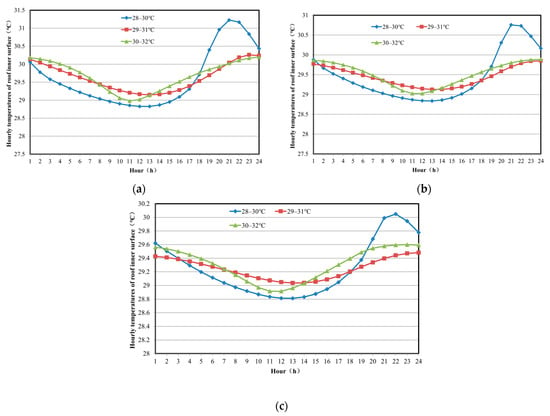

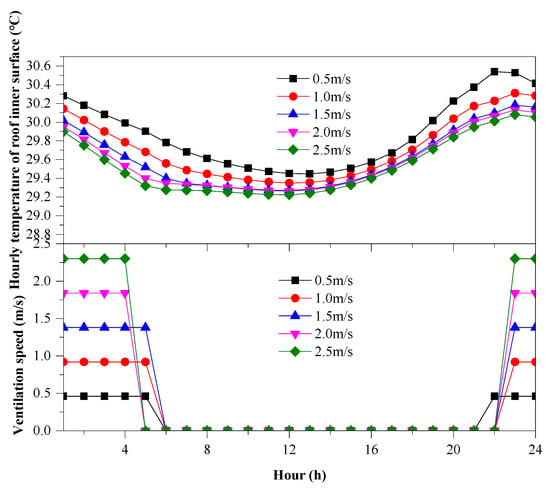

3.1.2. Mechanical Ventilation Speed

Based on the above research, this section studies the influence of different ventilation speeds (0.5 m/s, 1.0 m/s, 1.5 m/s, 2.0 m/s and 2.5 m/s) on the thermal performance of VRSP with the conditions of the optimum thickness of PCM and the optimum melting temperature of VRSP.

- (1)

- The VRSPM

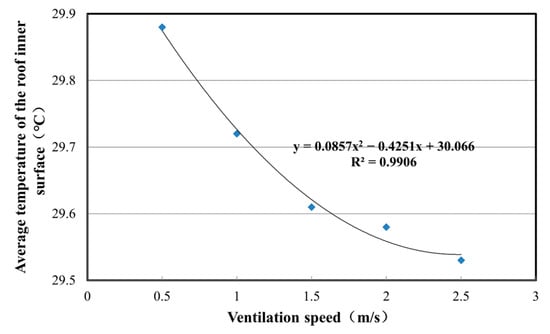

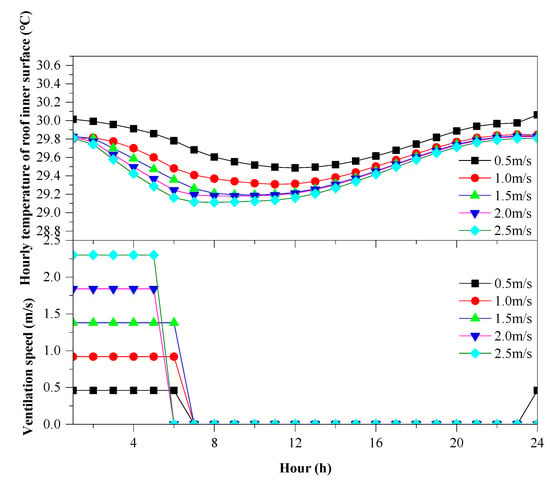

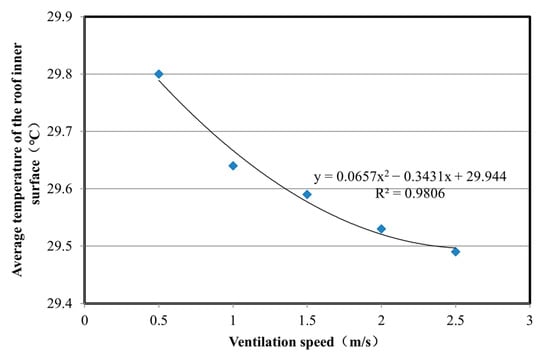

With the thickness of PCM at 25 mm and the melting temperature at 33~35 °C, the hourly temperatures of the roof’s inner surface and cavity ventilation times of the VRSPM at different ventilation speeds are shown in Figure 16. The thermal performance evaluation indexes of the roof are shown in Table 8. With the ventilation speed increasing, the peak temperature, minimum temperature, average temperature and temperature amplitude of the roof’s inner surface all decrease, whereas the average latent heat utilization rate of PCM is growing. The fitting curve between the average temperature of the roof’s inner surface and ventilation speed is shown in Figure 17. According to the fitting formula, when the ventilation speed is 2.5 m/s, the decreasing speed of the roof’s inner surface average temperature is 0, and the roof’s inner surface temperature is the lowest. Therefore, the optimum ventilation speed is 2.5 m/s.

Figure 16.

Hourly inner surface temperature and ventilation time of the VRSPM at different ventilation speeds.

Table 8.

Thermal performance of the VRSPM at different ventilation speeds.

Figure 17.

The average temperature of the inner surface with different ventilation speeds for VRSPM.

- (2)

- The VRSPO

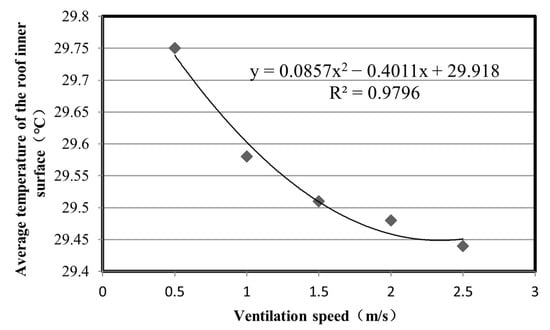

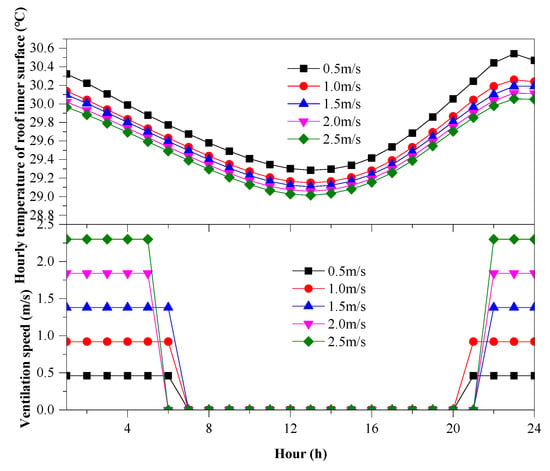

With the thickness of PCM as 35 mm and melting temperature as 35~37 °C, the hourly temperatures of the roof’s inner surface and cavity ventilation times of VRSPO at different ventilation speeds are shown in Figure 18. The thermal performance of the roof is shown in Table 9. When the ventilation speed increases from 0.5 m/s to 2.5 m/s, the average temperature of the inner surface decreases by 0.31 °C, and the ventilation time decreases from 6 h to 4 h based on the automatic ventilation control method, whereas the latent heat utilization rate of PCM increases gradually because the minimum liquid rate is reduced at night. The fitting curve of the average temperature of the inner surface and ventilation speed is shown in Figure 19. With the increase in ventilation speed, the decrease in the average temperature of the interior surface decreases gradually. According to the fitting formula, when the ventilation speed is 2.5 m/s, the decreasing speed of the roof’s inner surface average temperature is 0, and the average temperature is the lowest. Therefore, the optimum ventilation speed is additionally 2.5 m/s.

Figure 18.

Hourly inner surface temperatures and ventilation time of VRSPO at different ventilation speeds.

Table 9.

Thermal performance of the roof at different ventilation speeds.

Figure 19.

Average temperatures of the inner surface with different ventilation speeds for VRSPO.

- (3)

- The VRSPI

With the thickness of PCM as 15 mm and melting temperature as 30~32 °C, the hourly temperatures of the roof’s inner surface and cavity ventilation times of the VRSPI at different ventilation speeds are shown in Figure 20. The thermal performance of the roof is shown in Table 10. The fitting curve of the average temperature of the roof’s inner surface and ventilation speed is shown in Figure 21. It can be concluded that the results are similar to those of the VRSPM and VRSPO. According to the fitting formula, when the ventilation speed is 2.6 m/s, the decrement in the roof’s inner surface average temperature is 0; therefore, it is the optimum condition of the VRSPI and the hourly temperature of the inner surface of the roof is lowest (°C).

Figure 20.

Hourly inner surface temperatures and ventilation times of the VRSPI.

Table 10.

Thermal performance of VRSPI at different ventilation speeds.

Figure 21.

Curve of average temperatures of the roof’s inner surface with ventilation speeds of VRSPI.

3.1.3. Cavity Size

The cavity size is an important parameter for the VRSP. It can influence the ventilation volume and the heat conductivity coefficient of the slab. An amount of 40 mm is a typical cavity radius, which is stipulated in the national standard (GB/T 14040-2007) [48] and is widely used in practice. This section will study the optimal cavity size that can improve the thermal performance of the roof and meet the demands of the structure.

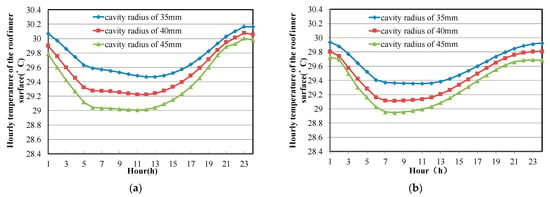

Based on the simulation results, the thermal performances of the VRSPM and VRSPO with cavity radii of 35 mm, 40 mm and 45 mm were studied. When the cavity radius is 40 mm, the optimum ventilation speed is 2.5 m/s. In the case of the same ventilation air volume, the ventilation speeds are 3.625 m/s and 1.975 m/s when the cavity radii are 35 mm and 45 mm, respectively.

Portraying the optimum design (for VRSPM, the melting temperature was 33~35 °C and the PCM layer thickness was 25 mm; for VRSPO, the melting temperature was 35~37 °C and the PCM layer thickness was 35 mm), the hourly inner surface temperature of the roof with different cavity radii at the same ventilation air volume is shown in Figure 22. When the air volume is constant, as the radius of the cavity increases, the ventilation speed in the cavity decreases, and the hourly inner surface temperature decreases. As the variation trend is the same, therefore the case for VRSPI is not studied. For the middle layer and the outer layer of phase change roofing, both were studied, and the cavity size of 40 cm was selected considering the strength of the roof panel. Considering the consistent trend of influence, that is, as the size of the cavity increases, the better the insulation performance of the roof panel, it is necessary to meet the requirements of strength; therefore, the 40 cm specified in the specification of the cavity panel was selected.

Figure 22.

Inner surface temperature of roof with different cavity radii at the same ventilation air volume: (a) inner surface temperature of VRSPM and (b) temperature of VRSPM.

According to the “Central and South China Engineering Construction Standard Design Atlas”, when the precast concrete hollow floor slab thickness is 120 mm, to meet the stress and strength requirements of the slab structure, the suitable cavity radius is 40 mm. The latent heat utilization of each PCM layer is shown in Table 11. As shown in Table 11, when the cavity radius is 40 mm, the average latent heat utilization rate is the highest for both VRSPM and VRSPO, reaching 89.72% and 97.51%, respectively. Therefore, considering the structural requirements and the thermal performance, under the outdoor climatic conditions of a typical summer day in Wuhan, the optimum cavity radius is 40 mm regardless of the position of the PCM.

Table 11.

Latent heat utilization rate of each PCM layer of VRSPM and VRSPO with different cavity sizes.

3.2. Comprehensive Comparative Analysis

According to the above simulation results, the optimum design parameters were obtained. For the VRSPM, the PCM thickness is 25 mm, the melting temperature is 33~35 °C and the ventilation speed is 2.5 m/s. For the VRSPO, the PCM thickness is 35 mm, the melting temperature is 35~37 °C and the ventilation speed is 2.5 m/s. For the VRSPI, the PCM thickness is 15 mm, the melting temperature is 29~31 °C and the ventilation speed is 2.6 m/s; in addition, the optimum cavity radii of the roofs are all 40 mm.

In order to analyze the thermal performances and energy-saving effects of the three kinds of VRSPs comparatively, the optimum structures of these three roofs were simulated and analyzed under several different weather conditions and compared with a non-phase change ventilated roof. The non-phase change ventilated roof is the structure that replaced the PCM layer of VRSPM or VRSPo with a concrete layer, and the cavity was not ventilated.

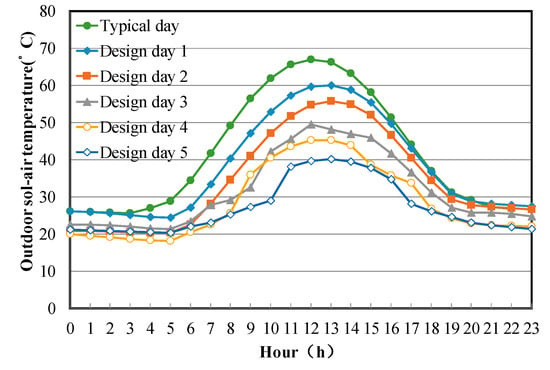

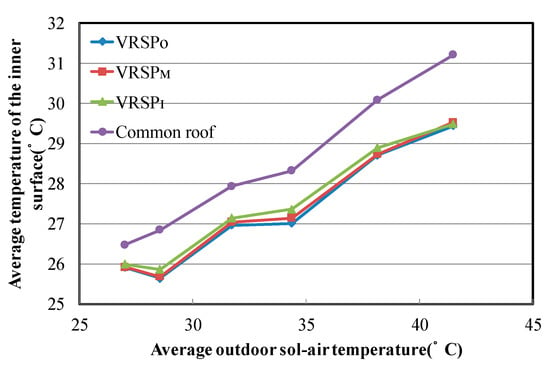

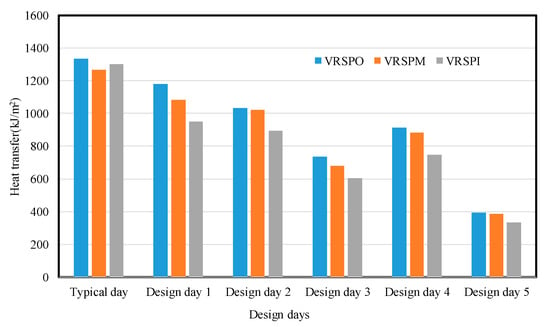

The outdoor sol-air temperature on a typical summer day (design day for an air-conditioning system) in Wuhan is 66.9 °C; therefore, 5 different days were selected in the range of 40 °C to 65 °C with a gradient of 5 °C. The meteorological parameters for each day are shown in Table 12, and the hourly outdoor sol-air temperatures for five days are shown in Figure 23. The comparison results of three VRSPs and a common roof are shown in Figure 24 and Figure 25, and the decrease in heat transfer is shown in Figure 26.

Table 12.

Meteorological parameters of different design days.

Figure 23.

Hourly outdoor sol-air temperatures of design days.

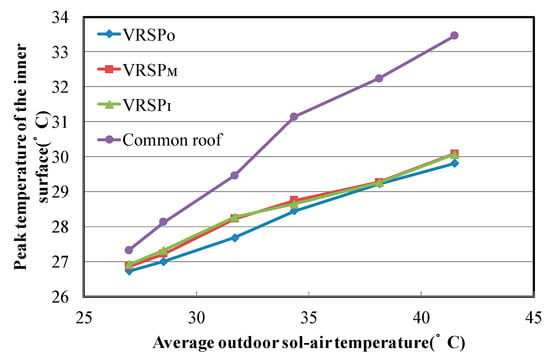

Figure 24.

The peak temperature of the inner surface.

Figure 25.

The average temperature of the inner surface.

Figure 26.

The heat transfer reduction of the VRSP compared to the non-phase change ventilated roof during the day.

As shown in Figure 24 and Figure 25, compared with the common roof, the VRSPO performed best in decreasing peak temperature, the average temperature of the roof’s inner surface and heat transfer during the several design days. However, the PCM layer thicknesses of the three VRSPs were different, which might lead to differences in thermal performance. In order to study the thermal performance of the three optimal VRSPs when the thicknesses of the PCM layers were the same, the thicknesses of the PCM layers of the optimal structures of the VRSPI and the VRSPM were set for 35 mm as well, with the other parameters unchanged. The simulation results under the outdoor weather conditions of Design Day 1 were as follows: the average temperature of the inner surface of the optimal structure of the VRSPO was 28.71 °C, and for the VRSPM and VRSPI, it was 28.65 °C and 28.59 °C, respectively. Therefore, when the thickness of the PCM layer was the same, the optimal structure of the VRSPI had a slightly better heat insulation effect; however, the advantage was not distinct, compared with the VRSPO, since the difference was only 0.12 °C.

Another important consideration in selecting the position of the PCM is the length of the PCM’s working time. The comparison results of the working time for three VRSPs and the common roof are shown in Table 13. It is found that the PCM can not melt until the outdoor sol-air temperature exceeds a certain value, which is called the critical outdoor sol-air temperature. For the optimum structure of VRSPO, the critical outdoor sol-air temperature is 43 °C. There are 75 days when the outdoor sol-air temperatures are higher than the critical value, and the number of hours is 372 throughout the whole year. For VRSPM and VRSPI, the critical outdoor sol-air temperatures are 48 °C and 49 °C, respectively, and the PCM can work for 60 and 58 days, specifically, 252 h and 230 h. It can be concluded that as the position of the PCM layer approaches the inner surface, the critical outdoor sol-air temperature is increasing, and the number of hours above the critical outdoor sol-air temperature is decreasing. Therefore, the PCM of VRSPO could be utilized for a longer period of time throughout the year than the other two types.

Table 13.

Analysis of energy-saving effects of three kinds of roofs.

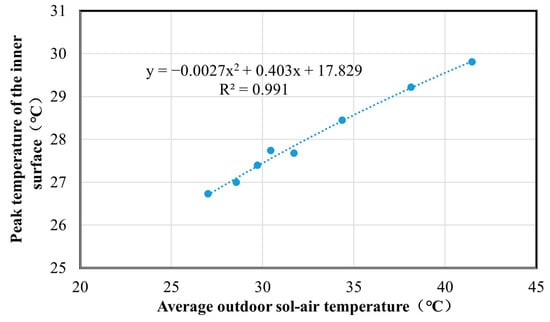

The inner surface temperature varies with the changes in outdoor temperature and solar radiation intensity. For the ventilated roof with PCM, night ventilation can not only take away the latent heat of phase change, however additionally play a certain role in cold storage. The maximum temperature of the inner surface of the roof is affected by solar radiation during the day and cold storage at night. Figure 27 shows the relationship between the maximum inner surface temperature of VRSPO and the daily average outdoor sol-air temperature. The formula for calculating the maximum inner surface temperature of VRSPO, based on the daily average outdoor sol-air temperature is as follows:

where y is the maximum inner surface temperature of VRSPO (°C) and x is the daily average outdoor sol-air temperature (°C).

y= −0.0027x2 + 0.403x + 17.829 (R2 = 0.991)

Figure 27.

The relationship between the maximum inner surface temperature of VRSPO and the daily average outdoor sol-air temperature.

With the increase in the average outdoor sol-air temperature, the maximum inner surface temperature of VRSPO is gradually increasing; however, the rate of increase is gradually decreasing. When the daily average outdoor sol-air temperature is 41.5 °C, the maximum temperature of the inner surface of the roof increases to 29.8 °C; when the daily average outdoor sol-air temperatures x are 40 °C, 35 °C and 30 °C, the maximum inner surface temperatures of VRSPO decrease to 29.6 °C, 28.6 °C and 27.5 °C, respectively.

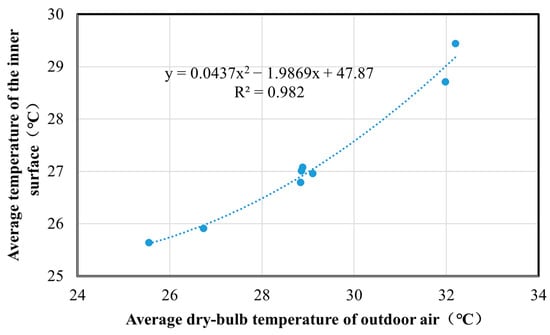

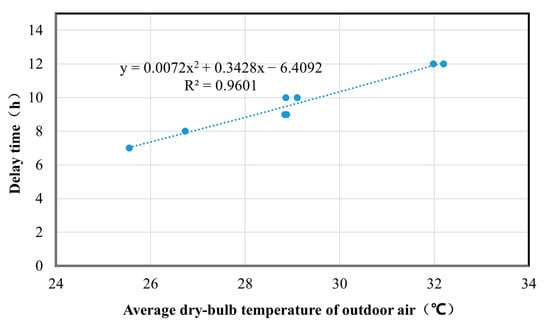

The relationships of delay time and average inner surface temperature with the outdoor average dry bulb temperature are fitted. The fitting curves are shown in Figure 28 and Figure 29. The fitting relation between average inner surface temperature and the daily average temperature of outdoor air is as follows:

where y is the average inner surface temperature of VRSPO (°C) and x is the daily average dry-bulb temperature of outdoor air (°C).

Figure 28.

Relationship between average inner surface temperature of VRSPO and daily average dry-bulb temperature of outdoor air.

Figure 29.

Relationship between delay time of VRSPO and the daily average dry-bulb temperature of outdoor air.

The fitting relation between delay time and the daily average temperature of outdoor air is given below:

where y is the delay time of VRSPO (h) and x is the daily average outdoor dry-bulb temperature of outdoor air (°C).

As the average outdoor air temperature increases, the average inner surface temperature and delay time of the roof rise. When the daily average outdoor dry-bulb temperature of the outdoor air is 32.20 °C, the average inner surface temperature and delay time of the roof rise to 29.44 °C and 12 h, respectively.

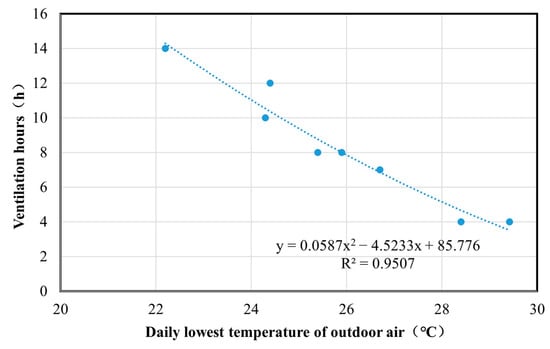

In this paper, according to the automatic control method by monitoring the ambient temperature and bottom temperature of the cavity surface at night, the daily start and ending times for ventilation are automatically determined. Ventilation time is affected by the outdoor air temperature during the ventilation period. The daily lowest temperature of outdoor air indicates the ventilation cooling capacity, therefore, if the relationship between ventilation time and the daily lowest temperature of outdoor air is fitted (Figure 30), it can be written as follows:

where, y is ventilation time (h), x is the daily average dry-bulb temperature of outdoor air (°C).

Figure 30.

Relationship between ventilation time and the daily lowest temperature of outdoor air.

With the increase in the daily lowest temperature of outdoor air, the number of ventilation hours decreases. When the daily lowest temperature of outdoor air rises to 29.4 °C, the ventilation time is only 4 h.

4. Discussion

Recently, some studies have additionally been conducted on ventilated roofs. Li et al. [49] investigated a new type of ventilated roof consisting of multiple PCMs, using experiments and numerical simulations. The ventilated air gap is situated between the external layer and internal layer and is 200 mm thick. Their study additionally utilized Tsol-air as a boundary condition; however, it was calculated from actual measurement data rather than information data. Additionally, the study defined some parameters to evaluate the performance. The results show that the inclusion of PCM can effectively improve the energy efficiency of the ventilated roof, and controlling the ventilation time can maximize the energy-saving potential. This is consistent with the findings of this study. It can be seen that study on the combination of PCM and ventilated roofs has value in advancing energy efficiency. Navarro [50] conducted a theoretical analysis of the thermal response of a prefabricated concrete slab with PCM macro-encapsulated in small tubes and inserted into its hollows. Hot air provided by a solar air collector is used to flow through the hollows and store the heat of the PCM in winter, and cool air from the outdoors is injected inside the slab to solidify the PCM. During the day in summer, when cooling is needed, the internal ambient air from the cubicle is pumped through the slab and cooled down due to the heat exchange with the PCM, covering a part of the cooling load. The test results show that in summer, the indoor air temperature was kept to under 25 °C (±0.5 °C) all day without any conventional cooling system, instead with the active slab supply. In winter, 87% of the discharge period did not require the heat pump. It is suitable for the Mediterranean continental climate. In this study, a PCM with a melting temperature of 21–22.5 °C can be used in both summer and winter due to the climate in this area. This is because the climatic conditions of different regions allow the structure to be used in winter and summer, which is not possible with VRSP. It additionally differs from the VRSP in the form of the PCM and the melting temperature. If PCM is designed to store solar heat in the winter, an additional layer of PCM with a low melting temperature is needed for further research.

In this study, the thermal characteristics possessed by the VRSP when placing PCM in different positions in the roof are investigated. It is additionally optimized for the design, which is a guideline for the application of ventilated roofs in reality. The results of this study show that the highest utilization of the PCM can be obtained when the PCM is located in the outermost layer, and night ventilation is used. The cooling season in the city is only 100 days a year, instead of 365 days. The utilization time of PCM increases from 58 to 75 days; in other words, the utilization time of PCM increases from 58% to 75%. This is very valuable. If other optimization evaluation indexes are expected, the optimal location of the PCM should be reconsidered, for example, with the lowest inner roof surface temperature and the least amount of heat passing through the roof. The optimal location of the PCM can additionally be considered according to actual engineering needs, such as safety and maintenance factors. In the actual use of VRSP, it should be selected according to the actual location, climate, building type and design goals. Weighting issues and optimization for other metrics regarding VRSP will be studied in the future.

The Chinese government is printing and distributing “peak carbon dioxide emissions” on 26 October 2021 and clearly requires the promotion of low-carbon urban and rural construction. VRSP is a new type of energy-efficient roof that has a very broad application prospect in hot regions during summer. The roof can be constructed with precast concrete panels and buried ducts, or it can be retrofitted with natural ventilation and PCMs from existing overhead roofs. It has been cooperating with two enterprises to demonstrate the application of this structure in office buildings and residential buildings in the hot summer and cold winter zones of China and then will carry out the promotion application.

This structure additionally has some limitations. First, this structure consumes energy due to the use of fans to remove the PCM condensation heat, and PCM additionally needs an initial investment. Economic studies will be conducted in the future to determine the proper ventilation speed. Second, the noise of the fan should be considered. The determination of wind speed needs to consider noise in addition to the energy consumption of the fan. Third, the structure can sharply reduce the inner surface temperature and cooling requirements in summer. However, in winter, because of the low temperatures, the PCM can not change phase; it acts as a common material, which can play a certain role in thermal insulation to the indoor heat loss in winter. The heating load can be slightly reduced. For its small thickness and low thermal resistance, therefore, the impact of PCM on winter roof performance is very small. Therefore, it is suitable for areas during hot and long summers. Fourth, the material and form of the PCM were not studied. Additionally, no other shapes of the hollow plate were considered. Optimizing structural styles can additionally increase energy-saving potential.

Considering the application and function, a roof can be constructed with precast concrete panels and buried ducts, or it can be retrofitted with natural ventilation and PCMs from existing overhead roofs. The research team has been cooperating with two enterprises to demonstrate the application of this structure and then will carry out the promotion application. This structure has a very broad application prospect in hot regions during summer. The research team will now work with relevant companies to realize the application of phase change ventilated roofs in practice. The research on the optimization and energy conservation properties of phase change materials in energy storage will be further carried out, for example, in combination with solar energy and on the impact of phase change heat exchangers on the energy-saving characteristics of air-conditioning systems.

5. Conclusions

The thermal performances of ventilation roofs with different positionings of shape-stabilized PCM were simulated by a CFD program. In this study, shape-stabilized paraffin PCM with the latent heat of 161 kJ/kg is used. The optimum designs for VRSPO, VRSPM and VRSPI including the selection of PCM and the determination of ventilation strategies were studied in Wuhan. The position of the PCM in the roof was determined by comparing it with the inner surface temperature of the roof. The following conclusions are drawn:

- (1)

- The optimum designs of the three structures are obtained. The optimum cavity radii are all 40 mm. For the VRSPM, the PCM thickness is 25 mm, melting temperature is 33~35 °C and ventilation speed is 2.5 m/s; in this case, the average temperature of the inner surface of the roof is the lowest, at 29.53 °C, and the latent heat utilization rate was the highest, at 89.72%. For the VRSPO, the PCM thickness is 35 mm, the melting temperature is 35~37 °C, the ventilation speed is 2.5 m/s and the ventilation time is 5 h. The average temperature of the inner surface of the roof is the lowest, at 29.44 °C, and the latent heat utilization rate of PCM is the highest, at 97.51%. For the VRSPI, the PCM thickness is 15 mm, melting temperature is 29~31 °C and ventilation speed is 2.6 m/s; in this condition, the inner surface average temperature is the lowest, at 24.49 °C; the latent heat utilization rate of PCM was the highest, at 60.16%.

- (2)

- The best position of the PCM in the roof is determined. A phase transition process occurs in the PCM of VRSPO in 75 days (specifically, 372 h), whereas for VRSPM and VRSPI, there are just 60 days (252 h) and 58 days (230 h), respectively. Therefore, considering the thermal insulation effect of the whole summer, the VRSPO is the optimal structure among the studied structures. The relationship between the maximum inner surface temperature of VRSPO and the daily average outdoor sol-air temperature, as well as the relationships of delay time and average inner surface temperature with the daily outdoor average dry-bulb temperature are investigated.

The ventilation roof with shaped-stabilized PCMs proposed can remove the solidification heat of PCMs by night ventilation in the hollow core of the roof, and the PCMs store the cooling energy of the night air, which could be used to decrease the indoor temperature during the daytime. This roof provides a good solution to the problem of the solidification heat of PCM releasing into the room, and it is of great significance to building energy conservation.

Author Contributions

Project administration, J.Y.; writing and data curation, H.Y.; software and validation, J.T.; formal analysis and investigation, J.Z.; supervision, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

National Natural Science Foundation of China, 51778255: study on the mechanism of active thermal insulation and cool storage of the outer-layer shape-stabilized phase change and pipe-embedded ventilated roof. And the Fundamental Research Funds for the Central Universities of China [grant number 2018KFYYXJJ131].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in this study.

Data Availability Statement

Data is contained within the article. The data presented in this study are available in the figures and tables.

Acknowledgments

The support from the state and government for this study is greatly appreciated. The efforts of the research team of students and faculty members are also greatly appreciated, which contributed to the integrity and advancement of this study.

Conflicts of Interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work. We do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

References

- International Energy Agency, Transition to Sustainable Buildings: Strategies and Opportunities to 2050. 2013. Available online: https://www.oecd.org/publications/transition-to-sustainable-buildings-9789264202955-en.htm (accessed on 10 June 2019).

- Souayfane, F.; Fardoun, F.; Biwole, P.-H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Kumar, P.; Rathore, S.; Shukla, S.K. Potential of macroencapsulated PCM for thermal energy storage in buildings: A comprehensive review. Constr. Build. Mater. 2019, 225, 723–744. [Google Scholar] [CrossRef]

- Tang, X.M. Study the Impact of Cool Roofs on Energy Consumption and Carbon Reduction of Office Buildings in Chongqing. Master’s Thesis, Chongqing University, Chongqing, China, 2013. [Google Scholar]

- Luo, Y.; Cui, D.; Hu, L.; Ochs, F.; Tosatto, A.; Xu, G.; Tian, Z.; Dahash, A.; Yu, J.; Yuan, G.; et al. Semi-analytical modeling of large-scale water tank for seasonal thermal storage applications. Energy Build. 2023, 278, 112620. [Google Scholar] [CrossRef]

- Luo, Y.; Cheng, N.; Zhang, S.; Tian, Z.; Xu, G.; Yang, X.; Fan, J. Comprehensive energy, economic, environmental assessment of a building integrated photovoltaic-thermoelectric system with battery storage for net zero energy building. In Building Simulation; Tsinghua University Press: Beijing, China, 2022; Volume 15, pp. 1923–1941. [Google Scholar]

- VRao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-mortar based construction materials for energy efficient buildings: A review on research trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Ben Khedher, N. Numerical Study of the Thermal Behavior of a Composite Phase Change Material (PCM) Room. Eng. Technol. Appl. Sci. Res. 2018, 8, 2663–2667. [Google Scholar] [CrossRef]

- Lei, J.; Yang, J.; Yang, E.-H. Energy performance of building envelopes integrated with phase change materials for cooling load reduction in tropical Singapore. Appl. Energy 2016, 162, 207–217. [Google Scholar] [CrossRef]

- He, W.; Yu, C.; Yang, J.; Yu, B.; Hu, Z.; Shen, D.; Liu, X.; Qin, M.; Chen, H. Experimental study on the performance of a novel RC-PCM-wall. Energy Build. 2019, 199, 297–310. [Google Scholar] [CrossRef]

- Lu, S.; Chen, Y.; Liu, S.; Kong, X. Experimental research on a novel energy efficiency roof coupled with PCM and cool materials. Energy Build. 2016, 127, 159–169. [Google Scholar] [CrossRef]

- Lu, S.; Xu, B.; Tang, X. Experimental study on double pipe PCM floor heating system under different operation strategies. Renew. Energy 2019, 145, 1280–1291. [Google Scholar] [CrossRef]

- Ben Khedher, N.; Bantan, R.A.; Kolsi, L.; Omri, M. Performance investigation of a vertically configured LHTES via the combination of nano-enhanced PCM and fins: Experimental and numerical approaches. Int. Commun. Heat Mass Transf. 2022, 137, 106246. [Google Scholar] [CrossRef]

- Yang, Y.K.; Kim, M.Y.; Chung, M.H.; Park, J.C. PCM cool roof systems for mitigating urban heat island—An experimental and numerical analysis. Energy Build. 2019, 205, 109537. [Google Scholar] [CrossRef]

- Yu, J.; Yang, Q.; Ye, H.; Luo, Y.; Huang, J.; Xu, X.; Gang, W.; Wang, J. Thermal performance evaluation and optimal design of building roof with outer-layer shape-stabilized PCM. Renew. Energy 2019, 145, 2538–2549. [Google Scholar] [CrossRef]

- Elarga, H.; Fantucci, S.; Serra, V.; Zecchin, R.; Benini, E. Experimental and numerical analyses on thermal performance of different typologies of PCMs integrated in the roof space. Energy Build. 2017, 150, 546–557. [Google Scholar] [CrossRef]

- Arivazhagan, R.; Prakash, S.A.; Kumaran, P.; Sankar, S.; Loganathan, G.B.; Arivarasan, A. Performance analysis of concrete block integrated with PCM for thermal management. Mater. Today: Proc. 2020, 22, 370–374. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Liu, C.; Wu, G. Numerical analysis on thermal performance of roof contained PCM of a single residential building. Energy Convers. Manag. 2015, 100, 147–156. [Google Scholar] [CrossRef]

- Xamán, J.; Rodriguez-Ake, A.; Zavala-Guillén, I.; Hernández-Pérez, I.; Arce, J.; Sauceda, D. Thermal performance analysis of a roof with a PCM-layer under Mexican weather conditions. Renew. Energy 2020, 149, 773–785. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Numerical model for evaluating thermal performance of residential building roof integrated with inclined phase change material (PCM) layer. J. Build. Eng. 2020, 28, 101018. [Google Scholar] [CrossRef]

- Meng, E.; Wang, J.; Yu, H.; Cai, R.; Chen, Y.; Zhou, B. Experimental study of the thermal protection performance of the high reflectivity-phase change material (PCM) roof in summer. Build. Environ. 2019, 164, 106381. [Google Scholar] [CrossRef]

- de Gracia, A. Dynamic building envelope with PCM for cooling purposes—Proof of concept. Appl. Energy 2019, 235, 1245–1253. [Google Scholar] [CrossRef]

- Solgi, E.; Hamedani, Z.; Fernando, R.; Skates, H.; Orji, N.E. A literature review of night ventilation strategies in buildings. Energy Build. 2018, 173, 337–352. [Google Scholar] [CrossRef]

- Yu, J.; Ye, H.; Xu, X.; Huang, J.; Liu, Y.; Wang, J. Experimental study on the thermal performance of a hollow block ventilation wall. Renew. Energy 2018, 122, 619–631. [Google Scholar] [CrossRef]

- Ran, J.; Tang, M. Passive cooling of the green roofs combined with night-time ventilation and walls insulation in hot and humid regions. Sustain. Cities Soc. 2018, 38, 466–475. [Google Scholar] [CrossRef]

- Ji, W.; Wang, H.; Du, T.; Zhang, Z. Parametric study on a wall-mounted attached ventilation system for night cooling with different supply air conditions. Renew. Energy 2019, 143, 1865–1876. [Google Scholar] [CrossRef]

- Ji, W.; Luo, Q.; Zhang, Z.; Wang, H.; Du, T.; Heiselberg, P.K. Investigation on thermal performance of the wall-mounted attached ventilation for night cooling under hot summer conditions. Build. Environ. 2018, 146, 268–279. [Google Scholar] [CrossRef]

- Athienitis, A.K.; Chen, T.Y. Experimental and theoretical investigation of floor heating with thermal storage. ASHRAE Trans 1993, 99, 1049–1057. [Google Scholar]

- Ciampi, M.; Leccese, F.; Tuoni, G. Ventilated facades energy performance in summer cooling of buildings. Sol. Energy 2003, 75, 491–502. [Google Scholar] [CrossRef]

- Park, B.; Krarti, M. Optimal control strategies for hollow core ventilated slab systems. J. Build. Eng. 2019, 24, 100762. [Google Scholar] [CrossRef]

- Yanbing, K.; Yi, J.; Yinping, Z. Modeling and experimental study on an innovative passive cooling system—NVP system. Energy Build. 2003, 35, 417–425. [Google Scholar] [CrossRef]

- Gunay, H.B.; Isgor, O.B.; Razaqur, A.G.; Foo, S. Improving the Energy Efficiency of Buildings with Hollow Core Slabs: A Numerical Investigation. In Proceedings of the 2nd International Engineering Mechanics and Materials Specialty Conference, Ottawa, ON, Canada, 14–17 June 2011. [Google Scholar]

- Faheem, A.; Ranzi, G.; Fiorito, F.; Lei, C. A numerical study on the thermal performance of night ventilated hollow core slabs cast with micro-encapsulated PCM concrete. Energy Build. 2016, 127, 892–906. [Google Scholar] [CrossRef]

- Hu, Y.; Heiselberg, P.K.; Guo, R. Ventilation cooling/heating performance of a PCM enhanced ventilated window—An experimental study. Energy Build. 2020, 214, 109903. [Google Scholar] [CrossRef]

- Dabiri, S.; Mehrpooya, M.; Nezhad, E.G. Latent and sensible heat analysis of PCM incorporated in a brick for cold and hot climatic conditions, utilizing computational fluid dynamics. Energy 2018, 159, 160–171. [Google Scholar] [CrossRef]

- Alqallaf, H.J.; Alawadhi, E.M. Concrete roof with cylindrical holes containing PCM to reduce the heat gain. Energy Build. 2013, 61, 73–80. [Google Scholar] [CrossRef]

- Muhammad, M.D.; Badr, O.; Yeung, H. Validation of a CFD Melting and Solidification Model for Phase Change in Vertical Cylinders. Numer. Heat Transfer, Part A: Appl. 2015, 68, 501–511. [Google Scholar] [CrossRef]

- Buratti, C.; Palladino, D.; Moretti, E.; Di Palma, R. Development and optimization of a new ventilated brick wall: CFD analysis and experimental validation. Energy Build. 2018, 168, 284–297. [Google Scholar] [CrossRef]

- Diarce, G.; Campos-Celador, Á.; Martin, K.; Urresti, A.; García-Romero, A.; Sala, J. A comparative study of the CFD modeling of a ventilated active façade including phase change materials. Appl. Energy 2014, 126, 307–317. [Google Scholar] [CrossRef]

- Gagliano, A.; Nocera, F.; Aneli, S. Thermodynamic analysis of ventilated façades under different wind conditions in summer period. Energy Build. 2016, 122, 131–139. [Google Scholar] [CrossRef]

- Li, H.; Tong, S. Natural convective heat transfer in the inclined rectangular cavities with low width-to-height ratios. Int. J. Heat Mass Transf. 2016, 93, 398–407. [Google Scholar] [CrossRef]

- Gagliano, A.; Patania, F.; Nocera, F.; Ferlito, A.; Galesi, A. Thermal performance of ventilated roofs during summer period. Energy Build. 2012, 49, 611–618. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, K.; Yang, R.; Di, H.; Jiang, Y. Preparation, thermal performance and application of shape-stabilized PCM in energy efficient buildings. Energy Build. 2006, 38, 1262–1269. [Google Scholar] [CrossRef]

- Zhang, Z.; Fang, X. Study on paraffin/expanded graphite composite phase change thermal energy storage material. Energy Convers. Manag. 2006, 47, 303–310. [Google Scholar] [CrossRef]

- Zhang, R. Phase Change Materials and Phase Change Energy Storage Technology; Science Press: Beijing, China, 2009. [Google Scholar]

- GB 50736-2012; Design Code for Heating, Ventilation and Air Conditioning in Civil Buildings. China Academy of Building Science: Beijing, China, 2012.

- Liu, S. Research on Energy-Saving Roofs with Integrated Phase Change Materials and Reflective Thermal Insulation Coatings. Master’s Thesis, Tianjin University, Tianjin, China, 2014. [Google Scholar]

- GB/T 14040-2007; Prestressed Concrete Hollow-Core Slabs. Standards Press of China: Beijing, China, 2008.

- Li, H.; Li, J.; Xi, C.; Chen, W.; Kong, X. Experimental and numerical study on the thermal performance of ventilated roof composed with multiple phase change material (VR-MPCM). Energy Convers. Manag. 2020, 213, 112836. [Google Scholar] [CrossRef]

- Navarro, L.; Gracia, A.; Castell, A.; Álvarez, S.; Cabeza, L.F. PCM incorporation in a concrete core slab as a thermal storage and supply system: Proof of concept. Energy Build. 2015, 103, 70–82. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).