Abstract

By enhancing the bitumen properties with the additives produced from waste, not only can the performance of flexible pavements be improved, but it can also contribute to the environment. This research aims to produce a novel pyrolytic char from different wastes and to investigate the usability of this char as an additive in bitumen. In this study, first, the pyrolytic char was produced from the co-pyrolysis of three different wastes, including waste paper cups, polypropylene (PP), and polyethylene terephthalate (PET) waste. Properties of the char were determined by using CHN (carbon, hydrogen, and nitrogen) and Fourier transform infrared spectroscopy (FTIR) analyses. The high-temperature rheological properties of binders were evaluated by using DSR (dynamic shear rheometer), RV (rotational viscometer), softening point, and penetration tests. Additionally, specific gravity, storage stability, high-temperature performance grades (PGs), and temperature susceptibilities of binders were determined. Test results showed that this pyrolytic char enhanced the high-temperature properties of neat bitumen by increasing softening point, viscosity, rutting resistance, and high-temperature PG of pure bitumen. Additionally, it can be said that the bituminous binder modified with this pyrolytic char had good storage stability when it was used at an 8% ratio in neat bitumen.

1. Introduction

Bitumen, which is a petroleum product, is widely used as a binder for flexible pavements [1]. Bitumen is a viscoelastic material, and it behaves as a viscous liquid at high temperatures and behaves as an elastic solid at low temperatures [1,2,3,4]. Using modified bituminous binders could decrease flexible pavement deformations. For the purpose of long-lasting flexible pavement roads, bitumen has been modified with different kinds of additives such as thermoplastic elastomers, different polymers, nanomaterials, as well as chemical modifiers, fillers, waste engine oils, pyrolytic bio-oils, and other vegetable oils from different origins [1,3,5,6,7,8]. Different kinds of oil additives and other bio-oils, which are liquid pyrolysis products obtained from different biomasses, can soften the consistency of bitumen, and these additives can enhance the low-temperature properties of bitumen [6,7,8]. On the other hand, polymers, some nanomaterials, and polyphosphoric acid can enhance the bitumen’s high-temperature properties by increasing the viscosity and rutting resistance of neat bitumen [3,5,6]. However, phase separation problems may occur in modified bitumen with some polymers [3,5].

In recent years, modification of bitumen with different biochars has been investigated [9,10,11,12,13,14]. It was determined that biochar had better effects than commercial graphite on the high-temperature performance of bitumen [9]. Using pyrolysis chars as additives in bitumen can not only enhance the high-temperature properties of flexible pavements, but also dispose of waste in a sustainable way [9,11,14,15]. The amount of waste in the world is rising day by day with the increasing population growth. Many researchers have studied recycling waste in different ways to reduce the environmental damage it causes. One of the processes used for recycling waste is the pyrolysis method [15,16,17]. Pyrolysis is a thermochemical conversion method that is carried out in an oxygen-free environment at high temperatures [17,18,19,20,21]. Liquid, solid, and gas products can be obtained from raw materials by using the pyrolysis method [17,18,19,20,21]. Additionally, all of these pyrolysis products can be potentially used for different purposes in various areas [15,16,22]. Biochar, which is the solid pyrolysis product of biomass, is a carbon-rich material and has a large surface area with high porosity [11,13,19,23]. Therefore, biochar can form a stiff structure with bitumen and can enhance the physical properties and high-temperature performance of the bitumen due to its high porosity and high absorption properties [11,13].

As a result of biomass pyrolysis, valuable products can be obtained [18,19,20,22]. Many studies have shown that more valuable pyrolysis products (char, pyrolytic oil, and gas) can be obtained from co-pyrolysis of various kinds of plastics with biomasses than the pyrolysis of biomass alone [17,19,22,24]. Two or more different raw materials could be co-pyrolyzed in order to obtain higher-quality pyrolysis products [16,19,22,25,26,27,28]. By using the co-pyrolysis method, a synergistic effect may occur between various kinds of raw materials as a result of the reactions during the thermal degradation process [17,22,24,25,26].

Generally, co-pyrolysis of various biomasses with different kinds of plastic wastes have been studied in order to enhance the quality and to increase the amount of liquid product [17,19,22,27,29]. In addition, the synergistic interaction between various plastics and biomasses can affect not only the quality of liquid products but also the qualities of solid and gas products [19,22,24,27,28]. The studies have shown that the properties of the products obtained from the co-pyrolysis process may be greatly based on the properties of raw materials and the blending ratio of different kinds of plastic waste and biomasses, besides the temperature, which is one of the crucial parameters of co-pyrolysis conditions [19,22,24,25,28].

In the literature, different biochars obtained from various biomasses have been used as additives in pure bitumen [9,10,11,12,13]. In a study [9], pure bitumen was modified with biochar added into the neat bitumen at different ratios, such as at 2%, 4%, and 8%. The results demonstrated that the viscosity value of neat bitumen increased by using this biochar as an additive and enhanced the resistance of pure bitumen against rutting deformations. In another study [10], the biochar from pyrolysis of mesua ferrea seed cover was used in pure bitumen at different rates ranging from 5% to 20% by weight of pure bitumen. According to the experimental results, it was reported that the biochar of mesua ferrea seed cover enhanced the pure bitumen rutting resistance and viscosity value. The research [11] on the modification of bitumen with the biochar from straw stalks demonstrated that the biochar enhanced the bitumen rutting factor, viscosity, softening point, and temperature sensitivity. In a study [12], biochars obtained from walnut shells and apricot shells were studied for improving the pure bitumen properties by using them as additives at various ratios, such as at 5%, 10%, and 15% by weight of pure bitumen. It was found that both the walnut shell biochar and the apricot shell biochar increased the rutting resistance and viscosity value of pure bitumen for all additive contents. Additionally, it was also detected that these biochars raised the high-temperature PG of pure bitumen. However, the biochars obtained from walnut shells and apricot shells increased the temperature susceptibility of pure bitumen for different ratios and had a negative effect on bitumen for given ratios [12]. In another study [13], oat hull biochar was used as a modifier in bitumen at different contents of 2.5%, 5%, and 7.5% by weight of bitumen. It was determined that oat hull biochar increased the softening point and viscosity values while decreasing the penetration value of pure bitumen.

In the literature, different biochars from various biomasses have been used as additives in pure bitumen [9,10,11,12,13,14]. However, no study was found in which bitumen was modified with the char fabricated from co-pyrolysis of three different wastes including paper cups, PET, and PP waste. Additionally, no study was also found in which the storage stabilities of bituminous binders modified with the char fabricated from co-pyrolysis of biomass and plastics were investigated.

This research aims to fabricate a novel pyrolytic char from different wastes, including waste paper cups, PET, and PP waste, and to investigate the usability of this char as an additive in bitumen. In order to achieve this goal, firstly, the char was produced from co-pyrolysis of three different raw materials, including waste paper cups, PET, and PP waste. This pyrolytic char was fabricated from co-pyrolysis of the combination of the waste materials in different ratios, which has not been found in any study before. Thus, this new co-pyrolysis char was used as an additive in bitumen for the first time. Additionally, no study was also found in which the storage stabilities of bituminous binders modified with the char obtained from co-pyrolysis of biomass and plastics were investigated. Therefore, this study can contribute to developing pyrolytic products used in bitumen as additives. The pyrolytic char was characterized by using FTIR and CHN analyses. In this research, the high-temperature rheological properties and the storage stability of binders were detected by using DSR [30], RV [31], and storage stability [32] tests. Additionally, softening point [33], penetration [34], and specific gravity [35] tests were applied to all binders. Penetration index [1] values were also detected for evaluating the temperature susceptibilities of binders. Additionally, high-temperature PGs of all bituminous binders were detected as a result of the DSR test.

2. Materials and Methods

2.1. Materials

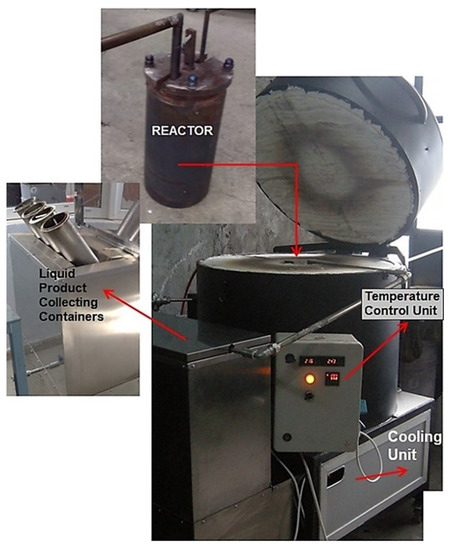

Pure bitumen was used, and the additive was produced by using co-pyrolysis method in this study. Bitumen used in this study was supplied from Kırıkkale Refinery through Konya Municipality. Some properties of pure bitumen are seen in Table 1. The additive used in this study is the pyrolytic char produced from co-pyrolysis of a novel combination of waste materials by using pyrolysis system shown in Figure 1. The waste materials used in this study (Figure 2) were supplied from household waste, including paper cups, PP plastic cups, and PET bottle waste.

Table 1.

Some properties of neat bitumen.

Figure 1.

Pyrolysis system.

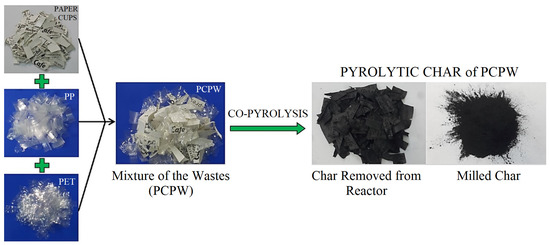

Figure 2.

Paper cups, PP waste, PET waste, the mixture of the wastes (PCPW), and char.

The synergistic effect between various plastics and biomasses can be improved by using specific intermediate plastic ratios in the blend [16,24,25,26,27]. For instance, considerable interaction and synergistic effect between biomass and PET (polyethylene terephthalate) could be obtained when the amount of biomass was used higher than the PET content in the mixture, such as at a 3:1 ratio [16,25,26].

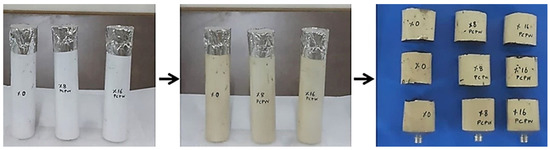

In this study, the raw material comprises a mixture of paper cups, PP plastic waste, and PET plastic waste. The mixture ratio of the wastes was determined as 3:3:1 (paper cup: PP: PET). This ratio was selected based on the studies on co-pyrolysis of different raw materials in the literature [16,24,25,26,27] in order to obtain more effective product for bitumen modification. The mixture of wastes, including paper cups, PP, and PET plastic waste, was called ‘PCPW’. The wastes in this study that were cut into small pieces are seen in Figure 2.

Paper cups used as one of the raw materials in this study consist of approximately 95% of paper and 5% of polyethylene (PE) [15,36]. Polypropylene (PP) waste, used as another raw material in the study, is a commonly used type of plastic, and the melting point of PP is approximately 170 °C [28,29]. The other raw material used in this study is PET plastic waste, and the melting point of PET is approximately 250–280 °C [5,28].

In this study, PCPW was subjected to the co-pyrolysis experiment, and the char was produced. Pure bitumen was modified with this pyrolytic char produced from PCPW.

2.2. Co-Pyrolysis Method

Pyrolysis is a thermochemical decomposition method that is carried out in absence of oxygen at high temperatures. Two or more different raw materials could be co-pyrolyzed [16,19,25,26,27] in order to obtain higher-quality pyrolysis products [17,19,22,24,26]. By using co-pyrolysis method, a synergistic effect may occur between various kinds of raw materials as a result of the reactions during the thermal degradation process [17,22,24,25,26].

Paper cup waste is composed of cellulosic woody pulp and PE [15,36]. Plastics contain relatively high quantities of carbon and hydrogen [21,22,26,29]. During the co-pyrolysis process, biomass degradation could be enhanced with the hydrogen from decomposition of plastic, and the cracking of plastic can also be improved by the oxygen radicals produced from biomass. Additionally, biomass structures can act as catalysts in plastic degradation [17,24,25,29].

The primary components of plant-based biomasses are hemicellulose (20–35%), cellulose (about 30–60%), and lignin (about 10–30%) [18,20,22]. Hemicellulose decomposes at about temperatures of 200–250 °C and cellulose at about temperatures of 240–350 °C. Lignin has a wide decomposition temperature range at about 280–500 °C compared with cellulose and hemicellulose [15,18]. On the other hand, melting points of PP and PET are at about 170 °C [28,29] and approximately 250–280 °C, respectively [5,28]. Many researchers have studied PP pyrolysis and PET pyrolysis at about temperature of 500 °C [15,22].

During co-pyrolysis of biomasses and plastics, various synergistic effects may occur throughout different stages of co-pyrolysis, and the whole synergistic effect is the sum of them [24,25]. These synergistic interactions consist of three stages, including the following:

- the synergistic interaction among cellulose, hemicellulose, and lignin;

- the synergistic interaction between the biomasses and plastic melt;

- the synergistic interaction among the vapors of plastic and biomass.

Decomposition of cellulose and hemicellulose are endothermic reactions [18,24] that are formed at lower temperatures, and plastic decomposition is mainly an endothermic reaction [24,37] that is formed at high temperatures. On the other hand, lignin degradation is an exothermic reaction [18,24] that occurs at high temperatures.

Plastics are degraded at high temperatures [21,24,25,37], while cellulose and hemicellulose degradation are carried out at lower temperatures [18,24,25]. During thermal decomposition of plastic and biomass with co-pyrolysis method, plastic is found as melted phase when the decomposition of hemicellulose and cellulose occurs [21,24,25,28]. This may cause a synergistic effect between melted plastic and biomass. Hydrogen can be provided from the melted plastic to the biomass, and cellulose and hemicellulose char may behave as a catalyst. These interactions can impact the pyrolytic products of plastic [21,24,25,28]. The blending ratio of plastic and biomass is among the most important factors that influence the product yields obtained from co-pyrolysis [16,19,24,25,27]. The presence of plastic can accelerate the decomposition of biomass by supplying high hydrogen, and the increment of plastic ratio in the blend can support the liquid yield [16,19,24,25,27]. The various synergistic effects can be obtained by using specific intermediate plastic ratios in the blend [16,24,25,26,27]. For instance, studies showed that considerable interaction and synergistic effect between biomass and PET (polyethylene terephthalate) could be obtained when the amount of biomass used was higher than the PET content in the mixture, such as in a 3:1 ratio [16,26].

In addition, during thermal degradation of different plastics with co-pyrolysis process, the formation of new groups could be observed as a result of the interaction between different plastic polymers. As a result of PET degradation, benzoic acid, CO, CO2, and high quantity of oxygenated groups could be observed [21]. When it comes to the other plastic polymer degradations, methane and methylene groups can be observed [21].

Production of the PCPW Co-Pyrolysis Char

In this study, PCPW char was fabricated by using a scale laboratory pyrolysis test system which consists of a steel reactor with a 25 cm height and 16.5 cm outer diameter, temperature control unit, liquid product collecting tubes, cooling unit, and nitrogen gas which is used for oxygen-free environment. In the study, the scale laboratory pyrolysis system shown in Figure 1 was used.

For the co-pyrolysis of PCPW raw material, first, the cooling unit was operated for condensation. Then, the reactor was loaded with the raw material at room temperature. After the reactor was placed into the furnace, pyrolysis parameters were set for the pyrolysis experiment. The pyrolysis tests were started at room temperature of 25 °C, and then nitrogen gas flow was supplied for 15 min into the reactor in order to purge out the oxygen. Co-pyrolysis of PCPW was carried out from temperature of 25 °C to the desired temperatures (505 and 525 °C) by heating the reactor, and the pyrolysis tests were completed in approximately 2 h and 10 min. After cooling the reactor to room temperature, co-pyrolysis PCPW char (solid product) was removed. The produced co-pyrolysis char from PCPW is shown in Figure 2.

2.3. Properties of the Char

Elemental analysis of the char can be evaluated by using CHN analysis [13,36,38,39]. In addition, the chemical groups in the char can be determined by using FTIR analysis. FTIR analysis performed between the range of 4000 cm−1 and 400 cm−1 wavenumbers can be used for determining the functional groups in the structure of char [11,13,19,38,39].

2.4. Softening Point, Penetration, and Specific Gravity Tests

Consistency of bituminous binders can be measured by using softening point and penetration tests. The penetration experiment was applied according to ASTM D5 [34], and the softening point tests were carried out according to ASTM D36 [33] standards. As the consistency of binder hardens, the penetration value decreases, and the softening point increases. Specific gravities of bituminous binders are determined by using ASTM D70 [35] standard test method.

2.5. Penetration Index (PI)

The temperature susceptibilities of binders can be assessed by using PI values. As the PI values of bituminous binders increase, the temperature susceptibilities decrease. PI values are determined by using the results obtained from the softening point and penetration tests [1]. In Equation (1), used to compute the PI values, ‘(SP)’ symbolizes the softening points of the binders, and ‘(Pen)’ symbolizes the penetration values at 25 °C.

2.6. Rotational Viscosity (RV) Test

To sufficiently obtain fluid and workable bituminous binders when mixing at high temperatures, the viscosities of binders must be determined. The fluidity and workability of bituminous binders can be examined by using rotational viscosity test. The viscosity of bituminous binders must not exceed 3000 cP, which is the specification criteria at the test temperature of 135 °C [1,2]. Rotational viscometer test was applied according to the ASTM D4402 [31].

2.7. Dynamic Shear Rheometer (DSR) Test

Rheological characteristics of bituminous binders at high temperatures can be assessed with DSR test. Bituminous binders’ behaviors at high temperatures are like those of viscous fluids; however, their behaviors at low temperatures are like those of elastic solids. DSR was developed to assess the viscoelastic behaviors of binders at high and medium temperatures. The G*/sin δ value was determined as the rutting parameter for rutting resistance, and low δ and high G* values are required.

The rutting parameter G*/sin δ value for un-aged bituminous binders is limited to the minimum 1.0 kPa value at the test temperature [1,2]. The PGs of the bituminous binders at high temperatures can be detected as a result of the DSR test. This value is obtained with the temperature at which the bituminous binders provide the minimum 1.0 kPa, which is the G*/sin δ rutting parameter specification criterion. In the Superpave PG system, the physical properties of bituminous binders are constant; however, these properties are obtained at different temperatures for different bituminous binders [1,2].

2.8. Storage Stability Test

Storage stabilities of modified binders can be determined by using EN 13399 [32] standard test method. According to this test, aluminum tubes filled with modified binders are kept vertically at temperature of 180 °C for 72 h. The modified binders in the aluminum tubes are cut up into three equal parts. For determining the storage stability of binders, softening point and penetration tests are performed on the top and bottom parts of binders in the aluminum tubes. The variation between softening point values of bottom and top parts of the binders must not exceed 5 °C, and the penetration value difference must not exceed 9 mm−1 [40].

3. Results and Discussions

3.1. The Results of the Co-Pyrolysis of PCPW

3.2. Product Yields from Co-Pyrolysis of PCPW

As a result of the PCPW pyrolysis, yields of 15.6% solid pyrolysis product (char), 21.7% liquid product, and 62.7% gas product were obtained (Table 2). It was seen that a relatively high amount of gas product was obtained. Additionally, the proportion of liquid product yield was higher than the solid product yield. This may be because of the presence of plastics in the blend [17,19,22,24,27], and this result is consistent with the studies on co-pyrolysis of different plastic wastes with biomasses in the literature [17,19,22,24,27]. The studies in the literature showed that the presence of plastics in the blend may increase the liquid and gas product yields [17,19,22,24,27]. The amounts of liquid, gas, and solid products obtained from the co-pyrolysis process may highly depend on the blending ratio and structural properties of different raw materials, as well as pyrolysis temperature, retention time, and heating rate [16,17,24,25,26].

Table 2.

Product yields from co-pyrolysis of PCPW.

3.3. CHN Elemental Analysis Results

The elemental analysis test results are seen in Table 3. The results indicate that PCPW char has a high amount of carbon content, as expected. In a study, it was reported that the char from paper cups has 77.7% carbon content [36]. It is seen that the amount of carbon in the structure of PCPW char is lower than the carbon content of paper cup char. On the other hand, when comparing to the paper cup char [36], it is also seen that the hydrogen and nitrogen contents of PCPW char are less than the contents of paper cup char. This may be due to the presence of PP and PET plastics in the mixture. The nitrogen content of the char may originate from the raw material subjected to the pyrolysis. The nitrogen content of the char may change with the various kinds of raw materials [27,41].

Table 3.

Elemental analysis test results.

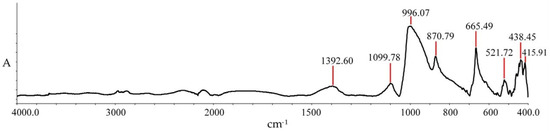

3.4. FTIR Test Results

The chemical groups in the PCPW char can be determined by using FTIR analysis. FTIR analysis performed between the range of 4000 cm−1 and 400 cm−1 wavenumbers can be used for determining the functional groups in the structure of char [10,11,19,38,39].

From the FTIR analysis results of PCPW char, the highest peak at 996.07 cm−1 and the other relatively high peaks at 665.49 cm−1 and 870.79 cm−1 are observed (Figure 3). Additionally, it is also observed that the intensity of peaks that occurred is mainly between around 1400–400 cm−1. In this study, FTIR analysis results showed that almost no vibrations between 3200 cm−1 and 3600 cm−1. This may be attributed hardly no O–H groups in the char structure [19,26,38]. The peak at 870.79 may be attributed to the aromatic C–H group vibrations [38,39]. The relatively weak peak of 1392.60 cm−1 may be ascribed to C–H groups [26,39]. Additionally, the peaks between 950 and 1300 cm−1 may be attributed to C–O vibrations [19,39]. This result may be obtained due to the impact of the presence of PET and PP as different plastic waste materials in the mixture.

Figure 3.

FTIR analysis results of PCPW char.

Compared with the FTIR test results of single-source chars, some differences can be seen. For instance, in a study [11], the characterization of the straw stalk biochar was investigated by using FTIR analysis, and the hydroxyl peak was observed at 3440 cm−1; relatively low peaks at 2930 cm−1 and at 1640 cm−1 were also observed. Additionally, a peak at 1100 cm−1, which is attributed to the ester carbonyl group, and a peak at 793 cm−1 were observed from the chemical structure of the straw stalk biochar. In another study [10], the results of the FTIR analysis of biochar from mesua ferrea seed biomass demonstrated the existence of two high peaks at 3420 cm−1, which was assigned to O–H groups, and at 1639 cm−1, which was attributed to C=C rings. In addition, another peak was seen at 2910 cm−1, which was related to C–H aliphatic vibrations, and a peak at 632 cm−1 was also observed. In a study [38], the characterization of char obtained from some mixed plastic wastes was studied by using FTIR analysis. As a result of the FTIR test, it was reported that the highest peak was found at 1400 cm−1. Additionally, two peaks at 2920 cm−1 and at 2850 cm−1 were also found, which were assigned to long aliphatic chains. The 1020 cm−1 and 870 cm−1 peaks were attributed to the aromatic C–H bond rings [38]. In a study [19], the structures of the chars obtained from co-pyrolysis of different biomass and different plastic blends were compared. It was stated that the peaks at 3600–3200 cm−1 were not observed in the structure of some chars. Weak C–O vibrations at 1300–950 cm−1 in the structure of some chars were observed. In addition, peaks at 800–600 cm−1 were also found in the structure of some chars from different biomass and plastic blends [19].

3.5. Bitumen Modification

The pyrolytic char produced from co-pyrolysis of PCPW raw material was used as an additive in pure bitumen at different ratios, including 8% and 16% by weight of neat bitumen. This modification was applied at a temperature of 160 ± 1 °C for 2 h at a mixing speed of 1200 rpm. In this study, modification parameters were determined as a result of investigating the studies in the literature [9,10,11,12,13,14].

3.6. Softening Point, Penetration, and Specific Gravity Test Results

Softening point and penetration experiments applied on bituminous binders showed that the PCPW co-pyrolysis char hardened the pure bitumen consistency. This pyrolytic char additive reduced the penetration value of pure bitumen (Table 4). In addition, this char increased the specific gravity and softening point of pure bitumen. As the amount of PCPW char additive rises, the softening point of pure bitumen also increases while the penetration value decreases. Compared with some other single-source biochars, this result is compatible with bitumens modified with different biochars [11,12]. In the studies [11,12] in which different biochars were used in bitumen as additives, it was reported that the biochar additives raised the softening point and reduced the penetration value of pure bitumen.

Table 4.

Some properties of bituminous binders.

3.7. Penetration Index (PI) Results

Temperature susceptibilities of bituminous binders were determined by using penetration and softening point test results with PI values calculated with Equation (1) [1]. From Table 5, the PCPW char increased the PI value of pure bitumen, and it can be seen that the PI values of 8% and 16% of modified binders are close to each other. Consequently, the addition of the PCPW char decreased the temperature susceptibility by increasing the PI value of pure bitumen, and this additive positively affected the bitumen temperature sensitivity. Compared with some other single-source biochars, which have a negative effect on the temperature sensitivity of bitumen [12], it can be seen that this PCPW pyrolytic char has a positive effect on the temperature susceptibility of neat bitumen. In a study [12] in which the biochar from apricot shells was used in bitumen as an additive, the biochar of apricot shell additive had a negative effect on the temperature sensitivity of pure bitumen by decreasing the PI value of neat bitumen. Additionally, another biochar from walnut shells also had a negative effect on temperature susceptibility when pure bitumen was modified with 10% and 15% biochar from walnut shell additive [12]. However, in a study [11], it was reported that the straw stalk biochar used as an additive in bitumen increased the PI value of neat bitumen and decreased the temperature sensitivity. It can be deduced that the structural and chemical properties of pyrolytic chars used as additives in bitumen affect the variation of temperature sensitivity of bitumen.

Table 5.

PI values of bituminous binders.

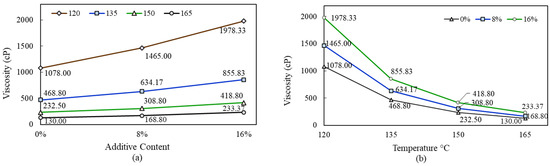

3.8. Rotational Viscosity (RV) Test Results

RV test results demonstrated that PCPW char raised the pure bitumen viscosity value. Additionally, as the PCPW char content increased, the pure bitumen viscosity value also increased at all temperatures (Figure 4a). Additionally, from Figure 4b, the viscosity of neat bitumen decreases with increasing temperature, as expected.

Figure 4.

(a) Change in viscosity of binders with additive; (b) change in viscosity of binders with temperature.

Figure 4b presents that the viscosities of 8% and 16% modified binders are higher than pure bitumen viscosity at approximately 35.3% and 82.5% ratios at a temperature of 135 °C, respectively. Additionally, this result is suitable with the softening point and penetration test results.

A measure of the resistance of fluids against the flow is defined as viscosity. Different liquids have different viscosity properties at given temperatures. This is because of the shear stress between fluid layers [1,2]. Bitumen is a viscoelastic material and behaves like a viscous liquid at high temperatures [1,2]. An increment in the viscosity of bitumen at constant temperature demonstrates the increasing resisting stress between bitumen layers [1,2]. PCPW char increased the viscosity of neat bitumen. This is because adding PCPW char may form a stiff structure in neat bitumen [11,13]. In the literature, it was detected that the addition of different biochars increased the viscosity of neat bitumen [9,10,11,12,13,14] due to the biochars absorbing the light components of the bitumen [11,13]. It is seen that the increment of viscosity of bitumen by adding PCPW char is compatible with the viscosity results of single-biochar modified binders in the literature. According to the experimental results, it was found that pure bitumen and PCPW char-modified binders did not exceed 3000 cp, which is the specification limit. It can be concluded that all modified bituminous binders with PCPW are sufficiently fluid and suitable for workability.

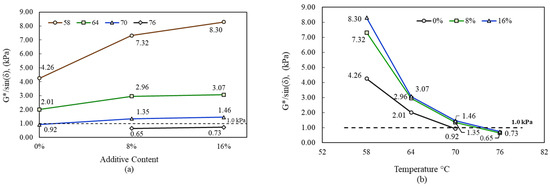

3.9. Dynamic Shear Rheometer Results

Rheological performances of binders at high temperatures were evaluated with the DSR test applied according to the AASHTO T315 [30]. From Figure 5a, the PCPW char increased the rutting parameter value of neat bitumen. In addition, the G*/sin δ value increases with increasing PCPW char additive content. From Figure 5b, the G*/sin δ value decreases with increasing temperature, as expected. This result is suitable with viscosity test results.

Figure 5.

(a) Change in G*/sin δ of binders with additive; (b) change in G*/sin δ of binders with temperature.

Bitumen viscosity decreases at high temperatures, and this is one of the most important reasons for rutting deformations. Bitumen is a viscoelastic material that behaves like a viscous liquid at high temperatures and behaves like an elastic solid at low temperatures [1,2]. To assess the viscoelastic behavior, both elastic responses and viscous responses of the binder are detected with the phase angle and complex modulus. The complex modulus (G*) indicates the deformation resistance of bitumen. The components of the complex modulus (G*) are the loss modulus and storage modulus. The storage modulus (G′) is the elastic portion of the resistance of bitumen and demonstrates the amount of stored energy. The loss modulus (G″), which indicates the amount of energy lost, is the viscous part. Binder stiffness increases with increasing complex modulus (G*) [1,2]. Additionally, the phase angle (δ°) is the relative amount of viscous and elastic deformations. As the phase angle reduces, the elastic portion of the complex modulus increases. It means that the bituminous binder provides a higher amount of recoverable deformation. When evaluating the resistance of binders against rutting deformations, a lower phase angle (δ°) and higher complex modulus (G*) are desired to provide higher rutting parameters (G*/sin δ) [1,2].

In this study, PCPW char increased the G*/sin δ value of pure bitumen. This is because the addition of PCPW char may stiffen the pure bitumen by absorbing the light components [11,13]. This result indicates that the addition of PCPW char improves the resistance of pure bitumen against rutting deformations. Additionally, it can be seen that this result is compatible with single-biochar-modified bituminous binders in the literature. Compared to the studies in the literature, it was found that the single biochars used as additives [9,10,11,12] also increased the rutting parameter.

3.10. Performance Grades of Bituminous Binders

Performance grades of the binders at high temperatures were detected, as seen in Table 6. DSR test results showed that 8% and 16% modified binders provided a 1.0 kPa specification value at 70 °C, while pure bitumen provided this value at 64 °C. PCPW char increased the pure bitumen performance grade from PG 64 to PG 70. Additionally, it can be seen from Table 6 that although the failure temperatures rose with increasing additive content, high-temperature PGs of modified binders did not increase more than PG 70. Compared to the research in the literature [10,12], it was seen that different single biochars increased the high-temperature PG of neat bitumen.

Table 6.

High-temperature PG of bituminous binders.

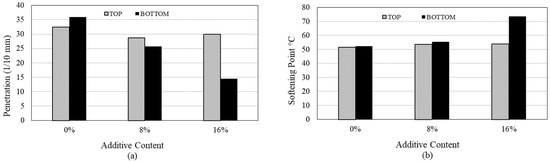

3.11. Storage Stability Test Results

Storage stabilities of all bituminous binders were determined in accordance with the EN 13399 [32] standard method, as shown in Figure 6.

Figure 6.

Storage stability test of the binders.

To determine the storage stability of the binders, softening point tests and penetration tests are applied on the bottom and top parts of the binders in aluminum tubes. The difference in penetration values between the bottom and top parts of the binders must not exceed 9 mm−1, and the difference in softening point values must not exceed 5 °C [40].

The lower differences between the bottom and top parts of penetration and softening point values of the binder indicate the higher stability binder for storage. Storage stability test results are demonstrated in Table 7 and Figure 7.

Table 7.

Storage stability test results of the bituminous binders.

Figure 7.

Storage stability results: (a) penetration differences; (b) softening point differences.

From the storage stability test results displayed in Table 7 and Figure 7, it was observed that the PCPW char additive accumulated at the bottom of the tube, and therefore, the softening point values of the bottom parts of the modified binders in the tube were higher, and the penetration values were lower than the top parts of the modified binders. This result is compatible with the specific gravities (Table 4) of modified binders with PCPW char. It can be said that the storage stability of 8% modified bitumen is suitable. On the other hand, if the additive was used at a rate of 16%, it was determined that the softening point and penetration value differences between the bottom and top parts of the tube exceeded the specification limits. This means that 16% modified bitumen is not suitable for storage.

4. Conclusions

The PCPW co-pyrolysis char was produced and used as an additive in pure bitumen. The following conclusions were obtained:

- The char produced from co-pyrolysis of different raw materials, including paper cups, PP plastic waste, and PET plastic waste, improved the rutting resistance and the viscosity of neat bitumen;

- It was determined that the PCPW co-pyrolysis char reduced the penetration value and increased the softening point of neat bitumen. In addition, it can be said that this co-pyrolysis char additive positively affected pure bitumen properties by decreasing the temperature sensitivity of neat bitumen;

- The highest viscosity increment, which is approximately 82.5% at 135 °C, was acquired by using this char additive at a 16% ratio in bitumen. In addition, all binders did not exceed the 3000 cp specification limit;

- The highest rutting resistance increment, which is approximately 59% at 70 °C, was obtained by using 16% additive in pure bitumen;

- This char additive raised the high-temperature PG of neat bitumen from PG64 to PG70;

- According to the test results, the PCPW char additive increased the rutting resistance of neat bitumen at high temperatures;

- From the storage stability test results, it can be said that the binder modified with this pyrolytic char had good storage stability when this char was used at an 8% ratio in pure bitumen.

It was determined that the PCPW co-pyrolysis char increased the viscosity, softening point, and rutting resistance of pure bitumen. It can be concluded that this additive positively affects the bitumen performance at high temperatures. It is considered that it may be appropriate to use this pyrolytic char as an additive in pure bitumen in hot climate regions. Furthermore, the PCPW co-pyrolysis char may have a positive effect on the environment, because wastes have been used as raw materials during its production.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The author would like to thank The Bilecik Şeyh Edebali University Central Research and Application Laboratory for CHN and FTIR analysis and thank the 3rd Regional Directorate of Highways Konya for the DSR test.

Conflicts of Interest

The author declares no conflict of interest.

References

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; Gerlis, R., Taylor, R., Eds.; Shell International Petroleum Company Ltd.: London, UK, 2015. [Google Scholar]

- McGennis, R.B.; Shuler, S.; Bahia, H.U. Background of Superpave Asphalt Binder Test Methods; FHWA SA 94-069; Asphalt Institute: Washington, DC, USA, 1994. [Google Scholar]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and bitumen modification: A review on latest advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Strelets, L.A.; Ilyin, S.O. Infrared spectral classification of natural bitumens for their rheological and thermophysical characterization. Molecules 2023, 28, 2065. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Abbas, S.; Zaidi, S.B.A.; Ahmed, I. Performance evaluation of asphalt binders modified with waste engine oil and various additives. Int. J. Pavement Eng. 2022. [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Rheological and adhesive properties of nanocomposite bitumen binders based on hydrophilic or hydrophobic silica and modified with bio-oil. Constr. Build. Mater. 2022, 342, 127946. [Google Scholar] [CrossRef]

- Abe, A.A.; Rossi, C.O.; Caputo, P. Biomaterials and their potentialities as additives in bitumen technology: A review. Molecules 2022, 27, 8826. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, Q.; You, Z.; Wang, H.; Peng, C. Rheological performance of bio-char modified asphalt with different particle sizes. Appl. Sci. 2018, 8, 1665. [Google Scholar] [CrossRef]

- Kumar, A.; Choudhary, R.; Narzari, R.; Kataki, R.; Shukla, S.K. Evaluation of bio-asphalt binders modified with biochar: A pyrolysis by-product of Mesua ferrea seed cover waste. Cogent Eng. 2018, 5, 1548534. [Google Scholar] [CrossRef]

- Ma, F.; Dai, J.; Fu, Z.; Li, C.; Wen, Y.; Jia, M.; Wang, Y.; Shi, K. Biochar for asphalt modification: A case of high-temperature properties improvement. Sci. Total Environ. 2021, 804, 150194. [Google Scholar] [CrossRef]

- eloğlu, M.E.; Yılmaz, M.; Kök, B.V.; Yalçın, E. Effects of various biochars on the high temperature performance of bituminous binder. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Martínez-Toledo, C.; Valdés-Vidal, G.; Calabi-Floody, A.; González, M.E.; Reyes-Ortiz, O. Effect of biochar from oat hulls on the physical properties of asphalt binder. Materials 2022, 15, 7000. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Chaves-Pabón, S.B.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Use of biochar in asphalts: Review. Sustainability 2022, 14, 4745. [Google Scholar] [CrossRef]

- Czajczyńska, D.; Anguilano, L.; Ghazal, H.; Krzyżyńska, R.; Reynolds, A.; Spencer, N.; Jouhara, H. Potential of pyrolysis processes in the waste management sector. Therm. Sci. Eng. Prog. 2017, 3, 171–197. [Google Scholar] [CrossRef]

- Wang, Z.; Burra, K.G.; Lei, T.; Gupta, A.K. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals-A review. Prog. Energy Combust. Sci. 2021, 84, 100899. [Google Scholar] [CrossRef]

- Seah, C.C.; Tan, C.H.; Arifin, N.; Hafriz, R.; Salmiaton, A.; Nomanbhay, S.; Shamsuddin, A. Co-pyrolysis of biomass and plastic: Circularity of wastes and comprehensive review of synergistic mechanism. Results Eng. 2023, 17, 100989. [Google Scholar] [CrossRef]

- Demirbaş, A. Mechanisms of liquefaction and pyrolysis reactions of biomass. Energy Convers. Manag. 2000, 41, 633–646. [Google Scholar] [CrossRef]

- Epelioğullar, Ö.; Pütün, A.E. Products characterization study of a slow pyrolysis of biomass-plastic mixtures in a fixed-bed reactor. J. Anal. Appl. Pyrolysis 2014, 110, 363–374. [Google Scholar] [CrossRef]

- Zhou, X.; Broadbelt, L.J.; Vinu, R. Mechanistic understanding of thermochemical conversion of polymers and lignocellulosic biomass. Chapter Two. Adv. Chem. Eng. 2016, 49, 95–198. [Google Scholar] [CrossRef]

- Singh, R.; Ruj, B.; Sadhukhan, A.; Gupta, P. A TG-FTIR investigation on the co-pyrolysis of the waste HDPE, PP, PS and PET under high heating conditions. J. Energy Inst. 2019, 93, 1020–1035. [Google Scholar] [CrossRef]

- Uzoejinwa, B.B.; He, X.; Wang, S.; Abomohra, A.E.-F.; Hu, Y.; Wang, Q. Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: Recent progress and future directions elsewhere worldwide. Energy Convers. Manag. 2018, 163, 468–492. [Google Scholar] [CrossRef]

- Leng, L.; Xiong, Q.; Yang, L.; Li, H.; Zhou, Y.; Zhang, W.; Jiang, S.; Li, H.; Huang, H. An overview on engineering the surface area and porosity of biochar. Sci. Total Environ. 2021, 763, 144204. [Google Scholar] [CrossRef]

- Esso, S.B.E.; Xiong, Z.; Chaiwat, W.; Kamara, M.F.; Longfei, X.; Xu, J.; Ebako, J.; Jiang, L.; Su, S.; Hu, S.; et al. Review on synergistic effects during co-pyrolysis of biomass and plastic waste: Significance of operating conditions and interaction mechanism. Biomass-Bioenergy 2022, 159, 106415. [Google Scholar] [CrossRef]

- Kumagai, S.; Fujita, K.; Takahashi, Y.; Kameda, T.; Saito, Y.; Yoshioka, T. Impacts of pyrolytic interactions during the co-pyrolysis of biomass/plastic: Synergies in lignocellulose-polyethylene system. J. Jpn. Inst. Energy 2019, 98, 202–219. [Google Scholar] [CrossRef]

- Mishra, R.K.; Sahoo, A.; Mohanty, K. Pyrolysis kinetics and synergistic effect in co-pyrolysis of Samanea saman seeds and polyethylene terephthalate using thermogravimetric analyser. Bioresour. Technol. 2019, 289, 121608. [Google Scholar] [CrossRef]

- Sajdak, M. Impact of plastic blends on the product yield from co-pyrolysis of lignin-rich materials. J. Anal. Appl. Pyrolysis 2017, 124, 415–425. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, S.; Yang, X.; Li, G.; Zhou, H.; Li, Q.; Zhang, Y. Thermal behavior and kinetic study of co-pyrolysis of mi-croalgae with different plastics. Waste Manag. 2021, 126, 331–339. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Wu, Y.; Wu, K.; Chen, Y.; Hu, H.; Yang, M. Study on pyrolytic kinetics and behavior: The co-pyrolysis of microalgae and polypropylene. Bioresour. Technol. 2015, 192, 522–528. [Google Scholar] [CrossRef] [PubMed]

- The American Association of State Highway and Transportation Officials (AASHTO). AASHTO T-315, Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer; The American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2012. [Google Scholar]

- American Society for Testing and Materials. ASTM D-4402, Standard Test for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; American Society for Testing and Materials: West Conshohocken, PA, USA, 2002. [Google Scholar]

- European Standard. EN-13399; Bitumen and Bituminous Binders-Determination of Storage Stability of Modified Bitumen. British Standards Institution (BSI): London, UK, 2017.

- American Society for Testing and Materials. ASTM D-36, Standard Test for Softening Point of Bitumen (Ring-and-Ball Apparatus); American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2006. [Google Scholar]

- American Society for Testing and Materials. ASTM D-5, Standard Test for Penetration of Bituminous Materials; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2006. [Google Scholar]

- American Society for Testing and Materials. ASTM D-70, Standard Test Method for Specific Gravity and Density of Semi-Solid Bituminous Materials (Pycnometer Method); American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2003. [Google Scholar]

- Biswal, B.; Kumar, S.; Singh, R.K. Production of hydrocarbon liquid by thermal pyrolysis of paper cup waste. J. Waste Manag. 2013, 2013, 731858. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, Z.; Wang, W.; Ji, G.; Zhao, M.; Li, A. Kinetics, product evolution, and mechanism for the pyrolysis of typical plastic waste. ACS Sustain. Chem. Eng. 2021, 10, 91–103. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Piñar, A.; Ligero, A.; Blázquez, G.; Calero, M. Characterization and use of char produced from pyrolysis of post-consumer mixed plastic waste. Water 2021, 13, 1188. [Google Scholar] [CrossRef]

- Li, C.; Sun, Y.; Li, Q.; Zhang, L.; Zhang, S.; Wang, H.; Hu, G.; Hu, X. Effects of volatiles on properties of char during sequential pyrolysis of PET and cellulose. Renew. Energy 2022, 189, 139–151. [Google Scholar] [CrossRef]

- European Standard. EN-14023, Bitumen and Bituminous Binders-Specification Framework for Polymer Modified Bitumens; British Standards Institution (BSI): London, UK, 2010.

- Sajdak, M.; Słowik, K. Use of plastic waste as a fuel in the co-pyrolysis of biomass: Part II. Variance analysis of the co-pyrolysis process. J. Anal. Appl. Pyrolysis 2014, 109, 152–158. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).