Abstract

Sustainability concerns are rising as an interesting topic in both academia and industry. Many scholars revealed that green innovation is an excellent solution to enable organizations to achieve various benefits, such as enhancing their reputation and competitive advantages. Thus, this is the first study in Vietnam to consider the barriers to implementing green innovation. The research aims to identify the obstacles to green innovation practices in the Vietnamese manufacturing sector. The interpretive structural modeling (ISM) approach has been conducted to provide the interactions among the green innovation implementation barriers. The authors ground this study to bridge the theoretical and practical for green innovation practices in the Vietnam situation. Based on the experts’ perspectives, they proposed that Vietnamese manufacturers must deal with thirteen essential barriers to green innovation adoption. Further, six interaction levels and the MICMAC analysis clarified cross-relationships among challenges by evaluating the driving and dependence power. Indeed, the empirical results emphasized that financial capability constraints and lack of government support are the most decisive challenges. In contrast, market competition and uncertainty concern is the easiest obstacle to address by the Vietnamese manufacturers. Therefore, this study has provided some insightful contributions for the top managers and other scholars to consider.

1. Introduction

The ecology suffers from significant adverse impacts from factories, such as emissions and pollution, which have forced governments and stakeholders to take solutions to reduce environmental degradation [1]. As a result, eco-friendly practices have been obtaining attention from both academic and practical, leading to green initiatives are being proposed and implemented more and more in various fields [2]. Toward sustainability, many scholars stressed that green innovation is an excellent solution to help organizations gain two goals simultaneously, including ecological balance and economic profitability [3]. Besides, it can enhance the organization’s position, brand value, and competitive advantage in the market [4,5]. Undoubtedly, research on the green innovation topic has witnessed a rapidly increasing trend in recent years [2]. In addition, several investigations have revealed the importance of green initiatives, such as meeting the green purchasing of customers [6], obtaining the environmental standard [7], or improving financial performance [8]. More importantly, researchers suggested that organizations should integrate green innovation ideas into their development strategies [9].

Nevertheless, the implementation struggles with various obstacles, which may impact the firms’ efforts to reduce emissions and make green products. Moreover, Al-Abdallah and Al-Salim (2021) claimed that they must identify the barriers to green innovation implementation, aiming to help the enterprises to overcome them more easily [4]. The examples can be Gohoungodji et al., (2020) systematically reviewed previous studies and found that the automotive industry must overcome six major challenges [9]. Previously, Geibler et al., (2018) has considered the business opportunities if the firms conduct green innovation; five main barriers divided into twenty sub-barriers are the basis for the fuel-cell market [10]. Recently, some scholars have studied in the context of Middle-East countries such as Saudi Arabia [11,12]; Yemen [13]; UAE [14]. Surprisingly, they consistently identify the six essential barriers even in various research contexts, consisting of technical, legal, information, market, financial, and managerial. However, the variety of influence factors such as research contexts, analytical techniques, and industries are the reasons for no consistency in overcoming obstacles of green innovation implementation, particularly in emerging countries [3,15].

Vietnam is a developing country with a dominant agricultural economy, which has a close relationship with the local community and ecology [16]. The Vietnamese government and domestic organizations are looking for solutions to revert environmental pollution issues. Investing in green innovation by adopting green technology, renewable energies were proposed [17]. Meanwhile, the trend of green consumption is changing strongly, leading to the perception of consumers and stakeholders has been changing and made more stringent requests for the product without harm to the ecological [18]. Hence, the close correlation between green innovation and ecological protection is an urgent problem in Vietnam, which forced the government and stakeholders have required manufacturing industries to have more responsibilities to society and the environment through related certifications [18,19]. Several studies found that the organization’s performance will be improved by the adopted green initiatives [19,20,21]. However, the green innovation implementation research scope is still limited to developed countries such as in Europe [10] or in the Middle East area [11,12]. Thus, this is a unique study in Vietnam to consider the obstacles to implementing green innovation and address existing research gaps by its insightful results. Firstly, the research seeks to identify the barriers to green innovation practices in the Vietnamese manufacturing sector. Discussing the findings would provide good contributions in both theoretical and practical based on the particular context. More importantly, the second target is that the authors would evaluate the driving and dependence power among barriers to clarify interrelationships among challenges. Thereby, the findings would offer several promising suggestions that enable the firms to successfully remove green innovation obstacles.

2. Literature Review

Green innovation includes initiatives that reduce specific environmental harms and drive organizations to produce eco-friendly goods. For instance, reducing greenhouse gas emissions, improving the efficiency of the used-product recyclability, or taking advantages of recycled materials [9,22]. Apart from having to deal with the pressure from the local government and the community about the upgrade quality environment standards, the holistic interests in both financial and ecological balance have become the dynamics for the enterprises conducting toward sustainability [4,23].

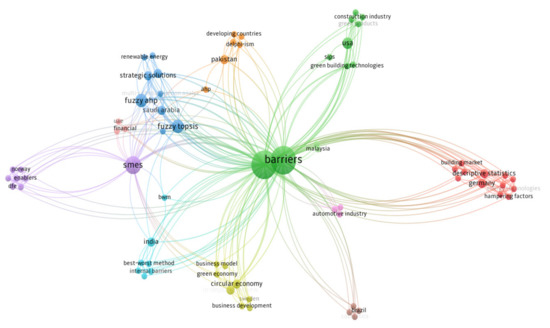

Aiming to find the research gaps and determine the essential barriers to implementing green innovation, the authors have systematically reviewed the existing green innovation barriers topic. Thus, analyzing the database which has collected from two resources are the SCOPUS and Web of Science. Some related keywords that have been conducted for the scan include “green innovation”, “barriers”, and “obstacles”. As a result, a total of nineteen journal papers have been found. Moreover, they are related to the research of green innovation practices barriers in different contexts, such as nations, industries, and approaches (as shown in Table 1 and Figure 1). The green innovation barriers literature demonstrated that SMEs have exceptional attention to green innovation through some practical evidence from Pakistan [15], UAE [14], India [24], or European countries [25]. Besides that, they provided the most excellent solutions for the senior managers to remove green innovation implementation barriers, leading to the importance and ranking of these obstacles have been defined. Furthermore, the authors have found that various methodologies have been adopted in this regard. However, the majority of these studies seem to have likely preferred to use two techniques involving fuzzy AHP (n = 5) and fuzzy TOPSIS (n = 4) over others. Moreover, almost studies conflict in determining the exact total of barriers and the obstacles that must be removed. For instance, Dugonski and Tumelero (2021) identified three levels of barriers and divided them into fourteen sub-barriers [26]. After collecting data in reality from the Brazilian cosmetics sector, the authors suggested focusing on ten critical barriers. Meanwhile, some scholars have believed that SMEs must solve twenty-four barriers, which are classified into six major groups [11,12,13].

Table 1.

Listing of existing studies about green innovation adoption barriers.

Figure 1.

The keyword map of the green innovation barriers publications.

Hence, the research gaps that need to be addressed are determined as follows.

Firstly, from the existing studies of barriers of green innovation implementation, the authors found that Vietnam is an emerging economy attempting to obtain sustainable development goals; meanwhile, the Vietnamese enterprises have deeply demands to conduct sustainability innovations [16,19]. Therefore, this is a unique study in Vietnam to carry out the big challenge in identifying the barriers to implementing green innovation.

Secondly, the manufacturing sector has a significant influence on the ecology. Therefore, green innovation practices in this industry would inevitably result in a slew of barriers and struggles for the enterprises to gain sustainability. Thereby, identifying various most significant obstacles and clarifying relationships among them by employing the interpretive structural modeling (ISM) approach could be addressed for research objectives in this work. Moreover, the findings would provide several new methodological insights for green innovation topics by combining theoretical and practical.

3. Research Methodology

3.1. The Interpretive Structural Modeling Approach

Vietnamese firms have realized that they have to change systematically to integrate green innovation practices into their operation management. But they struggle to identify and remove obstacles to adopting green innovation to attain different requirements in the new era [17,35]. Besides, various cross relationships are existing among these barriers inside, which may hinder the transformation efforts of the firms.

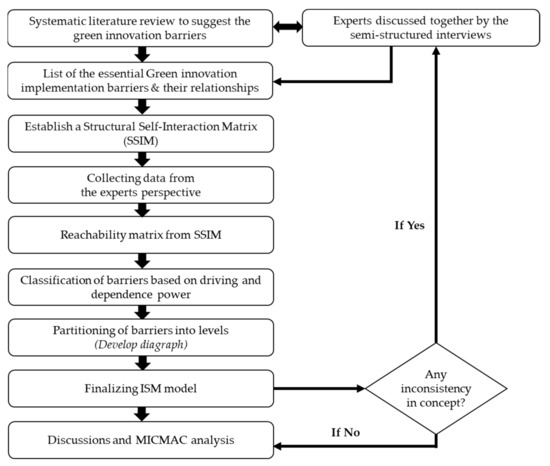

Thus, the authors employed the interpretive structural modeling (ISM) technique to address these research objectives. The ISM analysis has particular characteristics and advantages to deal with the research requirements [36], more importantly, clarifying the interactions among the green innovation variables [37]. Thanks to the expert’s opinion, they have suggested the essential factors, which as a basis for making decisions related to defining cross-relationships among them, including direct and indirect. The excellent advantage of the ISM technique could solve unclear relationships, and create a complete model. Indeed, the ISM approach recently has been trusted and more widely employed in various contexts, such as determining the barriers to the adoption of sustainability philosophy in Egyptian industries supply chain [38], evaluating the variables for the purchase of green products [37], green innovation practices in India and Pakistan, respectively [3,27]. Noticeably, the literature review has witnessed the various multi-criteria decision-making methods to deal with the cross relationships among elements, such as AHP [13], TOPSIS [12,39], and DEMATEL [40]. However, these techniques have some limitations regarding internal consistency and assessing indirect relationships [36,41]. Thus, the authors believe in the suggestion of several authors such as Movahedipour et al., (2017), Gupta and Barua (2021), and Singh and Gupta (2021). They argued that the ISM approach is the most suitable technique to understand the interrelationships among barriers. Thus, it would address these research objectives for this article due to its advantages [27,37,41]. According to the perspectives of experts about relationships among specific elements, the ISM technique has been conducted and able to determine the problems and critical role of elements. As a result, the driving and dependence power of green innovation barriers would be evaluated, then to point out the ranking of each barrier by its driving power. The process of the ISM approach includes the following stages would be presented in Figure 2.

Figure 2.

Flowchart of the proposed research.

3.2. Data Collection

The authors have collected the data by conducting semi-structured interviewing. To integrate insights between theoretical and practical; thus, in detail, nine respondents had participated in this study from both academic (four senior lecturers from the Vietnamese universities) and industry (five top managers from the Vietnamese manufacturers) areas that may help obtain the highest reliability and variety. Notably, the respondents have deep green innovation knowledge or work related to green innovation practices in Vietnam. Moreover, they all have at least ten years of experience and they would be considered the decision-makers for this research (presented in Table 2).

Table 2.

Summary of respondent’s information.

4. Results

4.1. Identifying Essential Barriers of Green Innovation Implementation

Following the flowchart of the proposed research process (Figure 2), the essential barriers to green innovation implementation in the Vietnamese manufacturing sector are identified and illustrated in Table 3. The systematic review of previous studies is the basis for referring to their recommendations and defining the research objectives. Further, professionals have enthusiastically responded to the questionnaire to explore the challenges of eco-innovation in Vietnam. Consequently, they recommended the most significant barriers that may interfere with implementing green innovation in the Vietnamese manufacturing industry. Besides that, nine experts have been requested to evaluate the importance of each barrier on a scale from 1 (strongly important) to 9 (strongly important) before clarifying the contextual relationships among them.

Table 3.

The proposed essential barriers for green innovation implementation.

4.2. Developing Structural Self-Interaction Matrix (SSIM)

The authors will synthesize the expert’s perspectives to clarify the contextual relationship among these thirteen obstacles.

A contextual relationship has been clarified as “Bi leads to Bj” for the professionals to consider. Consequently, the SSIM has established for all thirteen proposed green innovation barriers in Vietnamese manufacturing (see Table 4). In detail, four symbols are: V, A, X, O will represent the different relationships in the matrix, and could be explained by the following:

Table 4.

Structural self-interaction matrix (SSIM).

- V: Barrier j will be obtained by barrier i;

- A: Barrier i will be obtained by barrier j;

- X: Barrier i and j will help obtain each other;

- O: Barrier i and j are not related to each other;

- i and j: Barriers in row and column, respectively.

4.3. Establishing Reachability Matrix

The binary matrix would be considered in this stage, which has transformed from the SSIM (see Table 5).

Table 5.

Initial reachability matrix.

Two values as “1” and “0” would replace for four symbols (V, A, X, O) by following the rules of the ISM technique and be shown in the initial reachability matrix (IRM). In detail,

- If the (i,j) entry in the SSIM is V, then the (i,j) entry in the IRM becomes “1” and the (j,i) entry is “0”;

- If the (i,j) entry in the SSIM is A, then the (i,j) entry in the IRM becomes “0” and the (j,i) entry is “1”;

- If the (i,j) entry in the SSIM is X, then both the (i,j) entry and the (j,i) entry in the IRM becomes “1”;

- If the (i,j) entry in the SSIM is O, both the (i,j) entry and the (j,i) entry in the IRM becomes “0”.

Nevertheless, due to the cross relationships among those green innovation implementation barriers in the Vietnamese manufacturing industries, hence, the integrating transitivity phase will be concerned to attain the final reachability matrix (FRM). In Table 6, the entries “1*” indicates transitivity links among barriers. Moreover, two essential values could be calculated as “driving power” and “dependence power”. Evaluation of these two values by the total of barrier’s entries per row and column, respectively (including itself).

Table 6.

Final reachability matrix.

4.4. Partitioning of Reachability Matrix

Aiming to clarify the influence and relationships among barriers, the authors performed level partitioning based on the FRM (Table 6) to point out the intersection of reachability and antecedent sets is derived for all thirteen green innovation barriers in the Vietnamese manufacturer.

The ISM technique stipulates that the reachability set consists of the barrier itself and the barriers it assists in attaining (each row). Meanwhile, an antecedent set includes the barrier itself and other barriers, which help to achieve it (each column) [50]. Hence, the intersection sets are identified from all thirteen obstacles after deriving these two sets. Moreover, stratification in the ISM model would be based on the related barriers, which have the identical “reachability and intersection set” values. For example, market competition and uncertainty (MCU) at level 1 (see Table 7), meaning that the MCU barrier has no significant impact on other obstacles; therefore, it becomes the top position of the hierarchy. After that, the MCU barrier could be deleted, and then the authors continue the iterative process until the position level of all obstacles is determined. Consequently, the final level partitioning (FLP) demonstrated six iterations (six levels) for all thirteen green innovation barriers in the case of Vietnam.

Table 7.

Final level partitioning.

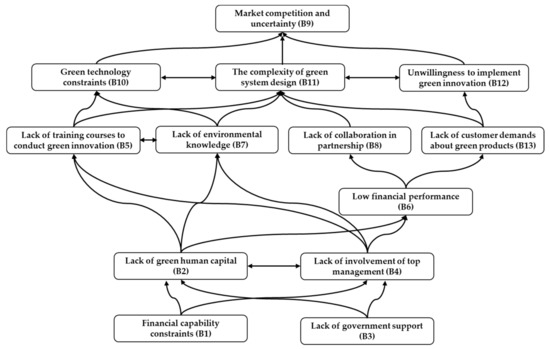

4.5. Finalizing ISM Model

Figure 3 depicts the chart showing the relationships among various barriers of green innovation implementation for the Vietnamese manufacturing sector. Drawing the finally ISM model based on the FRM includes describing the relationships among obstacles, and the direction arrows indicate the existing correlation between the barriers i and j.

Figure 3.

The ISM model of barriers of green innovation implementation for the Vietnamese manufacturing sector.

Match to the results of the FLP stage (see Table 7), thirteen barriers of green innovation implementation for the Vietnamese manufacturing sector have been classified into six levels and arranged from the lowest to the highest level, respectively. At the lowest level are two barriers as B1 and B3: financial capability constraints (FCC) and lack of government support (LGS). It documents that these two barriers (FCC and LGS) drive all other obstacles in this regard. However, there is no correlation between them. Next to the fifth level includes lack of green human capital (LGH) and lack of involvement of top management (LIT). Those play the mediation role to bridge the sixth level (FCC and LGS) and the fourth level is low financial performance (LFP) barrier.

At the third level, four barriers are here, including Lack of training courses to conduct green innovation (LTC); lack of environmental knowledge (LEK); lack of collaboration in partnership (LCP); and lack of customer demands about green products (LCD). Notably, there is only one peer relation between LTC and LEK. Move to the second level in the ISM model, where the attendance of three challenges as green technology constraints (GTC); The complexity of green system design (CGS); and unwillingness to implement green innovation (UIG). Surprisingly, these three barriers correlate with each other and affect the last obstacle as market competition and uncertainty (MCU).

5. Discussion and Managerial Implications

In the current globalization situation, Vietnamese manufacturers must address various problems related to stakeholders. Such as the pressure from the government to improve to meet high-quality standards, the pressure from other competitors, and the consumers’ perception regarding green products that require the firms to change if they want to toward sustainability [18,21]. Further, pursuing sustainability targets requires the organizations to conduct green innovation ideas to cover the broad goals [23,37]. Therefore, switching to eco-products trending through adopting green innovations is considered an excellent solution to improve business performance besides another goal [19]. In the case of the Vietnamese manufacturing industries, the authors have successfully identified thirteen obstacles, which are the most significant challenges that the firms must remove.

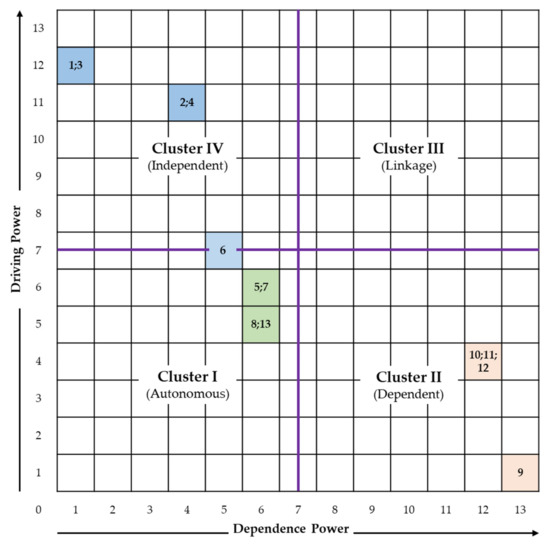

However, the difference in the manufacturer’s capacity and the cross relationships among barriers are the reasons for the confusion of firms to implement green innovation. Therefore, based on the two important values as “driving power” and “dependence power” from the FRM (Table 5), the authors conducted the MICMAC analysis, which indicates the significance of each challenge and also clarifies the essential barriers to overcome. Consequently, all thirteen barriers are divided into four separate areas on the diagram (Figure 4), and each cluster indicates a different significance.

Figure 4.

The diagram of driving power and dependence of barriers.

Firstly, in terms of the “autonomous” quadrant, this cluster consist of the barriers which are weak in both driving and dependence power. This includes four challenges including lack of training courses to conduct green innovation (B5) [10,15,24]; lack of environmental knowledge (B7) [7,47]; lack of collaboration in partnership (B8) [8,32,48]; and lack of customer demands about green products (B13) [5,6]. This group is in the middle of the identifying list for Vietnamese manufacturers to be concerned with. It means that these challenges are not too hard to remove, and it is in line with the suggestion of Al Asbahi et al., (2020) through the case of the Yemen energy industry, a developing country whic has a situation similar to that of Vietnam [13]. However, this study findings conflict with Ullah et al., (2021), they found that no barriers has positions in the autonomous cluster via the case study in Pakistan [3].

Secondly, in the category of “dependent” barriers, the authors observed that four variables (from B9 to B12) are gathered in this area. It indicates that having a weak driving power, but having a strong reliance power. Combined with the diagram of six levels (Figure 3), only green technology has constraints (B10) [15,26]. The complexity of green system design (B11) [13,15,26], and unwillingness to implement green innovation (B12) [3,11,13] are in the same place. Meanwhile, market competition and uncertainty (B9) [5,8,49] is at the furthest point compared to the rest. It corresponds to the presentation in Figure 3, the MCU barrier at the first level of the diagram, meaning that it was not affecting other obstacles and is dependent on them. Hence, in the context of Vietnam, this challenge could be ignored or pay least attention, and it consistent with the conclusions of scholars Al Asbahi et al., (2020) [13].

Thirdly, regarding the “Linkage” cluster, which has been defined as the set of barriers that are strong in both driving power and dependence power. Surprisingly, the authors found no presence of any obstacles in this quadrant. Whereas this result is in stark contrast to the conclusions of Ullah et al., (2021), they reported that most of their identified challenges (n = 16) belong to the linkage quadrant [3].

Finally, the map’s highest point has realized two obstacles: Financial capability constraints (B1) [22,27,28] and lack of government support (B3) [6,8,26]. This leads to second-place which includes lack of green human capital (B2) [8,42] and lack of involvement of top management (B4) [8,24,43]. These four barriers are placed in an essential group called the “independent” quadrant. This area describes the variables which have the most fabulous driving while lowest influencing power to others. Thus, the Vietnamese manufacturing sector must overcome these challenges before addressing others. The influence of problems related to the government’s role and organization management is critical and decisive for the rest [11]. Besides, this suggestion is in line with some previous studies. The examples can be the statements about the great role of government in strengthening helping organizations transform to meet the modern standards related to social and ecological responsibilities [12,14]. Furthermore, Stucki (2019) stressed the financial regard barriers have strongly affected the dynamic to implement green innovation of the enterprises. Therefore, the participation of experienced leaders in eco-friendly issues would make more advantages and drive to all operation systems easier access [28]. Notably, the challenge’s location concerns Low financial performance (B6) [44,45,46]. Only the LFP barrier is at the fourth level of the ISM model. It is also located on the border of two quadrants I and IV. However, its driving power is slightly higher than the relevant power.

Thanks to experts’ enthusiasm in discussions and prior studies’ recommendations, this study has been grounded in a way that can bridge the theoretical and practical for green innovation implementation in the Vietnam case. As participants’ contribution of knowledge related to the main topic, such as eco-friendly actions, green technology, and sustainability, consequently, they have identified a total of thirteen most critical obstacles for the Vietnamese manufacturing sector. These research findings have offered some insights into managerial implications to be considered in both the theoretical and the real world. Successfully implementing green innovation requires the efforts of whole industries and stakeholders. Ideally, all challenges need to be surpassed simultaneously if the firms want to achieve advantages from these initiatives. Unfortunately, the limitations related to management experience, finances, and external factors have a substantial impact on the strategies of each organization [12,27]. Hence, apart from contributing to the green innovation literature through the case of a transitional economy such as Vietnam, the worth research findings about the cross-relationship concerns among barriers has been determined. Based on the evaluation of two values as “driving power” and “dependence power”, there are six levels of the ISM model, and four quadrants aim to reveal the importance level of each obstacle. Thanks to these valuable suggestions, the top managers could refer to making management decisions in their organizations. Besides that, other scholars also gained for themself other insight ideas, which may enable them to develop further research in the future.

6. Conclusions

Promoting sustainability is an inevitable trend in the global, particularly in transitional economies [15,23,48]. Moreover, various pressures from the stakeholders and the development demands of industries have forced manufacturers to transform to meet the ecology requirements [12,15]. Further, some authors revealed that green innovation is an excellent way that brings particular advantages for the firms on the market [4,21,49]. Aiming to develop green innovation philosophy and broaden green initiatives in the manufacturing sector, the authors have chosen the case study of Vietnam, a rapidly growing country but witnessing a lack of research on green innovation adoption. Therefore, this study has some insightful contributions in both theoretical and practical. The Vietnamese manufacturers must deal with thirteen essential barriers to green innovation adoption consisting of internal and external challenges. Hence, the authors conducted the ISM approach for this research to explore the significance and cross-relationship of all barriers. Indeed, the empirical results emphasized that financial capability constraints (B1) and lack of government support (B3) are the most decisive, indicating the effect on other obstacles. In contrast, stratification based on cross-relationships divided them into six levels; challenge regarding market competition and uncertainty is at the first level, meaning that the lowest driving power and it has been easiest to address by the Vietnamese firms. Further, the mutual relationships among the remaining barriers also were discussed. A combination simultaneously the ISM model and the MICMAC analysis has revealed that the empirical research in the contextual case leads to the particular findings compared with other studies. Thus, the research findings are excellent reference resources that offer great ideas for senior administrators to make management decisions.

Considering the case of an essential industry in a transitional economy such as Vietnam, this is the first seriously empirical research focusing on green innovation topic and determining exactly obstacles in implementation. But, unsurprisingly, there are still some certain limitations in this research, which should be kept in mind in future research. Firstly, this manuscript grounds the qualitative approach by conducting the semi-structured interview of nine respondents. Although the small size of samples can be accepted in the ISM technique, the participants are experts who have deep knowledge. Unfortunately, they did not represent all Vietnamese manufacturers in general. Thus, the findings could be limited in their perspectives, leading to conflict with other studies about identified green innovation implementation barriers and their importance. Secondly, the experts have proposed only thirteen green innovation implementation barriers for this case in Vietnam, the results being inconsistent with another research worldwide. Therefore, the authors recommend identifying more challenges by other academics to broaden the green innovation theory. Finally, aiming to contribute more insight into the literature by bridging theoretical to practical, the authors hope the flexibility of this research framework could be evaluated in other industries or countries.

Author Contributions

Conceptualization, Y.-F.H. and M.-H.D.; methodology, M.-H.D. and J.-C.C.; software, A.P.-S.C. and J.-C.C.; validation, A.P.-S.C. and J.-C.C.; formal analysis, A.P.-S.C.; investigation, M.-H.D.; resources, Y.-F.H. and M.-H.D.; data curation, M.-H.D.; writing—original draft preparation, M.-H.D. and J.-C.C.; writing—review and editing, M.-H.D.; visualization, A.P.-S.C.; supervision, Y.-F.H.; project administration, Y.-F.H. and A.P.-S.C. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by grants from the Ministry of Education, Taiwan, R.O.C. (Intelligent commerce and marketing craft the social practice model for the prionailurus bengalensis and agricultural optimized regional revitalization in Chungliao; No. 1112300210V).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

All authors declare no conflict of interest in this paper.

References

- Soewarno, N.; Tjahjadi, B.; Fithrianti, F. Green Innovation Strategy and Green Innovation: The Roles of Green Organizational Identity and Environmental Organizational Legitimacy. Manag. Decis. 2019, 57, 3061–3078. [Google Scholar] [CrossRef]

- Takalo, S.K.; Tooranloo, H.S.; Parizi, Z.S. Green Innovation: A Systematic Literature Review. J. Clean. Prod. 2021, 279, 122474. [Google Scholar] [CrossRef]

- Ullah, S.; Ahmad, N.; Khan, F.U.; Badulescu, A.; Badulescu, D. Mapping Interactions among Green Innovations Barriers in Manufacturing Industry Using Hybrid Methodology: Insights from a Developing Country. Int. J. Environ. Res. Public Health 2021, 18, 7885. [Google Scholar] [CrossRef] [PubMed]

- Al-Abdallah, G.M.; Al-Salim, M.I. Green Product Innovation and Competitive Advantage: An Empirical Study of Chemical Industrial Plants in Jordanian Qualified Industrial Zones. Benchmarking 2021, 28, 2542–2560. [Google Scholar] [CrossRef]

- Lin, W.L.; Ho, J.A.; Sambasivan, M.; Yip, N.; Mohamed, A. Bin Influence of Green Innovation Strategy on Brand Value: The Role of Marketing Capability and R&D Intensity. Technol. Forecast. Soc. Change 2021, 171, 120946. [Google Scholar]

- Sharma, A.; Foropon, C. Green Product Attributes and Green Purchase Behavior: A Theory of Planned Behavior Perspective with Implications for Circular Economy. Manag. Decis. 2019, 57, 1018–1042. [Google Scholar] [CrossRef]

- Polas, M.R.H.; Tabash, M.I.; Bhattacharjee, A.; Dávila, G.A. Knowledge Management Practices and Green Innovation in SMES: The Role of Environmental Awareness towards Environmental Sustainability. Int. J. Organ. Anal. 2021. [Google Scholar] [CrossRef]

- Jun, W.; Ali, W.; Bhutto, M.Y.; Hussain, H.; Khan, N.A. Examining the Determinants of Green Innovation Adoption in SMEs: A PLS-SEM Approach. Eur. J. Innov. Manag. 2021, 24, 67–87. [Google Scholar] [CrossRef]

- Gohoungodji, P.; N’Dri, A.B.; Latulippe, J.M.; Matos, A.L.B. What Is Stopping the Automotive Industry from Going Green? A Systematic Review of Barriers to Green Innovation in the Automotive Industry. J. Clean. Prod. 2020, 277, 123524. [Google Scholar] [CrossRef]

- von Geibler, J.; Bienge, K.; Schüwer, D.; Berthold, O.; Dauensteiner, A.; Grinewitschus, V.; Hoffmann, D.; Renner, W.; Ostermeyer, Y. Identifying Business Opportunities for Green Innovations: A Quantitative Foundation for Accelerated Micro-Fuel Cell Diffusion in Residential Buildings. Energy Rep. 2018, 4, 226–242. [Google Scholar] [CrossRef]

- Musaad, O.A.S.; Zhuo, Z.; Musaad O, A.O.; Siyal, Z.A.; Hashmi, H.; Shah, S.A.A. A Fuzzy Multi-Criteria Analysis of Barriers and Policy Strategies for Small and Medium Enterprises to Adopt Green Innovation. Symmetry 2020, 12, 116. [Google Scholar] [CrossRef] [Green Version]

- Chien, F.; Kamran, H.W.; Nawaz, M.A.; Thach, N.N.; Long, P.D.; Baloch, Z.A. Assessing the Prioritization of Barriers toward Green Innovation: Small and Medium Enterprises Nexus. Environ. Dev. Sustain. 2022, 24, 1897–1927. [Google Scholar] [CrossRef]

- Al Asbahi, A.A.M.H.; Fang, Z.G.; Chandio, Z.A.; Tunio, M.K.; Ahmed, J.; Abbas, M. Assessing Barriers and Solutions for Yemen Energy Crisis to Adopt Green and Sustainable Practices: A Fuzzy Multi-Criteria Analysis. Environ. Sci. Pollut. Res. 2020, 27, 36765–36781. [Google Scholar] [CrossRef]

- Chien, F.; Ngo, Q.T.; Hsu, C.C.; Chau, K.Y.; Iram, R. Assessing the Mechanism of Barriers towards Green Finance and Public Spending in Small and Medium Enterprises from Developed Countries. Environ. Sci. Pollut. Res. 2021, 28, 60495–60510. [Google Scholar] [CrossRef]

- Fahad, S.; Alnori, F.; Su, F.; Deng, J. Adoption of Green Innovation Practices in SMEs Sector: Evidence from an Emerging Economy. Econ. Res. Istraživanja 2022. [Google Scholar] [CrossRef]

- Do, T.N.; Kumar, V.; Do, M.H. Prioritize the Key Parameters of Vietnamese Coffee Industries for Sustainability. Int. J. Product. Perform. Manag. 2020, 69, 1153–1176. [Google Scholar] [CrossRef]

- Le, T.-H.; Doan, N.-T.; To, T.-T. Effects of R&D, Networking and Leadership Roles on Environmental Innovation Adoption in Vietnam’s SMEs. Econ. Res. Istraživanja 2021. [Google Scholar] [CrossRef]

- Huang, Y.F.; Do, M.H.; Kumar, V. Consumers’ Perception on Corporate Social Responsibility: Evidence from Vietnam. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 1272–1284. [Google Scholar] [CrossRef]

- Do, M.-H.; Huang, Y.-F.; Do, T.-N. The Effect of Total Quality Management-Enabling Factors on Corporate Social Responsibility and Business Performance: Evidence from Vietnamese Coffee Firms. Benchmarking Int. J. 2021, 28, 1296–1318. [Google Scholar] [CrossRef]

- Nguyen, Q.A.; Hens, L. Environmental Performance of the Cement Industry in Vietnam: The Influence of ISO 14001 Certification. J. Clean. Prod. 2015, 96, 362–378. [Google Scholar] [CrossRef]

- Le, T.T.; Ikram, M. Do Sustainability Innovation and Firm Competitiveness Help Improve Firm Performance? Evidence from the SME Sector in Vietnam. Sustain. Prod. Consum. 2022, 29, 588–599. [Google Scholar] [CrossRef]

- Aron, A.S.; Molina, O. Green Innovation in Natural Resource Industries: The Case of Local Suppliers in the Peruvian Mining Industry. Extr. Ind. Soc. 2020, 7, 353–365. [Google Scholar] [CrossRef] [Green Version]

- Ullah, S.; Khan, F.U.; Ahmad, N. Promoting Sustainability through Green Innovation Adoption: A Case of Manufacturing Industry. Environ. Sci. Pollut. Res. 2021, 29, 21119–21139. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. A Framework to Overcome Barriers to Green Innovation in SMEs Using BWM and Fuzzy TOPSIS. Sci. Total Environ. 2018, 633, 122–139. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Dugonski, F.C.V.; Tumelero, C. Barriers and Facilitators of Technological Eco-Innovations: A Multilevel Analysis in a Brazilian Cosmetics Company. Innov. Manag. Rev. 2021. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. Chapter 8: Evaluation of Manufacturing Organizations Ability to Overcome Internal Barriers to Green Innovations. In Strategic Decision Making for Sustainable Management of Industrial Networks; Rezaei, J., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 139–160. ISBN 978-3-030-55385-2. [Google Scholar]

- Stucki, T. What Hampers Green Product Innovation: The Effect of Experience. Ind. Innov. 2019, 26, 1242–1270. [Google Scholar] [CrossRef]

- Ilg, P. How to Foster Green Product Innovation in an Inert Sector. J. Innov. Knowl. 2019, 4, 129–138. [Google Scholar] [CrossRef]

- Aid, G.; Eklund, M.; Anderberg, S.; Baas, L. Expanding Roles for the Swedish Waste Management Sector in Inter-Organizational Resource Management. Resour. Conserv. Recycl. 2017, 124, 85–97. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; He, B.J.; Olanipekun, A.O. Examining Issues Influencing Green Building Technologies Adoption: The United States Green Building Experts’ Perspectives. Energy Build. 2017, 144, 320–332. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to Green Innovation Initiatives among Manufacturers: The Malaysian Case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Bar, E.S. A Case Study of Obstacles and Enablers for Green Innovation within the Fish Processing Equipment Industry. J. Clean. Prod. 2015, 90, 234–243. [Google Scholar]

- McCoy, A.P.; Ahn, Y.H.; Pearce, A.R. Towards Establishing Diffusion Barriers for Innovative Green Building Products: A Survey of Sips Builders. J. Green Build. 2012, 7, 153–176. [Google Scholar] [CrossRef]

- Fadly, D. Greening Industry in Vietnam: Environmental Management Standards and Resource Efficiency in SMEs. Sustainability 2020, 12, 7455. [Google Scholar] [CrossRef]

- Ahmad, N.; Qahmash, A. Smartism: Implementation and Assessment of Interpretive Structural Modeling. Sustainability 2021, 13, 8801. [Google Scholar] [CrossRef]

- Singh, S.; Gupta, A. An ISM Modeling for Factors Affecting the Purchase of Green Products. J. Model. Manag. 2021, 16, 103–123. [Google Scholar] [CrossRef]

- Zayed, E.O.; Yaseen, E.A. Barriers to Sustainable Supply Chain Management Implementation in Egyptian Industries: An Interpretive Structural Modeling (ISM) Approach. Manag. Environ. Qual. Int. J. 2021, 32, 1192–1209. [Google Scholar] [CrossRef]

- Do, M.-H.; Huang, Y.-F. Evaluation of Parameters for the Sustainable Supply Chain Management: A Taiwanese Fresh-Fruit Sector. AIMS Environ. Sci. 2022, 9, 16–32. [Google Scholar] [CrossRef]

- Goyal, S.; Routroy, S.; Singhal, A. Analyzing Environment Sustainability Enablers Using Fuzzy DEMATEL for an Indian Steel Manufacturing Company. J. Eng. Des. Technol. 2019, 17, 300–329. [Google Scholar] [CrossRef]

- Movahedipour, M.; Zeng, J.; Yang, M.; Wu, X. An ISM Approach for the Barrier Analysis in Implementing Sustainable Supply Chain Management: An Empirical Study. Manag. Decis. 2017, 55, 1824–1850. [Google Scholar] [CrossRef]

- Agyabeng-Mensah, Y.; Tang, L. The Relationship among Green Human Capital, Green Logistics Practices, Green Competitiveness, Social Performance and Financial Performance. J. Manuf. Technol. Manag. 2021, 32, 1377–1398. [Google Scholar] [CrossRef]

- Song, W.; Yu, H.; Xu, H. Effects of Green Human Resource Management and Managerial Environmental Concern on Green Innovation. Eur. J. Innov. Manag. 2020, 24, 951–967. [Google Scholar] [CrossRef]

- Chouaibi, S.; Chouaibi, J.; Rossi, M. ESG and Corporate Financial Performance: The Mediating Role of Green Innovation: UK Common Law versus Germany Civil Law. EuroMed J. Bus. 2022, 17, 46–71. [Google Scholar] [CrossRef]

- Aastvedt, T.M.; Behmiri, N.B.; Lu, L. Does Green Innovation Damage Financial Performance of Oil and Gas Companies? Resour. Policy 2021, 73, 102235. [Google Scholar] [CrossRef]

- Xu, Q.; Xu, L.; Xie, Z.; Jin, M. Does Business Group Matter for the Relationship between Green Innovation and Financial Performance? Evidence from Chinese Listed Companies. Sustainability 2021, 13, 13204. [Google Scholar] [CrossRef]

- Hall, J.; Matos, S.; Bachor, V. From Green Technology Development to Green Innovation: Inducing Regulatory Adoption of Pathogen Detection Technology for Sustainable Forestry. Small Bus. Econ. 2019, 52, 877–889. [Google Scholar] [CrossRef] [Green Version]

- Tumpa, T.J.; Ali, S.M.; Rahman, M.H.; Paul, S.K.; Chowdhury, P.; Rehman Khan, S.A. Barriers to Green Supply Chain Management: An Emerging Economy Context. J. Clean. Prod. 2019, 236, 117617. [Google Scholar] [CrossRef]

- Tu, Y.; Wu, W. How Does Green Innovation Improve Enterprises’ Competitive Advantage? The Role of Organizational Learning. Sustain. Prod. Consum. 2021, 26, 504–516. [Google Scholar] [CrossRef]

- Menon, R.R.; Ravi, V. Analysis of Barriers of Sustainable Supply Chain Management in Electronics Industry: An Interpretive Structural Modelling Approach. Clean. Responsible Consum. 2021, 3, 100026. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).