Abstract

The aim of this study was to investigate the relationship between sustainability management accounting, environmental management system, and organizational performance for the Malaysian manufacturing industry. The data were collected from 350 manufacturing companies in Malaysia using online questionnaires. Structural equation modeling was used to investigate the relationship between sustainability management accounting, environmental management system, and organizational performance. The findings showed that there was a significant positive relationship between sustainability management accounting and organizational performance (β = 0.530, p < 0.001), sustainability management accounting and environmental management system (β = 0.583, p < 0.001), and environmental management system and organizational performance (β = 0.168, p < 0.05). The findings also found an indirect effect of sustainability management accounting on organizational performance (β = 0.271, p < 0.05) through environmental management system implementation. Results show that environmental management systems can be considered as partial mediators. The environmental management system as a mediator for the Malaysian manufacturing industry increased the impact of sustainability management accounting on organizational performance. This study provides a fundamental approach for practitioners and manufacturing researchers to improve organizational performance through the implementation of sustainability management accounting and environmental management systems.

1. Introduction

Malaysia’s manufacturing sector plays an important role in the country’s economic development. The contribution to the country’s export income and job creation ensured the growth of the country [1]. Priority will remain to produce high-value-added, diversified, and complex products, particularly in the catalytic sub-sectors, namely electricity and electronics, machinery and equipment, and chemical products. In Malaysia, the manufacturing industry contributed 24.30% to the national gross domestic product in 2021 [2]. This suggests that the manufacturing industry is one of the sectors that promises to accelerate the development of the country. However, in the absence of positive environmental initiatives, manufacturing activities will lead to the creation of a large amount of waste, the exploitation of natural resources, as well as too much energy consumption. This requires the development and implementation of sustainability initiatives in the manufacturing industry. However, in developing countries such as Malaysia, sustainability is still in its infancy in promoting sustainability practices [3]. In addition, manufacturing firms do not give much attention to sustainability management accounting (SMA) [3]. Therefore, the manufacturing industry in Malaysia was selected in this study to improve SMA and organizational performance (OP), especially in the Malaysian manufacturing industry.

SMA is a challenge faced by management accounting related to sustainability activities. The implementation of SMA is still weak in the manufacturing industry, especially in developing countries such as Malaysia [3]. In addition, SMA plays an important role in the practice of managing sustainability activities in the manufacturing industry. Therefore, the implementation of SMA is important to increase OP for the Malaysian manufacturing industry. To meet the requirements of the SMA, the implementation of an environmental management system (EMS) can assist organizations in managing, measuring, and improving environmental management [4]. In addition, an EMS provides guidelines in the manufacturing industry to manage the environment [5]. A study by Ong et al. [6] suggested that more companies in Malaysia need to adopt EMSs to improve OP. However, the authors mentioned that the implementation of an EMS has limitations in the organization. Thus, the EMS as a mediator variable is chosen because an EMS might be related to SMA and OP. This research has four main objectives, which are as follows:

- To investigate the relationship between SMA and OP for the Malaysian manufacturing industry;

- To investigate the relationship between SMA and EMS for the Malaysian manufacturing industry;

- To investigate the relationship between EMS and OP for the Malaysian manufacturing industry;

- To investigate whether the EMS mediates the relationship between SMA and OP for the Malaysian manufacturing industry.

The paper is organized into six sections. Section 1 introduces the research back-ground and highlights the concepts of SMA, EMS, and OP. Section 2 presents a current literature review on SMA, EMS, and OP and the development of hypotheses. Section 3 de-tails the chosen methodology and its justification. Section 4 provides the findings of this study. Section 5 and Section 6 discuss the results of this study and present the limitations, future research opportunities, and conclusions.

2. Literature Review

2.1. Contingency Theory

Contingency theory began to develop in 1970 to explain management accounting practices. Contingency theory has received a lot of attention from researchers and has been adopted by the industry as a management philosophy [7]. Moreover, the theory of contingency is related to the relationship between internal organizations and the environment [8]. Meanwhile, contingent refers to any variable that affects the organizational dimension of performance [9]. Contingency theory is known to be one of the best management approaches to practice in an organization influenced by various aspects of the environment and can explain accounting and sustainability management performance.

A review of the literature shows that contingency theory has been used in management accounting research and it is associated with SMA [8,9]. Therefore, the accounting literature proposes several variables that affect the design associated with management accounting. The main contingent of variables includes management, organization, management systems, and the environment [10]. Most of these variables can be used to be associated with SMA, EMS, and OP, and thus have been used to develop hypotheses related to this study. In the context of SMA, contingency theory is one of the reasons SMA leads to improved performance [11]. Thus, SMA increases the importance not only for management, but also for sustainability activities, such as sustainability management, environmental costs, and performance measurement.

2.2. Organizational Performance

Manufacturers face the challenge of improving organizational performance (OP) in the manufacturing industry. The importance of sustainability goals can be measured by OP for sustainability improvement in the manufacturing industry [12,13]. Increasing the OP of the manufacturing industry necessitates intensifying the energy consumption of products, the use of materials, or recycling to improve the company’s operations.

OP can also be measured to improve the performance of companies, especially for the Malaysian manufacturing industry. Performance measurements can be identified by OP indicators to improve sustainability management in the manufacturing industry [14,15]. Several studies have examined that OP provides benefits not only for organizations but also for overall performance in organizations [16,17,18,19]. OP consists of environmental aspects such as production, waste, and emissions in managing the company’s operations. OP measurement can help organizations improve manufacturing operations such as quality, cost, and processes [20,21,22]. By implementing OP, companies can achieve organizational goals that can be applied to the Malaysian manufacturing industry.

2.3. Sustainability Management Accounting

One of the sustainability practices that includes the organization’s activities is the implementation of SMA that provides environmental information to reduce environmental issues and improve performance and sustainability [23,24]. In this regard, the implementation of SMA can improve management accounting by providing useful environmental information that helps organizations to manage and improve OP, especially for the Malaysian manufacturing industry.

Most of the research is related to SMA and focuses on the manufacturing industry [23,25]. This is because the manufacturing industry has gained awareness of environmental issues as a result of the operations carried out. This can help reduce environmental impacts and improve environmental programs, environmental management, and performance. The implementation of SMA in the manufacturing industry operating in Malaysia can help reduce environmental issues. The implementation of SMA helps companies improve environmental benefits and achieve better performance, especially for the Malaysian manufacturing industry. Therefore, the implementation of the SMA can be emphasized in the Malaysian manufacturing industry.

2.4. Environmental Management System

In Malaysia, there are environmental challenges of implementing environmental management systems (EMS) in organizations, especially in the manufacturing industry [26]. In this regard, the implementation of EMSs has helped the companies respond to environmental challenges [27,28]. Furthermore, organizations that implement an EMS can improve environmental policy. EMSs are useful for organizations to improve environmental management, especially for the Malaysian manufacturing industry. Therefore, the implementation of EMSs can help the organization achieve the company’s objectives. In addition, an EMS can assist organizations in addressing environmental issues and aims to reduce costs and improve sustainability management, performance, and reputation [29].

An EMS refers to the principle of continuous improvement related to the activities of the company [30]. Therefore, an EMS benefits processes, procedures, structures, and improvements to improve sustainability management, especially for the Malaysian manufacturing industry. An EMS refers to systematic procedures aimed at ensuring continuous improvement in performance [31,32]. In addition, an EMS is a management method for managing the environment and achieving goals in improving OP. This is supported by Ociepa-Kubicka et al. [33], who mentioned that the implementation of an EMS can improve OP in the organization. Organizations should be aware of environmental issues by using the implementation of an EMS. This study aims to prove that EMSs can be implemented in the Malaysian manufacturing industry to improve performance.

2.5. Sustainability Management Accounting and Organizational Performance

Sari et al. [34] conducted studies from manufacturing companies in Indonesia to assess the influence of SMA and OP. The results show that SMA is positive in relation to OP. SMA is an important tool for organizations in improving OP to achieve higher performance [23,35,36]. Another study conducted by Schaltegger et al. [37] also showed that SMA is associated with OP. This is because the implementation of SMA can increase OP to manage environmental impacts. SMA has implications for OP in terms of operational performance and financial performance to reduce environmental issues in the industry [38,39]. Therefore, the implementation of SMA can help organizations to determine OP measurements. A recent study by Song et al. [40] in China showed that SMA can provide benefits for improving OP, such as better reputation and competitiveness, efficient use of resources, better productivity, and increased profitability. Meanwhile, Wijewardana [41] conducted research to study the effects of SMA and OP in Sri Lanka. The findings suggested that there is a positive relationship between these variables. Based on the reviews of literature, the following hypothesis is proposed:

Hypothesis 1 (H1).

There is a significant positive relationship between sustainability management accounting and organizational performance.

2.6. Sustainability Management Accounting and Environmental Management System

The research was conducted by [42] in Saudi Arabia to study the relationship between SMA and EMS, the results were similar to Massoud [43]. The authors suggested that the use of SMA was an important role in improving an EMS and can achieve environmental objectives and goals. This is because an EMS aims to encourage organizations to control environmental impacts and evaluate environmental management to achieve continuous improvement. In improving SMA, an EMS provides methods to help organizations evaluate environmental activities within the company [43]. The SMA approach can be carried out through an EMS to assist organizations in improving sustainability management. Therefore, SMA also requires an EMS to manage sustainability improvements in the Malaysian manufacturing industry. Research conducted by Massoud [43] in Mexico involving 220 manufacturing organizations shows that there was a significant relationship between these variables. The implementation of SMA contributes to the development of an EMS, which can reduce sustainability issues for the Malaysian manufacturing industry.

In other words, the implementation of SMA is to develop and enhance EMSs more efficiently and effectively [44]. Research conducted in Australia involving 286 companies showed that SMA was positive in relation to EMSs [45]. This practice can improve production processes, reduce waste, and reduce environmental pollution in the manufacturing industry. This can be achieved through EMSs to assess the sustainability impact in the organization. Therefore, SMA plays an important role as a tool for EMSs to improve procedures, laws, and structures for the Malaysian manufacturing industry. Based on the reviews of the literature, the following hypothesis is formulated:

Hypothesis 2 (H2).

There is a significant positive relationship between sustainability management accounting and the environmental management system.

2.7. Environmental Management System and Organizational Performance

Zobel and Malmgren [46] conducted research in the Swedish manufacturing industry and found that there was a significant relationship between these variables. The implementation of an EMS can help organizations to improve OP. Herghiligiu [47] conducted research in Romanian organizations to find out the relationship between EMSs and OP. The results of the study found that the implementation of the EMS is significant in relation to OP. OP can be improved by implementing an EMS in the organization. This is supported by Low et al. [4], who pointed out that the implementation of EMSs in manufacturing organizations in Malaysia has increased OP. The research was conducted in Malaysian manufacturing involving 346 organizations, and the results showed that there is a positive relationship between these variables. Therefore, this study shows that EMSs can increase OP for the Malaysian manufacturing industry. Based on reviews of the literature on EMSs and OP, the following hypothesis is proposed:

Hypothesis 3 (H3).

There is a significant positive relationship between environmental management system and organizational performance.

2.8. Sustainability Management Accounting and Organizational Performance: Environmental Management System as a Mediator

This study used EMSs as a mediator in the relationship between SMA and OP for the Malaysian manufacturing industry. Solovida and Latan [48] conducted research in Indonesia to investigate the relationship between SMA, EMS, and OP. The results showed that there was a positive and significant relationship between SMA, EMS, and OP. This is because an EMS helps organizations to evaluate sustainability management [49]. Therefore, this study aims to examine the indirect relationship between SMA and OP through the use of EMSs for the Malaysian manufacturing industry. In addition, this study analyzes the impact of EMSs through the relationship between SMA and OP using the structural equation modeling method [50]. Therefore, an EMS is important in SMA and OP for the Malaysian manufacturing industry. Jalil et al. [51] conducted research in the Iranian industry to investigate the effects of SMA and EMS. The implementation of SMA and an EMS is important to improve the OP. It is necessary for organizations to implement an EMS to improve SMA and OP, such as reducing environmental costs, improving the quality of environmental management, reducing material and energy consumption, and assessing the environmental impact of processes. Therefore, the implementation of an EMS can be considered to improve SMA and OP for the Malaysian manufacturing industry. Based on the reviews of the literature, the following hypothesis is proposed:

Hypothesis 4 (H4).

Environmental management system mediates the relationship between sustainability management accounting and organizational performance.

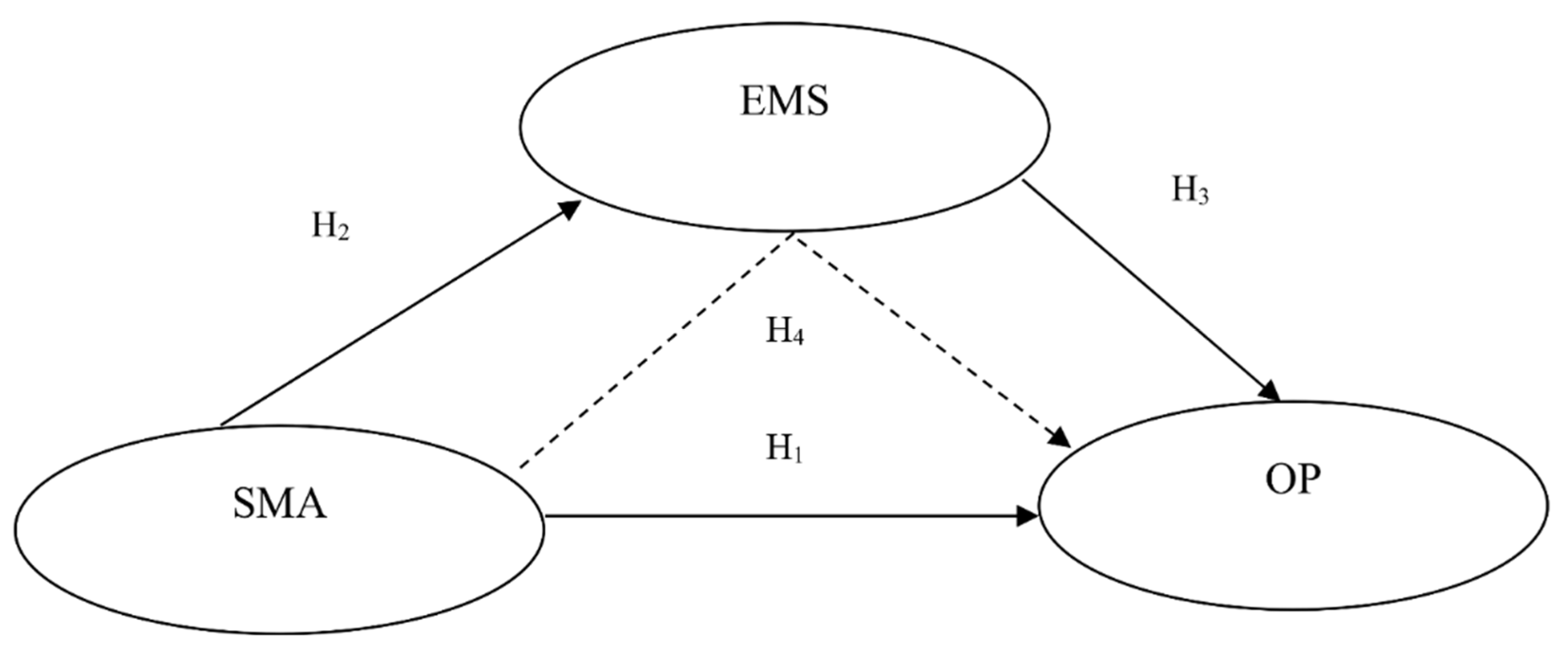

This research model aims to examine the EMS as a mediating variable of the relationship between SMA and OP for the Malaysian manufacturing industry. To understand the relationship between SMA, EMS, and OP, the following hypotheses are used and tested in this study. Figure 1 represents the research framework proposed by the researcher.

Figure 1.

Research framework. Note: SMA = sustainability management accounting; EMS = environmental management system; OP = organizational performance.

3. Research Methodology

3.1. Sample and Procedures

The population in this study focused on the manufacturing industry. The sample companies were selected from Malaysian manufacturing companies listed in the Federation of Malaysian Manufacturers (FMM). The data were collected using questionnaire surveys from 2700 manufacturing companies selected from the 2021 FMM Directory. In this study, an online survey was conducted by distributing questionnaires to all manufacturers who are listed in the FMM Directory (2021). Questionnaires were distributed to respondents using online survey tools as well as via email followed by phone calls to improve response rates. Researchers listed all company information from the FMM Directory 2021 based on email address, contact number, and office/factory address. Respondents from each selected manufacturer were contacted by email to ask for their permission and willingness to answer the questionnaire. In this study, 2700 questionnaires were distributed over a 6-month period to top management. The respondents completed the survey within the period between 1st June until 30th November 2021. After 6 months, a total of 382 questionnaires were returned. However, a preliminary analysis of the data revealed 32 outliers in the data set. These were the unusual multivariate assumptions, normality, linearity, homoscedasticity, and multicollinearity in this study [52]. Therefore, only 350 surveys were assessed, i.e., sufficient sample size for the structural equation modeling (SEM) analysis approach [53].

The unit of analysis is an organization. The manufacturing companies participating in the survey comprised automotive/machine, plastic/rubber/metal, food/tobacco, electrical/electronic, and chemical/wood. Researchers selected respondents from those who held top management positions in the company such as managing director, quality control manager, manufacturing manager, and accountant to answer questions about the SMA, EMS, and OP.

This study presents the characteristics of Malaysian manufacturing companies (type of ownership, industrial sector, number of employees, current position, current position (year), and company certified to quality system standards) from a sample size of 350 respondents. First, the measure of demographic information is a type of ownership. The majority of the companies involved are wholly owned by Malaysians (57.14%), followed by 42.86% owned by foreigners. Respondents came from companies with different industrial sectors in the manufacturing industry. Types of industrial sectors were categorized into six categories. There were automotive/machine, plastic/rubber/metal, food/tobacco, electric/electronic, chemical/wood, and others. Among the six types of industrial sectors, most companies were automotive/machinery with 35.71%. This was followed by plastic/rubber/metal (15.71%), food/tobacco (9.43%), electricity/electronics (14.29%), chemical/wood (6.29%), and other industrial sectors (18.57%). The next survey involved the number of employees: 37.14% of companies had more than 300 employees, 28.57% of companies had between 200 and 300 employees, 20% of companies had between 100 and 200 employees, and 14.29% had less than 100 employees. As for the respondent’s position, 60% held middle management positions, 15.71% of Malaysian respondents held senior management positions, and this was followed by other positions at 24.29%. Meanwhile, respondents who held current positions (years) for more than 6 years were 42.86%, the position between 3 to 6 years was 34.29%, the position between 1 and 3 years was 14.29%, and the position held less than 1 year was 8.57%. For certification, some companies had more than one certification: 38.57% of companies had ISO 14001 certification, while 27.14% ISO 9001:2008 certification. Lastly, 18.57% of companies has ISO/TS 16949, while 12.86% had OHSAS 18001. Table 1 shows the demographics of respondents.

Table 1.

Demographics of respondents.

As suggested by Krejcie and Morgan [54], the sample size of the population of 2700 is 335. In determining a reasonable sample size, the minimum recommended sample size for this study is approximately 200–400 [55]. On the other hand, at least 100 to 500 is a reasonable sample size for testing research hypotheses using structural equation modeling analysis (SEM) [56]. To assess the basic assumptions of the study, the covariance-based structural equation model (CB-SEM) was used to test the relationship between endogenous variables and exogenous variables [56] as proposed in the research hypothesis. The capacity of CB-SEM to test intricate and complete models leads to its selection compared to other methods of analysis. CB-SEM can minimize measurement error with confirmatory factor analysis (CFA), may evaluate direct and indirect interactions, including estimates of sample parameters to be evaluated simultaneously, and can improve model presentation. Therefore, this study used CB-SEM as a statistical analysis technique.

3.2. Measurement

All constructs were evaluated using validated measures commonly used in previous studies. Data for this study were collected through survey techniques, using instruments adopted and adapted from previous studies to measure the variables specified within the proposed framework, namely SMA, EMS, and OP (Appendix A). In this study, three variables were studied, namely SMA, EMS, and OP for the Malaysian manufacturing industry. SMA consisted of 5 dimensions (environmental costs, environmental regulations, environmental safety, management commitments, and customer focus) and 25 measurement items. The scale of SMA was measured using 25 items adapted from Al-Mawali et al. [12]. Meanwhile, EMS consisted of 4 dimensions and 20 measurement items covering planning, implementation and operation, auditing and evaluation, as well as corrective actions. The EMS scale was measured using 20 items adapted from Ann et al. [26] and Farok and Searcy [27]. Finally, the OP consisted of 2 dimensions (financial performance and operational performance) and 10 measurement items. The OP scale was measured using 10 items adapted from Sari et al. [34]. Therefore, a total of 55 questions were designed to obtain respondents’ views for the Malaysian manufacturing industry. In this study, respondents were asked to rate their responses on a seven-point scale for SMA and EMS, where “1—Very Low”, “2—Low”, “3—Slightly Low”, “4—Medium”, “5—Slightly High”, “6—High”, and “7—Very High”. Meanwhile, respondents were asked to rate their responses on seven-point scales for OP, where “1—Strongly Disagree”, “2—Disagree”, “3—Somewhat Disagree”, “4—Neither Agree nor Disagree”, “5—Somewhat Agree”, “6—Agree”, and “7—Strongly Agree”.

The questionnaire was pre-tested and piloted to determine the construct reliability, face validity, and content validity prior to conducting the main study [19,56]. To determine if the scale items accurately reflect the variables evaluated, content validity was investigated by analyzing the literature linked to the study measures used in prior investigations. In addition, pre-tests were conducted with a small group of academics who have expertise in SMA to see if the scale items accurately reflected the concepts evaluated. Emails were used to contact and obtain feedback from a panel of experts. Based on feedback, some items were modified to reflect more appropriate words, ensuring that the information was accessible and clear to fit the context of the study. This suggests that the validity of the content was finally ensured. To determine face validity for this study, the initial draft of the questionnaire was tested on the respondent sample. Then, the feasibility of the study was assessed with a pilot test.

4. Empirical Study

4.1. Exploratory Factor Analysis (EFA)

In this study, the EFA was conducted in three variables, namely EFA for SMA dimensions, EFA for EMS dimensions, and EFA for OP dimensions. EFA began with the determination of the Kaiser–Meyer–Olkin (KMO) measure to reduce the adequacy, and the Bartlett’s test of sphericity (p < 0.001) was used to check the strength of the correlations between the items. Second, the EFA used the sum of the variance described to determine the number of items with Eigenvalues >1. Finally, the result of a matrix of rotating components was used to identify each item factor sufficient to load the factor. Table 2 presents the summary of EFA.

Table 2.

Summary of EFA for SMA, EMS, and OP.

4.2. Common Method Bias

Three strategies were attempted to address the issue of common method bias, which arises from one-time data collection and will cause overestimation [57]. First, the modification of the item was carried out while maintaining the respondent’s confidentiality by obtaining measuring items from various sources. Since the majority of CEOs in manufacturing organizations have achieved certification to quality system standards, both statistics are collected from them. After that, all measurement items were used in the exploratory factor analysis to run the Harman single-factor test [57]. There is no common technique bias in this research, as seen by the results, which reveal that the exploratory factor analysis is 40% and less than 50% [58].

4.3. Confirmatory Factor Analysis (CFA)

The first step was to test all measurement models using confirmatory factor analysis (CFA). The data collected were tested for reliability and validity by using CFA to test SMA, EMS, and OP measurement models. In order to achieve fit statistics tests, this study was based on the recommended goodness-of-fit indices such as χ2 test (χ2/degree of freedom), the goodness fit index (GFI), the adjusted goodness-of-fit index (AGFI), the comparative fit index (CFI), the Tucker Lewis index (TLI), and the root mean square error of approximation (RMSEA). The model showed a good fit: the value of χ2/df was 2.627, less than 3.0. GFI was 0.909 and AGFI was 0.881. Meanwhile, the CFI was 0.954 and the TLI was 0.947. The RMSEA value was 0.064, less than 0.080, which indicated the appropriateness of the acceptable result. As shown in Table 3, the measurement model was suitable for measuring the construct validity and reliability.

Table 3.

Measurement model.

Convergent validity examines whether the constructs are positive in relation to other measures of the constructs, while the discriminant validity is a test to determine whether correlations exist between items of latent constructs. This approach can be used to verify construct validity involving convergent validity, as proposed by Hair et al. [53]. The convergent validity used in the measurement model can be examined from the item loadings, composite reliability (CR), and average variance extracted (AVE), as shown in Table 4. For composite reliability, the value for each construct was greater than 0.70. The AVE of each construct was more than 0.50, which is the recommended value by Samsudin et al. [59].

Table 4.

Evaluation of the measurement model.

4.4. Main Results

Structural models for SMA, EMS, and OP were first checked for the appropriate fit index. The goodness-of-fit index for structural models (χ2/df = 2.580, GFI = 0.937, AGFI = 0.905, CFI = 0.915, TLI = 0.900, and RMSEA = 0.063) showed the appropriate data. Therefore, a suitable overall model was sufficient to test the proposed hypothesis. The standardized regression weight of the relationship between SMA, EMS, and OP is presented in Table 5.

Table 5.

Regression weights of the relationship between SMA, EMS, and OP.

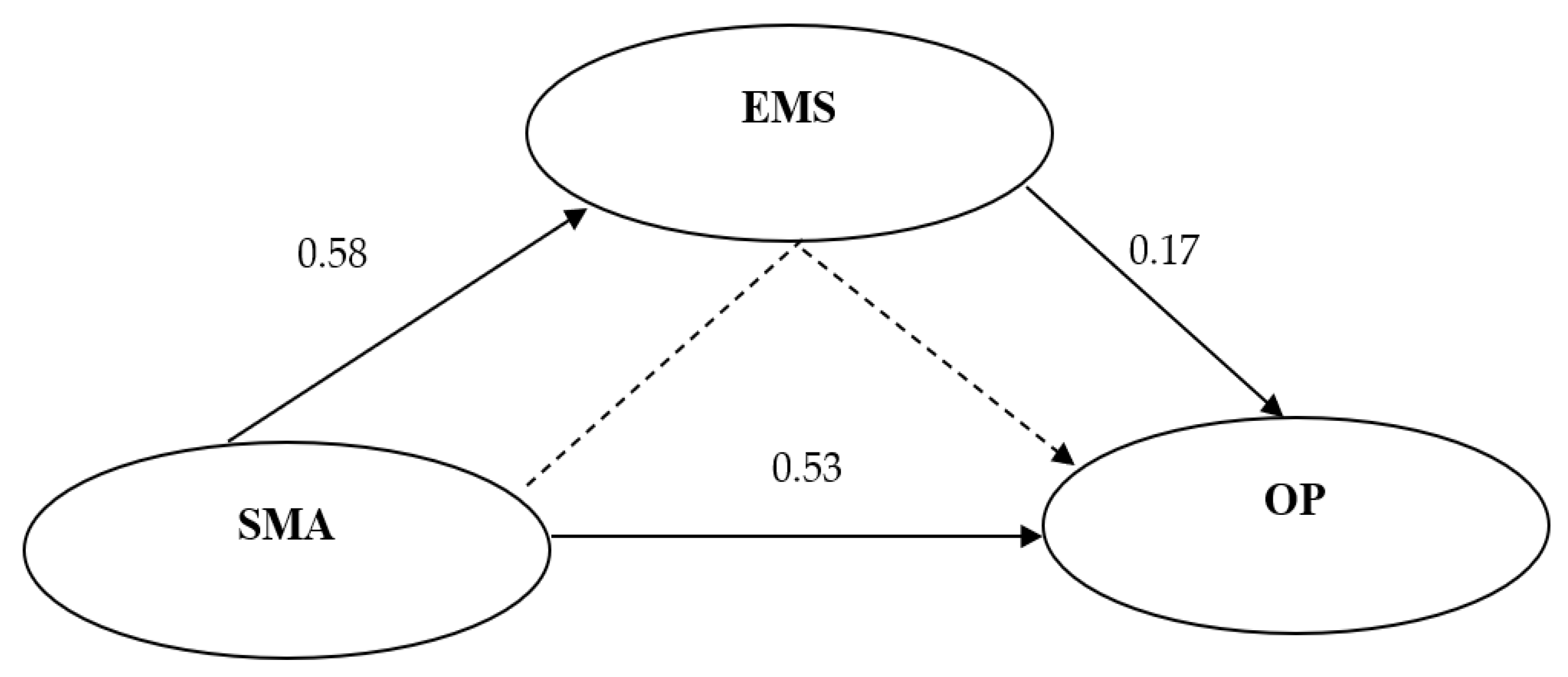

Table 6 shows that the result of indirect effects of SMA on OP is 0.271, which is more than 0.038. Since the p-value for the direct effect between SMA and OP was less than 0.050, the EMS can be considered a partial mediator. Thus, the EMS mediates the relationship between SMA and OP. These findings support H4, which states that the impact of SMA implementation on OP increased through EMS mediation (Figure 2).

Table 6.

The results of direct effect and indirect effect analysis (EMS).

Figure 2.

Conceptual model of the environmental management system as a mediator in the relationship of sustainability management accounting and organizational performance.

5. Discussion

Based on the findings, it is shown that Hypothesis 1 to Hypothesis 4 are accepted. The discussion of the results of the research focuses on four hypotheses: three direct relationships and one indirect relationship of the study. The discussion of the results of this research is in line with the objectives of this research study.

According to H1, there is a significant positive relationship between SMA and OP for the Malaysian manufacturing industry. This supports H1, which states that SMA has a significant relationship in OP for the Malaysian manufacturing industry. Thus, H1 states that SMA has a positive relationship with OP supported. Previous studies have consistently proven a link between SMA and OP [23,24,25]. Research conducted by Russell et al. [60] also showed that there is a significant relationship between these variables.

The result for H2 is 0.583 and a significance of p < 0.001, therefore H2 is accepted. According to H2, the findings suggest that there is a significant link between SMA and EMS for the Malaysian manufacturing industry. Therefore, H2 is accepted due to the positive and significant results of the relationship between SMA and EMS. Therefore, in this study, it is hypothesized that SMA has a positive effect on the EMS for the Malaysian manufacturing industry. Previous studies have proven that SMA has a direct impact on the EMS. To some extent, the results support previous research [44,50] by showing a direct link between SMA and the EMS. To improve SMA, an organization can use an EMS as a guideline for the Malaysian manufacturing industry. Therefore, SMA is an important determinant of EMSs for the Malaysian manufacturing industry.

The result for H3 shows that the relationship between EMS and OP is 0.168 and this is important with a p-value of 0.038, which is less than 0.050. Therefore, H3 is accepted. According to H3, the findings show a significant relationship between the EMS and OP for the Malaysian manufacturing industry. Therefore, it is hypothesized that the EMS provides a positive and significant link to OP for the Malaysian manufacturing industry. The results of EMS and OP in this study show a positive relationship between these variables. This result is consistent with previous research conducted in the manufacturing industry [61,62]. This study concludes that the implementation of an EMS can be positive to OP for the Malaysian manufacturing industry. In addition, the implementation of an EMS can increase OP [63,64,65]. Therefore, the results show that the implementation of an EMS can lead to better OP for organizations, especially for the Malaysian manufacturing industry.

Finally, the results of SMA, EMS, and OP were 0.271 > 0.038. Since the p-value between SMA and OP is less than 0.050, the EMS can be considered a partial mediator. Thus, the EMS mediates the relationship between SMA and OP. According to H4, the findings suggest there is a significant positive relationship between SMA, EMS, and OP for the Malaysian manufacturing industry. The results show a positive and indirect relationship, therefore H4 is accepted. Therefore, the EMS mediates the relationship between SMA and OP. The implementation of SMA and EMS is important to increase OP [66,67,68]. The implementation of the EMS as a guideline can help organizations to improve SMA and OP, especially for the Malaysian manufacturing industry. There are implications for the theoretical and practical implications that are discussed below.

5.1. Theoretical Implications

Based on the theoretical implications, the identification of the EMS is important for SMA and OP in the Malaysian manufacturing industry based on contingency theory. This research focuses on an EMS as a mediating variable in the relationship between SMA and OP for the Malaysian manufacturing industry. Empirical research was conducted to assess the relationship between SMA and OP, the relationship between SMA and EMS, the relationship between EMS and OP, and the EMS as a mediator between SMA and OP. The findings showed a significant association between SMA, EMS, and OP for the Malaysian manufacturing industry. Thus, the SMA, EMS, and OP relationships can help the Malaysian manufacturing industry to improve the company’s sustainability management accounting, especially in a dynamic environment [69,70].

5.2. Practical Implications

For practical implications, this research provides important guidelines for manufacturers and related companies to implement SMA, EMS, and OP. The findings from this research also provide useful guidelines for the Malaysian manufacturing industry, particularly in implementing an EMS. Therefore, the Malaysian manufacturing industry may need to consider SMA, EMS, and OP measurements that benefit their companies, especially for sustainability management accounting. In addition, it enhances our understanding of SMA, EMS, and OP. The results also provide a link between SMA, EMS, and OP. This study uses one mediating variable, the EMS, which is partially mediated between SMA and OP. These findings suggest that the Malaysian manufacturing industry may use the EMS as a guideline to improve SMA and OP. The conceptual framework developed in this study can be used as a guideline by manufacturers to implement new approaches that combine SMA, EMS, and OP. Findings from this study can be used by policymakers to identify the implementation of SMA by manufacturers in Malaysia in terms of policies and regulations.

6. Limitations, Future Research, and Conclusions

Some limitations in this study need to be acknowledged. First, the research used only five SMA dimensions and one mediator of EMS. It is possible that ongoing studies could combine more dimensions on SMA and EMS. Second, this research only used survey techniques and was conducted in the Malaysian manufacturing industry. In addition, although the research covered various sectors, the samples were only taken from Malaysia. Regarding the research methodology, the study is based on a quantitative approach through conducting a survey. Fourth, it is difficult to find some aspects for SMA and EMS issues in the management accounting literature. Another limitation of this study is the lack of literature on the relationship between SMA and EMS. However, the researchers assume that there is greater scope for investigations into SMA and EMS issues regarding OP relationships. An understanding of the importance of studying the relationship between SMA, EMS, and OP was emphasized in this study. In fact, the findings of this study together with its limitations have paved the way for future research in the field of SMA, EMS, and OP. The results of this study have provided valuable insight into the assessment of the relationship between SMA and EMS on OP for the Malaysian manufacturing industry. Therefore, the findings from this study offer useful guidelines to other industries in Malaysia in making decisions on the implementation of SMEs. One of the challenges in this study is that questionnaire answer rate was low. However, the minimum response rate of respondents was sufficient for this study. Another challenge that researchers had to face was to remind respondents to fill out the questionnaire within a set time frame. In future studies, researchers may need to consider sending questionnaires by mail, fax, telephone calls, or email. If necessary, the researcher may also need to follow up with the respondents to increase the response rate.

Author Contributions

N.M.F. focused on writing—original draft preparation, S.A. was in charge of the methodology, M.R.R. conducted the formal analysis, S.Y.Y.O. was in charge of writing—review and editing, J.O. prepared the conceptualization and resources, S.K. conducted the validation, S.Z.M.A. supervised, N.S.J. managed the project administration, and K.A. was in charge of investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Many thanks to all the contributions and support given by the authors in preparing the writing of this article.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Measurement Items of SMA.

Table A1.

Measurement Items of SMA.

| Measurement Items |

|---|

Environmental Cost

|

Environmental Regulation

|

Environmental Safety

|

Management Commitment

|

Table A2.

Measurement Items of EMS.

Table A2.

Measurement Items of EMS.

| Measurement Items |

|---|

Planning

|

Implementation and Operation

|

Auditing and Evaluation

|

Checking and Correction Action

|

Table A3.

Measurement Items of OP.

Table A3.

Measurement Items of OP.

| Measurement Items |

|---|

Financial Performance

|

Operational Performance

|

References

- Malaysian Investment Development Authority (MIDA). Available online: https://www.mida.gov.my/industries/manufacturing/ (accessed on 28 September 2022).

- Department of Statistics Malaysia. Gross domestic product (GDP) by state 2021. Available online: https://www.dosm.gov.my/v1/ (accessed on 28 September 2022).

- Jamil, C.Z.M.; Mohamed, R. Antecedent factors of environmental Manag. accounting practice. Int. J. Econ. Res. 2017, 14, 543–553. [Google Scholar]

- Low, H.H.; Tan, O.K.; Choi, S.L.; Husna, A.R.R. The adoption of environmental management system in Malaysia’s manufacturing organizations. J. Eco. Bus. Manag. 2015, 3, 93–97. [Google Scholar] [CrossRef]

- Phan, T.N.; Baird, K. The comprehensiveness of environmental management systems: The influence of institutional pressures and the impact on environmental performance. J. Environ. Manag. 2015, 160, 45–56. [Google Scholar] [CrossRef] [PubMed]

- Ong, T.S.; Teh, B.H.; Ng, S.H.; Soh, W.N. Environmental management system and financial performance. Inst. Econ. 2018, 8, 26–52. [Google Scholar]

- Jablin, F. The selection interview: Contingency theory and beyond. Hum. Resour. Manag. 1975, 14, 1–9. [Google Scholar] [CrossRef]

- Otley, D. The contingency theory of management accounting and control: 1980–2014. Manag. Account. Res. 2016, 31, 45–62. [Google Scholar] [CrossRef]

- Donaldson, L. Structural contingency theory. Int. Encycl. Soc. Behav. Sci. 2015, 2, 609–614. [Google Scholar]

- Hall, M. Realising the richness of psychology theory in contingency-based management accounting research. Manag. Account. Res. 2016, 31, 63–74. [Google Scholar] [CrossRef]

- Ong, T.S.; Teh, B.H.; Lee, A.S. Contingent factors and sustainable performance measurement (SPM) practices of Malaysian electronics and electrical companies. Sustainability 2019, 11, 1058–1091. [Google Scholar] [CrossRef]

- Al-Mawali, H.; Sharif, A.A.; Rumman, G.A.; Kerzan, F.; Liu, G. Environmental strategy, environmental management accounting and organizational performance: Evidence from the United Arab Emirates market. J. Environ. Account. Manag. 2018, 6, 109–118. [Google Scholar] [CrossRef]

- Ensslin, S.R.; Rodrigues, K.T.; Yoshiura, L.J.M.; da Silva, J.C.; Longaray, A.A. Organizational performance management and the ‘sustainability’ of the performance evaluation system: A view guided by the integrative review perspective. Sustainability 2022, 14, 11005. [Google Scholar] [CrossRef]

- Gadenne, D.; Mia, L.; Sands, J.; Winata, L.; Hooi, G. The influence of sustainability performance management practices on organisational sustainability performance. J. Account. Organ. Change 2012, 8, 210–235. [Google Scholar] [CrossRef]

- Gomes, P.; Mendes, S.M.; Carvalho, J. Impact of PMS on organizational performance and moderating effects of context. Int. J. Product. Perform. Manag. 2017, 66, 517–538. [Google Scholar] [CrossRef]

- Wang, Y.; Bhanugopan, R.; Lockhart, P. Examining the quantitative determinants of organizational performance: Evidence from China. Meas. Bus. Excell. 2015, 19, 23–41. [Google Scholar] [CrossRef]

- Al-Tit, A.A. Factors affecting the organizational performance of manufacturing firms. Int. J. Eng. Bus. Manag. 2017, 9, 1–9. [Google Scholar] [CrossRef]

- Zopf, C.; Guenther, E. Corporate performance: The need for application of multiple perspectives and theories to assess strategic and operational CEP. Ann. Soc. Responsib. 2015, 1, 131–194. [Google Scholar] [CrossRef]

- Adam, S.; Fuzi, N.M.; Ramdan, M.R.; Mat Isa, R.; Ismail, A.F.M.F.; Hashim, M.Y.; Ong, S.Y.Y.; Ramlee, S.I.F. Entrepreneurial orientation and organizational performance of online business in Malaysia: The mediating role of the knowledge management process. Sustainability 2022, 14, 5081. [Google Scholar] [CrossRef]

- Almatrooshi, B.; Singh, S.K.; Farouk, S. Determinants of organizational performance: A proposed framework. Int. J. Product. Perform. Manag. 2016, 65, 844–859. [Google Scholar] [CrossRef]

- Singh, S.; Darwish, T.K.; Potocnik, K. Measuring organizational performance: A case for subjective measures. Br. J. Manag. 2016, 27, 214–224. [Google Scholar] [CrossRef]

- Lo, M.C.; Wang, Y.C.; Wah, C.R.J. The critical success factors for organizational performance of SMEs in Malaysia: A partial least squares approach. Rev. Bus. Manag. 2016, 18, 370–391. [Google Scholar]

- Gunarathne, N.; Lee, K. Environmental management accounting (EMA) for environmental management and organizational change. J. Account. Organ. Change 2015, 11, 362–383. [Google Scholar] [CrossRef]

- Gunarathne, A.D.N.; Alahakoon, Y. Environmental management accounting practices and their diffusion: The Sri Lankan experience. J. Manag. 2016, 2, 1–26. [Google Scholar] [CrossRef]

- Zyznarska-Dworczak, B. The development perspectives of sustainable management accounting in central and Eastern European Countries. Sustainability 2018, 10, 1445. [Google Scholar] [CrossRef]

- Ann, G.E.; Zailani, S.; Wahid, N.A. A study on the impact of environmental management system (EMS) certification towards firms’ performance in Malaysia. Manag. Environ. Qual. Int. J. 2006, 17, 73–93. [Google Scholar]

- Farok, G.M.G.; Searcy, C. Analysis of ISO 14001: A balanced tool of environmental management system. Res. J. Agric. Environ. Manag. 2015, 4, 483–490. [Google Scholar]

- Feng, T.; Wang, D. The influence of environmental management systems on financial performance: A moderated-mediation analysis. J. Bus. Ethics 2016, 135, 265–278. [Google Scholar] [CrossRef]

- Feng, T.; Cai, D.; Wang, D.; Zhang, X. Environmental management systems and financial performance: The joint effect of switching cost and competitive intensity. J. Clean. Prod. 2016, 113, 781–791. [Google Scholar] [CrossRef]

- Voinea, C.L.; Hoogenberg, B.-J.; Fratostiteanu, C.; Azam Hashmi, H. The relation between environmental management systems and environmental and financial performance in emerging economies. Sustainability 2020, 12, 5309. [Google Scholar] [CrossRef]

- Tseng, C.-H.; Chang, K.-H.; Chen, H.-W. Strategic orientation, environmental management systems, and eco-innovation: Investigating the moderating effects of absorptive capacity. Sustainability 2021, 13, 2147. [Google Scholar] [CrossRef]

- Petrová, E.; Štofa, T.; Šoltés, M. Exploration of the factors that influence the implementation of environmental management systems—The case of Slovakia. Economies 2021, 9, 68. [Google Scholar] [CrossRef]

- Ociepa-Kubicka, A.; Deska, I.; Ociepa, E. Organizations towards the evaluation of environmental management tools ISO 14001 and EMAS. Energies 2021, 14, 4870. [Google Scholar] [CrossRef]

- Sari, R.N.; Pratadina, A.; Anugerah, R.; Kamaliah, K.; Sanusi, Z.M. Effect of environmental management accounting practices on organizational performance: Role of process innovation as a mediating variable. Bus. Process. Manag. J. 2020, 27, 1296–1314. [Google Scholar] [CrossRef]

- Magara, R.; Aming’a, N.N.; Momanyi, E. Effect of environmental accounting on company financial performance in Kisii county. Br. J. Econ. Manag. Trade 2015, 10, 1–11. [Google Scholar] [CrossRef]

- Ntalamia, W.L. Factors influencing adoption of environmental management accounting (EMA) practices among manufacturing firms in Nairobi, Kenya. J. Financ. 2017, 5, 1–16. [Google Scholar]

- Schaltegger, S.; Christ, K.L.; Wenzig, J.; Burritt, R.L. Corporate sustainability management accounting and multi-level links for sustainability—A systematic review. Int. J. Manag. Rev. 2022, 1, 1–22. [Google Scholar] [CrossRef]

- Smit, A.M.; Dikgwatlhe, P. Assessing the awareness of environmental management accounting in the mining industry in South Africa. Environ. Econ. 2015, 6, 115–122. [Google Scholar]

- Smit, A.M.; Kotzee, E. Investigating environmental management accounting in the chemical industry in South Africa. Invest. Manag. Financ. Innov. 2016, 13, 151–160. [Google Scholar]

- Song, H.; Zhao, C.; Zeng, J. Can environmental management accounting improve financial performance: An empirical study of A-shares listed companies in China. J. Clean. Prod. 2017, 141, 1051–1056. [Google Scholar] [CrossRef]

- Wijewardana, W.P. The adoption of environmental management accounting practices among manufacturing companies in Sri Lanka. Glob. Sci. J. 2017, 5, 95–104. [Google Scholar]

- Al-Darrab, I.A.; Gulzar, W.A.; Ali, K.S. Status of implementation of safety, quality and environmental management systems in Saudi Arabian industries. Total Qual. Manag. Bus. Excell. 2013, 24, 336–354. [Google Scholar] [CrossRef]

- Massoud, J.A.; Daily, B.F.; Bishop, J.W. Perceptions of environmental management systems: An examination of the Mexican manufacturing sector. Ind. Manag. Data Syst. 2011, 111, 5–19. [Google Scholar] [CrossRef]

- Hariz, S.; Bahmed, L. Assessment of environmental management system performance in the Algerian companies certified ISO 14001. Manag. Environ. Qual. Int. J. 2011, 24, 228–243. [Google Scholar] [CrossRef]

- Neves, F.D.O.; Salgado, E.G.; Beijo, L.A. Analysis of the environmental management system based on ISO 14001 on the American continent. J. Environ. Manag. 2017, 199, 251–262. [Google Scholar] [CrossRef]

- Zobel, T.; Malmgren, C. Evaluating the management system approach for industrial energy efficiency improvements. Energies 2016, 774, 774. [Google Scholar] [CrossRef]

- Herghiligiu, I.V.; Lupu, M.L.; Robledo, C.; Kobi, A. Research on the factors that determine the quality of environmental management systems implementation in the case of Romanian organizations. Environ. Eng. Manag. J. 2014, 13, 1893–1900. [Google Scholar] [CrossRef]

- Solovida, G.T.; Latan, H. Linking environmental strategy to performance: Mediation role of environmental management accounting. Sustain. Account. Manag. Policy J. 2017, 8, 595–619. [Google Scholar] [CrossRef]

- Solovida, G.; Rohman, A.; Ahmad, T. Environmental management accounting, environmental innovation and corporate environmental performance. Int. J. Res. Bus. Techol. 2015, 7, 1–10. [Google Scholar] [CrossRef]

- Prajogo, D.; Tang, A.K.Y.; Lai, K. The diffusion of environmental management system and its effect on environmental management practices. Int. J. Oper. Prod. Manag. 2014, 34, 565–585. [Google Scholar] [CrossRef]

- Jalil, M.H.; Abar, M.N.; Dadashian, F. Environmental management accounting model on the basis of environmental management system in leather industry. Int. J. Environ. Sci. Dev. 2016, 7, 52–58. [Google Scholar] [CrossRef][Green Version]

- Tabachnick, B.G.; Fidell, L.S. Using Multivariate Statistics; Pearson Education Inc.: Upper Saddle River, NJ, USA, 2019. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: A Global Perspective, 7th ed.; Pearson Education Inc.: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Krejcie, R.V.; Morgan, D.W. Determining sample size for research activities. Educ. Psychol. Meas. 1970, 30, 607–610. [Google Scholar] [CrossRef]

- Oke, A.E.; Ogunsami, D.R.; Ogunlana, S. Establishing a common ground for the use of structural equation modelling for construction related research studies. Aust. J. Constr. Econ. Build. 2012, 12, 89–94. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a silver bullet. J. Mark. Theory Pract. 2011, 19, 139–151. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Ramdan, M.R.; Abd Aziz, N.A.; Abdullah, N.L.; Samsudin, N.; Singh, G.S.V.; Zakaria, T.; Fuzi, N.M.; Ong, S.Y.Y. SMEs performance in Malaysia: The role of contextual ambidexterity in innovation culture and performance. Sustainability 2022, 14, 1679. [Google Scholar] [CrossRef]

- Samsudin, N.; Ramdan, M.R.; Abd Razak, A.Z.A.; Mohamad, N.; Yaakub, K.B.; Abd Aziz, N.A.; Hanafiah, M.H. Related factors in undergraduate students’ motivation towards social entrepreneurship in Malaysia. Eur. J. Educ. Res. 2022, 11, 1657–1668. [Google Scholar] [CrossRef]

- Russell, S.; Milne, M.J.; Dey, C. Accounts of nature and the nature of accounts: Critical reflections on environmental management accounting and propositions for ecologically informed accounting. Account. Audit. Account. J. 2017, 30, 1426–1458. [Google Scholar] [CrossRef]

- Herghiligiu, I.V.; Robu, I.-B.; Pislaru, M.; Vilcu, A.; Asandului, A.L.; Avasilcăi, S.; Balan, C. Sustainable environmental management system integration and business performance: A balance assessment approach using fuzzy logic. Sustainability 2019, 11, 5311. [Google Scholar] [CrossRef]

- Fuzi, N.M.; Habidin, N.F.; Adam, S.; Ong, S.Y.Y. Environmental management system and organizational performance in Malaysian manufacturing industry. Int. J. Acad. Res. Bus. Soc. Sci. 2021, 11, 664–669. [Google Scholar] [CrossRef]

- Pauliková, A.; Lestyánszka Škůrková, K.; Kopilčáková, L.; Zhelyazkova-Stoyanova, A.; Kirechev, D. Innovative approaches to model visualization for integrated management systems. Sustainability 2021, 13, 8812. [Google Scholar] [CrossRef]

- Ramli, A.; Ismail, M.S. Environmental management accounting practices: A survey of ISO 14001 certified Malaysian organizations. J. Energy Technol. Policy 2013, 3, 415–432. [Google Scholar]

- Abdul-Rashid, S.H.; Sakundarini, N.; Ghazilla, R.A.R.; Thurasamy, R. The impact of sustainable manufacturing practices on sustainability performance: Empirical evidence from Malaysia. Int. J. Oper. Prod. Manag. 2017, 37, 182–204. [Google Scholar] [CrossRef]

- Pilar, C.; Ballester, M.; Simon, A. Union is strength: The integration of ISO 9001 and ISO 14001 contributes to improve the firms’ financial performance. Manag. Decis. 2017, 55, 81–102. [Google Scholar]

- Olaoye, F.O.; Adekanmbi, J.A. Impact of environmental management accounting practices and report on organisation performance. Eur. J. Bus. Manag. 2018, 10, 74–84. [Google Scholar]

- Waxin, M.-F.; Knuteson, S.L.; Bartholomew, A. Outcomes and key factors of success for ISO 14001 certification: Evidence from an emerging Arab Gulf Country. Sustainability 2020, 12, 258. [Google Scholar] [CrossRef]

- Ramdan, M.R.; Abdullah, N.L.; Isa, R.M.; Hanafiah, M.H. Exploring factors influencing the use of digital platform by micro and small enterprises. UKM J. Manag. 2020, 59, 37–51. [Google Scholar]

- Ramdan, M.R.; Abdullah, N.L.; Isa, R.M.; Hanafiah, M.H. Organizational ambidexterity within supply chain management: A scoping review. LogForum 2021, 17, 531–546. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).