Abstract

Sustainability in additive manufacturing refers mainly to the recycling rate of polymers and composites used in fused filament fabrication (FFF), which nowadays are rapidly increasing in volume and value. Recycling of such materials is mostly a thermomechanical process that modifies their overall mechanical behavior. The present research work focuses on the acrylonitrile-butadiene-styrene (ABS) polymer, which is the second most popular material used in FFF-3D printing. In order to investigate the effect of the recycling courses on the mechanical response of the ABS polymer, an experimental simulation of the recycling process that isolates the thermomechanical treatment from other parameters (i.e., contamination, ageing, etc.) has been performed. To quantify the effect of repeated recycling processes on the mechanic response of the ABS polymer, a wide variety of mechanical tests were conducted on FFF-printed specimens. Regarding this, standard tensile, compression, flexion, impact and micro-hardness tests were performed per recycle repetition. The findings prove that the mechanical response of the recycled ABS polymer is generally improved over the recycling repetitions for a certain number of repetitions. An optimum overall mechanical behavior is found between the third and the fifth repetition, indicating a significant positive impact of the ABS polymer recycling, besides the environmental one.

1. Introduction

Nowadays, polymer materials hold an important role in the industry, thanks to their unique properties, such as a wide range of operating temperatures, high thermal/electrical insulation, corrosion-and light-resistance and sufficient mechanical properties (high strength-to-weight ratio, stiffness, toughness and ductility) [1]. However, one of the main issues for their use is the environmental impact of the plastic residues accumulated in the natural environment and in landfills, due to their longevity which can reach several decades (if not millennia) to degrade [2]. Worldwide, the production of plastics was 360 million tons in the year 2018 [3].

In the literature, strategies have been studied regarding the recycle and reuse of plastic waste and the economic benefits derived from these strategies, i.e., Peeters et al. reviewed the circular economy-based potential of personal polymer fabrication, clean production and industrial ecology by providing an in depth analysis of the complex relationships among the identified recycling barriers [4]. Plastic recycling is a pivotal aspect of the circular economy strategy worldwide [4]. Thus, in recent years, there has been an increasing amount of interest in the scientific community and entrepreneurial initiatives to propose solutions to tackle the issue of plastic wastes, including the use of plastic recycling for 3D printing purposes.

It was also proved that there is an economic benefit on the indoor recycling [5] of a vast variety of polymer wastes from, e.g., electronics, wastelands or even industries and schools [6]. Several researches focus on the recyclability of polymer wastes by extruding them and then injection molding them into new parts or specimens to examine their mechanical, physical and thermal properties [7,8,9,10,11,12,13,14]. Another novel strategy is to mix natural biodegradable material wastes, i.e., banana fibers [15,16] or mussel shells [17] with recycled polymer wastes, that can lead to the effective reduction of plastic waste.

Recycling is also applied in various types of additive manufacturing (AM) technologies, for both polymers and metal materials that are recycled in a form suitable for use in AM, i.e., powder and filament. In the laser sintering AM technology, there is a research interest regarding the recyclability of sintering powders that are heat-exposed from the initial sintering procedure. For Polyethylene Terephthalate (PET) powders [18], Polyamide (PA) powders [19], aluminum oxide powders [20,21] or even stainless steel powders [22,23], research proved that these type of materials offer excellent recyclability and scalability.

Research is also focusing on the recyclability of polymeric wastes into filaments ready to print in a household 3D printer [1,24], and more specifically on the recyclability and blending of common polymer wastes like low-and high-density polyethylene (LDPE/HDPE) found in shopping bags and bottles with natural recyclable fibers like hemp fibers and sand [2,24,25,26].

For the fused filament fabrication (FFF), the literature reports the fine recyclability of printed parts, filaments and the production of novel materials containing virgin and recycled materials in blends like Low-density Polyethylene (LDPE), High-density Polyethylene (HDPE), Polyethylene (PE), Polypropylene (PP) [27,28,29,30,31], Nylon [32,33] or even recycled tires [34]. Regarding the recycling of Polylactic Acid (PLA) filaments, research was focused more on obtaining a further insight into the mechanical properties of 3D-printed parts and showed that there is a slight reduction in the mechanical properties of 3D-printed parts using recycled materials in comparison with the ones using virgin materials [35,36,37,38,39].

Moreover, regarding the ABS filament recycling research, which has the most interest due to its large filament market share (Figure 1), studies showed that it can be easily recycled multiple times through extrusion systems and successfully re-utilized in 3D printers. Specific studies in the literature report a reduction in the mechanical properties of recycled ABS in all cases studied [40,41,42], while a few researchers report an increase in the mechanical properties after the second or third recycle course [43,44].

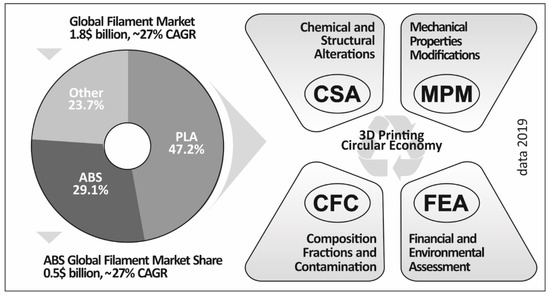

Figure 1.

3D printing circular economy critical parameters and global filament market volume in 2019 (market volume data source: https://www.marketwatch.com/).

The global 3D printing filament material market volume was 1.8 billion US$ in 2019, growing at a Compound Annual Growth Rate (CAGR) of 27% (Figure 1). The ABS filament is the second most popular material in the filament market, holding about 29% of the market, with a market share of about 0.5 billion US$. Thus, economically wise, it is considered necessary to evaluate the recyclability of the ABS material and further examine the mechanical and physical properties of the recycled material, to define their usability in FFF AM technology.

Furthermore, Figure 1 presents a 3D printing circular economy model, with the four main parameters affecting the process; that is, the chemical and structural alterations, mechanical properties modifications, composition fractions and contamination, and financial and environmental assessment. All these parameters are crucial for the economy of the recycling process and the material’s behavior after it is recycled.

This work focuses on the mechanical properties’ modifications due to recycling, by isolating the thermomechanical treatment from other parameters and experimentally studying various mechanical parameters of the recycled ABS polymer material. An experimental simulation has been developed, that accesses not only the indoor recyclability of ABS filament but also addresses and analyzes the mechanical properties of the recycled ABS filament in many recycling courses, to determine the effect of each thermomechanical treatment on the mechanical behavior of the material.

To address the effect of repeated recycling processes on the mechanic response of the ABS polymer via extrusion, a wide variety of mechanical tests were conducted on 3D-printed specimens including standard tensile testing, compression, flexion, impact and micro-hardness tests per recycle repetition. The findings prove that the mechanical response of the recycled ABS polymer is generally improved over the recycling repetitions, until the fifth repetition (and worsened in the sixth repetition), thus making the recycling of ABS waste a more inviting option. The recycling cost through this procedure is also estimated.

2. Materials and Methods

2.1. Materials

For the polymer matrix, acrylonitrile-butadiene-styrene (ABS) was selected and purchased from INEOS Styrolution. The ABS was industrial grade, delivered in a fine powder form, under the name Terluran Hi-10. The same quantity of raw material was used throughout the experimental course, and there was not any addition or blending of a virgin material at any stage of the present research. Before each step of the process, from powder to filament, from filament to masterbatch and from masterbatch to filament in each recycling course, the material was dried in a Memert industrial grade oven at 70 °C for 24 h.

2.2. Methods

2.2.1. Recycling Simulation and Experimental Course

For the current research, the ABS powder was used to produce a virgin ABS filament via the extrusion process. The produced filament passed through a quality control inspection to ensure that the tolerances in the required 1.75 mm diameter are within the extruder vendor specifications and that it has a smooth surface finish. Part of the initial ABS filament was used to produce the test specimens via 3D printing. The specimens were thoroughly measured and analyzed regarding their dimensions and their physical properties (i.e., color, surface finish). Tensile, compression, flexion, impact and micro-hardness tests were conducted in order to evaluate the mechanical properties of the 3D-printed virgin ABS specimens.

The remaining quantity was shredded into pellets and was then fed into the extrusion system, repeating the above process chain, in order to determine the mechanical properties of the 3D-printed ABS specimens of the first recycling course. The shredding process of the filament was performed with a 3devo shredder machine. According to the vendor specifications, the machine produces a masterbatch with a less than 4 mm size. Part of the re-extruded filament was employed to manufacture a new set of specimens which were also analyzed, while the remaining quantity of the filament was reprocessed into pellets for the next recycling course.

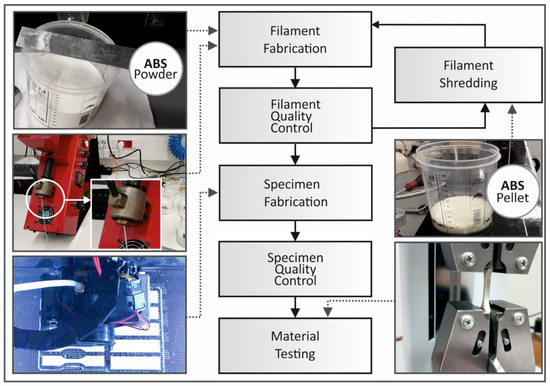

Specifically, 6 recycling processes (recycle courses) were performed. The implemented recycling simulation process is depicted in Figure 2 below. This process was followed in order to isolate the effect of the thermomechanical treatment on the polymer’s mechanical properties during the recycling process from other parameters, such as ageing, contamination and dirt.

Figure 2.

Recycling methodology flow chart followed in this work.

With this process, the filament undergoes one additional thermomechanical treatment in each recycle course. Additionally, in each recycle course, the material undergoes the 3D printing process, which also adds one more thermomechanical treatment to the process. So, in total in each recycle course, the material is thermomechanically treated the number of the recycle courses plus one more for the 3D printing process in each course.

The ABS filament in all recycle courses in this work was extruded through a Noztek Pro (from Noztek UK) single screw extruder and preheated at 350 °C, with a nozzle setup suitable for 3D printing filament production with a 1.75 mm diameter, provided by the extruder vendor. This working temperature was derived experimentally, with the extrusion system producing a constant 1.75 mm diameter filament with a good surface quality, while maintaining an uninterrupted extrusion flow. According to the specifications provided by the extruder vendor, the produced filament diameter tolerances are ± 0.04 mm, which was also verified with the sampling diameter measurements taken during the process. The filament was cooled with room temperature air and no cooling tubs were used, as this is not required, in order to produce a filament suitable for 3D printing, according to the extruder vendor. This was also verified by the fact that the produced filament was 3D printed with no issues during the process.

For the test scenarios studied, the specimens were manufactured using the same 3D printing parameters on a Flashforge inventor 3D printer. The specimens were built with a full infill (100% solid infill) with a honeycomb pattern at a 240 °C temperature, with the heat bed table of the 3D printer adjusted to 110 °C during the 3D printing process. The layer thickness used was 0.20 mm and the extrusion speed was set at 20 mm/s. All specimens were 3D printed in the horizontal orientation, as it is shown in Figure 2, and they were then tested for the determination of their mechanical properties in room temperature. The real density of the 3D-printed specimens was experimentally determined to be on average 1.18 g/mL, with a 0.05 g/mL deviation.

2.2.2. Tensile Specimens’ Fabrication and Testing

The specimens for the tensile tests were manufactured according to the ASTM D638-02a standard (type V specimens with 3.2 mm thickness). In total, 42 specimens were built consisting of 7 specimens for each recycle case scenario. The tensile tests were performed using an Imada MX2 tension/compression test device in the tension mode set up, using standardized grips. The tensile test machine chuck was set to a 10 mm/min speed for testing (Figure 3a).

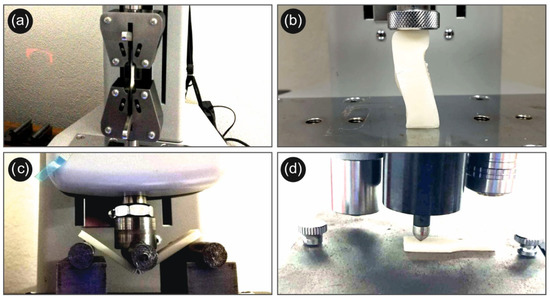

Figure 3.

(a) Tensile testing apparatus and procedure; (b) compression apparatus and procedure; (c) flexion experimental procedure; and (d) micro-hardness Vickers experimental procedure.

2.2.3. Compression Specimens’ Fabrication and Testing

The compression specimens specified in the ASTM D695-02a standard were manufactured with a 50.8 mm length, 12.7 mm width and 12.7 mm thickness. Seven specimens were tested for each case studied, to comply with the ASTM D695-02a standard, which requires at least 5 specimens to be tested for each case. The compressive tests were performed using a Schenk Trebel Co. tension/compression test machine, according to the ASTM D695 standard. CLG-2B load cells with a 2-ton capacity, 1 Kp sensitivity and 0.5% accuracy of the applied load were used to measure the forces during the experiments, while sensors (Sokki Kenkyujo Co. Ltd.: Tokyo, Japan) were online. An SDP-100c strain gauge (extensometer, capacity 100 mm, sensitivity 0.01 mm and nonlinearity 0.2% rated output-RO) was also used to record strain. The micro sensors (Kyowa Co. Ltd.: Okinawa, Japan) for the strain measurement were connected through a bridge circuit. Sensors were logged with Labview. The test machine’s chuck was set at the test speed prescribed by ASTM D695, i.e., 5 mm/min (Figure 3b).

2.2.4. Flexion Specimens’ Fabrication and Testing

The specimens for the flexural tests were 3D-printed, according to the ASTM D790 standard (64 mm length, 12.4 mm width, and 3.2 mm thickness). In total, 42 specimens were built consisting of 7 specimens for each case. The flexural tests were performed using an Imada MX2 in the flexion mode set up. The machine chuck was set at a 10 mm/min speed for testing (Figure 3c).

2.2.5. Impact Specimens’ Fabrication and Testing

The impact specimens were built according to the ASTM D6110 standard, measuring 80 mm in length, 8 mm in width and 10 mm in thickness. In total, 42 specimens were built. The specimens were all built with the ASTM standard’s impact notch. In these series of experiments, a Terco MT 220 Charpy’s apparatus was employed. The apparatus’s hammer was released from the same height for each experiment scenario in order to evaluate the impact energy. The initial hammer’s angle was set at 162° for all the implemented experiments.

2.2.6. Micro-Hardness Measurements

Regarding the micro-hardness, the specifications of the ASTM E384-17 standard were followed. The applied method was the micro-Vickers one, with a 0.2 kg force scale (1.962 N) and 10 s indentation time. The typical Vickers diamond pyramid was used as an indenter (apex angle of 136°), which was forced onto a polished surface of the specimens. The area of the remaining indentation, after the removal of the diamond pyramid, is calculated directly by the device, from the remaining imprint’s mean average of the diagonals. Experiments were held with the aid of an Innova Test 400-Vickers apparatus. Figure 3d shows the typical setup of the experimental tests conducted in this work (Figure 3d).

2.2.7. Morphological Characterization

In the cases that the fracture mode of the tested materials was to be further documented (especially in tension), a scanning electron microscopy (SEM) characterization was carried out. The SEM analysis was performed using a JEOL JSM 6362LV electron microscope in the high-vacuum mode at a 5 kV acceleration voltage on the uncoated samples.

2.2.8. Differential Scanning Calorimetry (DSC) Analysis

Differential scanning calorimetry (DSC) was performed in the virgin ABS polymer and after each recycling course in order to obtain information about the effect of recycling on the glass transition temperature (Tg) of the polymer. The measurements were taken via a Perkin Elmer Diamond DSC with a temperature cycle of 50 to 350 °C, with a heating step of 10 °C/min, and then cooled back down to 50 °C.

3. Results

3.1. Tension Results

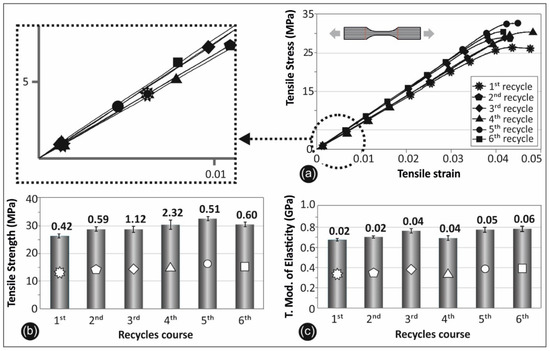

In Figure 4, the tensile mechanical behavior results of the virgin and recycled ABS are presented. More specifically, in Figure 4a, the tensile stress vs. strain curves for each studied recycle course are summarized. A specific specimen of each course is presented (in all cases, specimen number 3 was selected). Figure 4b presents the average value and the deviation of the tensile strength results for all the recycle courses, while Figure 4c depicts the average value and the deviation of the tensile modulus of elasticity values for the aforementioned recycle courses.

Figure 4.

Recycle courses’ comparative graph: (a) tensile stress vs. strain; (b) tensile strength; (c) and tensile modulus of elasticity.

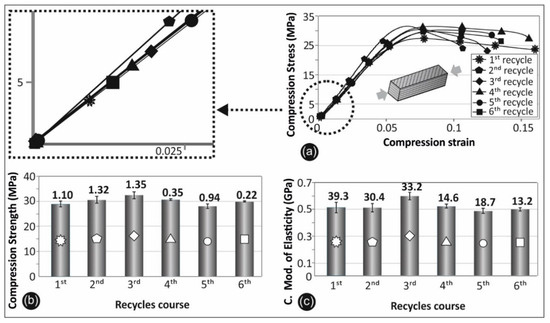

3.2. Compression Results

In Figure 5, the results of the compression mechanical behavior of the virgin and recycled ABS are presented. More specifically, in Figure 5a, the compression stress vs. strain curves for each studied recycle course are summarized for a specific specimen of each course (in all cases, specimen number 3 was selected). Figure 5b presents the average value and the deviation of the compressive strength results for all the recycle courses, while Figure 5c depicts the average value and the deviation of the compressive modulus of elasticity values for the aforementioned recycle courses.

Figure 5.

Recycles courses’ comparative graph: (a) on compressive stress vs. strain; (b) compressive strength; and (c) compressive modulus of elasticity.

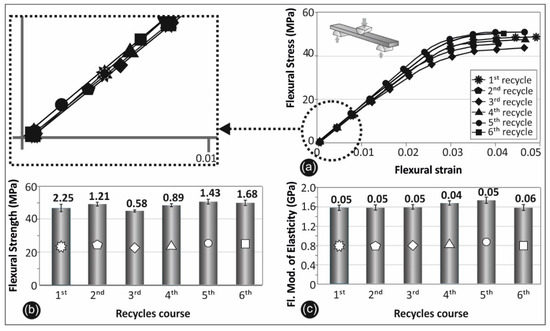

3.3. Flexion Results

In Figure 6, the results of the flexural mechanical behavior of the virgin and recycled ABS are presented. More specifically, in Figure 6a, the flexural stress vs. strain curves for each studied recycle course are summarized for a specific specimen of each course (in all cases, specimen number 3 was selected). Figure 6b presents the average value and the deviation of the flexural strength results for all the recycle courses, while Figure 6c depicts the average value and the deviation of the flexural modulus of elasticity values for the aforementioned recycle courses.

Figure 6.

Recycles courses’ comparative graph: (a) flexural stress vs. strain; (b) flexural strength; and (c) flexural modulus of elasticity.

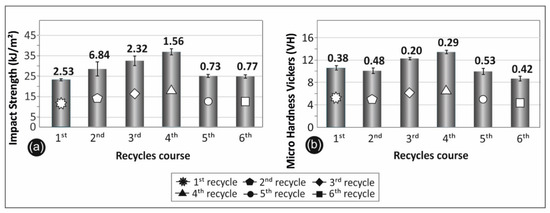

3.4. Impact and Micro-Hardness Results

Regarding the impact testing, the results are summarized in Figure 7a, while the results of the micro-hardness tests are depicted in Figure 7b.

Figure 7.

Results for all the recycle courses studied: (a) impact strength; and (b) micro-hardness Vickers.

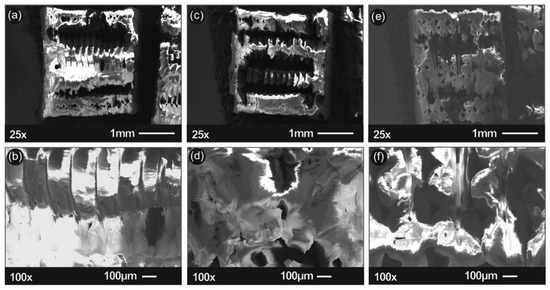

3.5. Morphological Characterization

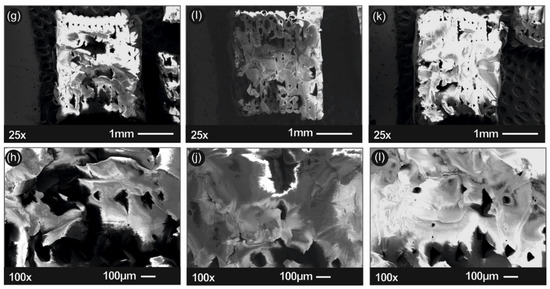

Regarding the morphological characterization of the studied ABS specimens, SEM images of the representative tensile specimens’ fracture area are presented in Figure 8 and Figure 9.

Figure 8.

SEM images of the tensile fracture area of the representative specimens for 1st (a,b), 2nd (c,d) and 3rd (e,f) recycle course.

Figure 9.

SEM images of the tensile fracture area of the representative specimens for 4th (g,h), 5th (i,j) and 6th (k,l) recycle course.

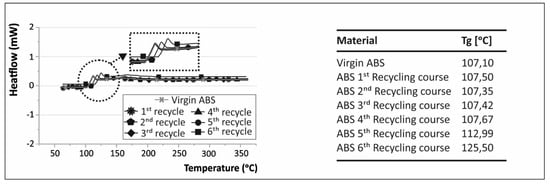

3.6. DSC Analysis Results

The DSC analysis results are summarized in Figure 10.

Figure 10.

The differential scanning calorimetry (DSC) curves for the virgin and recycled acrylonitrile-butadiene-styrene (ABS) and the Tg temperatures determined in the DSC analysis for the materials studied.

4. Discussion

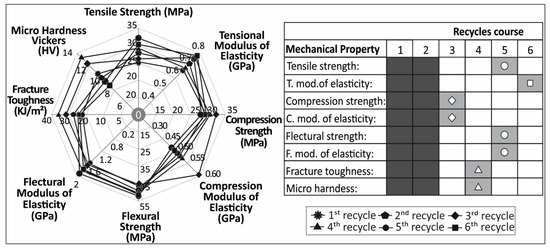

The mechanical properties of the 3D-printed specimens with the virgin ABS polymer have been thoroughly studied and discussed in the literature [45,46,47,48], with the results of the current study for the virgin ABS mechanical properties being in good agreement with the literature, as it is analyzed in detail below. The overall results on the mechanical properties of the virgin and recycled ABS showed an increase in the mechanical properties until the fifth recycling course. More specifically, in tensile strength, there was an increase of 20% reported on the 3D-printed specimens of the fifth recycle course, when directly compared with the virgin ABS printed specimens. An increase is evident in the compression strength of the third recycle course specimens by 12%. An increase of 8% was found in the specimens of the fifth recycle course as well, regarding their flexion strength. Moreover, the impact strength results showed a remarkable 59% increase in the impact strength in the specimens of the fourth recycle course, when compared with the first recycle course specimens. Finally, regarding the micro-hardness, there was an increase of 27% in the specimens of the fourth recycle course. The total results on the mechanical properties of the virgin and recycled ABS are summarized in Figure 11 below.

Figure 11.

Overall results on the mechanical properties of the virgin and recycled ABS in the 6 recycle courses studied.

Regarding the tensile modulus of elasticity (Figure 4c), it was shown that the values of all courses were similar. The peak value for the tensile modulus was found in the fifth recycle chain, with an increase of 15% when compared with the first recycle course. The values of the flexural modulus of elasticity (Figure 6c) follow a similar pattern as the peak value appears also on the fifth recycle course, with an increase of 15.8% when compared with the first course. Finally, regarding the compression modulus of elasticity (Figure 5c), the highest value was present on the third recycling course, with an increase of 16.7% compared with, as always, the initial course.

The mechanical properties values of the virgin ABS found in the current work are similar to the values reported in the other literature studies. More specifically, Chacon et al. [49] reports tensile strength values for virgin 3D-printed ABS specimens of 36–71.6 MPa, tensile modulus of elasticity of 99.7–2413 MPa, flexural strength of 48–110 MPa and finally flexural modulus of elasticity of 1917–2507 MPa. It is evident that the polymeric 3D-printed specimens exhibit a large degree of anisotropy, depending on the printing system and of course the polymer itself (additives).

Regarding the mechanical properties of the recycled ABS in the literature, Garcia et al. [11] investigated the recycling of an ABS filament and the mechanical properties of injection molded specimens. It was found that the tensile strength increases, reaching its peak value at the third recycling course (36.54 MPa), with an increase of 13% compared with a virgin ABS filament (32.26 MPa).

Similar results were reported by Hirayama et al. [44]. The tensile strength values and modulus of elasticity on the recycled virgin ABS were increased by 1.5%, while a drop in the impact strength of 300% was also reported. Furthermore, a slight increase of 4% in the tensile strength of recycled ABS filament specimens was also found in the work of Woern et al. [43].

Moreover, regarding the recycling of extruded ABS FFF specimens, Mohammed et al. [42] reported a reduction of 14.5% in the tensile strength of recycled ABS specimens when compared with virgin ABS specimens. Those values were found depending on the deposition orientation. A similar decrease was also found in PLA recycling in the work of Zhao et al. [50], who reported a 1% decrease in the tensile strength and a 3% decrease in the flexural strength and flexural modulus of elasticity. The morphological characterization showed a change in the fracture mode of the specimens when compared with the recycling courses. More specifically, there seemed to be no significant change in the layer deposition and the fusion of each layer with the increase of the recycling courses, but there was a change in the fracture mode making the specimens of the sixth recycling course more brittle (Figure 9k) when compared with the first recycling course specimens. This finding can be also be validated from the tensile stress and strain curves in Figure 4a. No literature is yet available for 3D-printed ABS specimens from recycled filament regarding the fracture toughness and micro-hardness Vickers properties.

The increase in the mechanical properties of the specimens until the fifth cycle and the decrease in the sixth cycle can be justified due to the assumption that the first polymer thermal cycling courses cause re-alignment of the amorphous polymer chains, thus increasing the molecule interactions, stability and overall mechanical response of the polymer. After the fifth recycling course, chemical degradation takes place, breaking parts of the polymer chains, which is responsible for the decrease in the mobility of the ABS chains and increase in the Tg temperature of the polymer [51,52]. This assumption was also verified by the DSC analysis performed, in which it was shown that for almost every case studied, the Tg temperature had no significant variation until the fifth recycling course, when the Tg starts to increase.

Recycling has important benefits for the environment. This work shows that the recycling of the ABS polymer does not affect its mechanical properties for up to five recycling courses, with an increase in its mechanical strength expected. The efficiency of the process, apart from the environmental impact, depends highly on its cost. The cost of the ABS powder for the filament production is about 5 €/kg, while the ABS filament costs about 50 €/kg. So, the proposed process should have a retail cost on the recycled filament produced less than this amount.

The cost of the recycled process depends on the cost of the equipment and the labor cost. The higher the cost of the equipment (extruder, shredder, etc.), the higher the production value per day, making the process more efficient. Various types of ABS items can be recycled with this process, from misprints, to faulty filament, masterbatch and plastic parts of items that are no longer operational. An entry level shredder costs about 2000 €. A 1500 € extruder can produce up to 4 Kg of filament per day, while a 5000 € extruder can produce up to 20 Kg of filament per day. One worker costs about 100 €/day and can operate more than one extruder on a daily basis. Assuming a production with two 5000 € extruders, one worker and a shredder, the daily production can be 40 Kg of ABS filament. The labor cost per Kg for this production is 2.5 €, with the rest of the operating costs (power cost, building costs, machines maintenance and depreciation) roughly estimated at 5 €. So, the cost for the filament production in this case is roughly 7.5 €/Kg, making the process efficient for the market.

5. Conclusions

In this work, standard tensile, compression, flexion, impact and micro-hardness tests were performed per ABS filament recycle repetition for six recycling courses, in order to evaluate the effect of the thermomechanical treatment on the ABS polymer during the recycling process. The above findings prove that the mechanical response of the recycled ABS polymer is generally improved over the recycling repetitions for a certain number of repetitions. An optimum overall mechanical behavior is found between the third and the fifth repetition, indicating a significant positive impact of the ABS polymer recycling, besides the environmental and the economy sectors.

It became evident that the recycling courses alter the mechanical properties of ABS, resulting in an average 30% increase in all mechanical properties studied herein, between the third and fifth recycle courses, while the polymer seems to be rapidly degraded after the fifth recycling course. The next steps based upon this work are to study the structuring, morphology and thermal properties changes of ABS filament throughout this recycling process.

Author Contributions

Conceptualization, N.V. and E.K.; methodology, A.M. and M.P.; validation, A.M. and A.V.; formal analysis, N.V. and J.K.; investigation, M.P. and J.K.; resources, N.V. and E.K.; data curation, N.V., M.P. and A.M.; writing—original draft preparation, A.M.; writing—review and editing, N.V., M.P.; visualization, A.M.; supervision, N.V., J.K.; project administration, N.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

Authors would like to thank Hellenic Mediterranean University, Mechanical Engineering Department student Maria Kolotourou for her contribution in the implementation of this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Association of Plastics Manufacturers, Plastics—The Facts 2019. Available online: https://www.plasticseurope.org (accessed on 20 April 2020).

- Peeters, B.; Kiratli, N.; Semeijn, J. A barrier analysis for distributed recycling of 3D printing waste: Taking the maker movement perspective. J. Clean. Prod. 2019, 241, 118313. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Santander, P.; Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M. Closed loop supply chain network for local and distributed plastic recycling for 3D printing: A MILP-based optimization approach. Resour. Conserv. Recycl. 2020, 154, 104531. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Rahimi, M.; Esfahanian, M.; Moradi, M. Effect of reprocessing on shrinkage and mechanical properties of ABS and investigating the proper blend of virgin and recycled ABS in injection molding. J. Mater. Process. Technol. 2014, 214, 2359–2365. [Google Scholar] [CrossRef]

- Mao, N.D.; Thanh, T.D.; Thuong, N.T.; Grillet, A.C.; Kim, N.H.; Lee, J.H. Enhanced mechanical and thermal properties of recycled ABS/nitrile rubber/nanofil N15 nanocomposites. Compos. Part B Eng. 2016, 93, 280–288. [Google Scholar] [CrossRef]

- Scaffaro, R.; Botta, L.; Di Benedetto, G. Physical properties of virgin-recycled ABS blends: Effect of post-consumer content and of reprocessing cycles. Eur. Polym. J. 2012, 48, 637–648. [Google Scholar] [CrossRef]

- García, M.D.G.T.; Schlatter, M.; Cabrera, F.M.; Manzanares, J.T.; Hanafi, I. Recycling of Acrylonitrile-butadiene-styrene Using Injection Moulding Machine. Procedia Technol. 2016, 22, 399–406. [Google Scholar]

- Manisha, M.; Gurjara, D.; Sharmaa, S.; Akasha, A.; Sarkara, M. A Review on testing methods of recycled Acrylonitrile Butadiene-Styrene. Mater. Today Proc. 2018, 5, 28296–28304. [Google Scholar] [CrossRef]

- Matias, Á.A.; Lima, M.S.; Pereira, J.; Pereira, P.; Barros, R.; Coelho, J.F.J.; Serra, A.C. Use of recycled polypropylene/poly(ethylene terephthalate) blends to manufacture water pipes: An industrial scale study. Waste Manag. 2020, 101, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Singh, R.; Ahuja, I.P.S.; Farina, I.; Fraternali, F. Metal matrix composite from recycled materials by using additive manufacturing assisted investment casting. Compos. Struct. 2019, 207, 129–135. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Singh, P. Prospect of 3D Printing for Recycling of Plastic Product to Minimize Environmental Pollution; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780128035818. [Google Scholar]

- Ortega, Z.; Monzón, M.; Paz, R.; Suárez, L. Banana Fiber Processing for the Production of Technical. Sustain. Des. Manuf. 2017. Smart Innov. Syst. Technol. 2017, 3, 11. [Google Scholar]

- Sauerwein, M.; Doubrovski, E.L. Local and recyclable materials for additive manufacturing: 3D printing with mussel shells. Mater. Today Commun. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Gu, H.; Bashir, Z.; Yang, L. The re-usability of heat-exposed poly (ethylene terephthalate) powder for laser sintering. Addit. Manuf. 2019, 28, 194–204. [Google Scholar] [CrossRef]

- Feng, L.; Wang, Y.; Wei, Q. PA12 powder recycled from SLS for FDM. Polymers (Basel) 2019, 11, 727. [Google Scholar] [CrossRef]

- Azuaje, J.; Tubío, C.R.; Escalante, L.; Gómez, M.; Guitián, F.; Coelho, A.; Caamaño, O.; Gil, A.; Sotelo, E. An efficient and recyclable 3D printed α-Al2O3 catalyst for the multicomponent assembly of bioactive heterocycles. Appl. Catal. A Gen. 2017, 530, 203–210. [Google Scholar] [CrossRef]

- Asgari, H.; Baxter, C.; Hosseinkhani, K.; Mohammadi, M. On microstructure and mechanical properties of additively manufactured AlSi10Mg_200C using recycled powder. Mater. Sci. Eng. A 2017, 707, 148–158. [Google Scholar] [CrossRef]

- Melugiri-Shankaramurthy, B.; Sargam, Y.; Zhang, X.; Sun, W.; Wang, K.; Qin, H. Evaluation of cement paste containing recycled stainless steel powder for sustainable additive manufacturing. Constr. Build. Mater. 2019, 227, 116696. [Google Scholar] [CrossRef]

- Gorji, N.E.; O’Connor, R.; Mussatto, A.; Snelgrove, M.; González, P.G.M.; Brabazon, D. Recyclability of stainless steel (316 L) powder within the additive manufacturing process. Materialia 2019, 8, 100489. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R. Prospect of Recycling of Plastic Product to Minimize Environmental Pollution; Elsevier Ltd.: Houston, TX, USA, 2020; ISBN 9780128035818. [Google Scholar]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling meal-ready-to-eat (MRE) pouches into polymer filament for material extrusion additive manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Suárez, L.; Domínguez, M. Sustainability and environmental impact of fused deposition modelling (FDM) technologies. Int. J. Adv. Manuf. Technol. 2020, 106, 1267–1279. [Google Scholar]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D printing of high density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.T.; Khalid, M.; Yang, T.C.K.; Hung, S.T.; Huang, C.M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Chong, S.; Yang, T.C.K.; Lee, K.C.; Chen, Y.F.; Juan, J.C.; Tiong, T.J.; Huang, C.M.; Pan, G.T. Evaluation of the physico-mechanical properties of activated-carbon enhanced recycled polyethylene/polypropylene 3D printing filament. Sadhana Acad. Proc. Eng. Sci. 2020, 45, 10–15. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Holzer, C.; Gonzalez-Gutierrez, J. Mechanical recyclability of polypropylene composites produced by material extrusion-based additive manufacturing. Polymers (Basel) 2019, 11, 1318. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R.; Fabbrocino, F.; Fraternali, F. Thermal characterization of recycled polymer for additive manufacturing applications. Compos. Part B Eng. 2016, 106, 42–47. [Google Scholar] [CrossRef]

- Farina, I.; Singh, N.; Colangelo, F.; Luciano, R.; Bonazzi, G.; Fraternali, F. High-Performance Nylon-6 Sustainable Filaments for Additive Manufacturing. Materials (Basel) 2019, 12, 3955. [Google Scholar] [CrossRef]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An Additive Manufacturing Solution to Produce Big Green Parts from Tires and Recycled Plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A comparison between mechanical properties of specimens 3D printed with virgin and recycled PLA. Procedia CIRP 2019, 79, 143–146. [Google Scholar]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled poly(lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 8, 1–12. [Google Scholar]

- Zhao, X.G.; Hwang, K.J.; Lee, D.; Kim, T.; Kim, N. Enhanced mechanical properties of self-polymerized polydopamine-coated recycled PLA filament used in 3D printing. Appl. Surf. Sci. 2018, 441, 381–387. [Google Scholar]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled glass fiber composites fromwind turbine waste for 3D printing feedstock: Effects of fiber content and interface on mechanical performance. Materials (Basel) 2019, 12, 3929. [Google Scholar]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of Closed-Loop Manufacturing with Acrylonitrile Butadiene Styrene over Multiple Generations Using Additive Manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar]

- Goutham, R.; Veena, T.R.; Babagowda; Prasad, K.R.S. Study on mechanical properties of recycled Acrylonitrile Butadiene Styrene (ABS) blended with virgin Acrylonitrile Butadiene Styrene (ABS) using Taguchi method. Mater. Today Proc. 2018, 5, 24836–24845. [Google Scholar]

- Mohammed, M.I.; Das, A.; Gomez-kervin, E.; Wilson, D.; Gibson, I. EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; pp. 532–542. [Google Scholar]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused particle fabrication 3-D printing: Recycled materials’ optimization and mechanical properties. Materials (Basel) 2018, 11, 1413. [Google Scholar]

- Hirayama, D.; Saron, C. Morphologic and mechanical properties of blends from recycled acrylonitrile-butadiene-styrene and high-impact polystyrene. Polymer (Guildf) 2018, 135, 271–278. [Google Scholar]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of fiberglass wind turbine blades into reinforced filaments for use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Vidakis, N.; Vairis, A.; Petousis, M.; Savvakis, K.; Κechagias, J. Fused Deposition Modelling Parts Tensile Strength Characterisation. Acad. J. Manuf. Eng. 2016, 14, 87–94. [Google Scholar]

- Vidakis, N.; Maniadi, A.; Petousis, M.; Koudoumas, E.; Kenanakis, G. Mechanical and Electrical Properties Investigation of 3D-Printed Acrylonitrile-butadiene-styrene Graphene and Carbon Nanocomposites. J. Mater. Eng. Perform. 2020. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A parametric determination of bending and Charpy’s impact strength of ABS and ABS-plus fused deposition modeling specimens. Prog. Addit. Manuf. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: Effect of process parameters on mechanical properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Hamming, L.M.; Qiao, R.; Messersmith, P.B.; Brinson, L.C. Effects of dispersion and interfacial modification on the macroscale properties of TiO(2) polymer matrix nanocomposites. Compos. Sci. Technol. 2009, 69, 1880–1886. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Heijmansa, T.; Bennekom, S.; Woldhuis, H.; Wijniab, S.; Witha, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modelling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).