Compressive Behavior of Sustainable Steel-FRP Composite Bars with Different Slenderness Ratios

Abstract

1. Introduction

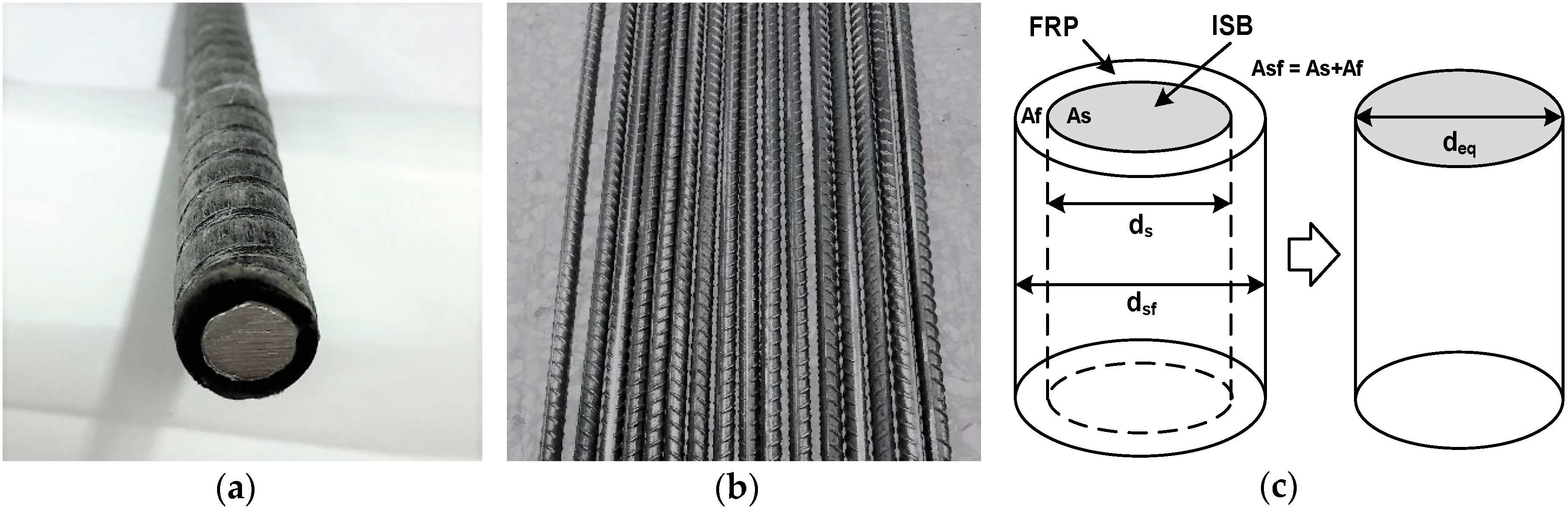

2. Equivalent Flexural Stiffness Principle of the SFCB

3. Experimental Program

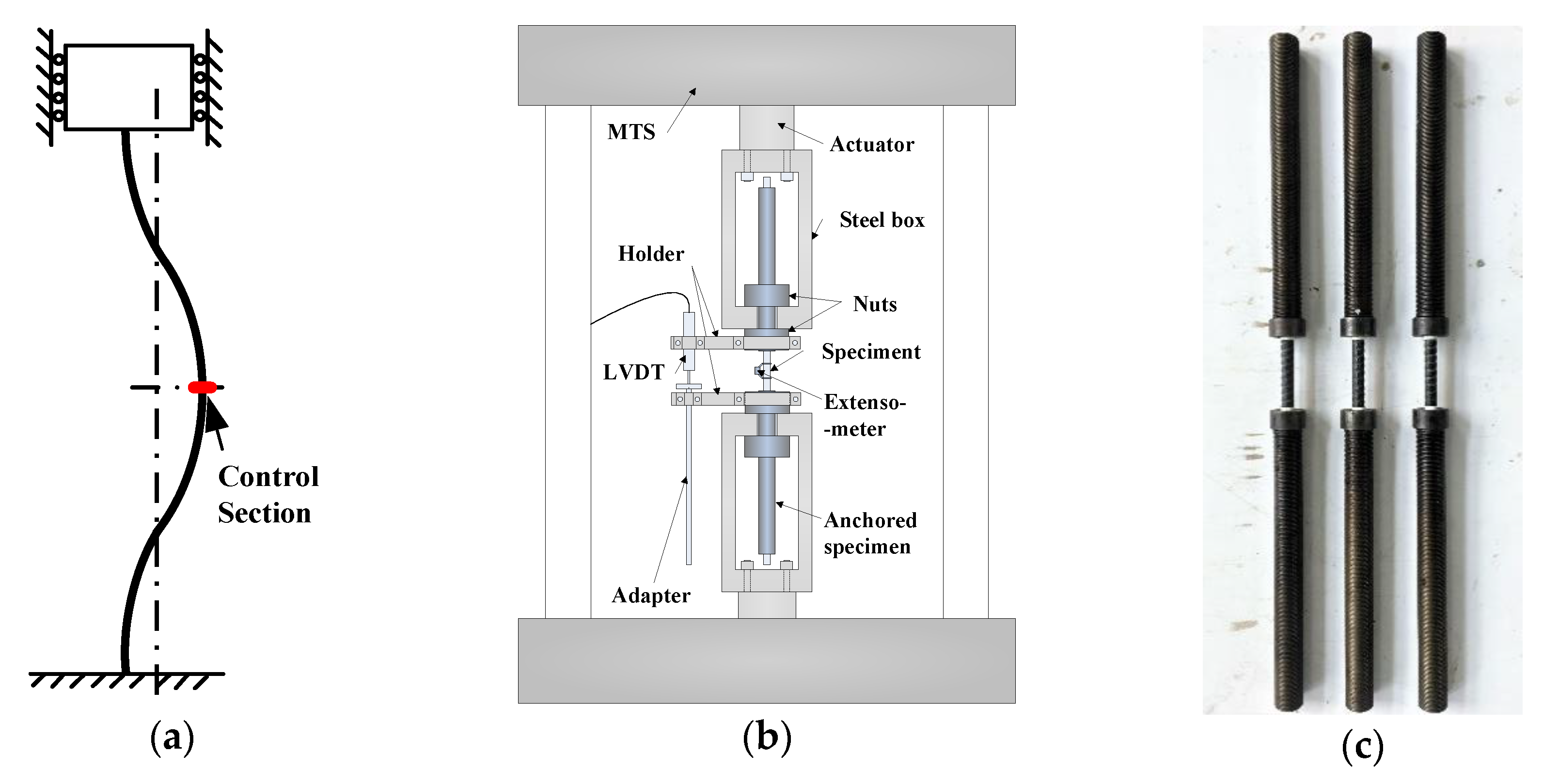

3.1. Test Instruments

3.2. Specimen Design

3.3. Loading Program

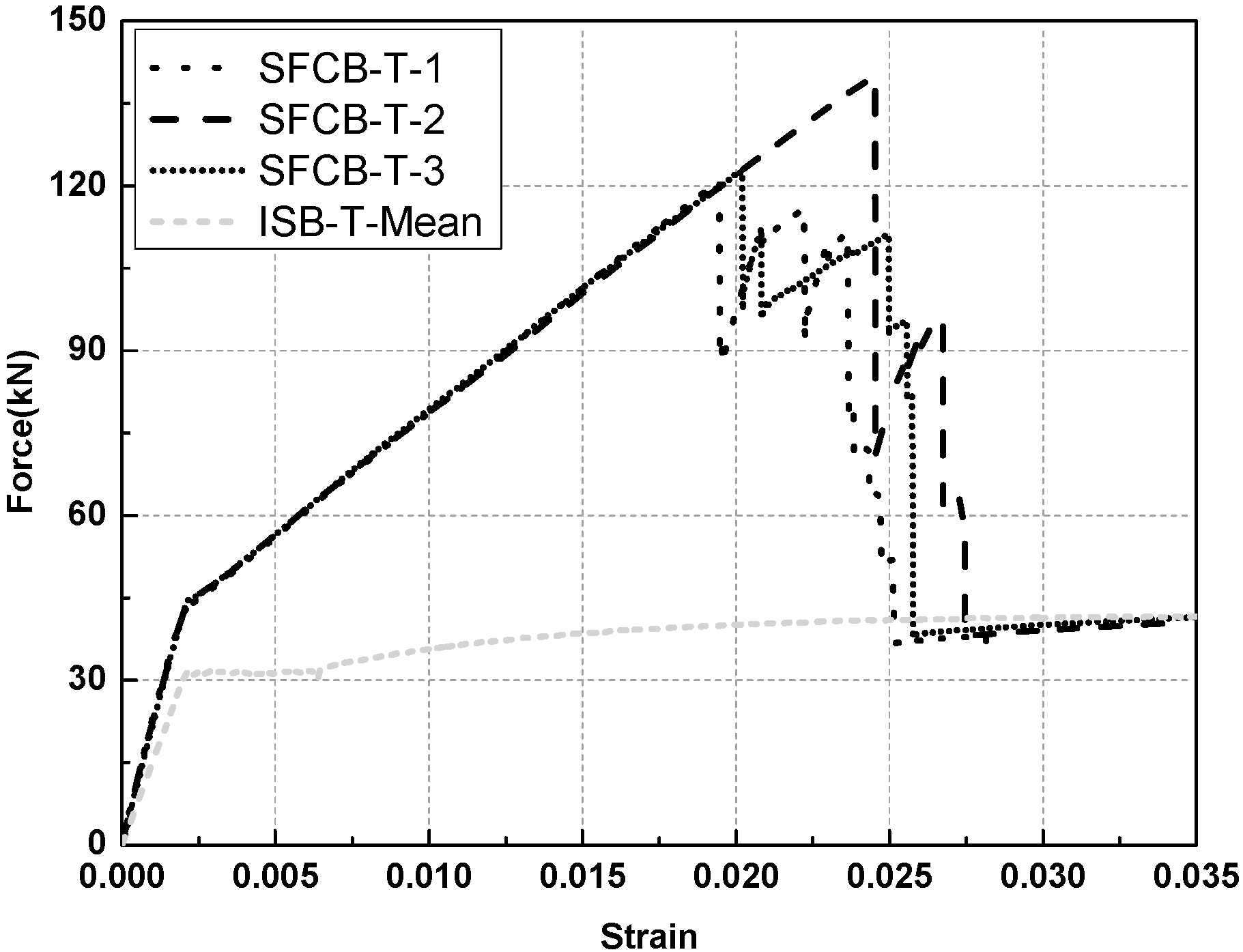

4. Uniaxial Tensile Properties of the SFCB

5. Uniaxial Compressive Behavior of the SFCB

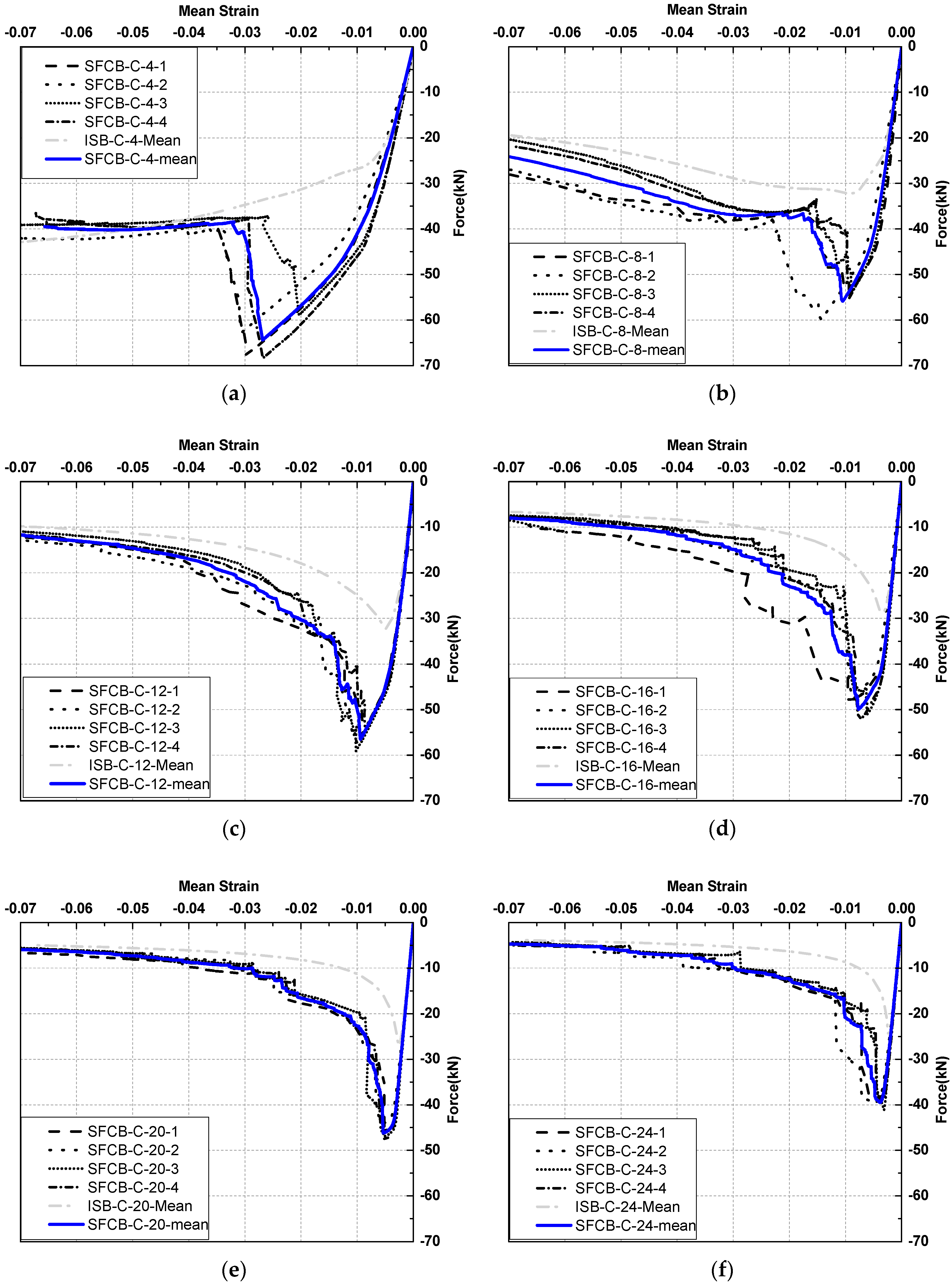

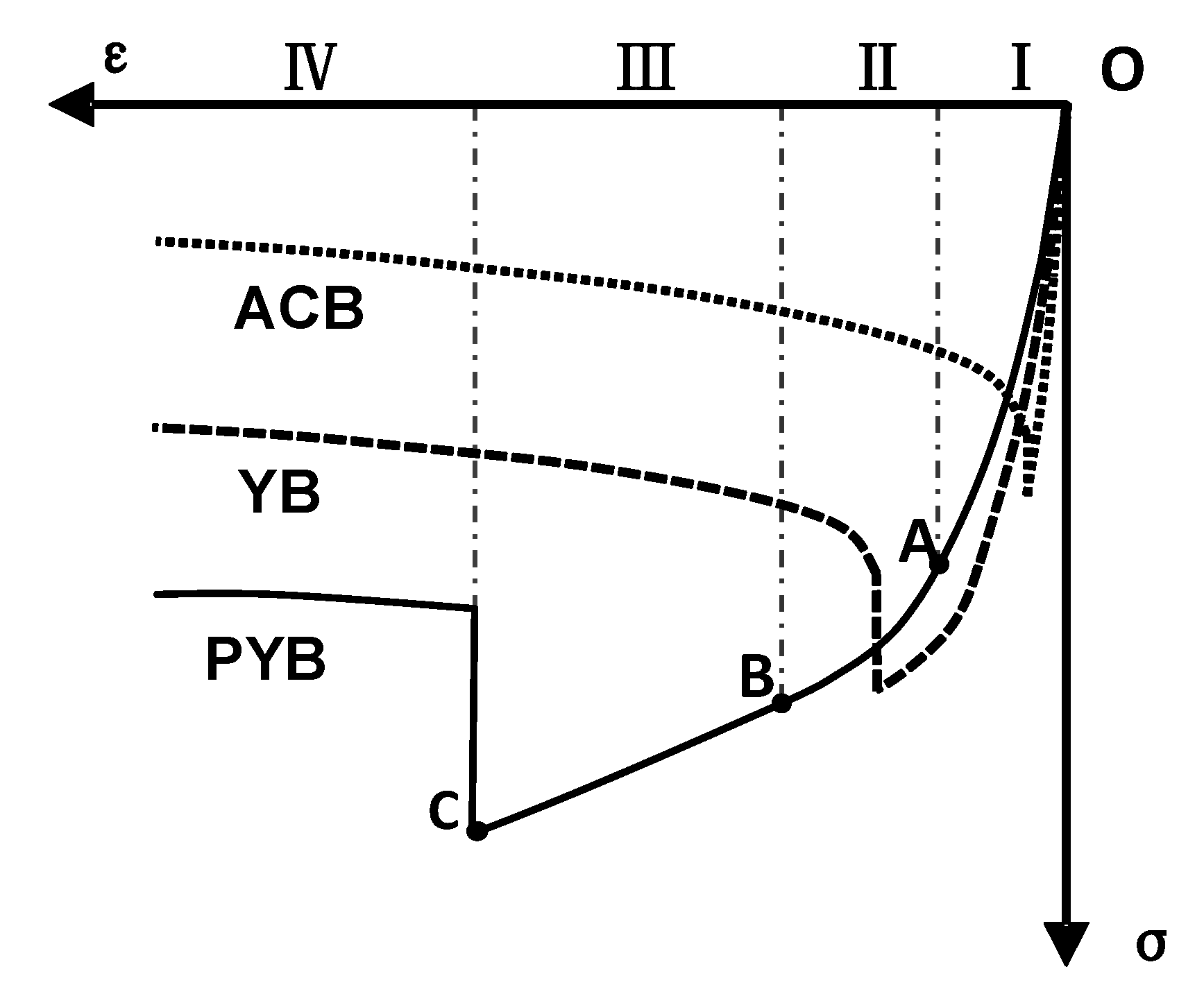

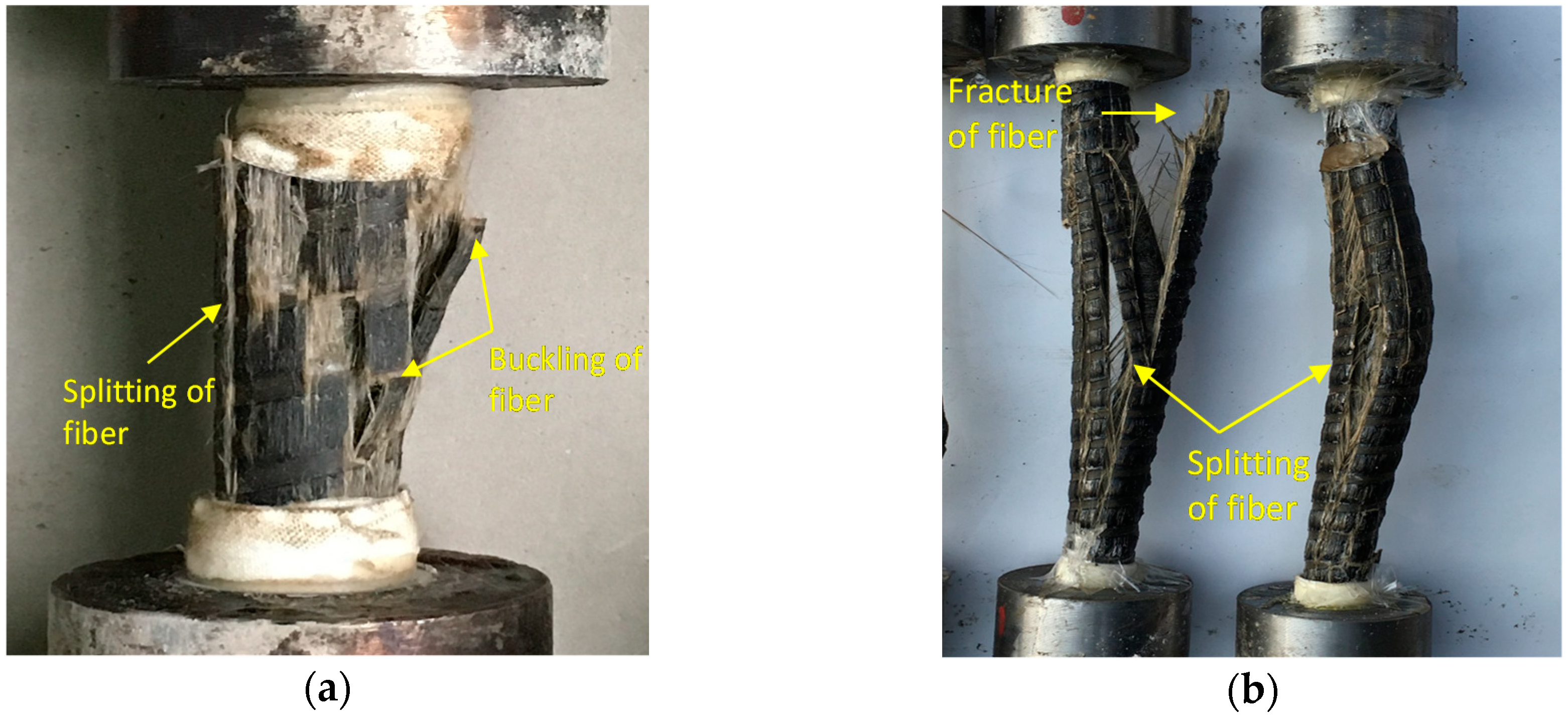

5.1. Test Results

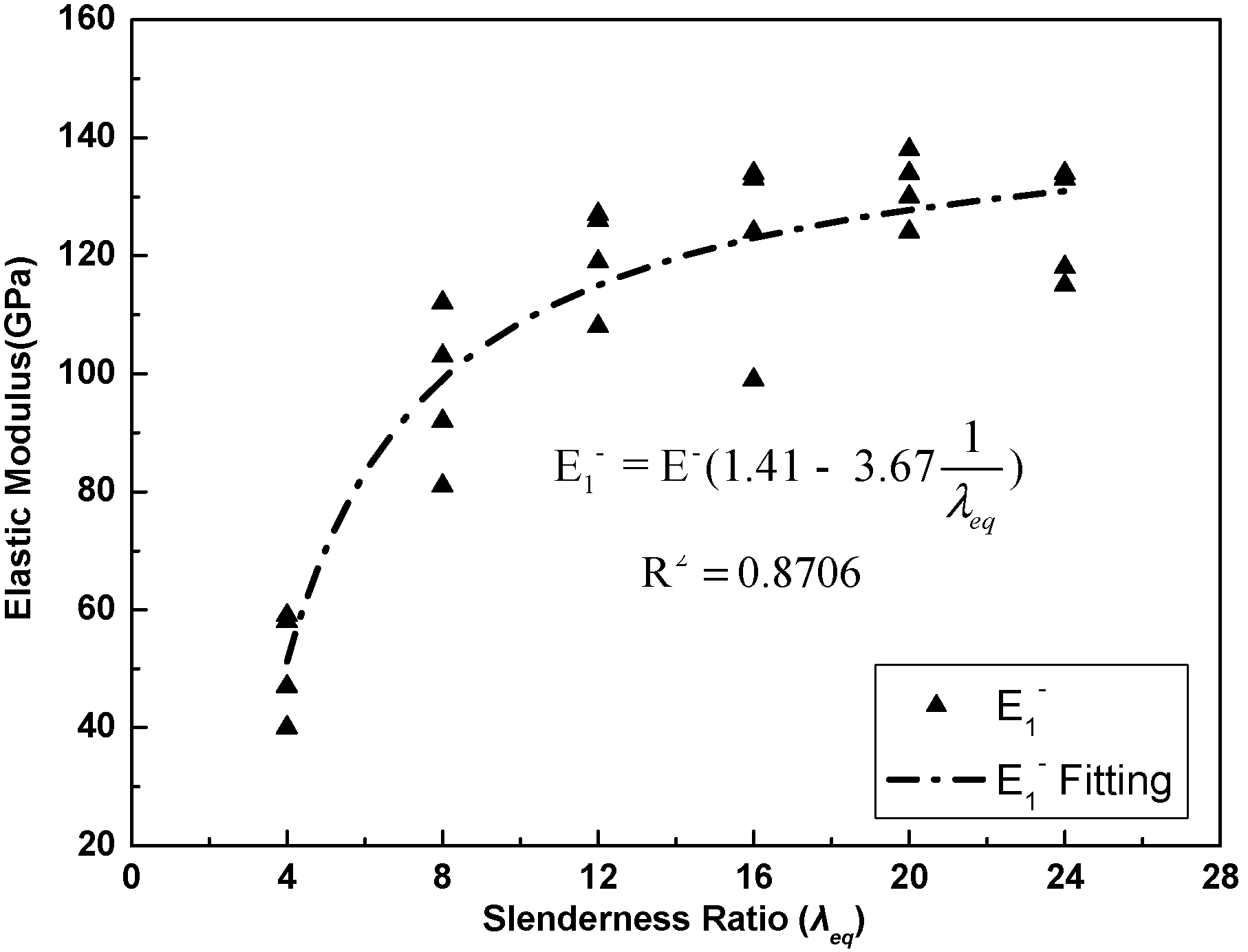

5.2. Initial Compressive Elastic Modulus

5.3. Nominal Initial Compressive Elastic Modulus

5.4. Compressive Post-Yield Modulus

5.5. Compressive Yield Load and Stress

5.6. Ultimate Compressive Load and Stress

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Suda, K.; Murayama, Y.; Ichinomiya, T.; Shimbo, H. Buckling behavior of longitudinal reinforcing bars in concrete column subjected to reverse Lateral Loading. In Proceedings of the 11th World Conference on Earthquake Engineering, Acapulco, Mexico, 23–28 June 1996. [Google Scholar]

- Dhakal, R.P.; Maekawa, K. Reinforcement stability and fracture of cover concrete in reinforced concrete members. J. Struct. Eng. 2002, 128, 1253–1262. [Google Scholar] [CrossRef]

- Monti, G.; Nuti, C. Nonlinear Cyclic Behavior of Reinforcing Bars Including Buckling. J. Struct. Eng.-ASCE 1992, 118, 3268–3284. [Google Scholar] [CrossRef]

- Dhakal, R.P.; Maekawa, K. Modeling for postyield buckling of reinforcement. J. Struct. Eng. 2002, 128, 1139–1147. [Google Scholar] [CrossRef]

- Bae, S.; Mieses, A.M.; Bayrak, O. Inelastic buckling of reinforcing bars. J. Struct. Eng. 2005, 131, 314–321. [Google Scholar] [CrossRef]

- Kashani, M.M.; Crewe, A.J.; Alexander, N.A. Nonlinear stress–strain behaviour of corrosion-damaged reinforcing bars including inelastic buckling. Eng. Struct. 2013, 48, 417–429. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.-F.; Dai, M.-J. Degradation of steel-to-concrete bond due to corrosion. Constr. Build. Mater. 2018, 158, 1073–1080. [Google Scholar] [CrossRef]

- Kashani, M.M.; Barmi, A.K.; Malinova, V.S. Influence of inelastic buckling on low-cycle fatigue degradation of reinforcing bars. Constr. Build. Mater. 2015, 94, 644–655. [Google Scholar] [CrossRef]

- Mander, J.; Panthaki, F.; Kasalanati, A. Low-cycle fatigue behavior of reinforcing steel. J. Mater. Civil Eng. 1994, 6, 453–468. [Google Scholar] [CrossRef]

- Massone, L.M.; Moroder, D. Buckling modeling of reinforcing bars with imperfections. Eng. Struct. 2009, 31, 758–767. [Google Scholar] [CrossRef]

- Kashani, M.M.; Lowes, L.N.; Crewe, A.J.; Alexander, N.A. Phenomenological hysteretic model for corroded reinforcing bars including inelastic buckling and low-cycle fatigue degradation. Comput. Struct. 2015, 156, 58–71. [Google Scholar] [CrossRef]

- Yuan, F.; Chen, M. Numerical Sensing of Plastic Hinge Regions in Concrete Beams with Hybrid (FRP and Steel) Bars. Sensors 2018, 18, 3255. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, Z. Distributed long-gauge optical fiber sensors based self-sensing FRP bar for concrete structure. Sensors 2016, 16, 286. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.-F.; Meda, H.; Chen, W.J.S. The Design and Analysis of Internally Stiffened GFRP Tubular Decks—A Sustainable Solution. Sustainability 2018, 10, 4538. [Google Scholar] [CrossRef]

- Cascone, S.M.; Sapienza, V.; Lionti, I.; Porto, S.M.C.J.S. Fiber-reinforced polymer nets for strengthening lava stone masonries in historical buildings. Sustainability 2016, 8, 394. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, X.; Wu, G. Advancement of structural safety and sustainability with basalt fiber reinforced polymers. In Proceedings of the 6th International Conference on FRP Composites in Civil Engineering, CICE 2012, Rome, Italy, 13–15 June 2012; pp. 15–29. [Google Scholar]

- ACI. Guide for the Design and Construction of Concrete Reinforced with FRP Bars; ACI 440 1R-06; ACI: Detroit, MI, USA, 2006; Available online: http://www.radyab.co/content/media/article/13.pdf (accessed on 13 January 2017).

- Malvar, L.J. Tensile and bond properties of GFRP reinforcing bars. Mater. J. 1995, 92, 276–285. [Google Scholar]

- Wu, Z.; Wang, X.; Wu, G. Basalt FRP composite as reinforcements in infrastructure. In Proceedings of the 17th Annual International Conference on Composites/Nano Engineering (ICCE-17), Honolulu, HI, USA, 26 July–1 August 2009; pp. 21–24. [Google Scholar]

- Wu, W.-P. Thermomechanical properties of fiber reinforced plastic (FRP) bars. Diss. Abstr. Int. (USA) 1992, 52, 292. [Google Scholar]

- Nanni, A.; Henneke, M.J.; Okamoto, T. Tensile properties of hybrid rods for concrete reinforcement. Constr. Build. Mater. 1994, 8, 27–34. [Google Scholar] [CrossRef]

- Saikia, B.; Thomas, J.; Ramaswamy, A.; Rao, K.N. Performance of hybrid rebars as longitudinal reinforcement in normal strength concrete. Mater. Struct. 2005, 38, 857–864. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Wu, G.; Wu, Z.S.; Zhang, M.; Hu, X.Q. Experimental study on the bond behavior between steel fiber composite bar (SFCB) and concrete. Earthq. Resist. Eng. Retrofit. 2009, 31, 21–27. [Google Scholar]

- Wang, X.; Jiang, L.; Shen, H.; Wu, Z. Long-Term Performance of Pultruded Basalt Fiber Reinforced Polymer Profiles under Acidic Conditions. J. Mater. Civil Eng. 2018, 30, 04018096. [Google Scholar] [CrossRef]

- Ibrahim, A.I.; Wu, G.; Sun, Z.-Y. Experimental Study of Cyclic Behavior of Concrete Bridge Columns Reinforced by Steel Basalt-Fiber Composite Bars and Hybrid Stirrups. J. Compos. Constr. 2016, 21, 04016091. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, Y.; Qin, W.; Ren, S.; Wu, G. Experimental study on flexural behavior of concrete beams reinforced by steel-fiber reinforced polymer composite bars. J. Reinf. Plast. Comp. 2012, 31, 1737–1745. [Google Scholar] [CrossRef]

- Sun, Z.-Y.; Wu, G.; Wu, Z.-S.; Zhang, J. Nonlinear Behavior and Simulation of Concrete Columns Reinforced by Steel-FRP Composite Bars. J. Bridge Eng. 2013, 19, 220–234. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Z.-S.; Luo, Y.-B.; Sun, Z.-Y.; Hu, X.-Q. Mechanical properties of steel-FRP composite bar under uniaxial and cyclic tensile loads. J. Mater. Civil Eng. 2010, 22, 1056–1066. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Z.; Luo, Y.; Wei, H. A new reinforcement material of steel fiber composite bar (SFCB) and its mechanics properties. In Proceedings of the 9th International Symposium on Fiber Reinforced Polymer Reinforcement for Reinforced Concrete Structures (FRPRCS-9), Sydney, Australia, 13–15 July 2009. [Google Scholar]

- Sun, Z.; Tang, Y.; Luo, Y.; Wu, G.; He, X. Mechanical Properties of Steel-FRP Composite Bars under Tensile and Compressive Loading. Int. J. Polym. Sci. 2017, 2017, 5691278. [Google Scholar] [CrossRef]

- Euler, L. Methodus Inveniendi Lineas Curvas Maximi Minimive Proprietate Gaudentes sive Solutio Problematis Isoperimetrici Latissimo Sensu Accepti; Springer Science & Business Media: Berlin, Germany, 1952; Volume 1. [Google Scholar]

| Type | Elastic Modulus (GPa) | Tensile Strength (MPa) | Density (g/cm3) | Diameter (μm) | Elongation Rate (%) |

|---|---|---|---|---|---|

| Basalt fiber | 90 | 2250 | 2.63 | 13 | 2.5 |

| vinyl epoxy resin | 3.6 | 95 | 1.06 | — | 6.1 |

| Specimen | λeq | E+ (GPa) | E2+ (GPa) | rsf+ (E2+/E) | σsfy+ (MPa) | σsfu+ (MPa) | σsy+ (MPa) | σsu+ (MPa) |

|---|---|---|---|---|---|---|---|---|

| SFCB-T-1 | 52 | 112 | 22 | 0 | 413 | 1162 | — | — |

| SFCB-T-2 | 52 | 108 | 22 | 0 | 419 | 1348 | — | — |

| SFCB-T-3 | 52 | 107 | 23 | 0 | 426 | 1181 | — | — |

| SFCB-T-Mean | 52 | 109 | 22 | 0 | 419 | 1230 | — | — |

| ISB-T-1 | 60 | 189 | — | — | — | — | 400 | 528 |

| ISB-T-2 | 60 | 191 | — | — | — | — | 400 | 533 |

| ISB-T-3 | 60 | 190 | — | — | — | — | 400 | 530 |

| ISB-T-Mean | 60 | 190 | — | — | — | — | 400 | 530 |

| Specimen | L (mm) | Leff (mm) | λeq | E− (GPa) | E2− (GPa) | rsf − (E2+/E) | Fsfy− (kN) | σsfy− (MPa) | Fsfu− (kN) | σsfu− (MPa) | Fsu− (kN) | σsu− (MPa) | Py (MPa) | Pcr-eq (MPa) | Failure Mode |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFCB-C-4-1 | 46 | 23 | 4 | 95 | 11 | 0.12 | −44 | −426 | −68 | −651 | — | — | −33 | — | PYB |

| SFCB-C-4-2 | 46 | 23 | 4 | 97 | 10 | 0.10 | −43 | −410 | −63 | −604 | — | — | −34 | — | PYB |

| SFCB-C-4-3 | 46 | 23 | 4 | 107 | 12 | 0.11 | −42 | −408 | −59 | −567 | — | — | −38 | — | PYB |

| SFCB-C-4-4 | 46 | 23 | 4 | 103 | 11 | 0.11 | −44 | −424 | −68 | −658 | — | — | −36 | — | PYB |

| SFCB-C-4-Mean | 46 | 23 | 4 | 101 | 11 | 0.11 | −43 | −417 | −64 | −620 | — | — | −36 | — | — |

| SFCB-C-8-1 | 92 | 46 | 8 | 111 | 19 | 0.17 | −43 | −416 | −55 | −528 | — | — | −39 | −768 | PYB |

| SFCB-C-8-2 | 92 | 46 | 8 | 80 | 17 | 0.21 | −45 | −438 | −60 | −577 | — | — | −28 | −295 | PYB |

| SFCB-C-8-3 | 92 | 46 | 8 | 103 | 21 | 0.20 | −42 | −406 | −54 | −521 | — | — | −36 | −646 | PYB |

| SFCB-C-8-4 | 92 | 46 | 8 | 94 | 23 | 0.24 | −43 | −417 | −55 | −531 | — | — | −33 | −509 | PYB |

| SFCB-C-8-Mean | 92 | 46 | 8 | 103 | 20 | 0.21 | −43 | −419 | −56 | −539 | — | — | −36 | −646 | — |

| SFCB-C-12-1 | 138 | 69 | 12 | 110 | 24 | 0.22 | −45 | −433 | −55 | −533 | — | — | −39 | −335 | PYB |

| SFCB-C-12-2 | 138 | 69 | 12 | 109 | 21 | 0.19 | −43 | −416 | −57 | −551 | — | — | −38 | −328 | PYB |

| SFCB-C-12-3 | 138 | 69 | 12 | 104 | 22 | 0.21 | −43 | −415 | −59 | −569 | — | — | −37 | −294 | PYB |

| SFCB-C-12-4 | 138 | 69 | 12 | 101 | 24 | 0.24 | −44 | −425 | −54 | −523 | — | — | −36 | −274 | PYB |

| SFCB-C-12-Mean | 138 | 69 | 12 | 106 | 23 | 0.22 | −44 | −422 | −56 | −544 | — | — | −37 | −307 | — |

| SFCB-C-16-1 | 184 | 92 | 16 | 111 | — | — | −41 | −394 | −48 | −466 | — | — | −39 | −192 | YB |

| SFCB-C-16-2 | 184 | 92 | 16 | 100 | 22 | 0.22 | −41 | −398 | −48 | −463 | — | — | −35 | −150 | YB |

| SFCB-C-16-3 | 184 | 92 | 16 | 109 | 20 | 0.18 | −42 | −404 | −51 | −493 | — | — | −38 | −184 | YB |

| SFCB-C-16-4 | 184 | 92 | 16 | 105 | 22 | 0.21 | −43 | −419 | −52 | −501 | — | — | −37 | −169 | YB |

| SFCB-C-16-Mean | 184 | 92 | 16 | 106 | 21 | 0.20 | −42 | −404 | −50 | −481 | — | — | −37 | −173 | — |

| SFCB-C-20-1 | 230 | 115 | 20 | 109 | — | — | −44 | −426 | −48 | −463 | — | — | −38 | −118 | YB |

| SFCB-C-20-2 | 230 | 115 | 20 | 99 | — | — | −41 | −393 | −44 | −424 | — | — | −35 | −94 | YB |

| SFCB-C-20-3 | 230 | 115 | 20 | 110 | — | — | −44 | −427 | −47 | −452 | — | — | −39 | −120 | YB |

| SFCB-C-20-4 | 230 | 115 | 20 | 103 | — | — | -44 | −423 | −46 | −441 | — | — | −36 | −103 | YB |

| SFCB-C-20-Mean | 230 | 115 | 20 | 105 | — | — | −43 | −417 | −46 | −445 | — | — | −37 | −108 | — |

| SFCB-C-24-1 | 276 | 138 | 24 | 98 | — | — | — | — | −39 | −373 | — | — | −35 | −63 | ACB |

| SFCB-C-24-2 | 276 | 138 | 24 | 96 | — | — | — | — | −39 | −379 | — | — | −34 | −60 | ACB |

| SFCB-C-24-3 | 276 | 138 | 24 | 105 | — | — | — | — | −41 | −396 | — | — | −37 | −75 | ACB |

| SFCB-C-24-4 | 276 | 138 | 24 | 104 | — | — | — | — | −39 | −373 | — | — | −37 | −73 | ACB |

| SFCB-C-24-Mean | 276 | 138 | 24 | 101 | — | — | — | — | −39 | −380 | — | — | −36 | −68 | — |

| ISB-C-4-1 | 46 | 23 | 4.6 | 188 | — | — | — | — | — | — | — | — | −31 | — | — |

| ISB-C-4-2 | 46 | 23 | 4.6 | 189 | — | — | — | — | — | — | — | — | −31 | — | — |

| ISB-C-4-3 | 46 | 23 | 4.6 | 188 | — | — | — | — | — | — | — | — | −31 | — | — |

| ISB-C-4-4 | 46 | 23 | 4.6 | 190 | — | — | — | — | — | — | — | — | −31 | — | — |

| ISB-C-4-Mean | 46 | 23 | 4.6 | 189 | — | — | — | — | — | — | — | — | −31 | — | — |

| ISB-C-8-1 | 92 | 46 | 9.2 | 191 | — | — | — | — | — | — | −33 | −415 | −31 | −434 | — |

| ISB-C-8-2 | 92 | 46 | 9.2 | 190 | — | — | — | — | — | — | −32 | −413 | −31 | −434 | — |

| ISB-C-8-3 | 92 | 46 | 9.2 | 188 | — | — | — | — | — | — | −32 | −404 | −31 | −434 | — |

| ISB-C-8-4 | 92 | 46 | 9.2 | 187 | — | — | — | — | — | — | −33 | −417 | −31 | −434 | — |

| ISB-C-8-Mean | 92 | 46 | 9.2 | 189 | — | — | — | — | — | — | −32 | −412 | −31 | −434 | — |

| ISB-C-12-1 | 138 | 69 | 13.8 | 188 | — | — | — | — | — | — | −33 | −423 | −31 | −193 | — |

| ISB-C-12-2 | 138 | 69 | 13.8 | 187 | — | — | — | — | — | — | −32 | −408 | −31 | −193 | — |

| ISB-C-12-3 | 138 | 69 | 13.8 | 189 | — | — | — | — | — | — | −34 | −427 | −31 | −193 | — |

| ISB-C-12-4 | 138 | 69 | 13.8 | 191 | — | — | — | — | — | — | −32 | −402 | −31 | −193 | — |

| ISB-C-12-Mean | 138 | 69 | 13.8 | 189 | — | — | — | — | — | — | −33 | −415 | −31 | −193 | — |

| ISB-C-16-1 | 184 | 92 | 18.4 | 188 | — | — | — | — | — | — | −30 | −377 | −31 | −109 | — |

| ISB-C-16-2 | 184 | 92 | 18.4 | 189 | — | — | — | — | — | — | −29 | −366 | −31 | −109 | — |

| ISB-C-16-3 | 184 | 92 | 18.4 | 187 | — | — | — | — | — | — | −28 | −354 | −31 | −109 | — |

| ISB-C-16-4 | 184 | 92 | 18.4 | 188 | — | — | — | — | — | — | −31 | −391 | −31 | −109 | — |

| ISB-C-16-Mean | 184 | 92 | 18.4 | 188 | — | — | — | — | — | — | −29 | −372 | −31 | −109 | — |

| ISB-C-20-1 | 230 | 115 | 23 | 188 | — | — | — | — | — | — | −29 | −365 | −31 | −69 | — |

| ISB-C-20-2 | 230 | 115 | 23 | 189 | — | — | — | — | — | — | −28 | −357 | −31 | −69 | — |

| ISB-C-20-3 | 230 | 115 | 23 | 191 | — | — | — | — | — | — | −26 | −332 | −31 | −69 | — |

| ISB-C-20-4 | 230 | 115 | 23 | 189 | — | — | — | — | — | — | −26 | −335 | −31 | −69 | — |

| ISB-C-20-Mean | 230 | 115 | 23 | 189 | — | — | — | — | — | — | −27 | −347 | −31 | −69 | — |

| ISB-C-24-1 | 276 | 138 | 27.6 | 192 | — | — | — | — | — | — | −24 | −302 | −31 | −48 | — |

| ISB-C-24-2 | 276 | 138 | 27.6 | 190 | — | — | — | — | — | — | −25 | −317 | −31 | −48 | — |

| ISB-C-24-3 | 276 | 138 | 27.6 | 189 | — | — | — | — | — | — | −27 | −348 | −31 | −48 | — |

| ISB-C-24-4 | 276 | 138 | 27.6 | 187 | — | — | — | — | — | — | −29 | −364 | −31 | −48 | — |

| ISB-C-24-Mean | 276 | 138 | 27.6 | 190 | — | — | — | — | — | — | −26 | −333 | −31 | −48 | — |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Sun, Z.; Wu, G. Compressive Behavior of Sustainable Steel-FRP Composite Bars with Different Slenderness Ratios. Sustainability 2019, 11, 1118. https://doi.org/10.3390/su11041118

Tang Y, Sun Z, Wu G. Compressive Behavior of Sustainable Steel-FRP Composite Bars with Different Slenderness Ratios. Sustainability. 2019; 11(4):1118. https://doi.org/10.3390/su11041118

Chicago/Turabian StyleTang, Yu, Zeyang Sun, and Gang Wu. 2019. "Compressive Behavior of Sustainable Steel-FRP Composite Bars with Different Slenderness Ratios" Sustainability 11, no. 4: 1118. https://doi.org/10.3390/su11041118

APA StyleTang, Y., Sun, Z., & Wu, G. (2019). Compressive Behavior of Sustainable Steel-FRP Composite Bars with Different Slenderness Ratios. Sustainability, 11(4), 1118. https://doi.org/10.3390/su11041118