Abstract

The rapid growth of electric vehicles (EVs) in the Jakarta Greater Area is expected to significantly increase the volume of end-of-life (EoL) batteries, necessitating an efficient and sustainable waste management system. This study designs a reverse logistics network that includes Collection Centers (CCs), a combined Remanufacturing and Recycling Center (RMC), and a Waste Disposal Center (WDC). Dealer clusters are identified using K-means clustering to determine the optimal CC locations. A deterministic mixed-integer linear programming (MILP) model is developed to minimize total costs. It comprises acquisition, transportation, processing, facility, and carbon tax components. The model yields a minimum total cost of IDR 1,236,435,000,187, with processing costs contributing the largest share (56.68%), followed by transportation (29.30%). The selected facilities include five CCs (CCA-1, CCE-2, CCK-3, CCM-4, and CCR-5), one RMC (RMC-1), and one WDC (WDC-1). Based on battery health, the batteries are classified into three categories: L1 (>80% health, suitable for remanufacturing), L2 (60–80%, suitable for recycling), and L3 (<60%, directed to disposal). L1 and L2 batteries are directed to RMC-1, while L3 batteries and solid waste are routed to WDC-1, totaling 1.029 tons. The results emphasize the need for improving processing efficiency and strategic facility placement to enhance the sustainability and cost-effectiveness of EoL battery management in urban EV ecosystems.

1. Introduction

The global transition to electric vehicles (EVs) is occurring rapidly, offering significant environmental benefits through reductions in carbon emissions, with a 1% increase in EV sales resulting in a 0.096% decrease in emissions in a city [1]. However, the rapid growth of EVs poses significant challenges concerning the management of end-of-life (EoL) batteries, which still hold residual value and potential for reuse [2].

In 2023, 14 million new electric cars were sold globally, bringing the total population to 40 million units [3]. Indonesia aims to reach 400,000 EV units by 2025 and 2 million units by 2030, but it still lacks specific regulations concerning the management of EoL EV batteries [4].

Electric vehicle batteries typically last 8 to 10 years and are often replaced before the vehicle’s lifespan ends, for both performance and safety reasons [5]. EoL batteries still retain 60–80% of their initial capacity, along with high-value metals such as lithium and cobalt [6,7]. If not managed properly, it not only pollutes the environment but also causes economic losses. Therefore, managing EoL batteries through reuse, recycling, or remanufacturing is crucial to supporting a circular economy and reducing dependence on primary raw materials [8,9]. One strategic approach is to handle this by establishing a reverse logistics network (RLN), a system designed to manage the return of products from consumers to producers for value recovery [10]. Effective RLN design will help reduce costs while considering social and environmental factors [11,12].

One of the more advanced reverse logistics systems was implemented in the United States of America and Europe. Ref. [13] provides a comprehensive map for the reverse systems in the USA, which include (a) collection and sorting facilities, (b) reuse and repurposing facilities, (c) dismantling centers, (d) refurbishers and remanufacturers, (e) scrap recyclers, and (f) recycling facilities. In Europe, producers develop take-back schemes and separate ready-to-reuse batteries (to refurbishment facilities) and EoL batteries (to car dismantlers) [14]. The remaining parts of the batteries would be sent to recycling plants.

In Indonesia, the management of EoL EV batteries is still in its very early stages. It lacks an organized network [15], a condition similar to that in other developing countries [7]. The Jakarta Greater Area is a priority region due to its high EV adoption rate and potential to generate a large volume of end-of-life (EoL) batteries in the future [4]. However, despite the growing urgency, no structured or integrated system has yet been established to handle the increasing volume of EoL EV batteries in urban areas, such as the Jakarta Greater Area. This lack of infrastructure, regulatory clarity, and localized strategy represents a critical gap in Indonesia’s transition toward sustainable electric mobility.

Given these challenges, it is crucial to develop a well-structured and efficient reverse logistics network (RLN) to support the sustainable management of EoL electric car batteries, particularly in high-density urban areas such as the Jakarta Greater Area. An adequately designed RLN can ensure the effective collection, sorting, and processing of EoL batteries, thereby maximizing material recovery, minimizing the environmental impact, and supporting the circular economy. While the urgency of this issue is acknowledged, especially in rapidly growing EV markets such as Indonesia, practical implementation remains limited due to a lack of integrated infrastructure, regulatory frameworks, and region-specific strategies. Therefore, designing a location-optimized RLN tailored to the unique characteristics of the Jakarta Greater Area is a critical step towards achieving sustainable battery waste management.

Table 1 presents a comprehensive synthesis of previous studies that have designed RLNs for various types of waste, particularly EoL EV batteries, as well as e-waste and plastic waste, for comparative reference. These studies span a range of application domains and methodological approaches, including MILP, Fuzzy MILP, MINLP, Robust MILP, and stochastic models—each applied under different assumptions of certainty or uncertainty. They also differ in terms of objective functions (single vs. multi-objective) and the sustainability aspects considered (economic, environmental, and social).

Table 1.

Literature review on reverse logistics network design for different waste types.

Moreover, the RLNs developed across these studies encompass a diverse range of facilities, including collection and inspection points, dismantling, disassembly, remanufacturing, recycling, and final disposal centers. These variations reflect the growing complexity and multidisciplinary nature of RLN design in response to specific contextual and policy challenges. The structured comparison provided in Table 1 aims to situate the present study within this broader research landscape, identifying both shared patterns and critical gaps across geographical, operational, and methodological dimensions.

Various previous studies have developed RLN models to manage EoL EV batteries, as well as other types of waste, using diverse modeling techniques and facility configurations. For example, a study in Turkey employed a Fuzzy MILP approach to design a comprehensive RLN involving collection, dismantling, processing, recycling, and disposal facilities, with both economic and environmental objectives [16]. In China, a MIP-based RLN was formulated to connect Collection Centers with Remanufacturing and Recycling Centers and Waste Disposal Centers, which were optimized under multi-objective conditions [17]. Broader applications are seen in Iran, where a stochastic MILP model for e-waste included inspection, disassembly, recovery, and secondary market facilities, addressing economic, environmental, and social aspects [18].

In China, MINLP was used to design a service-oriented network involving recall and echelon use facilities [19], while a Fuzzy MILP approach was applied to create a large-scale RLN with layered Collection Centers, Inspection Disassembly Centers, Recycling and Remanufacturing Centers, disposal centers, and secondary markets [7]. In Sweden, a MIP model focused on optimizing logistics nodes, such as product acquisition sites and inter-modal terminals, while excluding collection and disposal facilities [20]. More recent Chinese studies emphasized uncertainty handling and circularity through the inclusion of testing centers, processing centers, and battery markets [1]; dealership hubs and energy markets [6]; and conventional collection–remanufacturing–disposal chains using MINLP [9].

Other works targeted sustainability goals. One Fuzzy MILP study incorporated recycling points, collection and utilization centers, and waste disposal facilities, taking into account social and environmental considerations [12]. In Brazil, a simulation–genetic algorithm model was used to optimize e-waste collection and recycling under uncertainty and social equity concerns [21]. Germany applied MILP for integrating collection, disassembling, and recycling Facilities [22], while Turkey implemented a hybrid SF-AHP and MILP model to include storage sites, landfills, and secondary material markets in a multi-objective RLN [23].

Although differing in waste type, a study in Indonesia focused on plastic waste offers contextual relevance; it employed a Robust MILP to model a system with waste banks, hoarders, recyclers, and temporary disposal sites [24]. This approach is especially informative for countries like Indonesia, where the informal sectors are significant in waste flow. A comprehensive RLN was also proposed in China, integrating collection, testing, repair, cascade utilization, recycling, and waste treatment centers; manufacturing facilities; and landfills under a Fuzzy MILP framework [25]. Another study utilized Robust MILP to design an RLN involving a market business center alongside standard processing facilities [8], while an advanced Fuzzy model combined with robust and goal programming strategies was developed for complex e-waste treatment in Iran [26].

In Indonesia, a MILP-based RLN was developed for e-waste, encompassing informal collectors, tiered collection systems, repair and recycling centers, and secondary markets [27]. Building on insights from these various works, this study proposes an RLN for the Jakarta Greater Area using a MILP model that includes a Collection Center, a Remanufacturing and Recycling Center, and a Waste Disposal Center, with a focus on economic and environmental optimization.

The inclusion of e-waste [18,21,26,27] and plastic waste [24] studies is justified by their shared characteristics with EoL EV batteries—namely, the need for hazardous material handling, disassembly processes, informal sector involvement, and the urgency for integrated systems. These studies provide technical modeling insights and serve as conceptual references for facility design in similarly developing contexts. Moreover, non-EV studies in Indonesia [24,27] remain relevant due to their realistic, localized approaches and emphasis on informal networks—essential considerations when designing RLNs for EV batteries in regions with immature infrastructure.

This study offers a novel contribution by designing a greenfield RLN for EoL EV battery management in Indonesia using dealership-level battery flow data and contextual spatial criteria—an approach that has not been previously applied in the Indonesian context. To the best of our knowledge, no prior research has developed a location-optimized RLN based on real dealership-originated battery volumes within a developing country, making this work a significant departure from generalized or assumption-based models. While the objective functions and core facility types—namely the Collection Center, the Remanufacturing and Recycling Center, and the Waste Disposal Center—are consistent with previous studies, this study explicitly designs facility locations from scratch (a greenfield design) to illustrate how an ideal EV battery waste flow could be realized in the Jakarta Greater Area without being constrained by existing infrastructure. Unlike most prior studies that optimize networks from pre-existing or assumed facility locations, this research determines optimal facility sites through a rigorous evaluation of contextual spatial factors, ensuring practical relevance for decision makers.

Furthermore, instead of aggregating battery returns into a single generalized flow, this model traces EoL volumes from individual dealerships, offering a more detailed and realistic upstream representation. This approach is especially suited for the Indonesian context, where infrastructure and data availability remain limited. A deterministic modeling framework is adopted to simplify the analysis and support practical decision-making regarding siting and flow allocation. By grounding the RLN in local realities and prioritizing practicability, this study makes a significant contribution to the early-stage development of sustainable EoL EV battery systems in developing economies and lays a foundation for future expansion toward more complex and adaptive models.

The main objective of this study is to formulate and optimize the RLN model that minimizes operational costs while enabling effective facility siting for sustainable EoL battery management in the Jakarta Greater Area. Specifically, this research develops a mixed-integer linear programming optimization model to determine facility locations within an RLN for EoL battery management of EVs in the Jakarta Greater Area. Unlike some previous studies that adopt multi-objective formulations to minimize both cost and emissions simultaneously, this study employs a single-objective approach, focusing solely on minimizing total operational costs, while emissions are assessed in a post-optimization analysis.

To achieve this goal, this research is organized into five sections. Section 1: The introduction discusses the research background and motivation, the research gap, the objectives of the study, and the research positioning. Section 2: The methodology covers the research framework, data collection, the application of k-means clustering for locating candidate facilities in the RLN, and the mathematical model. Section 3: The results present the findings of this research. Section 4 provides a discussion and implications based on the results obtained. Section 5: The conclusion summarizes the findings, discusses the research contribution, and offers recommendations for further research.

2. Materials and Methods

This section outlines the methodological steps and analytical tools employed in designing an RLN for managing EoL EV batteries in the Jakarta Greater Area. The research adopts a combination of spatial analysis using K-means clustering and mathematical optimization through a MILP model. Data collection was conducted from both primary and secondary sources, including geographic data on EV dealers, regional spatial plans, and numerical estimates required for model formulation, such as costs, distances, and emissions. Each phase, from data preparation and clustering to model development, is described in detail to ensure reproducibility and transparency of the research process.

2.1. Overview of Methodology

This study employs a structured methodological approach to design an optimal RLN for managing EoL electric vehicle batteries in the Jakarta Greater Area. It is selected as the object of this study because of its role as the epicenter of the EV market in Indonesia. There were thousands of active EVs and hundreds of charging facilities in the regions, with the most sophisticated facilities compared with other urban settings in Indonesia. If the government were to initiate a reverse logistics program for waste, the Jakarta Greater Area would be the ideal location for the pilot systems.

The research process commenced with a comprehensive literature review to identify the key components of reverse logistics systems, including facility types, network structures, and operational strategies. Based on the review, three primary facilities were identified as essential in the RLN: the Collection Center (CC), the Remanufacturing and Recycling Center (RMC), and the Waste Disposal Center (WDC).

To determine the most suitable locations for these facilities, this study incorporates a spatial analysis phase. The first step involved compiling the geographical distribution of EV dealers, which serve as initial collection points. Using K-means clustering, these dealers were grouped based on spatial proximity to identify central points within each cluster. These centroids were then evaluated and validated using the Regional Spatial Plan to ensure compliance with local zoning and land-use regulations. Candidate locations for each facility type were selected based on their proximity to cluster centroids, suitability of land use, and logistical feasibility. Following the location selection process, a MILP model was developed to optimize the network configuration. The model formulation includes the definition of sets and indices, parameters, decision variables, the objective function, and operational constraints. The objective is to minimize total operational costs while satisfying logistical and spatial constraints. Python, implemented on Google Colab, was used as the computational platform for implementing and optimizing the model. The final model outputs include the selection of facility locations and the corresponding flow of EoL batteries across the network, which are subsequently analyzed and interpreted.

2.2. Clustering of EV Dealers and Identification of Candidate Facility Location

To determine potential locations for reverse logistics facilities, this study begins by analyzing the spatial distribution of EV dealers across the Jakarta Greater Area. A total of 254 EV dealers—representing both fully electric and hybrid electric vehicles—were recorded based on the top-selling brands in Indonesia during 2024. These dealers serve as the primary source of EoL batteries and thus play a crucial role in network planning. The location data, including latitude and longitude, was collected and prepared in a structured format to support clustering analysis. By applying K-means clustering, dealers are grouped based on geographic proximity to identify logical cluster centers. These centers offer initial insights into optimal facility zones, ensuring efficiency in battery transportation flows. The resulting cluster centroids serve as additional sites for the CC, RMC, and WDC, which will later be used as inputs for the MILP model.

K-means clustering is one of the most widely used machine learning algorithms for data segmentation. It aims to divide data into multiple K clusters based on similarity by minimizing the distance between the data points and the centroid of each cluster [28]. K-means is a distance-based algorithm that typically uses the Euclidean or Manhattan distance metric to calculate the distance between data points and centroids. The optimization process in K-means centers on determining the best centroid position that minimizes the sum of squares of the distance between data points and their nearest centroid, known as the Within-Cluster Sum of Squares (WCSS) or inertia in the scikit-learn library [28].

To determine the optimal number of clusters, two primary evaluation methods are used: the Elbow Method and the Silhouette Score. The Elbow Method assesses the Within-Cluster Sum of Squares (WCSS) based on the distance between the data points and the centroids within each cluster, with the optimal number of clusters identified by the “elbow” point on the WCSS graph. The WCSS formula is as follows [29]:

where k is the number of clusters, is the i-th cluster, x is data points, and is centroid.

Meanwhile, the Silhouette Score measures how well a point fits into its cluster compared to other clusters, with scores ranging from −1 (poor) to 1 (good). The formula is as follows [21]:

where a(i) represents the average distance from data point i to all points in its cluster, while b(i) denotes the average distance from i to points in the nearest cluster. The interpretation of SC values can be categorized into several classifications [30]: SC values between 0.7 and 1 indicate that clusters have a very strong structure; SC values between 0.5 and 0.7 suggest a medium structure; SC values between 0.25 and 0.5 imply a weak structure; and SC values below 0.25 indicate that clusters have no clear structure.

The detailed steps of the K-means clustering algorithm used in this study are described as follows [31]:

- Determine the desired number of clusters (K) from the data set.

- Randomly determine a value for the initial cluster center (centroid) of k.

- Calculate the distance of each input data point to the nearest centroid using a distance metric such as the Euclidean distance until the closest distance between each data point and the centroid is found. The following is (Equation (3)) regarding the Euclidean distance:

- 4.

- Cluster each data point based on its proximity to the centroid (smallest distance).

- 5.

- Update or recalculate the position or centroid value based on the newly formed cluster members. The new centroid value is obtained from the average of the cluster concerned using Equation (4), where

- 6.

- Repeat steps 2 to 5 until the cluster members have not changed, in other words, until the centroid position no longer changes (converges).

- 7.

- If step 6 has been fulfilled, then the cluster centroid value at the last repetition will be used as a parameter to determine the classification of the data.

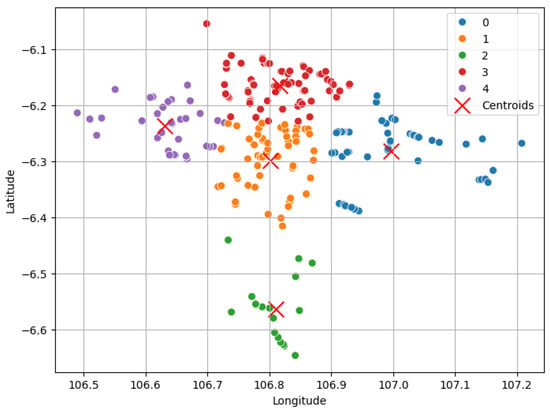

The clustering process leads to two main conclusions: the visualization of clustering results and the identification of candidate logistics facility locations. Utilizing the K-means algorithm, five clusters were successfully formed from the dealer location data, with each cluster represented by the following centroid: Cluster 1 (Orange): Centroid at (−6.29831986, 106.801635); Cluster 2 (Green): Centroid at (−6.5637955, 106.8099795); Cluster 3 (Red): Centroid at (−6.16541688, 106.81689429); Cluster 4 (Purple): Centroid at (−6.236655, 106.63144639); and Cluster 5 (Blue): Centroid at (−6.28131137, 106.99607157).

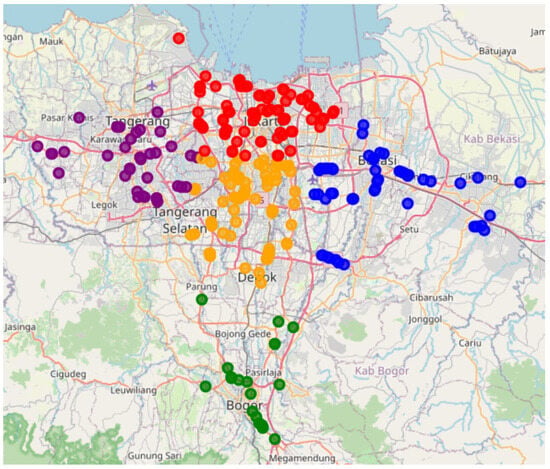

To provide a clearer view of the spatial distribution of dealers within the five clusters, Figure 1 presents a scatter plot of the clustering results with centroid indications, while Figure 2 displays the corresponding map-based visualization.

Figure 1.

K-means clustering results for 254 EV dealers in Greater Jakarta—cluster plot with centroids.

Figure 2.

Geographic distribution of clustered EV dealers in Greater Jakarta, with centroid locations marked on the map. The orange dots represent Cluster 1, green dots represent Cluster 2, red dots represent Cluster 3, purple dots represent Cluster 4, and blue dots represent Cluster 5.

Next, each centroid was evaluated against the official Regional Spatial Plan to ensure that it does not fall within restricted zones such as green areas or dense residential zones. If a centroid was located in an unsuitable location, candidate CCs were manually selected from nearby industrial or logistics permitted zones. The cluster itself, however, remains as the reference service area to maintain the structure of the RLN. Note that 254 EV dealers are included. This presents a challenge in solving this model to optimality. Therefore, restricting the locations based on clusters when solving this model reduces the solution space, simplifying the computations.

As a result of this spatial validation, several candidate facility locations were identified:

- Twenty candidate CC locations (four per cluster).

- Four candidate RMC locations.

- Two candidate WDC locations.

These candidate locations are used as input alternatives for optimization in the MILP model. The complete list of candidate CC facility locations and their coordinates is presented in Table 2, while the candidate locations for the RMC and WDC are detailed in Table 3.

Table 2.

Selected candidate locations and coordinates for the CC in the RLN.

Table 3.

Selected candidate locations and coordinates for the RMC and WDC in the RLN.

2.3. MILP Model Formulation

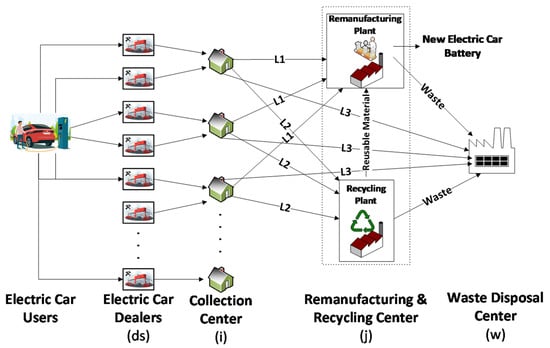

The RLN model was developed based on several key references. A network structure consisting of three main facilities—the CC, RMC, and WDC—was proposed in [16]. The detailed processes at each facility were described in [9], while the role of dealers as the initial collection point for batteries from electric vehicle users was emphasized in [19]. Furthermore, the integration of automobile sales and service dealerships into the RLN system was examined in [6]. Based on these studies, the conceptual model for designing a reverse logistics network for end-of-life (EoL) electric car batteries in the Jakarta Greater Area is illustrated in Figure 3.

Figure 3.

Conceptual model of the RLN for EoL EV batteries.

According to Figure 2 above, electric car dealerships act as the primary collection points for used batteries from consumers. Dealers were chosen because they are a trusted service provider for customers and have the necessary expertise and technology to manage battery EoL processes. Their established presence facilitates coordination of battery collection. Given that Indonesia currently lacks sufficient reverse logistics infrastructure for EoL electric car batteries, a tailored approach is crucial in identifying the locations of facilities that support this system, such as dealerships. The battery collection strategy plays a pivotal role in ensuring the success of this RLN. One possible solution is to enlist authorized car dealers as the initial collection point for consumers, before the batteries are sent to the CC. Essentially, these dealers serve as the link connecting consumers with the system. They not only function as the first collection point for the batteries but also ensure that the flow of batteries is organized before being forwarded to the CC.

Each dealer can only deliver batteries in pack form to one nearby CC in the same predetermined cluster, with no flexibility to divert the delivery to another CC. Further, at the CC, the batteries are disassembled into individual cells. It is then classified into three quality categories: L1 for remanufacturing, L2 for recycling, and L3 for going directly to the WDC. The classification is based on the state of health (SoH) or remaining capacity of the battery cell. Specifically, L1 includes cells with SoH > 80%. L2 ranges from 60 to 80%, and L3 includes cells with SoH < 60% [16]. There are only two possible flows from the CC: either to the RMC for L1 and L2 or to the WDC for L3. Individual batteries or cells that have entered the CC, RMC, and WDC cannot be returned to the previous facility. Additionally, there is a special flow from the RMC to the WDC in the form of solid waste generated by the recycling and remanufacturing process. The flow of reusable materials in this model is not taken into account.

With the conceptual understanding of the reverse logistics system model described earlier, the next step is to formulate a mathematical model in the form of MILP to optimize the network. This model formulation starts by defining sets and indices that represent the main elements in the system. These elements are outlined in Table 4.

Table 4.

Sets and indices used in the model.

Next, parameter determination is carried out to ensure that the model accurately represents real-world conditions. The complete list of parameters used in the model, along with descriptions, is presented in Table 5.

Table 5.

List of parameters used in the MILP model.

Next, decision variables are determined to represent the choices or actions in the mathematical model that will be optimized. The complete list of decision variables is presented in Table 6.

Table 6.

Decision variables in the MILP model.

The objective function in this model is formulated as a single-objective function, aiming to minimize the total cost associated with the reverse logistics network for end-of-life electric car batteries. The objective functions are first presented in a simplified form in Equation (5), which outlines the total cost components in general terms. The complete formulation, incorporating all decision variables and parameters in mathematical detail, is then elaborated in Equation (6). The total cost in this model consists of five key components:

- Acquisition costs ( for collecting used batteries from dealers to collection centers.

- Fixed costs ( related to the leasing and operation of reverse logistics facilities, including CC, RMC, and WDC.

- Processing costs () for handling and treating batteries based on their type and condition.

- Transportation costs () incurred during the movement of batteries between nodes in the reverse logistics network and between nodes in the logistics network. In this study, we assume that homogeneous trucks are used to transport used batteries.

- Carbon tax costs, which are calculated by multiplying the total carbon emissions—consisting of emissions from battery processing () and transportation ()—by a fixed carbon fix rate .

By minimizing the sum of these components, the model identifies the most cost-effective facility configuration and material flow while internalizing the environmental impact through the carbon tax component included in the total cost.

The decision-making aspects in this model include the selection of facility locations (the CC, RMC, and WDC) as well as the allocation of battery flows between these facilities. These decisions are made to achieve economic efficiency while indirectly acknowledging the environmental impact through the inclusion of carbon tax costs as part of the total cost. By integrating the carbon tax directly into the cost function, the model enables environmental considerations to be internalized within the economic objective, thereby eliminating the need for a separate emission-based objective. This simplification maintains practical applicability while still promoting environmentally responsible decisions.

In this model, which is assumed to be an incapacitated reverse logistics network (excluding facility capacity constraints), several constraints are designed to ensure the logical validity of the reverse logistics system for end-of-life electric car batteries in the Jakarta Greater Area. First, there are individual cell mass balance and quality distribution constraints that ensure that all batteries of type b collected at each CC in cluster k are disassembled into individual cells and distributed to the destination facility (the RMC or WDC) based on the quality proportion (, as formulated in Equations (7)–(10). Second, the solid waste mass balance constraint in Equation (11) ensures that 20% of the cell mass processed at the RMC as solid waste is fully delivered to the WDC. Third, the number of facilities selected constraint, as in Equations (12)–(14), stipulates that only one CC is selected per cluster, and only one RMC and one WDC can be opened in the network.

Furthermore, the flow constraints in Equations (15)–(19) are used to ensure that the logistics flow is logical in accordance with the system structure. The flow from dealers is only allowed to CCs within the same cluster (Equations (15) and (16)), and from CCs individual cells are flowed to destination facilities according to their quality classification: L1 to the RMC for remanufacturing (Equation (17)), L2 to the RMC for recycling (Equation (18)), and L3 to the WDC for disposal (Equation (19)). Solid waste from the RMC should only flow to the active WDC. In addition, flow validation constraints based on cell quality (Equations (20)–(22)) are applied to ensure that only L3 cells can flow to the WDC, while L1 and L2 cells must be processed at the RMC. Finally, constraints for decision variables ensure that all flow variables are non-negative (Equation (23)), and facility selection is expressed through binary variables (24).

2.4. Tools and Software

The optimization model in this study was developed and executed using the Python programming language, which provides extensive libraries for operations research and data processing. The coding process was carried out on Google Colaboratory (Colab), a cloud-based Jupyter notebook environment that enables users to write and execute Python code directly in a browser, eliminating the need for local setup.

Key Python libraries used include the following:

- PuLP for formulating and solving the MILP model.

- Pandas for data manipulation and preprocessing.

- Matplotlib.pyplot for visualizing data and clustering results.

While the model was run in the cloud, the personal computer (PC) used for supporting tasks was equipped with an Intel(R) Core(TM) i5-10210U CPU running at 1.60 GHz (up to 2.11 GHz), 8.00 GB of installed RAM (7.80 GB usable), and a 64-bit operating system with an x64-based processor architecture. The operating system used was Windows 10.

2.5. Model Parameters and Data Sources

The mathematical model in this study is built upon a diverse range of data obtained through a combination of calculations, estimations, publicly available reports, field data, and literature-based benchmarks. The battery quantity data between electric vehicle dealers and candidate CCs was calculated based on the proportional distribution of each brand’s national sales data. City-level EoL battery estimates were derived using the number of dealers per city and the total national sales, then proportionally allocated to each dealer. The acquisition cost per battery cell by quality category (L1, L2, and L3) and battery type (e.g., LFP and NiMH) was estimated by referencing the new battery cost as a percentage of vehicle prices. These values were adjusted for depreciation and assumptions regarding remaining capacity. The quality distribution proportions of received batteries at each CC were adapted from technical assumptions and the literature and generalized across all clusters and battery types.

For the fixed facility costs (CC, RMC, and WDC), baseline values from previous studies were adjusted to the local context using warehouse rental price data from Indonesian real estate platforms. Additional adjustments were made to reflect the average building size for each facility type. Processing costs at each facility were benchmarked based on international studies (primarily using NMC chemistry) and recalculated to account for the weight differences in local battery types, such as LFP and NiMH. Similarly, processing emissions were derived from literature values and adjusted accordingly.

Transportation distances between all facilities (dealers to CCs, CCs to RMC/WDC, and RMC to WDC) were calculated using actual road routes obtained from Google Maps to reflect real-world conditions rather than Euclidean (straight-line) distances. Over 1000 dealer–CC distances, as well as 80 CC-RMC, 40 CC-WDC, and 8 RMC-WDC routes, were computed. Transportation costs were calculated using vendor-based estimates for transporting heavy goods, specifically battery packs and individual cells. The cost per km per unit or per cell was derived from battery weight and the standard cost per kg per km. Specific rates for hazardous waste disposal transport were also included, based on local vendor benchmarks. Transportation emissions per km were estimated using average truck fuel consumption, effective payload assumptions, and vehicle specifications relevant to local logistics fleets (e.g., Isuzu GIGA payload standards). Emission factors were calculated for three types of logistics: battery pack delivery, cell transportation, and waste transport.

Carbon tax values were applied in accordance with the Indonesian government’s regulations, particularly the carbon tax law, which stipulates the monetary cost per kilogram of CO2 emitted.

The battery specifications, including the number of individual cells per pack, were determined by referring to actual electric vehicle models marketed in Indonesia. Specifically, LFP battery data was based on the BYD Seal, which has a capacity of 82.5 kWh and contains 172 cells, while NiMH battery data was derived from the Innova Zenix, which has approximately 205 cells per pack. These specifications were essential to calibrate the weight, cost, and emissions-related parameters at a granular level.

All key parameters were documented in the form of indexed sets, values, and equations, with the complete list available in the model tables. If requested, the authors are ready to provide the raw data, assumptions, and calculations for review or validation purposes.

3. Results

The optimization was carried out using a single-objective MILP model. The model was designed to minimize the total cost (Z), considering acquisition, facility, processing, transportation, and carbon tax costs. Table 7 presents the status of the model solution and the corresponding values of the objective function. Although carbon emissions were not explicitly included as an optimization objective, they were implicitly accounted for through the inclusion of the carbon tax cost in the total cost. This ensures that emissions are still minimized indirectly from an economic perspective.

Table 7.

Solution status and objective function value.

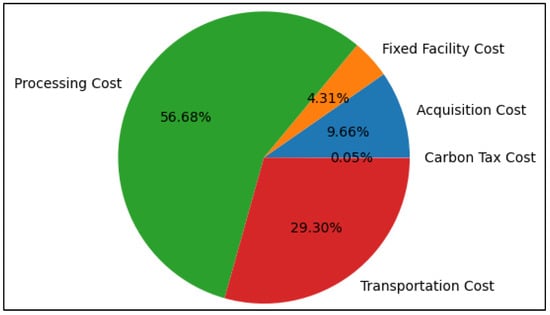

To better understand the cost structure, Table 8 and Figure 3 illustrate the composition of the total cost across the network. Figure 4 clearly shows that processing costs account for the largest share of the total cost at 56.68%, followed by transportation costs at 29.30%. Acquisition and fixed facility costs contribute 9.66% and 4.31%, respectively. Carbon tax contributes a tiny proportion, accounting for only 0.05% of the total cost. The total carbon emissions generated across the network were 21,113,153.46 kg CO2, which served as the basis for calculating the carbon tax cost.

Table 8.

Cost composition across the reverse logistics network.

Figure 4.

Cost composition across the reverse logistics network.

Based on the optimization results of the single-objective MILP model, the system automatically determines the most optimal facility location to support the EoL management of electric car batteries in the Jakarta Greater Area. Facility selection was driven by cost minimization while also considering dealer proximity within each cluster. Although carbon emissions were not explicitly minimized, they were indirectly accounted for through the inclusion of carbon tax costs in the objective function. The optimization results showed that five CCs, one CC per cluster; one RMC; and one WDC were selected. These facilities were deemed the most cost-effective for supporting the collection, processing, and disposal of used batteries. Table 9 lists the selected facilities based on the optimization results.

Table 9.

Selected facilities (optimization results).

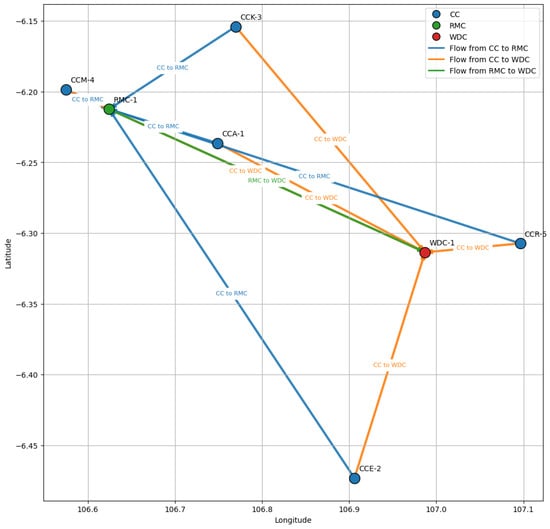

In this model, batteries are converted from packs to individual cells upon arrival at the CC to facilitate classification and further processing. Once classified, the battery cells from the CC are routed to RMC-1 for two categories: the L1 category, which is suitable for remanufacturing (denoted as Qm), and the L2 category, which is ideal for recycling (Qr). Meanwhile, batteries belonging to the L3 category, i.e., those not suitable for further processing as well as solid waste generated from processing at RMC-1, are directly sent to WDC-1 for disposal (Qw). A visualization of the flow of individual EoL battery cells from the Collection Center (CC) to the processing facility is shown in Figure 5.

Figure 5.

Flow of individual battery cells from the CC to the processing facility.

Table 10 below presents the flow of individual cells from each CC in each cluster to the processing facilities, namely RMC-1 and WDC-1. Each cluster sends two types of batteries, LFP and NiMH, which have been converted into a total of 4,042,685 individual cells. Of these, 2,430,360 cells were from LFP, while 1,612,325 cells were from NiMH batteries. The flow from CCs to processing facilities is divided into three categories based on cell quality: category L1 (Qm) for remanufacturing, category L2 (Qr) for recycling, and category L3 (Qw) for disposal. The proportion of cell quality distribution in this model is 15.4% for L1, 61.3% for L2, and 23.3% for L3, which is consistent across clusters and battery types. These results show that the cell flow is proportionally distributed by quality, with the model maintaining a balance between total supply and output. In addition, clusters with higher dealer concentrations, such as cluster 3, contribute more to the logistics flow than other clusters.

Table 10.

Individual cell flow from the CC to the processing facility.

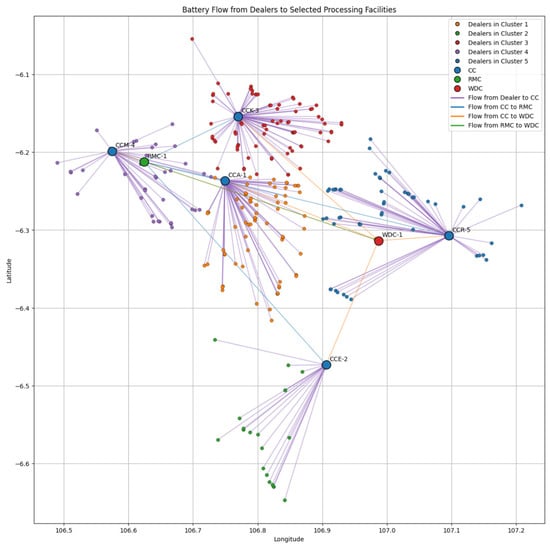

Figure 6 presents a visualization of the overall flow of EoL electric car batteries in the designed RLN. The flow starts from the dealers within each cluster, moves to the collection center in that cluster, and then continues to the selected processing facility that has been optimized using the MILP model. Each dealer in the cluster is visualized with a different color: orange for cluster 1, green for cluster 2, red for cluster 3, purple for cluster 4, and blue for cluster 5, while the flow path from the dealer to the CC is shown in purple. The flow directions between processing facilities are depicted using different colored arrows to clarify the logistics routes in the RLN.

Figure 6.

Battery flow from the dealer to the CC and selected processing facilities.

Furthermore, Table 11 displays the amount of solid waste generated from the RMC-1 facility that was transported to WDC-1, categorized by the type of battery processed.

Table 11.

Weight of solid waste from RMC-1 to WDC-1.

4. Discussion

This section discusses the results obtained from the MILP-based reverse logistics network model and interprets them from technical, managerial, and environmental perspectives. The discussion includes a detailed cost and emissions analysis, spatial facility selection logic, and their alignment with sustainability goals. Furthermore, the implications for managerial decision-making and public policy are elaborated to provide practical value. Lastly, several limitations of the current study are addressed to guide future research directions.

4.1. Analysis of Results

The results of the single-objective MILP model show that the solution satisfies all operational constraints while minimizing the total cost of the reverse logistics network. The model generated a technically feasible and economically efficient solution, with optimal facility locations that support cost-effective EoL battery management in the Jakarta Greater Area.

The cost structure analysis indicates that the most significant portion of the total cost is attributed to processing activities, which account for 56.68% of the total cost. This suggests that operations within facilities, particularly at the RMC and WDC, have the most significant influence on the total cost. This high processing cost is also a key factor in facility location decisions, as process efficiency directly affects total operating costs. Therefore, enhancing process efficiency at the RMC and WDC is a significant opportunity for cost savings. Meanwhile, transportation costs account for 29.30% of total expenses, influenced by the distance between facilities, the volume of flow, and the frequency of delivery. Optimizing logistics has proven vital for reducing costs. Conversely, acquisition costs (9.66%) and fixed costs (4.31%) contribute less, indicating that the cost structure is driven more by daily operations than by the initial investment.

Although emission minimization was not the primary objective in this study, a post-optimization emission analysis was conducted. The results show that processing activities generated approximately 91.8% of the total carbon emissions, while transportation activities contributed only 8.2%. This aligns with previous studies [16], which also identified processing as the dominant source of emissions in reverse logistics systems. These results suggest that technological efficiency at processing facilities is the key determinant of overall emissions. Therefore, investment in energy-efficient and environmentally friendly technologies at the RMC and WDC is critical. This underscores the importance of adopting green processing technologies, energy-efficient recycling, and carbon mitigation strategies, as highlighted in studies on sustainable waste management [32]. Optimizing these technical processes offers a promising approach to simultaneously reduce emissions and lower carbon tax liabilities while enhancing the overall cost-effectiveness of the reverse logistics network. Emissions from transportation contribute to only 8.2%, so opting for alternative transportation modes will not significantly impact the overall total emissions. Therefore, the primary strategy proposed is to optimize technical processes at the facility to reduce costs and emissions simultaneously. This deterministic model, while effective for initial analysis, sets the stage for future research that could incorporate robust or stochastic approaches to account for inherent uncertainties in EoL battery volumes, processing costs, and quality variations [33]. Moreover, the analysis suggests a potential regulatory gap in Indonesia regarding explicit standards and financial incentives for green processing technologies, which could accelerate the adoption of such efficient practices within the RLN.

The developed MILP model is capable of selecting facility locations while considering cost efficiency as the primary objective. The distance between facilities is a crucial factor in the selection process. The chosen facilities are typically positioned close to dealer concentrations, such as CCA-1 in Pesanggrahan, South Jakarta, which serves strategically to cater to the local dealer cluster and reduce emissions and transportation costs. Additionally, some facilities, such as CCE-2 in Jatiuwung, Tangerang, were selected due to their proximity to the cluster’s centroid, thereby minimizing the distribution distance. Other facilities, including CCM-4 in Jatake and CCR-5 in MM2100, are situated in industrial estates that already have logistics infrastructure, making them efficient and practical choices.

The strategy of centralizing processing and disposal also proved effective, where only one RMC (RMC-1 in Tangerang) and one WDC (WDC-1 in Bantar Gebang) were selected. The location of RMC-1, which is centrally situated near several CCs, facilitates efficient battery flow, while WDC-1, as a regional disposal site, provides operational and policy advantages. In terms of volume, the most significant flow originates from i (West Jakarta), followed by CCA-1 (South Jakarta), reflecting the high number of dealers and potential supply of EoL batteries in these two regions.

The MILP model effectively selects the shortest route and facilities close to the concentration of dealers, as the processing cost is uniform, with distance being the primary determinant in decision-making. Thus, the logistical efficiency achieved not only reduces costs but also improves the overall system performance. Overall, the results indicate that optimizing technical processes at processing facilities, as well as enhancing logistical efficiency, is crucial in achieving a sustainable and economical RLN system for electric car battery management in urban areas, such as the Jakarta Greater Area.

4.2. Managerial and Policy Implications

This section discusses the practical implications of the research results for managerial decision-making and public policy related to the management of EoL electric car batteries in the context of implementing a reverse logistics network in the Jakarta Greater Area.

From a managerial perspective, agencies or companies entrusted by the government to manage the EoL of electric car batteries are advised to utilize the MILP-based reverse logistics network design model developed in this study. This model can serve as a valuable tool in strategic decision-making, particularly in determining the optimal location of facilities and designing efficient distribution channels. The application of this model enables cost savings through improved process efficiency at facilities such as RMC and WDC while improving the overall effectiveness of logistics management. For future development, managers should consider integrating capacity constraints into facility planning, as highlighted in comprehensive reviews on reverse logistics [10]. Moreover, when selecting optimal greenfield sites, exploring multi-criteria decision-making (MCDM) approaches could offer a broader perspective beyond mere cost minimization, allowing for the integration of various sustainability dimensions [34].

Meanwhile, in terms of public policy, the government plays a crucial role in encouraging the implementation of an optimal reverse logistics network. Policies that can be implemented include (1) centralization of processing and disposal facilities to facilitate supervision and improve logistics efficiency. This can be achieved by obligating the producers and dealers to provide take-back programs, which support the development of dismantling centers and facilitate the initiation of producer responsibility organizations; (2) strengthening collaboration among stakeholders that encourage the use of more efficient processing technologies to reduce costs and emissions; providing incentives and subsidy for recycling companies to increase their profit margin; and (3) developing logistics infrastructure that supports the effective and sustainable implementation of the reverse logistics network.

Building on these points, the findings from this study highlight several broader policy implications. First, there is a clear opportunity to establish public–private partnerships (PPPs) to finance and operate the capital-intensive processing facilities (RMC and WDC). Given the high processing costs identified in our model, government support through land subsidies, tax breaks, or direct investment can significantly mitigate the risks associated with these projects for private investors. Such partnerships can also bridge the gap between private sector expertise in technology and public sector goals for sustainable waste management. Second, the current regulatory framework in Indonesia for EoL battery management appears to have gaps. Specifically, there is a lack of a comprehensive extended producer responsibility (EPR) policy that mandates manufacturers to take back their products at the end of life. Implementing a robust EPR policy would not only formalize the collection process but also create a clear financial stream to support the reverse logistics network, as it shifts the responsibility and cost from the public to the private sector. Lastly, the government should consider establishing clearer technical standards and certifications for battery dismantling and recycling to ensure environmental and safety compliance, which would be crucial for attracting private sector investment and ensuring the long-term sustainability of the network.

These policies can create a battery EoL management ecosystem that is more efficient, environmentally friendly, and in line with the principles of a circular economy. Given the unique socio-economic landscape of Indonesia, future policy considerations should also explore the potential role of integrating the informal sector, such as waste pickers or unofficial dealers, into the formal RLN, as their contributions are significant in developing countries [35].

4.3. Research Limitations

Although the reverse logistics network model developed in this study is designed to provide an optimal solution for managing EoL EV batteries in the Jakarta Greater Area, several limitations must be acknowledged as the basis for future model refinement and practical implementation. The deterministic single-objective MILP formulation, while effective for a foundational analysis, inherently simplifies the complex, multifaceted nature of real-world reverse logistics. This is because the model’s primary assumptions, such as a singular focus on cost minimization, may overlook other critical factors.

First, this study adopts a simplifying assumption in which the proportion of battery cell quality—categorized as remanufacturable (L1), recyclable (L2), and disposable (L3)—is fixed and uniform across all clusters and battery types. This assumption was necessary due to the unavailability of detailed, dealer-specific data on battery quality returns in the Indonesian context. However, in real-world conditions, the composition of returned battery cell quality may vary significantly depending on the region, brand, user behavior, and usage environment. We acknowledge that this assumption may limit the model’s ability to reflect localized differences in battery degradation patterns. Therefore, future works should incorporate more flexible and dynamic modeling approaches by utilizing empirical data collected from individual dealers or OEMs. This enhancement would support a more realistic estimation of logistics flows, better accommodate spatial and technical heterogeneity among regions, and improve the alignment of logistics strategies with the dominant EoL battery conditions in each area.

Secondly, the current model adopts a deterministic approach, where all key parameters—such as the volume of returned batteries, processing costs, and the proportion of battery quality—are treated as fixed values. This simplification neglects the inherent uncertainties present in real-world reverse logistics systems. Factors such as seasonal fluctuations in EoL battery volume, market-driven changes in processing and disposal costs, and the stochastic nature of battery degradation could affect operational decisions and sustainability outcomes. Future studies are encouraged to develop stochastic- or fuzzy-based models that can better capture such uncertainties, thereby increasing the robustness, flexibility, and environmental responsiveness of reverse logistics planning. This model does not explicitly address uncertainty in input parameters, as it employs a deterministic MILP approach. Moreover, the involvement of informal actors in battery waste management has not been integrated due to limited data availability and regulatory ambiguity. While informal consultations were conducted during site selection to ensure regulatory compliance, formal validation with local stakeholders was not carried out.

Third, the model assumes unlimited processing capacities for CCs, RMC, and WDC, meaning that facility capacity constraints are not explicitly considered. This simplification was made primarily due to the current absence of established EoL battery processing facilities for electric vehicles in Indonesia, which results in a lack of reliable empirical data regarding actual capacity limitations in the national context. Nonetheless, we recognize that capacity constraints are crucial in real-world implementations to ensure the feasibility and applicability of optimization results. Although our model does not explicitly enforce these constraints, the resulting flows and facility load assignments remain within a reasonable range when compared to similar studies in countries with operational EoL infrastructures. Therefore, the assumption does not result in unrealistic or overloaded facility usage. We acknowledge this as a limitation of the model and recommend that future studies incorporate realistic capacity bounds as soon as relevant empirical data become available in the Indonesian context

Fourth, this study did not include a sensitivity analysis to evaluate the robustness of the results under varying parameter settings. The computational time required to solve the current MILP model was already substantial, and conducting multiple runs for sensitivity testing was not feasible within the available timeframe. This limits our ability to assess how changes in assumptions—such as cost parameters or demand volumes—might affect the outcomes. Future research is encouraged to incorporate sensitivity analysis using more computationally efficient solution methods.

5. Conclusions

This section summarizes the key findings of the study, highlights its theoretical and practical contributions, discusses the scalability of the proposed model, and provides directions for future research. The proposed reverse logistics network design model for managing end-of-life electric vehicle batteries in the Jakarta Greater Area demonstrates significant potential in terms of operational cost efficiency, environmental performance, and strategic applicability for larger regions.

5.1. Summary of Findings

This study aims to design an optimal reverse logistics network for managing EoL electric car batteries in the Jakarta Greater Area. By using a deterministic-based MILP approach, the developed model can produce solutions that focus on minimizing total operational costs, thereby supporting economic efficiency in reverse logistics system planning.

The designed MILP model can minimize the total operational cost up to IDR 1,236,435,000,187. The cost structure shows that processing is the most dominant component (56.68%), followed by transportation costs (29.30%), acquisition costs (9.66%), and facility fixed costs (4.31%). These findings indicate that process-related activities at the facilities play the most critical role in the overall cost structure.

The optimization solution determined the locations of the selected facilities, namely five Collection Centers (CCA-1, CCE-2, CCK-3, CCM-4, and CCR-5), one Remanufacturing and Recycling Center (RMC-1), and one Waste Disposal Center (WDC-1). The logistics flow pattern of the battery EoL follows a centralized scheme, where all L1 and L2 quality cells are sent to RMC-1, while L3 quality cells are sent to WDC-1. The solid waste generated from the process at RMC-1 and sent to WDC-1 totaled 1,028,738.78 kg, with the majority coming from LFP-type batteries.

Although emission minimization was not explicitly included in the optimization objective, a post-optimization emission analysis revealed that processing activities contributed approximately 91.8% of the total emissions (21,108,271 kg CO2), while transportation accounted for only 8.2%. This finding highlights the significant role of technological and energy efficiency in processing operations, which reduces the environmental impact and potential carbon tax liabilities.

5.2. Research Contribution

This study, based on the findings from our model, makes several key contributions, both theoretically and practically, to the development of reverse logistics systems for managing EoL electric car batteries, particularly in the Jakarta Greater Area.

- Methodological Contribution: This research develops a deterministic-based MILP model that integrates cost and emission aspects simultaneously in facility siting and logistics flow design. The model also considers the quality classification of battery cells (L1, L2, and L3) and maps the flow distribution hierarchically from the dealer to the next facility (the CC, RMC, and WDC), a detail not previously explained in studies.

- Practical and Contextual Contributions: This study provides strategic solutions that government agencies and industry players in Indonesia can implement. Specifically, by leveraging the model’s real cost structure and emission estimation, the model results can serve as a basis for facility placement decision-making, as well as logistics network optimization, based on local data from the Jakarta Greater Area. This is highly relevant in supporting the energy transition and sustainable development agenda.

- Contribution to Environmental Policy and Management: The results of this study, particularly the finding that processing activities are the most dominant source of both costs and emissions, provide quantitative justification for the importance of centralization of processing and disposal facilities and process efficiency as key factors in reverse logistics policy planning, which can assist the government in designing evidence-based policies to support efficient and environmentally friendly management of electric car battery waste.

5.3. Model Scalability and Application in Larger Regions

The developed MILP model is scalable to broader geographical scopes, such as the entire West Java Province or even the whole island of Java. Although this study focuses on the Jakarta Greater Area, the model structure allows for straightforward replication and extension to larger regions without altering its mathematical formulation.

The primary requirement for scaling up involves adjusting input parameters and defining candidate facility sets. For instance, in a larger-scale application, an initial clustering process can be conducted to group EV battery sources (dealers) into multiple clusters across the wider region. Within each cluster, up to four candidate sites for CCs can be preselected based on relevant criteria, such as land-use planning policies, variations in fixed investment costs, and proximity to high-density supply areas. In contrast, candidate locations for the RMC and WDC do not need to follow the clustering logic. These facilities can instead be strategically placed based on regional accessibility, land-use planning policies, proximity to industrial zones, availability of supporting infrastructure, or alignment with provincial-level environmental regulations and waste management strategies.

5.4. Recommendations for Further Research

As a follow-up to the findings and limitations identified in this study, the following recommendations are proposed to support the development of models and future studies:

- Development of Constraint Flexibility: The developed MILP model can be made more flexible by incorporating semi-flexible constraints, particularly those concerning the flow of L2 quality cells. The cells may have the option to flow to multiple alternative facilities, accompanied by appropriate cost or emission penalties. This approach allows the model to adapt to changes in policy and stakeholder preferences, resulting in a broader range of trade-off solutions.

- Variation in Cost and Emission Parameters between Facilities: With further development, it is advisable to differentiate the cost and emission values among facilities to capture variations in technological efficiency. This will enhance the model’s accuracy in reflecting real-world conditions and strengthen the validity of the results for informed strategic decision-making.

- An Uncertainty-Based Approach: Developing stochastic or robust optimization models to address data uncertainty that frequently arises in real-world situations, such as fluctuations in end-of-life battery volume, changes in processing costs, and variations in technical conditions, is essential. This will offer a more resilient solution to system dynamics.

- Facility Capacity Considerations: The developed MILP model can gain flexibility by applying semi-flexible constraints, particularly those regarding the flow of L2 quality cells. These cells can be permitted to flow to various alternative facilities with suitable cost or emission penalties. This approach enables the model to respond to shifts in policy and stakeholder preferences, producing a wider array of trade-off solutions.

- Future research is encouraged to conduct detailed cost validation through collaboration with local institutions to enhance the financial accuracy and practical relevance of the reverse logistics network model.

- We believe that extending the model to a multi-objective framework or integrating life cycle assessment (LCA) methods could enrich the environmental and social perspectives, further enhancing the sustainability value of the proposed system.

- Developing more efficient solution approaches, such as metaheuristics, is also a promising direction for future research. This would enable the model to handle larger problem sizes and allow sensitivity analyses to be conducted more efficiently.

Future research should build upon the foundational model of this study by addressing its simplifying assumptions to create a more comprehensive and realistic framework. It is recommended to move beyond a single-objective formulation by exploring multi-objective optimization, which could better balance economic costs with critical environmental and social impacts. Additionally, incorporating more flexible cost structures that reflect economies of scale or technology-dependent variations would enhance the model’s accuracy. A key direction for future work is to move away from the deterministic approach, where all parameters are treated as fixed values, and instead explore stochastic or robust models. This would allow the framework to reflect better real-world uncertainties, such as fluctuating battery returns or dynamic changes in processing costs, ultimately providing a more holistic and robust framework for decision-making.

Author Contributions

Conceptualization, I.Z.B. and R.A.; methodology, I.Z.B., R.A., and N.Y.S.; writing—original draft preparation, I.Z.B.; writing—review and editing, I.Z.B., R.A., and N.Y.S.; supervision, R.A. and N.Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by Universitas Indonesia through Hibah Publikasi Terindeks International (PUTI) Q1 2025–2026, No. PKS-267/UN2.RST/HKP.05.00/2025.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to institutional restrictions.

Acknowledgments

The authors would like to thank the Department of Industrial Engineering at Universitas Indonesia for its academic guidance and support throughout the completion of this research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lin, J.; Li, X.; Zhao, Y.; Chen, W.; Wang, M. Design a reverse logistics network for end-of-life power batteries: A case study of Chengdu in China. Sustain. Cities Soc. 2023, 98, 104807. [Google Scholar] [CrossRef]

- Etxandi-Santolaya, M.; Casals, L.C.; Corchero, C. Extending the electric vehicle battery first life: Performance beyond the current end of life threshold. Heliyon 2024, 10, e26066. [Google Scholar] [CrossRef] [PubMed]

- International Energy Agency (IEA). Global EV Outlook—Executive Summary; International Energy Agency: Paris, France, 2024; p. 11. [Google Scholar]

- Padhilah, F.A.; Surya, I.R.F.; Aji, P.; Tumiwa, F.; Arinaldo, D. Electrifying Transport Sector: Tracking Indonesia EV Industries and Ecosystem Readiness; Institute for Essential Services Reform (IESR): Jakarta, Indonesia, 2023. [Google Scholar]

- He, M.; Li, Q.; Wu, X.; Izui, K. Designing a multi-level reverse logistics network for waste batteries of electric vehicles under uncertainty—A case study in the Yangtze River Delta Urban Agglomerations of China. J. Clean. Prod. 2024, 472, 143418. [Google Scholar] [CrossRef]

- Wang, C.; Feng, X.; Woo, S.; Wood, J.; Yu, S. The optimization of an EV decommissioned battery recycling network: A third-party approach. J. Environ. Manag. 2023, 348, 119299. [Google Scholar] [CrossRef]

- Liao, W.; Hu, G.; Luo, X. Collaborative reverse logistics network for electric vehicle batteries management from sustainable perspective. J. Environ. Manag. 2022, 324, 116352. [Google Scholar] [CrossRef]

- Du, Y.; Zhou, Y.; Jia, D.; Li, X. The end-of-life power battery recycling and remanufacturing center location-adjustment problem considering battery capacity and quantity uncertainty. J. Environ. Manag. 2024, 357, 120774. [Google Scholar] [CrossRef]

- Li, J.; Liu, F.; Zhang, J.Z.; Tong, Z. Optimal configuration of electric vehicle battery recycling system under across-network cooperation. Appl. Energy 2023, 338, 120898. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Valenzuela, J.; Alfaro, M.; Fuertes, G.; Vargas, M.; Sáez-Navarrete, C. Reverse logistics models for the collection of plastic waste: A literature review. Waste Manag. Res. J. A Sustain. Circ. Econ. 2021, 39, 1116–1134. [Google Scholar] [CrossRef]

- Mu, N.; Wang, Y.; Chen, Z.-S.; Xin, P.; Deveci, M.; Pedrycz, W. Multi-objective combinatorial optimization analysis of the recycling of retired new energy electric vehicle power batteries in a sustainable dynamic reverse logistics network. Environ. Sci. Pollut. Res. 2023, 30, 47580–47601. [Google Scholar] [CrossRef]

- Slattery, M.; Dunn, J.; Kendall, A. Charting the Electric Vehicle Battery Reuse and Recycling Network in North America. Waste Manag. 2024, 174, 76–87. [Google Scholar] [CrossRef] [PubMed]

- Bergh, W. Mapping the European Reverse Logistics of Electric Vehicle Batteries. Master’s Thesis, Lund University, Lund, Swedia, 2020. [Google Scholar]

- Fadhli Ruhman, A.R.F.P. Anticipating Electric Vehicle Battery Waste Through Circular Economy. Antara News, 3 March 2023. Available online: https://en.antaranews.com/news/274512/anticipating-electric-vehicle-battery-waste-through-circular-economy (accessed on 20 June 2025).

- Kuşakcı, A.O.; Ayvaz, B.; Cin, E.; Aydın, N. Optimization of reverse logistics network of End of Life Vehicles under fuzzy supply: A case study for Istanbul Metropolitan Area. J. Clean. Prod. 2019, 215, 1036–1051. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Yang, W. Optimal design of electric vehicle battery recycling network–From the perspective of electric vehicle manufacturers. Appl. Energy 2020, 275, 115328. [Google Scholar] [CrossRef]

- Moslehi, M.S.; Sahebi, H.; Teymouri, A. A multi-objective stochastic model for a reverse logistics supply chain design with environmental considerations. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 8017–8040. [Google Scholar] [CrossRef]

- Hao, H.; Sun, Y.; Mei, X.; Zhou, Y. Reverse logistics network design of electric vehicle batteries considering recall risk. Math. Probl. Eng. 2021, 2021, 5518049. [Google Scholar] [CrossRef]

- Tadaros, M.; Migdalas, A.; Samuelsson, B.; Segerstedt, A. Location of facilities and network design for reverse logistics of lithium-ion batteries in Sweden. Oper. Res. 2022, 22, 895–915. [Google Scholar] [CrossRef]

- Oliveira Neto, G.C.D.; De Araujo, S.A.; Gomes, R.A.; Alliprandini, D.H.; Flausino, F.R.; Amorim, M. Simulation of electronic waste reverse chains for the Sao Paulo circular economy: An artificial intelligence-based approach for economic and environmental optimizations. Sensors 2023, 23, 9046. [Google Scholar] [CrossRef]

- Rosenberg, S.; Glöser-Chahoud, S.; Huster, S.; Schultmann, F. A dynamic network design model with capacity expansions for EoL traction battery recycling–A case study of an OEM in Germany. Waste Manag. 2023, 160, 12–22. [Google Scholar] [CrossRef]

- Kilic, H.S.; Kalender, Z.T.; Solmaz, B.; Iseri, D. A two-stage MCDM model for reverse logistics network design of waste batteries in Turkey. Appl. Soft Comput. 2023, 143, 110373. [Google Scholar] [CrossRef]

- Ardi, R.; Nurkamila, S.; Citraningrum, D.L.; Zahari, T.N. Reverse logistics network design for plastic waste management in Jakarta: Robust optimization method. Int. J. Technol. 2023, 14, 1560–1569. [Google Scholar] [CrossRef]

- He, M.; Li, Q.; Wu, X.; Han, X. A novel multi-level reverse logistics network design optimization model for waste batteries considering facility technology types. J. Clean. Prod. 2024, 467, 142966. [Google Scholar] [CrossRef]

- Najm, H.; Asadi-Gangraj, E. Designing a robust sustainable reverse logistics to waste of electrical and electronic equipment: A case study. Int. J. Environ. Sci. Technol. 2024, 21, 1559–1574. [Google Scholar] [CrossRef]

- Sari, D.P.; Masruroh, N.A.; Asih, A.M.S. Economic and environmental benefits of e-waste management networks design in Yogyakarta province, Indonesia. J. Ind. Eng. Manag. 2024, 17, 292–320. [Google Scholar] [CrossRef]

- Sharma, P. K-Means Clustering Algorithm. Analytics Vidhya, 1 May 2025. Available online: https://www.analyticsvidhya.com/blog/2019/08/comprehensive-guide-k-means-clustering/ (accessed on 20 June 2025).

- Agustin, R.R. Geo-location clustering untuk menentukan tempat tujuan wisata dengan menggunakan algoritma PAM (Partitioning Around Medoids). J. Informatics Commun. Technol. 2023, 4, 2. [Google Scholar] [CrossRef]

- Gentle, J.E.; Kaufman, L.; Rousseuw, P.J. Finding groups in data: An introduction to cluster analysis. Biometrics 1991, 47, 788. [Google Scholar] [CrossRef]

- Saji, B. Elbow Method for Optimal Cluster Number in K-Means. Analytics Vidhya, 4 April 2025. Available online: https://www.analyticsvidhya.com/blog/2021/01/in-depth-intuition-of-k-means-clustering-algorithm-in-machine-learning/ (accessed on 20 June 2025).

- Lu, Z.; Zhang, X.; Li, J.; Chen, M. Critical pathways for transforming the energy future: A review of innovations and challenges in spent lithium battery recycling technologies. Materials 2025, 18, 2987. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Ghasemzadeh, Z.; Sadeghieh, A.; Shishebori, D. A stochastic multi-objective closed-loop global supply chain concerning waste management: A case study of the tire industry. Environ. Dev. Sustain. 2020, 23, 5794–5821. [Google Scholar] [CrossRef]

- Gutberlet, J.; Carenzo, S. Waste pickers at the heart of the circular economy: A perspective of inclusive recycling from the Global South. Worldw. Waste J. Interdiscip. Stud. 2020, 3, 1. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).