Abstract

The switching action of the main circuit breaker of the train will produce switching overvoltage. In order to suppress the switching overvoltage, the phase selection control of the circuit breaker is required. However, the mechanical structure of the train-mounted electronically controlled pneumatic vacuum main circuit breaker is too complicated, resulting in a large dispersion of its closing action time, which is not suitable for the traditional phase selection control system. In order to obtain the accurate closing action time, a method for predicting the closing action time of train electronically controlled pneumatic vacuum main circuit breaker based on the PCA and GBDT algorithm is proposed. The relationship between the closing phase of AC25 kV power supply train and the peak value of switching overvoltage is obtained by simulation and field test, and the accuracy requirement of the prediction model is determined, that is, the prediction error should be within ±3.3 ms. The final prediction results show that the prediction error of the on-board electronically controlled pneumatic vacuum main circuit breaker closing action time prediction model based on the PCA and GBDT algorithm is controlled within ±3.3 ms, and the probability is 92%, which meets the accuracy requirements of phase selection control.

1. Introduction

China’s electrified railway has achieved a historic leap from a “catch-up” to a “leader” with innovation-driven and technological self-reliance as the core. By 2025, the national railway operating mileage will reach about 170,000 km, including 50,000 km of high-speed rail [1]. At present, the traction power supply system of the train adopts the single-phase power frequency AC power supply system. The power supply of the train starts from the three-phase high-voltage power grid and is converted into a single-phase power frequency AC power suitable for the catenary through the traction substation [2]. In order to prevent different power supply sections from affecting the power system due to voltage or phase differences, a phase separation zone is set between adjacent sections. When the train passes through the phase separation zone, the train disconnects the main circuit breaker and cuts off the traction power supply; subsequently, the train slides through the phase separation zone relying on inertia; after fully leaving the phase separation zone, the main circuit breaker is closed again and the traction power is restored [3,4]. The frequent opening and closing operation of the main circuit breaker will lead to the formation of high-frequency resonance between the inductance and the distributed capacitance, causing an instantaneous voltage surge, resulting in an operating overvoltage [5]. Overvoltage and its accompanying arc discharge can cause burns to pantographs and other catenary components, causing tripping of traction substations, further leading to power supply interruption of some traction networks and shutdown of electric locomotives. At the same time, the electric power and thermal effects generated by its strong short-circuit current are harmful to equipment such as traction main transformers and feeder circuit breakers, and can threaten the stable operation of the traction power supply system. In terms of reducing the harm of switching overvoltage of vacuum circuit breaker, scholars at home and abroad have carried out many studies, mainly through the installation of arresters and other protective measures to reduce the harm of switching overvoltage. Li et al. [6] studied the influence of harmonic voltage on the amplitude and phase angle of arrester leakage current. Based on the experimental data, the high frequency equivalent circuit model of the arrester was established, and the thermal collapse mechanism under high frequency harmonics was found. Lv Fangcheng et al. [7] built a fluorescent optical fiber temperature measurement system for the roof arrester of the train, set the valve plate defects in the simulation model, and further studied the effects of defect location, defect number and air flow rate on the temperature distribution characteristics of the arrester. In addition to installing arresters, many scholars have designed simulation models to analyze the generation mechanism of switching overvoltage of vacuum circuit breakers and improved the materials and structures of the phase separation zone to reduce the harm of switching overvoltage [8,9,10,11,12]. In order to further suppress the switching overvoltage, many scholars have carried out research on the phase selection control technology of circuit breakers. Wang et al. [13] developed a phase selection controller based on ARM and FPGA dual-core architecture to perform logic control, delay time calculation, and other functions, respectively, and realize phase selection control in the field of power grid. Yang Zhijun [14] improved the key link of the phase selection controller and introduced the design of IGBT and relay hybrid outlet. The simulation results show that the phase selection controller has better anti-interference and improves the time accuracy. Xu et al. [15] proposed a phase selection control strategy based on grid parameters, which set the short circuit point and greatly improved the accuracy of phase selection control. The phase selection control technology needs to provide the accurate action time of the circuit breaker to calculate the signal delay time, so it is mostly used for electromagnetic circuit breakers with stable action time. The pneumatic vacuum circuit breaker has a large dispersion of closing action time due to its complex mechanical structure, so that the phase selection control technology can not be directly used in the pneumatic vacuum circuit breaker. In this paper, according to the working principle of the vehicle-mounted pneumatic vacuum main circuit breaker, the factors affecting the closing action time are theoretically analyzed, and a large number of test data are collected. A prediction model based on principal component analysis (PCA) and gradient boosting decision tree (GBDT) algorithm is established. Considering the accuracy of model prediction accuracy and the importance analysis of influencing factors, the test data is normalized to obtain a prediction model with higher accuracy. Joining the traditional phase selection control system, a phase selection control method suitable for pneumatic vacuum circuit breakers is obtained.

2. Analysis of Closing Characteristic Factors of Circuit Breaker

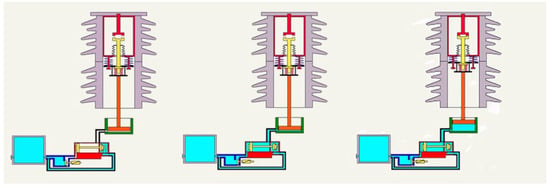

Through the theoretical analysis of the opening and closing process of the pneumatic vacuum circuit breaker, the types of characteristic factors in the opening and closing process are analyzed. The closing of the circuit breaker relies on the external high-pressure air to drive the cylinder piston to operate. When the solenoid valve is powered, the intake valve is opened, and the high-pressure air enters the cylinder through the solenoid valve and the conversion valve to drive the piston movement in the cylinder. The piston pushes the insulating rod, and the insulating rod pushes the vacuum tube moving contact movement. Finally, it is closed and pressed with the static contact, and the closing is completed. At the same time, the reset spring assembled on the moving contact is compressed and stored as shown in Figure 1. When the circuit breaker is opened, the solenoid valve loses power to close the air supply valve, and the high-pressure air is quickly discharged through the conversion valve. The cylinder piston cannot continue to compress the reset spring. The spring releases the elastic potential energy and pushes the moving contact away. The insulation rod and the cylinder piston are reset to the disconnected state, and the opening action time is relatively stable.

Figure 1.

The closing process of the pneumatic vacuum circuit breaker.

The mechanical structure of the pneumatic vacuum circuit breaker and the components involved in the closing process are analyzed. The characteristic factors that cause the dispersion of the closing action time are as follows:

(1) Pressure factor

After the solenoid valve is powered, the compressed air enters the transmission cylinder to push the transmission rod to move so that the main contact is closed. The air pressure in the transmission cylinder directly determines the thrust of the driving rod, which affects the time required for the main contact to close after the solenoid valve is electrified. The characteristic factor is the internal pressure at the moment of closing (A1).

(2) Reset spring mechanism

When the circuit breaker is closed, the transmission rod compresses the reset spring to make the contacts closely contact, and the total compression stroke of the reset spring is unchanged during each closing. When the train is running normally, the circuit breaker is in the closing state and the reset spring is in the compression state. In this state, the spring will creep, that is, the spring will increase with time under the condition of keeping the stress unchanged. Due to creep, the stress state of the spring at a certain instant is generally related not only to the instantaneous deformation, but also to the deformation process before the instant. Therefore, the duration of each closing state of the circuit breaker will affect the action time of the next closing of the circuit breaker [16]. The characteristic factors are the duration of the last closing state (A2), the internal pressure of the last closing (A3), the internal pressure difference between the two closings (A4), and the time of the last closing action (A5).

(3) Environmental temperature

The mechanical structure of pneumatic vacuum circuit breaker is complex, and the change of ambient temperature may affect the material and mechanical properties, resulting in pressure fluctuation or control signal deviation of internal compressed air. The characteristic factor is ambient temperature (A6).

(4) Solenoid valve performance

The solenoid valve is one of the core components of the pneumatic circuit breaker. It is composed of soft magnetic materials such as moving and static iron cores and reset springs. When the train comes to the closing command, the coil is energized to generate a magnetic field. The moving and static iron cores are excited to suck each other to achieve the valve opening function. The iron core uses the electromagnetic force generated by the coil to overcome the spring pressure movement, so the electromagnetic force generated by the coil will affect the closing action time of the circuit breaker.

The formula for calculating the magnetic induction intensity generated by the coil in the solenoid valve can be expressed as

where is the control voltage, is the diameter of enameled wire, and is the permeability; is the resistivity of copper, is the axis diameter of the enameled wire winding on the coil skeleton, is the outer diameter of the enameled wire on the coil skeleton, and is the air gap length. The electromagnetic force formula of the solenoid valve can be simplified as follows:

is the air gap area. It can be obtained from the formula that the electromagnetic force of the solenoid valve is proportional to the square of the control voltage, and the following characteristic factor is proposed: control voltage (A7). In addition, the electromagnetic force is inversely proportional to the square of the resistivity of copper, and the resistivity of metal conductor will be affected by temperature. The specific formula is as follows [17]:

where is the coil temperature and the following characteristic factor is determined: coil temperature (A8).

In summary, through the analysis of the principle of the closing process of the pneumatic vacuum circuit breaker, eight characteristic factors affecting the closing action time are proposed: the internal pressure at the moment of closing (A1), the duration of the last closing state (A2), the internal pressure of the last closing (A3), the internal pressure difference between the two closings (A4), the last closing action time (A5), ambient temperature (A6), control voltage (A7), and coil temperature (A8).

3. Data Acquisition

In order to verify the influence of eight characteristic factors on the closing action time of pneumatic circuit breakers and establish a data set, a test platform was built to test the closing action time of three types of electronically controlled pneumatic vehicle-mounted vacuum main circuit breakers of 22CBCK (E), 22CBCK (D), and BVAC.N99E1, and 1000 sets of action time data and corresponding characteristic factor data were obtained, respectively. In order to ensure the reliability of the experimental data, the test conditions should be in line with the actual operation of the train, as follows: (1) connect the solenoid valve with an adjustable DC power supply, and the voltage adjustment range is based on the rated control voltage of the train, DC77 V~137.5 V; (2) use the auxiliary heat device to make the test environment temperature as close as possible to the rated operating temperature of the on-board circuit breaker, 10~40 °C; (3) the air compressor with drying function is used as the air source, and the pressure fluctuation range is according to the rated working pressure of the circuit breaker, 450 kPa~1000 kPa. (4) According to the interval time of each passing phase, each closing test interval is 20~30 min.

3.1. Closing Action Time Collection

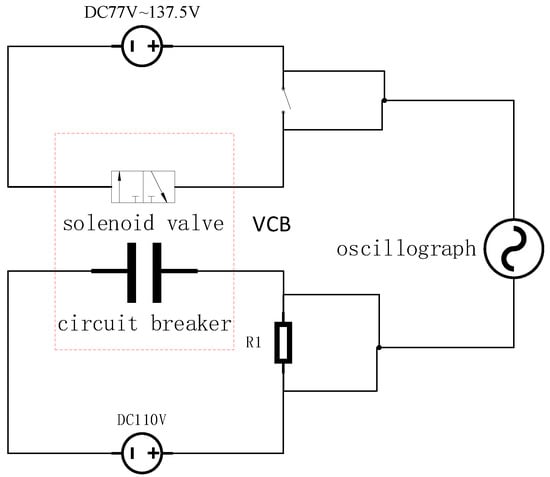

The DC77 V~137.5 V power supply is connected to the low voltage control port of the circuit breaker, and the conduction of the circuit is controlled by the switch. After a resistor is connected in series at both ends of the circuit breaker contact, the fixed value power supply is connected. The DC77 V~137.5 V power supply is used to simulate the closing signal emitted by the train. When the solenoid valve is powered, the intake valve is opened, and the high-pressure air enters the cylinder through the solenoid valve and the conversion valve to drive the piston movement in the cylinder. The piston pushes the insulation rod, and the insulation rod pushes the vacuum tube moving contact movement and finally closes and presses the static contact. The oscilloscope is used to collect the electrical signals of the two loops at the same time. When the switch is closed, the two loops are connected in turn. The conduction time difference is the closing action time of the circuit breaker. The test principle is shown in Figure 2.

Figure 2.

Schematic diagram of closing action time test.

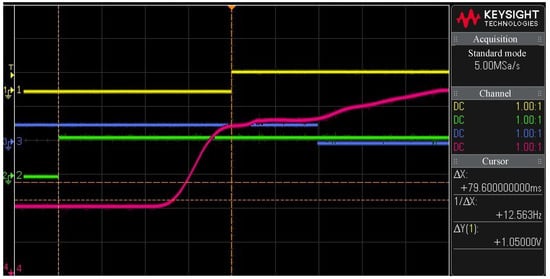

The test results are shown in Figure 3, where channel two (green) represents the change of control voltage, and channel one (yellow) represents the change of electrical signal at both ends of the circuit breaker contact. The sudden change of the electrical signal of channel two indicates that the electromagnetic valve is powered when the circuit breaker is subjected to the closing command, and then the sudden change of the electrical signal of channel one indicates that the circuit breaker contacts are closed to complete the closing action. At this time, the difference between the change time of the two is 79.6 ms, which is the closing action time of the circuit breaker.

Figure 3.

Diagram of the test result of the closing action time.

3.2. Collection of Related Characteristic Factors

In order to construct the prediction model, in addition to the closing action time test, it is also necessary to monitor the corresponding characteristic factor values at each closing.

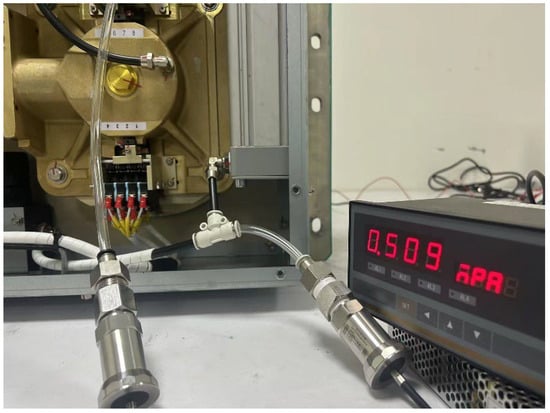

(1) Pressure factor collection (internal pressure at the moment of closing (A1), internal pressure at the last closing (A3), internal pressure difference between the two closings (A4)).

The air compressor is used to provide dry high-pressure air for the circuit breaker, and the trachea between the air storage cylinder and the pressure regulating valve is cut off. The three-way interface is used to access the pneumatic sensor, and the pneumatic sensor is connected to the display screen to monitor the internal air pressure in real time, as shown in Figure 4. (In order to reduce the error, the model of the external gas pipe between the three-way interface and the pneumatic sensor should be consistent with the model of the internal gas pipe of the circuit breaker, which is 8 mm in outer diameter and 6 mm in inner diameter).

Figure 4.

Pneumatic sensors monitor the internal air pressure.

(2) Temperature factor acquisition (ambient temperature (A6), coil temperature (A8)).

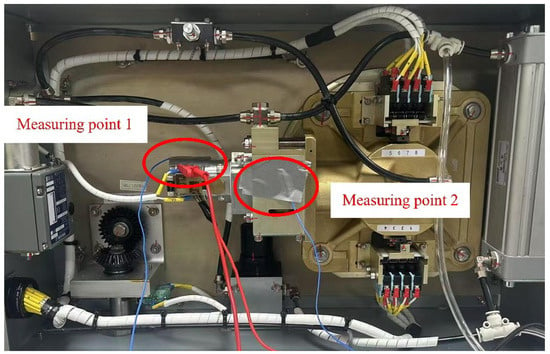

The thermocouples of the multi-channel temperature measuring instrument are attached to the solenoid valve coil housing (measuring point one) and the conversion valve housing (measuring point one) respectively, and the real-time solenoid valve temperature and the overall ambient temperature are monitored, respectively. The measuring points are shown in Figure 5 below.

Figure 5.

Solenoid valve temperature and ambient temperature measurement points.

4. GBDT Regression Algorithm to Construct the Closing Action Time Prediction Model of Circuit Breaker

Gradient Boosting Decision Tree (GBDT) is an iterative decision tree algorithm, which belongs to a part of Boosting algorithm family [18]. By constructing a set of weak learners (trees), each time based on the current prediction, the next weak classifier fits the residual of the error function to the predicted value and accumulates the results of multiple decision trees as the final prediction output. The corresponding formula is as follows [19]:

where is the input sample; is the model parameter; is the classification regression tree; is the weight of each tree. Compared with the other Boosting algorithms, which construct a learner to reduce the loss along the steepest gradient direction at each step of the iteration to make up for the shortcomings of the existing model, the gradient boosting algorithm uses the negative gradient of the loss function as the residual fitting method. Under the regression task, each iteration has a predicted value for each sample, and the loss function at this time is the mean square error loss function [20]:

4.1. Feature Importance Screening

In order to further determine the main characteristic factors, in order to select the phase control board for real-time acquisition, principal component analysis (PCA) is used for feature screening. PCA itself is mainly used for dimensionality reduction, rather than directly evaluating the importance of features. In this paper, the results of PCA are used to estimate the importance of the original features. Through the cumulative variance interpretation rate, we analyze which principal components retain most of the information, and then combine the load of these principal components to judge the importance of the features. The coefficients in the load matrix represent the contribution of the original features to the principal components. The greater the absolute value, the greater the contribution, the higher the importance may be. The calculation formula [21] is as follows:

The above formula indicates that the th principal component is a linear combination of the original features , , …, , where is the coefficient of the j-th feature in the load matrix to the i-th principal component. The greater the absolute value of , the greater the influence of the characteristic on the principal component . Combining the variance interpretation rate of the principal component to enhance the importance of the calculation features, the calculation formula is as follows:

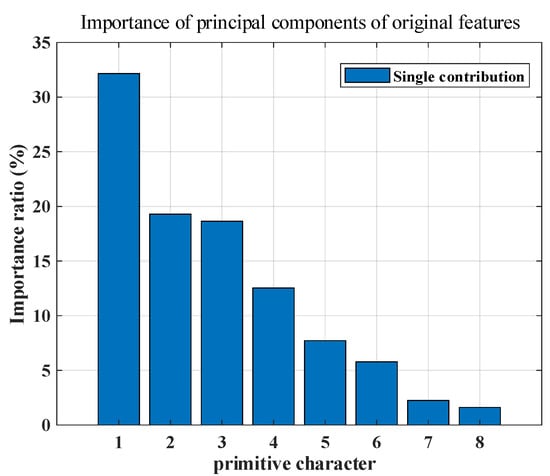

where represents the number of selected principal components (the components with cumulative variance greater than 90% are selected in this paper), and represents the variance contribution rate of the i-th principal component. Finally, the importance ratio of the original eight features is shown in Figure 6.

Figure 6.

The importance judgment of closing action time characteristics of pneumatic circuit breaker based on PCA.

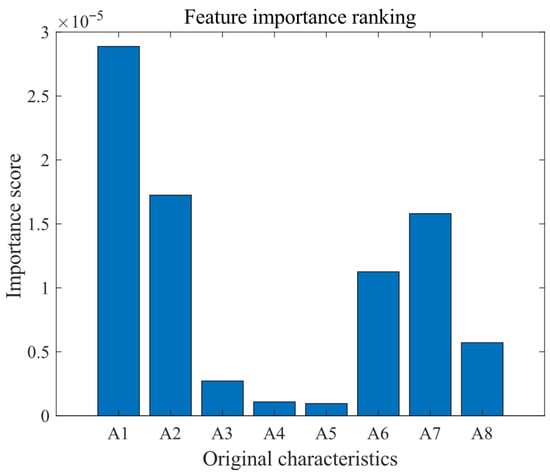

In order to ensure the accuracy of feature factor screening, the GBDT model’s own feature importance evaluation function is used to screen the test data. The results are shown in Figure 7.

Figure 7.

The importance judgment of closing action time characteristics of pneumatic circuit breaker based on GBDT.

The analysis results show that the characteristic factors that have a great influence on the prediction results: the internal pressure at the moment of closing (A1), the duration of the last closing state (A2), and the control voltage (A7). The influence of these factors on the prediction results is too small. The characteristic factors are the internal pressure difference between the two closings (A4) and the time of the last closing action (A5). In order to optimize the model and improve the prediction accuracy, the characteristic factors A4 and A5 are discarded.

4.2. The Establishment of Closing Action Time Prediction Model of Circuit Breaker

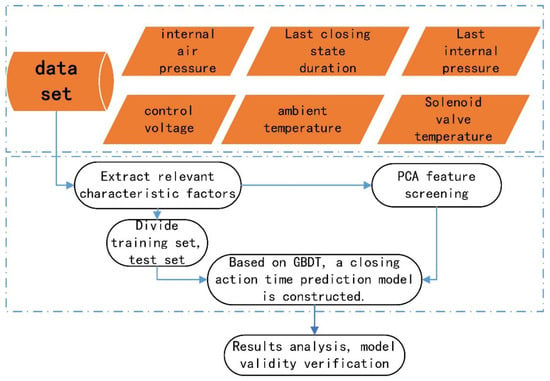

In this paper, combined with the data obtained from the test, six characteristic factors are used as the input values of the model, and the closing action time of the circuit breaker is used as the output result to establish the prediction model of the closing action time of the circuit breaker. Based on the GDBT regression algorithm, the model structure is shown in Figure 8.

Figure 8.

Flow chart of closing action time prediction model of pneumatic circuit breaker based on GBDT and PCA.

After classifying the data, it is imported into the programmed GBDT regression algorithm. Feature factors are extracted to judge the importance of features, and feature factors are further screened and determined. After the data is normalized, the training set and the test set are divided, and the algorithm model is trained and learned. The prediction results of the test set output are compared with the real values. The validity of the model is verified, the model parameters are constantly modified, and the types of characteristic factors are adjusted. Finally, a high-precision prediction model is obtained.

The validity test of the regression model is to evaluate the accuracy of the predicted data of the model. The determination coefficient (R-squared, R2), root mean squared error (RMSE), mean absolute error (MAE), and mean bias error (MBE) are selected as evaluation indicators. The coefficient of determination is used to determine the closeness of the data to the fitted regression line, and the numerical range is 0 to 1. The closer the value is to 1, the better the model fits the data; the closer to 0, the worse the fitting degree of the model to the data. On the contrary, the smaller the remaining error index value, the higher the accuracy of the model. The formulas are as follows:

where is the true value, is the predicted value, and is the number of samples.

5. Analysis of Prediction Results

5.1. Prediction Accuracy Evaluation Index

The prediction of the closing action time of the on-board electronically controlled pneumatic vacuum main circuit breaker is to solve the uncertainty problem of the closing time of the pneumatic circuit breaker, so that the pneumatic circuit breaker can be adapted to the traditional phase selection control system. In order to suppress the overvoltage, the target phase angle is set to 0°, and the theoretical value of the switching overvoltage generated by the closing of the circuit breaker is 0. The operating overvoltage amplitude generated by the circuit breaker closing at different phase angles and the actual withstand overvoltage amplitude of the train are analyzed, and the allowable range of the prediction error is obtained as the evaluation index of the model prediction accuracy. With reference to the AC25 kV power supply system train operating overvoltage standard, the peak voltage of the train itself is 40 kV, and the allowable value of the operating overvoltage is 60 kV, as shown in Table 1 below.

Table 1.

Reference value of switching overvoltage.

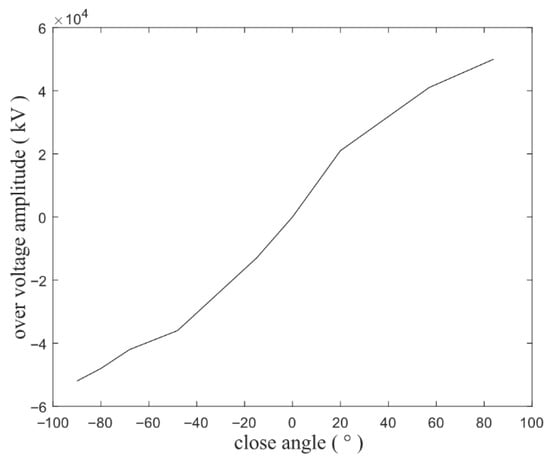

Taking the AC25 kV power supply system train as a reference, the maximum voltage of the catenary itself is 40 kV, and the maximum voltage standard that the catenary and the pantograph can withstand is 60 kV. The phase selection control is carried out with 0° angle as the target phase angle (the theoretical value of the switching overvoltage is 0 at this time). If the actual switching overvoltage is greater than 40 kV, it is considered that the train will be affected by the switching overvoltage. Using MATLAB (R2022b)/Simulink (R2023b) to simulate the switching overvoltage amplitude of different phase closing [22], The statistical results are shown in Figure 9 below.

Figure 9.

The relationship between the closing angle and the amplitude of the overvoltage. (Simulation).

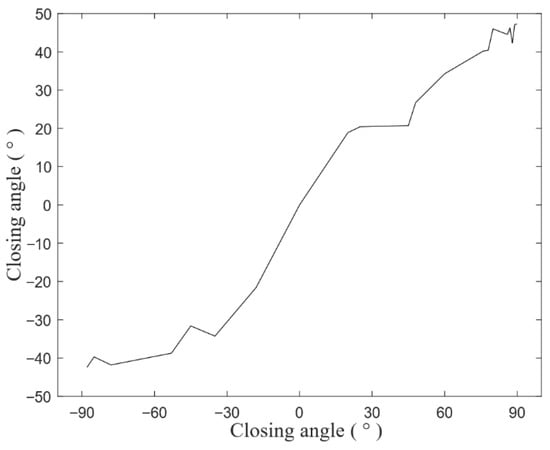

In order to improve the reliability of the data, the static switching overvoltage test was carried out on six carriages of a certain type of train. The relationship between the closing angle and the overvoltage amplitude is shown in Figure 9 below.

Combined with Figure 9 and Figure 10, it can be seen that when the closing phase angle is within ±60°, the closing overvoltage amplitude is less than 40 kV. The phase selection control target is positioned at the phase 0° angle, and the actual closing phase difference needs to be controlled with in ±60°, and the time error of converting to the prediction result should be within about ±3.3 ms.

Figure 10.

The relationship between the closing angle and the amplitude of the overvoltage. (Network side test results).

5.2. Comparative Analysis of Prediction Results

Since the GBDT regression algorithm uses the CART regression decision tree, which belongs to the weak classifier, its parameters are basically derived from the decision tree class. In this paper, the closing action time prediction model of train-mounted electronically controlled pneumatic vacuum main circuit breaker constructed by GBDT is used to divide the training set and the test set. When considering all the feature numbers, the default value three is taken in the selection of the maximum depth of the decision tree, and the number of iterations (the number of trees) is 300. In the case of the same remaining parameters, the learning rate and the minimum sample number of leaf nodes are adjusted respectively for testing, and the best parameters are selected with the average RMSE of 10 consecutive test sets as a reference. As shown in Table 2: the learning rate is 0.01, and the minimum number of samples of leaf nodes is four.

Table 2.

The best learning rate and the minimum sample number of leaf nodes are selected.

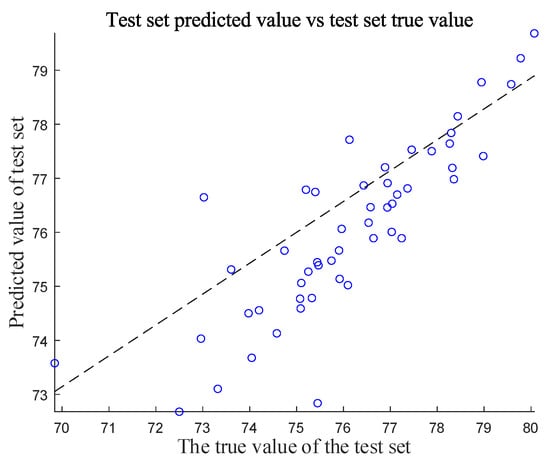

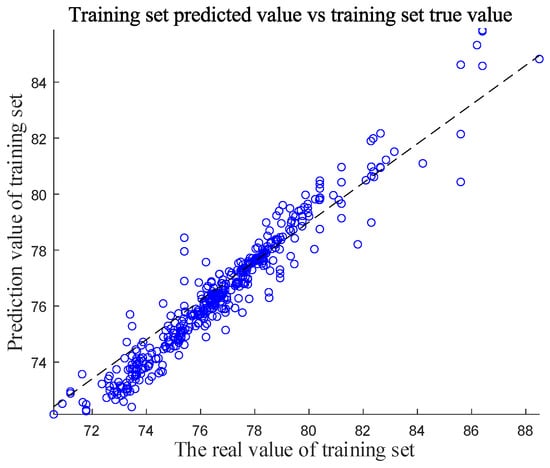

After adjusting the optimal parameters, the experimental data are normalized and input into the prediction model according to the divided training set (80% of the total data) and the test set (20% of the total data). The fitting line between the true value and the predicted value of the training set and the test set is obtained.

As shown in Figure 11 and Figure 12, the dotted line in the graph represents the real data, and the predicted value represented by the scatter points is basically around the dotted line. The determination coefficient R2 of the fitting curve of the prediction effect of the test set and the training set is 0.90923 and 0.70051, respectively, which has a good fitting effect. In order to more intuitively reflect the prediction effect of the model, the comparison between the predicted value of the model output and the real value of the test set in the form of scatter plot and residual plot is as follows.

Figure 11.

The predicted value and the real value of the training set of the pneumatic circuit breaker prediction model fit a straight line.

Figure 12.

The prediction model of pneumatic circuit breaker. The predicted value of the test set is fitted with the real value.

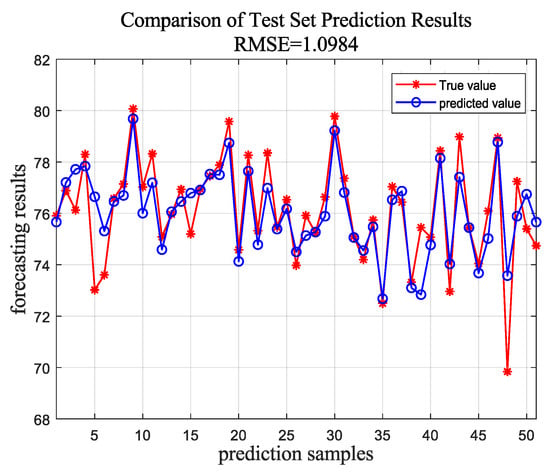

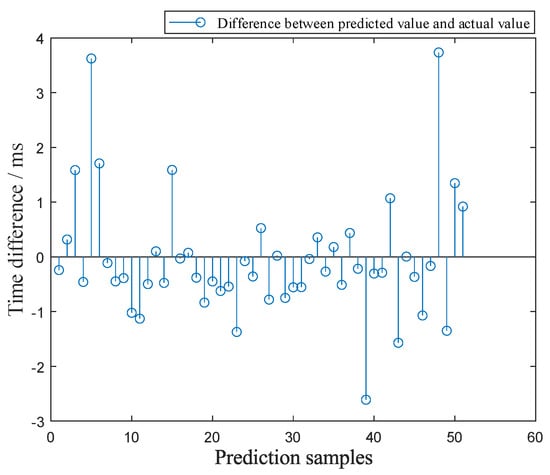

In Figure 13 above, red represents the real value of closing action time in the test set, and blue represents the predicted value of closing action time output after model training. The fitting degree of the model prediction curve and the real value curve is high, indicating that the prediction accuracy of the model is high. Figure 14 shows the difference between the predicted value and the real value. The difference between the predicted value and the real value is within ±4 ms, mostly less than 2.5 ms.

Figure 13.

Prediction effect of closing action time model of pneumatic circuit breaker.

Figure 14.

Model prediction results scatter residual plot.

In addition, the random forest algorithm (RF) and support vector regression (SVR) are used to predict the closing action time of the pneumatic circuit breaker with the same test set and training set. The error indexes of each model are compared as shown in Table 3.

Table 3.

Comparison of prediction results of different models.

It can be seen from the above table that the R2 of the SVR model is significantly lower than the other two models and the error is larger, indicating that the algorithm is not suitable for the prediction of the closing action time of the pneumatic circuit breaker. The various parameters of the RF model are similar to the GBDT model but still need to be further optimized. Therefore, the GBDT model is more suitable for the prediction of the closing action time of the pneumatic circuit breaker, and has better learning ability and higher accuracy.

When the traditional phase selection control of the pneumatic circuit breaker is carried out with the 0° angle as the target phase, the closing action time of the circuit breaker needs to be stored in advance. The deviation between the actual closing phase and the target phase is the error between the actual closing action time of the circuit breaker and the stored closing action time. Since the jitter value of the closing action time of the pneumatic circuit breaker is greater than 10 ms, the actual phase of the circuit breaker closing is randomly and evenly distributed on ±90° in theory. The prediction model is added to the phase selection control system, and the closing action time is predicted before each operation for phase selection control. The deviation between the actual closing phase and the target phase is the prediction error of the prediction model each time. The prediction model is used to predict the above test data for 20 consecutive times (the training set and the test set are divided into the same), and the prediction error is recorded. The statistical access prediction model for phase selection control is calculated and the closing effect of the average closing action time stored for traditional phase selection control is shown in Table 4 below.

Table 4.

Comparison of phase selection control effect.

Similarly, the phase selection control target phase is set to 0° angle as an example. After the phase selection control of the circuit breaker is carried out by using the predicted value output by the prediction model, the probability of the actual closing phase at ±45° is 88%, which is 33% higher than that of the traditional phase selection control. The probability of the actual closing phase at ±60° is 92%, which is 32% higher than that of the traditional phase selection control. The effect has initially reached expectations.

6. Conclusions

In this paper, aiming at the problem that the electronically controlled pneumatic train-mounted vacuum main circuit breaker cannot be applied to the traditional phase selection control system due to the large dispersion of closing action time, the action time prediction model of pneumatic circuit breaker based on the PCA and GBDT regression algorithm is constructed through theoretical analysis, test platform construction, and algorithm compilation. The following conclusions are obtained:

(1) The closing process of the pneumatic circuit breaker is analyzed theoretically, and the role of each electrical component in the closing process is studied. Eight characteristic factors affecting the closing time of the pneumatic circuit breaker are obtained. Through PCA, the feature importance screening was carried out, and six main feature factors were finally determined.

(2) The overvoltage amplitude corresponding to the closing phase of AC25 kV power supply train is analyzed by simulation and field test. It is determined that the error of the prediction model should be controlled within 3.3 ms at least.

(3) The closing action time model of pneumatic circuit breaker is established based on GBDT algorithm, and the parameters are optimized. The probability that the prediction error is controlled within 3.3 ms reaches 92%. It provides theoretical support for the design of a phase control system of electronically controlled pneumatic train vacuum main circuit breakers in the future.

Author Contributions

Conceptualization, Q.W. and R.L.; methodology, Q.W. and R.L.; software, R.L.; validation, R.L., J.Z. and X.L.; formal analysis, Q.W.; investigation, Q.W. and R.L.; resources, Q.W., J.Z. and X.L.; data curation, R.L.; writing—original draft preparation, R.L.; writing—review and editing, Q.W. and R.L.; supervision, Q.W., X.L. and J.Z.; project administration, Q.W., X.L. and J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request. The data are not publicly available as they are also part of an ongoing study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, Z. China’s high-speed rail operating mileage reached 45,000 kilometers. People’s Railw. 2024. [Google Scholar] [CrossRef]

- Qin, J. Development and Prospect of Electrified Railways in China—Commemoration of the National Electrified Railway Breaking through 10,000 km. Railw. Eng. J. 1998, 15, 4–9. [Google Scholar]

- Li, G.; Feng, X.; Wang, L.; Chen, S. Research and Simulation of Automatic Neutral Section Passing Control Strategy for High-speed EMU. J. Electr. Technol. 2007, 7, 181–185. [Google Scholar] [CrossRef]

- Liu, J. Research on the control method of fast passing neutral section of high-speed EMU. Locomot. Electr. Drive 2022, 6, 95–102. [Google Scholar] [CrossRef]

- Li, Y. CR200J type power concentrated EMU neutral section technical analysis and Suggestions. Electr. Locomot. Urban Rail Veh. 2023, 46, 117–120. [Google Scholar] [CrossRef]

- Li, T.; Sun, J.; Wu, M.; Yang, S.; Song, K.; Li, J. Study on failure mechanism of arrester on roof of high-speed electric multiple units under high-order harmonics. China Saf. Sci. J. 2019, 29 (Suppl. S1), 88. [Google Scholar]

- Lyu, F.; Zhang, Q.; Wang, S. Temperature distribution measurement and defect simulation of roof arrester of EMU. Power Syst. Technol. 2021, 46, 1223–1231. [Google Scholar]

- Ghafourian, S.M.; Arana, I.; Holbøll, J.; Sørensen, T.; Popov, M.; Terzija, V. General Analysis of Vacuum Circuit Breaker Switching Overvoltages in Offshore Wind Farms. IEEE Trans. Power Deliv. 2016, 31, 2351–2359. [Google Scholar] [CrossRef]

- Florkowski, M.; Furgał, J.; Kuniewski, M.; Pająk, P. Overvoltage Impact on Internal Insulation Systems of Transformers in Electrical Networks with Vacuum Circuit Breakers. Energies 2020, 13, 6380. [Google Scholar] [CrossRef]

- Qin, Q.; Zhang, J.; Wang, Q.; Li, X. Simulation Analysis and Experimental Research of Main Breaker Operation Overvoltage for Train Body Based on 3D Structure. Railw. Stand. Des. 2024, 68, 174–180. [Google Scholar]

- Xiao, S.; Tong, M.; Rao, Y.; Li, Y.; Ye, Z.; Shen, Y.; Hou, H.; Gao, G.; Wu, G.; Jin, Y.; et al. The characteristic analysis of the operational overvoltage caused by the vacuum circuit breakers on High-speed trains. J. Electr. Eng. Technol. 2022, 17, 221–236. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, J.; Wang, Q.; Li, X.; Tang, X.; Qin, Q. Study on the Simulation of the EMU Body Operating Main Breaker Overvoltage and High-Voltage Side Suppression Method Based on the 3D Structure. Electronics 2023, 12, 3037. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Tang, L.; Wang, Y.; Lei, B. A high voltage switch phase selection controller design. Comput. Meas. Control 2024, 32, 98–104+111. [Google Scholar] [CrossRef]

- Yang, Z. Research on overvoltage suppression method of high voltage circuit breaker based on phase selection control. Bonding 2021, 46, 158–161. [Google Scholar]

- Xu, X.; Lin, J.; Tian, Y.; Li, Z.; Zhang, R.; Tian, Y. Study on phase selection control characteristics of fast vacuum circuit breakers suitable for new power systems. J. Phys. Conf. Ser. 2024, 2814, 012046. [Google Scholar] [CrossRef]

- Kobelev, V. Relaxation and creep in twist and flexure. Multidiscip. Model. Mater. Struct. 2014, 10, 304–327. [Google Scholar] [CrossRef]

- Shi, Y.; Pan, Y. Calculation and analysis of the influence of temperature on solenoid valve drive. Electromech. Inf. 2022, 20, 48–51. [Google Scholar] [CrossRef]

- Dindaroğlu, T.; Kılıç, M.; Günal, E.; Gündoğan, R.; Akay, A.E.; Seleiman, M. Multispectral UAV and satellite images for digital soil modeling with gradient descent boosting and artificial neural network. Earth Sci. Inform. 2022, 15, 2239–2263. [Google Scholar] [CrossRef]

- Ke, G.; Xu, Z.; Zhang, J.; Bian, J.; Liu, T.Y. DeepGBM: A deep learning framework distilled by GBDT for online prediction tasks. In Proceedings of the 25th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, Anchorage, AK, USA, 4–8 August 2019. [Google Scholar]

- Zhang, Z.; Jung, C. GBDT-MO: Gradient-boosted decision trees for multiple outputs. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 3156–3167. [Google Scholar] [CrossRef] [PubMed]

- Wen, W.; Wan, Y.-H.; Zhang, X.H.; Wen, Z.Y. Text feature selection based on improved CHI and PCA. Comput. Eng. Sci. Jisuanji Gongcheng Yu Kexue 2021, 43, 1645. [Google Scholar]

- Li, J. Research on Key Technology of Phase Selection Closing of On-Board Circuit Breaker for High-Speed EMU. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2020. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).