Twin Screw Granulation: An Investigation of the Effect of Barrel Fill Level

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Powder

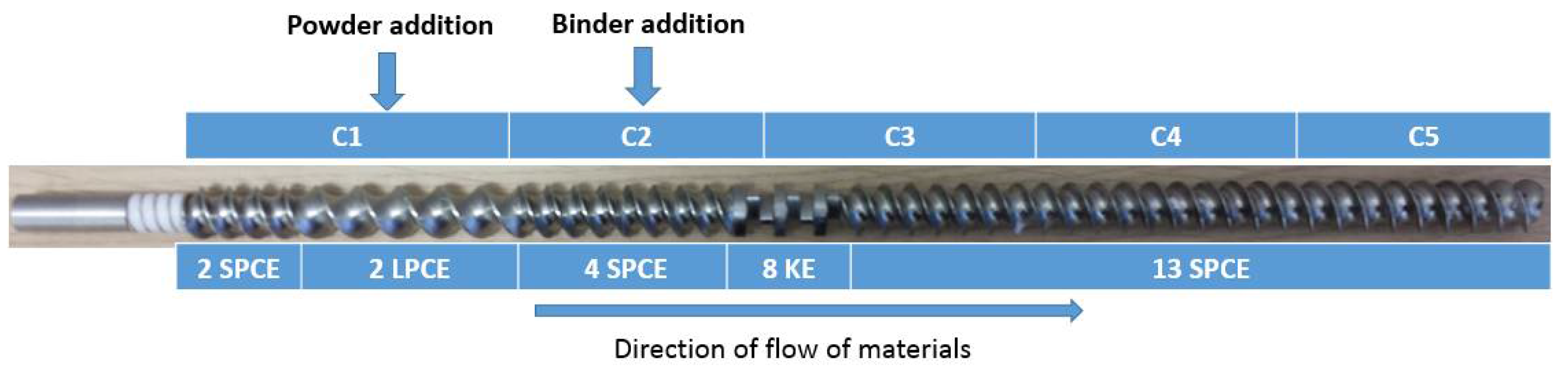

2.1.2. Granulator

2.2. Methods

2.2.1. Granulation

2.2.2. Mean Residence Time (MRT) Measurement

2.2.3. Peak Shear Rate

- where, D = screw diameter (15.6 mm)

- N = screw speed (rpm)

- h = overflight gap (i.e., gap between screw tip and barrel wall) (0.2 mm).

2.2.4. Analysis of Granules

Size and Shape Analysis of Granules

2.2.5. Tableting

Analysis of Tablets

3. Results

3.1. Lactose Powder

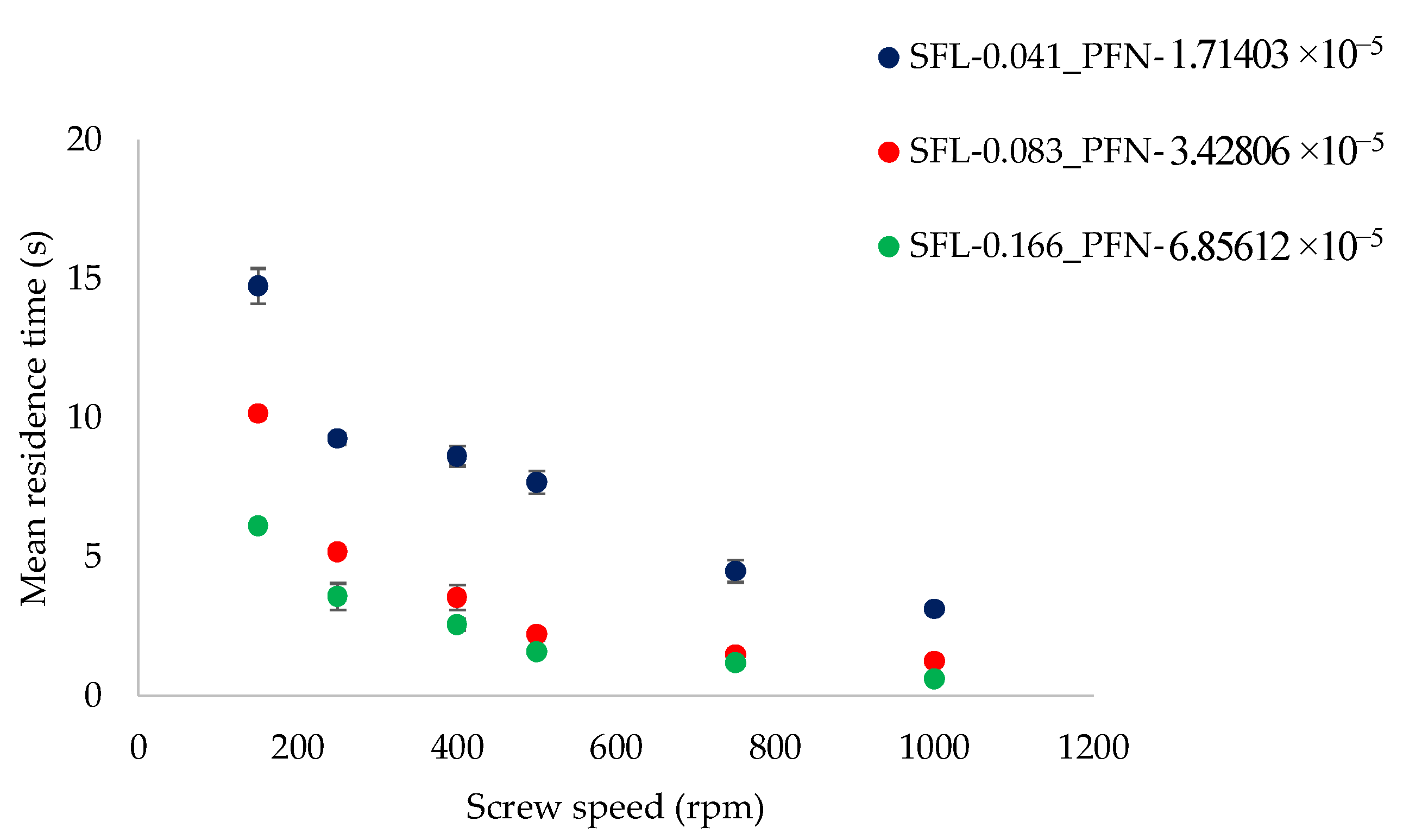

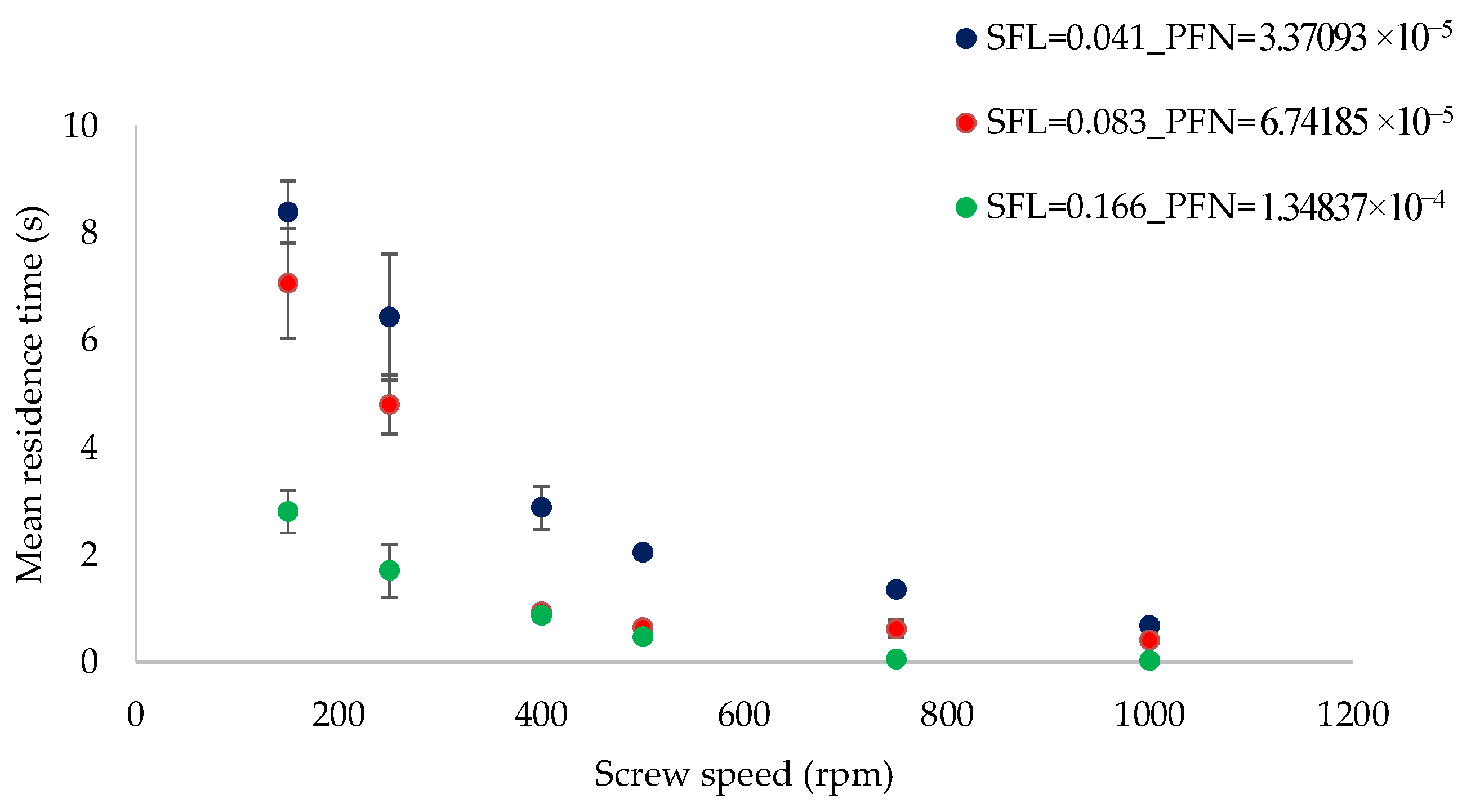

3.1.1. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on Mean Residence Time

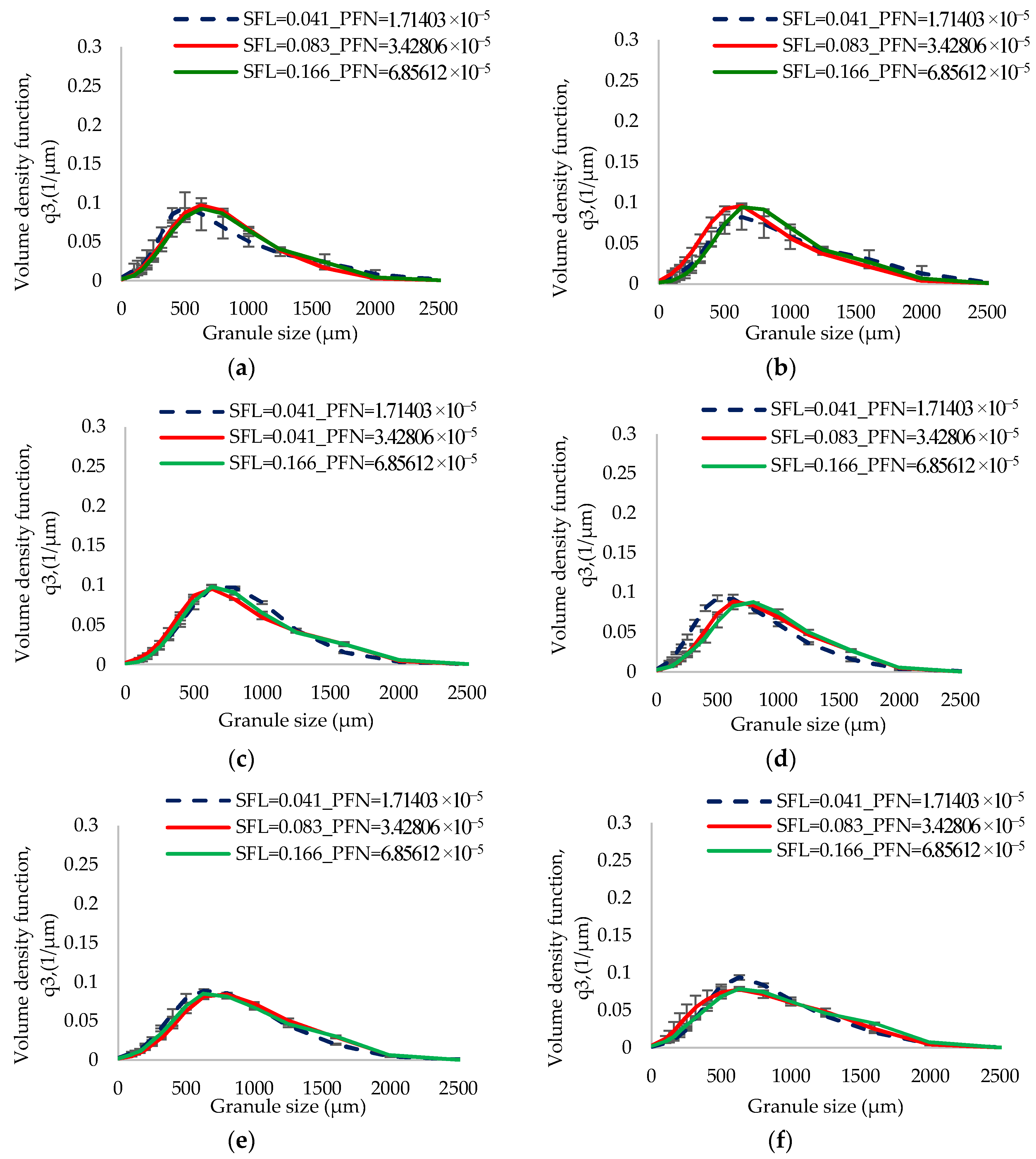

3.1.2. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on Granule Size

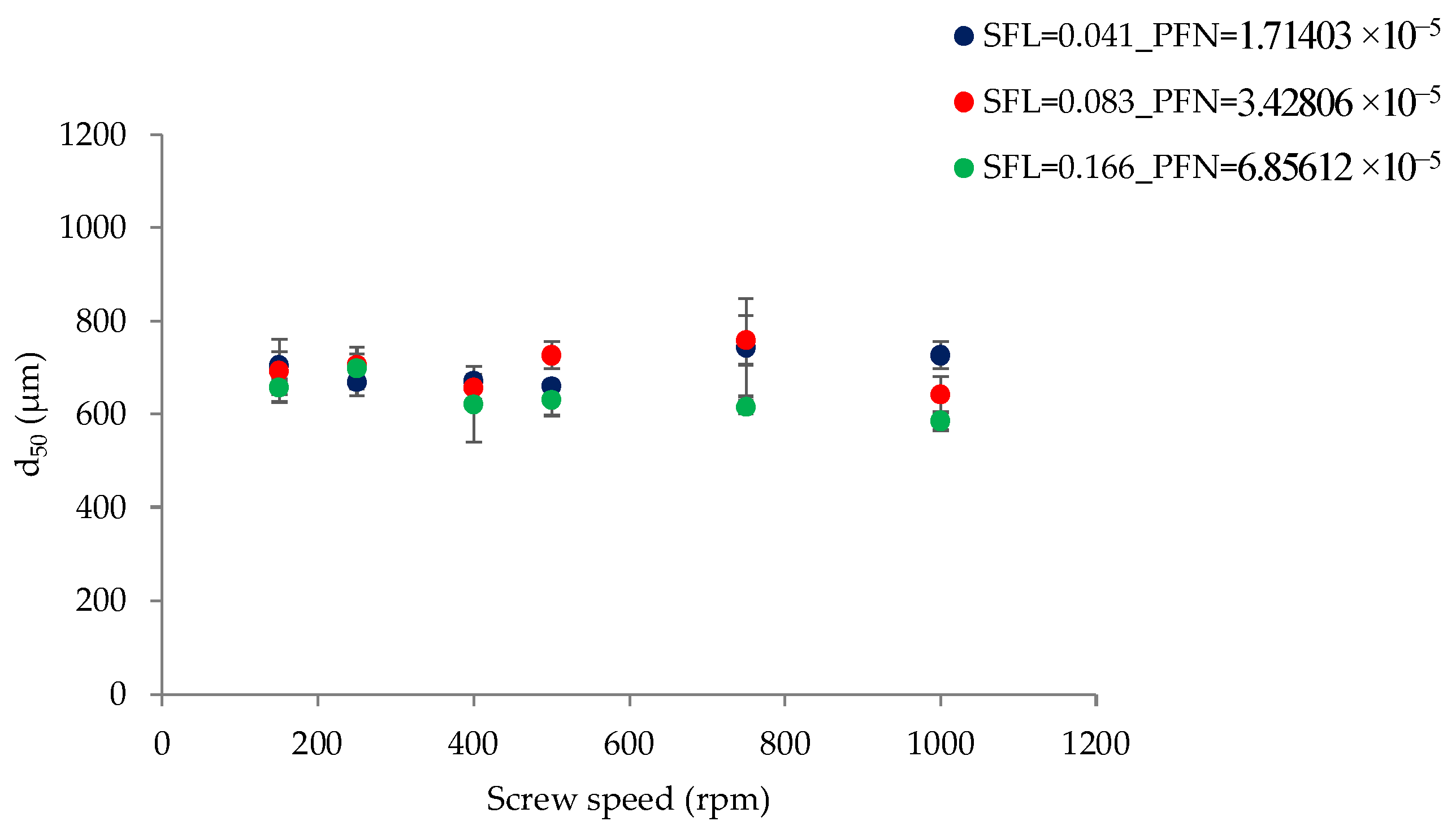

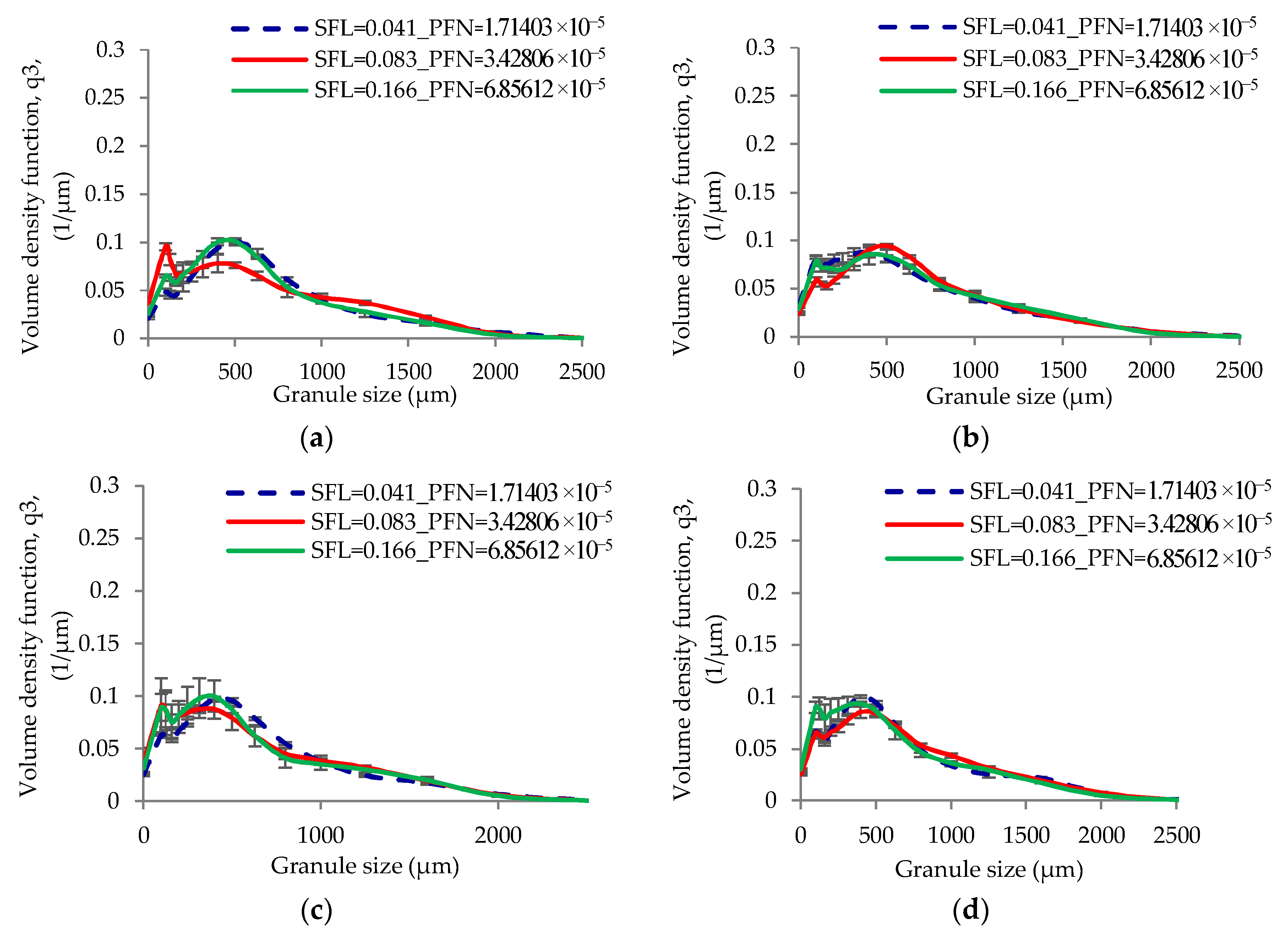

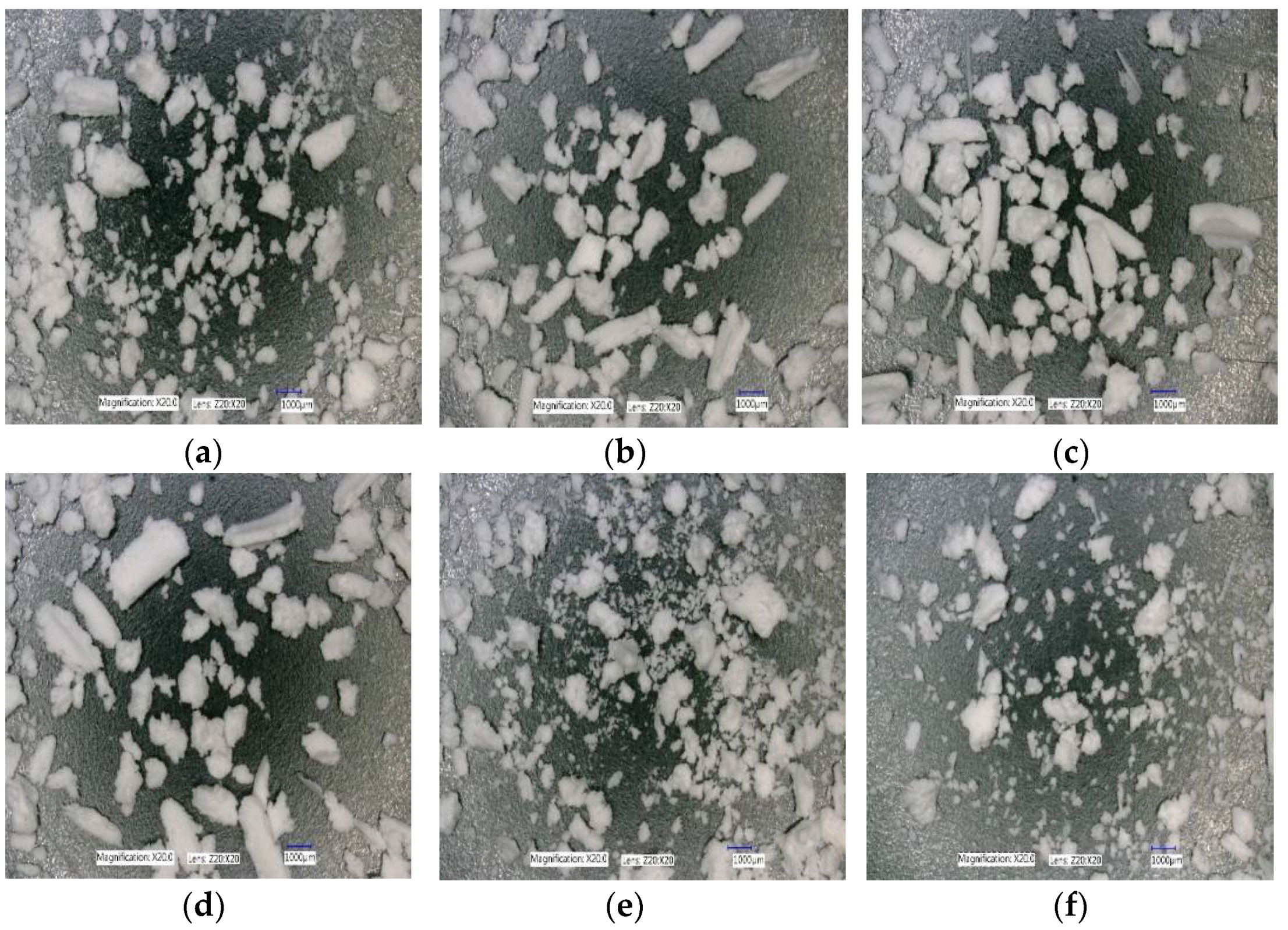

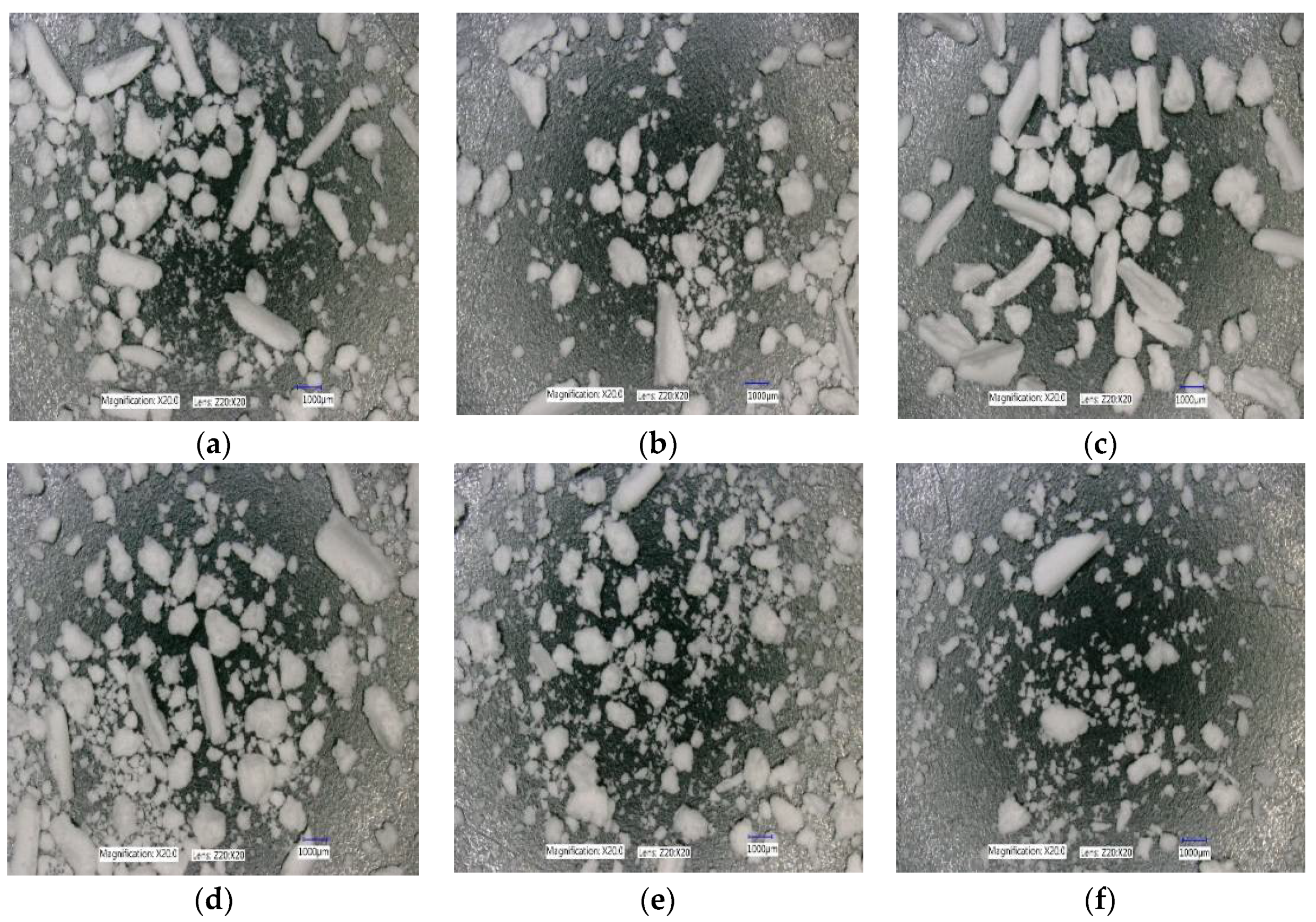

3.1.3. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on Granule Shape

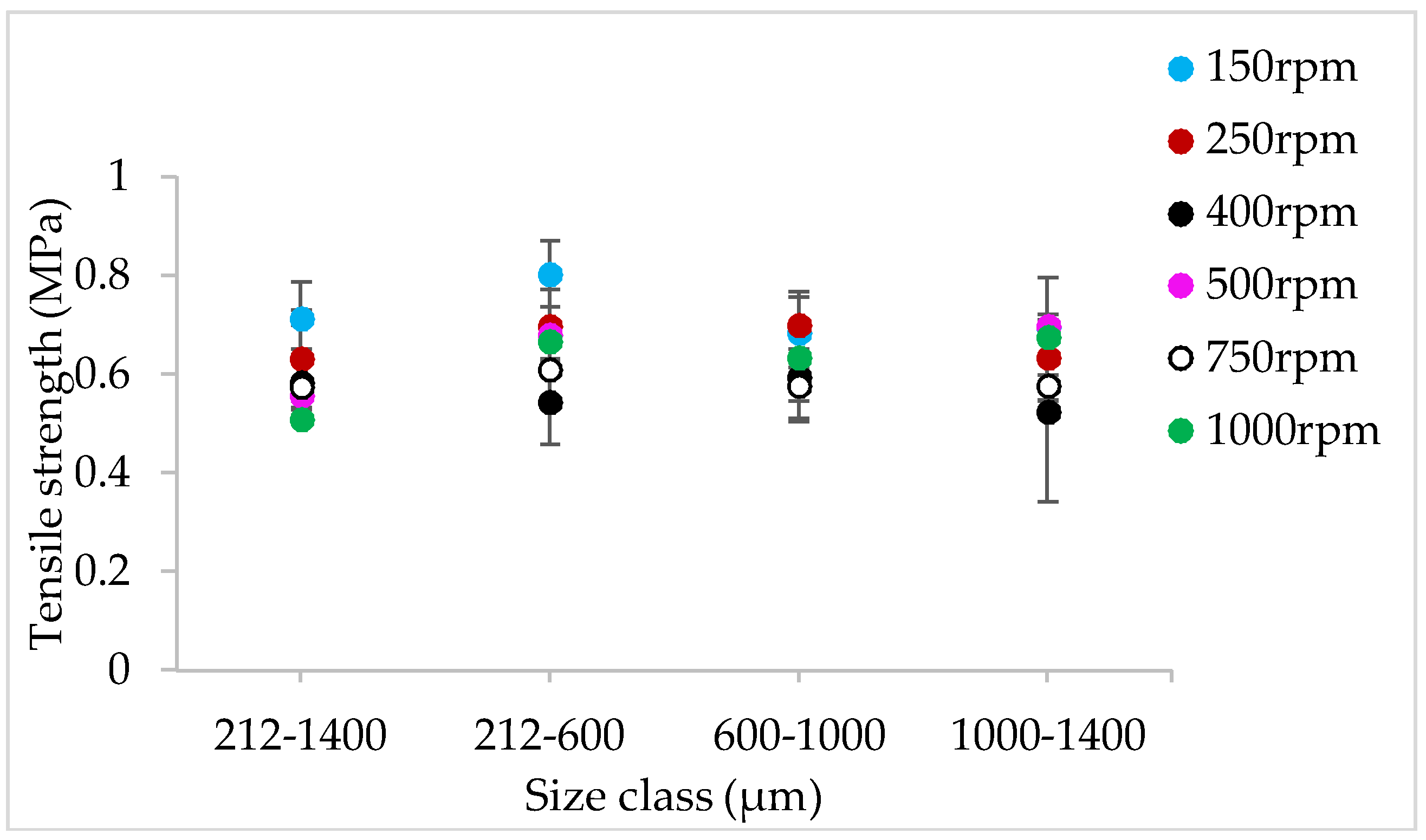

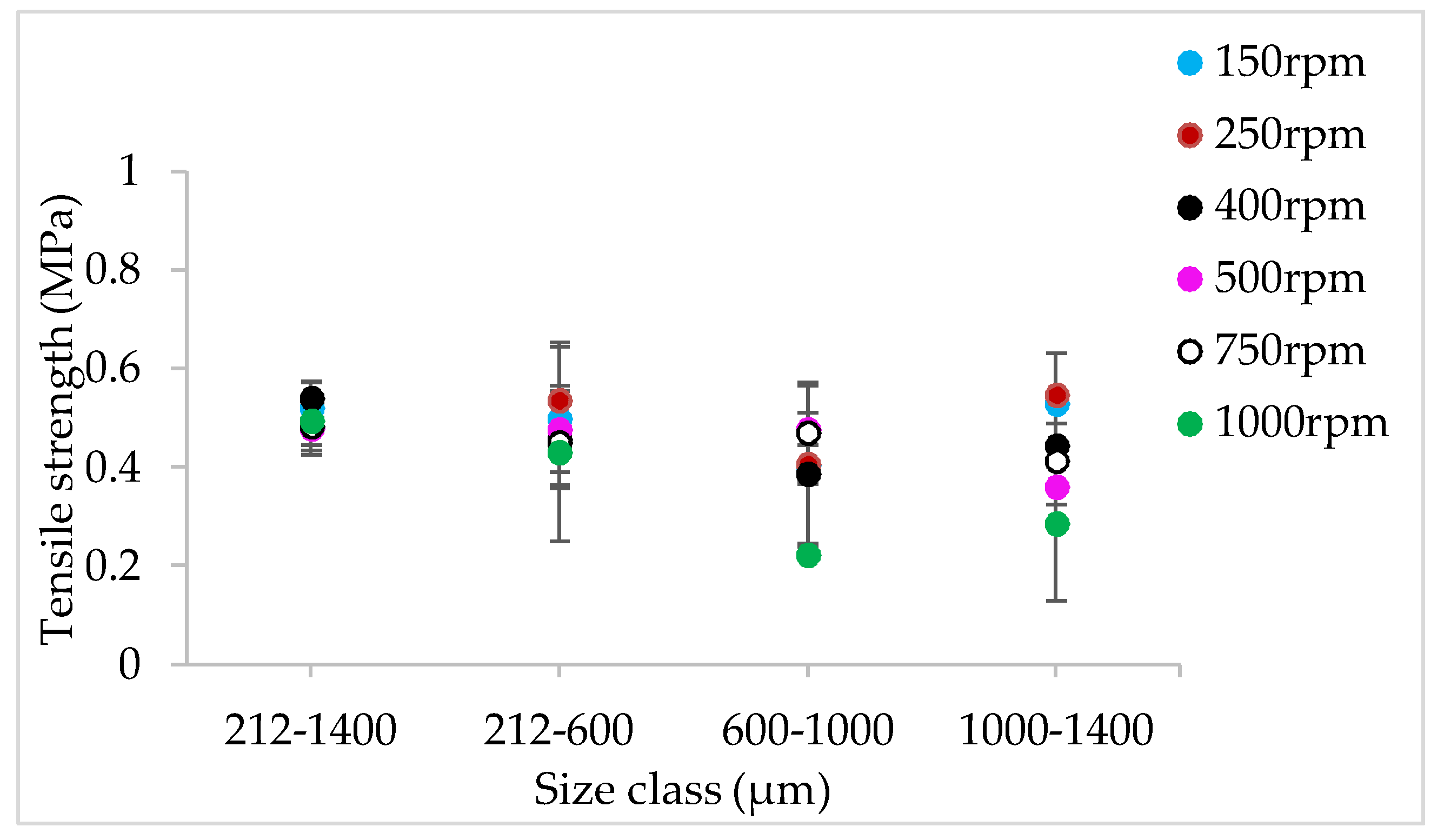

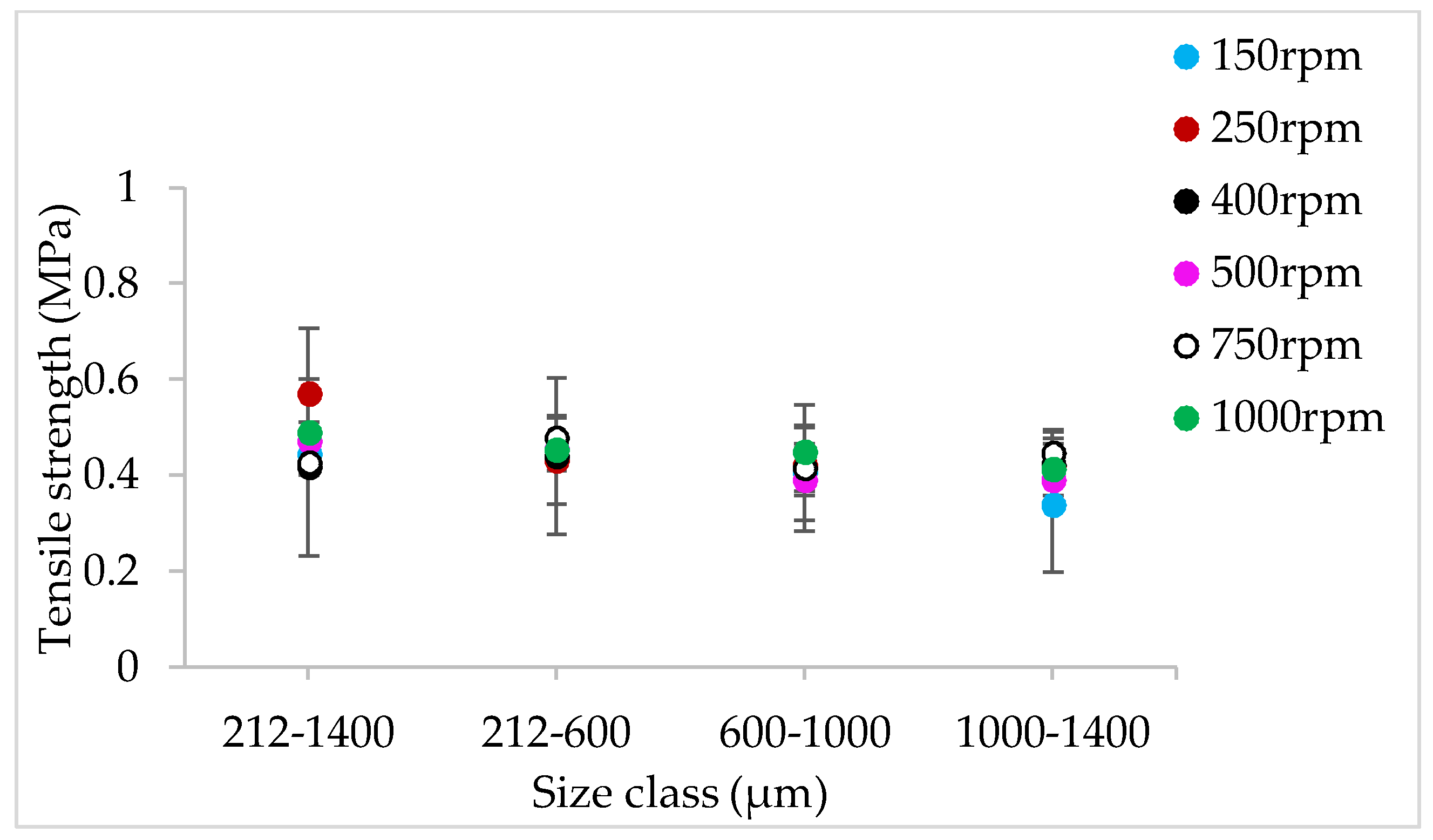

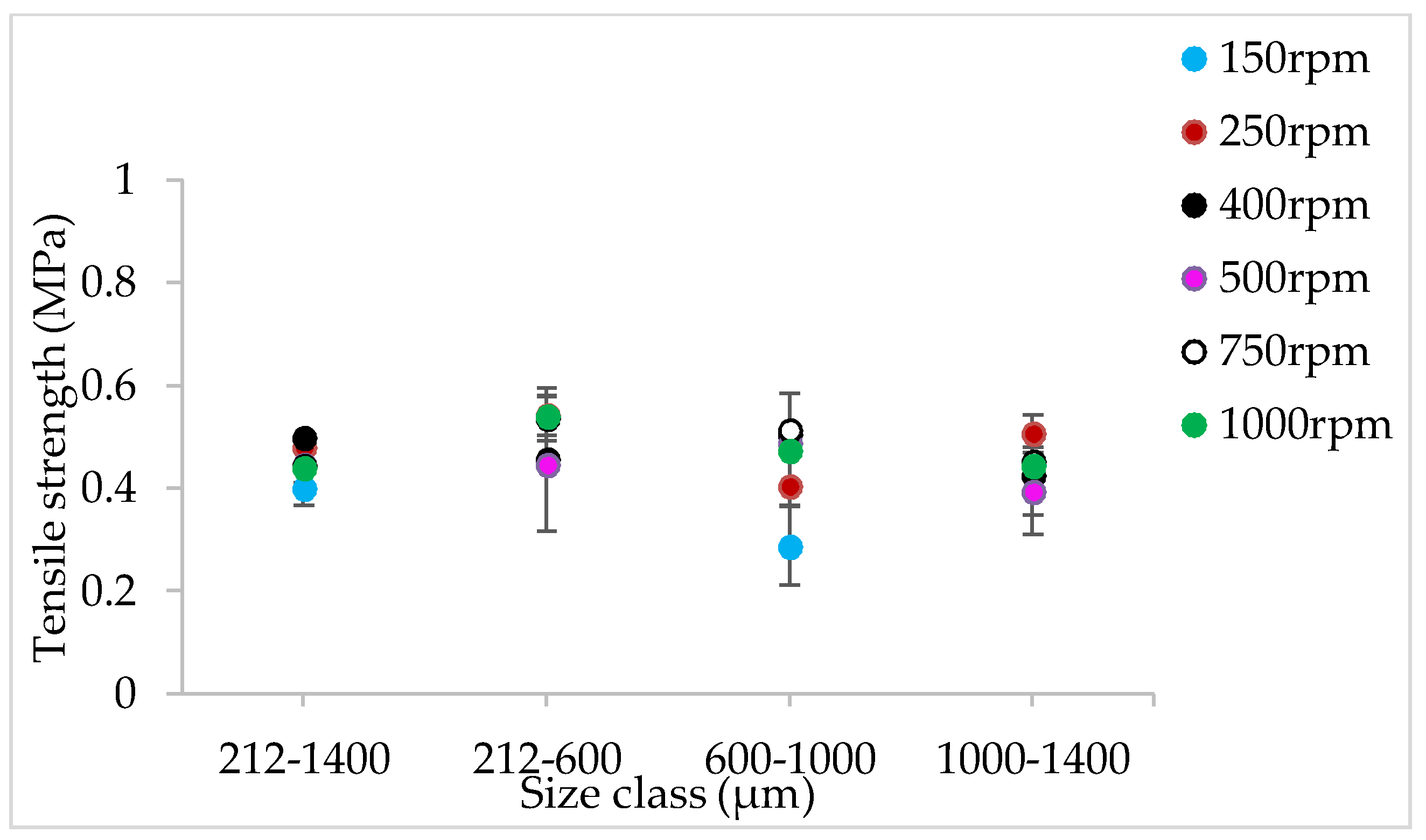

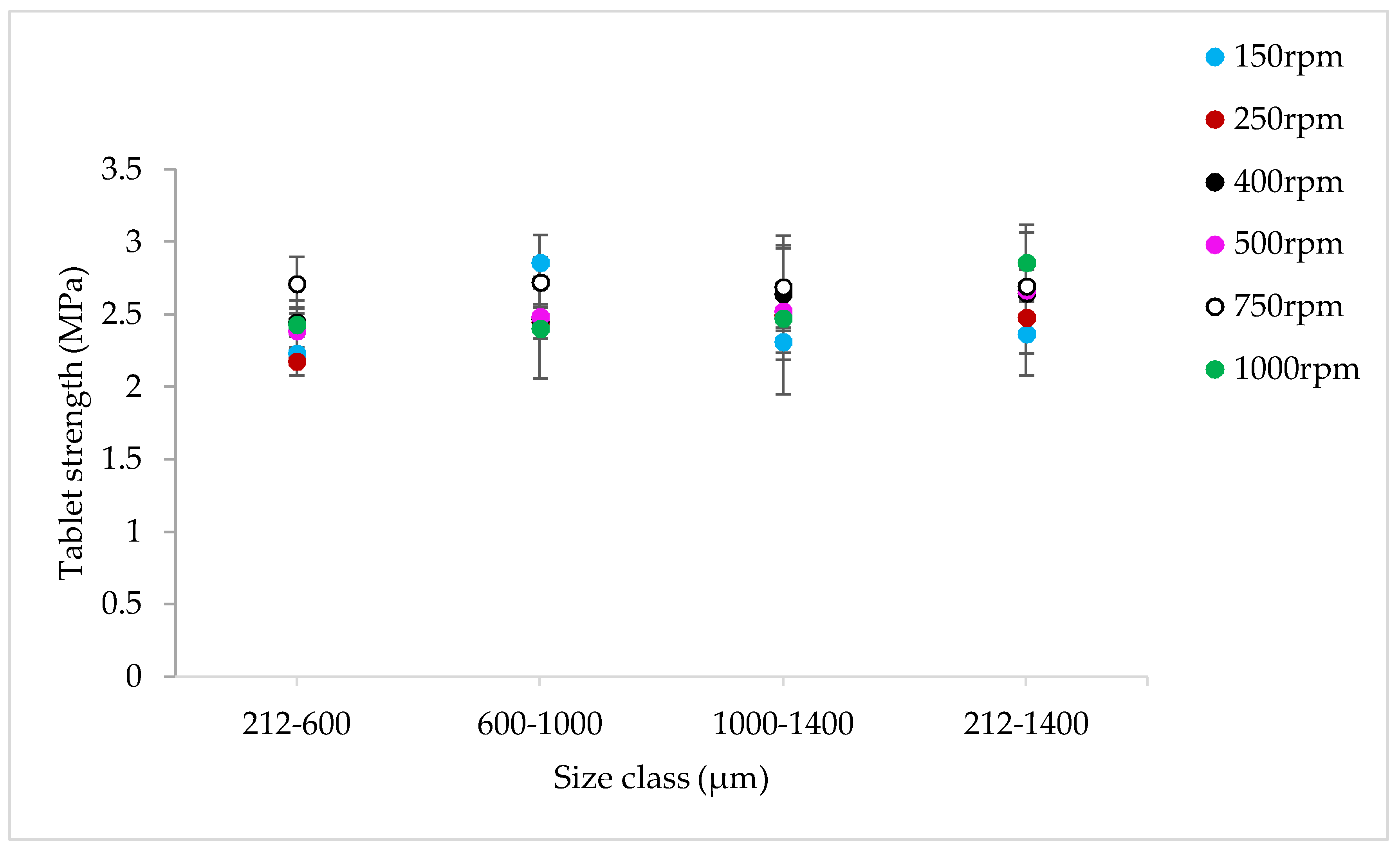

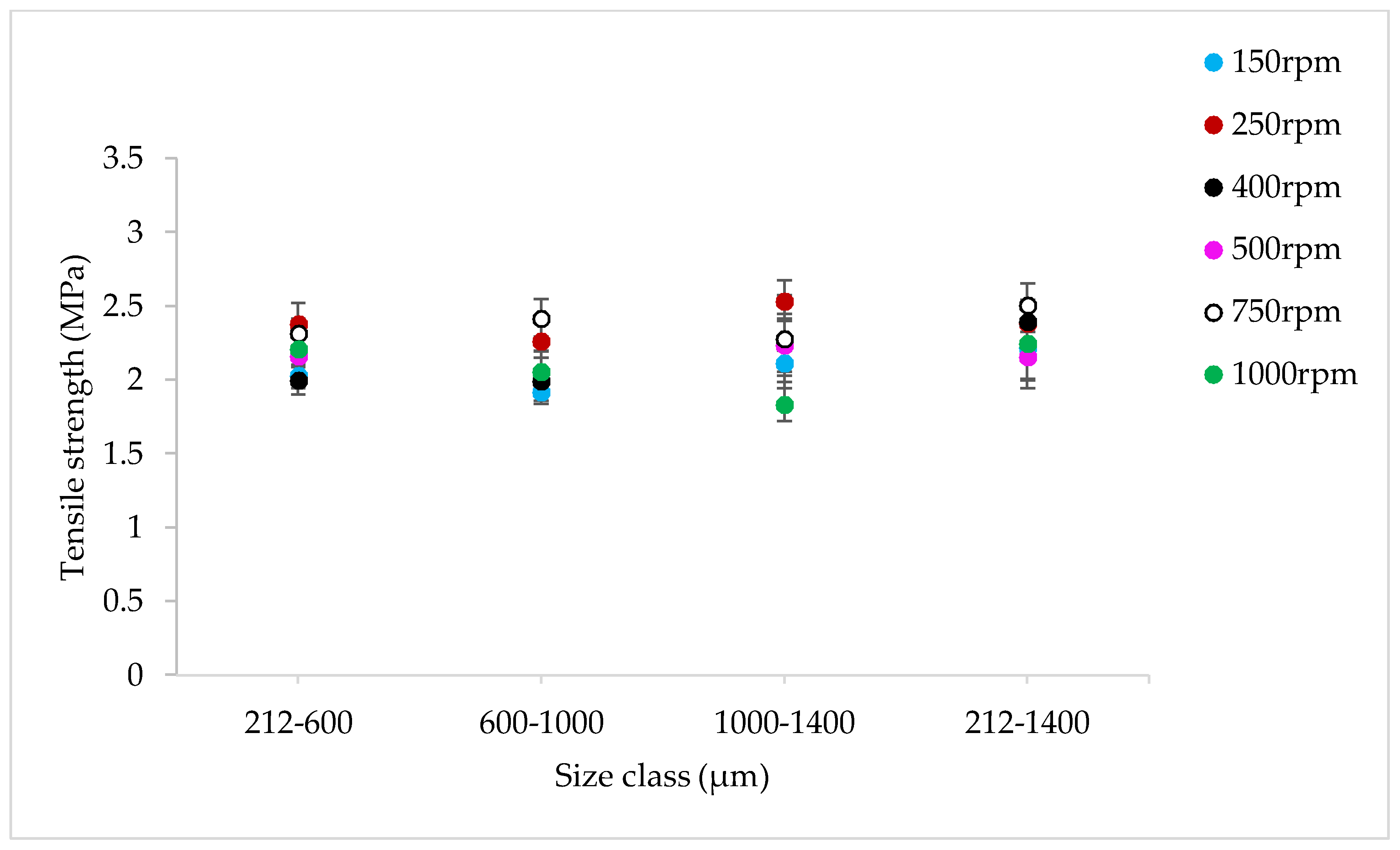

3.1.4. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on Tablet Tensile Strength

3.2. Microcrystalline Cellulose (MCC) Powder

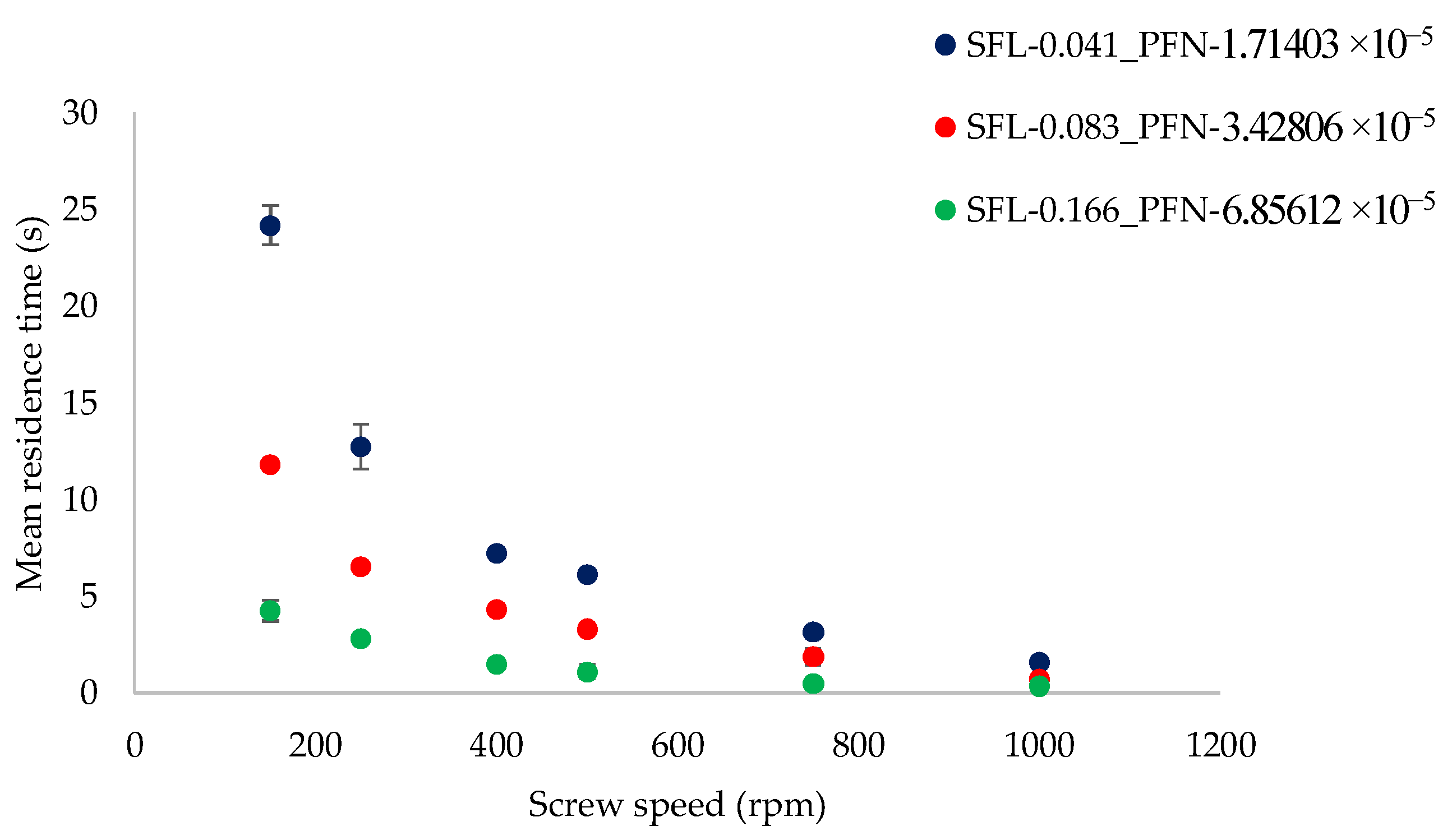

3.2.1. The Effect of Varying SFL–PFN at Different Screw Speed on Mean Residence Time

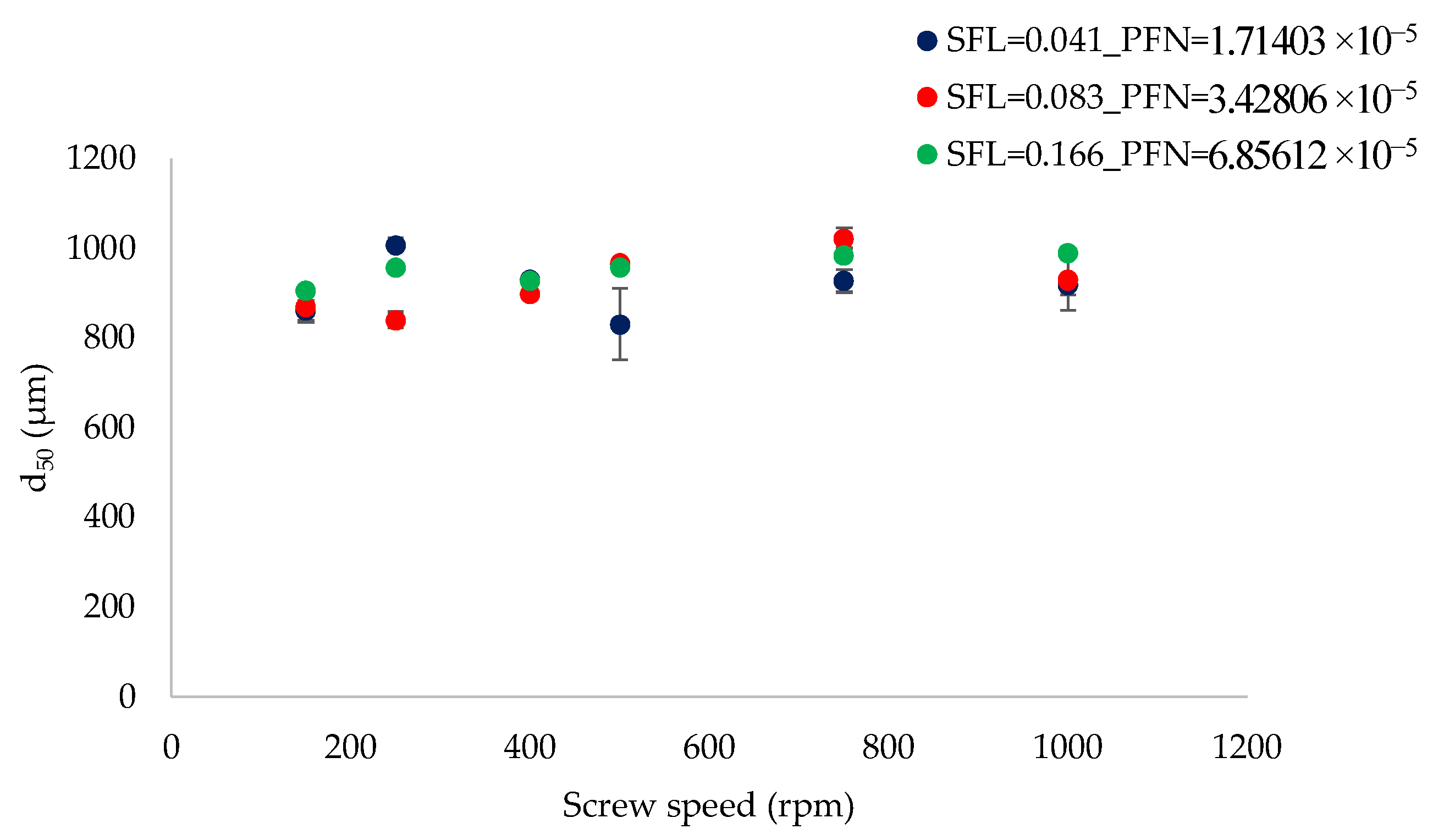

3.2.2. The Effect of Varying SFL–PFN at Different Screw Speed on Granule Size

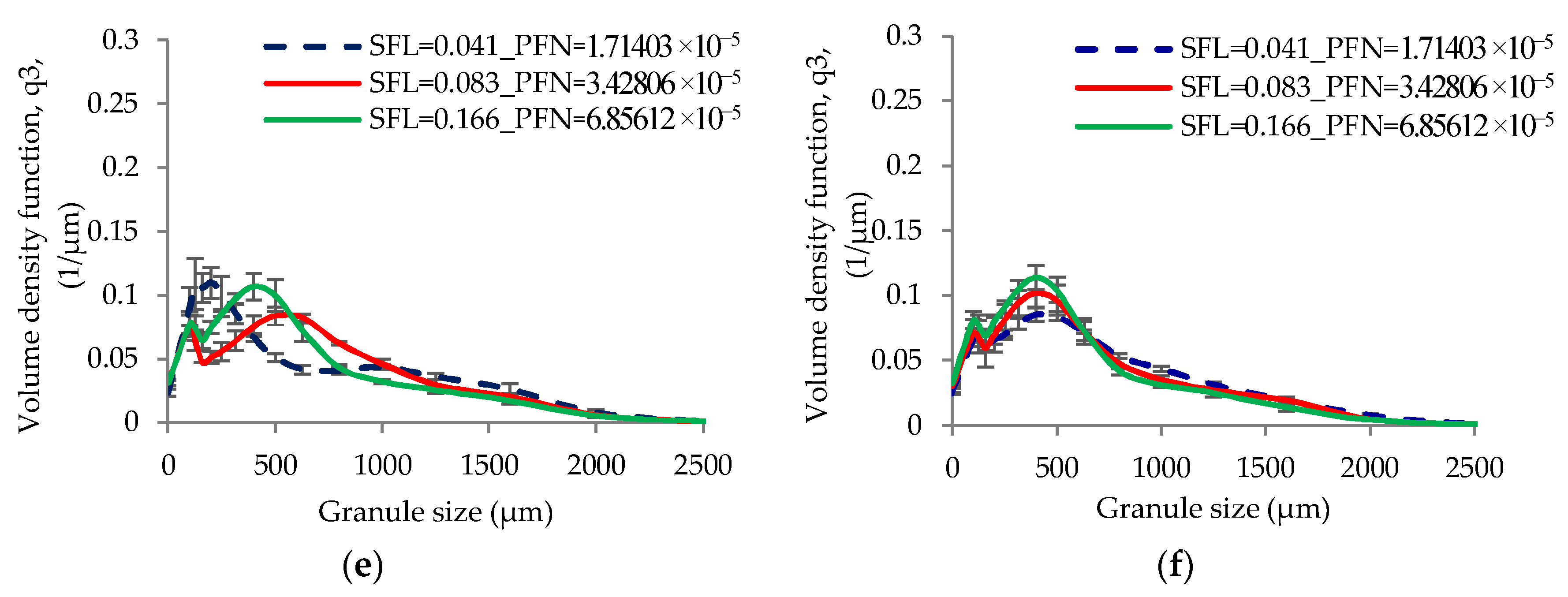

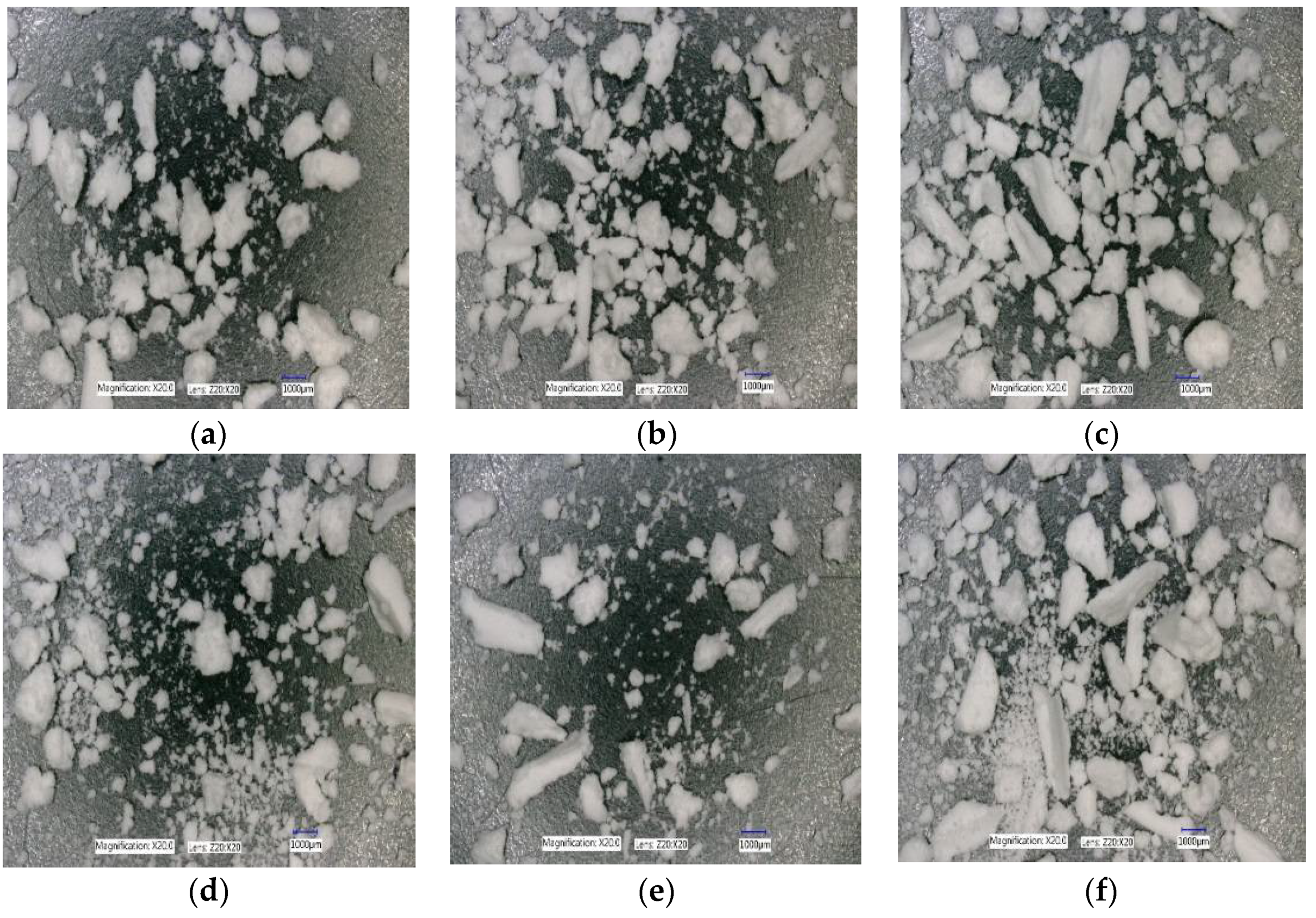

3.2.3. The Effect of Varying SFL–PFN at Different Screw Speed on Granule Shape

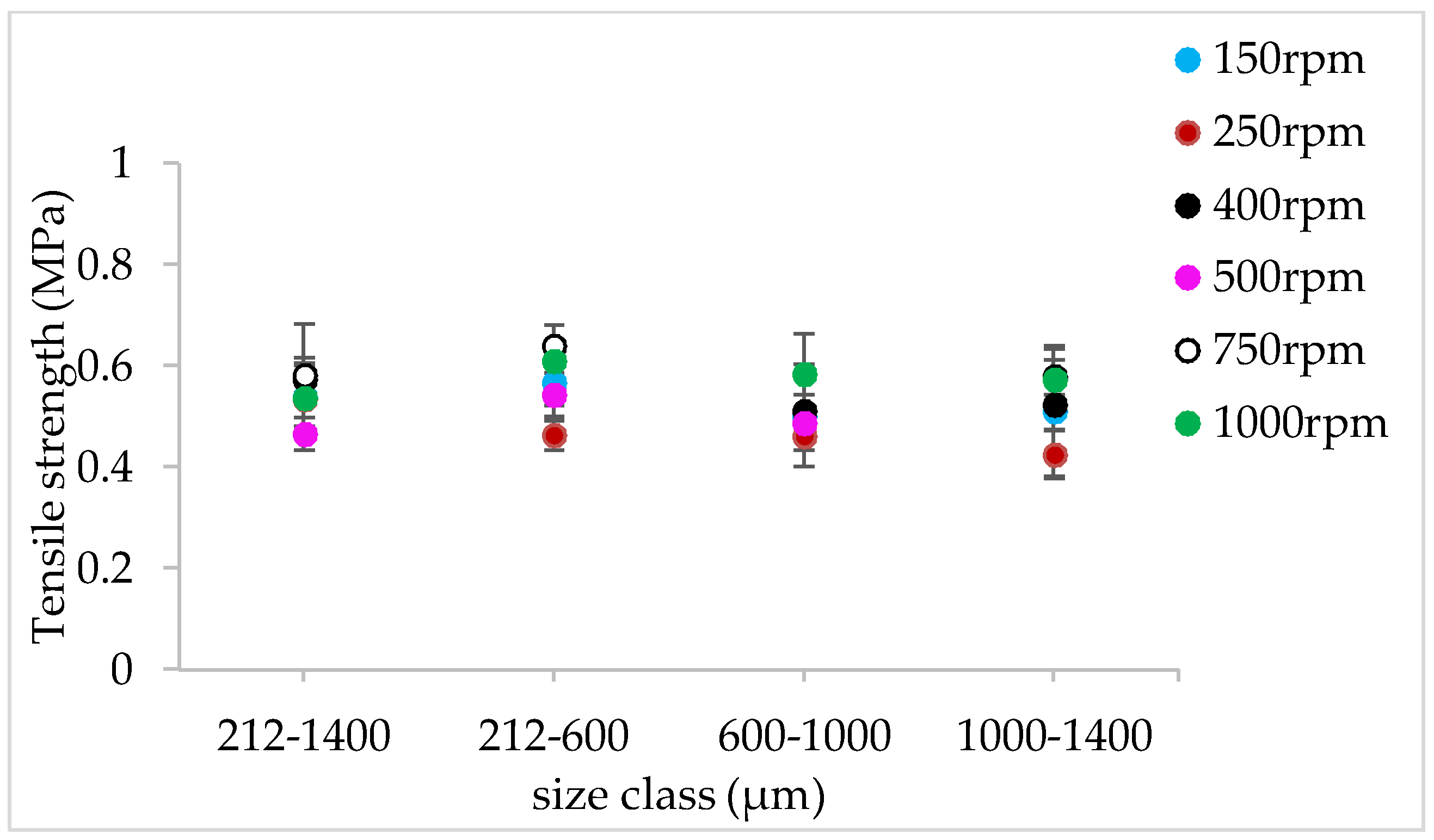

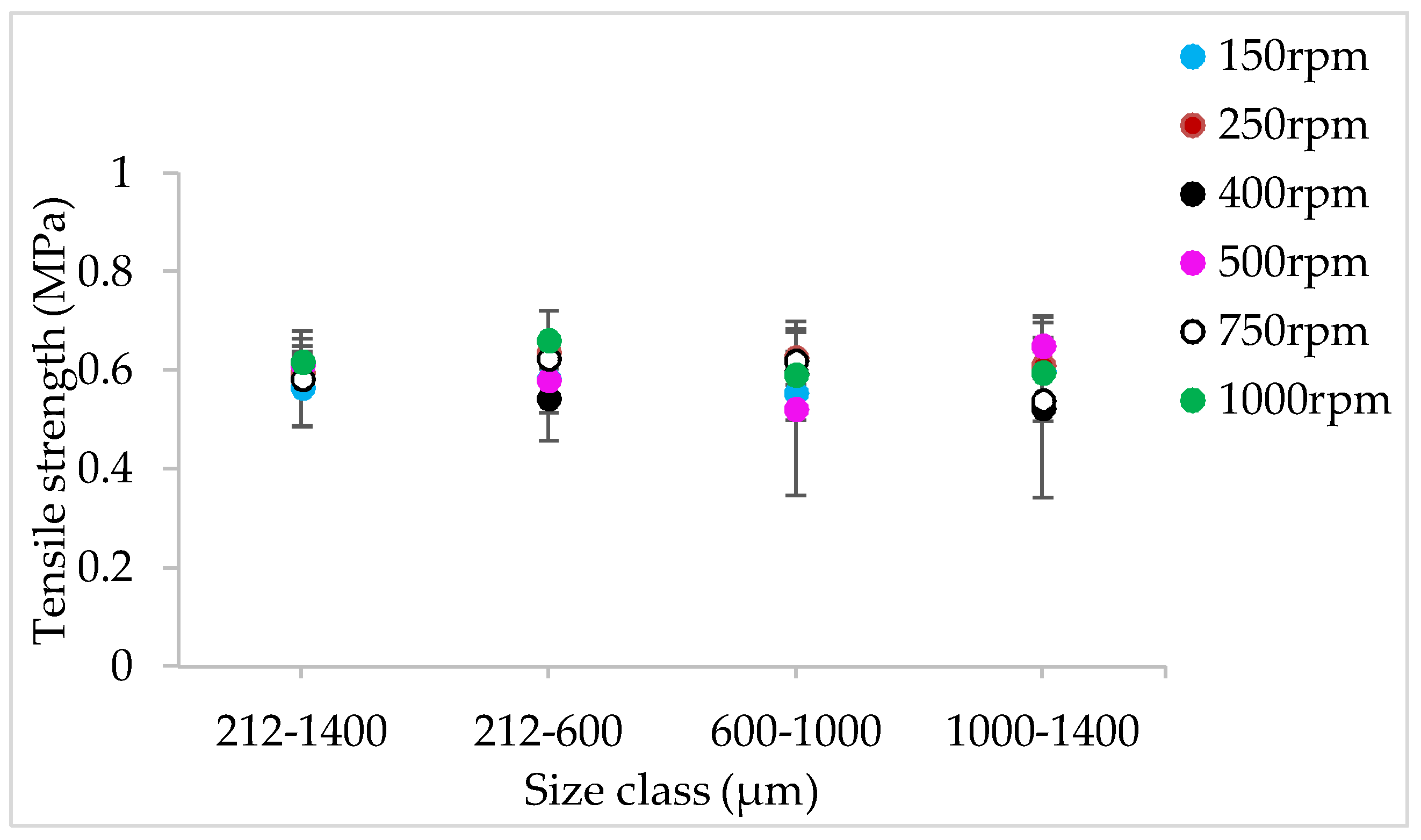

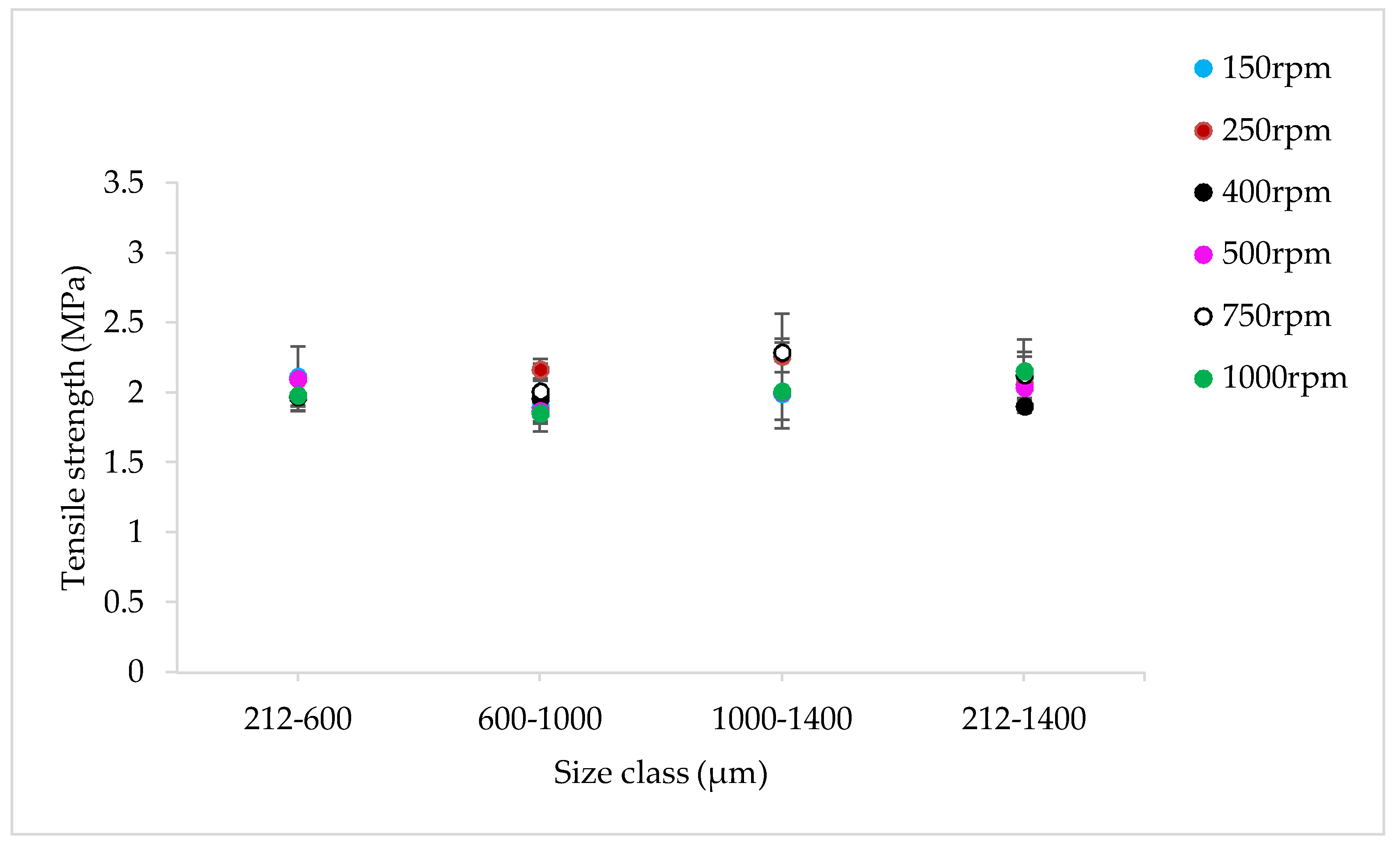

3.2.4. The Effect of Varying SFL–PFN at Different Screw Speed on Tablet Tensile Strength

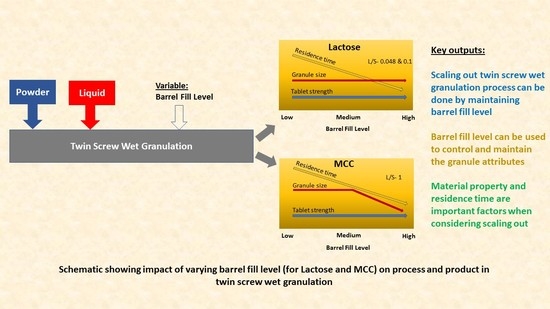

4. Discussion

4.1. Lactose Powder

4.1.1. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on MRT

4.1.2. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on Granule Size

4.1.3. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on Granule Shape

4.1.4. The Effect of Varying SFL–PFN at Different Screw Speed and L/S on Tablet Tensile Strength

4.2. Microcrystalline Cellulose (MCC) Powder

4.2.1. The Effect of Varying SFL–PFN at Different Screw Speed on MRT

4.2.2. The Effect of Varying SFL–PFN at Different Screw Speed on Granule Size

4.2.3. The Effect of Varying SFL–PFN at Different Screw Speed on Granule Shape

4.2.4. The Effect of Varying SFL–PFN at Different Screw Speed on Tablet Tensile Strength

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Vercruysse, J.; Córdoba Díaz, D.; Peeters, E.; Fonteyne, M.; Delaet, U.; Van Assche, I.; De Beer, T.; Remon, J.P.; Vervaet, C. Continuous twin screw granulation: Influence of process variables on granule and tablet quality. Eur. J. Pharm. Biopharm. 2012, 82, 205–211. [Google Scholar] [CrossRef] [PubMed]

- Djuric, D.; Van Melkebeke, B.; Kleinebudde, P.; Remon, J.P.; Vervaet, C. Comparison of two twin-screw extruders for continuous granulation. Eur. J. Pharm. Biopharm. 2009, 71, 155–160. [Google Scholar] [CrossRef] [PubMed]

- Dhenge, R.M.; Fyles, R.S.; Cartwright, J.J.; Doughty, D.G.; Hounslow, M.J.; Salman, A.D. Twin screw wet granulation: Granule properties. Chem. Eng. J. 2010, 164, 322–329. [Google Scholar] [CrossRef]

- Djuric, D.; Kleinebudde, P. Continuous granulation with a twin-screw extruder: Impact of material throughput. Pharm. Dev. Technol. 2010, 15, 518–525. [Google Scholar] [CrossRef] [PubMed]

- Thompson, M.R.; Sun, J. Wet Granulation in a Twin-Screw Extruder: Implications of Screw Design. J. Pharm. Sci. 2010, 99, 2090–2103. [Google Scholar] [CrossRef] [PubMed]

- Dhenge, R.M.; Cartwright, J.J.; Doughty, D.G.; Hounslow, M.J.; Salman, A.D. Twin screw wet granulation: Effect of powder feed rate. Adv. Powder Technol. 2011, 22, 162–166. [Google Scholar] [CrossRef]

- Dhenge, R.M.; Washino, K.; Cartwright, J.J.; Hounslow, M.J.; Salman, A.D. Twin screw granulation using conveying screws: Effects of viscosity of granulation liquids and flow of powders. Powder Technol. 2013, 238, 77–90. [Google Scholar] [CrossRef]

- Kumar, A.; Dhondt, J.; Vercruysse, J.; De Leersnyder, F.; Vanhoorne, V.; Vervaet, C.; Remon, J.P.; Gernaey, K.V.; De Beer, T.; Nopens, I. Development of a process map: A step towards a regime map for steady-state high shear wet twin screw granulation. Powder Technol. 2016, 300, 73–82. [Google Scholar] [CrossRef]

- Liu, H.; Galbraith, S.C.; Ricart, B.; Stanton, C.; Smith-Goettler, B.; Verdi, L.; O’Connor, T.; Lee, S.; Yoon, S. Optimization of critical quality attributes in continuous twin-screw wet granulation via design space validated with pilot scale experimental data. Int. J. Pharm. 2017, 525, 249–263. [Google Scholar] [CrossRef] [PubMed]

- Dhenge, R.M.; Cartwright, J.J.; Hounslow, M.J.; Salman, A.D. Twin screw wet granulation: Effects of properties of granulation liquid. Powder Technol. 2012, 229, 126–136. [Google Scholar] [CrossRef]

- El Hagrasy, A.S.; Hennenkamp, J.R.; Burke, M.D.; Cartwright, J.J.; Litster, J.D. Twin screw wet granulation: Influence of formulation parameters on granule properties and growth behavior. Powder Technol. 2013, 238, 108–115. [Google Scholar] [CrossRef]

- Dhenge, R.M.; Cartwright, J.J.; Hounslow, M.J.; Salman, A.D. Twin screw granulation: Steps in granule growth. Int. J. Pharm. 2012, 438, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Keleb, E.I.; Vermeire, A.; Vervaet, C.; Remon, J.P. Continuous twin screw extrusion for the wet granulation of lactose. Int. J. Pharm. 2002, 239, 69–80. [Google Scholar] [CrossRef]

- Keleb, E.I.; Vermeire, A.; Vervaet, C.; Remon, J.P. Twin screw granulation as a simple and efficient tool for continuous wet granulation. Int. J. Pharm. 2004, 273, 183–194. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.T.; Ingram, A.; Rowson, N.A. Twin screw wet granulation: The study of a continuous twin screw granulator using Positron Emission Particle Tracking (PEPT) technique. Eur. J. Pharm. Biopharm. 2012, 81, 666–673. [Google Scholar] [CrossRef] [PubMed]

- Saleh, M.F.; Dhenge, R.M.; Cartwright, J.J.; Hounslow, M.J.; Salman, A.D. Twin screw wet granulation: Binder delivery. Int. J. Pharm. 2015, 487, 124–134. [Google Scholar] [CrossRef] [PubMed]

- Saleh, M.F.; Dhenge, R.M.; Cartwright, J.J.; Hounslow, M.J.; Salman, A.D. Twin screw wet granulation: Effect of process and formulation variables on powder caking during production. Int. J. Pharm. 2015, 496, 571–582. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Reynolds, G.K.; Huang, Z.; de Matas, M.; Salman, A.D. Granulation of increasingly hydrophobic formulations using a twin screw granulator. Int. J. Pharm. 2014, 475, 82–96. [Google Scholar] [CrossRef] [PubMed]

- Djuric, D.; Kleinebudde, P. Impact of screw elements on continuous granulation with a twin-screw extruder. J. Pharm. Sci. 2008, 11, 4934–4942. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Vercruysse, J.; Bellandi, G.; Gernaey, K.V.; Vervaet, C.; Remon, J.P.; De Beer, T.; Nopens, I. Experimental investigation of granule size and shape dynamics in twin-screw granulation. Int. J. Pharm. 2014, 475, 485–495. [Google Scholar] [CrossRef] [PubMed]

- Lute, S.V.; Dhenge, R.M.; Hounslow, M.J.; Salman, A.D. Twin screw granulation: Understanding the mechanism of granule formation along the barrel length. Chem. Eng. Res. Des. 2016, 110, 43–53. [Google Scholar] [CrossRef]

- Meier, R.; Thommes, M.; Rasenack, N.; Moll, K.P.; Krumme, M.; Kleinebudde, P. Granule size distributions after twin-screw granulation—Do not forget the feeding systems. Eur. J. Pharm. Biopharm. 2016, 106, 59–69. [Google Scholar] [CrossRef] [PubMed]

- Gorringe, L.J.; Kee, G.S.; Saleh, M.F.; Fa, N.H.; Elkes, R.G. Use of the channel fill level in defining a design space for twin screw wet granulation. Int. J. Pharm. 2017, 519, 165–177. [Google Scholar] [CrossRef] [PubMed]

- Lute, S.V.; Dhenge, R.M.; Hounslow, M.J.; Salman, A.D. Twin screw wet granulation: Effect of fill level. In Proceedings of the 7th International Granulation Workshop, Sheffield, UK, 29–30 June 2015. [Google Scholar]

- Osorio, J.G.; Sayin, R.; Kalbag, A.V.; Litster, J.D.; Martinez-Marcos, L.; Lamprou, D.A.; Halbert, G.W. Scaling of continuous twin screw wet granulation. AIChE J. 2017, 63, 921–932. [Google Scholar] [CrossRef]

- Kohlgrüber, K. Co-Rotating Twin-Screw Extruders. In Co-Rotating Twin-Screw Extruder; Hanser: Munich, Germany, 2008. [Google Scholar] [CrossRef]

- Kolter, K.; Karl, M.; Gryczke, A. Hot-Melt Extrusion with BASF Pharma Polymers. In Extrusion Compendium; 2nd Revised and Enlarged Edition BASF SE; BASF: Ludwigshafen, Germany, 2012. [Google Scholar]

- Kumar, A.; Alakarjula, M.; Vanhoorne, V.; Toiviainen, M.; De Leersnyder, F.; Vercruysse, J.; Juuti, M.; Ketolainen, J.; Vervaet, C.; Remon, J.P.; et al. Linking granulation performance with residence time and granulation liquid distributions in twin-screw granulation: An experimental investigation. Eur. J. Pharm. Sci. 2016, 90, 25–37. [Google Scholar] [CrossRef] [PubMed]

- Nikitine, C.; Rodier, E.; Sauceau, M.; Fages, J. Residence time distribution of a pharmaceutical grade polymer melt in a single screw extrusion process. Chem. Eng. Res. Des. 2009, 87, 809–816. [Google Scholar] [CrossRef]

- Fell, J.T.; Newton, J.M. Determination of Tablet Strength by the Diametral-Compression Test. J. Pharm. Sci. 1970, 59, 688–691. [Google Scholar] [CrossRef] [PubMed]

- Mangwandi, C.; Albadarin, A.B.; JiangTao, L.; Allen, S.; Walker, G.M. Development of a value-added soil conditioner from high shear co-granulation of organic waste and limestone powder. Powder Technol. 2014, 252, 33–41. [Google Scholar] [CrossRef]

- Verstraeten, M.; Van Hauwermeiren, D.; Lee, K.; Turnbull, N.; Wilsdon, D.; am Ende, M.; Doshi, P.; Vervaet, C.; Brouckaert, D.; Mortier, S.T.F.C.; et al. In-depth experimental analysis of pharmaceutical twin-screw wet granulation in view of detailed process understanding. Int. J. Pharm. 2017, 529, 678–693. [Google Scholar] [CrossRef] [PubMed]

- Iveson, S.M.; Litster, J.D.; Hapgood, K.; Ennis, B.J. Nucleation, growth and breakage phenomena in agitated wet granulation processes: A review. Powder Technol. 2001, 117, 3–39. [Google Scholar] [CrossRef]

- Thompson, M.R.; O’Donnell, K.P. “Rolling” phenomenon in twin screw granulation with controlled-release excipients. Drug Dev. Ind. Pharm. 2015, 41, 482–492. [Google Scholar] [CrossRef] [PubMed]

- Kleinebudde, P.; Jumaa, M.; El Saleh, F. Influence of degree of polymerization on behavior of cellulose during homogenization and extrusion/spheronization. AAPS PharmSci 2000, 2, 18–27. [Google Scholar] [CrossRef]

| Expt. No. | Powder Feed Rate (g/min) | Screw Speed (rpm) | SFL (g) | PFN (-) for Lactose | PFN (-) for MCC |

|---|---|---|---|---|---|

| 1 | 6.25 | 150 | 0.041 | 1.71403 × 10−5 | 3.37093 × 10−5 |

| 2 | 10.41 | 250 | |||

| 3 | 16.66 | 400 | |||

| 4 | 20.83 | 500 | |||

| 5 | 31.25 | 750 | |||

| 6 | 41.66 | 1000 | |||

| 7 | 12.50 | 150 | 0.083 | 3.42806 × 10−5 | 6.74185 × 10−5 |

| 8 | 20.83 | 250 | |||

| 9 | 33.33 | 400 | |||

| 10 | 41.66 | 500 | |||

| 11 | 62.50 | 750 | |||

| 12 | 83.33 | 1000 | |||

| 13 | 25.00 | 150 | 0.166 | 6.85612 × 10−5 | 1.34837 × 10−4 |

| 14 | 41.66 | 250 | |||

| 15 | 66.66 | 400 | |||

| 16 | 83.33 | 500 | |||

| 17 | 125.00 | 750 | |||

| 18 | 166.66 | 1000 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lute, S.V.; Dhenge, R.M.; Salman, A.D. Twin Screw Granulation: An Investigation of the Effect of Barrel Fill Level. Pharmaceutics 2018, 10, 67. https://doi.org/10.3390/pharmaceutics10020067

Lute SV, Dhenge RM, Salman AD. Twin Screw Granulation: An Investigation of the Effect of Barrel Fill Level. Pharmaceutics. 2018; 10(2):67. https://doi.org/10.3390/pharmaceutics10020067

Chicago/Turabian StyleLute, Sushma V., Ranjit M. Dhenge, and Agba D. Salman. 2018. "Twin Screw Granulation: An Investigation of the Effect of Barrel Fill Level" Pharmaceutics 10, no. 2: 67. https://doi.org/10.3390/pharmaceutics10020067

APA StyleLute, S. V., Dhenge, R. M., & Salman, A. D. (2018). Twin Screw Granulation: An Investigation of the Effect of Barrel Fill Level. Pharmaceutics, 10(2), 67. https://doi.org/10.3390/pharmaceutics10020067