Abstract

The investigation conducted in this study focused on assessing the withdrawal resistance of T-joints and the bending moment capacity in the tension and compression of corner joints. For samples, preparation glued-in loose tenons (Domino dowels) and dismountable connectors were used as connecting elements. The joints were made of European beech wood and a D3-grade PVAc adhesive was utilized for bonding. The effect of the joint type, the shoulders’ bonding, and the load application direction were investigated. The test results revealed that the withdrawal resistance of Domino dowel joints exhibited twice the strength compared to Domino connectors. Moreover, the presence of a bonded area on the shoulders did not significantly impact the strength of the joints. In the case of corner joints, the bending moment capacity in compression was notably influenced by the bond line on the shoulders, although such an effect was not significant in tension. Domino dowel joints provided a robust and reliable permanent connection between wooden elements, surpassing Domino connectors; however, in both cases, the strength values exceeded those of conventional dowels and cam lock connector joints.

1. Introduction

Furniture have different structures based on their functions. Storage furniture typically features a panel structure which is commonly found in cabinets, wardrobes, and bookshelves. On the other hand, seating furniture, tables, and beds have frame structures, consisting of interconnected rails and stiles. And, there are also pieces of furniture with combined structures, where both panel and frame elements are used to achieve specific design or functional goals. The integrity of these structures, capable of withstanding the loads on the furniture during its lifecycle, is assured by the connections between the constituent elements [1]. Both dismountable and glued connections are commonly used in furniture manufacturing to assure reliable assembly between the components. Dismountable connections allow for easy assembly and disassembly, which can be beneficial for transport and storage. Glued connections, on the other hand, offer a permanent bond between the structural elements, generally enhancing the mechanical properties and stability of the furniture piece. Despite the great variety of furniture joints, only a few types are used in mass production technologies. In the case of glued joints the varieties of mortise and tenon (M&T) and dowel joints are the most common [2,3], while in the case of dismountable connections the cam fittings and the bolt and barrel nut connectors are the most widespread solutions. Due to their wide distribution, a considerable part of the research has been directed towards these furniture joint types.

Regardless of the structure type, the strength and durability of furniture primarily depend on the physical and mechanical performance of the connections between the structural elements [4,5]. The strength and durability of these furniture joints are influenced by various factors, each contributing to different degrees to the ability of the structure to withstand static, dynamic, and cyclic loads. Comparing these factors, we find the quality of materials used, the geometry and dimensions of the joints, the adhesive system used, the precision of the assembly process, and the type of load the furniture is expected to bear [2,6,7,8,9,10]. These factors exert their influence on the joint strength both individually and in interaction with each other, forming a very complex system.

One of the most influential factor groups is the joint material—joint geometry—precision of execution mix where the intrinsic strength properties of the materials, the dimensions of the tenons and dowels, and the tightness between the connecting elements play a pivotal role. In one of the earliest studies on this area, Milham (1949) demonstrated that the highest load-bearing capacities in mortise and tenon joints are achieved when there is a close tolerance between the tenon and mortise [11]. Additionally, tenon shoulders positively affect joint capacity. Later, Dupont (1963) also emphasized the importance of maintaining close tolerances in the joints [12]. The significance of a tight fit between the tenon and mortise joints in order to obtain optimal strength was underlined through another study conducted by Tankut (2007) [13]. Oktaee et al. (2014) explored the effects of tenon geometry on the bending moment capacity of mortise and tenon joints, noting that tight-fitting shoulders and square tenons led to higher joint strengths [14]. Aman et al. (2008) compared loose mortise and tenon joints with traditional M&T joints using test specimens made from cherry, oak, and maple. Experiments have shown that the strength of the joint with a loose mortise and tenon is within the strength of the dowel joint and the conventional M&T joint [15]. Wilczynski and Warmbier (2003) conducted a study to determine the effect of tenon dimensions on the bending strength and stiffness of mortise and tenon joints [16]. They found that the moment capacity of the joint was positively influenced by tenon length and width, but the effect of the thickness was less significant. The effect of tenon length and tenon width on the withdrawal strength of the mortise and tenon joint was studied by Zhang and Hu (2021) [17]. They found that the tenon length has a higher effect on the joint’s strength than the width and recommended setting the tenon length between the single and double width values. A combined Finite Element Analysis (FEM) and Response Surface Methodology (RSM) model was used to optimize the tenon dimensions. The same combined model was employed to determine the optimal length, width, and height of the tenons for the bending moment capacity of the joints by Hu and Na (2020) [18] and Hu and Chen [19]. The higher sensitivity of the tenon length compared to the width to the bending moment capacity was demonstrated by Kasal et al. [20] and by Hajdarević, S. and Martinović [21]. Similar findings were observed by Derikvand et al. (2014), who studied T-shaped mortise and loose tenon furniture joints and concluded that tenon dimensions, wood species, and dowel reinforcement played vital roles in determining the bending moment capacity [22]. Sparkes (1968) compared square-end and round-end mortise and tenon joints and found them to be equally effective [23]. However, when a square-end tenon was fitted into a round-end mortise, the joint’s capacity was reduced by 15% compared to joints with matched components. Hill and Eckelman (1973) demonstrated that the bending moment capacity of the joint was directly related to the shear strength of the wood species used and to the tenon dimensions; the rail shoulder increased the joint’s stiffness [24]. Hao et al. (2020) quantitatively studied the effects of the dowel dimension, position, and loading distance on bending moment capacity [25]. Their research established the critical role of top dowels in determining the joint moment capacity and provided insights into optimizing joint parameters. Chen et al. (2018) studied the tensile and bending strength of double-wood dowels in medium-density fiberboard components [7]. They found a positive correlation between dowel diameter and both tensile and bending strength. The interference fit for the wood dowel joint was analyzed by Wang and Lee [26]. According to their results the highest withdrawal strength of dowels was found using quarter-sawn-type board and a perpendicular ring angle. Uysal studied the effect of the withdrawal strength of laminated veneer dowels from particleboard and medium-density fiberboard panels. He recommended the use of beech and poplar hybrid dowels for MDF panels as the optimum solution against withdrawal forces [27]. The stiffness of rounded dovetail joints was significantly improved by Tannert using various methods, like tenon oversizing, adhesive application, and self-tapping screw use. However, neither method increased the joint capacity [28]. A study by Hu et al. (2023) analyzed the reinforcement effect of dowels on dovetail joints [29]. They found the method effective both to improve the strength of the joint and postpone the crack propagation. For optimization they used the Response Surface Methodology. Dowel reinforcement of a tongue and groove miter joint proved to be a good solution to improve the joint’s cracking resistance [30]. The authors, Wu et al. (2023), determined the optimal distance between the inserted dowels as 27 mm.

In addition to the above group of factors, the adhesive system also plays an important role in the strength of the furniture joints. Studies by Vassiliou and Barboutis (2008) and Atar et al. (2009) focused on strength evaluations of furniture joints, highlighting the significance of adhesive choice and its influence on joint performance [31,32]. The work of Hu and Guan (2019) emphasized the importance of glue distribution, the friction coefficient, and reinforcement in the mechanical behavior of mortise and tenon joints [33]. Their numerical model provided insights into the distribution of glue and friction coefficients, enhancing the understanding of joint performance. Bomba et al. also underlined the importance of the glue line of wood joints [6]. They found that an increase in the glue line thickness from 0.1 mm to 0.5 mm resulted in a decrease in bending strength when a D3-type PVAc adhesive was used and an increase in the case of a D4-type adhesive. Tankut (2007) investigated the impact of moisture content and bond line thickness on the strength of mortise and tenon joints [13]. Their results indicated that maintaining a tight fit between the tenon and mortise was essential for optimal joint strength. Moisture content changes after assembly were shown to significantly affect the ultimate moment capacity of the joints. Aman et al. found that the optimum capacity was obtained when the glue was applied to both sides of the tenon and mortise [15]. A study by Kasal et al. on the effect of the adhesive type on the bending moment capacity of mortise and tenon T-joints [34] revealed that the capacity of joints glued using PVAc adhesive was higher than of PU adhesive and the joints made from a hardwood species (Turkish Beech) performed better. In another study [19], they found that in the case of L-type joints both tenon length and width increases positively influenced the bending moment capacity and the joints glued using PU adhesive were stronger than those glued using PVAc resin. They also developed a predictive formula which estimates the ultimate bending moment capacity of mortise and tenon joints under compression and tension. Altun et al. (2010) investigated the bending moment capacity of miter corner joints with plastic dovetail fitting in frames made using medium-density fiberboard (MDF) [2]. They found that certain adhesives, specifically PU and CA adhesives, were ineffective in increasing the bending moment capacity under diagonal compression and tensile loads. Záborský et al. (2018) investigated the effects of stress type, joiner size, wood species, and adhesive type on dowel joint stiffness. Their study provided valuable insights into optimizing joint designs for increased stiffness and resistance in furniture structures [35].

The contribution of the individual joints to the strength of a full chair structure was studied by Kasal et al. [36]. They used a typical chair structure with round edge mortise and tenon joints and applied a horizontal static load to the front rail. According to the results the ultimate bending moment capacity of the whole structure was 1.4 times higher than the sum of the individual T- and L-type joints’ moment capacities. Zaborsky et al. (2018) studied the effect of load direction, wood species, adhesive type, and dowel dimensions on the joint stiffness [37]. They used a special dowel, the so-called Domino joint, which is a combination of the dowel and loose mortise and tenon joint. Based on their findings we can conclude that the stiffness of the Domino joints is significantly higher in compression than in tension, the one-third-thickness pin is stiffer than the half-thickness pin. A Domino dowel inserted into beech wood provided approximately twice the stiffness compared to the dowel inserted into spruce. The effect of the adhesive type was not relevant.

The Domino dowels developed by the Festool company (Wendlingen, Germany) are flat pins with rounded edges, combining the advantages of tenon and dowel joints. The increased surface provides higher bonding strength, the flat shape prevents twisting. The company recently developed the dismountable version of the Domino dowels; however, these metallic Domino connectors are recommended by manufacturer as only connecting and not supporting elements in furniture structures.

This study aims to determine the withdrawal strength and bending moment capacity of the Domino joints and compare them with the properties of the similarly sized Domino connectors of 8 × 22 × 40 mm. The effect of the joints’ shoulder gluing and load types were investigated, and the load-bearing capacity of the bonded and dismountable joints were analyzed. The results can contribute to the more reliable engineering design of furniture structures and to the determination of the application areas of Domino joints and connectors.

2. Materials and Methods

2.1. Materials and Samples Preparation

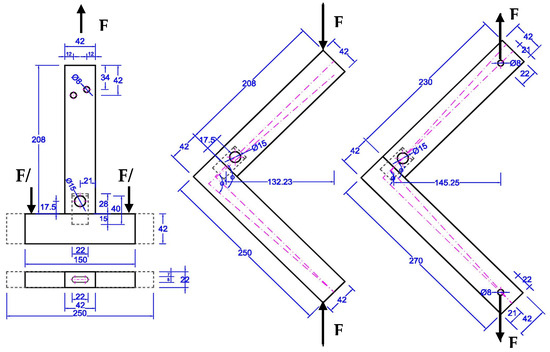

For the test sample preparation, European beech wood (Fagus sylvatica L.) was used with a mean density of 705 kg/m3 and 43 kg/m3 standard deviation. The beech wood species was selected due to its wide range of applications in the European furniture industry. A significant part of the wood material contained false heartwood. From the conditioned boards, rails and stiles were prepared with uniform width and thickness and in various lengths. Grain orientation was not considered during the specimens’ preparation. The rails and stiles had parallel, perpendicular, and inclined annual ring orientations. This could contribute to the higher variability of the data. From the rails and stiles, T-joints and corner joints were prepared using the geometry shown in Figure 1.

Figure 1.

Geometry of the joint specimens (dimensions in mm).

A total of 10 specimens per joint and test type were prepared; the moisture content of the samples was 10% ± 1%. In the case of the tension specimens, the lengths of the rails and stiles were extended so that the lever arm equaled the lever arm of the compression samples at the axis lines. However, the point of application of the external forces differs: in one case, this point is at the corner of the sample, while in the other case, the point of application is located on the axis resulting in a small difference in the lever arm’s length (135.23 mm and 145.25 mm). The bending moments were determined accordingly.

The glued joints were assembled using 8 × 22 × 40 mm beech Domino dowels; for the detachable joints the KV D8/50 type corner connectors were used (Figure 2).

Figure 2.

The Domino dowel (a), the Domino connector (b) (source: beavertools.com), and the anchoring effect of the connector (c).

The connector has similar dimensions to the 8 × 22 × 40 mm Domino dowel with an additional 15 mm drill hole placed on the side to house the anchor nut. The strength of the joint is assured by the split anchor with threaded sides, the wedge inserted into one of the pieces, and the anchor nut secured using a plastic tray in the other piece. The tight connection is ensured by the threaded shaft of the bolt, which stretches the anchor with the help of the wedge, and the wedge-grooved shaft of the bolt enables the stretching of the clamping screw. For the joint’s preparations, the Festool’s Domino Joiner DF 500 Q-Plus machine (Wendlingen, Germany) was used.

Joints using the Domino dowels were glued using a Polyvinyl acetate (PVAc)-type resin, specifically Ponal Super 3 from Henkel with a solid content of 50% ± 2% and D3-class water resistance. The glue was applied using a small brush on both sides of the drill hole and a Domino dowel at a spread rate of 160–180 g/m2. In order to separate the extra bonding strength provided by the glued joint shoulders, a set of joints were prepared without adhesive on shoulders using a masking tape to cover the area. In this way we could more accurately compare the joint strength of the dowel and connector joints. The connectors were installed following the Festool’s instructions: exactly the same drilling holes were prepared as for the dowels, 15 mm diameter extra drill holes were prepared on the sides of the shorter pieces, the cross anchors with threaded pins were positioned and fixed using the plastic trays, the split anchors were inserted into the mortises made in the longer pieces, the threaded bolts were tightened to expand the anchor sides laterally, and the other sides of bolts were fit into the cross anchors and stiffened with the pins. Figure 2c shows how the connector anchors into the drill hole sides. Ten different joint types were produced and tested subsequently. The specimens’ codes and names are summarized in Table 1.

Table 1.

Codes and Specimens’ full name.

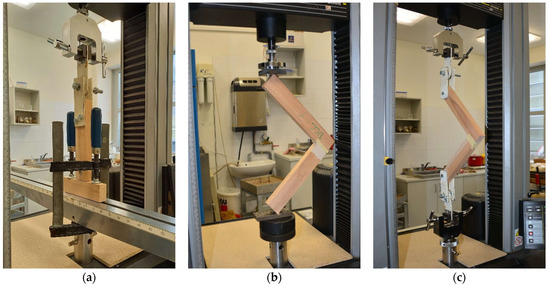

2.2. T-Joints Withdrawal Test

The perpendicular load-bearing capacity of T-joints using the Domino dowels and connectors was determined using a withdrawal test. Four sets of ten specimens were prepared: one set with Domino dowels (DTW), one with dowels, and the shoulders masked (DTW_AB), one with dowels but extended stile length (DTW_L) and one set with connectors (CTW). The stiles were clamped to the lower crossbar using C-clamps, the rails were drilled with two holes and fixed to the crosshead through two steel plates and nut and bolt connections. A third steel plate was placed between the two previous plates and fixed to the tension grips of the testing machine (Figure 3a). All steel plates were striated on their surface to increase the gripping force and avoid the wood material failing in shear during the test. Due to the design (central steel plate can rotate), just normal stresses occurred in the rails.

Figure 3.

The experimental test setups, (a) withdrawal; (b) compression, (c) tension.

2.3. Corner Joints Compression and Tension Tests

Corner joint specimens were subjected to diagonal tensile and compression loads using a universal testing machine with custom made fixtures. The compression specimens were supported using V-grooved plates to avoid the lateral slip. (Figure 3b) Tension tests were conducted as shown in Figure 3c: 8 mm diameter holes were drilled at the end of the stiles and rails and two steel plates were tightly fixed to the specimens’ using a nut and bolt connection; between the steel plates another plate was placed which was connected to the tension fixtures of the testing machine. This third plate could easily rotate around the bolt; therefore, the applied load always acted perpendicularly, avoiding any lateral auxiliary moments. The striated plates assured a strong grip without any slipping.

An INSTRON Model 5566 universal testing machine (Norwood, MA, USA) was used for all tests with a 10 kN maximum capacity. The rate of static loading was 2 mm/min. Loading continued until an irreversible decrease in the load was observed. The force and displacement data were recorded, and the maximum load was determined. Bending moment capacities of the corner joints were calculated using the following formula:

M–bending moment capacity, Nm; Fmax–maximum load, N; L–moment arm, m.

2.4. Statistical Analysis

Statistical analysis was performed to compare the strength of different joint types and determine the maximum load-bearing capacities of the Domino dowels and connectors. All statistical analyses were performed using the Tibco-Statistica-13 software. First, the homogeneity of variances was checked using Fisher’s F-tests. The statistically significant differences between sample means were checked using t-tests for dependent variables. The confidence level was set at 95% for all tests (p < 0.05). Visualization of data set variations was performed using the Box-Plot diagrams for mean.

3. Results and Discussion

3.1. Withdrawal Strength of T-Joints

The withdrawal strength test of a joint estimates the connection’s load-bearing capacity when axial forces act on a structure. In this study, a total of 40 specimens were tested for withdrawal, i.e., 10 specimens per joint type, to determine the axial load-bearing capacity of T-joints using Domino dowels and connectors. Two stile lengths, 150 and 250 mm, were tested because some of the short stiles failed in tension perpendicular to grain in the joint zone. The withdrawal resistance of the joints expressed in Newtons (N) is listed in Table 2 with the major statistics. T-joints with longer stiles show a more consistent withdrawal strength (CV = 0.05), while in the case of shorter stiles the two characteristic failure modes (glue shear and perpendicular tension) increased significantly with the data dispersion (CV = 0.12). T-joints using the Domino connector showed the highest variation and the lowest mean value which was less than half of the glued joint’s similar values.

Table 2.

Withdrawal strength of T-joints.

Figure 4 shows the typical load–displacement graphs for the four joint types. The diagrams’ steepness comparison reveals that the end gluing of the rails does not influence the stiffness of the joints. Except for two specimens, the Domino dowel joints with longer stiles were the stiffest connections; however, the correlation between load and displacement was not completely linear. This joint type presented the more consistent maximum load values, while the others were more dispersed, especially the connector joints. The load–displacement diagrams of the joints with Domino connectors show high non-linearity which is the result of the uneven dislocation of the split anchor.

Figure 4.

The load–displacement diagrams of T-joints’ withdrawal tests (colors depicting the samples).

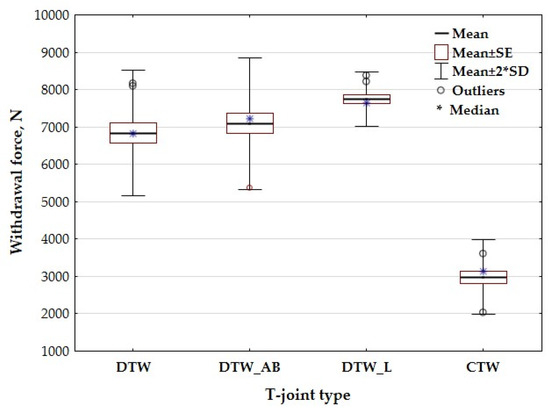

The Box-Plot diagrams of the joint types (Figure 5) present the most important statistics of the measured values. Differencies in themean and variance of the data were tested using independent Student’s t-tests. All tests were performed at a p = 0.05 significancy level. The results show that there is no statistically signficant difference in load-bearing capacity between the masked and unmasked T-joints when the shorter stiles are used. However, the length of the stiles significantly influenced the withdrawal strength, the longer stiles resulted in higher values. The diagram also reveals the significantly lower values of the connector joints.The mean withdrawal strength values of the glued joints slightly overperformed the strength of the traditional spiral beech dowel joints [38] and are comparable with values obtained in a previous study [39].

Figure 5.

Box-Plot diagrams of the T-joints tested for withdrawal resistance.

3.2. Bending Moment Capacity of Corner Joints in Compression and Tension

The bending moment capacities of the corner joints loaded in tension and in compression are listed in Table 3. The corner joints with Domino dowels and with the shoulders glued provided the highest average capacity; the Domino connector joints performed much worse having about half the bending moment capacity of the glued ones.

Table 3.

Bending moment capacity of the corner joints in compression and tension.

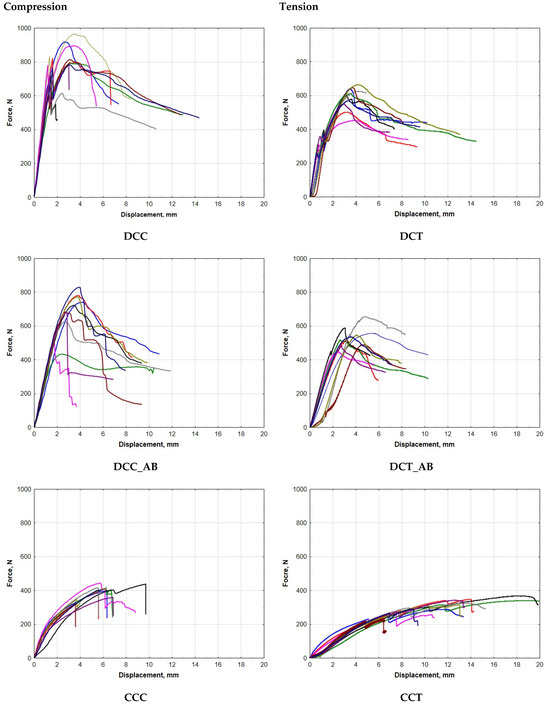

The load–displacement diagrams of the corner joints (Figure 6) reveals the stiffness of the joints. Joints using the Domino dowels are stiffer in compression than in tension, while the Domino connector joints show a creep behavior. A consistent cut-off point can be observed on the load–displacement diagrams of the corner joints with glued shoulders tested in tension (DCT) which can be attributed to the failure of the shoulder’s bond line. Joints with the shoulders masked displays more inconsistency than the glued joints. The Domino connector joints loaded in tension exhibit a long quasi-flat displacement zone, where the anchoring maintains a constant load bearing despite the steady creep.

Figure 6.

The load–displacement diagrams of the corner joints in comression and tension Colors depict different samples).

The Box-Plot diagrams of the corner joints (Figure 7) expose the high variability of the data. The Domino dowel joints exhibit large plots as a result of the higher dispersion of the bending moment capacity values both in compression and tension. In the case of the compression tests, gluing the joints’ shoulders has a significant impact on the moment capacity of the corner joints. The shoulder’s bond line increased the bending moment capacity by almost 20% in compression. Contrary to this, shoulder gluing does not significantly affected the moment capacity of the joints in tension. The corner joints with the shoulders glued performed better in compression than in tension; the difference was 21%. This difference cannot be seen when we compare the masked joints’ bending moment capacities. The statistically significant difference between the Domino dowel and Domino connector joints is obvious from the Box-Plot diagrams and the independent Student’s t-tests confirmed this. The connector joint performed significantly better in compression than in tension.

Figure 7.

Bending moment capacities of the corner joints.

The typical failure modes occurred during the tests are presented in Figure 8. The Domino connector joints failed in shear predominantly when the anchor nut compressed the hole side (Figure 8a,c) or the split anchor compressed the end zone (Figure 8b). Figure 8d shows the deterioration in the anchor grips during the withdrawal tests. In the case of the corner joints with dowels tested in compression, the sliding out of the dowels was the typical failure mode (Figure 8f) accompanied by wood failure in the shoulder’s bond line in conjunction with tension failure perpendicular to the grain (Figure 8e). In tension tests, the Domino dowels had been broken in several cases or the dowels slipped out similarly to the compression tests. T-joints with dowels failed in tension perpendicular to grains mostly when short stiles were used.

Figure 8.

Typical failure modes of the T- and corner joints.

4. Conclusions

The loose tenon joint developed by Festool under the Domino dowel name successfully combines the advantages of the traditional tenon and dowel joints. In this study, the load-bearing capacity of the Domino dowel and fastener joints were determined in tension and compression. Several conclusions can be drawn from the results:

- The withdrawal strength of the T-joints made of beech wood and using a D3-grade PVAc adhesive performs as well as the joints connected using conventional beech dowels and loose tenons. The load-bearing capacity of the glued Domino dowel joints is twice that of Domino connectors.

- The adhesive’s presence or absence on the rail shoulder does not significantly influence the withdrawal strength. The withdrawal strength of the joints is of the same order of magnitude as the tensile strength perpendicular to the wood grain; therefore, special attention must be given to the wooden structure’s dimensioning.

- The bending moment capacities of the corner joints showed high dispersion; however, the statistical tests revealed the importance of shoulder gluing in compression tests. In tension tests the presence of glue on the stiles’ shoulders is negligible.

- In the case of Domino dowel connections, the corner joints’ load-bearing capacity is higher by about 20% in compression than in tension. This joint type provided the stiffest connection also.

- The bending moment capacity of the connector is approximately half of the capacity of dowel connections; however, this value is large enough to use the connectors not only as a connecting element but also as a supporting element as well.

- The lower bending moment capacities of the connector joints occur due to the vulnerability of the anchor’s ridge and to the steady outslipping of the anchor. Special attention must be paid to joint dimensioning to avoid the shear failure of the joints.

Author Contributions

Conceptualization and methodology, L.D.; software, S.B. and L.D.; validation, S.B., L.D., and C.C.; formal analysis, L.D.; investigation, S.B.; resources, C.C.; data curation, S.B. and L.D.; writing—original draft preparation, L.D. and S.B.; writing—review and editing, C.C.; visualization, L.D. and S.B.; supervision, L.D.; project administration, L.D.; funding acquisition, C.C. and L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially supported by the Competitiveness Operational Program 2014—2020 Priority Axis 1—Research, Technological Development and Innovation (RDI) in support of Economic Competitiveness and Business Development Action 1.1.1—Large CD infrastructures (project type: innovation clusters; project title: ‘Transylvanian Furniture Cluster—an innovative cluster of European interest’) by the Sectoral Operational Program Human Resources Development (SOP HRD), ID134378 financed by the European Social Fund and by the Romanian Government. The research was also supported by project No. TKP2021-NKTA-43, implemented with the support provided by the Ministry of Innovation and Technology of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NKTA funding scheme. The article publication was also supported by the intramural research program of the U.S. Department of Agriculture, National Institute of Food and Agriculture, McIntire-Stennis Program. The findings and conclusions in this publication have not been formally disseminated by the U.S. Department of Agriculture and should not be construed to represent any agency determination or policy.

Data Availability Statement

The data presented in this article are available upon request from the corresponding author.

Acknowledgments

The authors express their sincere appreciation to Festool Hungary and Henkel Hungary for their in-kind contributions to this research, and we are also grateful to the Woodshop staff from the Sopron University for their valuable contributions in sample preparation.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Eckelman, C.A. Textbook of Product Engineering and Strength Design of Furniture; Purdue University: West Lafayette, IN, USA, 2003; pp. 65–67. [Google Scholar]

- Altun, S.; Burdurlu, E.; Kılıç, M. Effect of adhesive type on the bending moment capacity of miter frame corner joints. BioResources 2010, 5, 1473–1483. [Google Scholar] [CrossRef]

- Tankut, A.N.; Tankut, N. The effects of joint forms (shape) and dimensions on the strengths of mortise and tenon joints. Turk. J. Agric. For. 2005, 29, 493–498. [Google Scholar]

- Eckelman, C.A. Bending strength and moment rotation characteristics of two-pin moment resisting dowel joints. For. Prod. J. 1971, 21, 35–39. [Google Scholar]

- Smardzewski, J.; Lewandowski, W. Elasticity modulus of cabinet furniture joints. Mater. Des. 2014, 60, 260–266. [Google Scholar] [CrossRef]

- Bomba, J.; Šedivka, P.; Hýsek, Š.; Fáber, J.; Oberhofnerová, E. Influence of Glue Line Thickness on the Strength of Joints Bonded with PVAc Adhesives. For. Prod. J. 2017, 68, 120–126. [Google Scholar] [CrossRef]

- Chen, M.; Li, X.; Lyu, J. Influence of Dowel Diameter and Curing Time on Strength of Double Dowel Joint. Wood Res. 2018, 63, 591–598. [Google Scholar]

- Eckelman, C.A.; Haviarova, E. Withdrawal Capacity of Joints Constructed with 9.5-mm and 15.9-mm Through-Bolts and Diameter Nominal 15-mm and 25-mm Pipe-Nut Connectors. For. Prod. J. 2011, 61, 257–264. [Google Scholar] [CrossRef]

- Erdil, Y.Z.; Eckelman, C.A. Withdrawal Strength of Dowels in Plywood and Oriented Strand Board. Turk. J. Agric. For. 2001, 25, 319–327. [Google Scholar]

- Erdil, Y.Z.; Kasal, A.; Eckelman, C.A. Bending moment capacity of rectangular mortise and tenon furniture joints. For. Prod. J. 2005, 55, 209. [Google Scholar]

- Milham, R.M. A Comparison of Strength Characteristic of the Mortise and Tenon Joint and Dowel Joint. Master’s Thesis, University of Michigan, Ann Arbor, MI, USA, 1949; pp. 25–30. [Google Scholar]

- Duppont, W. Rationalization of Glue Joints in the Woodworking Industry; Department of Forestry, Forest Products Laboratory: Madison, Wisconsin, 1963; pp. 1–8. [Google Scholar]

- Tankut, N. The effect of adhesive type and bond line thickness on the strength of mortise and tenon joints. Int. J. Adhes. Adhes. 2007, 27, 493–498. [Google Scholar] [CrossRef]

- Oktaee, J.; Ebrahimi, G.; Layeghi, M.; Ghofrani, M.; Eckelman, C.A. Bending moment capacity of simple and haunched mortise and tenon furniture joints under tension and compression loads. Turk. J. Agric. For. 2014, 38, 291–297. [Google Scholar] [CrossRef]

- Aman, R.; West, H.; Cormier, D. An evaluation of loose tenon joint strength. For. Prod. J. 2008, 58, 61–64. [Google Scholar]

- Wilczyński, A.; Warmbier, K. Effect of joint dimensions on strength and stiffness of tenon joints. Folia For. Pol. 2003, 34, 53–66. [Google Scholar]

- Zhang, T.; Hu, W. Numerical study on effects of tenon sizes on withdrawal load capacity of mortise and tenon joint. Wood Res. 2021, 66, 321–330. [Google Scholar] [CrossRef]

- Hu, W.; Liu, N. Numerical and Optimal Study on Bending Moment Capacity and Stiffness of Mortise-and-Tenon Joint for Wood Products. Forests 2020, 11, 501. [Google Scholar] [CrossRef]

- Hu, W.; Chen, B. A Methodology for Optimizing Tenon Geometry Dimensions of Mortise-and-Tenon Joint Wood Products. Forests 2021, 12, 478. [Google Scholar] [CrossRef]

- Kasal, A.; Eckelman, C.A.; Haviarova, E.; Erdil, Y.Z.; Yalcin, I. Bending Moment Capacities of L-Shaped Mortise and Tenon Joints under Compression and Tension Loadings. Bioresources 2015, 10, 7009–7020. [Google Scholar] [CrossRef]

- Hajdarević, S.; Martinović, S. Effect of Tenon Length on Flexibility of Mortise and Tenon Joint. Procedia Eng. 2014, 69, 678–685. [Google Scholar] [CrossRef][Green Version]

- Derikvand, M.; Ebrahimi, G.; Eckelman, C.A. Bending Moment Capacity of Mortise and Loose-Tenon Joints. Wood Fiber Sci. 2014, 46, 1–8. [Google Scholar]

- Sparkes, A.J. The Strength of Mortise-and-Tenon Joints, Furniture Industry Research Association; FIRA Technical report (Issue 33); Furniture Industry Research Association: Stevenage, UK, 1968; pp. 48–52. [Google Scholar]

- Hill, M.D.; Eckelman, C.A. Flexibility and bending strength of mortise and tenon joints. Purdue Univ. J. 1973, 4758, 25–33. [Google Scholar]

- Hao, J.; Xu, L.; Wu, X.; Li, X. Analysis and modeling of the dowel connection in wood T type joint for optimal performance. Compos. Struct. 2020, 253, 112754. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, S.-H. Design and Analysis on Interference Fit in the Hardwood Dowel-glued Joint by Finite Element Method. Procedia Eng. 2014, 79, 166–172. [Google Scholar] [CrossRef][Green Version]

- Uysal, B. Withdrawal Strength of Various Laminated Veneer Dowels from Composite Materials. Wood Fiber Sci. 2005, 37, 213–219. [Google Scholar]

- Tannert, T. Improved performance of reinforced rounded dovetail joints. Constr. Build. Mater. 2016, 118, 262–267. [Google Scholar] [CrossRef]

- Hu, W.-G.; Luo, M.; Hao, M.; Tang, B.; Wan, C. Study on the Effects of Selected Factors on the Diagonal Tensile Strength of Oblique Corner Furniture Joints Constructed by Wood Dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Liu, Y.; Xu, W.; Konukcu, A.C. Experimental and numerical studies on the mechanical properties and behaviors of a novel wood dowel reinforced dovetail joint. Eng. Fail. Anal. 2023, 152, 107440. [Google Scholar] [CrossRef]

- Vassiliou, V.; Barboutis, I. Strength of furniture joints constructed with biscuits. In Proceedings of the International Conference of Nabytok, Bratislava, Slovakia, 13–15 May 2008; pp. 1–6. [Google Scholar]

- Atar, M.; Ozcifci, A.; Altinok, M.; Celikel, U. Determination of diagonal compression and tension performances for case furniture corner joints constructed with wood biscuits. Mater. Des. 2009, 30, 665–670. [Google Scholar] [CrossRef]

- Hu, W.G.; Guan, H.Y. A finite element model of semi-rigid mortise-and-tenon joint considering glue line and friction coefficient. J. Wood Sci. 2019, 65, 14. [Google Scholar] [CrossRef]

- Kasal, A.; Haviarova, E.; Efe, H.; Eckelman, C.A.; Erdil, Y.Z. Effect of Adhesive Type and Tenon Size on Bending Mo-ment Capacity and Rigidity of T-Shaped Furniture Joints Constructed of Turkish Beech and Scots Pine. Wood Fiber Sci. 2013, 45, 287–293. [Google Scholar]

- Záborský, V.; Kamboj, G.; Sikora, A.; Borůvka, V. Effects of selected factors on spruce dowel joint stiffness. BioResources 2018, 14, 1127–1140. [Google Scholar] [CrossRef]

- Kasal, A.; Kuşkun, T.; Efe, H.; Erdil, Y.Z. Relationship Between Static Front to Back Loading Capacity of Whole Chair and The Strength of Individual Joints. In Proceedings of the 27th International Conference Research for Furniture Industry, Ankara, Turkey, 17 September 2015. [Google Scholar]

- Záborský, V.; Borůvka, V.; Kašičková, V.; Gaff, M. The Effect of Selected Factors on Domino Joint Stiffness. BioResources 2018, 13, 2424–2439. [Google Scholar] [CrossRef]

- Podlena, M.; Böhm, M.; Hýsek, S.; Procházka, J.; Černý, R. Evaluation of parameters influencing the withdrawal strength of oak and beech dowels. BioResources 2020, 15, 1665–1677. [Google Scholar] [CrossRef]

- Derikvand, M.; Smardzewski, J.; Ebrahimi, G.; Dalvand, M.; Maleki, S. Withdrawal force capacity of mortise and loose tenon T-type furniture joints. Turk. J. Agric. For. 2013, 37, 377–384. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).