Abstract

The bark of cork oak (Quercus suber L.) is mostly used for cork stopper production; when bark undergoes a series of industrial procedures, boiling usually leads to changes in the characteristics of its tissue. Trees are traditionally grown under natural conditions; however, irrigation is now being used in plantations. This permanent water availability affects cork oak development, while its effects on industrial procedures are unknown. This study provides the first insight into the behaviour of the cell walls of cork during the process of swelling and boiling when trees have been grown under irrigation, that is, subject to a specific water regime. Cork tissue is analysed using environmental and scanning electron microscopy under three regimes: raw conditions, following immersion in water, and after boiling. Additionally, the radial expansion of samples is determined. The results show greater cell wall expansion in cork from the irrigated site than in cork from the traditional rainfed plot when hydrated for 24 h. After boiling, the cell walls of the cork from the rainfed site are thinner than in the raw stage, which is in contrast to the irrigated cork. This study suggests that irrigation during cork oak growth produces a higher capacity for adsorption, increasing cell wall thickness from the raw stage to the boiling stage.

1. Introduction

The cork industry is a major forestry sector that contributes to Portuguese gross domestic product. It accounts for 1.2% of total employment in the Portuguese manufacturing sector [1] and sustains the economy in inland areas.

A range of activities fall under the umbrella of the cork industry: cork preparation, the manufacturing of cork stoppers, the wholesale trade, and the production of other cork products such as agglomerates. Cork exports account for 2% of all Portuguese-manufactured products, while 2% of all companies in Portugal are involved in the trade. However, there has been a reduction of 2.7% in the volume of cork production over the last 10 years [1]. The levels of forestry productivity have decreased as a consequence of cork oak decline in the current areas of implantation, associated with several factors in which climate change—associated with increasingly frequent or severe drought events and heatwaves [2]—plays a role. Climate change due to greenhouse gas emissions associated with heat stress has also impacted other species, leading to the mortality of species and the vulnerability of forest ecosystems [3]. In order to promote tree vitality, tree growth, and cork production, a new silviculture model of fertigation in stands where water is available has been introduced (the Regasuber, Irricork, and GO-Regacork projects), and it is currently the subject of a number of studies in progress.

Cork from Quercus suber L. is a sustainable, renewable material produced by means of the phellogen of cork cambium, which is most active during two periods: spring and autumn. Through periclinal divisions, phellogen produces an interior live tissue called phelloderm and an exterior group of dead cells called phellem [4]. Cork rings present different cell dimensions and cell wall characteristics along the extension of the annual cork ring [5]. Cells produced during the autumn growth period (late cork) are smaller in size than cells produced during the spring growth period (early cork). Cell rows grow in the radial direction after the differentiation of cork cells, with the appearance of layers of bricks in the radial and transverse directions [6]. Spring growth represents 90–95% of the total volume and mainly accounts for cork cell characteristics [6]. These cell wall features and the biochemical properties of the cell walls have an influence on some cork characteristics [6]. During cell growth, there is a thickening of the cellular membranes found within the cells of the developing phellem, which is the result of the deposition of some cell wall layers with different structures and a different chemical composition [7]. Pereira [8] determined the chemical composition of cork throughout Portugal as 42.8% suberin, 22% lignin, about 20% cellulose and hemicellulose, and 16.2% extractives. According to Sen et al. [9], compounds differ in accordance with regional location: Turkish and Bulgarian cork contains higher levels of lignin and lower levels of extractives than Portuguese cork. Inside the cell walls, plasmodesmata may be observed, which are responsible for cell connections by crossing cell walls at the sub-microscopic level [6]. Plasmodesmata are intercellular structures found in plants consisting of pores and channels, lying between individual plant cells and connected cells. Cell size depends on seasonal growth. Spring cells are larger and show a greater range in size (30–40 µm), and their cell wall thickness varies from 1–1.5 µm, whereas the height of autumn cells is 10 µm less, and their cell walls are twice as thick [10]. Such characteristics are important for the type of cork goods produced and are often studied by means of microscopic approaches, such as the scanning electron microscopic (SEM) approach [6,7]. The use of environmental scanning electron microscopy (ESEM) additionally enables the dynamic process of water interaction and the thermodynamic stability of moist [11] samples to be analysed without specific sample preparation [12]. Although this method is not often used in cork tissue analysis, it is used in wood research with great potential [11]. ESEM can preserve the hydration of samples due to its saturated water vapour environment within the analytical chamber [12], so, in this study, it was used to analyse cork cells after 24 h hydration.

At the end of each cork growth cycle, the cork harvest is obtained by means of the physical rupture of the phellogen cells when they are most active, from May to August. After that, a new traumatic phellogen is formed by means of meristematic activation [7].

After harvesting, there are several stages in the industrial preparation of cork, such as waiting and boiling procedures. First of all, it needs to be stabilised in order for some tangential tensions to be released and a reduction in moisture content to be achieved; the second stage is the boiling process, which is used to remove some residues and to increase thickness by 15%. After two days of stabilisation, planks are ready for the stopper manufacturing process to begin. In accordance with the literature, the boiling procedure produces changes in some cork characteristics, such as cork thickness, porosity, and density [7]. Cork is a poor water conductor due to the lack of intercellular spaces and the presence of gas in the cells; nevertheless, it can absorb water up to 10% w/w over sorption [13], causing cell wall swelling. Water diffuses throughout the cell walls until saturation is reached and it penetrates the cells. Through a process of evapotranspiration and condensation, water can penetrate the cell walls [14]. The aim of this study was to evaluate the cell wall thickness of cork from two study sites under three sets of conditions: under raw conditions, after immersion in water, and after boiling. The cork expansion observed in macrosamples was also analysed, simulating industrial procedures. Our hypothesis is as follows: as cork from trees subjected to fertigation has thinner cell walls [15], different behaviour when swelling and boiling will occur. Such information would contribute to improving our understanding of the behaviour of cork grown under a different water regime in the industrial boiling procedure. SEM under high vacuum conditions was used for raw conditions and after boiling, while ESEM was used on samples after swelling following 24 h hydration.

2. Material and Methods

2.1. Study Sites

Fertigated site: The fertigated site (39°2′49.77″ N, 7°57′32.08″ W, UTM coordinates) was installed in 2003 near an intensive olive plantation with some centenary cork oaks scattered throughout the stand, and it is located 35 km from the rainfed site. The fertigation system is coupled to the olive plantation. Since 2003, the cork oaks have been irrigated during the summer, usually for four months. The average watering value from the cork formation period was 1928.6 m3 ha−1 (2011–2017), and the annual precipitation for the same period was 452.19 mm. The plot is located on a Luvisol with 164 trees per hectare, a basal area of 16.93 m2, and an average stem perimeter at a breast height of 81.2 ± 40.28 cm. Trees on the plot present a mean ± SD of 8.50 ± 1.76 m of tree height and no decline symptoms. Tree age (years) is 18 y + 13 centenary trees.

Rainfed site: A set of permanent plots was installed in 1995 in cork oak forests in the centre of Portugal (39°05′54.93″ N, 8°21′26.23″ W UTM coordinates). The centenary cork oaks have been systematically monitored for tree growth and cork production [16]. The study site presented an annual precipitation of 400.93 mm for the period of 2008–2017, and it is located on a Cambisol with no limitations on cork oak growth. The site has around 150 trees per hectare, a basal area of 6.94 m2, and a stem perimeter at a breast height (mean ± SD) of 134.6 ± 37.20 cm. The trees showed no decline symptoms, and tree height (mean ± SD) is 10.33 ± 2.01 m.

2.2. Sampling

Cork was harvested in 2017 from the two sites. Before harvesting, a 20 × 20 cm square sample was taken from each truck at a height of 130 cm. The six samples selected for the analysis were from centenary trees: three from each plot. The heights (mean ± SD) of the study trees were 11.23 ± 1.68 m for the irrigated plot and 9.93 ± 1.90 m for the rainfed plot. The stem perimeters at breast height (mean ± SD) were 214.3 ± 15.28 cm for the irrigated plot trees and 139.5 ± 45.89 cm for the rainfed plot trees. The harvested cork weights (mean ± SD) were 51.73 ± 7.93 kg for the irrigated site and 24.9 ± 12.36 kg for the rainfed site.

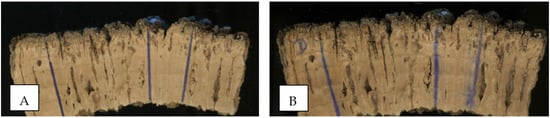

2.3. Cell Walls—Raw Sample Measurements

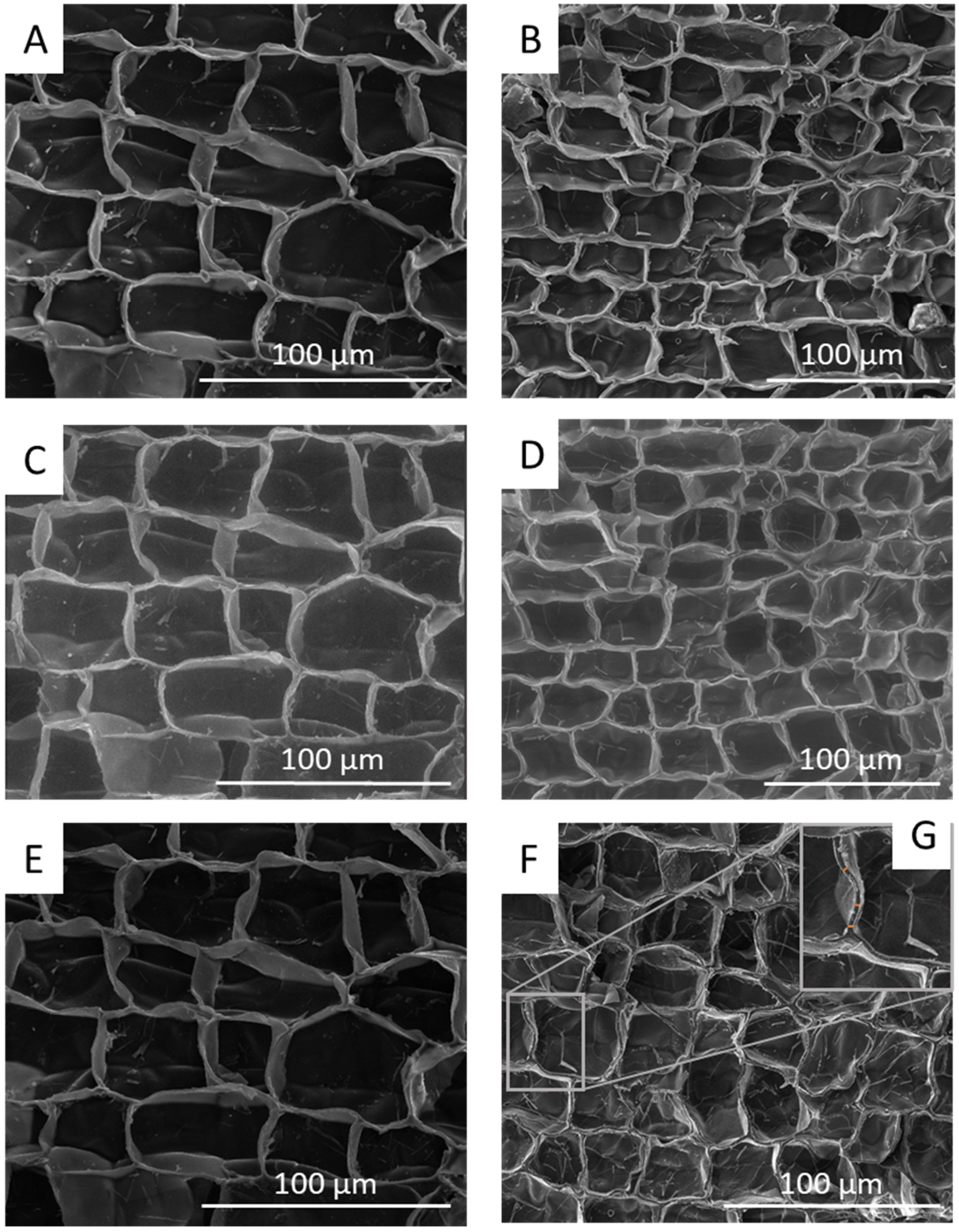

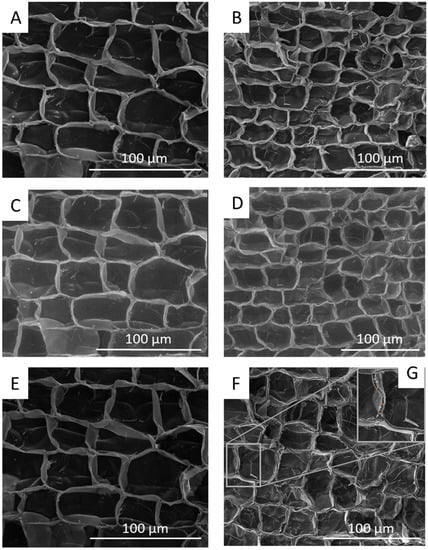

Samples prepared for SEM analysis were cut with a movable blade microtome (Reichert, with Jung blades) in the transverse plane (cross-section) with 1 mm thickness [15]. Samples were fixed on aluminium specimen holders using conductive double-sided adhesive carbon tabs and coated with 40 nm carbon using the EMITECH K905 Carbon Coater (Emitech Ltd., Ashford, UK). For each raw sample, one image was acquired using MAPS software (MAPS version 2.1.38.1199, Thermo Fisher Scientific, Waltham, MA, USA) at a 10 kV beam energy and a spot size of 2.5 under high vacuum conditions using SEM (Quanta FEG 650, Thermo Fisher Scientific, Waltham, MA, USA). For each sample (6), an image with 168–224 subframes was taken with high magnification (Figure 1A,B). Subframes were stitched together using MAPS software for image analysis. Cell wall thickness was measured using the ImageJ program (version 1.52a, Wayne Rasband, National Institutes of Health, Bethesda, MD, USA). A total of 200 measurements per image were performed.

Figure 1.

Microphotographs of the cork cell structure of a transverse section of a cork sample from the fertigated plot (A,C,E) and a cork sample from the rainfed plot (B,D,F): (A,B) were obtained using SEM on raw cork; (C,D) were obtained using ESEM after 24 h immersion in cold water; (E,F) were obtained with SEM after boiling and two days of drying. (G) Yellow marks represent an example of a cell wall thickness measurement.

2.4. Cell Walls—24 h Water Immersion and 98% Humidity Measurements

Samples prepared for raw measurement were immersed for 24 h in cold water, and one image was acquired per sample (3 samples per treatment) with MAPS software using ESEM (Quanta FEG 650, Thermo Fisher Scientific, Waltham, MA, USA) (Figure 1C,D). Cell wall swelling was analysed under 98% humidity at 10 kV beam energy and a spot size of 2.5 under 98% humidity (800 Pa; 4–6 °C and working distance of 6.5) within the same area as the raw sample measurements. For each sample acquired, 200 measurements were performed using the ImageJ program (version 1.52a, Wayne Rasband, National Institutes of Health, Bethesda, MD, USA).

2.5. Cell Walls—After Boiling Measurements—1 h at 100 °C

Following the cork industrial processing, previous hydrated samples were boiled in water (100 °C) for one hour and dried under environmental conditions for two days. One image per sample (3 samples per treatment) was acquired using MAPS software in SEM (Figure 1E,F). A total of 200 measurements were performed using ImageJ, as in previous analyses.

The measurements in every condition (raw, hydrated, and boiled) were performed on the same samples and the same sample spots.

2.6. Radial Macrosamples—Boiling Procedure

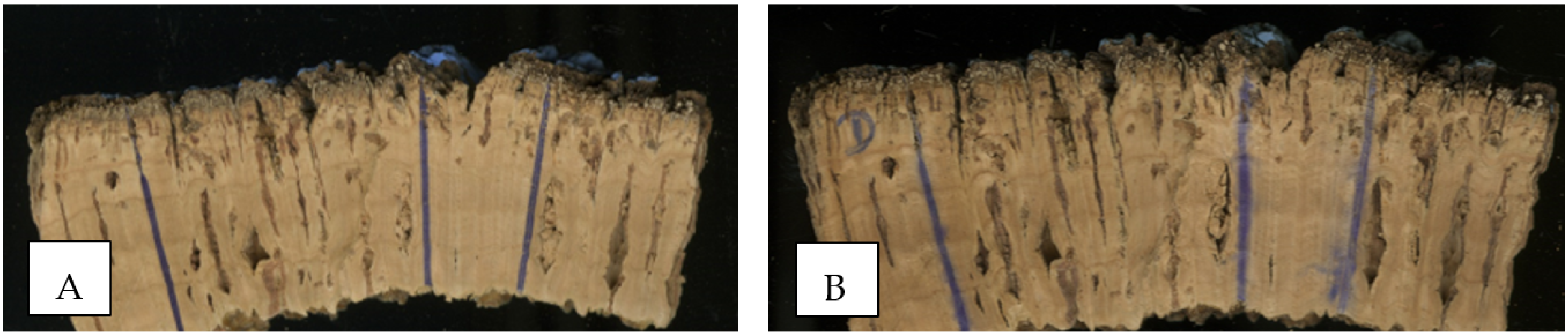

From the original harvested cork samples, pieces of around 10 cm long and 3 cm thick were cut and scanned using Epson Scan-Expression 11000XL. For each sample, three random lines (Figure 2) along the radial length were tagged with a permanent marker pen and measured using ImageJ. Samples were boiled at 100 °C for one hour, simulating the industrial procedure. After boiling, samples were scanned, and radial swelling was measured at the same spots using ImageJ.

Figure 2.

Example of a macrosample from the irrigated plot: (A) before the boiling procedure; (B) after the boiling procedure.

2.7. Statistical Analysis

Statistical analysis was carried out using SPSS v.25 software package (IBM Corp., Armonk, NY, USA). Analysis of variance (ANOVA) was performed to compare samples from the fertigated site and the rainfed site, with regard to raw conditions, hydrated conditions, and after the boiling stage, at a cell wall thickness level. ANOVA was also performed to compare the radial swelling of the macrosamples in both sites. The following statistical explanations were used: p > 0.05, not significant; p < 0.05, significant; p < 0.01, very significant; and p < 0.001, highly significant.

3. Results

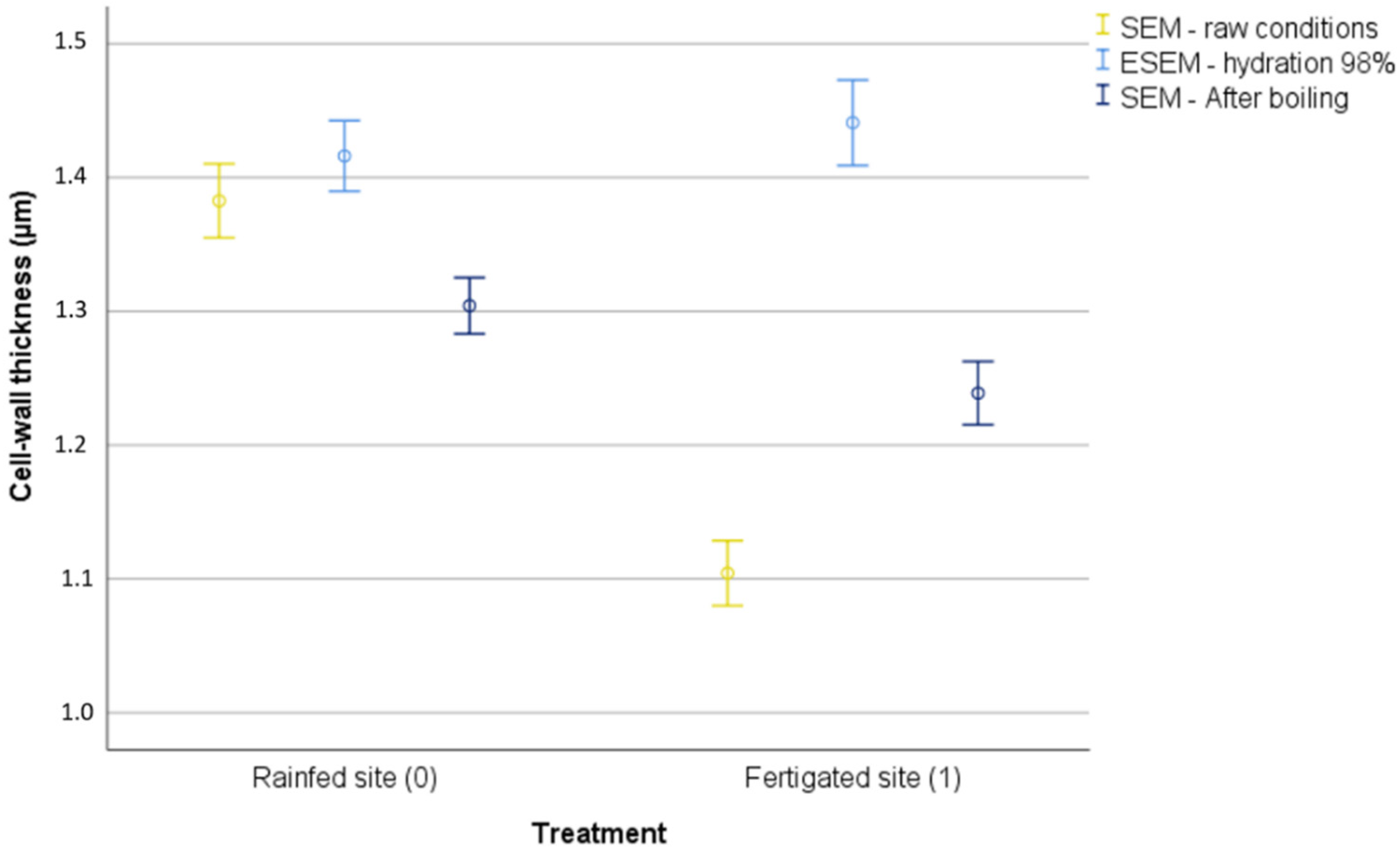

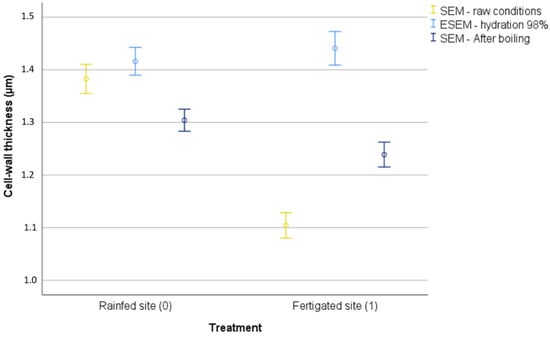

Cork from the fertigated site showed raw cell walls measuring 1.10 ± 0.30 µm, hydrated cell walls measuring 1.44 ± 0.40 µm, and cell walls after boiling measuring 1.24 ± 0.30 µm, while cork from the rainfed site presented raw cell walls measuring 1.38 ± 0.34 µm, hydrated cell walls measuring 1.42 ± 0.33 µm, and cell walls after boiling measuring 1.30 ± 0.26 µm (Figure 3). While the cell walls of cork from the fertigated plot were thinner than those of the cork from the rainfed plot under raw conditions [15], the former expanded to a greater degree during hydration (Figure 3). After boiling, both treatments presented a decrease in thickness compared with the hydration stage, but cell walls from the irrigated site showed a gain in thickness as compared with cork under raw conditions.

Figure 3.

Mean ± standard deviation of cell wall thickness with regard to raw conditions, hydrated conditions, and after the boiling stage, for cork samples from the rainfed site (0) and the fertigated site (1).

The relationships between the cell wall thickness at the different stages (raw conditions, hydrated conditions, and after the boiling stage, Figure 3) and Type of treatment, Sample within treatment, and Residual were established by means of a general linear model.

The source of variation designated as Treatment provided an important contribution to the variation in raw cell wall thickness (p = 0.002), demonstrating the significant influence of irrigation on this characteristic, accounting for 86.7% of the total variation (Table 1). However, the treatment effect did not lead to significant differences in cell wall thickness in the hydrated stage. This means that the cell walls of cork from the fertigated plot adsorbed large amounts of water, reaching a cell wall thickness statistically equal to that of cork from the rainfed site (there was a difference of only 0.02 µm between the two). After the boiling procedure, no significant differences were found between the cell wall thicknesses of the cork from the two treatments (p = 0.183). Nevertheless, the boiling procedure accounted for 36.9% of the variation in cell wall thickness (Table 1). Sample within treatment, referring to the sample variability in the cork in addition to the treatment, proved to provide an important contribution to cell wall thickness, accounting for 92.7% of the variation when hydrated and 40.7% of the variation after boiling (Table 1). This indicates the high variability within the cork samples. A gain in cell wall thickness after boiling was observed in the cork from the fertigated plot when compared to raw conditions.

Table 1.

Analysis of variance for Type of treatment, Sample within treatment, and Residual for cell walls, with regard to raw conditions, hydrated conditions, and after the boiling stage.

Regarding cork thickness after the boiling procedure observed in macrosamples (on the basis of three radial measurements of each 10 cm strip, Figure 2), mean ± std. deviations for the expansion of 2.29 ± 1.06 cm for cork from the rainfed plot and 2.17 ± 1.02 cm for cork from the irrigated plot were recorded. The values for the expansion after boiling were 6.5% for cork from the irrigated plot and 7.6% for cork from the rainfed plot. Analysis of variance showed that there was no significant contribution of Treatment to expansion (p = 0.822 and F = 0.058) or any significant contribution of Sample within Treatment (p = 0.387 and F = 1.132). However, Residual, designated as Measurements within each Sample, accounted for the main source of variation: 96% of variation.

4. Discussion

Cork from the fertigated plot, with a higher rate of growth, presented a lower density than cork from the traditional rainfed site [15], which affected the cell wall thickness. The results found in Poeiras et al. [15], where cork from the traditional plot showed greater cell wall thicknesses under raw conditions, as well as those present in Figure 3, represent the starting point. This is in accordance with Natividade [5], who found a greater cell wall thickness in cork from sites in Algeria and Morocco than cork from Portugal, where it is comparatively slow growing, which is associated with the local climatic conditions. Although cork is a poor water conductor due to its lack of intercellular spaces and the presence of gas in the cells, cork from the fertigated plot presented a higher level of water sorption, which may also be related to cell wall structure and composition. Despite cork tissue not having intercellular voids [6], some channels called plasmodesmata with a cross-sectional diameter of approximately 100 nm may appear to cross cell walls [6]. Their presence may provide an explanation for the increased cell wall thickness of the cork from the irrigated site when hydrated. Teixeira and Pereira [17] stated that plasmodesmata are present during suberization, which is a rapid process. Furthermore, these authors [17] found that cell walls were thinner in areas where plasmodesmata were found, which is in accordance with the thinner cell walls found in the cork from the irrigated site in this study. Cork from both treatments may present different chemical composition content as observed by Sen et al. [9] in cork from different sites with regard to lignin and the amount of extractives. Pereira [6] found differences between the chemical compositions of cork from 29 locations, with a range of variations and differences in structural components. Therefore, different cell wall behaviours under hydration conditions could also be explained by a variation in chemical composition, such as suberin and lignin content, differentiated due to growth conditions such as fertigation. Suberin is a structural component of cork that provides integrity to cork tissue [6] and whose deposition starts during cell formation. Lignin is, likewise, a structural cell wall component. The behaviour of cork with a higher growth rate (with a higher level of water sorption) may suggest a lower content of these components. Following the boiling procedure, the level of tension and wrinkles in the cell walls decreased, producing a loss in cell wall thickness after hydration in both treatments. However, cork from the fertigated plot showed an increase in thickness as compared with raw conditions. Despite cork from the fertigated site showing a greater porosity coefficient [15], analysis of variance with regard to the cork expansion of macro-sized samples did not reveal a significant influence of treatments (p = 0.822). In the present study, no differences were found between cork from the fertigated site and cork from the rainfed site with regard to cork expansion, which is an important aspect of industrial procedures. Furthermore, fertigation showed no significant changes in expansion rates after the boiling procedure on a large scale. In addition, a slight negative correlation was found between the expansion of the cell walls when boiled and the expansion of the macrosamples’ thicknesses (p = 0.963; Pearson correlation = −0.025). However, on a small scale, the hydration and boiling procedures had significant effects on the cell walls, which raises the question of whether there are possible differences between the chemical composition content of the treatments that lead to some changes in structure.

5. Conclusions

The aim of this study was to gauge the effect of two different tree-growing regimes on cork cell walls in regard to swelling and boiling and the differences in the expansion of cork thickness. For the purpose of cell analysis, SEM under high vacuum and under environmental conditions after hydration was used. As cork from the specific fertigated site showed a lower density [15], it was expected that the increase in the thickness of the macrosamples would be higher than that of the macrosamples from the rainfed plot. However, no statistical significance was found. At the cellular level, after 24 h hydration, differences in thickness were greater for cork from the fertigated site than for cork from the traditional rainfed plot. The findings of this study suggest that the cell walls of cork from fertigated cork oaks display a greater capacity for adsorbing water, which may be associated with the fact that their cell walls are thinner—the consequence of water being available during all periods of cork growth. A decrease in the thickness of the cork cell walls from the rainfed site was found between the raw stage and the boiling stage, which is in contrast to cork from the irrigated site, where an increase in cell wall thickness was observed. These findings are helpful in clarifying the effects of sorption on cell structure and provide the basis for the further analysis of cork structures, including their chemical composition and the presence of ultrastructural channels, deriving from the application of different water regimes.

Author Contributions

Conceptualisation, A.P.P., P.S., M.E.S. and N.d.A.R.; formal analysis, A.P.P. and M.E.S.; funding acquisition, N.d.A.R.; investigation, A.P.P., C.C.-A. and N.d.A.R.; methodology, A.P.P., C.V. and B.G.; writing—original draft, A.P.P.; writing—review and editing, C.V., B.G., C.C.-A., P.S., M.E.S. and N.d.A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by PDR2020-101-FEADER-031427 “GO-RegaCork”; an Erasmus + grant for research carried out at TU Dresden; funded by National Funds through FCT—Foundation for Science and Technology under the Project UIDB/05183/2020; supported by the Strategic Project (UIDB/04033/2020) of CITAB, by national funding from Foundation for Science and Technology (FCT); and by Regacork-TraDE Project—ALT20-03-0246-FEDER-000061.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We would thank the DFG Core facility environmental analytic (CFEA) at the Faculty of Environmental Science, Technische Universität Dresden, for support in the acquisition of the SEM and ESEM data; we would thank to Casa Agrícola da Herdade do Conqueiro, S.A., Herdade da Machoqueira do Grou C.R.L andto Amorim Florestal, S.A.

Conflicts of Interest

The authors declare no conflict of interest.

References

- De Castro, A.; Avillez, F.; Rodrigues, V.; da Silva, F.G.; Santos, F.; Rebelo, F.; Jorge, M.N.; Aires, N. The Cork Sector: From the Forest to the Consumer; APCOR: Santa Maria de Lamas, Portugal, 2020. [Google Scholar]

- Leite, C.; Oliveira, V.; Miranda, I.; Pereira, H. Cork oak and climate change: Disentangling drought effects on cork chemical composition. Sci. Rep. 2020, 10, 7800. [Google Scholar] [CrossRef] [PubMed]

- Allen, C.D.; Macalady, A.K.; Chenchouni, H.; Bachelet, D.; McDowell, N.; Vennetier, M.; Kitzberger, T.; Rigling, A.; Breshears, D.D.; Hogg, E.H.; et al. A global overview of drought and heat-induced tree mortality reveals emerging climate change risks for forests. For. Ecol. Manag. 2010, 259, 660–684. [Google Scholar] [CrossRef] [Green Version]

- Meyer, B.; Anderson, D.B.R. Introdução à Fisiologia Vegetal; Fundação Calouste Gulbenkian: Lisboa, Portugal, 1970. [Google Scholar]

- Natividade, J. Cortiças—Contributo Para o Estudo do Melhoramento da Qualidade; Direção Geral dos Serviços Florestais e Agrícolas: Lisboa, Portugal, 1934; Volume 1. [Google Scholar]

- Pereira, H. The rationale behind cork properties: A review of structure and chemistry. BioResources 2015, 10, 6207–6229. [Google Scholar] [CrossRef]

- Fortes, M.A.; Rosa, M.E.; Pereira, H. A Cortiça; ITS Press: Lisboa, Portugal, 2004. [Google Scholar]

- Pereira, H. Variability of the chemical composition of cork. BioResources 2013, 8, 2246–2256. [Google Scholar] [CrossRef]

- Sen, A.U.; Zhianski, M.; Glushkova, M.; Petkova, K.; Ferreira, J.; Pereira, H. Chemical composition and cellular structure of corks from Quercus suber trees planted in Bulgaria and Turkey. Wood Sci. Technol. 2016, 5, 1261–1276. [Google Scholar] [CrossRef]

- Silva, M.E. Contributo Para o Estudo da Qualidade da Cortiça: Avaliação das Relações Exixtentes Entre Parâmetros Definidores da Sua qualidade; Universidade de Trás-os-Montes e Alto Douro: Vila Real, Portugal, 1996. [Google Scholar]

- Fránková, M.; Poulíčková, A.; Neděla, V.; Tihlaříková, E.; Šumberová, K.; Letáková, M. The low temperature method for environmental scanning electron microscopy—A new method for observation of diatom assemblages in vivo. Diatom Res. 2018, 33, 397–403. [Google Scholar] [CrossRef]

- Turkulin, H.; Holzer, L.; Richter, K.; Sell, J. Application of the ESEM technique in wood research: Part I. Optimization of imaging parameters and working conditions. Wood Fiber Sci. 2005, 37, 552–564. [Google Scholar]

- Zajączkowska, U. Cork. eLS 2016, 1–8. [Google Scholar] [CrossRef]

- Rosa, M.; Fortes, M. Water absorption by cork. Wood Fiber Sci. 1993, 25, 339–348. [Google Scholar]

- Poeiras, A.P.; Silva, M.E.; Günther, B.; Vogel, C.; Surový, P.; de Almeida Ribeiro, N. Cork influenced by a specific water regime—Macro and microstructure characterization: The first approach. Wood Sci. Technol. 2021, 55, 1653–1672. [Google Scholar] [CrossRef]

- Ribeiro, N.A. Modelação do Crescimento da Árvore em Povoamentos de Sobreiro. Ph.D. Thesis, Universidade de Évora, Évora, Portugal, 2006. [Google Scholar]

- Teixeira, R.T.; Pereira, H. Ultrastructural observations reveal the presence of channels between cork cells. Microsc. Microanal. 2009, 15, 539–544. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).