Characteristics of Pulsed-Laser-Induced Layers with Cracks Prepared for SiC Grinding Processes

Highlights

- The dimensions of the laser-induced crack layer can be controlled.

- The dimensions of the controlled cracks contribute to a decrease in grinding force and specific grinding energy.

- Controlling the dimensions of the laser-induced layer helps reduce material consumption in silicon–carbon splitting during separation processes.

- The grinding characteristics of the rough surface after silicon–carbon separation improve the quality of the ground surface.

- Pulsed-laser parameters play an important role in material separation.

Abstract

1. Introduction

2. Experimental Section

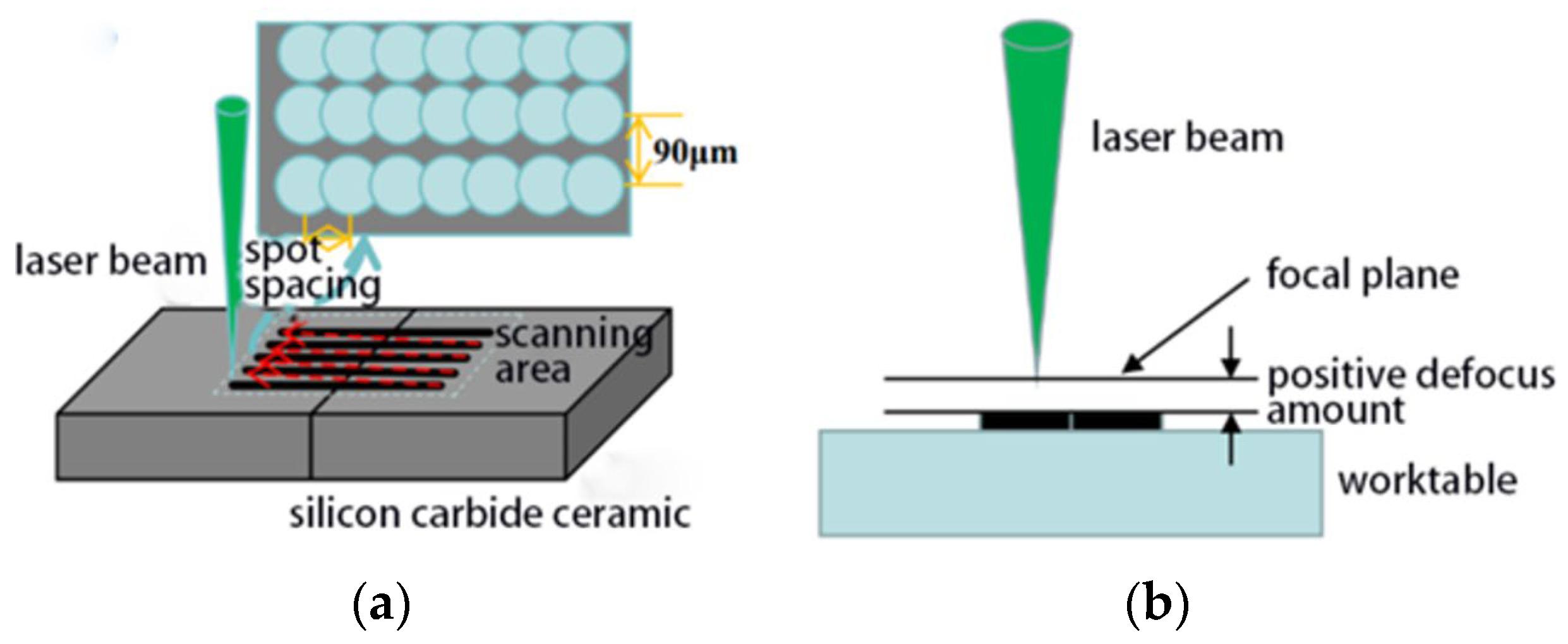

2.1. Sample Surface Preparation

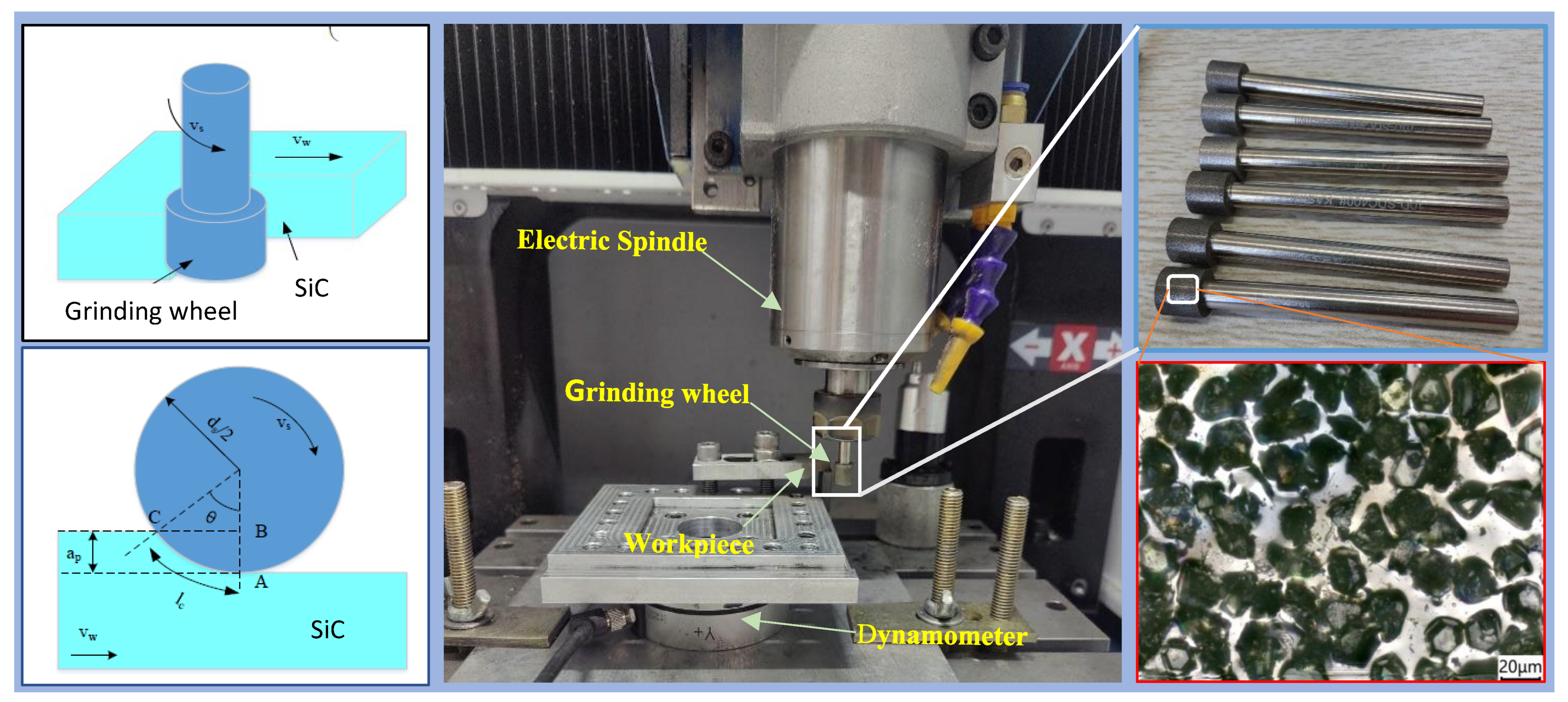

2.2. Grinding Experiment Scheme

3. Results

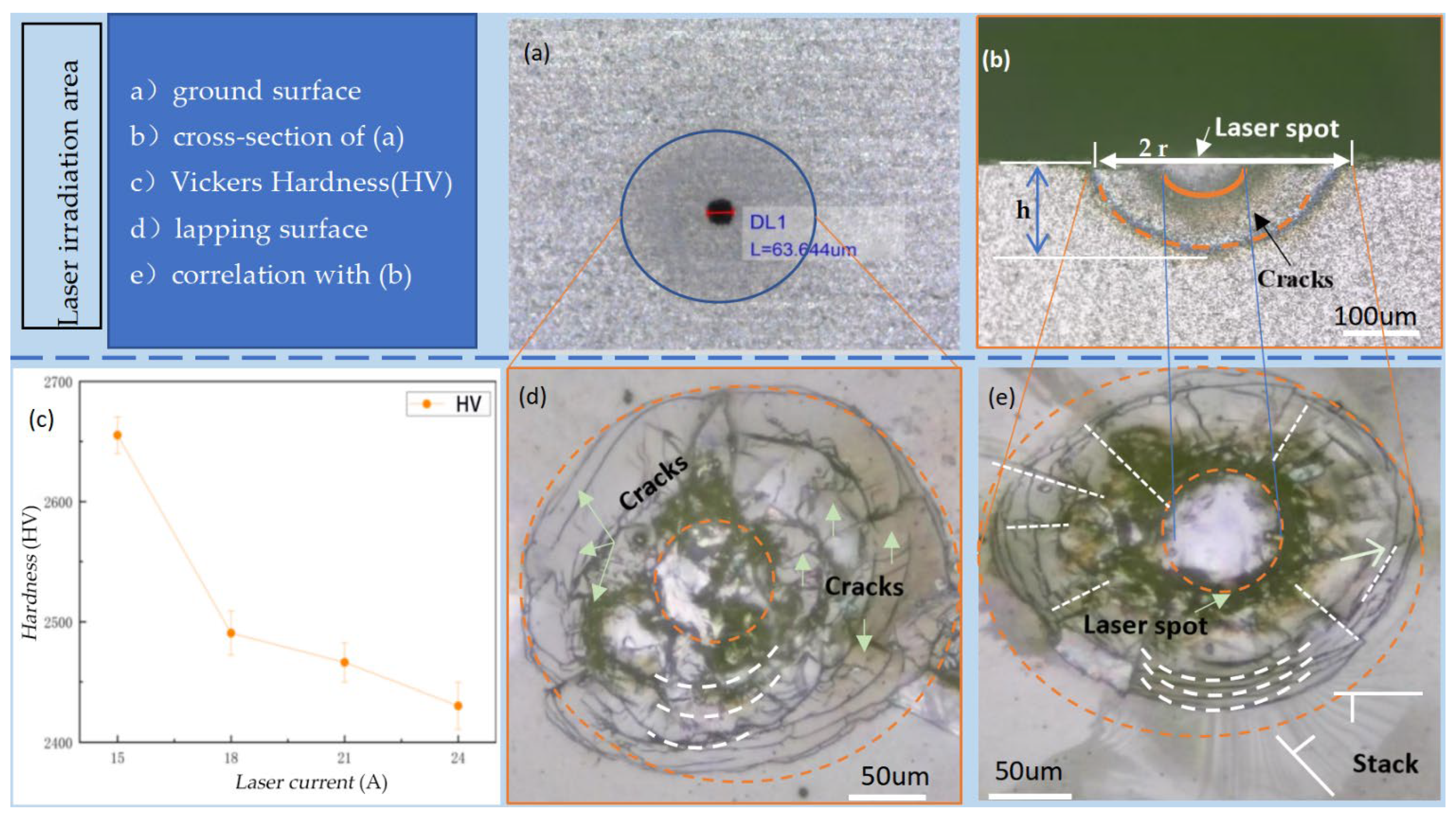

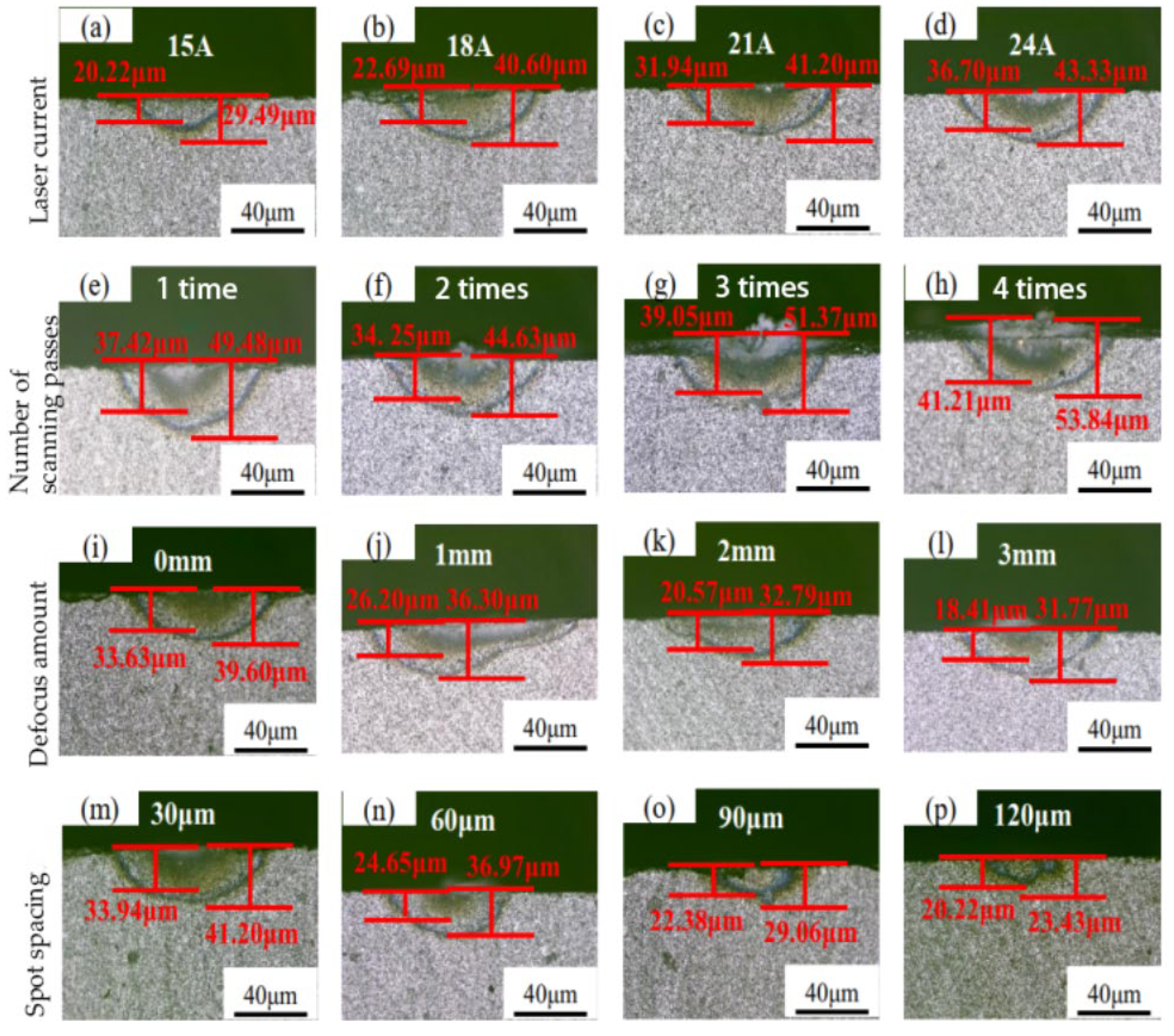

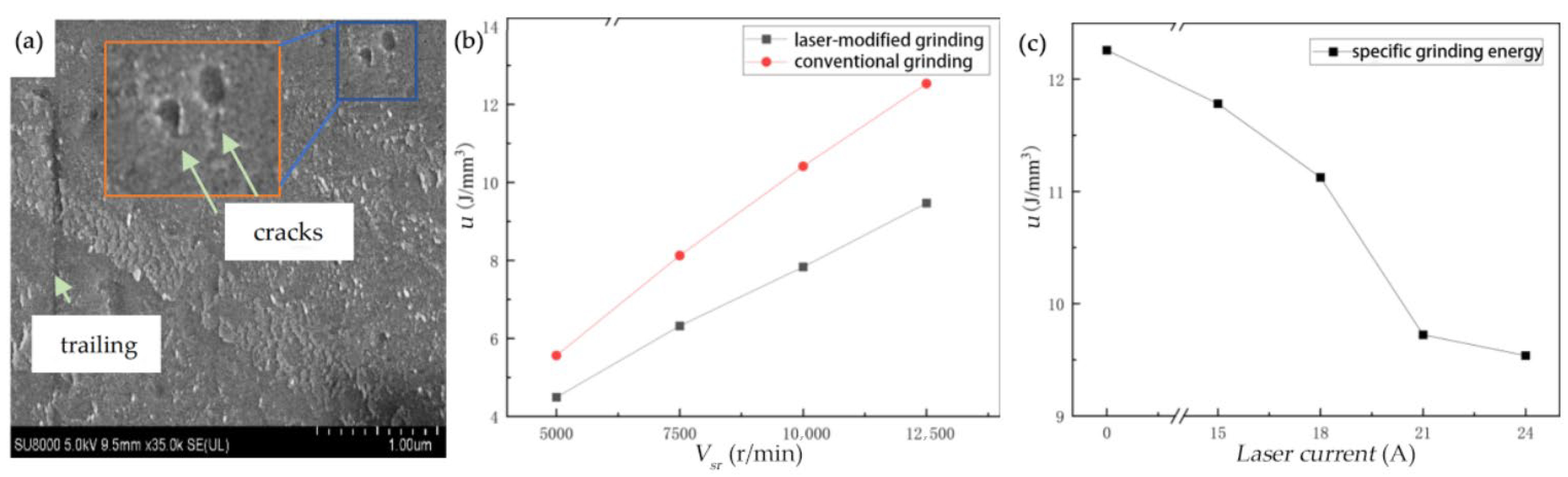

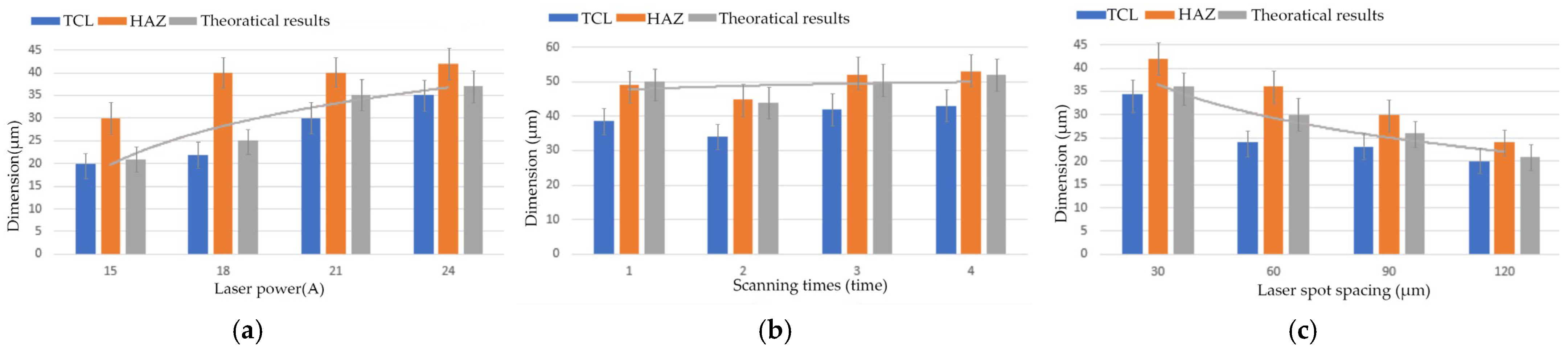

3.1. Crack Dimensions

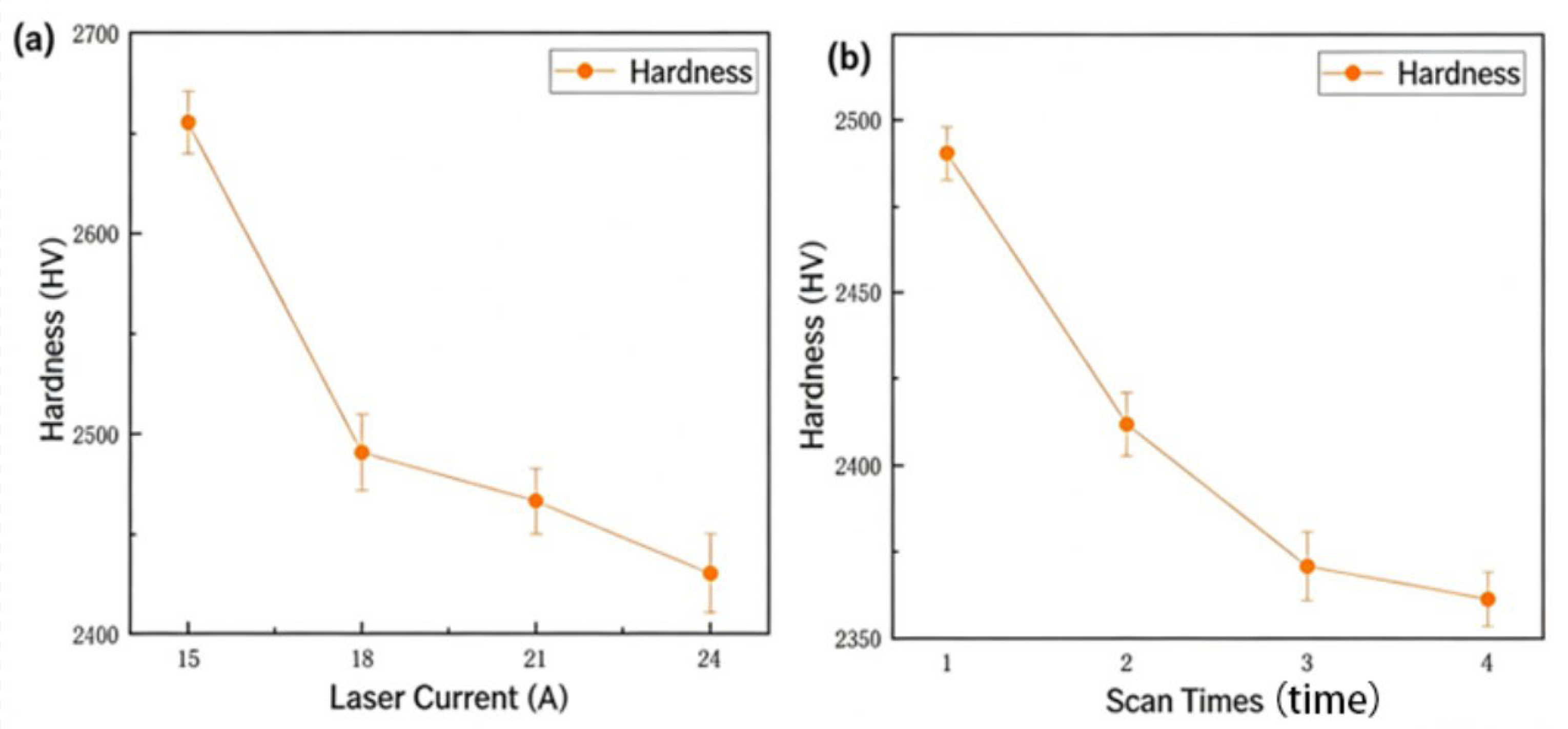

3.2. Surface Hardness

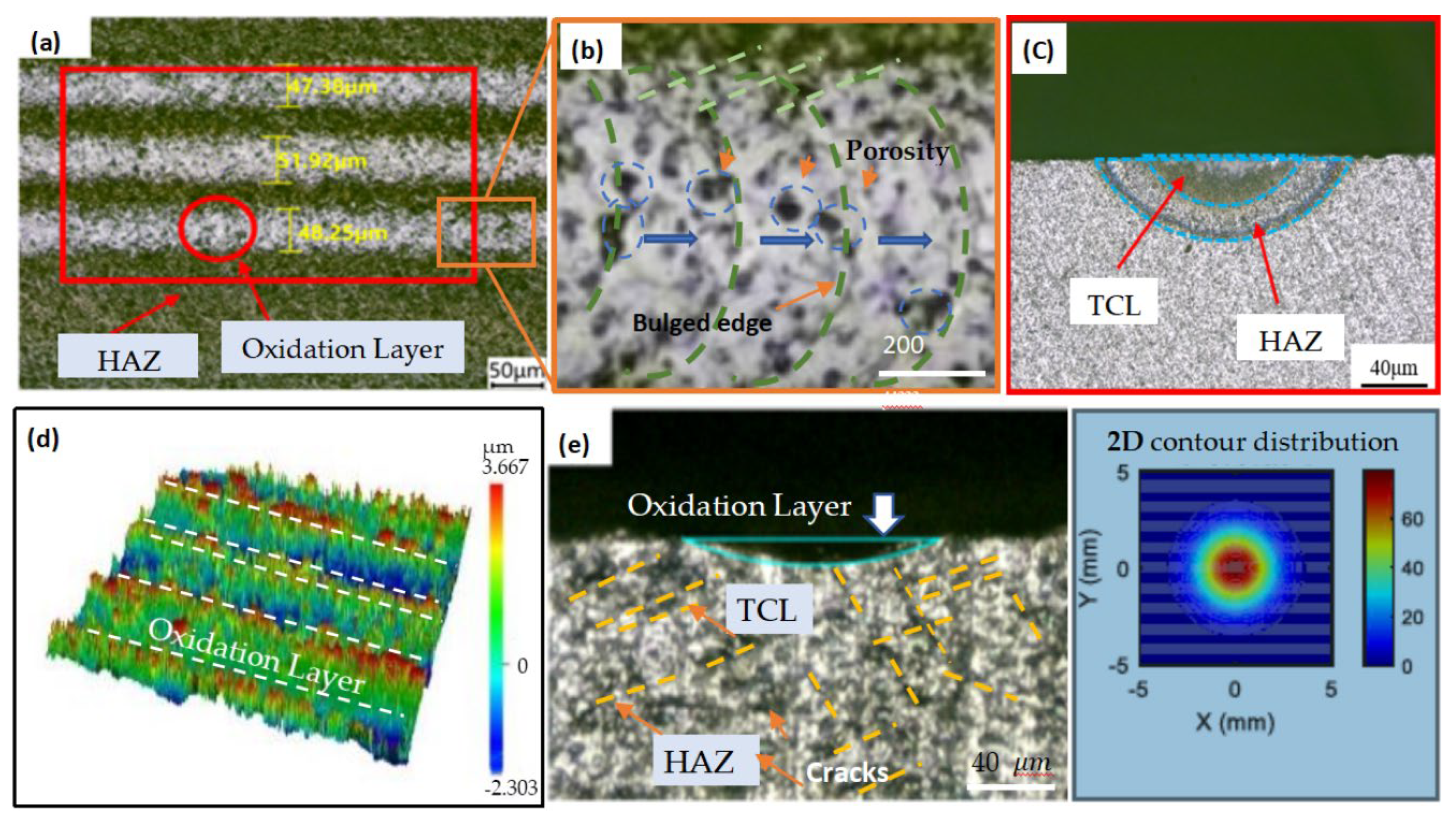

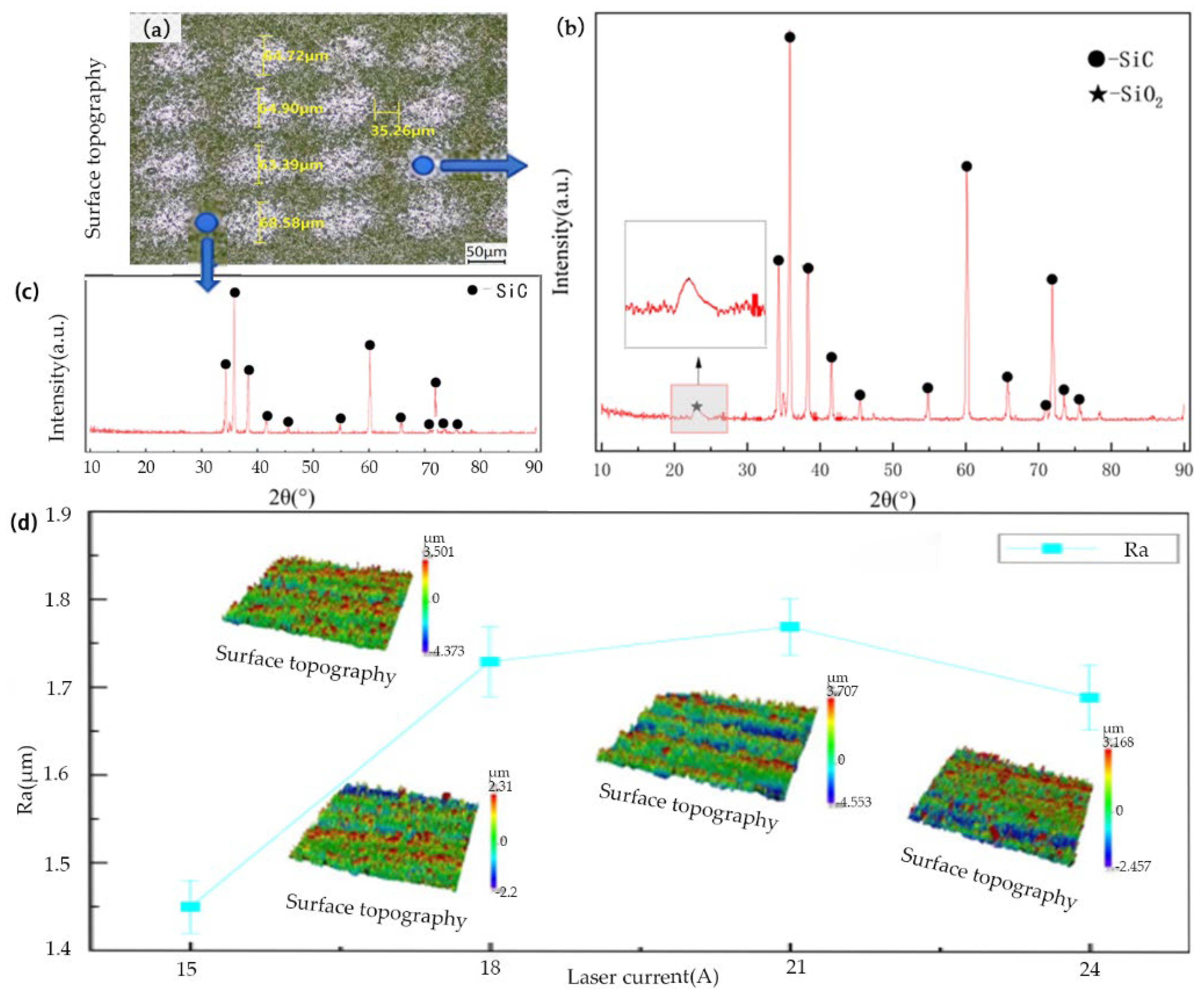

3.3. Surface Topography and Composition

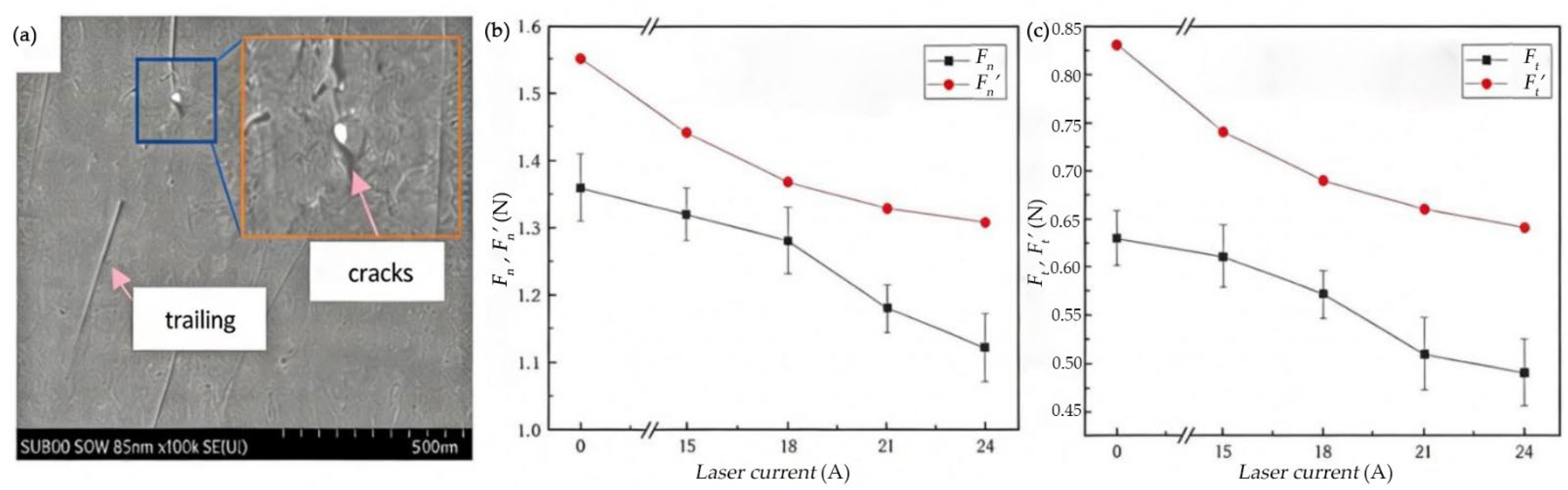

3.4. Grinding Process

4. Discussion

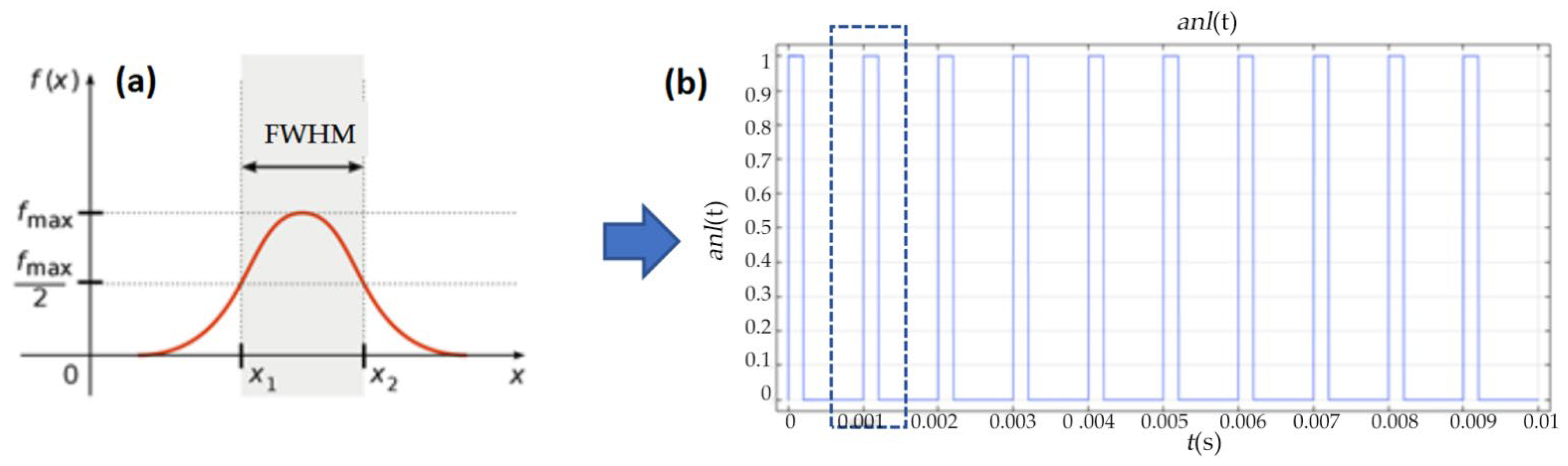

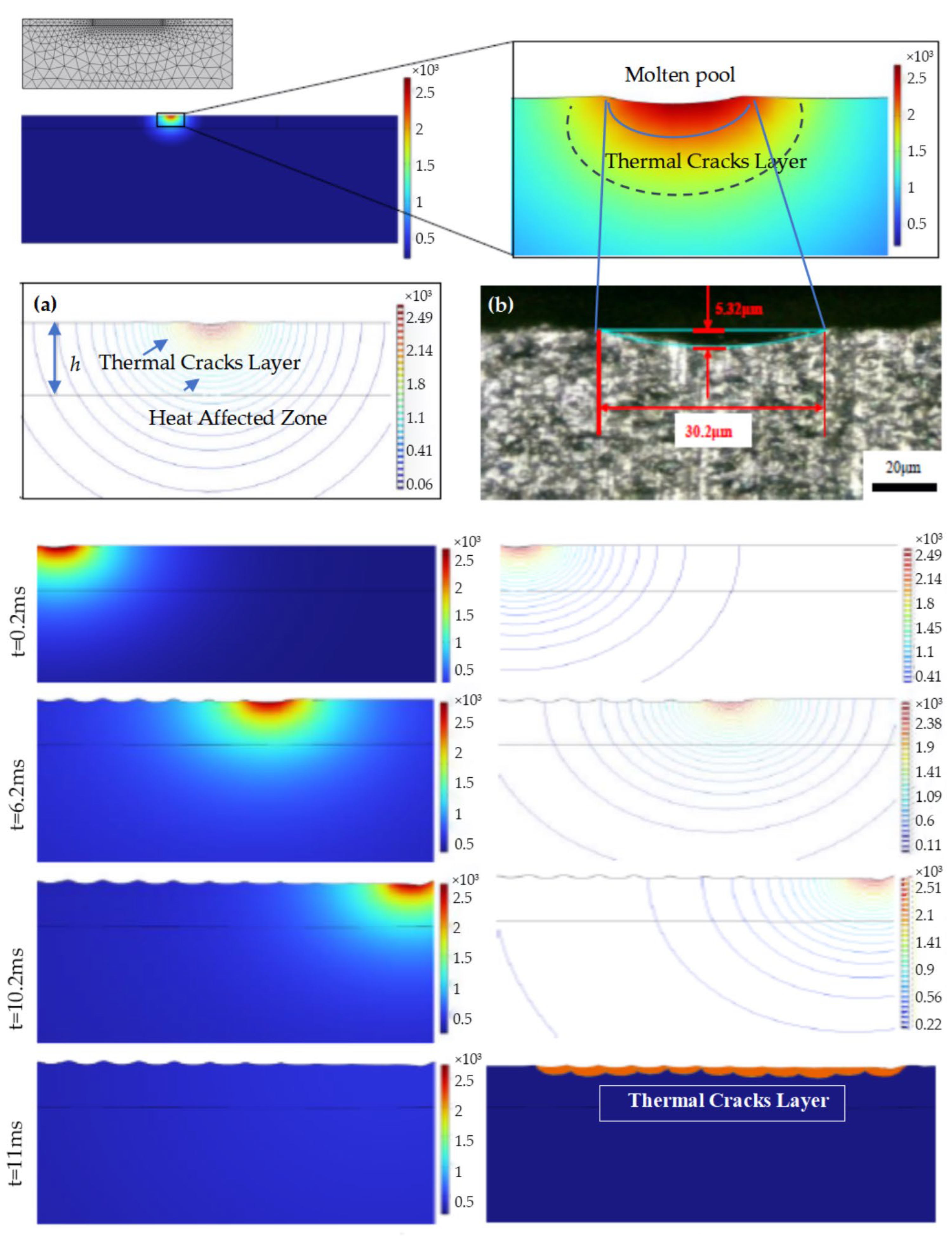

4.1. Thermal Distribution Simulation

4.2. Dimensions of the TCL

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Gao, Y.; Li, X.; Pu, T.; Yin, Y. Analytical Prediction of Subsurface Microcrack Damage Depth in Diamond Wire Sawing Silicon Crystal. Mater. Sci. Semicond. Process. 2020, 112, 105015. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, P.; An, T.; Dai, Y.; Qin, F. Analytical Prediction for Depth of Subsurface Damage in Silicon Wafer Due to Self-Rotating Grinding Process. Curr. Appl. Phys. 2019, 19, 570–581. [Google Scholar] [CrossRef]

- Li, H.N.; Yu, T.B.; Zhu, L.D.; Wang, W.S. Analytical Modeling of Grinding Induced Subsurface Damage in Monocrystalline Silicon. Mater. Des. 2017, 130, 250–262. [Google Scholar] [CrossRef]

- Sun, J.; Qin, F.; Chen, P.; An, T. A Predictive Model of Grinding Force in Silicon Wafer Self-Rotating Grinding. Int. J. Mach. Tools Manuf. 2016, 109, 74–86. [Google Scholar] [CrossRef]

- Lawn, B.; Wilshaw, R. Indentation Fracture: Principles and Applications. J. Mater. Sci. 1975, 10, 1049–1065. [Google Scholar] [CrossRef]

- Kizaki, T.; Ogasahara, T.; Sugita, N.; Mitsuishi, M. Ultraviolet-laser-assisted precision cutting of yttria-stabilized tetragonal zirconia polycrystal. J. Mater. Process. Technol. 2014, 214, 267–275. [Google Scholar] [CrossRef]

- Azarhoushang, B.; Soltani, B.; Zahedi, A. Laser-assisted grinding of silicon nitride by picosecond laser. Int. J. Adv. Manuf. Technol. 2017, 93, 2517–2529. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Chen, G.; Yu, Z.; Li, Y.; Xu, J.; Yu, H. Thermal modification and material removal mechanism of C/SiC composites in laser-ultrasonic hybrid machining. J. Eur. Ceram. Soc. 2025, 45, 117664. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, J.; Chen, X.; Zhu, Y.; Yu, Y.; Li, X.; Xu, J. Defect suppression mechanism for laser in-situ assisted diamond cutting of reaction-bonded silicon carbide. In Proceedings of the 2nd International Forum of Young Scientists on Advanced Optical Manufacturing (AOMTA and YSAOM 2022), Changchun, China, 29–31 July 2022. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, S.; Wang, X.; Wang, J.; Pang, Y.; Sun, W.; Monka, P.P. Research on the ablation mechanism and feasibility of UV laser drilling to improve the machining quality of 2.5D SiC/SiC composites. Opt. Laser Technol. 2025, 181, 111754. [Google Scholar] [CrossRef]

- Xu, S.; Yao, Z.Q.; He, J.W.; Xu, J. Grinding characteristics, material removal and damage formation mechanisms of zirconia ceramics in hybrid laser/grinding (HLG). J. Manuf. Sci. Eng. 2018, 140, 071010. [Google Scholar] [CrossRef]

- Erdenechimeg, K.; Jeong, H.; Lee, C. A Study on the Laser-Assisted Machining of Carbon Fiber Reinforced Silicon Carbide. Materials 2019, 12, 2061. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Z.; Zhang, Y.; Geng, F.; Wang, S.; Fan, F.; Zhang, Q.; Xu, Q. High-Power Femtosecond Laser Processing of SiC Ceramics with Optimized Material Removal Rate. Micromachines 2023, 14, 1960. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Xia, H.; Zhang, Y.; Li, L.; He, N.; Hansen, H.N. Laser-induced oxidation assisted micro milling of high aspect ratio microgroove on WC-Co cemented carbide. Chin. J. Aeronaut. 2021, 34, 465–475. [Google Scholar] [CrossRef]

- Dai, D.; Cai, Y.; Zhao, Y.; Aslam, J.; Tang, Y.; Liang, X.; Liu, Z. Study on the plastic removal behavior of SiC ceramic materials in laser-assisted high -temperature turning. Opt. Laser Technol. 2025, 192, 113566. [Google Scholar] [CrossRef]

- Qian, W.; Zhao, G.; Yang, H.; Nian, Z.; Xin, L.; Li, L. Combined hybrid machining of laser ablation-drilling small holes in Cf/SiC composites. Ceram. Int. 2024, 50, 55892–55905. [Google Scholar] [CrossRef]

- Li, S.; Chen, P.; Qin, F. The separation mechanism of 4H-SiC dicing by continuous laser. In Proceedings of the 23rd International Conference on Electronic Packaging Technology (ICEPT), Dalian, China, 9–11 August 2022. [Google Scholar]

- Ma, Z.; Wang, Q.; Chen, H.; Chen, L.; Qu, S.; Wang, Z.; Yu, T. A grinding force predictive model and experimental validation for the laser-assisted grinding (LAG) process of zirconia ceramic. J. Mater. Process. Technol. 2022, 302, 117492. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, T.; He, J.L.; Zhang, J.; Zhang, Y.; Long, J.; Xie, X. Full Dicing of Ultra-thin Silicon Carbide Substrate by Femtosecond Laser. Surf. Technol. 2023, 52, 306–313. [Google Scholar]

- Kong, X.; Liu, S.; Hou, N.; Zhao, M.; Liu, N.; Wang, M. Cutting performance and tool wear in laser-assisted grinding of SiC/SiC ceramic matrix composites. Mater. Res. Express 2022, 9, 125601. [Google Scholar] [CrossRef]

- Hao, J.; Ma, S.; Luo, H.; Chen, Z.; Song, S.; Shen, B.; Zhang, J.; Xiao, J.; Xu, J. Machinability of reaction-bonded silicon carbide by applying in-situ laser-vibration hybrid assisted diamond cutting. Ceram. Int. 2025, 51, 42961–42972. [Google Scholar] [CrossRef]

- Kumar, M.; Melkote, S.; Lahoti, G. Laser-assisted microgrinding of ceramics. CIRP Ann. Manuf. Technol. 2011, 60, 367–370. [Google Scholar] [CrossRef]

- Cao, C.; Zhao, Y.; Zhang, G.; Li, Z.; Zhao, C.; Yu, H.; Zhao, D.; Zhang, H.; Dai, D. Experimental study of plastic cutting in laser-assisted machining of SiC ceramics. Opt. Laser Technol. 2024, 169, 110098. [Google Scholar] [CrossRef]

- Lin, J.; Kang, M.; Gu, Y.; Xi, Y.; Gao, Y.; Wu, M.; Liang, G.; Xie, L. Wear mechanism analysis of PCD tools during the cutting process of SiCp/Al with a 45% volume fraction using nanosecond pulsed laser-assisted cutting. Int. J. Adv. Manuf. Technol. 2025, 138, 5645–5662. [Google Scholar] [CrossRef]

- Agarwal, S.; Rao, P.V. Experimental investigation of surface/subsurface damage formation and material removal mechanisms in SiC grinding. Int. J. Mach. Tools Manuf. 2008, 48, 698–710. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, Y.; Yu, Y.; Chen, X.; Zhang, J.; Xiao, J.; Xu, J. Subsurface deformation and crack propagation between 3C-SiC/6H-SiC interface by applying in-situ laser-assisted diamond cutting RB-SiC. Mater. Lett. 2023, 336, 133878. [Google Scholar] [CrossRef]

- Yang, H.; Fu, M.; Zhang, X.; Zhu, K.; Cao, L.; Hu, C. Material Removal Mechanisms of Polycrystalline Silicon Carbide Ceramic Cut by a Diamond Wire Saw. Materials 2024, 17, 4238. [Google Scholar] [CrossRef]

- Groeb, M.; Catrin, R.; Groeb, J. Hybrid laser and subtractive machining of reaction bonded silicon carbide. In Laser Metrology and Machine Performance XV, Proceedings of the 15th International Conference and Exhibition on Laser Metrology, Machine Tool, CMM & Robotic Performance, Edinburgh, UK, 14–15 March 2023; Euspen: Cranfield, UK, 2023; pp. 95–101. [Google Scholar]

- Li, Z.; Zhang, F.; Luo, X. Subsurface damages beneath fracture pits of reaction-bonded silicon carbide after ultra-precision grinding. Appl. Surf. Sci. 2018, 448, 341–350. [Google Scholar] [CrossRef]

- Chen, M.; Dai, H. Molecular dynamics study on grinding mechanism of polycrystalline silicon carbide. Diam. Relat. Mater. 2022, 130, 109541. [Google Scholar] [CrossRef]

- Xu, S.; Yao, Z.; Zhang, M. Material removal behavior in scratching of zirconia ceramic surface treated with laser thermal shock. Int. J. Adv. Manuf. Technol. 2016, 85, 2693–2701. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, F.; Luo, X.; Chang, W.; Cai, Y.; Zhong, W.; Ding, F. Material removal mechanism of laser-assisted grinding of RB-SiC ceramics and process optimization. J. Eur. Ceram. Soc. 2019, 39, 705–717. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, Q.; To, S.; Guo, B.; Zhai, W. Diamond wheel wear mechanism and its impact on the surface generation in parallel diamond grinding of RB-SiC/Si. Diam. Relat. Mater. 2017, 74, 16–23. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F.; Cai, Y.; Sun, J.; Liu, H. Material removal mode and friction behaviour of RB-SiC ceramics during scratching at elevated temperatures. J. Eur. Ceram. Soc. 2019, 39, 3534–3545. [Google Scholar] [CrossRef]

- Qu, S.; Wei, C.; Yang, Y.; Yao, P.; Chu, D.; Gong, Y.; Zhao, D.; Zhang, X. Grinding mechanism and surface quality evaluation strategy of single crystal 4H-SiC. Tribol. Int. 2024, 194, 109515. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Z.; Su, H.; Zhao, Q.; To, S. Role of Si in the surface damage mechanism of RB-SiC/Si under mechanical loading. J. Mater. Eng. Perform. 2019, 28, 254–262. [Google Scholar] [CrossRef]

- Wu, M.; Guo, B.; Zhao, Q.; Zhang, J.; Fang, X.; He, P. High efficiency precision grinding of micro-structured SiC surface using laser micro-structured coarse-grain diamond grinding wheel. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 577–586. [Google Scholar] [CrossRef]

- Yin, G.; Yang, L.; Niu, T.; Guo, H.; Zhou, Y.; Sun, Y. Study on the removal mechanism of 4H-SiC materials based on single grain grinding and optimization of process parameters. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 107. [Google Scholar] [CrossRef]

- Temmler, A.; Braun, K.; Uluz, E. Heat accumulation and surface roughness evolution in CO2 nanosecond laser ablation of quartz glass. Opt. Laser Technol. 2021, 144, 107426. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Density (kg·cm−3) | 3.12 |

| Elastic Modulus (GPa) | 415 |

| Vickers Hardness (HV) | 3000 |

| Fracture Toughness (MPa·m1/2) | 4.5 |

| Thermal Conductivity (W/m·k) | 148 |

| Melting Point (°C) | 2700 |

| Poisson’s Ratio | 0.24 |

| Thermal Expansion Coefficient (×10−6 °C−1) | 4.2 |

| Parameter | Value |

|---|---|

| Wavelength λ (nm) | 532 |

| Beam diameter D (μm) | 50 |

| Maximum scanning speed V (points/s) | 1000 |

| Maximum output power P (W) | 5 |

| Frequency f (kHz) | 1 |

| Single-pulse energy Q (mJ) | 2.5 |

| Maximum scanning area S (mm2) | 90 × 90 × 90 |

| Parameter | Value |

|---|---|

| Wheel speed Vsr, r/min | 5000, 7500, 10,000, 15,000 |

| Worktable speed Vw, mm/min | 2.5, 5, 7, 10 |

| Grinding wheel | Electroplated diamond |

| Grain size, μm | 38 |

| Parameter | Value |

|---|---|

| Spot Radius (μm) | 45 |

| Scanning Speed (mm/s) | 60 |

| Melting Point (°C) | 2700 |

| Heat of Sublimation (kJ/kg) | 11,562.5 |

| Density (kg/m3) | 3200 |

| Laser Frequency (kHz) | 1 |

| Pulse Width (s) | 0.0002 |

| Surface Emissivity | 0.79 |

| Thermal Conductivity (W/(m·K)) | 236 |

| Constant-Pressure Specific Heat Capacity (J/(kg·K)) | 680 |

| Ambient Temperature (°C) | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Li, H.; Jiang, Y.; Yang, Y.; Yang, J.; Zhu, L. Characteristics of Pulsed-Laser-Induced Layers with Cracks Prepared for SiC Grinding Processes. Materials 2026, 19, 397. https://doi.org/10.3390/ma19020397

Li H, Jiang Y, Yang Y, Yang J, Zhu L. Characteristics of Pulsed-Laser-Induced Layers with Cracks Prepared for SiC Grinding Processes. Materials. 2026; 19(2):397. https://doi.org/10.3390/ma19020397

Chicago/Turabian StyleLi, Hu, Yanjiao Jiang, Yujia Yang, Jianyu Yang, and Lida Zhu. 2026. "Characteristics of Pulsed-Laser-Induced Layers with Cracks Prepared for SiC Grinding Processes" Materials 19, no. 2: 397. https://doi.org/10.3390/ma19020397

APA StyleLi, H., Jiang, Y., Yang, Y., Yang, J., & Zhu, L. (2026). Characteristics of Pulsed-Laser-Induced Layers with Cracks Prepared for SiC Grinding Processes. Materials, 19(2), 397. https://doi.org/10.3390/ma19020397