Abstract

Aluminum, the primary structural material used in spacecraft, operates in low Earth orbit (LEO). It is subjected to high-energy electron irradiation with energies ranging from 0.1 to 10 MeV, which produces significant irradiation damage. Understanding the characteristics of irradiation defects with crystallographic orientations is crucial for analyzing the failure of spacecraft components and for developing aerospace materials with improved irradiation resistance. In this study, pure aluminum was irradiated in situ at room temperature using 200 kV transmission electron microscopy. The irradiation defects were comparatively analyzed for four crystallographic orientations, focusing on the size, density, and interstitial content of <111> and <110> dislocation loops. For all four irradiation directions, the interstitial atom density (IAD) within <111> loops is significantly higher than that in <110> loops. Notably, under [110]-direction irradiation, IAD in <111> loops is approximately 55 times that in <110> loops. This phenomenon is attributed to the one-dimensional migration of <110> loops. Among the four irradiation directions, the total IAD in the two types of loops decreases in the order: [110] > [111] > [310] > [100]. The threshold displacement energy (Ed) of aluminum at room temperature is inferred to follow the relationship: [110] < [111] < [310] < [100].

1. Introduction

Aluminum and its alloys are widely utilized in the aerospace industry [1,2]. For example, AA6061 aluminum alloy is extensively employed in structural components such as satellite primary structures, solar array support frames, and ring-frame structural modules of space stations [3]. In contrast, AA2219 aluminum alloy is predominantly used in rocket propellant tanks and large sealed compartments of manned spacecraft [4]. Satellites, space stations, and other spacecraft operating in low Earth orbit (LEO) experience harsh service environments, where external surface temperatures fluctuate between 93 and 453 K [5], and continuous exposure to radiation from high-energy charged particles such as electrons and protons occurs [6,7,8].

To date, research on aluminum irradiated by space particles has been relatively limited. However, extensive studies have been conducted on the mechanical properties of aluminum alloys. AA6061-T6 aluminum alloy exhibits excellent mechanical performance at low temperatures. At 77 K, the yield strength, ultimate tensile strength, and elongation to failure increase by approximately 18%, 33%, and 53%, respectively. After cyclic stress loading at 108 K, the alloy shows pronounced cyclic hardening behavior, accompanied by an approximately 143% improvement in fatigue life [9]. Previous studies have demonstrated that low-temperature deformation leads to pronounced dislocation tangling near grain boundaries, whereas at room temperature, dislocations tend to pass through grain boundaries. Compared with room temperature, the altered dislocation behavior in aluminum alloys under low-temperature conditions results in different mechanical properties [10].

In contrast, studies on the effects of high-energy particle irradiation on the mechanical properties of aluminum alloys have predominantly focused on neutron irradiation. Neutron-induced nuclear transmutation reactions generate gaseous elements such as hydrogen and helium, which are among the key driving factors for irradiation swelling. Meanwhile, neutron irradiation introduces defects, such as dislocations and voids, in aluminum alloys and is accompanied by the formation of transmutation-induced silicon. The combined effect of these factors leads to irradiation hardening and embrittlement, thereby significantly altering the mechanical properties of aluminum alloys [11,12,13]. For example, earlier neutron irradiation studies on 6061 aluminum alloy demonstrated that high-dose irradiation leads to significant irradiation hardening and a corresponding decrease in ductility [12]. Studies on neutron irradiation effects in cold-worked commercial A5 aluminum have shown that irradiation induces silicon precipitation due to transmutation reactions, while the dislocation density introduced by cold working decreases with increasing neutron dose, accompanied by enhanced strength and ductility [14].

Neutron irradiation studies are mainly motivated by applications in nuclear reactor environments, whereas the dominant irradiation particles in space environments are electrons and protons [6,7,8]. Electron irradiation fundamentally differs from neutron irradiation in terms of energy transfer mechanisms and defect evolution processes [15]. Neutrons, especially fast neutrons, can induce nuclear transmutation reactions in lattice atoms, producing complex defect structures and compositional changes, which complicate the investigation of irradiation damage mechanisms in aluminum alloys. In contrast, when aluminum and its alloys are irradiated by electrons with energies above a certain threshold, only isolated Frenkel defect pairs are generated in the material, without the formation of displacement cascades [16]. Therefore, electron irradiation provides a more suitable approach for investigating irradiation-induced microstructural defect evolution. However, studies on electron irradiation effects in aluminum and its alloys remain limited, particularly with regard to the influence of electron irradiation direction on the evolution of defects such as dislocation loops.

The radiation environment in near-Earth space is primarily dominated by the inner radiation belt and the lower portion of the outer radiation belt [7,8,17,18]. The inner radiation belt is located at an altitude of approximately 600–10,000 km above the equatorial plane and is mainly composed of high-energy protons and electrons. Proton energies may exceed 100 MeV, while electron energies typically range from approximately 0.1 to 10 MeV. The outer radiation belt extends from about 10,000–60,000 km, and its lower region (approximately 13,500–20,000 km) overlaps with the upper boundary of near-Earth space. This region is predominantly characterized by trapped high-energy electrons with energies up to 7 MeV, accompanied by a small fraction of low-energy protons [17,19,20,21,22]. When the kinetic energy transferred from energetic electrons or protons to a lattice atom exceeds the displacement threshold energy (Ed), the atom may be displaced from its lattice site, leading to the formation of a Frenkel defect pair consisting of a vacancy and a self-interstitial atom (SIA), which marks the onset of irradiation damage. The irradiation damage behavior of aluminum and its alloys is closely related to the service reliability of spacecraft components and serves as an important basis for failure analysis. Metals such as Al [23], Be [24], and Mg [25,26] exhibit relatively low Ed. For example, the Ed of Al is approximately 16 eV [27,28], which corresponds to a minimum electron threshold energy (Et) of about 169 eV required to initiate atomic displacement. Be has an Ed of 15 eV with a corresponding Et of 58 eV, whereas Mg exhibits an even lower Ed of 10 eV and an Et of 101 eV [29,30]. These values clearly indicate that high-energy electrons present in the LEO environment can readily induce irradiation damage in these metals.

Pure aluminum exhibits a simple face-centered cubic (FCC) crystal structure and contains no alloying elements, second-phase particles, or precipitates, thereby effectively avoiding the additional complexity introduced by solute atoms, precipitate interfaces, and compositional heterogeneity. These factors are known to significantly influence the nucleation, migration, and interaction of irradiation-induced defects in alloy systems, increasing the difficulty of mechanistic interpretation [15]. Moreover, previous studies have shown that, during transmission electron microscopy (TEM) observations of aluminum alloys, precipitates may interfere with the identification and analysis of dislocation loops formed under electron irradiation [31]. Thus, pure aluminum provides a well-defined and simplified material choice for investigating the evolution of irradiation-induced defects, such as dislocation loops, under electron irradiation. More importantly, the insights obtained from pure aluminum provide an essential foundation for understanding irradiation behavior in aluminum alloys. At present, the studies on aluminum alloys under space-relevant particle irradiation, particularly electron irradiation, remain limited. Therefore, elucidating the orientation dependence of irradiation-induced damage in pure aluminum establishes a foundation for subsequent investigations of irradiation damage in aluminum-based structural materials. Addressing this key issue, together with future measurements and analyses of Ed in engineering aluminum alloys containing alloying elements such as Si, Mg, and Cu, will further advance the understanding of electron irradiation damage mechanisms in structural materials.

The relatively low Ed and Et values of Al allow a 200 keV electron beam in a conventional TEM to induce irradiation damage within the specimen volume [30]. Meanwhile, the nucleation and evolution of irradiation-induced defects can be directly observed and analyzed during electron irradiation, thereby enabling in situ irradiation damage studies. In this context, for irradiation damage research in metals, a standard 200 kV TEM plays a role in low-threshold-energy materials such as Al, Be, and Mg, comparable to that of an ultra-high-voltage electron microscope (UHVEM) on metals with high-threshold energies such as Fe, Cu, and W. The ability to perform in situ irradiation experiments in conventional TEMs, therefore, partially mitigates the limitations caused by the global scarcity of UHVEMs, thereby enabling broader investigations into the fundamental mechanisms of irradiation damage [16].

Li et al. [29] performed in situ observations and analyses to investigate the migration behavior of interstitial loops in hydrogen-implanted pure aluminum during electron irradiation. They reported, for the first time, the long-range one-dimensional (1D) migration of dislocation loops, with migration distances of up to approximately 1500 nm. A well-designed experimental strategy was implemented in which the electron beam irradiation position was deliberately shifted to modify the spatial concentration gradient of irradiation-induced SIAs. Consequently, the migrating dislocation loops were observed to reverse their migration direction. These results demonstrated that the concentration gradient of irradiation-produced SIAs acted as the driving force governing the 1D migration of dislocation loops. Du et al. [32] employed a conventional TEM to perform in situ observations on the evolution of gas bubbles in pure Al implanted with He, Ne, and Ar ions under electron irradiation. Their results showed that all three types of bubbles underwent coalescence and growth when exposed to a 200 keV electron beam. Accompanying the bubble evolution, the selected-area electron diffraction (SAED) patterns revealed a transition in the surrounding matrix from a single-crystal spot pattern to a polycrystalline ring pattern. The authors proposed that under electron irradiation, the high pressure gas inside the bubbles could be ionized into plasma, releasing substantial energy that induces local recrystallization, thereby leading to the formation of polycrystalline structures. Similarly, Li et al. [33] reported bubble growth and rupture in D- and H-ion-implanted Al samples. Consistent with the evolution of bubbles, polycrystalline diffraction rings appeared in the SAED. Furthermore, Chen et al. [34] observed abnormal exothermic behavior in bubbles formed by implantation of D, H, He, Ne, and Ar ions when irradiated with a 200 kV TEM. They proposed that this abnormal heat release is influenced by multiple factors, including bubble morphology and internal pressure, gas species and density, electron beam energy, and irradiation duration.

Although significant progress has been made in in situ irradiation damage studies of Al, the influence of crystallographic orientation on the evolution of dislocation loops in Al has rarely been reported. In this paper, we investigate the effect of crystallographic orientation on the evolution of dislocation loops in aluminum.

2. Materials and Methods

The materials used in this study were high-purity aluminum (99.99 wt.%) supplied by Beijing Cuibolin Nonferrous Metals Technology Development Center Co., Ltd., Beijing, China. The as-cast aluminum specimens were machined into 3 mm discs, sealed in evacuated quartz tubes, and annealed at 200 °C for 100 min to remove residual stresses and pre-existing dislocations. The foils were prepared by twin-jet electropolishing to obtain electron-transparent areas with a thickness of approximately 100 nm suitable for TEM observation. The electrolyte consisted of 25% nitric acid and 75% methanol (by volume). Electropolishing was performed at −25 °C with an applied voltage of approximately 20 V using a TenuPol-5 twin-jet electropolisher (Struers, Ballerup, Denmark).

The electron irradiation and in situ observation were performed by a conventional FEI Tecnai F20 TEM (Thermo Fisher Scientific, Hillsboro, OR, USA) with an accelerating voltage of 200 kV. To avoid the influence of grain boundaries on the evolution of irradiation-induced defects, grains with diameters larger than 4 µm were selected during the electron irradiation experiments, and the irradiation area was confined to a circular region with a diameter of 1.2 µm.

In irradiation damage processes, the projection of target atoms onto a plane perpendicular to the incident beam direction plays a particularly important role. The atomic density on this projected plane strongly influences the scattering cross section for irradiation damage as well as the collision probability between incident particles and target atoms. In in situ TEM electron irradiation experiments, the crystallographic orientation of the irradiated crystal and the irradiation direction can be determined using selected-area electron diffraction. The zone-axis direction identified in the electron diffraction pattern corresponds to the irradiation direction of the electron beam. Further details can be found elsewhere [24,25,35,36,37,38]. The electron beam was aligned along four crystallographic orientations: [100], [310], [110], and [111]. For each irradiation condition, the TEM magnification and irradiation area size were kept constant, and the irradiation duration was set to 10 min. After irradiation, two g vectors were selected for each irradiation direction of the electron beam, and the dislocation loops were analyzed using the two-beam diffraction condition. The dislocation loop size, number density, and spatial distribution formed under electron irradiation along the four crystallographic orientations were statistically evaluated. Based on the extinction rules of dislocation loops with Burgers vectors of (referred to as <111>) and (referred to as <110>) under different g conditions, the fraction, average size, and number density of both loop types were quantitatively determined. Furthermore, the interstitial atom density (IAD) corresponding to the <111> and <110> loops under different irradiation directions was calculated using the atom-occupied area per unit cell on the relevant crystallographic planes of the FCC lattice.

3. Results

3.1. Fraction, Density, and Average Size of Dislocation Loops Under Different Irradiation Directions

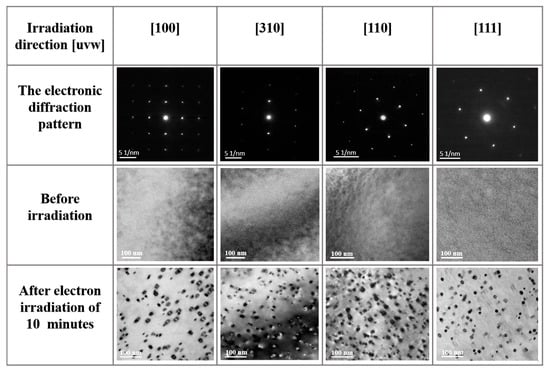

Prior to electron irradiation, the TEM bright-field images show that the annealed pure Al samples contain no dislocations or other defects. After irradiation with 200 keV electrons for 10 min along the [100], [310], [110], and [111] crystallographic orientations, high densities of small dislocation loops appeared within the irradiated regions, as revealed in Figure 1.

Figure 1.

Selected-area electron diffraction (SAED) patterns and TEM bright-field images of the sample acquired along the [100], [310], [110], and [111] crystallographic orientations, obtained before and after 10 min of electron irradiation.

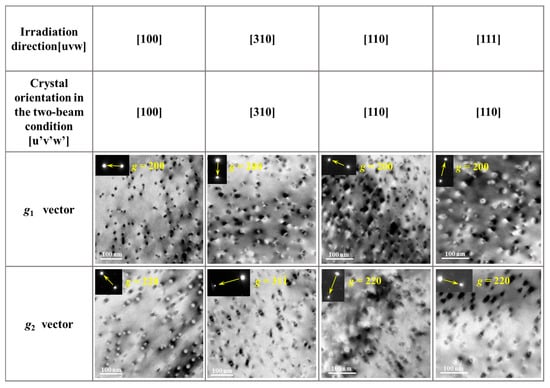

As an example, under [100] irradiation, after 10 min of electron irradiation, the dislocation loops exhibited an average diameter d[100] of 14.4 nm and a number density ρ[100] of 5.1 × 1021/m3, as shown in Figure 2. Because the first-order diffraction vectors in the SAED pattern for the [111] are all g = {220}, which is unfavorable for detailed characterization of the dislocation loops, the [110] zone axis was selected instead. Under this condition, two diffraction vectors, g = {200} and g = {220}, were employed to characterize the dislocation loops generated during electron irradiation along the [111] direction, as shown in Figure 2. The fractions of <111> and <110> dislocation loops were quantified based on their extinction behavior under the two g vectors. The extinction rules for both types of loops under the selected diffraction conditions are summarized in Table 1.

Figure 2.

Bright-field TEM images under two-beam conditions showing dislocation loops after 10 min of electron irradiation along the [100], [310], [110], and [111] orientations. Different diffraction g vectors were used as indicated in each image.

Table 1.

Extinction behavior of dislocation loops after electron irradiation.

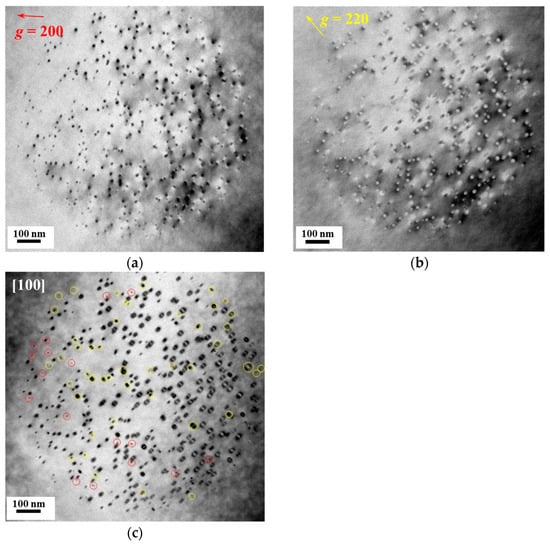

After 10 min of electron irradiation along the [100] direction, bright-field TEM images were obtained under three imaging conditions, as shown in Figure 3: the two-beam condition with (a) g = {200}, (b) g = {220}, and (c) along the [100] crystallographic orientation. Statistical analysis indicates that under the g = {200} condition, a total of 412 dislocation loops were counted, among which two-thirds of the <110> loops and all <111> loops were visible. Under the g = {220} condition, 385 dislocation loops were observed, with five-sixths of the <110> loops and half of the <111> loops visible. Using Equation (1), the numbers of <110> and <111> dislocation loops (N<110> and N<111>) were calculated to be 358 and 173, respectively. The fraction of <111> loops among the total dislocation loops, , is 33%, while that of <110> loops, , is 67%. Based on the observed area and the sample thickness (~100 nm), the densities of <111> and <110> dislocation loops were determined to be ρ<111> = 1.7 × 1021/m3 and ρ<110> = 3.4 × 1021/m3, respectively.

Figure 3.

Bright-field TEM images after 10 min of electron irradiation along the [100] direction: (a) two-beam condition with g = {200}, (b) two-beam condition with g = {220}, and (c) [100] crystallographic orientation.

The dislocation loops that were extinct under specific two-beam conditions were identified by comparing bright-field TEM images shown in Figure 3. The loops that became extinct under the g = {200} condition (Figure 3a) were marked with red circles in the [100] crystallographic orientation image (Figure 3c), while those extinct under the g = {220} condition (Figure 3b) are indicated by yellow circles in Figure 3c. The extinction behavior of dislocation loops under different irradiation directions and two-beam conditions is summarized in Table 1. After electron irradiation along the [100] direction, all loops extinct under the g = {200} condition were of the <110> type, whereas all <111> loops remained visible. Under the g = {220} condition, one-third of the extinct loops were <110> type, while two-thirds were <111> type. The average loop sizes generated during irradiation along the [100] direction were calculated to be 22.5 nm for <111> loops and 10.4 nm for <110> loops.

Using the approach described above, the fractions, average sizes, and densities of <111> and <110> dislocation loops were determined after electron irradiation along the [310], [110], and [111] directions, and the results are summarized in Table 2. Significant differences in loop densities, ρ[uvw], were observed for different irradiation directions, where [uvw] denotes the irradiation direction. The highest loop density was observed along the [111] direction, while the lowest occurred along [100]. The loop densities for the four irradiation directions decreased in the order: ρ[111] (1.2 × 1022/m3) > ρ[110] (1.0 × 1022/m3) > ρ[310] (7.8 × 1021/m3) > ρ[100] (5.1 × 1021/m3). Similarly, the average loop sizes, d[uvw], also varied with irradiation direction, following the trend: d[100] (14.4 nm) > d[310] (12.5 nm) > d[110] (12.4 nm) > d[111] (11.3 nm).

Table 2.

Size, density, and fraction of <111> and <110> loops under different irradiation directions.

Significant differences were observed in the fractions of <111> and <110> dislocation loops () generated under different irradiation directions, as summarized in Table 2. represents the percentage of <hkl>-type loops among the total number of loops for the [uvw] irradiation direction. For the [100] and [310] irradiation directions, was lower than . Along the [100] direction, was 33% and was 67%, while along the [310], was 43% and was 57%. In contrast, for the [110] and [111] directions, was higher than . Along the [110] direction, was 90% and was 10%, whereas along [111], was 78% and was 22%. The relative magnitude of among the four irradiation directions decreased in the order [110] > [111] > [310] > [100], whereas that of followed [100] > [310] > [111] > [110].

The densities of <111> and <110> dislocation loops generated along different irradiation directions were calculated using = [uvw] as summarized in Table 2. The ρ<111> values for the different irradiation directions decreased in the order: [111] > [110] > [310] > [100], with the maximum = 9.4 × 1021/m3 and the minimum = 1.7 × 1021/m3, giving a factor of 5.5 between the largest and smallest values. Similarly, the ρ<110> values followed the order [310] > [100] > [111] > [110], with the maximum = 4.5 × 1021/m3 and the minimum = 1.0 × 1021/m3, corresponding to a factor of 4.5 between the largest and smallest densities.

Comparison of <111> and <110> dislocation loops generated along the same irradiation direction revealed that d<111> was consistently larger than d<110>. For the [100], [310], and [110] irradiation directions, d<111> was approximately twice that of d<110>, whereas for the [111] direction, the average sizes of the two loop types were comparable. Both d<111> and d<110> reached their maximum values under [100] irradiation, 22.5 nm and 10.4 nm, respectively, which were significantly larger than the corresponding values in the other directions. The relative magnitudes of d<111> for the four irradiation directions decreased in the order [100] > [310] > [110] > [111], with the maximum approximately twice the minimum. For d<110>, the order was [100] > [111] > [310] > [110], with the maximum being 1.6 times the minimum.

3.2. IAD in Dislocation Loops Generated by Irradiation in Different Directions

The analysis above indicated that, although the dislocation loop densities decreased in the order ρ[111] > ρ[110] > ρ[310] > ρ[100], the average loop sizes followed d[100] > d[310] > d[110] > d[111]. This suggested that irradiation directions that produced smaller average loop sizes tended to correspond to higher loop densities. It is well established that dislocation loops generated in aluminum under 200 keV electron irradiation at room temperature are of interstitial type [29,30]. Therefore, the IAD within <111> and <110> loops was calculated for different irradiation directions to provide further insight into the effect of irradiation direction on dislocation loop evolution.

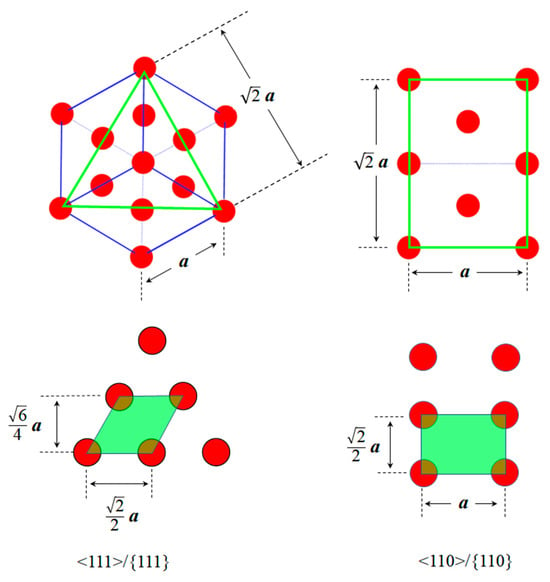

In FCC crystal structures, <111> dislocation loops have a habit plane belonging to the {111} planes, whereas <110> loops have a habit plane belonging to the {110} planes. As shown in Figure 4, the area occupied by a single atom on the (111) plane (green parallelogram) is , resulting in an atomic planar density of for the (111) plane. Similarly, the area occupied by a single atom on the (110) plane (green rectangle) is , giving an atomic planar density of for the (110) plane, where a is the lattice parameter. At room temperature, the lattice parameter of Al is 4.05 × 10−10 m [39]. Accordingly, the atomic planar densities of the {111} and {110} plane families were calculated to be 1.41 × 1019 atoms/m2 and 8.62 × 1018 atoms/m2, respectively.

Figure 4.

Atomic planar densities of the {111} and {110} planes in an FCC crystal.

The IAD within <hkl> dislocation loops along different irradiation directions, denoted as , was calculated using the following equation:

In Equation (2), represents the IAD within <hkl>-type dislocation loops along the [uvw] irradiation direction, with units of atoms/m3. Physically, it corresponded to the number of SIAs contained in <hkl> loops per unit volume generated during electron irradiation. denotes the average area of <hkl> dislocation loops along the [uvw] direction, with units of m2. is the number density of <hkl> loops along the [uvw] direction, in units of m−3. A(hkl) is the atomic planar density of the habit plane of <hkl>-type dislocation loops, with units of atoms/m2.

In Equation (3), denotes the average size of <hkl>-type dislocation loops along the [uvw] irradiation direction, with units of m. π is the mathematical constant, taken as approximately 3.14. By substituting Equation (3) into Equation (2), Equation (4) was obtained:

By substituting the results from Table 2 into Equation (4), the IAD values in <111> and <110> dislocation loops, , were calculated for the four irradiation directions, where [uvw] denotes the electron beam direction, and <hkl> represents the dislocation loop type. For example, corresponds to the IAD within <111> loops generated under [110] irradiation. The total IAD contained in dislocation loops with the two kinds of Burgers vectors under different irradiation directions, , is defined as ; for instance, represents the sum of and , i.e., the total IAD within dislocation loops after irradiation along [110]. The atomic fractions of <111> and <110> loops along [uvw], denoted as and , were also determined. The detailed results are summarized in Table 3, which shows IAD values in <111> and <110> dislocation loops under the four irradiation directions.

Table 3.

IAD in <111> and <110> dislocation loops under four irradiation directions.

For all irradiation directions, both C<111> and were significantly higher than C<110> and . Under [110] irradiation, the IAD and were 1.7 × 1025 atoms/m3 and 3.0 × 1023 atoms/m3, respectively, representing the largest difference among the four irradiation directions; was approximately 56 times higher than . The corresponding atomic fractions, and , were 98.3% and 1.7%, indicating that <111> loops contributed the vast majority of SIAs under [110] irradiation.

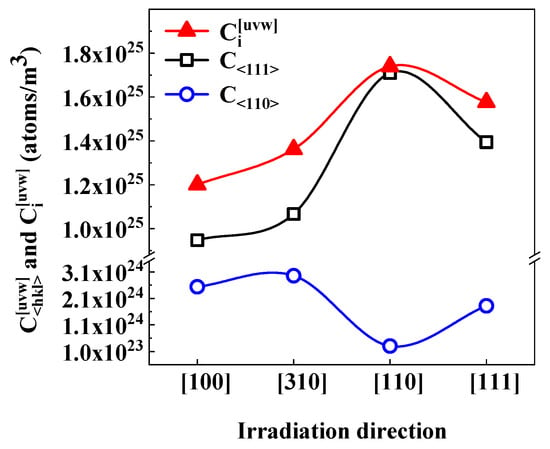

Across all irradiation directions, the IAD of C<111> decreased in the order [110] > [111] > [310] > [100], whereas C<110> followed [100] > [310] > [111] > [110]. The total IAD in the two types of loops, , showed the maximum and minimum values of = 1.7 × 1025 atoms/m3 and = 1.2 × 1025 atoms/m3, respectively. The results for and are summarized in Figure 5. As shown, the trends in and were consistent, which was attributed to the dominant contribution of <111> loops to IAD, reflected by the high values of .

Figure 5.

and within dislocation loops under electron irradiation along four crystallographic orientations.

4. Discussion

4.1. Effect of Direction-Dependent Ed on Evolution of Dislocation Loops

After 10 min of electron irradiation along different crystallographic orientations, the total IAD in dislocation loops decreased in the order (1.7 × 1025 atoms/m3) > (1.6 × 1025 atoms/m3) > (1.4 × 1025 atoms/m3) > (1.2 × 1025 atoms/m3). This variation is primarily attributed to the direction dependence of the Ed. Ed is defined as the minimum energy required for an incident particle to produce a stable Frenkel pair (a self-interstitial atom and a vacancy) during irradiation-induced damage. Under room temperature electron irradiation, the anisotropy of Ed among different crystallographic orientations has a significant impact on the concentration of SIAs.

Previous studies have shown that the concentration of displaced atoms generated under an incident electron flux during irradiation is given by [16]

where Nd is the concentration of displaced atoms, with units of atoms/m3, ni is the atomic density of the specimen, with units of atoms/m3, t is the irradiation time (s), φ is the incident electron flux, with units of electrons/(s∙m2), σp is the primary total scattering cross-section of the incident electrons, and ν(Ep) is the displacement damage function. According to the NRT model [40], for 200 keV electron irradiation of pure Al, the displacement damage function is ν(Ep) = 1 during irradiation.

Nd = nitφσpν(Ep)

When the quantum effects of electrons are taken into account, the primary total scattering cross-section σp of the incident electrons is given by [16]

Z is the atomic number of the target material, e is the elementary charge, and β is the relative velocity of the electrons, defined as β = v/c, where c is the speed of light and v is the velocity of the incident electrons. m0 is the electron rest mass. Ep,max denotes the maximum transferable energy from an electron to an atom (in eV), and Ed is the displacement threshold energy of the material (in eV). The parameter α is defined as Z/137. Ep represents the energy transferred from an incident electron to a target atom (in eV). The corresponding expressions are as follows:

θ is the angle between the motion direction of the displaced atom and the incident electron beam. According to the calculations reported by Yin et al. on the relationship between TEM accelerating voltage and the energy transferred to target atoms, a 200 keV electron can transfer a maximum energy of Ep,max = 19.5 eV to an Al atom [30]. For 200 keV electrons, β = 0.7, π = 3.14, and α = 0.09. Substituting these values into Equation (6) yields the following:

The concentration of displaced atoms, Nd, does not necessarily equal the concentration of SIAs, Cd, because a displaced atom may recombine with other vacancies and could potentially be displaced multiple times during irradiation. According to previous studies, the atomic displacement efficiency, ξ, is close to 1 for electrons and light particles, indicating a low recombination rate between SIAs and vacancies under these irradiation conditions [15] (pp. 152–154). Therefore, under electron irradiation, the concentration of SIAs can be approximated as being equal to that of displaced atoms:

Cd ≈ Nd

In this study, the irradiation temperature, as well as the area and thickness of the irradiated region, were comparable among the samples. Moreover, the atomic density of the specimens ni, the irradiation time t, the electron flux φ, the atomic number of the target Z, the elementary charge e, the relative velocity of electrons β, and the electron mass m0 were all constants. Therefore, two constants, k1 and k2, can be introduced:

k1 > 0 and −1.4 ≤ k2 ≤ 1. The concentration of SIAs, Cd, can then be expressed as

Equation (11) illustrates the relationship between Ed and Cd under electron irradiation, indicating that a lower Ed results in a higher Cd. Higher SIA concentrations provide favorable conditions for the nucleation and growth of dislocation loops, thereby enhancing the IAD within dislocation loops . Based on the obtained irradiation results, > > > , it can be inferred that the corresponding Ed values for the four irradiation directions follow the order .

Tanaka et al. [35] measured the Ed of pure Al along different crystallographic orientations at 120 °C using the dislocation loop growth method. Their results showed that among the [100], [110], and [111] directions, [100] exhibited the highest Ed of 17 eV, which is consistent with the inference in this study. The high Ed along the [100] implies that Al atoms in the crystal lattice are less likely to be displaced by electrons, reducing the probability of atomic displacement and resulting in a lower SIA concentration, Cd, in agreement with the lowest observed in the present work. Nevertheless, the minimum Ed reported by Tanaka et al. was along [111] (14 eV), rather than [110] (16 eV), which is inconsistent with our inference. For FCC metals, the [110] is generally considered to have the lowest Ed, as reported for Cu [37,41] and Ni [42,43]. Hohenstein et al. [44] noted that the relatively high electron energy used during irradiation in Tanaka et al.’s experiments leads to more complex electron–lattice interactions, introducing significant uncertainty in the derived threshold surface. They further noted that if the irradiation electron energy were adjusted to 150–180 keV, the direction of minimum Ed in Al would be expected to shift to [110].

In addition, irradiation temperature can significantly affect the measured Ed [41]. Studies on the temperature dependence of Ed in Cu indicate that Ed increases with temperature for all orientations within a certain range, with the increase being more pronounced for [100] and [110] than for [111] [45]. Therefore, we speculate that the experimental temperature of 120 °C in Tanaka et al.’s study likely caused a sharp decrease in Ed along [111], resulting in the observed minimum Ed in that orientation.

It should be noted that the relative magnitudes of Ed along different characteristic directions in pure Al at room temperature have yet to be determined by precise measurements using the dislocation loop growth method [36], resistivity method [46], or reduced-voltage method [30,37].

4.2. Effect of 1D Migration of <110> Dislocation Loops

Another noteworthy experimental observation is that, under the [110] irradiation condition, both the density of <110> dislocation loops () and the IAD within these loops () are anomalously low, as shown in Figure 5. The IAD contained in loops is affected by the loop type, density, and size, all of which are governed by the nucleation and growth behavior of loops during irradiation. In general, a higher loop nucleation rate tends to produce a larger loop density, whereas a higher loop growth rate leads to larger loop sizes.

The nucleation and growth of dislocation loops are influenced by multiple factors, including the production rate of SIAs during irradiation, the recombination rate between SIAs and vacancies [32,33,34], the sink bias of dislocation loops with different Burgers vectors, the diffusion of SIAs, and, in particular, the long-range one-dimensional migration. The 1D migration of dislocation loops has been observed in various metals, such as Al, Fe, and Cu [29,47,48,49,50,51,52]. During 1D migration, loops undergo rapid motion along their Burgers vector direction. Li et al. [29] reported that <110> loops in pure Al can experience fast 1D migration at room temperature under electron irradiation, with a maximum migration distance up to 1500 nm. Such long-range, high-velocity 1D migration of loops significantly enhances the diffusion and transport of SIAs.

In pure aluminum, the stacking fault energy is high, and <111> loops correspond to faulted Frank loops. Such loops do not exhibit 1D migration along their Burgers vector and can only evolve through climb. In contrast, <110> dislocation loops are capable of 1D migration along their Burgers vectors [16,50,52,53]. This 1D migration of <110> loops can strongly affect the observable loop density. In this study, among the four irradiation orientations examined, the influence of 1D migration on loop density is most pronounced under [110] irradiation. This is because the ±[110] directions, which are perpendicular to the specimen surface, are available for loop migration during irradiation along [110]. Considering that the long-range 1D migration distance of dislocation loops in Al can greatly exceed the thickness of a TEM foil, <110> loops migrating along ±[110] can readily escape to the specimen surface.

Therefore, the remarkably low IAD within <110> loops, , obtained after [110] irradiation, is very likely attributable to the long-range 1D migration-assisted escape of <110> dislocation loops to the foil surface.

5. Conclusions

The study employed a 200 keV TEM electron beam to conduct in situ irradiation experiments on pure aluminum along four different crystallographic orientations. All irradiations were performed at room temperature for a duration of 10 min. The main conclusions are as follows:

- (1)

- The total density of dislocation loops formed under the four irradiation directions decreases in the order [111] > [110] > [310] > [100]. Among them, the loop densities produced under [111] and [110] irradiation are similar, both approximately twice those under [100] irradiation. The average loop sizes are relatively close, with the following order from largest to smallest: [100] > [310] > [110] > [111].

- (2)

- A comparison between the two Burgers vector types, <111> and <110> dislocation loops, shows that for all irradiation directions, the <110> loops exhibit smaller diameters than the <111> loops. Under [100] and [310] irradiation, the density of <111> loops is lower than that of <110> loops, whereas the opposite trend is observed under [110] and [111] irradiation. In particular, under [110] irradiation, the density of <111> loops is nine times that of <110> loops. This behavior is attributed to the fact that <111> loops in aluminum are difficult to migrate, whereas <110> loops can undergo long-range one-dimensional migration, resulting in a lower retained density.

- (3)

- The calculated interstitial atom density contained within the loops shows that, for different irradiation directions, the interstitial density decreases in the order [110] > [111] > [310] > [100]. Based on these results, the threshold displacement energy, Ed, of pure aluminum under electron irradiation at room temperature is inferred to follow the crystallographic orientation dependence: .

Author Contributions

Y.Y.: Writing—original draft, investigation. Q.F.: Writing—original draft, formal analysis, investigation. W.H.: Writing—review and editing, methodology, funding acquisition, resources, supervision, conceptualization, formal analysis, validation. X.Y.: Writing—original draft, writing—review and editing. P.L.: Writing—original draft, writing—review and editing. K.Y.: Writing—original draft, writing—review and editing. K.I.: Writing—original draft, writing—review and editing. Q.Z.: Writing—original draft, writing—review and editing. S.O.: Writing—original draft, writing—review and editing. F.W.: Supervision, formal analysis, conceptualization. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the CGN-USTB Joint Research and Development Center for Advanced Energy Materials and Service Safety (Grant No. 39031060).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. A review: Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Santos, M.C.; Machado, A.R.; Sales, W.F.; Barrozo, M.A.S.; Ezugwu, E.O. Machining of aluminum alloys: A review. Int. J. Adv. Manuf. Technol. 2016, 86, 3067–3080. [Google Scholar] [CrossRef]

- Yost, B.; Weston, S. Structures, Materials, and Mechanisms; NASA Ames Research Center, Small Spacecraft Systems Virtual Institute: Moffett Field, CA, USA, 2025. Available online: https://www.nasa.gov/wp-content/uploads/2025/02/soa-2024.pdf (accessed on 20 December 2025).

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Ghidini, T. Materials for space exploration and settlement. Nat. Mater. 2018, 17, 846–850. [Google Scholar] [CrossRef]

- Nwankwo, V.U.; Jibiri, N.N.; Kio, M.T. The Impact of Space Radiation Environment on Satellites Operation in Near-Earth Space. In Satellites Missions and Technologies for Geosciences; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Xapsos, M.A.; O’Neill, P.M.; O’Brien, T.P. Near-Earth Space Radiation Models. IEEE Trans. Nucl. Sci. 2013, 60, 1691–1705. [Google Scholar] [CrossRef]

- Feynman, J.; Gabriel, S.B. High-Energy Charged Particles in Space at One Astronomical Unit. IEEE Trans. Nucl. Sci. 1996, 43, 344–352. [Google Scholar] [CrossRef]

- Jin, M.; Lee, B.; Yoo, J.; Jo, Y.; Lee, S. Cryogenic Deformation Behaviour of Aluminium Alloy 6061-T6. Met. Mater. Int. 2024, 30, 1492–1504. [Google Scholar] [CrossRef]

- Noh, Y.; Lee, M.-S.; Chaudry, U.M.; Jun, T.-S. Effect of strain rate on the deformation of 6061-T6 aluminum alloy at cryogenic temperature. Mater. Charact. 2023, 206, 113403. [Google Scholar] [CrossRef]

- Farrell, K. Microstructure and tensile properties of heavily irradiated 5052-0 aluminum alloy. J. Nucl. Mater. 1981, 97, 33–43. [Google Scholar] [CrossRef]

- Gussev, M.N.; Sridharan, N.; Babu, S.S.; Terrani, K.A. Influence of neutron irradiation on Al-6061 alloy produced via ultrasonic additive manufacturing. J. Nucl. Mater. 2021, 550, 152939. [Google Scholar] [CrossRef]

- Gillemot, F.; Kolluri, M.; Szenthe, I.; Naziris, F.; Berzy, L. Review of Radiation Embrittlement of Aluminum Alloys Used in Research Reactors. Materials 2025, 18, 5236. [Google Scholar] [CrossRef] [PubMed]

- Munitz, A. Neutron irradiation effects on commercial purity type A5 aluminum. J. Nucl. Mater. 1989, 165, 305–312. [Google Scholar] [CrossRef]

- Was, G.S. Fundamentals of Radiation Materials Science; Springer Nature: Durham, NC, USA, 2016. [Google Scholar] [CrossRef]

- Farong, W. Radiation Damage in Metallic Materials; University of Science and Technology of China Press: Hefei, China, 2025. [Google Scholar]

- Klecker, B. Energetic particle environment in near-Earth orbit. Adv. Space Res. 1996, 17, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Hudson, M.K. Earth’s Van Allen Radiation Belts: From Discovery to the Van Allen Probes Era. J. Geophys. Res. Space Phys. 2019, 124, 8319–8351. [Google Scholar] [CrossRef]

- Stassinopoulos, E.G.; Raymond, J.P. The space radiation environment for electronics. Proc. IEEE 1988, 76, 1423–1442. [Google Scholar] [CrossRef]

- Pham, K.D.; Cox, J.L.; Johnston, W.R.; O’Brien, T.P.; Ginet, G.P.; Huston, S.L.; Guild, T.B.; Fennelly, J.A. AE9/AP9/SPM: New models for radiation belt and space plasma specification. In Proceedings of the Sensors and Systems for Space Applications VII; SPIE: Bellingham, WA, USA, 2014. [Google Scholar] [CrossRef]

- Abel, B.; Thorne, R.M.; Vampola, A.L. Energetic electron precipitation from the inner zone. Geophys. Res. Lett. 1997, 24, 1983–1986. [Google Scholar] [CrossRef]

- Van Allen, J.A.; Frannk, L.A. Radiation around the Earth to a radial distance of 107,400 km. Nature 1959, 183, 430–434. [Google Scholar] [CrossRef]

- Zhang, Y.; Hong, S.; Xie, X.; Jia, Y.; Diao, S.; Wang, J.; Xu, C. Selective evolution of <111> and <110> and dislocation loops in pure aluminum governed by grain boundaries during in situ irradiation. Phys. Scr. 2025, 100, 125940. [Google Scholar] [CrossRef]

- Wang, T.; Liu, P.; Jiang, S.; Wang, S.; Wang, S.; Fu, Y.; Chen, F.; Yi, X.; Han, W.; Zhan, Q.; et al. Experimental measurement of threshold displacement energy in beryllium. Scr. Mater. 2025, 268, 116891. [Google Scholar] [CrossRef]

- Dong, S.; Liu, H.; Yi, X.; Liu, P.; Ohkubo, K.; Han, W.; Ohnuki, S.; Hashimoto, N.; Wan, F. On the formation and evolution dynamics of electron irradiation defects in magnesium using high-voltage electron microscopy. J. Alloys Compd. 2025, 1044, 184501. [Google Scholar] [CrossRef]

- Yu, H.; Yi, X.; Chen, Q.; Fang, H.; Dong, S.; Li, S.; Han, W.; Liu, P.; Ohnuki, S.; Wan, F. Low-dose damage evolution in pure magnesium under electron irradiation: Effect of foil orientation and pre-existing dislocations. Nucl. Mater. Energy 2025, 42, 101845. [Google Scholar] [CrossRef]

- Simpson, H.M.; Chaplin, R.L. Damage and Recovery of Aluminum for Low-Energy Electron Irradiations. Phys. Rev. J. Arch. 1969, 185, 958–961. [Google Scholar] [CrossRef]

- Neely, H.H.; Bauer, W. Electron-Irradiation Damage-Rate Measurements in Aluminum. Phys. Rev. 1966, 149, 535–539. [Google Scholar] [CrossRef]

- Li, R.; Yi, X.; Han, W.; Liu, P.; Zhan, Q.; Matsukawa, Y.; Watanabe, H.; Wan, F. Micron-scale 1D migration of interstitial-type dislocation loops in aluminum. Mater. Charact. 2023, 203, 113149. [Google Scholar] [CrossRef]

- Yin, Y.; Zhan, R.; Du, Y.; Xu, C.; Ohnuki, S.; Wan, F.; Han, W. Evaluation of electron threshold energy for predicting radiation damage in transmission electron microscopy. Ultramicroscopy 2025, 280, 114279. [Google Scholar] [CrossRef]

- Mingler, B.; Karnthaler, H.P. Radiation damage during HRTEM studies in pure Al and Al alloys. Int. J. Mater. Res. 2022, 97, 1041–1045. [Google Scholar] [CrossRef]

- Du, Y.-F.; Cui, L.-J.; Li, J.-S.; Li, R.-R.; Wan, F.-R. Anomalous heat-releasing phenomenon from bubbles in aluminum induced by electron beam irradiation. Acta Phys. Sin. 2018, 67, 216101. [Google Scholar] [CrossRef]

- Li, J.; Gao, J.; Wan, F.-R. The change of microstructure in deuteron-implanted aluminum under electron irradiation. Acta Phys. Sin. 2016, 65, 026102. [Google Scholar] [CrossRef]

- Chen, Q.; Yin, Y.; Han, W.; Yi, X.; Liu, P.; Zhan, Q.; Ohnuki, S.; Wan, F. A review on the anomalous exothermic behavior of bubbles in aluminum induced by electron irradiation. J. Mater. Res. Technol. 2025, 35, 1283–1295. [Google Scholar] [CrossRef]

- Tanaka, K.; Shimomura, Y. Dependence of the Growth Rate of Interstitial Loops on Irradiated Crystallographic Directions in Electron Irradiated Pure Aluminum. Jpn. J. Appl. Phys. 1981, 20, 1393–1399. [Google Scholar] [CrossRef]

- Yoshida, N.; Urban, K. Direct evidence for a very low atom displacement threshold energy around the <110> directions in copper. Phys. Lett. A 1977, 63, 381–383. [Google Scholar] [CrossRef]

- Kenik, E.A.; Mitchell, T.E. Orientation dependence of the threshold displacement energy in copper and vanadium. Philos. Mag. 1975, 32, 815–831. [Google Scholar] [CrossRef]

- Jung, P.; Schilling, W. Anisotropy of the Threshold Energy for the Production of Frenkel Pairs in Tantalum. Phys. Rev. B 1972, 5, 2046–2056. [Google Scholar] [CrossRef]

- Figgins, B.F.; Jones, G.O.; Riley, D.P. LXXVII.The thermal expansion of aluminium at low temperatures as measured by an X-ray diffraction method. Philos. Mag. 1956, 1, 747–758. [Google Scholar] [CrossRef]

- Norgett, M.J.; Robinson, M.T.; Torrens, I.M. A proposed method of calculating displacement dose rates. Nucl. Eng. Des. 1975, 33, 50–54. [Google Scholar] [CrossRef]

- Urban, K.; Yoshida, N. The threshold energy for atom displacement in irradiated copper studied by high-voltage electron microscopy. Philos. Mag. A 1981, 44, 1193–1212. [Google Scholar] [CrossRef]

- Bourret, A. Irradiation damage in nickel and iron in a high-voltage electron microscope and threshold energy determination. Phys. Status Solidi A 1971, 4, 813–825. [Google Scholar] [CrossRef]

- Jan, R.V.; Seeger, A. Zur Deutung der Tieftemperatur-Elektronenbestrahlung von Metallen. Phys. Status Solidi B 1963, 3, 465–472. [Google Scholar] [CrossRef]

- Hohenstein, M.; Seeger, A.; Sigle, W. The anisotropy and temperature dependence of the threshold for radiation damage in gold-comparison with other FCC metals. J. Nucl. Mater. 1989, 169, 33–46. [Google Scholar] [CrossRef]

- Sigle, W.; Seeger, A. Temperature Dependence of the Threshold Energy for Atom Displacements in Cu. Phys. Status Solidi A 1994, 146, 57–69. [Google Scholar] [CrossRef]

- Kamada, K.; Kazumata, Y.; Suda, S. Displacement Threshold Energy and Focuson-Impurity Interaction in Copper near 10 °K. Phys. Status Solidi B 1964, 7, 231–239. [Google Scholar] [CrossRef]

- Hayashi, T.; Fukmuto, K.; Matsui, H. In situ observation of glide motions of SIA-type loops in vanadium and V–5Ti under HVEM irradiation. J. Nucl. Mater. 2002, 307–311, 993–997. [Google Scholar] [CrossRef]

- Satoh, Y.; Abe, H.; Matsukawa, Y.; Matsunaga, T.; Kano, S.; Arai, S.; Yamamoto, Y.; Tanaka, N. One-dimensional migration of interstitial clusters in SUS316L and its model alloys at elevated temperatures. Philos. Mag. 2015, 95, 1587–1606. [Google Scholar] [CrossRef]

- Satoh, Y.; Matsui, H. Obstacles for one-dimensional migration of interstitial clusters in iron. Philos. Mag. 2009, 89, 1489–1504. [Google Scholar] [CrossRef]

- Ono, K.; Miyamoto, M.; Yamahaku, K. In-Situ observation of the dynamic behavior of cascade defect clusters formed by irradiation with high-energy self-ions at 50 K in Cu. J. Nucl. Mater. 2018, 511, 122–127. [Google Scholar] [CrossRef]

- Arakawa, K.; Marinica, M.C.; Fitzgerald, S.; Proville, L.; Nguyen-Manh, D.; Dudarev, S.L.; Ma, P.W.; Swinburne, T.D.; Goryaeva, A.M.; Yamada, T.; et al. Quantum de-trapping and transport of heavy defects in tungsten. Nat. Mater. 2020, 19, 508–511. [Google Scholar] [CrossRef]

- Matsukawa, Y.; Zinkle, S.J. One-Dimensional Fast Migration of Vacancy Clusters in Metals. Science 2007, 318, 959–962. [Google Scholar] [CrossRef]

- Wan, F. Clusters of point defects and one-dimensional motion of clusters during irradiation damage in materials. Chin. J. Eng. 2020, 42, 1535–1541. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.