In-Situ Growth of Carbon Nanotubes on MOF-Derived High-Entropy Alloys with Efficient Electromagnetic Wave Absorption

Abstract

1. Introduction

2. Experimental Procedure

2.1. Synthesis of HEF@CNT

2.2. Microstructure Characterization

2.3. Electromagnetic Properties

3. Results and Discussion

3.1. Phase and Microstructure

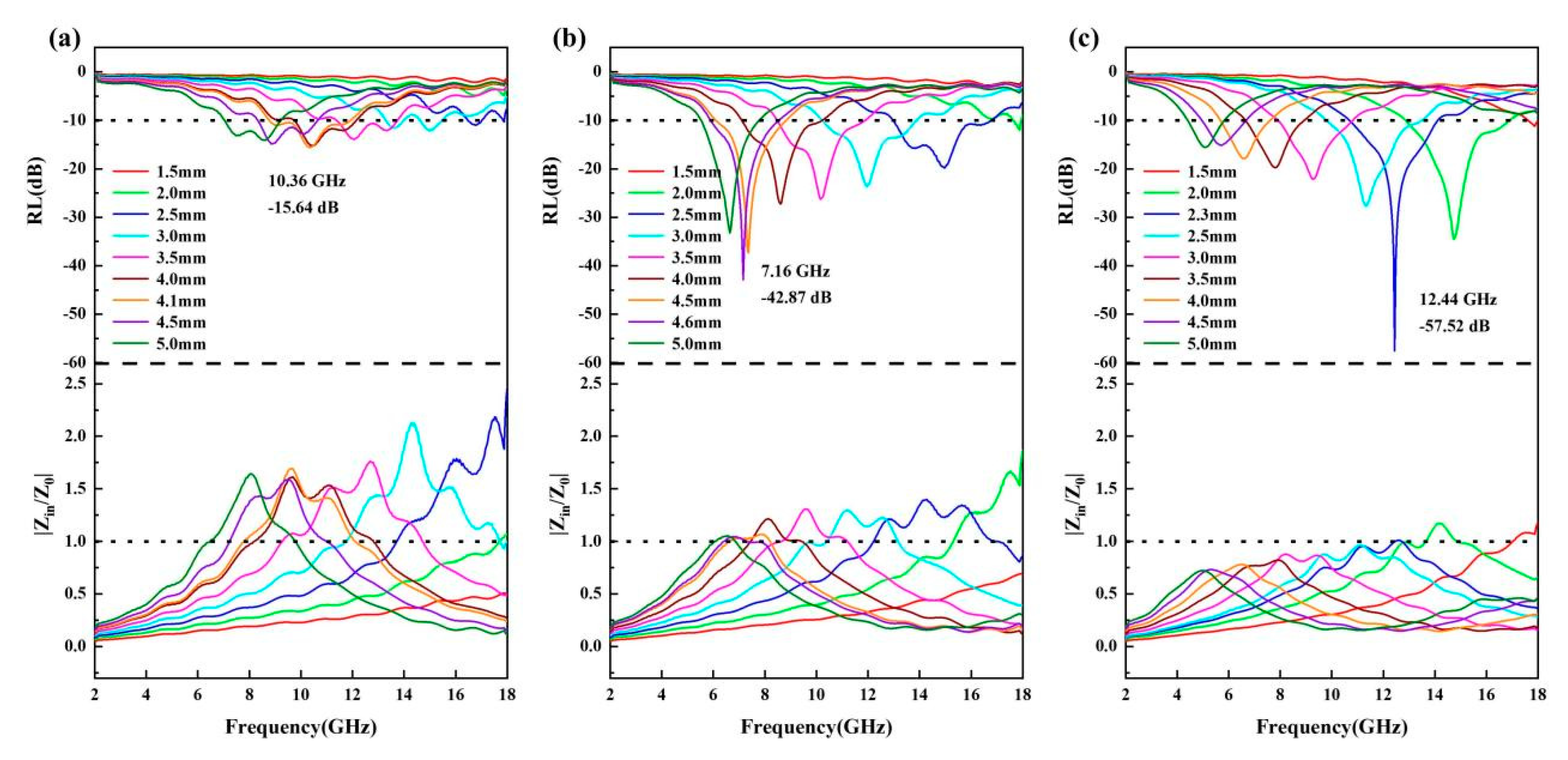

3.2. Electromagnetic Wave Absorption Performances

3.3. Electromagnetic Wave Absorption Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Lv, X.; Cui, G.; Sui, M.; Sun, X.; Yu, S. Direct Growth of a Polypyrrole Aerogel on Hollow CuS Hierarchical Microspheres Yields Particles with Excellent Electromagnetic Wave Properties. Polymers 2018, 10, 1286. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhang, Z.; Wang, L.; Xi, K.; Cao, Q.; Wang, D.; Yang, Y.; Du, Y. Excellent microwave absorption property of Graphene-coated Fe nanocomposites. Sci. Rep. 2013, 3, 3421. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Chen, H.; Wang, L.; An, L.; Qin, X.; Zhou, G. AlN/FeNi Microwave-Attenuating Ceramics with High-Efficiency Thermal Conductivity and Microwave Absorption. Materials 2025, 18, 367. [Google Scholar] [CrossRef]

- Ren, X.; Zhen, M.; Meng, F.; Meng, X.; Zhu, M. Progress, Challenges and Prospects of Biomass-Derived Lightweight Carbon-Based Microwave-Absorbing Materials. Nanomaterials 2025, 15, 553. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Huang, J.; Wang, X.; Li, J.; Yin, X.; Xu, Z.; Xiong, K. Microstructure and enhanced electromagnetic wave absorbing performance of Zn0.6Ni0.3Cu0.1Fe2O4 ferrite glass-ceramic. Ceram. Int. 2022, 48, 9090–9098. [Google Scholar] [CrossRef]

- Ma, J.; Zhao, B.; Xiang, H.; Dai, F.-Z.; Liu, Y.; Zhang, R.; Zhou, Y. High-entropy spinel ferrites MFe2O4 (M = Mg, Mn, Fe, Co, Ni, Cu, Zn) with tunable electromagnetic properties and strong microwave absorption. J. Adv. Ceram. 2022, 11, 754–768. [Google Scholar] [CrossRef]

- Chang, Q.; Xie, Z.; Shi, B.; Wu, H. Symbiotic strategy of Cu on CuFe2O4 realizing high-efficiency electromagnetic wave absorption. J. Colloid Interface Sci. 2023, 645, 841–849. [Google Scholar] [CrossRef]

- Yang, F.; Yao, J.; Shen, Z.; Ma, Q.; Peng, G.; Zhou, J.; Yao, Z.; Tao, X. Multifunctional carbon nanotubes-based hybrid aerogels with high-efficiency electromagnetic wave absorption at elevated temperature. J. Colloid Interface Sci. 2023, 638, 843–854. [Google Scholar] [CrossRef]

- Gao, H.; Qin, L.; Tao, S.; Xiong, Z.; Wu, F.; Lei, M. Multiple tuned carbon nanotubes by rare earth oxides for high-efficiency electromagnetic wave absorption. Adv. Compos. Hybrid Mater. 2024, 7, 135. [Google Scholar] [CrossRef]

- Luo, J.; Yan, W.; Li, X.; Shu, P.; Mei, J.; Shi, Y. Carbon nanotubes decorated FeNi/nitrogen-doped carbon composites for lightweight and broadband electromagnetic wave absorption. J. Mater. Sci. Technol. 2023, 158, 207–217. [Google Scholar] [CrossRef]

- Hou, W.; Peng, K.; Li, S.; Huang, F.; Wang, B.; Yu, X.; Yang, H.; Zhang, H. Designing flower-like MOFs-derived N-doped carbon nanotubes encapsulated magnetic NiCo composites with multi-heterointerfaces for efficient electromagnetic wave absorption. J. Colloid Interface Sci. 2023, 646, 265–274. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Lian, X.; Yao, Y.; Xiong, Z.; Duan, Y.; Wang, J.; Fu, S.; Dai, Y.; Zhou, W.; Zhang, Z. A Hybrid Perovskite-Based Electromagnetic Wave Absorber with Enhanced Conduction Loss and Interfacial Polarization through Carbon Sphere Embedding. Nanomaterials 2024, 14, 1566. [Google Scholar] [CrossRef]

- Li, G.; Zhao, H.; Wang, H.; Zhou, Z.; Gao, L.; Su, W.; Dong, C. Enhanced microwave absorption performances of FeCoNiCuCr high entropy alloy by optimizing particle size dehomogenization. J. Alloys Compd. 2023, 941, 168822. [Google Scholar] [CrossRef]

- Feng, S.; Wen, S.; Wang, R.; Yang, X.; Yuan, X.; Liu, Y.; Ma, J.; Li, Z. MXene/MOF-Derived Composites with Multidimensional Nanostructures: Synthesis Methods, Performance, and Applications in the Field of Energy Storage. Nanomaterials 2025, 15, 841. [Google Scholar] [CrossRef]

- Cao, K.; Ye, W.; Zhang, Y.; Chen, Z.; Zhao, R.; Xue, W. Fabrication of MOF-rGO aerogels to enhance electromagnetic wave absorption by adjusting the morphology and structure of MOFs by electron transfer. Chem. Eng. J. 2024, 489, 151384. [Google Scholar] [CrossRef]

- Luo, J.; Li, X.; Yan, W.; Shu, P.; Mei, J. RGO supported bimetallic MOFs-derived Co/MnO/porous carbon composite toward broadband electromagnetic wave absorption. Carbon 2023, 205, 552–561. [Google Scholar] [CrossRef]

- Tan, L.; Han, J.; Wang, C.; Zhang, G.; Feng, H.; Chen, N.; Zhao, D. MOFs-derived Co/C nanoparticle embedded in N, S co-doped graphene for superior electromagnetic wave absorption capacity. Ceram. Int. 2024, 50, 10016–10025. [Google Scholar] [CrossRef]

- Wang, X.; Luo, J.; Zhao, H.; Wu, Y.; Liu, X.; Xie, Y. LaFe-MOFs derivatives with different compositions for boosting low-frequency and broadband electromagnetic wave absorption. Mater. Today Nano 2024, 28, 100528. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Pei, K.; Li, B.; You, W.; Yang, L.; Zhou, G.; Zhang, J.; Liang, C.; Che, R. Heterogeneous Interface Engineering of Bi-Metal MOFs-derived ZnFe2 O4 –ZnO-Fe@C Microspheres via Confined Growth Strategy Toward Superior Electromagnetic Wave Absorption. Adv. Funct. Mater. 2024, 34, 2308898. [Google Scholar] [CrossRef]

- Wu, T.; Ren, F.; Guo, Z.; Wang, J.; Zong, Z.; Wang, L.; Jin, Y.; Chen, Z.; Ren, P. Hierarchical Assembly of Ternary MOF-Derived Sandwich Composites for High-Efficiency Tunable Electromagnetic Wave Absorption. Small 2024, 20, 2407599. [Google Scholar] [CrossRef]

- Huang, M.; Li, B.; Qian, Y.; Wang, L.; Zhang, H.; Yang, C.; Rao, L.; Zhou, G.; Liang, C.; Che, R. MOFs-Derived Strategy and Ternary Alloys Regulation in Flower-Like Magnetic-Carbon Microspheres with Broadband Electromagnetic Wave Absorption. Nano-Micro Lett. 2024, 16, 245. [Google Scholar] [CrossRef]

- Man, Q.; Lei, Z.; Wang, A.; Zheng, C.; Zhuang, X.; Tan, G.; Chen, S.; Hou, J.; Ning, M.; Li, R.-W. In situ-derived carbon nanotubes decorated the surface of CoxNiy@C composites from MOFs for efficient electromagnetic wave absorption. J. Alloys Compd. 2023, 932, 167726. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Y.; Chen, Z.; Zhang, Y.; Yang, B.; Xie, F.; Gong, X.; Zhang, T.; Huang, X. A simple co-doping strategy to synthesis of Ni@B/N carbon nanotubes with broadband and low-frequency electromagnetic wave absorption. Chem. Eng. J. 2024, 483, 149151. [Google Scholar] [CrossRef]

- Xiao, J.; Wen, B.; Liu, X.; Chen, Y.; Niu, J.; Yang, S.; Yuan, W.; Yu, M.; Yang, G.; Ding, S. In-situ growth of carbon nanotubes for the modification of wood-derived biomass porous carbon to achieve efficient Low/Mid-Frequency electromagnetic wave absorption. J. Colloid Interface Sci. 2024, 676, 33–44. [Google Scholar] [CrossRef]

- Zhan, Y.; Xia, L.; Yang, H.; Zhou, N.; Ma, G.; Zhang, T.; Huang, X.; Xiong, L.; Qin, C.; Guangwu, W. Tunable electromagnetic wave absorbing properties of carbon nanotubes/carbon fiber composites synthesized directly and rapidly via an innovative induction heating technique. Carbon 2021, 175, 101–111. [Google Scholar] [CrossRef]

- Kong, L.; Qi, J.; Li, M.; Chen, X.; Yuan, X.; Wang, T.; Yang, J.; Huang, J.; Fan, X. Electromagnetic wave absorption properties of Ti3C2Tx nanosheets modified with in-situ growth carbon nanotubes. Carbon 2021, 183, 322–331. [Google Scholar] [CrossRef]

- Weng, J.; Liu, Y.; Huang, X. Synthesis of in situ grown CNTs on MOF-derived Ni@CNT with tailorable microstructures toward regulation of electromagnetic wave absorption performance. Carbon 2025, 231, 119678. [Google Scholar] [CrossRef]

- Pan, F.; Liu, Z.; Deng, B.; Dong, Y.; Zhu, X.; Huang, C.; Lu, W. Lotus Leaf-Derived Gradient Hierarchical Porous C/MoS2 Morphology Genetic Composites with Wideband and Tunable Electromagnetic Absorption Performance. Nano-Micro Lett. 2021, 13, 43. [Google Scholar] [CrossRef]

- Xue, D.; Guo, Y.; Lu, B.; Xia, H.; Yan, W.; Xue, D.; Mu, S.; Zhang, J. Monomicelle-Directed Engineering of Strained Carbon Nanoribbons as Oxygen Reduction Catalyst. Adv. Sci. 2023, 10, 2302930. [Google Scholar] [CrossRef] [PubMed]

- Anju; Yadav, R.S.; Pötschke, P.; Pionteck, J.; Krause, B.; Kuřitka, I.; Vilcakova, J.; Skoda, D.; Urbánek, P.; Machovsky, M.; et al. High-Performance, Lightweight, and Flexible Thermoplastic Polyurethane Nanocomposites with Zn2+-Substituted CoFe2O4 Nanoparticles and Reduced Graphene Oxide as Shielding Materials against Electromagnetic Pollution. ACS Omega 2021, 6, 28098–28118. [Google Scholar] [CrossRef]

- Qi, X.; Hu, Q.; Cai, H.; Xie, R.; Bai, Z.; Jiang, Y.; Qin, S.; Zhong, W.; Du, Y. Heteronanostructured Co@carbon nanotubes-graphene ternary hybrids: Synthesis, electromagnetic and excellent microwave absorption properties. Sci. Rep. 2016, 6, 37972. [Google Scholar] [CrossRef]

- Wei, B.; Zhou, J.; Yao, Z.; Haidry, A.A.; Guo, X.; Lin, H.; Qian, K.; Chen, W. The effect of Ag nanoparticles content on dielectric and microwave absorption properties of β-SiC. Ceram. Int. 2020, 46, 5788–5798. [Google Scholar] [CrossRef]

- Yu, M.; Li, S.; Ren, X.; Liu, N.; Guo, W.; Xue, J.; Tan, L.; Fu, C.; Wu, Q.; Niu, M.; et al. Magnetic Bimetallic Heterointerface Nanomissiles with Enhanced Microwave Absorption for Microwave Thermal/Dynamics Therapy of Breast Cancer. ACS Nano 2024, 18, 3636–3650. [Google Scholar] [CrossRef]

- Xu, C.; Liu, P.; Wu, Z.; Zhang, H.; Zhang, R.; Zhang, C.; Wang, L.; Wang, L.; Yang, B.; Yang, Z.; et al. Customizing Heterointerfaces in Multilevel Hollow Architecture Constructed by Magnetic Spindle Arrays Using the Polymerizing-Etching Strategy for Boosting Microwave Absorption. Adv. Sci. 2022, 9, 2200804. [Google Scholar] [CrossRef]

- Wang, J.; Ren, J.; Li, Q.; Liu, Y.; Zhang, Q.; Zhang, B. Synthesis and microwave absorbing properties of N-doped carbon microsphere composites with concavo-convex surface. Carbon 2021, 184, 195–206. [Google Scholar] [CrossRef]

- He, L.; Zhao, Y.; Xing, L.; Liu, P.; Wang, Z.; Zhang, Y.; Wang, Y.; Du, Y. Preparation of reduced graphene oxide coated flaky carbonyl iron composites and their excellent microwave absorption properties. RSC Adv. 2018, 8, 2971–2977. [Google Scholar] [CrossRef]

- Qiu, Y.; Lin, Y.; Yang, H.; Wang, L.; Wang, M.; Wen, B. Hollow Ni/C microspheres derived from Ni-metal organic framework for electromagnetic wave absorption. Chem. Eng. J. 2020, 383, 123207. [Google Scholar] [CrossRef]

- Li, W.; Guo, F.; Zhao, Y.; Liu, Y. A Sustainable and Low-Cost Route to Design NiFe2O4 Nanoparticles/Biomass-Based Carbon Fibers with Broadband Microwave Absorption. Nanomaterials 2022, 12, 4063. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Yang, P.; Li, Y.; Wen, D.; Luo, J.; Wang, S.; Wu, F.; Fang, L.; Pang, Y. A Facile Synthesis of NiFe-Layered Double Hydroxide and Mixed Metal Oxide with Excellent Microwave Absorption Properties. Molecules 2021, 26, 5046. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Xu, L.; Xie, C.; Guo, L.; Zhang, L.; Guo, S.; Peng, J. Synthesis of CuCo2S4@Expanded Graphite with crystal/amorphous heterointerface and defects for electromagnetic wave absorption. Nat. Commun. 2023, 14, 5951. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Y.; Wei, Y.; Li, Y.; Li, F.; Li, B.; Wu, Q.; Zhao, J. Enhancement of microwave absorption performance of porous carbon induced by Ce(CO3)OH. Front. Chem. 2023, 10, 1100111. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, K.; Li, X.; Dong, W.; Wang, S.; Zhou, Y.; Wang, H. Natural iron embedded hierarchically porous carbon with thin–thickness and high-efficiency microwave absorption properties. RSC Adv. 2020, 10, 38989–38999. [Google Scholar] [CrossRef]

- Wen, B.; Miao, Y.; Zhang, Z.; Li, N.; Xiao, J.; Li, Y.; Feng, J.; Ding, S.; Yang, G. Tuning Electromagnetic Parameters Induced by Synergistic Dual-Polarization Enhancement Mechanisms with Amorphous Cobalt Phosphide with Phosphorus Vacancies for Excellent Electromagnetic Wave Dissipation Performance. Nanomaterials 2023, 13, 3025. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, Z.; Xu, C.; Yang, B.; Wang, L.; You, W.; Che, R. Hierarchical Ti3C2Tx MXene/Carbon Nanotubes Hollow Microsphere with Confined Magnetic Nanospheres for Broadband Microwave Absorption. Small 2022, 18, 2104380. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, L.; Zhao, W.; Wang, T.; Yuan, L.; Guo, Y.; Xie, Y.; Cheng, T.; Meng, A.; Li, Z. Boosted electromagnetic wave absorption performance from synergistic induced polarization of SiCNWs@MnO2@PPy heterostructures. Nano Res. 2022, 16, 3558–3569. [Google Scholar] [CrossRef]

- Feng, Z.; Liu, C.; Li, X.; Luo, G.; Zhai, N.; Hu, R.; Lin, J.; Peng, J.; Peng, Y.; Che, R. Designing Electronic Structures of Multiscale Helical Converters for Tailored Ultrabroad Electromagnetic Absorption. Nano-Micro Lett. 2025, 17, 20. [Google Scholar] [CrossRef]

- Afzali, S.-S.; Hekmatara, S.H.; Seyed-Yazdi, J.; Hosseini, S.M.B.M. Tuned MWCNT/CuO/Fe3O4/Polyaniline nanocomposites with exceptional microwave attenuation and a broad frequency band. Sci. Rep. 2022, 12, 9590. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Gu, W.; Wu, Y.; Zhang, B.; Wang, G.; Yang, Y.; Ji, G. Heterointerface Engineering in Electromagnetic Absorbers: New Insights and Opportunities. Adv. Mater. 2022, 34, 2106195. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhao, X.; Xu, L.; Peng, Q.; He, X. A Novel Hierarchically Lightweight Porous Carbon Derived from Egg White for Strong Microwave Absorption. Engineering 2022, 18, 161–172. [Google Scholar] [CrossRef]

- Qin, G.; Li, Y.; Zhou, W.; Xu, H.; Hu, F.; Zhou, X. In Situ Grown 1D/2D Structure of Dy3Si2C2 on SiCw for Enhanced Electromagnetic Wave Absorption. Materials 2023, 16, 3455. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Ma, S.; Li, Z.; Zhang, Y.; Diao, J.; Xia, L.; Zhang, Z.; Huang, Y. High-Quality Ferromagnet Fe3GeTe2 for High-Efficiency Electromagnetic Wave Absorption and Shielding with Wideband Radar Cross Section Reduction. ACS Nano 2022, 16, 7861–7879. [Google Scholar] [CrossRef] [PubMed]

- Qiao, L.; Bi, J.; Liang, G.; Liu, C.; Yin, Z.; Yang, Y.; Wang, H.; Wang, S.; Shang, M.; Wang, W. Synthesis and electromagnetic wave absorption performances of a novel (Mo0.25Cr0.25Ti0.25V0.25)3AlC2 high-entropy MAX phase. J. Mater. Sci. Technol. 2023, 137, 112–122. [Google Scholar] [CrossRef]

- Duan, Y.; Pang, H.; Wen, X.; Zhang, X.; Wang, T. Microwave absorption performance of FeCoNiAlCr0.9 alloy powders by adjusting the amount of process control agent. J. Mater. Sci. Technol. 2021, 77, 209–216. [Google Scholar] [CrossRef]

- Wu, P.; Kong, X.; Feng, Y.; Ding, W.; Sheng, Z.; Liu, Q.; Ji, G. Phase Engineering on Amorphous/Crystalline γ-Fe2O3 Nanosheets for Boosting Dielectric Loss and High-Performance Microwave Absorption. Adv. Funct. Mater. 2024, 34, 2311983. [Google Scholar] [CrossRef]

- Pang, H.; Duan, Y.; Gao, M.; Huang, L.; Liu, X.; Li, Z. Electromagnetic wave absorption performance of FeCoNiMn0.5Al0.2 high entropy alloys governed by nanocrystal evolution. Mater. Today Nano 2022, 20, 100243. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.; Bai, G.; Liu, X. Constructing FeCoNiCrAl high entropy alloys with tunable nanograin size and crystal structure to boost polarization loss for enhanced microwave absorption performances. J. Mater. Res. 2024, 39, 248–261. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Xiang, Z.; Zhu, X.; Dong, Y.; Huang, C.; Cai, L.; Lu, W. Biconical prisms Ni@C composites derived from metal-organic frameworks with an enhanced electromagnetic wave absorption. Carbon 2021, 184, 115–126. [Google Scholar] [CrossRef]

- Liu, Z.; Zeng, Y.; Long, L.; Li, Y.; Zhou, W. Lightweight UiO-66 MOF/CNT composites achieving high electromagnetic wave absorption. Diam. Relat. Mater. 2025, 157, 112500. [Google Scholar] [CrossRef]

- Liu, B.; Liang, B.; Xiao, J.; Feng, M.; Cheng, H.; Li, Y.; Cheng, Y.; Zhang, K. MOF derived NiFe@C composites with controllable multi-dimensional microstructures for broadband microwave absorption. Compos. Part Appl. Sci. Manuf. 2024, 176, 107869. [Google Scholar] [CrossRef]

- Fang, Y.; Dong, C.; Wang, W.; Liang, X.; Fang, M.; Zhang, Y.; Han, R. Broadband Microwave-Absorbing GO-CNT Nanocomposites Enabled by Synergistic FeCoNi Ternary Catalysis. Nanoscale 2025. accepted manuscript. [Google Scholar] [CrossRef]

- Duan, Y.; Pang, H.; Zhang, H. Structure and composition design on ternary CNT@ZnFe2O4@ZnO composite utilized as enhanced microwave absorbing materials. Diam. Relat. Mater. 2021, 120, 108701. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Wang, Z.; Meng, B.; Ping, X.; Yang, Q.; Wang, K.; Wang, S. In-Situ Growth of Carbon Nanotubes on MOF-Derived High-Entropy Alloys with Efficient Electromagnetic Wave Absorption. Materials 2026, 19, 239. https://doi.org/10.3390/ma19020239

Wang Z, Meng B, Ping X, Yang Q, Wang K, Wang S. In-Situ Growth of Carbon Nanotubes on MOF-Derived High-Entropy Alloys with Efficient Electromagnetic Wave Absorption. Materials. 2026; 19(2):239. https://doi.org/10.3390/ma19020239

Chicago/Turabian StyleWang, Zhongjing, Bin Meng, Xingyu Ping, Qingqing Yang, Kang Wang, and Shuo Wang. 2026. "In-Situ Growth of Carbon Nanotubes on MOF-Derived High-Entropy Alloys with Efficient Electromagnetic Wave Absorption" Materials 19, no. 2: 239. https://doi.org/10.3390/ma19020239

APA StyleWang, Z., Meng, B., Ping, X., Yang, Q., Wang, K., & Wang, S. (2026). In-Situ Growth of Carbon Nanotubes on MOF-Derived High-Entropy Alloys with Efficient Electromagnetic Wave Absorption. Materials, 19(2), 239. https://doi.org/10.3390/ma19020239