Abstract

Piezoelectric materials (PZTs) enjoy extensive applications in the field of electromechanical sensors due to their sensitive response to external electric fields. The limited piezoelectric response for single-layer piezoceramic pellets drives the use of multilayered technology to increase the electric displacement of a single piezo device. As is well known, Ag is commonly used as a metal for electrodes in devices based on traditional PZTs, which always densify at a high temperature above 1100 °C, resulting in Ag migration. Here, a high-performance samarium-ion-doped Sm0.01Pb0.99(Zr0.54Ti0.46)O3 ceramic was selected as parent materials to develop a new Ag-cofired ceramic matrix with a sintering temperature of 920 °C by glass flux. The ceramic composition with 2.0 wt% glass addition exhibits the excellent performance of piezoelectric d33~492 pC/N, planar electromechanical coupling coefficient kp~50.1%, mechanical quality factor Qm~68.71, and Curie temperature Tc~356 °C, respectively. The cyclic stability of d33 was measured below 6.6% at 30 kV/cm, which indicates that the piezoceramic has good temperature stability and fatigue resistance. Therefore, this study provides a novel high-performance piezoelectric system to meet the cofired requirement for multilayered piezoelectric devices.

1. Introduction

Piezoelectric materials possess a critical electrical characteristic that can directly convert energy between mechanical energy and electrical energy. This capability finds applications in various fields, including biomedicine, consumer electronics, and defense technology. Typically, Pb(Zr,Ti)O3-based ceramics are widely taken as core materials in the manufacturing of piezoelectric devices due to their excellent electromechanical responses, such as sensors, transducers, electrostatic capacitors, and power sub-devices [1,2,3,4].

Element doping has been an effective way to elevate the performance of Pb(Zr,Ti)O3-based piezoelectric ceramics. There are three kinds of doping methods: donor doping, acceptor doping, and equivalent doping [5,6]. Among them, rare-earth elements are promising dopants used in PZT ceramics, such as La [7,8,9], Er [10,11,12], Gd [13,14], Eu [15,16], Nd [17,18]. Among these rare-earth doping, Sm has shown good modification effects in recent studies. For example, Li et al. [11] synthesized a Sm3+-modified Pb(Mg1/3Nb2/3)O3-PbTiO3 piezoceramic with a Curie temperature of 89 °C and found that the piezoelectric performance of the Sm-PMN-PT piezoelectric ceramic was significantly improved compared to as-known piezoelectric ceramics. Shruti et al. [19] developed a 2 at% Sm-doped PZT composition in the Tc region, achieving a large d33 of 915 pm/V. The exceptionally high piezoelectricity could be ascribed to Sm doping, which could induce a series of microscopic changes, such as increased internal stress, interphase boundary motion, and increased energy for domain wall movement. Guo et al. [20] prepared Sm-modified 0.4Pb(Mg1/3Nb2/3)O3-(0.6-x)PbZrO3-xPbTiO3 piezoceramics by introducing PbZrO3 with Tc = 232 °C to form a ternary system. At x = 0.352, Both εr of 4090, Tc of 184 °C, and d33 of 910 pC/N can be achieved due to synergistic effects of morphotropic phase boundary (MPB) and the increased local structural heterogeneity.

The creation of multilayer piezoelectric ceramic devices can fulfill the demands for miniaturization, reduce driving electric fields, and be cost-effective in products that utilize base metal electrodes. Commonly, Ag (melting point~961.8 °C) is selected as an internal electrode in multilayered piezoelectric devices [21]. So, the reduction in sintering temperature is needed for the piezoelectric matrix. Numerous attempts have been made, such as liquid phase additives [22,23], nanosized raw materials [24,25], and the cold sintering method [26,27]. A common method involves adding flux to create a liquid phase, which facilitates the dissolution and migration of materials and accelerates grain growth. A variety of additives can be selected as modifiers, such as B2O3 [28,29], CuO [30,31], Bi2O3 [8,32], ZnO [33,34], glass [35,36], and so on. For instance, Nan et al. [37] investigated the effects of lithium carbonate on the sintering behavior, microstructure, and functional properties of Ba0.85Ca0.15Zr0.1Ti0.9O3 piezoceramics by the sol–gel method. The results showed that the addition of 0.5 wt% Li2CO3 significantly could enhance the sintering density and reduce the sintering temperature near 1300 °C. Dai et al. [38] reported that adding 0.7 wt% CdCO3 could effectively reduce the sintering temperature of the 0.8Pb(Zr0.48Ti0.52)O3-0.125Pb(Zn1/3Nb2/3)O3-0.075Pb(Mn1/3Nb2/3)O3 ceramics from 1150 °C to 980 °C. A low sintering temperature of 940 °C was selected by Lin et al. [39] in PZT-based piezoelectric ceramics, and excellent piezoelectric performance could also be achieved with a lithium carbonate addition of 0.2 wt%, resulting in kp~66.7%, Qm~71, and Tc~226 °C. Therefore, it is possible, in this case, that the addition of low-melting glass can reduce densifying temperature and maintain excellent piezoelectric properties.

In our previous work [40], Sm-modified composition, Sm0.01Pb0.99(Zr0.54Ti0.46)O3 exhibited promising electrotechnical responses with large ferroelectric polarization (Pr = 40.9 μC/cm2, Ec = 14.7 kV/cm), accompanying a piezoelectric d33 of 590 pC/N, a kp of 57.1%, an electric strain Smax of 0.31%, a d33* of 632 pm/V, and an especially high Tc above 330 °C, respectively. Here, the aim of this project is to develop a low-sintered composition to cofire with Ag electrodes for the fabrication of multilayer piezoelectric actuators. However, this composition Sm0.01Pb0.99(Zr0.54Ti0.46)O3 exhibited a high densification temperature above 1200 °C, exceeding the melting point of silver. Furthermore, silver migration always happens in the ceramic–electrode interfaces if the cofiring temperature is above 950 °C [41]. In view of this, a commercial lead-free glass (LF-glass) flux with a low melting point of ~650 °C was chosen to reduce the cofiring temperature, and the target temperature is 920 °C to meet the cofiring requirements.

2. Materials and Methods

Raw materials including PbO (97% purity, Shanghai Aladdin Reagent Co., Ltd., Shanghai, China), TiO2 (99.9% purity, Shanghai Aladdin Reagent Co., Ltd., Shanghai, China), ZrO2 (99.99% purity, Shanghai Aladdin Reagent Co., Ltd., Shanghai, China), and Sm2O3 (99.9% purity, Shanghai Aladdin Reagent Co., Ltd., Shanghai, China) were used with analytically pure grade. LF-glass powder was selected as sintering aid. The LF-glass powders with an initial melting temperature of ~500 °C were bought from Anmi Anywhere New Materials (Guangzhou) Co., Ltd. (Guangzhou, China). The Sm0.01Pb0.99(Zr0.54Ti0.46)O3 (SPZTO) compositions were synthesized through solid-state reactions. The materials were mixed in stoichiometric ratios and milled for 4 h at room temperature, then calcined at 900 °C for 3 h and ball-milled at room temperature again. The resultant mixture was granulated with PVA solution and subsequently pressed into disk-shaped pellets (Φ = 12 mm, d = 1 mm) under the pressure of 300 MPa. The binder was burned out, and the pellets were sintered at 920 °C for 3 h.

X-ray diffraction (XRD) analysis was conducted using a PANalytical diffractometer (Almelo, The Netherlands) with Cu kα radiation and a 2θ step size of 0.02°. Silver-plated ceramics were prepared for electrical measurement. The samples were poled in dimethyl silicone at 30 kV/cm and 120 °C for 20 min and piezoelectric properties were evaluated for the samples after one-day aging. An E4980A LCR meter (Santa Rosa, CA, USA) and a quasi-static piezoelectric d33 instrument (Type: ZJ-3A, Beijing, China) were used for dielectric temperature spectroscopy up to 360 °C at a heating rate of 1.5 °C/min. The S-E relationship was measured with a multilayer actuator system at 30 kV/cm and 10 Hz, while electromechanical coupling and piezoelectric coefficients were assessed using an HP4294 impedance analyzer (Santa Rosa, CA, USA). The kp value and the mechanical quality factor Qm were calculated according to Equations (1) and (2):

where parameters fr and fa denote the resonance frequency and anti-resonance frequency; R denotes the minimum impedance at resonance; C1 and C0, respectively, represent capacitance of the ceramic and capacitance under static electric field at resonance.

3. Results and Discussion

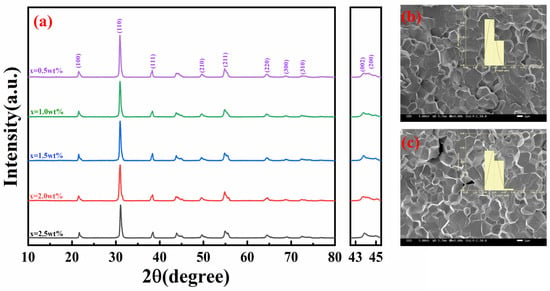

Figure 1a presents the XRD patterns of SPZTO ceramics with varying LF-glass contents. The results indicate that a pure perovskite phase is achieved, confirming the development of a complete solid solution. The broadening of the (200) peak is observed in the samples at the 2θ = 44~46° region (in other words, near the morphotropic phase boundary (MPB)), which is evidence of the coexistence of the tetragonal and rhombohedral phases. It is generally believed that piezoelectric ceramics have the optimum piezoelectric properties near the MPB. When the LF-glass contents increase, a distinct splitting of the (200)/(002) peaks can be observed, which implies that the coexistence of the rhombohedral-tetragonal phase near MPB tends to transform into the tetragonal-rich phase, which may enhance piezoelectric properties by flattening the free energy profile. When the material’s planar free energy is higher, it means that the material can more easily undergo changes in spontaneous polarization under the influence of an external electric field, which directly enhances the piezoelectric effect. Typically, the addition of glass flux cannot modify the crystal structure of the SPZTO ceramics, indicative of the occupation of the glass phase at the grain boundary. Figure 1b,c depict scanning electron microscope (SEM) images of fractured surfaces after sintering at 920 °C with different LF-glass. It is observed that as the grain size of the ceramics is basically unchanged with increasing LF-glass, grain size has a significant impact on the electrical performance of ceramics. Preliminary analysis suggests that the ceramic samples show optimal electrical performances at x = 2.0. This finding is supported by the results from X-ray diffraction (XRD) spectroscopy, which provide additional confirmation.

Figure 1.

(a) XRD patterns of the SPZTO + x wt% LF-glass ceramics at room temperature; (b) SEM images of fracture cross of SPZTO + 0.5 wt% LF-glass ceramics sintered at 920 °C at room temperature; (c) SEM images of fracture cross of SPZTO + 2.0 wt% LF-glass ceramics sintered at 920 °C at room temperature.

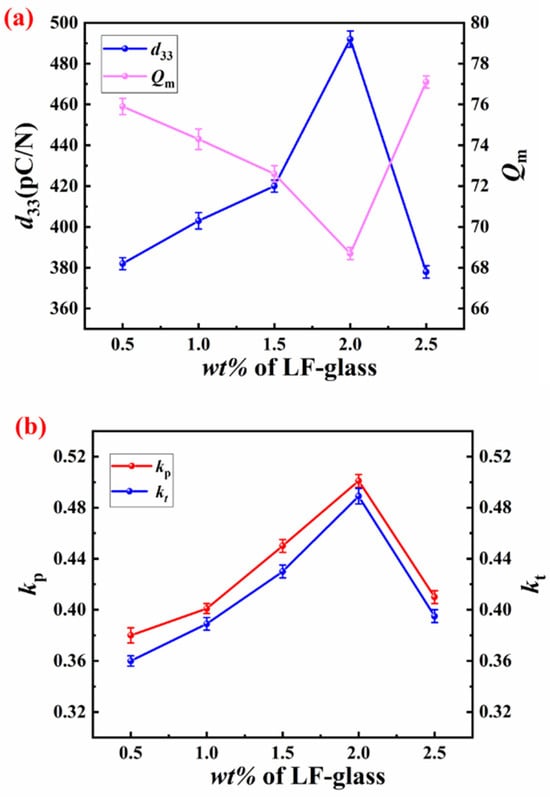

The piezoelectric coefficient quantifies the relationship between applied stress (or electric field) and the resulting electric displacement (or strain). Figure 2 shows piezoelectric performances of the glass-modulated SPZTO ceramics with different LF-glass contents. As shown in Figure 2, the enhanced piezoelectricity can be obtained at x = 2.0 with d33 = 492 pC/N, Qm = 68.71, kp = 50.1%, and kt = 48.9%. This indicates that the SPZTO ceramic sintered at 920 °C can be effectively fabricated, facilitating cofiring with a Ag electrode to prepare a multilayer-structured piezoelectric harvester. At x = 2.5%, redundant LF-glass cannot be completely discharged, affecting the electrical properties of the material.

Figure 2.

(a) The variation of d33 and Qm at room temperature; (b) the variation of kp and kt of SPZTO + x wt% LF-glass ceramics at room temperature.

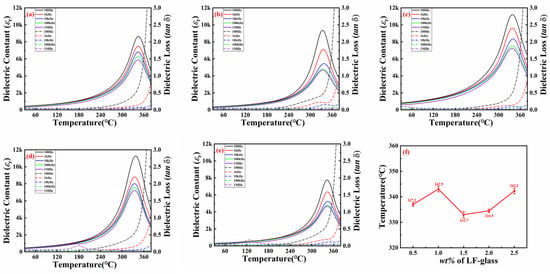

Figure 3 depicts dielectric property–temperature spectra of the SPZTO ceramics with various frequencies (100 Hz, 1 kHz, 10 kHz, and 100 kHz). As the testing frequency increases, there is no noticeable shift or broadening of the dielectric peak. This suggests the absence of relaxor behavior in the dielectric maximum peaks. With the increase in the LF-glass added, the Tc of the ceramic remains around 336 °C without any obvious change. Poled piezoelectric ceramics typically exhibit instability at temperatures slightly above half of the Curie temperature, which is suitable for their use as high-precision sensors. It can be inferred that piezoelectric devices made from these compositions are applicable at temperatures exceeding 160 °C.

Figure 3.

Dielectric–temperature spectra of the SPZTO + x wt% LF-glass ceramics: (a) x = 0.5; (b) x = 1.0; (c) x = 1.5; (d) x = 2.0; (e) x = 2.5; (f) the variation of Tc under different LF-glass content.

It can be observed that abnormal dielectric loss peaks far below Tc can be observed in high doping compositions for x = 2.0 at 180 °C and for x = 2.5 at 120 °C. It is possible that the extra dielectric loss peaks far below Tc can be ascribed to the doping glass.

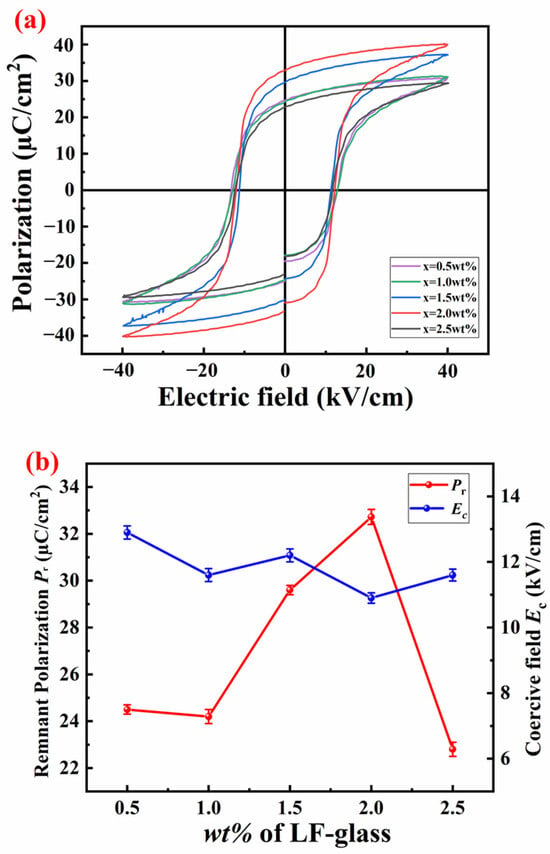

Figure 4a shows the P-E hysteresis loop at room temperature and polarization characteristics of SPZTO ceramics. Saturation polarization tests were achieved on the studied ceramic without breakdown. Figure 4b illustrates the trends in remnant polarization Pr and coercive field Ec for each composition. The SEM test results show that the samples obtained at x = 1.5 and 2.0% have larger grain sizes. As the grain size increases, the remnant polarization Pr of the PZT ceramic gradually increases, while the coercive field Ec gradually decreases. It is commonly understood that a lower Pr or a higher Ec indicates greater resistance to domain reversal, which is likely attributed to the influence of grain boundaries that restrict domain switching in samples with smaller grain sizes. Notably, the ceramics at x = 2.0 demonstrate the highest remnant polarization of 32.72 µC/cm2, along with the lowest coercive field of 10.9 kV/cm. This indicates significant potential for enhanced piezoelectric activity in this specific composition.

Figure 4.

(a) P-E hysteresis loops of the SPZTO + x wt% LF-glass ceramics at room temperature; (b) the variation of Pr and Ec under different LF-glass content at room temperature.

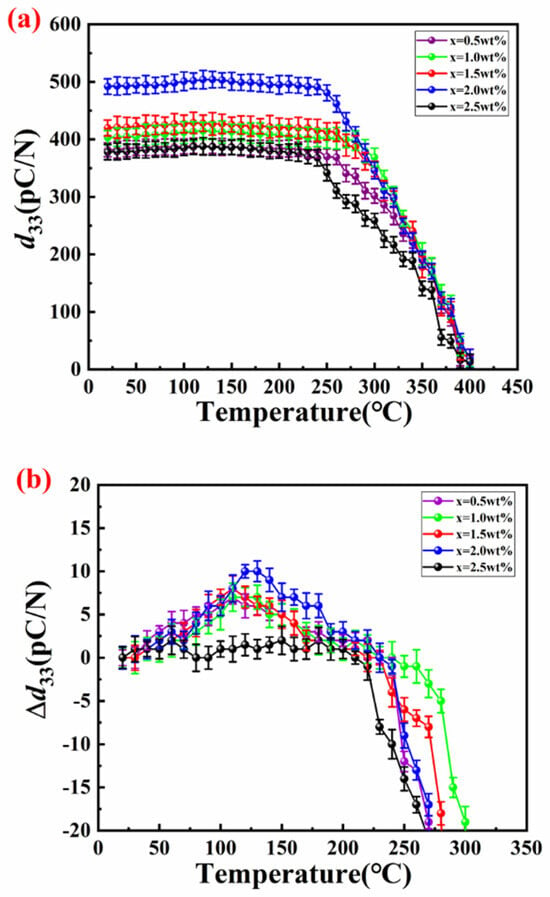

Typically, the operating temperature of piezoelectric ceramics is maintained below half of the Curie temperature to ensure optimal performance. This sensitivity to temperature is crucial, as depolarization can significantly affect the reliability and functionality of the device. Figure 5 shows the in situ d33 values of the piezoelectric ceramics exhibit variations with temperature. This figure illustrates how the piezoelectric response changes, highlighting the importance of temperature management in the application of these materials. The variation in d33 is less than 3%, indicating that d33 remains stable near Tc, attributed to the lower Gibbs free energy in the polarization curve at the ceramic boundary [42]. Figure 5b shows a slight increase in d33 as the temperature rises. It is widely recognized that compositions near the morphotropic phase boundary (MPB) typically exhibit an active mixed-phase behavior [43].

Figure 5.

(a) The in situ d33–temperature dependence of the SPZTO at room temperature + x wt% LF-glass ceramics; (b) the Δd33–temperature dependence of Sm0.01Pb0.99(Zr0.54Ti0.46)O3 + x wt% LF-glass ceramics at room temperature.

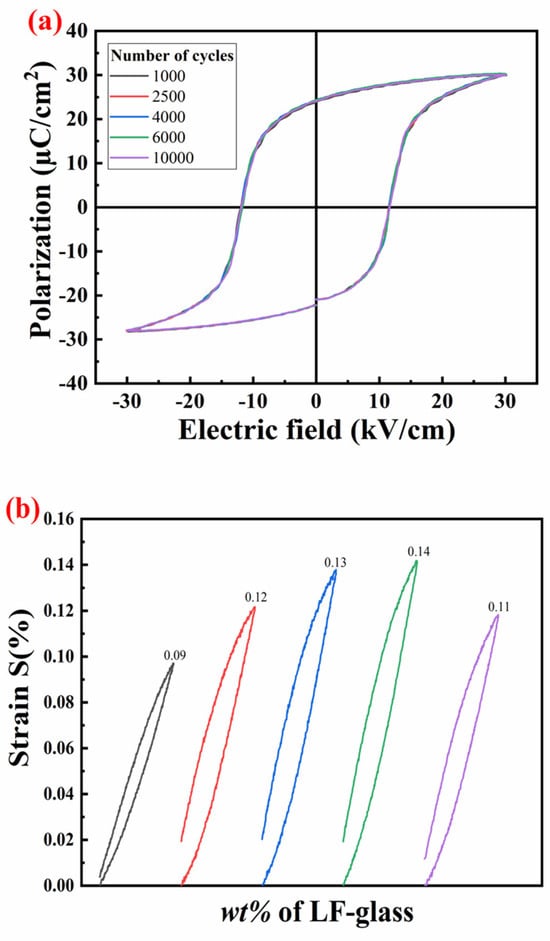

The orientation and arrangement of ceramic dipoles may alter under the influence of stress or an electric field, thereby impacting the material’s piezoelectric properties. During multiple cycles of loading and unloading, the charge distribution and lattice structure of the ceramic material may change, affecting its piezoelectric properties. Furthermore, the DC electric field aligns most domains, resulting in internal stress and an increased concentration of defects within the ceramics. When a DC electric field is applied to ferroelectric ceramics, it tends to align the domains, but this process generates internal mechanical stresses and can lead to the formation of defects due to the strain from the domain reorientation [44]. Consequently, cyclic performance emerges as another critical factor in determining the piezoelectric, ferroelectric, and dielectric properties of the materials. Figure 6a presents the changes in the P-E curves of the ceramic sample at x = 2 before and after 104 cycles under a 30 kV/cm electric field. Notably, after 104 cycles, the variation rate remains below 6.6%, demonstrating strong fatigue resistance and exceptional stability and reliability for prolonged use. The ceramics experience field-induced strain in response to an external electric field due to the inverse piezoelectric effect and the irreversible motion of domain walls. Figure 6b illustrates the continuous relationship between strain and electric field for all samples. Different compositions display varying strain responses when subjected to electric fields at a driving voltage of 30 kV/cm. When x = 2, the ceramic reaches a strain of 0.14%, comparable to traditional PZTs, which exhibit around 0.1%. Furthermore, the strain curves of the components of piezoelectric ceramics show excellent linearity, meaning that they can generate corresponding deformations in a stable and predictable manner when the electric field changes. This linear response is the foundation of the performance of piezoelectric actuators, ensuring the stability, predictability, and efficiency of the actuator. Therefore, the excellent linear characteristics make piezoelectric ceramics an ideal driving material.

Figure 6.

Cyclic and strain test diagrams of the SPZTO + x wt% LF-glass ceramics at room temperature; (a) the cyclic P-E curve of LF-glass = 2 wt% under 30 kV/cm; (b) S-E curves of ceramics under 30 kV/cm at room temperature.

4. Conclusions

In this work, high-performance SPZTO ceramics were prepared. LF-glass was used as a flux, and the sintering temperature was reduced to 920 °C with LF-glass of 2.0 wt% to achieve the best performance, including d33~492 pC/N, kp~50.1%, Qm~68.71, Tc~356 °C, and the ceramics could be fired with Ag in multilayer structure piezoelectric device fabrication. Under a voltage of 30 kV/cm, the piezoelectric strain is expected to reach 0.14%. Moreover, the ceramics maintained excellent stability and reliability over time and showed good temperature stability, indicating the potential of multilayer-structured piezoelectric devices.

Author Contributions

All authors contributed to the study’s conception and design. Material preparation, data acquisition, and review: Z.M., J.C. and Z.Y. (Zhonghua Yao); supervision, project administration, funding acquisition: Z.Y. (Zhonghua Yao), H.H., M.C. and H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key Research and Development Program of China (No. 2023YFB3812200) and Guangdong Basic and Applied Basic Research Foundation (No. 2022B1515120041).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fan, F.R.; Tang, W.; Wang, Z.L. Flexible Nanogenerators for Energy Harvesting and Self-Powered Electronics. Adv. Mater. 2016, 28, 4283–4305. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Wu, J.; Yu, Y.; Chu, Z.; Shi, H.; Dong, S. Giant Piezoelectric Coefficients in Relaxor Piezoelectric Ceramic PNN-PZT for Vibration Energy Harvesting. Adv. Funct. Mater. 2018, 28, 1706895. [Google Scholar] [CrossRef]

- Gu, W.; Zhao, B.; Yang, B.; Cai, Z.; Shang, X.; Zhou, T.; Guo, J. Achieving Superior Electrical Properties of PZT-PNN Piezoelectric Ceramics through Low-Temperature Sintering with PbO-CuO Eutectic Additives. J. Eur. Ceram. Soc. 2022, 42, 3831–3840. [Google Scholar] [CrossRef]

- Yang, S.; Li, J.; Liu, Y.; Wang, M.; Qiao, L.; Gao, X.; Chang, Y.; Du, H.; Xu, Z.; Zhang, S.; et al. Textured Ferroelectric Ceramics with High Electromechanical Coupling Factors Over a Broad Temperature Range. Nat. Commun. 2021, 12, 1414. [Google Scholar] [CrossRef] [PubMed]

- Abazari, M.; Safari, A. Effects of Doping On Ferroelectric Properties and Leakage Current Behavior of KNN-LT-LS Thin Films On SrTiO3 Substrate. J. Appl. Phys. 2009, 105, 094101. [Google Scholar] [CrossRef]

- Kizaki, Y.; Noguchi, Y.; Miyayama, M. Defect Control for Low Leakage Current in K0.5Na0.5NbO3 Single Crystals. Appl. Phys. Lett. 2006, 89, 142910. [Google Scholar] [CrossRef]

- Kour, P.; Pradhan, S.K.; Kumar, P.; Sinha, S.K.; Kar, M. Enhanced Ferroelectric and Piezoelectric Properties in La-Modified PZT Ceramics. Appl. Phys. A 2016, 122, 591. [Google Scholar] [CrossRef]

- Liu, C.; Du, Q.; Wu, J.; Zhang, G.; Shi, Y. Novel 3D Printed PZT-Based Piezoceramics for Piezoelectric Energy Harvesting Via Digital Light Processing. Chem. Eng. J. 2024, 492, 152004. [Google Scholar] [CrossRef]

- Shannigrahi, S.R.; Tay, F.E.H.; Yao, K.; Choudhary, R.N.P. WCA Effect of Rare Earth (La, Nd, Sm, Eu, Gd, Dy, Er and Yb) Ion Substitutions on the Microstructural and Electrical Properties of Sol-Gel Grown PZT Ceramics. J. Eur. Ceram. Soc. 2004, 24, 163–170. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.; Yoon, C.; Kim, H.; Lee, K. Low-Temperature Sintering of MnO2-Doped PZT-PZN Piezoelectric Ceramics. J. Electroceram. 2007, 18, 311–315. [Google Scholar] [CrossRef][Green Version]

- Li, F.; Lin, D.; Chen, Z.; Cheng, Z.; Wang, J.; Li, C.; Xu, Z.; Huang, Q.; Liao, X.; Chen, L.; et al. Ultrahigh Piezoelectricity in Ferroelectric Ceramics by Design. Nat. Mater. 2018, 17, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Li, S.; Gong, Y.; Meng, D.; Wang, J.; Jing, Q. Effects of Er3+–Doping On Dielectric and Piezoelectric Properties of 0.5Ba0.9Ca0.1TiO3–0.5BaTi0.88Zr0.12O3–0.12%La–XEr Lead–Free Ceramics. J. Alloy Compd. 2017, 692, 797–804. [Google Scholar] [CrossRef]

- Panigrahi, S.C.; Das, P.R.; Choudhary, R.N.P. Ferroelectric Studies for Soft Gd-Modified PZT Ceramics. Phase Transit. 2018, 91, 703–714. [Google Scholar] [CrossRef]

- Ye, J.; Ding, G.; Wu, X.; Zhou, M.; Wang, J.; Chen, Y.; Yu, Y. Development and Performance Research of PSN-PZT Piezoelectric Ceramics Based on Road Vibration Energy Harvesting Technology. Mater. Today Commun. 2023, 34, 105135. [Google Scholar] [CrossRef]

- Ying, H.; Ding, G.; Zhao, J.; Wang, J.; Liu, Z.; Zhou, M.; Ye, J. Properties of PSN-PZT Piezoelectric Ceramic Powder Prepared by Fast Solid-Phase Reaction Method. Mater. Today Commun. 2023, 35, 106086. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, J.; Yang, L.; Liu, S.; Xiao, J.; Li, X.; Wang, X.A.; Luo, H. Design and Comparison of PMN-PT Single Crystals and PZT Ceramics Based Medical Phased Array Ultrasonic Transducer. Sens. Actuators A Phys. 2018, 283, 273–281. [Google Scholar] [CrossRef]

- Kour, P.; Pradhan, S.K.; Kumar, P.; Sinha, S.K.; Kar, M. Effect of Nd Doping On Dielectric and Impedance Properties of PZT Nanoceramics. J. Electron. Mater. 2018, 47, 2861–2870. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Li, B.S.; Li, G.R.; Zhang, W.Z.; Yin, Q.R. Microstructure and Piezoelectric Properties of PMS–PZT Ceramics. Mater. Sci. Eng. B 2005, 117, 216–220. [Google Scholar] [CrossRef]

- Seshadri, S.B.; Nolan, M.M.; Tutuncu, G.; Forrester, J.S.; Sapper, E.; Esteves, G.; Granzow, T.; Thomas, P.A.; Nino, J.C.; Rojac, T.; et al. Unexpectedly High Piezoelectricity of Sm-Doped Lead Zirconate Titanate in the Curie Point Region. Sci. Rep. 2018, 8, 4120. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Li, F.; Xia, F.; Gao, X.; Wang, P.; Hao, H.; Sun, H.; Liu, H.; Zhang, S. High-Performance Sm-Doped Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3-Based Piezoceramics. ACS Appl. Mater. Interfaces 2019, 11, 43359–43367. [Google Scholar] [CrossRef]

- Hu, X.; Cao, T.; Wang, B.; Wen, Z.; Yan, K.; Wu, D. A Low-Cost Multilayer Piezoelectric Actuator for Ultrasonic Motor Stator Driving Fabricated by a Low-Temperature Co-Fired Ceramic Process. Ceram. Int. 2023, 49, 6119–6124. [Google Scholar] [CrossRef]

- Ghasemifard, M.; Hosseini, S.M.; Khorsand Zak, A.; Khorrami, G.H. Microstructural and Optical Characterization of PZT Nanopowder Prepared at Low Temperature. Physica. E Low-Dimens. Syst. Nanostructures 2009, 41, 418–422. [Google Scholar] [CrossRef]

- Thomazini, D.; Gelfuso, M.V.; Eiras, J.A. Microwave Assisted Hydrothermal Synthesis of Bi4Ti3O12 Nanopowders From Oxide as Raw Materials. Powder Technol. 2012, 222, 139–142. [Google Scholar] [CrossRef]

- Peng, Y.; Chen, H.; Shi, F.; Wang, J. Effect of Polyethylene Glycol on BaTiO3 Nanoparticles Prepared by Hydrothermal Preparation. IET Nanodielectr. 2020, 3, 69–73. [Google Scholar] [CrossRef]

- Wang, S.; Li, L.; Wang, X. Low-Temperature Firing and Microwave Dielectric Properties of MgNb2-XVx/2O6-1.25X Ceramics. Ceram. Int. 2022, 48, 199–204. [Google Scholar] [CrossRef]

- Rahsepar, H.; Hayati, R.; Javadpour, S. Evaluation of the Dielectric, and Piezoelectric Properties and Optimizing the Figure of Merit of the 0–3 KNN-0.8ZnO/PVDF-HFP Piezoelectric Composite by the Taguchi Method. J. Alloy Compd. 2024, 1006, 176373. [Google Scholar] [CrossRef]

- Vakifahmetoglu, C.; Karacasulu, L. Cold Sintering of Ceramics and Glasses: A Review. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100807. [Google Scholar] [CrossRef]

- Guerra, J.D.S.; Hathenher, C.R.; Lourenço, S.A.; Dantas, N.O. Investigation of the Physical Properties of New PZT Modified Tellurium Oxide (TeO2–B2O3–PbO2: TBP) Glasses. J. Non-Cryst. Solids 2010, 356, 2350–2354. [Google Scholar] [CrossRef]

- Saegusa, K. Preparation by a Sol-Gel Process and Dielectric Properties of Lead Zirconate Titanate Glass-Ceramic Thin Films. Jpn. J. Appl. Phys. 1997, 36, 3602–3608. [Google Scholar] [CrossRef]

- Kim, B.S.; Ji, J.; Koh, J. Improved Strain and Transduction Values of Low-Temperature Sintered CuO-Doped PZT-PZNN Soft Piezoelectric Materials for Energy Harvester Applications. Ceram. Int. 2021, 47, 6683–6690. [Google Scholar] [CrossRef]

- Li, S.; Fu, J.; Zuo, R. Middle-Low Temperature Sintering and Piezoelectric Properties of CuO and Bi2O3 Doped PMS-PZT Based Ceramics for Ultrasonic Motors. Ceram. Int. 2021, 47, 20117–20125. [Google Scholar] [CrossRef]

- Mao, W.; Xu, Q.; Huang, D.; Sun, H.; Zhang, F.; Xie, X. Low-Temperature Sintering Properties of Bi2O3 Doped PZT-5H Piezoelectric Ceramics. J. Electron. Mater. 2023, 52, 3334–3342. [Google Scholar] [CrossRef]

- Sharma, G.N.; Dutta, S.; Singh, S.K.; Chatterjee, R. Growth and Optical Properties of Nano-Textured (110) Pb(Zr0.52Ti0.48)O3/(001) ZnO Hetero-Structure On Oxidized Silicon Substrate. J. Mater. Sci. Mater. Electron. 2017, 28, 5058–5062. [Google Scholar] [CrossRef]

- Zhang, J. Dielectric, Ferroelectric and Piezoelectric Properties of PZT Ceramics by ZnO Doping. Integr. Ferroelectr. 2019, 199, 105–111. [Google Scholar] [CrossRef]

- Shi, J.; Guo, Y.; Wang, S.; Yu, X.; Jiang, Q.; Xu, W.; Yan, Y.; Chen, Y.; Zhang, H.; Wang, B. An Optimisation Method for Planning and Operating Nearshore Island Power and Natural Gas Energy Systems. Energy 2024, 308, 132797. [Google Scholar] [CrossRef]

- Zhao, S.Y.; Bian, J.J. Effects of Li2CO3–CuO Addition On the Sintering Behavior, Dielectric and Piezoelectric Properties of PZT Ceramics. J. Mater. Sci. Mater. Electron. 2023, 34, 1202. [Google Scholar] [CrossRef]

- Nan, B.; Paver, T.; Vigay, B.; Tim, B.; Li, L.; Fan, P. Journal Effect of lithium carbonate on the sintering, microstructure, and functional properties of sol–gel-derived Ba0.85Ca0.15Zr0.1Ti0.9O3 piezoceramics. J. Mater. Res. 2021, 36, 1105–1113. [Google Scholar] [CrossRef]

- Dai, L.; Gio, P. Effect of Li2CO3 Addition on the Sintering Behavior and Physical Properties of PZT-PZN-Pmnn Ceramics. Mater. Sci. Appl. 2013, 2, 89–93. [Google Scholar]

- Lin, Z.; Zhu, Z.; Yao, Z.; Zhang, H.; Hao, H.; Cao, M.; Liu, H. Piezoelectric Response and Cycling Fatigue Resistance of Low-Temperature Sintered PZT-Based Ceramics. Materials 2023, 16, 1679. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Yao, Z.; Lai, D.; Guo, Q.; Pan, W.; Hao, H.; Cao, M.; Liu, H. Unexpectedly High Piezoelectric Response in Sm-Doped PZT Ceramics Beyond the Morphotropic Phase Boundary Region. J. Alloy Compd. 2020, 836, 155474. [Google Scholar] [CrossRef]

- Lu, C.; Lin, J. WCA Interaction Between Lead Iron Niobate/Tungstate Ceramics and Silver/Palladium Metals. Ceram. Int. 1997, 23, 223–228. [Google Scholar] [CrossRef]

- Huang, C.; Cai, K.; Wang, Y.; Bai, Y.; Guo, D. Revealing the Real High Temperature Performance and Depolarization Characteristics of Piezoelectric Ceramics by Combined in Situ Techniques. J. Mater. Chem. C Mater. Opt. Electron. Devices 2018, 6, 1433–1444. [Google Scholar] [CrossRef]

- Naeem, F.; Saleem, M.; Jabbar, H.; Tanvir, G.; Asif, F.; Baluch, A.H.; Irfan, M.; Ghaffar, A.; Maqbool, A.; Rafiq, T. Enhanced Ferroelectric and Dielectric Properties of Niobium-Doped Lead-Free Piezoceramics. Materials 2023, 16, 477. [Google Scholar] [CrossRef] [PubMed]

- Geng, L.M.; Yang, W. Defect agglomeration in ferroelectric ceramics under cyclic electric field. Sci. China 2008, 51, 1296–1305. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).