Highlights

What are the main findings?

- Novel ZnNb2O6-Ca0.5Sr0.5TiO3 composite ceramics were designed.

- Compositional effect was systematically investigated.

- Optimum sintering system was established.

- Temperature-stable microwave ceramics were obtained.

What are the implications of the main findings?

- Theoretical guide and material support for designing and fabricating high-performance thermally stable microwave dielectric ceramics for future communication technologies.

Abstract

ZnNb2O6-based microwave dielectric ceramics have attracted considerable attention due to their high quality factor (Q × f) and low sintering temperature, but their application was limited by poor temperature stability with a large negative temperature coefficient of resonant frequency (τf). Herein, novel (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 (x = 0.05–0.125) composite ceramics were designed and fabricated. The used ZnNb2O6 and Ca0.5Sr0.5TiO3 were synthesized through solid-phase reaction by using stoichiometric metal oxides or carbonates as the raw materials at 650 and 1100 °C, respectively. The composite ceramics were prepared by solid-state sintering, and the sintering parameters were optimized at 1175 °C for 4 h by visual high-temperature deformation analysis. A focus was paid on the temperature stability and compositional effects of Ca0.5Sr0.5TiO3 of the obtained composited ceramics. As the Ca0.5Sr0.5TiO3 content increases, the dielectric constant (εr) and Q × f gradually decrease, while τf shifts toward positive values. At x = 0.075, the composite ceramics sintered at 1175 °C for 4 h exhibit near-zero τf (−8.99 ppm/°C), coupled with εr = 23.23 and Q × f = 21,686 GHz. This study provides theoretical guide and material support for designing and fabricating various high-performance thermally stable microwave dielectric ceramics for 5G communication devices and future communication technologies.

1. Introduction

The rapid development of 5G communication technology has led to a significant increase in global demand for high-performance microwave components [1,2,3]. As essential materials in modern communication systems, microwave dielectric ceramics are widely used in the fabrication of resonators, filters, substrates, antennas, waveguide circuits and so on [4,5,6,7,8]. These components form the foundation of wireless communication systems, enabling higher data transmission rates, broader bandwidths, and improved signal integrity. However, the ongoing evolution of 5G and the impending arrival of 6G technologies necessitate the development of microwave dielectric ceramics with superior performance to meet increasingly stringent requirements [9,10,11].

To meet these demands, high-performance microwave dielectric ceramics must satisfy three critical criteria: (i) an appropriate relative dielectric constant (εᵣ) for device miniaturization; (ii) a high quality factor (Q × f) or low dielectric loss to ensure energy efficiency; and (iii) a near-zero temperature coefficient of resonant frequency (τf) to guarantee stability under varying operating conditions [12,13,14]. However, single-phase ceramic materials often face inherent limitations in simultaneously achieving these properties. As a result, researchers have turned to composite strategies to optimize the overall performance of microwave dielectric ceramics [15,16].

In recent years, niobate-based microwave dielectric ceramics have attracted considerable attention due to their excellent dielectric properties [17,18,19]. Among them, ZnNb2O6 ceramics have become a research focus due to their low dielectric constant (εᵣ ≈ 25), high quality factor (Q × f ≈ 83,700 GHz), and low sintering temperature (1150 °C) [20,21]. However, ZnNb2O6 ceramics exhibit a large negative τf (−56.1 ppm/°C), resulting in poor temperature stability and limiting their practical applications [18,19,20]. Studies on ion substitution, such as Mg2+ or Ni2+ for Zn2+, have improved τf but introduced challenges such as increased sintering temperatures or dielectric losses [22,23,24].

To address this issue, composite strategies combining ZnNb2O6 with materials of positive τf values have been proposed [19,25,26,27,28,29,30]. Among such materials, Ca0.5Sr0.5TiO3, a perovskite-structured ceramic with εᵣ ≈ 236, Q × f ≈ 4100 GHz and τf ≈ +1230 ppm/°C, ushers in an ideal candidate for ZnNb2O6 [31,32,33]. Its structural compatibility with ZnNb2O6 facilitates the formation of composite ceramics, minimizing secondary phases and optimizing dielectric performance.

Therefore, this study designed and fabricated a series of novel (1 − x)ZnNb2O6−x Ca0.5Sr0.5TiO3 (x = 0.05–0.125) materials, aiming to search for a kind of composite ceramic with near-zero τf but acceptable Q × f. The used ZnNb2O6 and Ca0.5Sr0.5TiO3 were synthesized through solid-phase reaction by using stoichiometric metal oxides or carbonates as the raw materials. The composite ceramics were prepared by solid-state sintering, and the sintering parameters were optimized by using visual high-temperature deformation analysis. The effects of Ca0.5Sr0.5TiO3 content on the phase composition, microstructure, sintering behavior, and microwave dielectric properties of the obtained composite ceramics were systematically investigated. By optimizing the composition and sintering process, ZnNb2O6-Ca0.5Sr0.5TiO3 composite ceramics with excellent dielectric properties and high temperature stability were obtained. With x = 0.075 after sintering at 1175 °C for 4 h, the obtained composite ceramics exhibit near-zero τf (−8.99 ppm/°C), εr = 23.23 and Q × f = 21,686 GHz. This study provides theoretical guide and material support for designing and fabricating various high-performance microwave dielectric ceramics for 5G communication devices and future communication technologies.

2. Experimental

2.1. Sample Fabrication

The proposed (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 (x = 0.05–0.125) composite ceramics were prepared using the conventional solid-phase reaction and solid-state sintering method. Typically, high-purity raw materials, including Nb2O5 (99.99%), ZnO (99.99%), CaCO3 (99.99%), SrCO3 (99.99%), and TiO2 (99.99%), were weighed according to their stoichiometric ratios. The raw materials were mixed with anhydrous ethanol and ZrO2 grinding balls in a planetary ball mill. Specifically, Nb2O5 and ZnO were mixed and ball-milled for 6 h, while CaCO3, SrCO3, and TiO2 were mixed and ball-milled for 8 h. After ball milling, the slurries were quickly transferred to an oven and dried at 105 °C for 8 h. The dried mixtures were then ground into fine powders using an agate mortar. The powders were calcined in a muffle furnace to obtain ZnNb2O6 and Ca0.5Sr0.5TiO3. ZnNb2O6 was synthesized by calcining the Nb2O5-ZnO mixture at 650 °C for 4 h, while Ca0.5Sr0.5TiO3 was synthesized by calcining the CaCO3-SrCO3-TiO2 mixture at 1100 °C for 4 h. After crashing and grinding, the resultant ZnNb2O6 and Ca0.5Sr0.5TiO3 powders were weighed according to the designed ratios of composite ceramics, mixed, and ball-milled again for 6 h. The obtained slurries were dried at 105 °C for 8 h, and then the resultant powder chunks were ground and sieved to obtain homogeneous ceramic powders. To improve the formability of the powders, 0.5 wt.% polyvinyl alcohol (PVA) was added as a binder for the granulation of the composite powders. Afterwards, the granulated powders were pressed into pellets (ϕ5 × 1 mm, ϕ6 × 1 mm, and ϕ12 × 5 mm) using a hydraulic press under a pressure of 4 MPa for 90 s.

To determine the optimal sintering temperature, the green pellets (ϕ5 × 1 mm) were subjected to high-temperature deformation analysis using a visual high-temperature deformation analyzer (TA-16A01, Tianjin Zhonghuan Experimental Furnace Co., Ltd., Tianjin, China). The samples were heated at a rate of 5 °C/min up to 1350 and 1300 °C, respectively, and the data were analyzed to determine the optimal sintering temperature. The final sintering process was carried out in a muffle furnace. The samples were heated at a rate of 5 °C/min up to 500 °C, holding there for 30 min to remove the binder, and then heated up to the optimal sintering temperature (1175 °C), soaking for 4 h before cooling naturally to room temperature.

2.2. Material Characterization

The apparent density of the sintered ceramics was measured using the Archimedes method, following the ISO 18754 standard [34]. The relative density was calculated as the ratio of the apparent density to the theoretical density, expressed as a percentage. The phase composition of the ceramics was analyzed using an X-ray diffractometer (XRD, D/max-RB, Rigaku, Tokyo, Japan) with Cu-Kα radiation (λ = 1.5418 Å). The XRD patterns were collected in continuous scanning mode at a rate of 5°/min over a 2θ range of 10–80°. The microstructure of the ceramics was observed using a scanning electron microscope (SEM, Meilin Compact, Zeiss, Oberkochen, Germany). The average grain size and distribution were statistically analyzed from the SEM images using Nano Measurer software. The elemental composition and distribution were analyzed using an energy-dispersive X-ray spectrometer (EDX, Inca X-Max 80T, Oxford, UK).

The microwave dielectric properties, including the dielectric constant (εᵣ), quality factor (Q × f), and temperature coefficient of resonant frequency (τf), were measured using a vector network analyzer (E5063A, Keysight, San Diego, CA, USA) in TE01δ mode. The resonant frequency temperature coefficient (τf) was calculated using the following formula [33,35]:

where ft and f0 are the resonant frequencies at 80 °C and room temperature, respectively.

3. Results and Discussion

3.1. Synthesis and Sintering Behavior

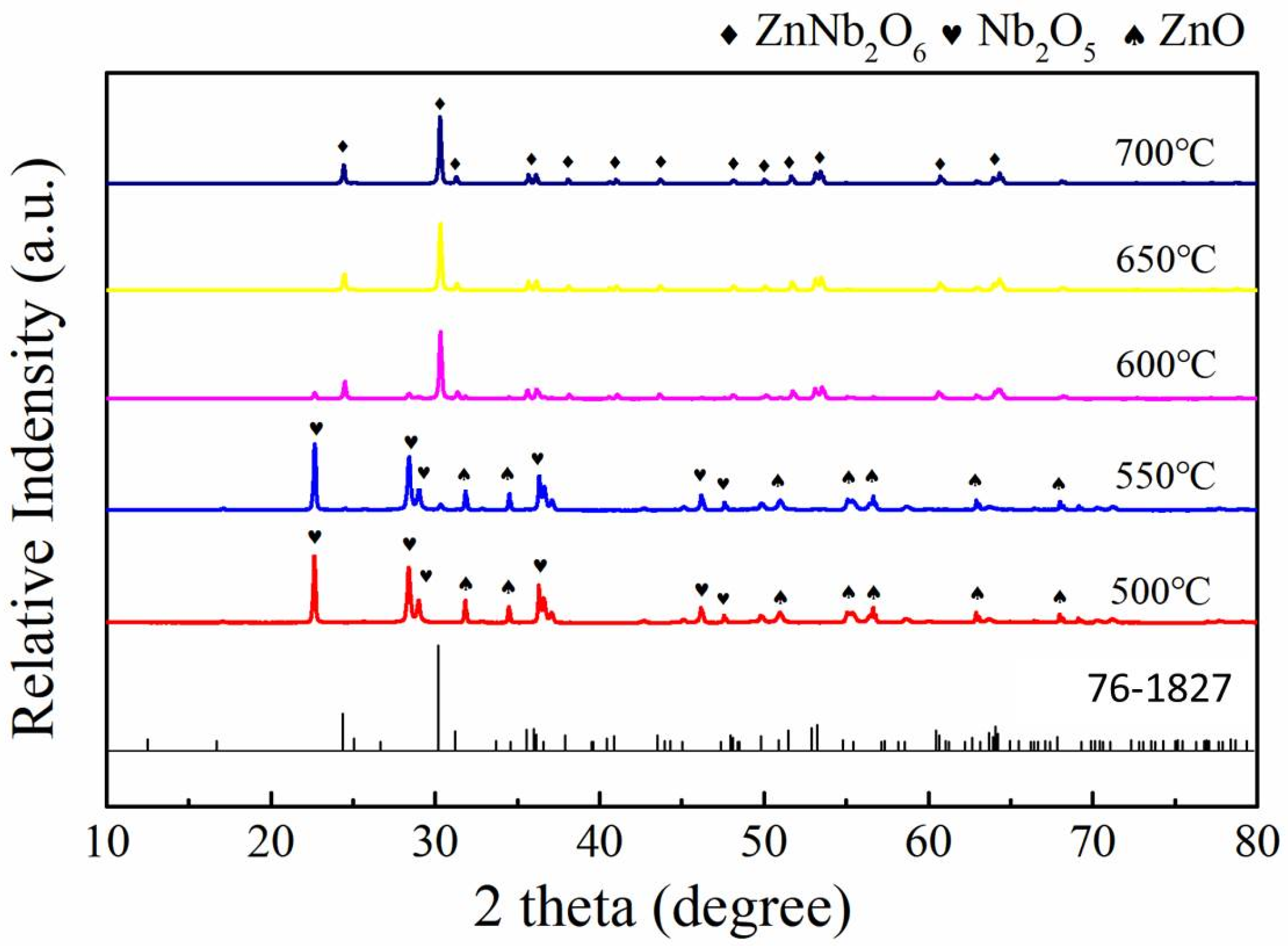

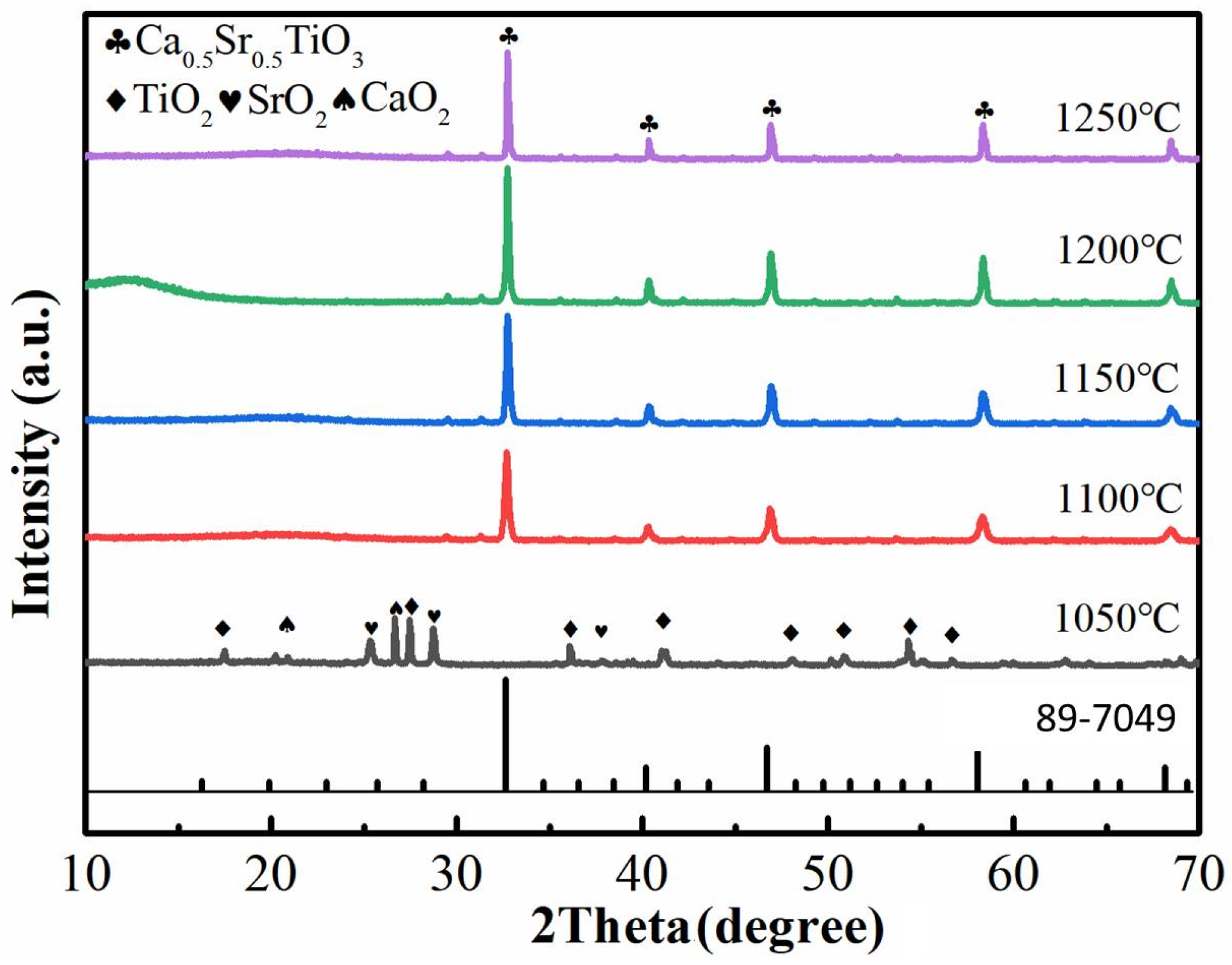

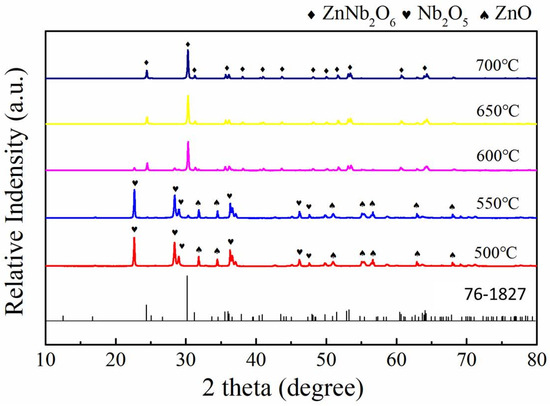

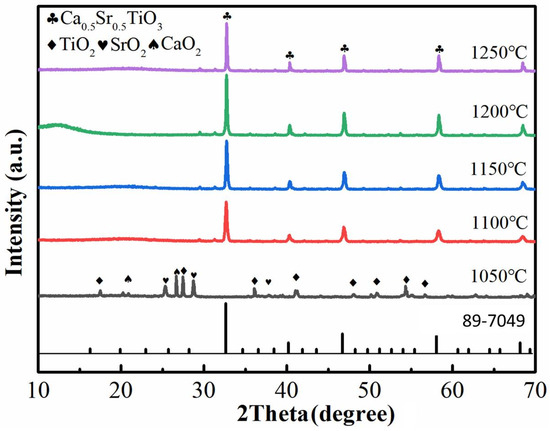

The synthesis of ZnNb2O6 and Ca0.5Sr0.5TiO3 raw powders via the solid-phase reaction method was confirmed by XRD analysis to determine the lowest synthesis temperature. High-purity Nb2O5 and ZnO were mixed in a molar ratio of 1:1, ball-milled with ethanol for 6 h, dried, and calcined at temperatures ranging from 500 to 700 °C for 4 h to obtain ZnNb2O6 [29,36]. As shown in Figure 1, the diffraction peaks of ZnNb2O6 were clearly observed at 600 °C, although a small amount of Nb2O5 still remained. At 650 °C, pure-phase ZnNb2O6 was obtained, and further increases in temperature did not alter the phase composition. Therefore, 650 °C was selected as the calcination temperature for ZnNb2O6 from Nb2O5 and ZnO mixed powders. Similarly, CaCO3, SrCO3, and TiO2 were mixed in a molar ratio of 1:1:2, ball-milled for 8 h, dried, and calcined at temperatures ranging from 1050 to 1250 °C for 4 h to obtain Ca0.5Sr0.5TiO3 [33,37]. From Figure 2, it can be observed that pure-phase Ca0.5Sr0.5TiO3 was obtained at 1100 °C, and no phase changes occurred at higher temperatures. Thus, 1100 °C was chosen as the calcination temperature for Ca0.5Sr0.5TiO3 from CaCO3, SrCO3, TiO2 mixed powders.

Figure 1.

XRD patterns of the products obtained after calcining Nb2O5 and ZnO mixed powders in a molar ratio of 1:1 at 500, 550, 600, 650 and 700 °C for 4 h, respectively.

Figure 2.

XRD patterns of the products obtained after CaCO3, SrCO3, TiO2 mixed powders in a molar ratio of 1:1:2 were calcined at 1050, 1100, 1150, 1200 and 1250 °C for 4 h, respectively.

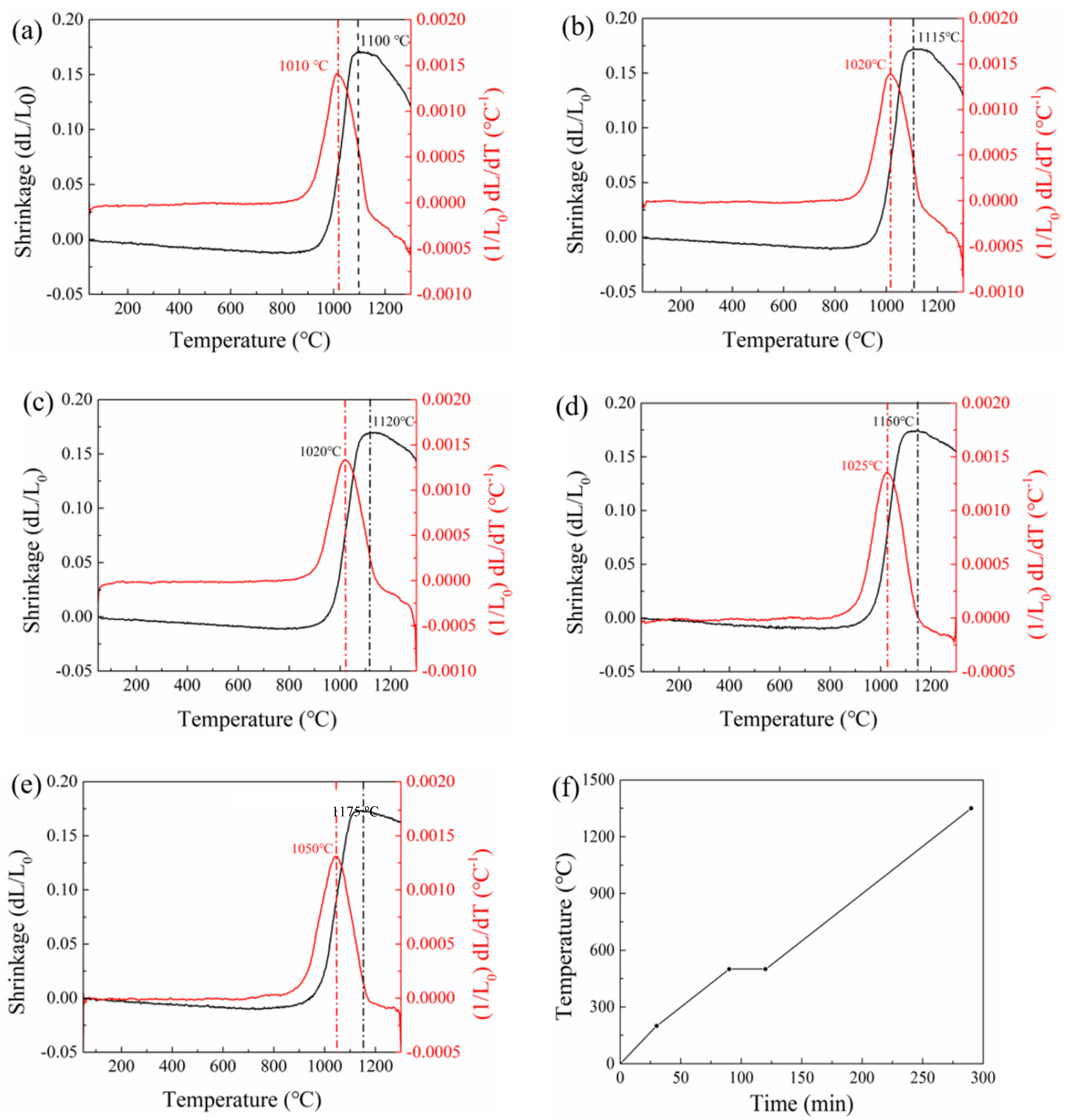

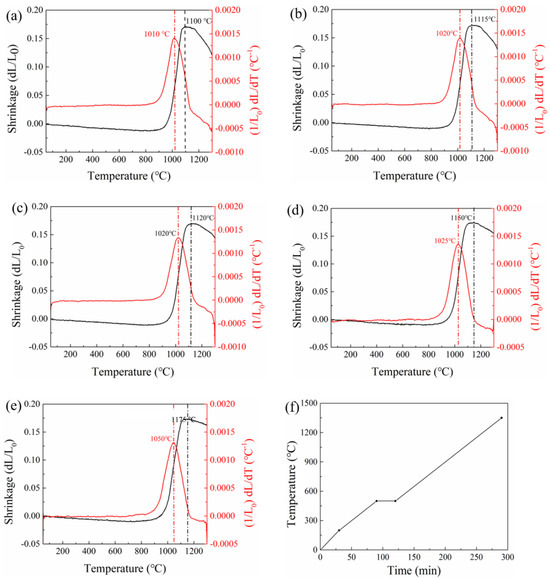

To determine the optimal sintering temperature for the proposed (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 (x = 0.05–0.125) composite ceramics, their green pellets (ϕ5 × 1 mm) were subjected to high-temperature deformation analysis. The collected shrinkage curves are shown in Figure 3a–e, for which the samples were heated according to the process as illustrated in Figure 3f. It can be seen from Figure 3a–e that the sintering temperature for the composite ceramics increased with higher Ca0.5Sr0.5TiO3 content, indicating that excessive Ca0.5Sr0.5TiO3 addition hindered their densification. Roughly at 1175 °C (see Figure 3e), the designed composition of composite ceramics with the highest Ca0.5Sr0.5TiO3 content can be sintered densely for 4 h. Based on these results, the optimal sintering parameters for all the proposed composite ceramics were determined to be 1175 °C for 4 h.

Figure 3.

Shrinkage behavior of (1−x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics as a function of temperature (a–e) and time (f): (a) x = 0.025, (b) x = 0.05, (c) x = 0.075, (d) x = 0.1, (e) x = 0.125. (f) Heating process for the deformation analysis of the present ZnNb2O6-Ca0.5Sr0.5TiO3 composite ceramics.

3.2. Composition and Microstructure

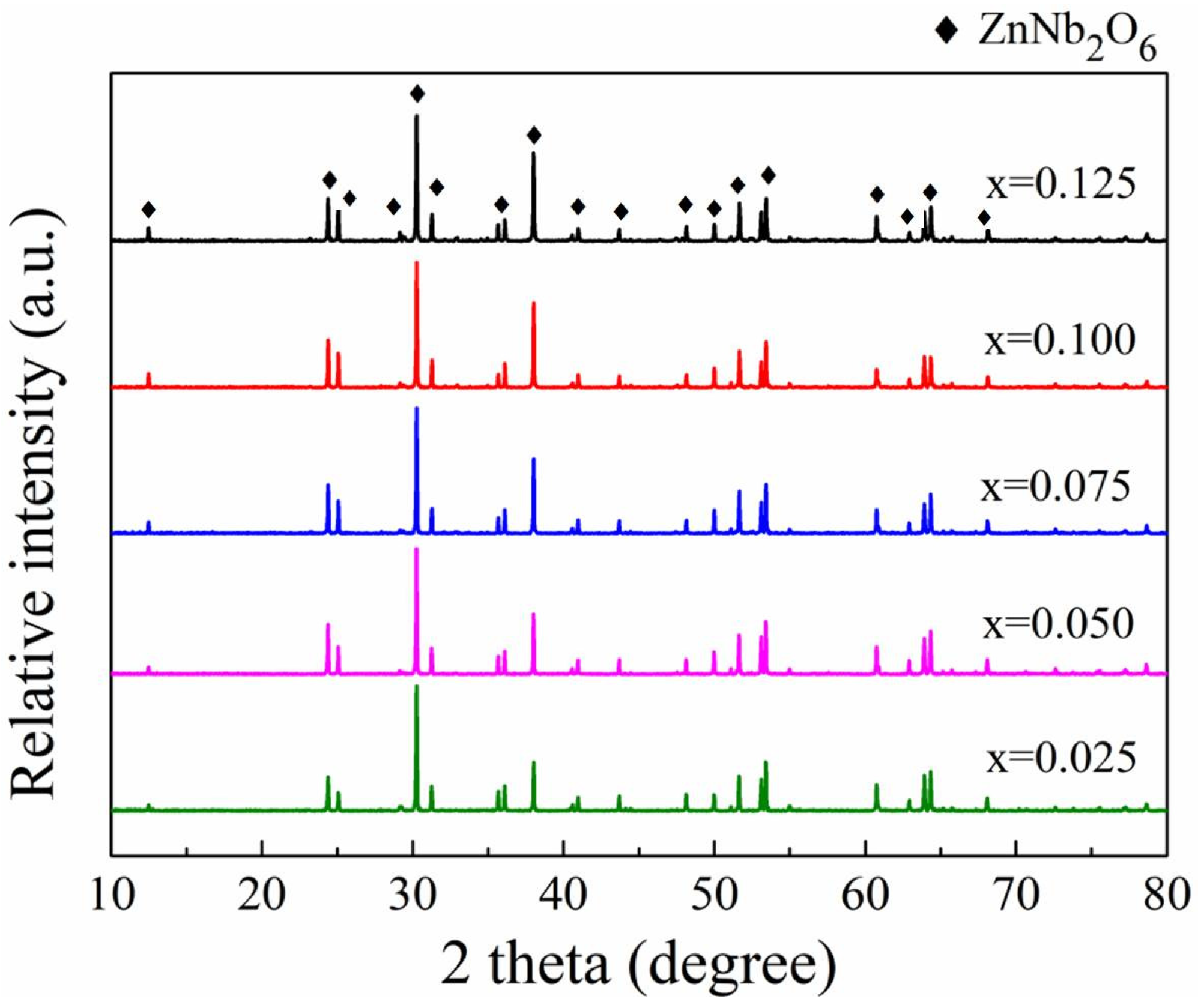

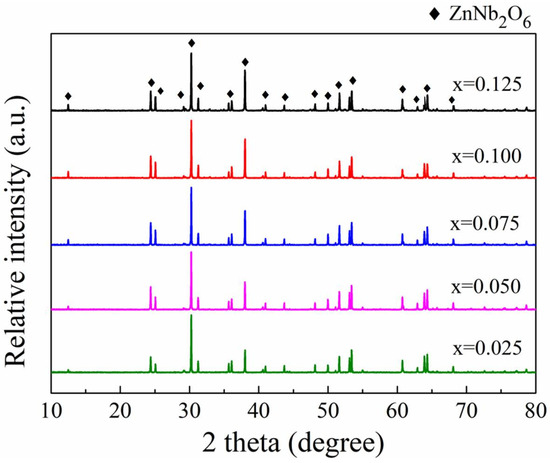

The XRD patterns of the obtained (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 (x = 0.05–0.125) ceramics sintered at 1175 °C for 4 h are shown in Figure 4. For all the samples, the primary phase was identified as ZnNb2O6, while the peaks of Ca0.5Sr0.5TiO3 phase were not detected due to its low content. This information indicates that the composition of the obtained ceramics is desirable as designed without extra reaction during sintering.

Figure 4.

XRD patterns of the (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics obtained by sintering at 1175 °C for 4 h.

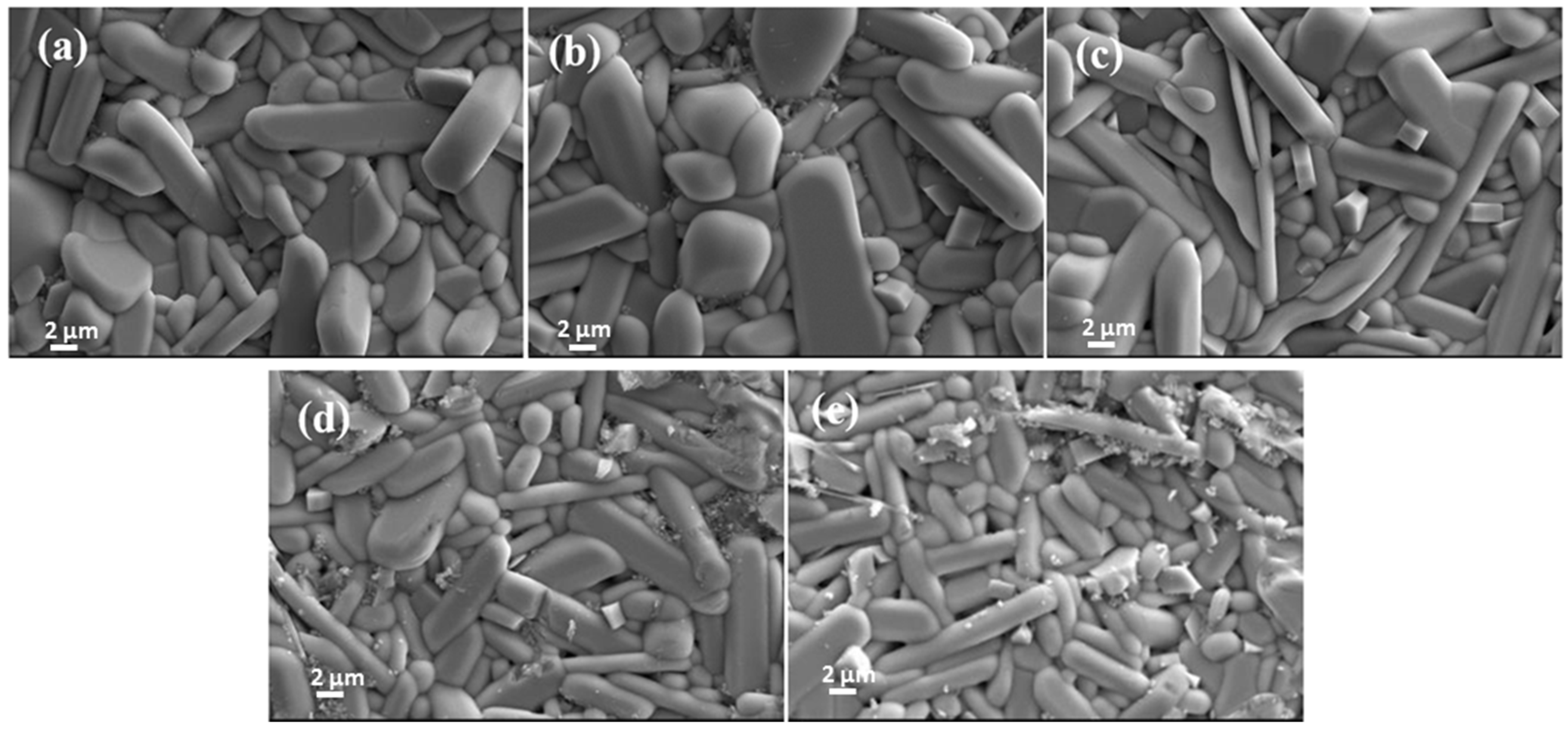

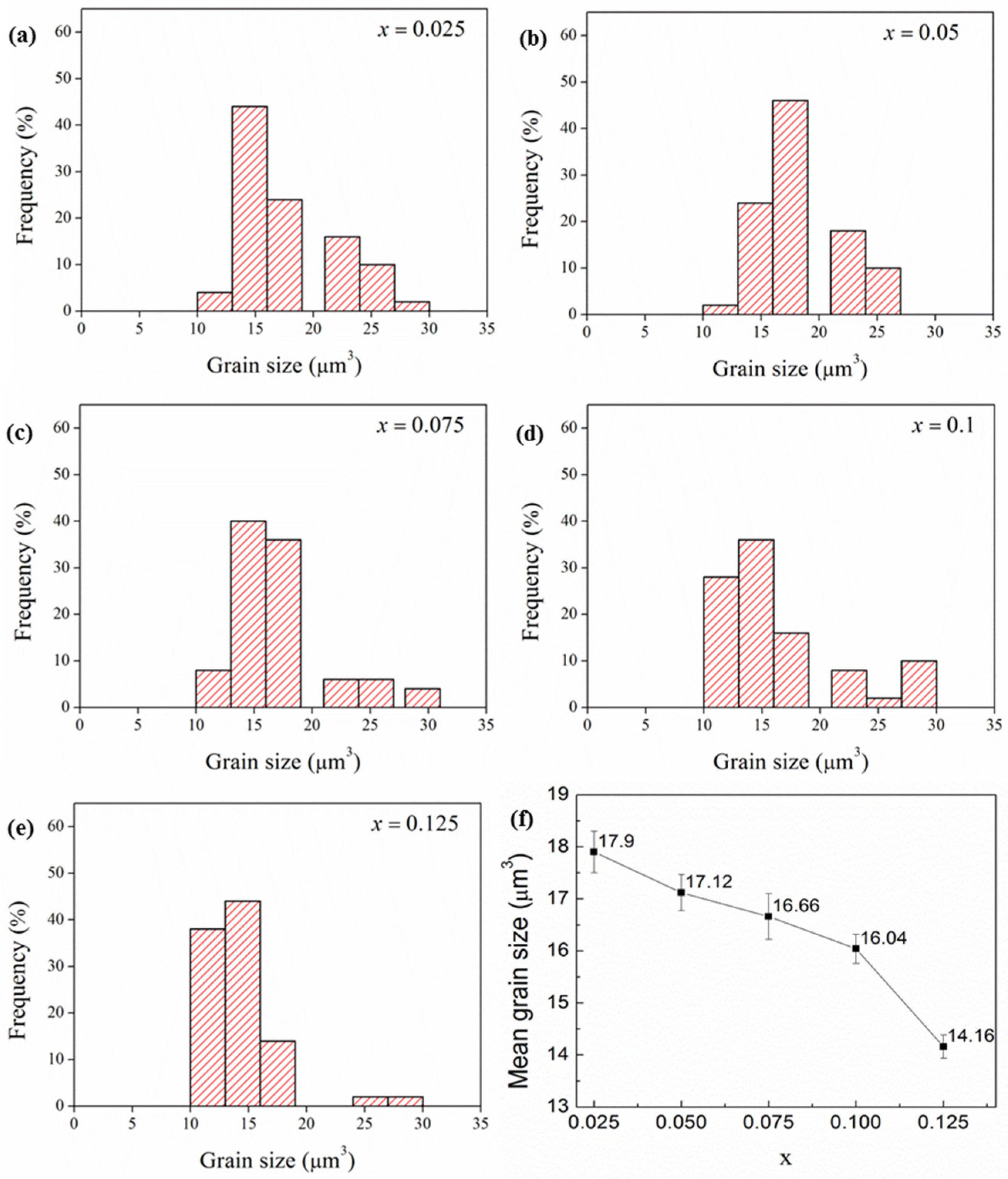

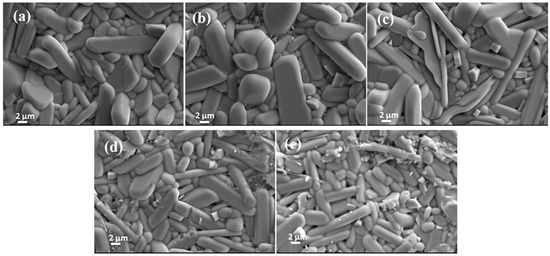

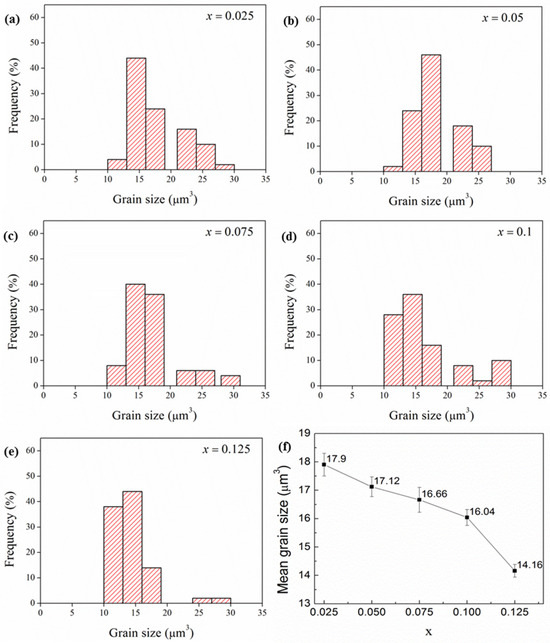

The microstructural features on the polished and thermally etched surfaces of the obtained samples (see Figure 5) revealed that the ceramics overwhelmingly consist of rod-like grains, typical morphology of ZnNb2O6 grains, because the content of Ca0.5Sr0.5TiO3 was generally very small. Statistical analysis on the size distribution of the ZnNb2O6 grains (volume, μm3, see Figure 6) indicated that the average grain size decreased with increasing Ca0.5Sr0.5TiO3 content. But, with more Ca0.5Sr0.5TiO3 added, the size of ZnNb2O6 grains became more homogeneous. This trend is attributed to the higher sintering temperature of Ca0.5Sr0.5TiO3 (~1400 °C) [32,33] compared to that of ZnNb2O6 (<1020 °C) [21,24], which would impede the grain growth of ZnNb2O6 and densification of the products, while the adding amount of Ca0.5Sr0.5TiO3 increased. In addition, with relatively high content of Ca0.5Sr0.5TiO3 (for example, Figure 5d), tiny grains were gradually examined from the images, which were identified by EDX analysis as Ca0.5Sr0.5TiO3.

Figure 5.

SEM images on the polished and thermally etched surfaces of (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics obtained by sintering at 1175 °C for 4 h: (a) x = 0.025, (b) x = 0.05, (c) x = 0.075, (d) x = 0.1, (e) x = 0.125.

Figure 6.

Distribution diagram of grain sizes (μm3) in the obtained (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics: (a) x = 0.025, (b) x = 0.05, (c) x = 0.075, (d) x = 0.1, (e) x = 0.125. (f) Average grain size changes with x.

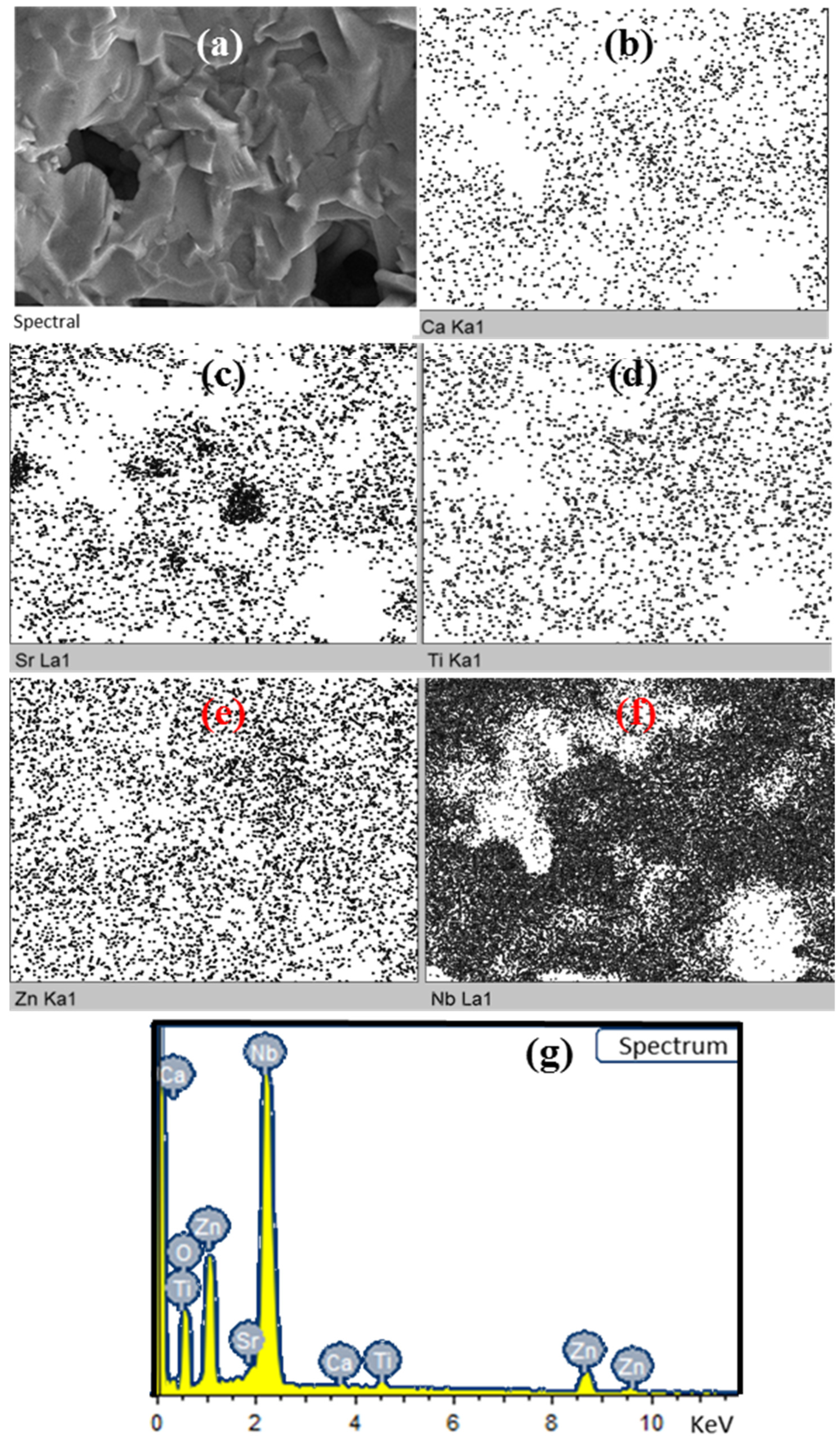

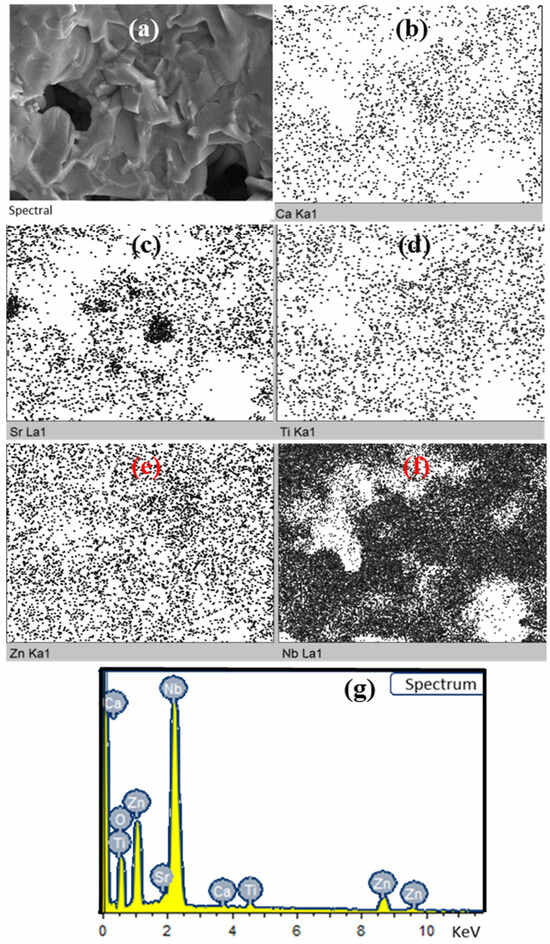

EDX mapping analysis (see Figure 7 and Table 1) confirmed the uniform distribution of Ca, Sr, Ti, Zn and Nb elements over the samples, where the concentrations of Ca, Sr and Ti approximated to the stoichiometric ratio of Ca0.5Sr0.5TiO3, and the ratio of Zn and Nb presented a deviation from the stoichiometric ratio of ZnNb2O6 due to the evaporation of low boiling-point Zn2+ ions [19,29]. Anyway, the elemental composition together with the XRD result suggests the formation of a composite between ZnNb2O6 and Ca0.5Sr0.5TiO3 [38,39].

Figure 7.

(a) Selected area on the fresh fracture surface of 0.925ZnNb2O6-0.075Ca0.5Sr0.5TiO3 ceramic sample. Corresponding elemental SEM-EDX mapping images: (b) Ca, (c) Sr, (d) Ti, (e) Zn, (f) Nb. And (g) the collected SEM-EDX spectrum.

Table 1.

The elemental compositions of typical samples measured by SEM-EDX.

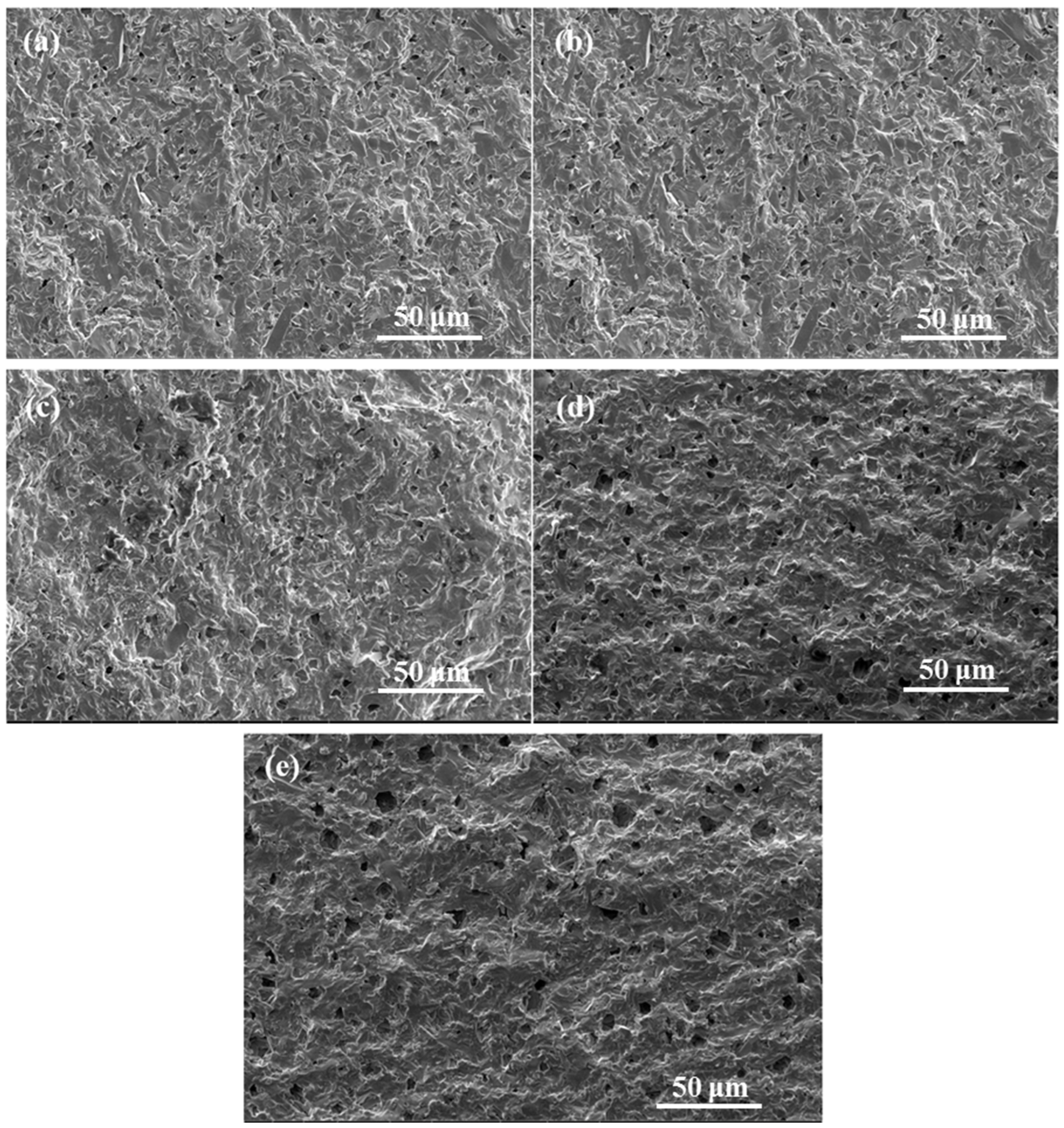

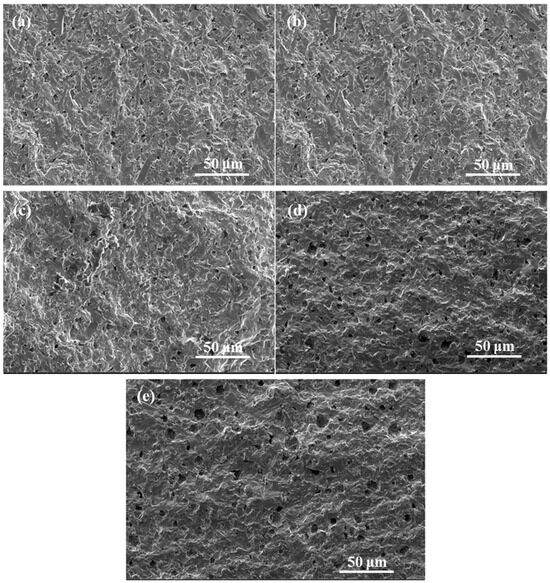

The SEM images on the fresh fracture surface of the obtained ZnNb2O6-Ca0.5Sr0.5TiO3 composite ceramics are shown in Figure 8. It can be clearly seen from this figure that with the increase in Ca0.5Sr0.5TiO3 content, the number and size of pores in the composite ceramic samples are increasing. This result confirms that during sintering, the addition of Ca0.5Sr0.5TiO3 would impede the densification of the designed ZnNb2O6-Ca0.5Sr0.5TiO3 composite ceramics. The phenomenon can be explained as follows. The sintering temperature of Ca0.5Sr0.5TiO3 ceramics is around 1400 °C, which is much higher than that of ZnNb2O6 (<1020 °C). And the increase in the content of high sintering temperature components is not conducive to the sintering of composite ceramics [40]. As a result, the pores cannot be removed in time during the growth of the grains, hindering the movement of the grains, finally resulting in a decrease in grain size and an increase in ceramic porosity.

Figure 8.

Images on the fresh fracture surface of (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics obtained by heating at 1175 °C for 4 h: (a) x = 0.025, (b) x = 0.05, (c) x = 0.075, (d) x = 0.1, (e) x = 0.125.

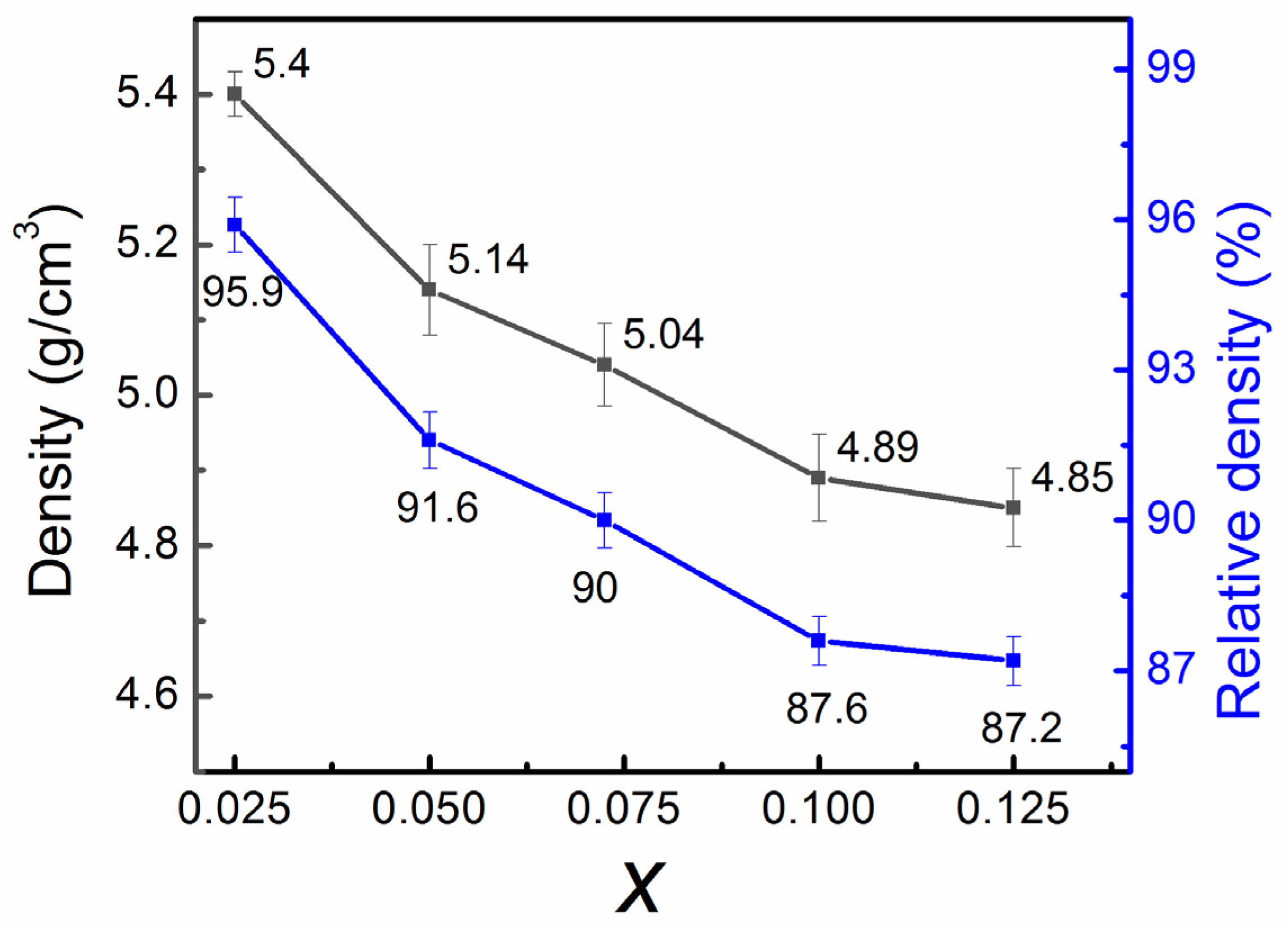

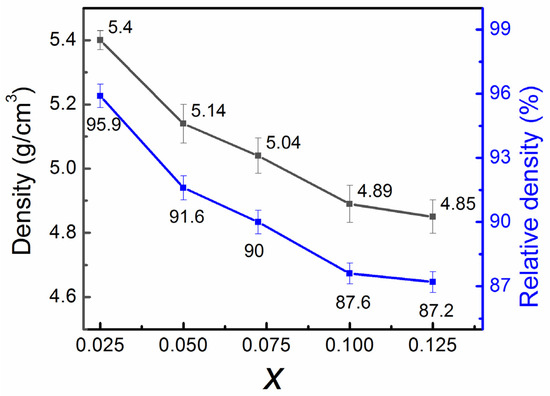

The apparent density and relative density of the ceramics were further measured by Archimedes method, and the results are shown in Figure 9. The apparent density of the samples decreased with increasing Ca0.5Sr0.5TiO3 content due to its lower density (4.7 g/cm3) [41] compared to that of ZnNb2O6 (5.65 g/cm3) [42] and decreased densification of the products. Accordingly, the relative density also decreased, primarily due to the increased porosity of the products. This result is completely consistent with the microstructure observation by SEM imaging (see Figure 8).

Figure 9.

Apparent density and relative density of the obtained (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 composite ceramics as a function of x.

3.3. Microwave Dielectric Properties

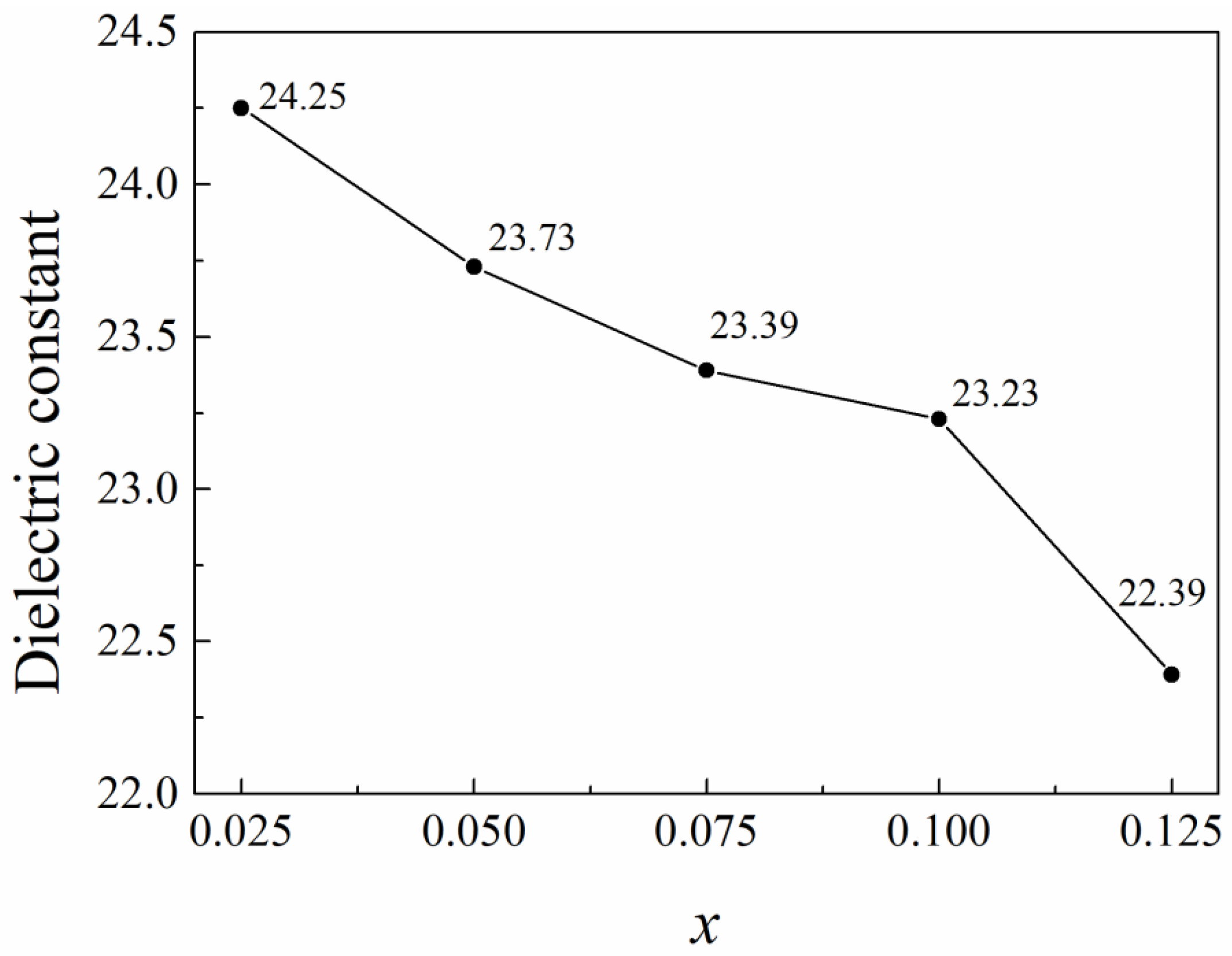

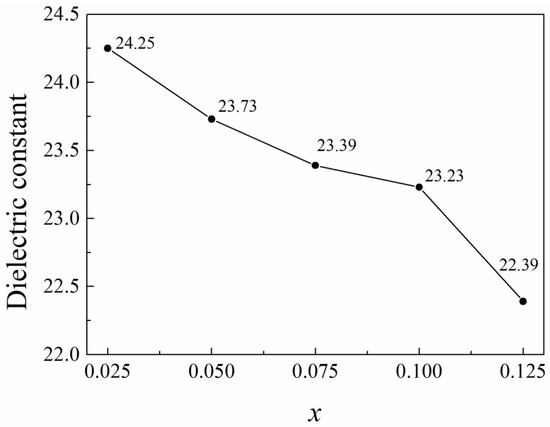

The dielectric constant (εᵣ) of the obtained (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics decreased with increasing Ca0.5Sr0.5TiO3 content (see Figure 10). Generally speaking, εr is mainly determined by the ionic polarizabilities, second phases and pores/density in microwave dielectric ceramics [43]. For the present (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 composite ceramics, the εr value would not be affected by ionic polarizabilities because ion substitution did not occur. Moreover, because the second phase of the added Ca0.5Sr0.5TiO3 has a much higher εr (236) [33] than that of ZnNb2O6 (25) [20,21], the theoretical εr value of the composite ceramics should increase with more Ca0.5Sr0.5TiO3 when the samples are of full densification. However, the actual measured εr value of the present composite ceramics decreased when more Ca0.5Sr0.5TiO3 was added, indicating that the effect of Ca0.5Sr0.5TiO3 on the εr value of the obtained ceramics could be neglected because the addition amount of Ca0.5Sr0.5TiO3 was very small. Therefore, it can be concluded that the increased porosity in the composite ceramics led to the reduction in εᵣ of the present (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 composite ceramics.

Figure 10.

Relationship between dielectric constant (εᵣ) and x of the obtained (1 − x) ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics.

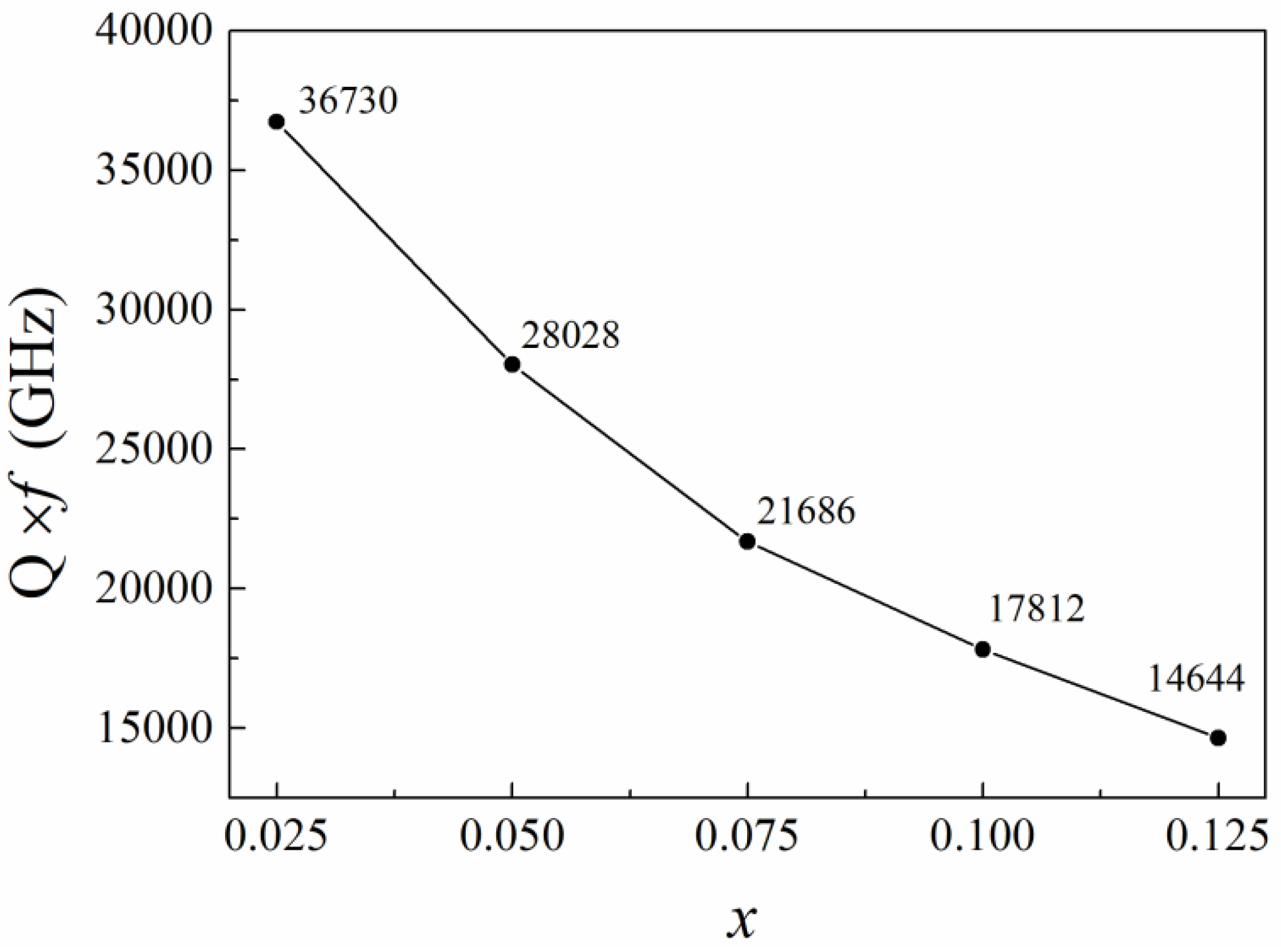

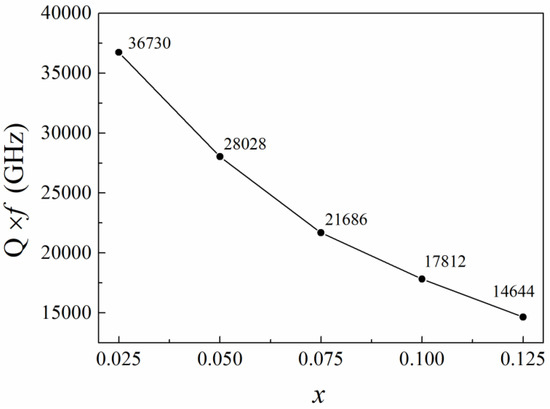

The quality factor (Q × f) also decreased with higher Ca0.5Sr0.5TiO3 content (Figure 11). It is known that the factors influencing the Q × f value of microwave ceramics include not only the intrinsic ones mainly contributing to the lattice vibration mode but also the extrinsic ones such as the second phases in them, grains morphology and densification of the samples [43]. For the present (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 composite ceramics, the extrinsic factors clearly play a major role in the Q × f value decrease, because the dominant phase in the composite ceramics is ZnNb2O6 with an almost constant intrinsic contribution to Q × f. In other words, the decrease in Q × f value is attributed to the lower Q × f of Ca0.5Sr0.5TiO3 (4100 GHz) [32,33], compared to that of ZnNb2O6 (83,700 GHz) [20,21], as well as the increased dielectric losses caused by increased porosity (see Figure 9) and more grain-boundary defects with decreased grain size (see Figure 6).

Figure 11.

Relationship between quality factor (Q × f) and x of the obtained (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics.

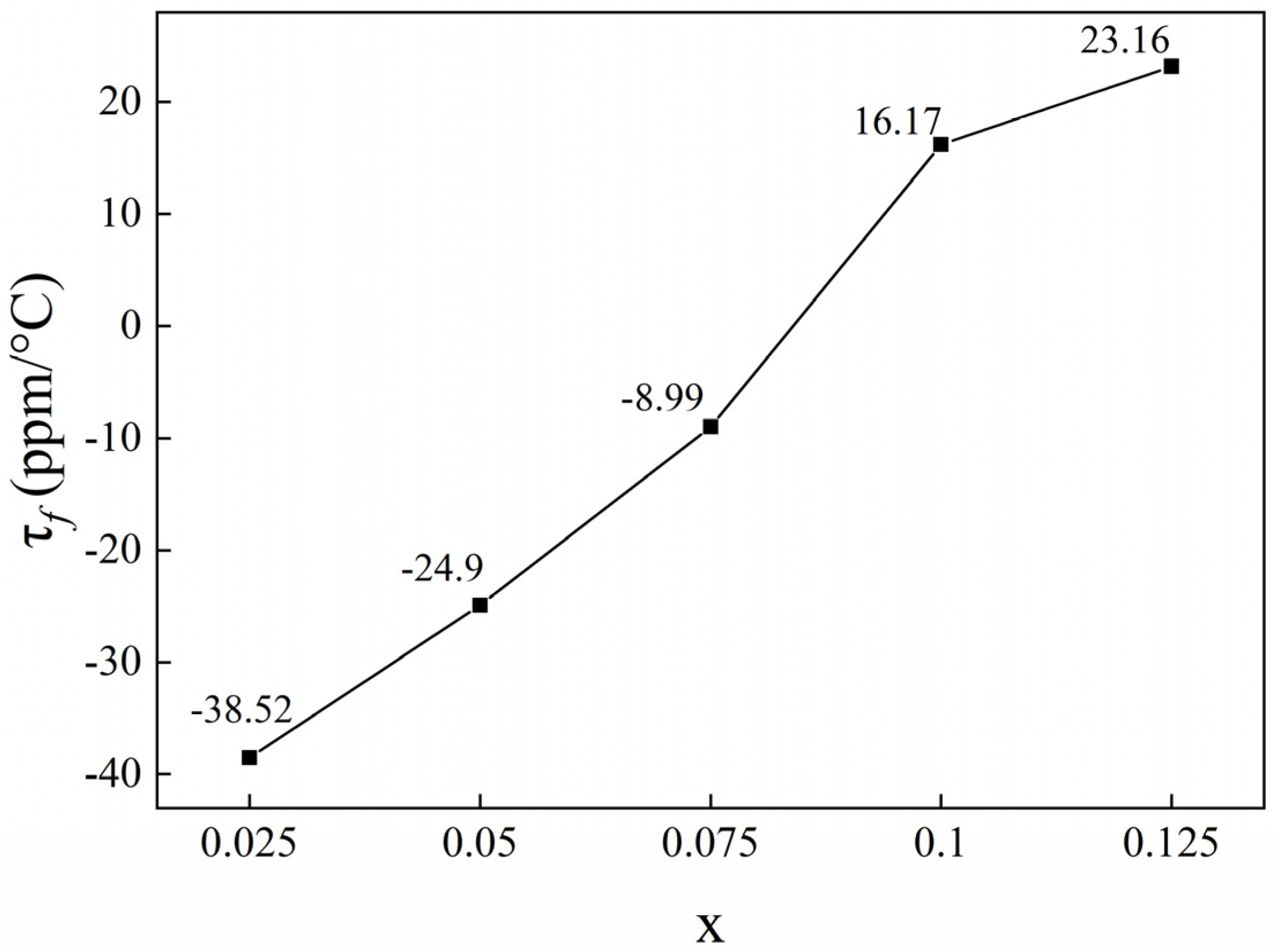

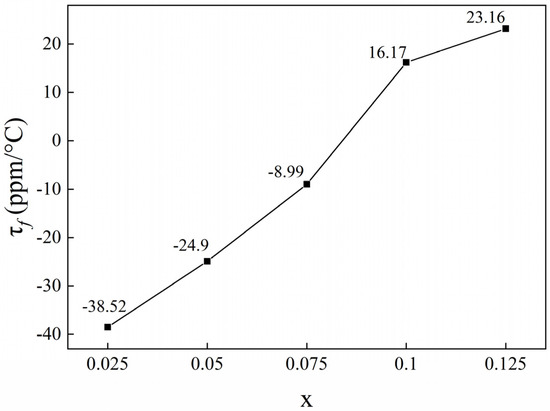

The temperature coefficient of resonant frequency (τf) shifted toward positive values with increasing Ca0.5Sr0.5TiO3 content (Figure 12). At x = 0.075, τf reached a near-zero value (−8.99 ppm/°C), consistent with theoretical predictions. This phenomenon can be explained as follows. Generally, the τf value of two-phase microwave dielectric composite ceramics was determined by the matrix and second phases in the samples, obeying the following mixing rule [43]:

where v1 and v2 represent the volume fraction of the components, and τf1 and τf2 are their τf value, respectively. For the present (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 composite ceramics, the τf value of matrix ZnNb2O6 is −56.1 ppm/°C, while that of the second phase Ca0.5Sr0.5TiO3 is +1230 ppm/°C. After adding Ca0.5Sr0.5TiO3, the τf value of the composite ceramics would be adjusted from negative to positive effectively.

Figure 12.

Relationship between frequency temperature coefficient (τf) and x of the obtained (1 − x)ZnNb2O6−xCa0.5Sr0.5TiO3 ceramics.

To make the merits of the obtained ZnNb2O6-Ca0.5Sr0.5TiO3 composite ceramics more clear, Table 2 compares the microwave dielectric properties of the present optimal 0.925ZnNb2O6-0.075Ca0.5Sr0.5TiO3 composite ceramics with those of the already-reported important ZnNb2O6-based microwave dielectric ceramics in the literature. It can be seen that the present 0.925ZnNb2O6-0.075Ca0.5Sr0.5TiO3 composite ceramics have a lower εr, relatively high Q × f and near-zero τf value, which would be a very promising candidate for 5G communication devices and future communication technologies.

Table 2.

Comparison on the microwave dielectric properties of the ZnNb2O6-based microwave dielectric ceramics between the present study and those in the literature.

4. Conclusions

This study successfully designed and fabricated novel (1 − x)ZnNb2O6−x Ca0.5Sr0.5TiO3 (x = 0.05–0.125) composite ceramics with near-zero τf but acceptable Q × f. The study systematically investigated the sintering behavior, microstructure, and microwave dielectric properties of the composite ceramics. The optimal sintering conditions were determined as 1175 °C for 4 h using a visual high-temperature deformation analyzer, ensuring full densification of all compositions. In the sintered ceramics, only the ZnNb2O6 phase was detected, while the Ca0.5Sr0.5TiO3 phase remained undetectable due to its low content. As the Ca0.5Sr0.5TiO3 content increased, the average grain size of the ceramics exhibited a decreasing trend and the relative density declined, attributed to the higher sintering temperature of Ca0.5Sr0.5TiO3, which impeded the grain growth and densification of ZnNb2O6-based ceramics.

With increasing Ca0.5Sr0.5TiO3 content, the dielectric constant (εᵣ) and quality factor (Q × f) decreased continuously, whereas the temperature coefficient of resonant frequency (τf) shifted toward positive values. For the optimal ceramics (with x = 0.075), the τf reached a near-zero value of −8.99 ppm/°C, accompanied by εᵣ = 23.23 and Q × f = 21,686 GHz.

These results demonstrate that adjusting the Ca0.5Sr0.5TiO3 content effectively optimizes the microstructure and microwave dielectric performance of ZnNb2O6-Ca0.5Sr0.5TiO3 composite ceramics, rendering them suitable for high-performance dielectric applications. This study provides the theoretical and material support for designing and fabricating various high-performance microwave dielectric ceramics for 5G communication devices and future communication technologies.

Author Contributions

Conceptualization, H.W., C.C. and Z.P.; methodology, H.W. and C.C.; software, H.W.; validation, H.W., C.C. and Z.P.; formal analysis, H.W. and C.C.; investigation, H.W. and C.C.; resources, X.F. and Z.P.; data curation, H.W. and C.C.; writing—original draft preparation, H.W. and Z.P.; writing—review and editing, X.F. and Z.P.; visualization, H.W.; supervision, X.F. and Z.P.; project administration, X.F.; funding acquisition, X.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China, grant number 12174035 and U21A6004.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Miao, Y.; Yang, K.; Zhao, P.; Yang, Z.H.; Yu, X.Y.; Duan, X.M.; Jia, D.C.; Zhou, Y. Development of industry system of microwave dielectric ceramics. Strateg. Study Chin. Acad. Eng. 2024, 26, 34–41. [Google Scholar]

- Sebastian, M.T.; Jantunen, H. Low loss dielectric materials for LTCC applications: A review. Int. Mater. Rev. 2008, 53, 57–90. [Google Scholar] [CrossRef]

- Zhang, P.; Lin, J.; Jia, Q.; Yang, X.J.; Li, H. Research progress and prospect of microwave dielectric ceramic materials for 5G communication. Adv. Ceram. 2024, 45, 44–58. [Google Scholar]

- Pang, Q.Y.; Chen, Y.; Wang, Z.X.; Zhou, B.; Li, X.; Mu, C.; Gu, G.P.; Wang, G.S. Structure, electric, and dielectric properties of (Sr0.7Ca0.3)1.02(Zr0.95−xTi0.05Mnx)O3+δ ceramics for BME-MLCCs application. J. Adv. Ceram. 2024, 13, 1382–1393. [Google Scholar] [CrossRef]

- Raveendran, A.; Sebastian, M.T.; Raman, S. Applications of microwave materials: A review. J. Electron. Mater. 2019, 48, 2601–2634. [Google Scholar] [CrossRef]

- Feng, C.; Zhou, X.; Tao, B.J.; Wu, H.T.; Huang, S.F. Crystal structure and enhanced microwave dielectric properties of the Ce2[Zr1−x(Al1/2Ta1/2)x]3(MoO4)9 ceramics at microwave frequency. J. Adv. Ceram. 2022, 11, 392–402. [Google Scholar] [CrossRef]

- Zhang, L.L.; Yu, H.L.; Song, T.; Shen, T.; Ma, G.H.; Zhang, Y.C.; Wang, H.R.; Tan, K. Research status of low temperature co-firing of microwave dielectric ceramics. Adv. Ceram. 2022, 43, 246–261. [Google Scholar]

- Zhang, J.T.; Xu, S.Q.; Zhou, D.X.; Xiong, Z.X.; Fang, Y.H. Development of microwave dielectric materials and its applications. J. Compon. Mater. 2004, 23, 6–9. [Google Scholar]

- Bao, J.; Zhang, Y.P.; Kimura, H.D.; Wu, H.T.; Yue, Z.X. Crystal structure, chemical bond characteristics, infrared reflection spectrum, and microwave dielectric properties of Nd2(Zr1−xTix)3(MoO4)9 ceramics. J. Adv. Ceram. 2023, 12, 82–92. [Google Scholar] [CrossRef]

- Tan, K.; Song, T.; Shen, T.; Yu, H.L.; Zhang, Y.C.; Cui, K.; Xu, X.B.; Li, W.; Wang, H.R. Research progress of low permittivity microwave dielectric ceramics. Adv. Ceram. 2022, 43, 11–29. [Google Scholar]

- Tian, H.R.; Zhang, X.H.; Zhang, Z.D.; Liu, Y.; Wu, H.T. Low-permittivity LiLn(PO3)4 (Ln = La, Sm, Eu) dielectric ceramics for microwave/millimeter-wave communication. J. Adv. Ceram. 2024, 13, 602–620. [Google Scholar] [CrossRef]

- Bijumon, P.V.; Mohanan, P.; Sebastian, M.T. High dielectric constant low loss microwave dielectric ceramics in the Ca5Nb2−xTaxTiO12 system. Mater. Lett. 2003, 57, 1380–1384. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Xiang, H.C.; Wu, X.Y.; Zhou, Y.; Tang, Y.; Fang, L. Low dielectric loss in vanadium-based zircon ceramics via high-entropy strategy. J. Adv. Ceram. 2025, 14, 9221012. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, W.; Lin, H. SrGa12O19: The first low-εr Ga-based microwave dielectric ceramic with anomalous positive τf. J. Adv. Ceram. 2024, 13, 1432–1441. [Google Scholar] [CrossRef]

- Liu, W.F.; Kong, F.Y.; Liang, Y.; Ran, D.S.; Zhao, Y.; Li, S.T. Strategy to achieve both enhanced dielectric tunability and reduced dielectric loss in the barium zirconium titanate ceramics. Ceram. Int. 2024, 50, 31759–31766. [Google Scholar] [CrossRef]

- Ma, C.; Su, T.; Li, Z.H.; Ren, B.; Meng, Z.Q.; Li, B.; Hao, R.X.; Miao, Y.; Gao, F. Preparation of (Ba0.25Ca0.25Sr0.25La0.25)Ti1-xAlxO3 high-entropy perovskite ceramics for enhanced microwave dielectric performance. J. Alloys Compd. 2025, 1010, 177719. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, S.R.; Fang, Z.X.; Chen, H.T.; Xiong, Z.; Tang, B. A new niobate-based CaO-2CuO-Nb2O5 microwave dielectric ceramic composite for LTCC applications. J. Mater. Sci. Mater. Electron. 2018, 29, 4533–4537. [Google Scholar] [CrossRef]

- Luo, W.J.; Wang, S.; Heng, S.Z.; Li, J.N.; Wang, M.L.; Wen, Y.Z.; Li, L.X.; Zhou, J. Dielectric response of ANb2O6 (A = Zn, Co, Mn, Ni) columbite niobates: From microwave to terahertz. J. Adv. Ceram. 2024, 13, 1189–1197. [Google Scholar] [CrossRef]

- Fu, Z.F.; Ma, J.L.; Cheng, Q.; Li, X.Y.; Zhai, S.M. Improved temperature stability of Li3Mg2NbO6 microwave dielectric ceramics by using CaTiO3 additives. Mater. Chem. Phys. 2024, 318, 129296. [Google Scholar] [CrossRef]

- Pan, H.L.; Cheng, L.; Mao, Y.X. Investigation and characterization on crystal structure of ixiolite structure ATiNb2O8 (A = Mg, Zn) ceramics at microwave frequency based on the complex chemical bond theory. J. Alloys Compd. 2017, 693, 792–798. [Google Scholar] [CrossRef]

- Belous, A.G.; Ovchar, O.V.; Kramarenko, A.V.; Jancar, B.; Bezjak, J.; Suvorov, D. Synthesis and microwave dielectric properties of Zn1+xNb2O6+x. Inorg. Mater. 2007, 43, 277–280. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Wang, J.; Yue, Z.X.; Gui, Z.L.; Li, L.T. Effects of Mg2+ substitution on microstructure and microwave dielectric properties of (Zn1−xMgx)Nb2O6 ceramics. Ceram. Int. 2004, 30, 87–91. [Google Scholar] [CrossRef]

- Lee, H.J.; Hong, K.S.; Kim, S.J.; Kim, I.T. Dielectric properties of MNb2O6 compounds (where M=Ca, Mn, Co, Ni, or Zn). Mater. Res. Bull. 1997, 32, 847–855. [Google Scholar] [CrossRef]

- Pullar, R.C. The synthesis, properties, and applications of columbite niobates (M2+Nb2O6): A critical review. J. Am. Ceram. Soc. 2009, 92, 563–577. [Google Scholar] [CrossRef]

- Anjana, P.S.; Jawahar, I.N.; Sebastian, M.T. Low loss, temperature stable dielectric ceramics in ZnNb2O6–Zn3Nb2O8 system for LTCC applications. J. Mater. Sci. Mater. Electron. 2009, 20, 587–596. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Yue, Z.X.; Yang, X.H.; Zhao, J.Q.; Gui, Z.L.; Li, L.T. Microwave dielectric ceramics (1−x)ZnNb2O6−xZnTa2O6 with high quality factors. Rare Met. Mater. Eng. 2003, 32, 572–574. [Google Scholar]

- Zhang, Y.; Ding, S.H.; You, L.; Zhang, Y.C. Temperature stable microwave dielectric ceramic CoTiNb2O8-Zn1.01Nb2O6 with ultra-low dielectric loss. J. Electron. Mater. 2019, 48, 867–872. [Google Scholar] [CrossRef]

- Zuo, J.; Wang, H.D.; Fu, X.L.; Peng, Z.J. Microwave Dielectric Behavior of CoTiTa2O8-MgNb2O6 Composite Ceramics: A Focus on Temperature Stability and Compositional Effects. Metals 2025, 15, 407. [Google Scholar] [CrossRef]

- Wu, M.J.; Zhang, Y.C.; Xiang, M.Q. Synthesis, characterization and dielectric properties of a novel temperature stable (1−x)CoTiNb2O8−xZnNb2O6 ceramic. J. Adv. Ceram. 2019, 8, 228–237. [Google Scholar] [CrossRef]

- Liao, Q.W.; Li, L.X.; Zhang, P.; Cao, L.F.; Han, Y.M. Correlation of crystal structure and microwave dielectric properties for ZnTi(Nb1−xTax)2O8 ceramics. Solid State Sci. 2011, 13, 1201–1204. [Google Scholar] [CrossRef]

- Wise, P.L.; Reaney, I.M.; Lee, W.E.; Price, T.J.; Iddles, D.M.; Cannell, D.S. Structure-microwave property relations in (SrxCa1−x)n+1TinO3n+1. J. Eur. Ceram. Soc. 2001, 21, 1723–1726. [Google Scholar] [CrossRef]

- Mohapatra, S.; Badapanda, T.; Barman, R.; Das, T.K.; Huang, Y.; Xiao, J.; Tripathy, S.N. Correlation of the crystal structure, bond characteristics, and microwave dielectric properties of (1−x)MgTiO3−xCa0.5Sr0.5TiO3 ceramic for DRA applications. Mater. Sci. Semicond. Process. 2025, 186, 109061. [Google Scholar] [CrossRef]

- Chen, C.Y.; Peng, Z.J.; Xie, L.Z.; Bi, K.; Fu, X.L. Microwave dielectric properties of novel (1−x)MgTiO3−xCa0.5Sr0.5TiO3 ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 13696–13703. [Google Scholar] [CrossRef]

- ISO 18754:2020; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Density and Apparent Porosity. ISO: Geneva, Switzerland, 2020.

- Ren, J.Q.; Bi, K.; Fu, X.L.; Peng, Z.J. Microstructure and microwave dielectric properties of Al2O3 added Li2ZnTi3O8 ceramics. Ceram. Int. 2018, 44, 8928–8933. [Google Scholar] [CrossRef]

- Sanoj, M.A.; Reshmi, C.P.; Varma, M.R. Finite size effect on the sinterability and dielectric properties of ZnNb2O6-ZBS glass composites. J. Am. Ceram. Soc. 2009, 92, 2648–2653. [Google Scholar] [CrossRef]

- Wang, W.; Pu, Y.P.; Guo, X.; Shi, R.K.; Yang, M.D.; Li, J.W. Enhanced energy storage and fast charge-discharge capability in Ca0.5Sr0.5TiO3-based linear dielectric ceramic. J. Alloys Compd. 2020, 817, 152695. [Google Scholar] [CrossRef]

- Kumada, N.; Koike, N.; Nakanome, K. Synthesis of rutile-type solid solution Ni1−xCoxTi(Nb1−yTay)2O8 (0 ≤ x ≤ 1, 0 ≤ y ≤ 1) and its optical property. J. Asian Ceram. Soc. 2017, 5, 284–289. [Google Scholar] [CrossRef]

- Liou, Y.C.; Sung, Y.L. Preparation of columbite MgNb2O6 and ZnNb2O6 ceramics by reaction-sintering. Ceram. Int. 2008, 34, 371–377. [Google Scholar] [CrossRef]

- Hu, J.; Liu, X.P.; Zhang, J. Research progress in the preparation technology of microwave dielectric ceramics. Inf. Rec. Mater. 2018, 19, 6–8. [Google Scholar]

- Shao, D.Y.; Hui, Q.; Li, X.; Chen, J.J.; Li, C.M.; Cheng, N.P. First-principles study on the elastic and thermal properties of Ca0.5Sr0.5TiO3. Acta Phys. Sin. 2016, 64, 207102. [Google Scholar] [CrossRef]

- Wang, H.; Fu, R.L.; Liu, Y.N.; Su, X.Q.; Xu, Y.; Zhao, G.H.; Liu, X.H. Enhanced dielectric properties and chemical bond characteristics of ZnNb2O6 ceramics due to zinc oxide doping. Ceram. Int. 2022, 48, 82–89. [Google Scholar] [CrossRef]

- Ren, J.Q.; Bi, K.; Fu, X.L.; Peng, Z.J. Novel Al2Mo3O12-based temperature-stable microwave dielectric ceramics for LTCC applications. J. Mater. Chem. C 2018, 6, 11465–11470. [Google Scholar] [CrossRef]

- Liou, Y.C.; Wu, Y.C. Microwave dielectric properties of ZnNb2O6-SrTiO3 stacked resonators. J. Electron. Mater. 2017, 46, 2387–2392. [Google Scholar] [CrossRef]

- Lei, S.H.; Fan, H.Q.; Ren, X.H.; Fang, J.W.; Ma, L.T.; Tian, H.L. Microstructure, phase evolution and interfacial effects in a new Zn0.9Mg0.1TiO3-ZnNb2O6 ceramic system with greatly induced improvement in microwave dielectric properties. Scr. Mater. 2018, 146, 154–159. [Google Scholar] [CrossRef]

- Qian, Y.J.; Su, H.; Tang, X.L.; Huang, F.Y.; Li, Y.X.; Zhang, Q. Temperature stability of low-temperature fired (1−x)ZnTiNb2O8−xCuTiNb2O8 microwave dielectric ceramics. Ceram. Int. 2021, 47, 24823–24830. [Google Scholar] [CrossRef]

- Bafrooei, H.B.; Feizpour, M.; Sayyadi-Shahraki, A.; Song, K.X. High-performance ZnTiNb2O8 microwave dielectric ceramics produced from ZnNb2O6-TiO2 nano powders. J. Alloys Compd. 2020, 834, 155082. [Google Scholar] [CrossRef]

- Wang, H.H.; Shang, Y.F.; Li, Y.X.; Liao, Y.L.; Ruan, L.M.; Liu, Y. Composite strategy toward thermally stable ZnNb2O6-based microwave ceramics with near-zero if. Ceram. Int. 2025, 51, 54959–54965. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).