Manufacturing Technology and Mechanical Properties of Novel Pre-Impregnated Coatings as Applied to FRP “Sandwich” Composites

Abstract

1. Introduction

2. Materials and Methods

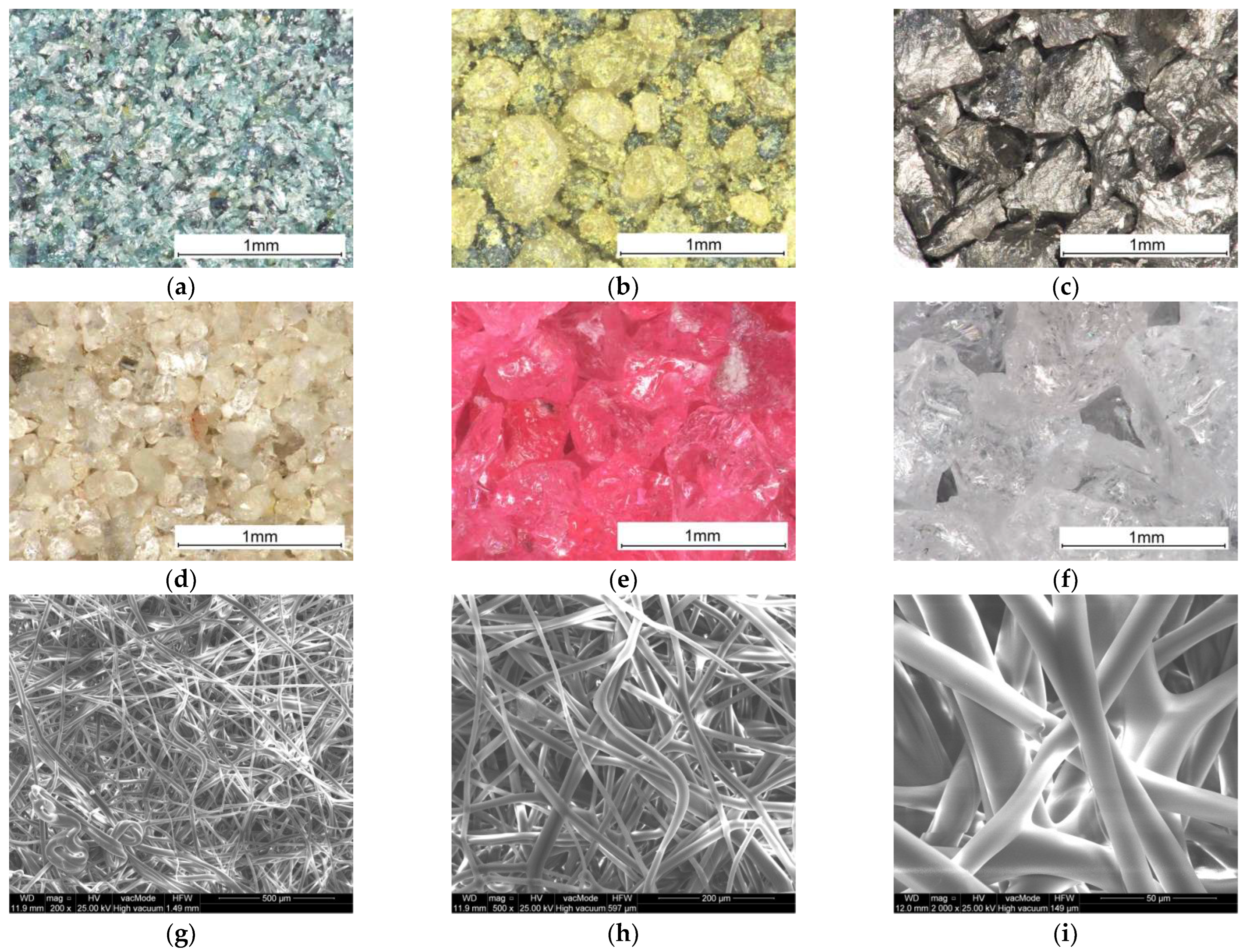

- Silicon carbide green;

- Glauconite;

- Stainless-steel shot;

- Quartz sand;

- Chrome electro-corundum.

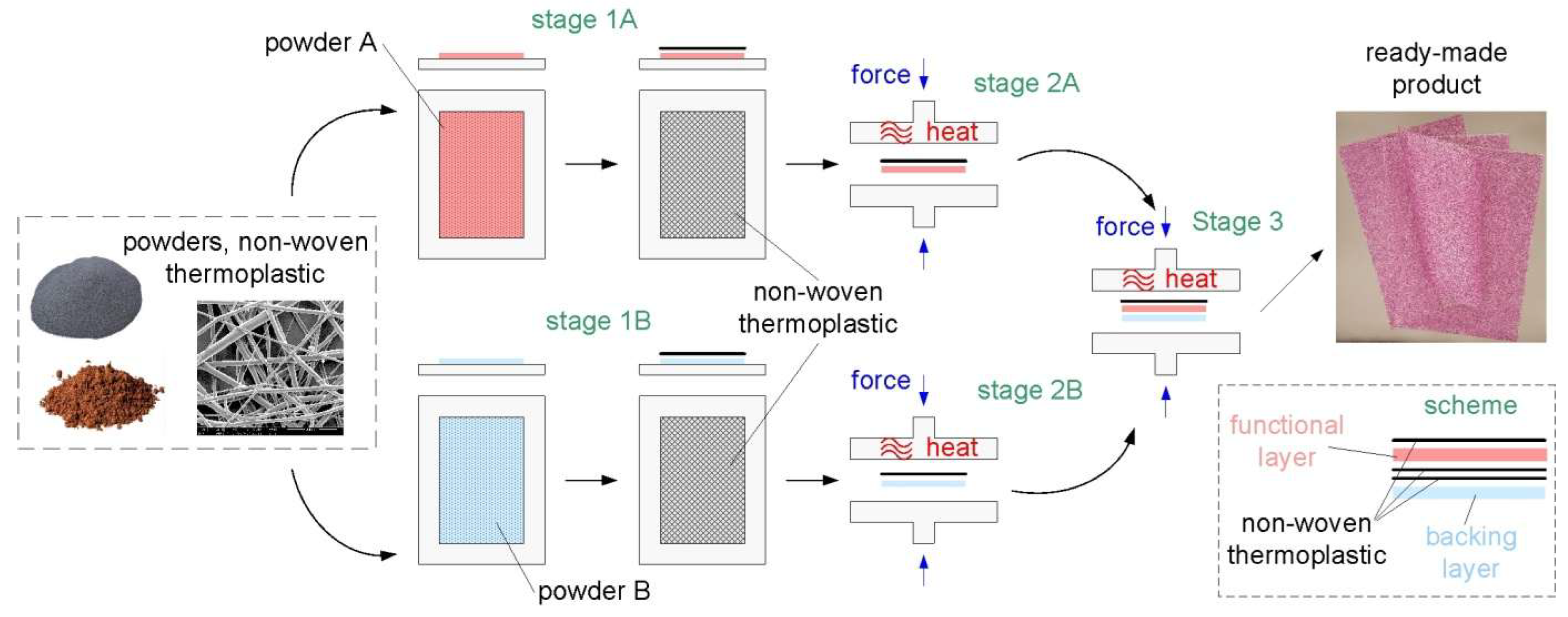

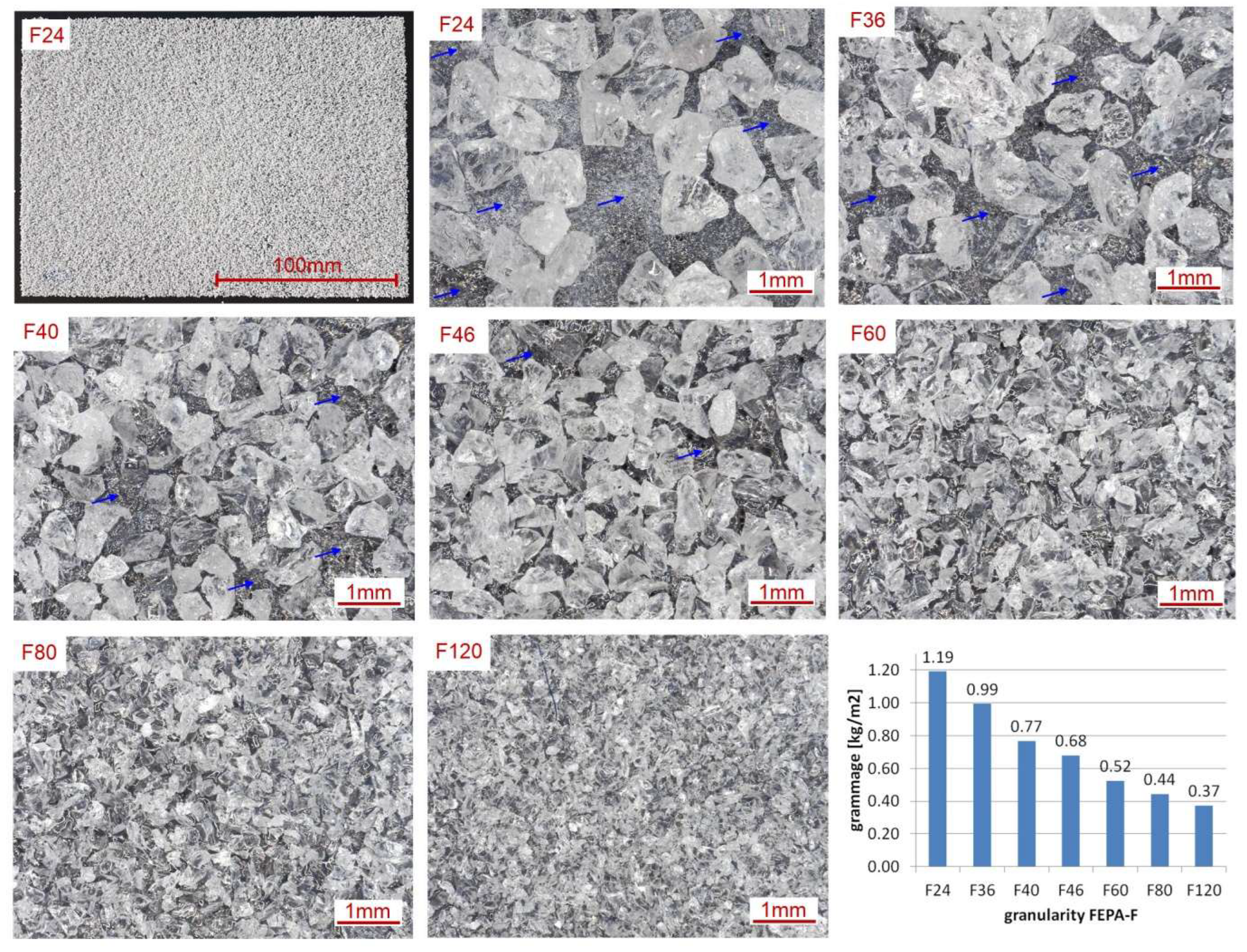

2.1. Manufacturing Technology for Pre-Impregnated Coatings

- -

- By adjusting the rotational speed of the powder feeder roller while maintaining the same number of passes;

- -

- By adjusting the number of passes while maintaining the same rotational speed of the feeder roller.

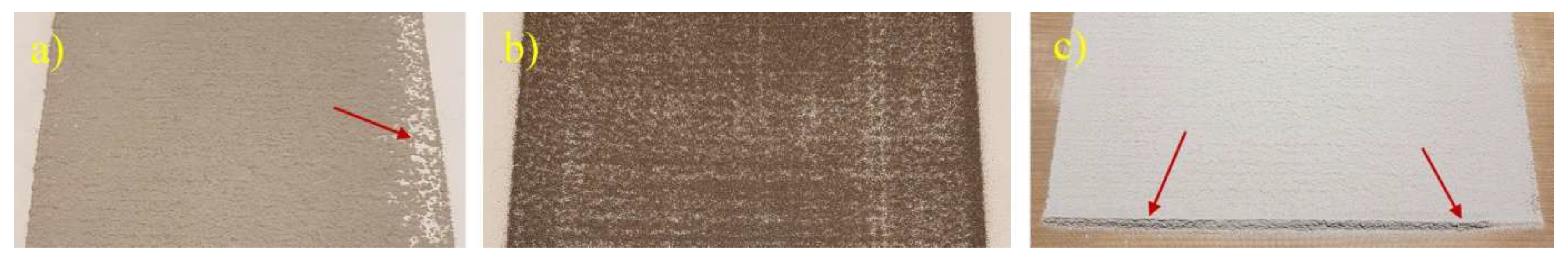

- One-sided cavities;

- Uniform defects covering the entire sheet;

- Excessive powder at the beginning and end of the layer, resulting from the delayed movement of the feeder.

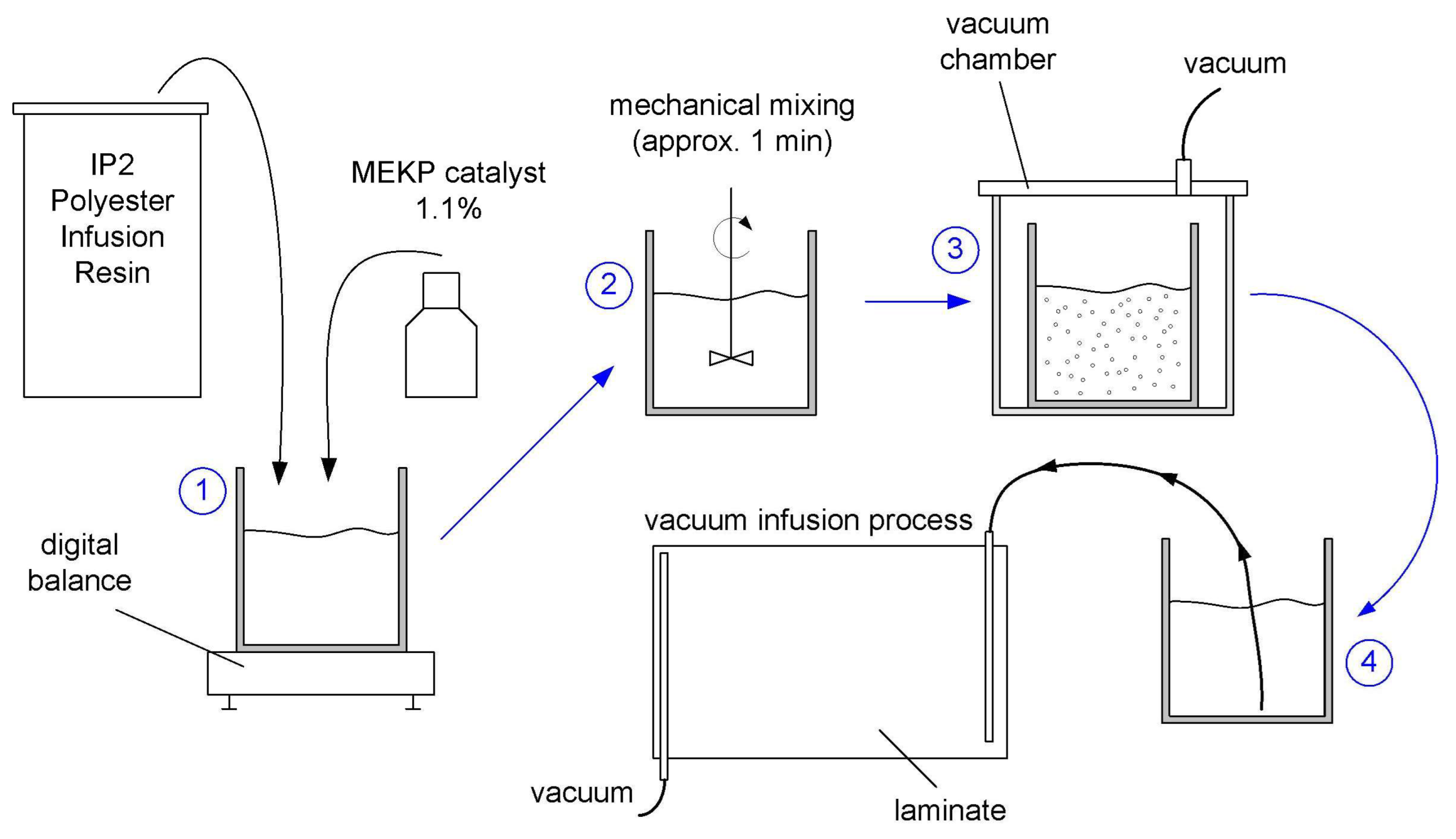

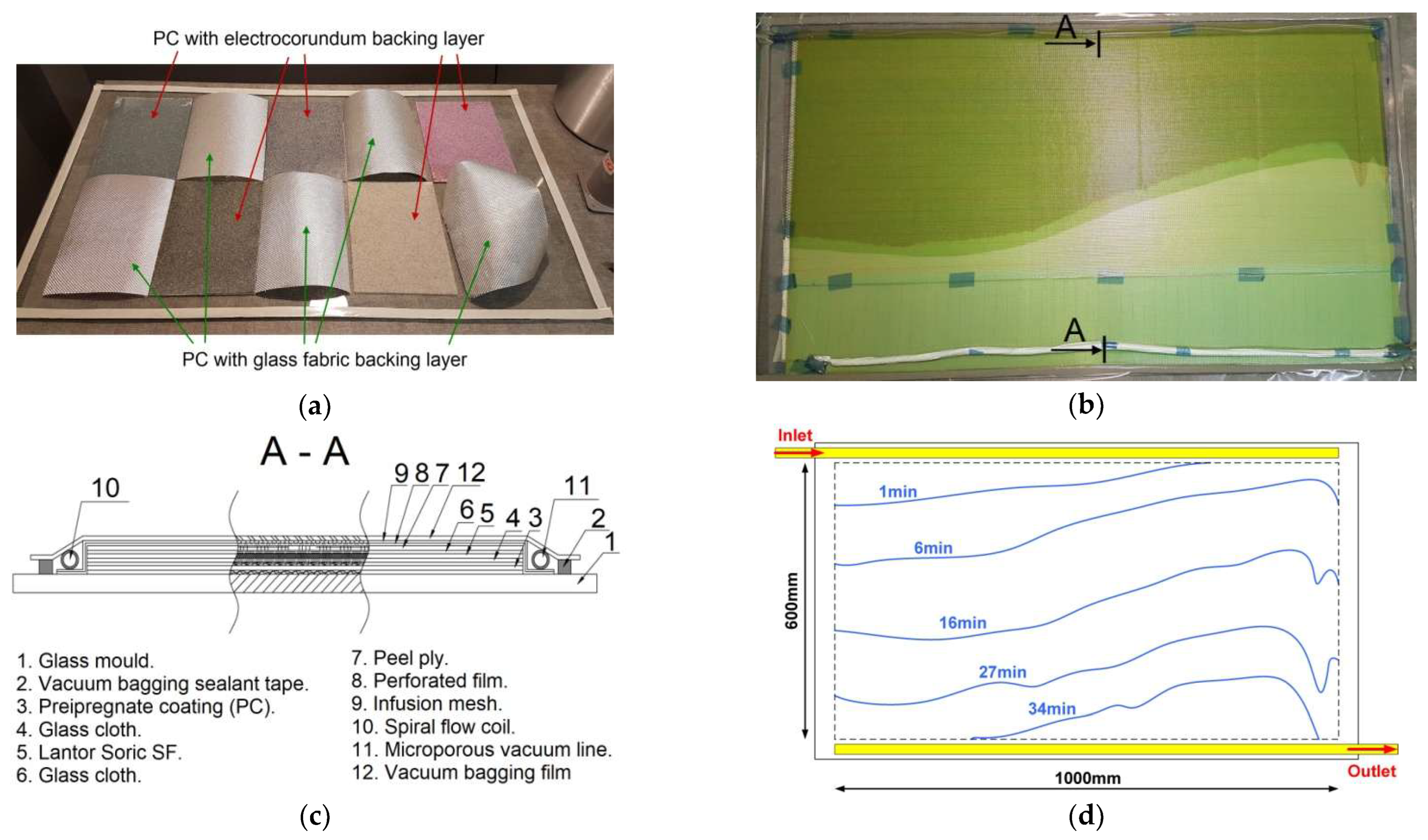

2.2. Vacuum Infusion Technology

- Preparing the glass plate by coating it with a thin layer of wax;

- Arrangement of the PC sheets so that the FL was on the glass side (Figure 8a);

- Placement of three layers of reinforcement involved a “Soric SF” core; again three layers of reinforcement; and also peel-ply, perforated film and infusion mesh. The package was closed with a vacuum bag, in which a vacuum of 300 hPa was applied;

- Preparation of the resin/catalyst mixture by mechanical mixing, placing the container with the mixture in a vacuum chamber to remove the air. This process is illustrated in Figure A2 in the Appendix.

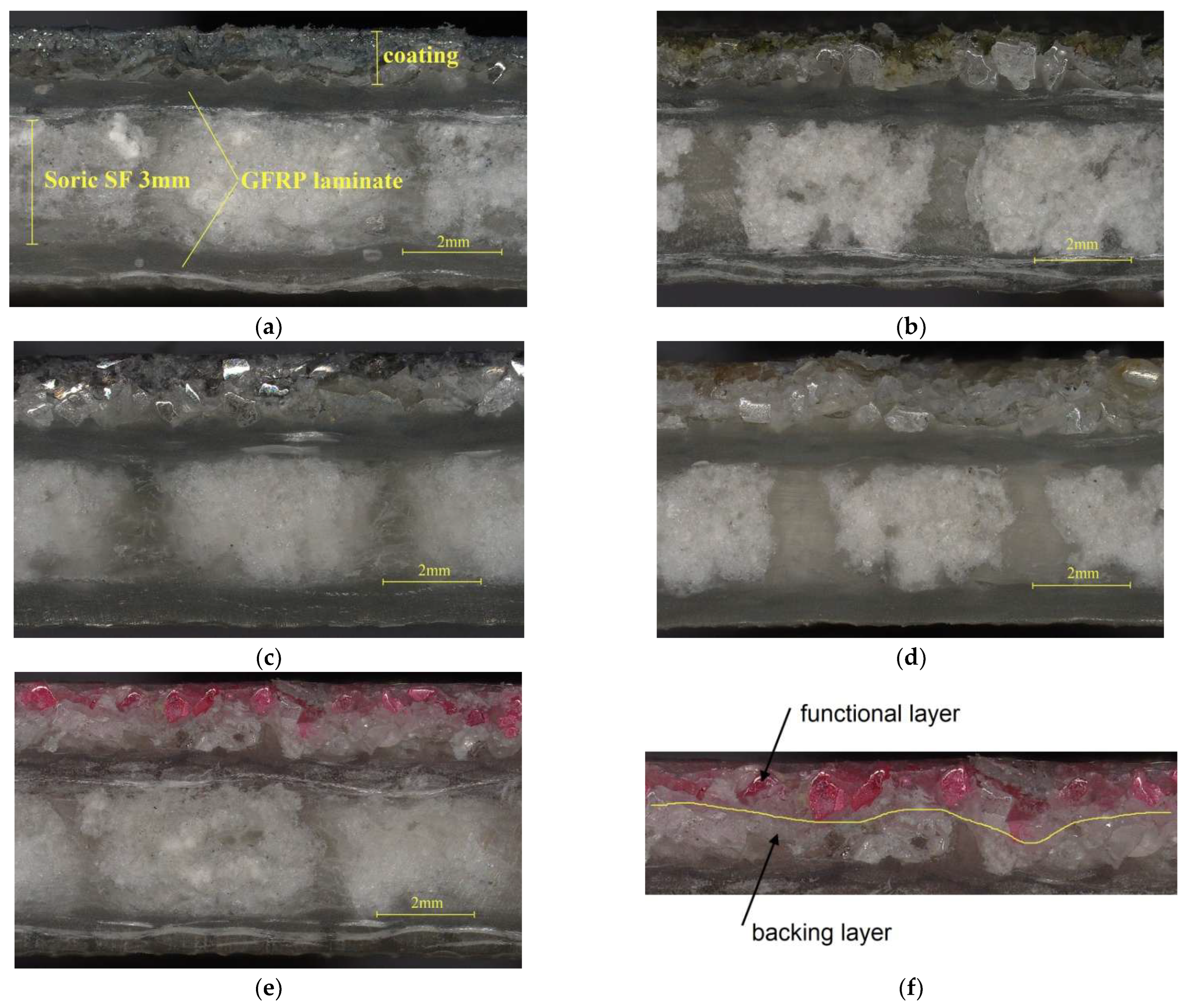

- A 3 mm thick "Soric SF" core;

- GFRP laminate layers on both sides;

- Single-sided PC coating.

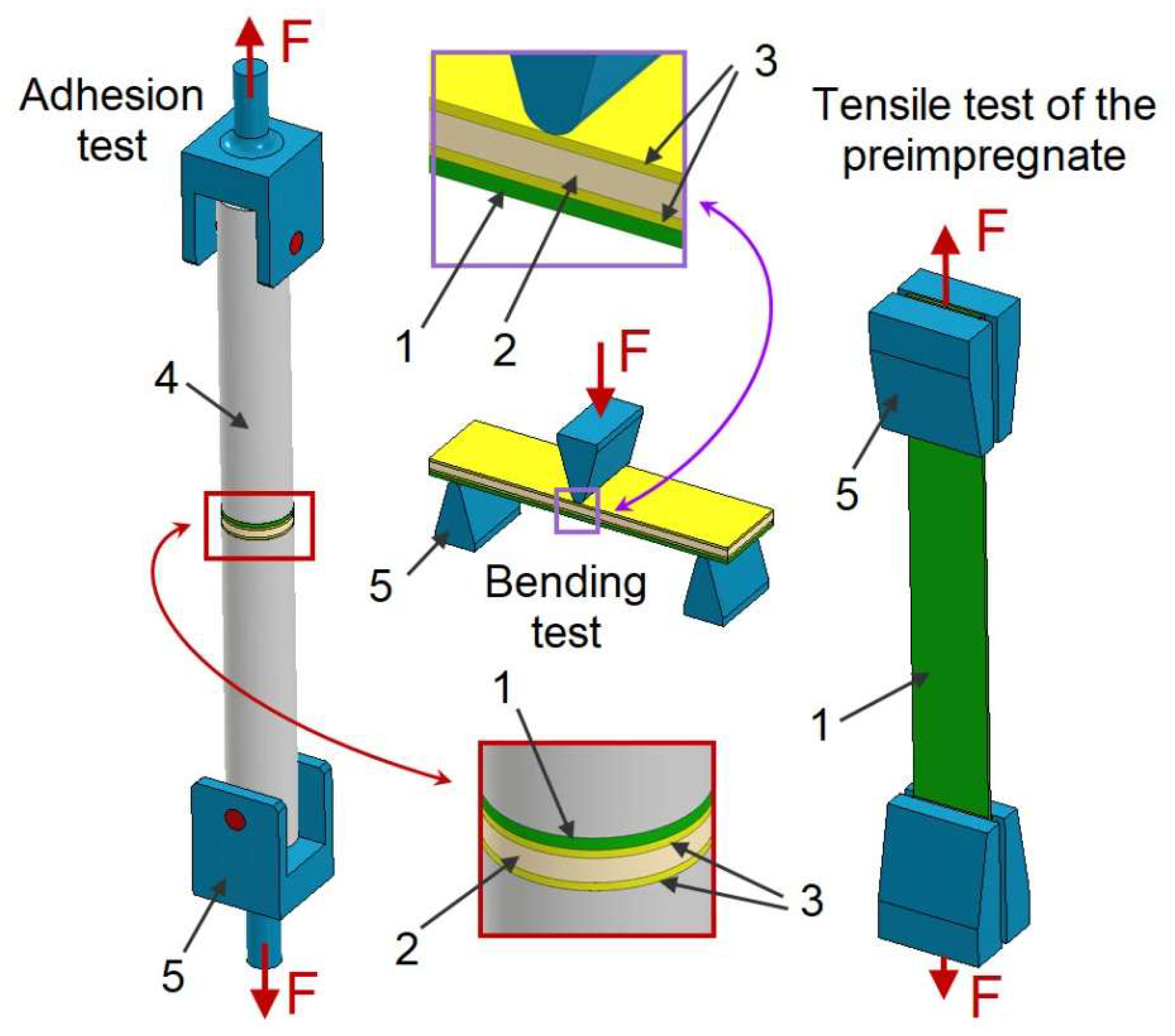

2.3. Strength Tests

- Pre-impregnate tensile for 30 mm × 250 mm specimens (Figure 11) measuring 30 mm × 250 mm—batch A (three specimens for each batch);

- Bending for PC “sandwich” composite—30 mm × 120 mm specimens—batch B (three specimens for each batch);

- Adhesion for the “sandwich” composite with PC—25 mm diameter circular specimens—batch C (five specimens for each batch).

3. Results and Discussion

- PC tensile strength test with different powders for the FL;

- Adhesion tests of the “sandwich” composite with PC;

- Three-point bending tests of the “sandwich” composite with PC.

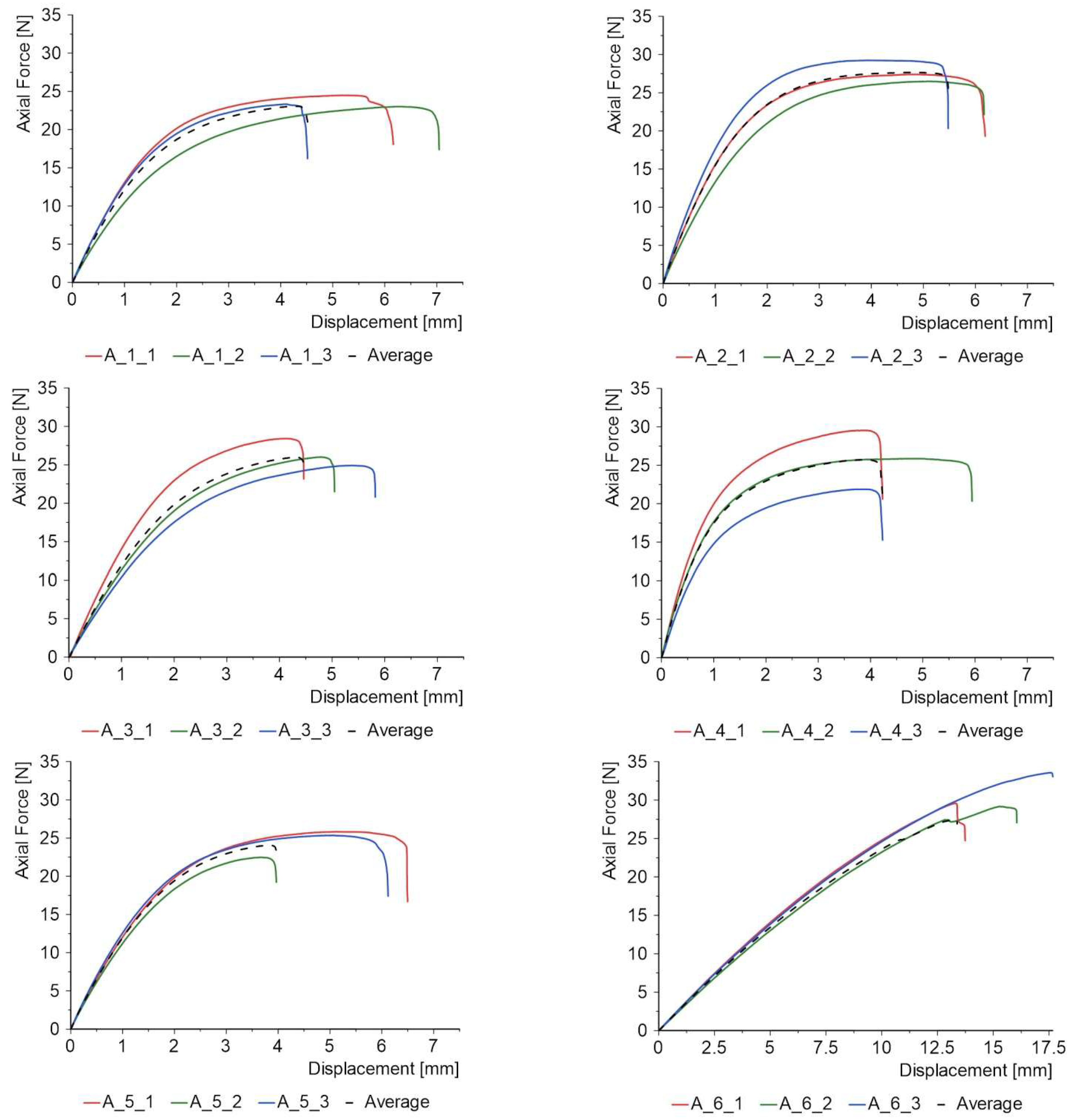

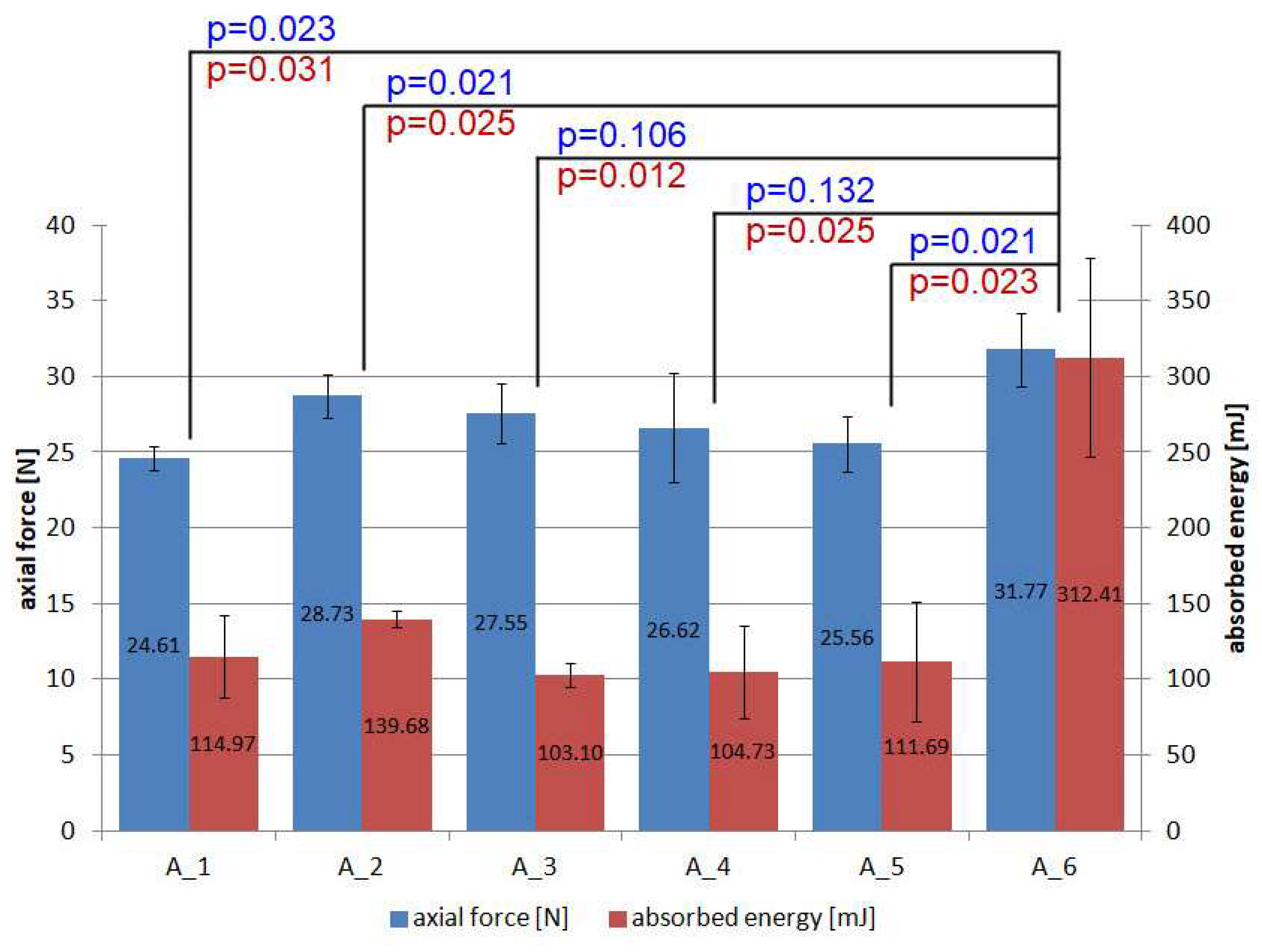

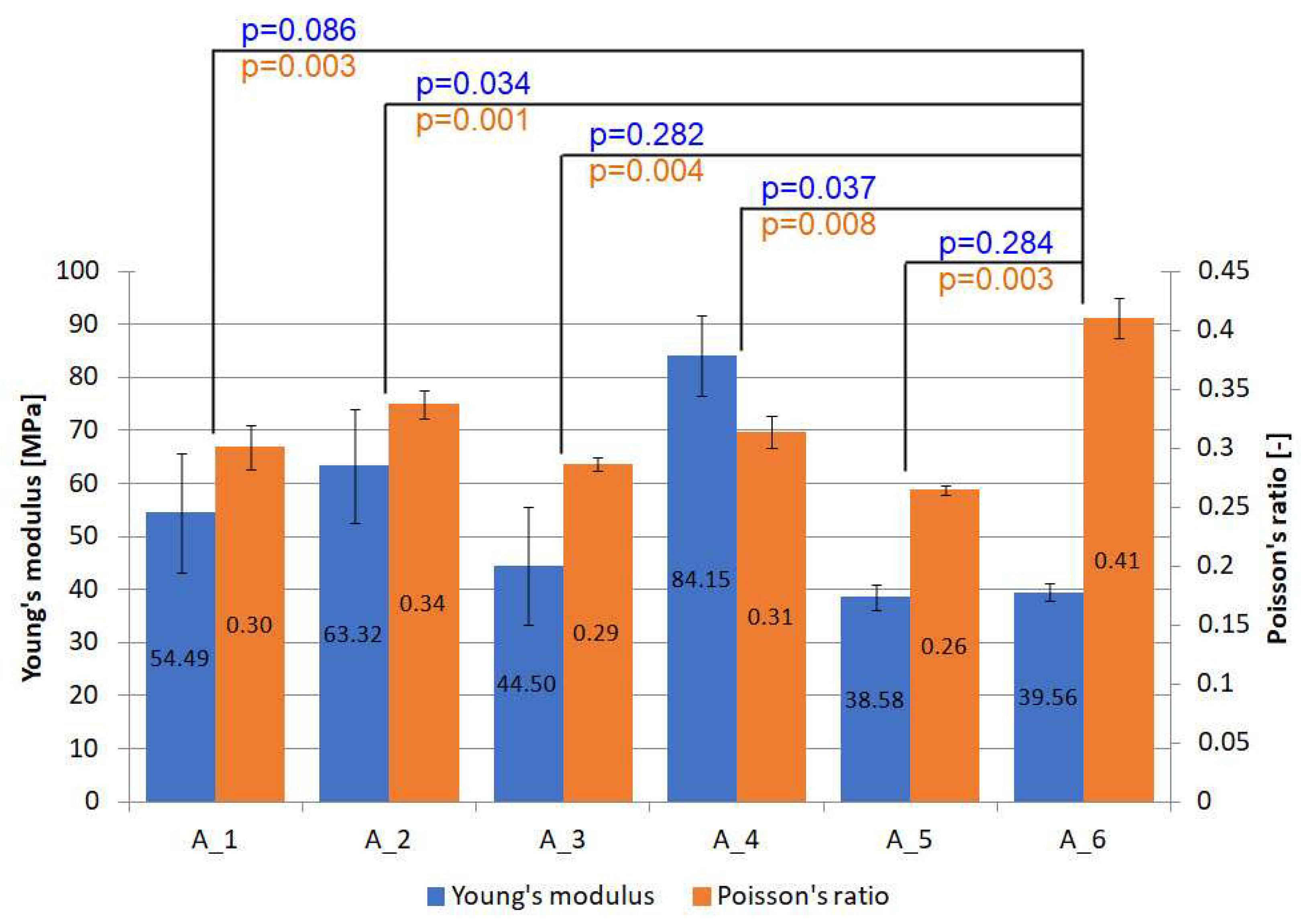

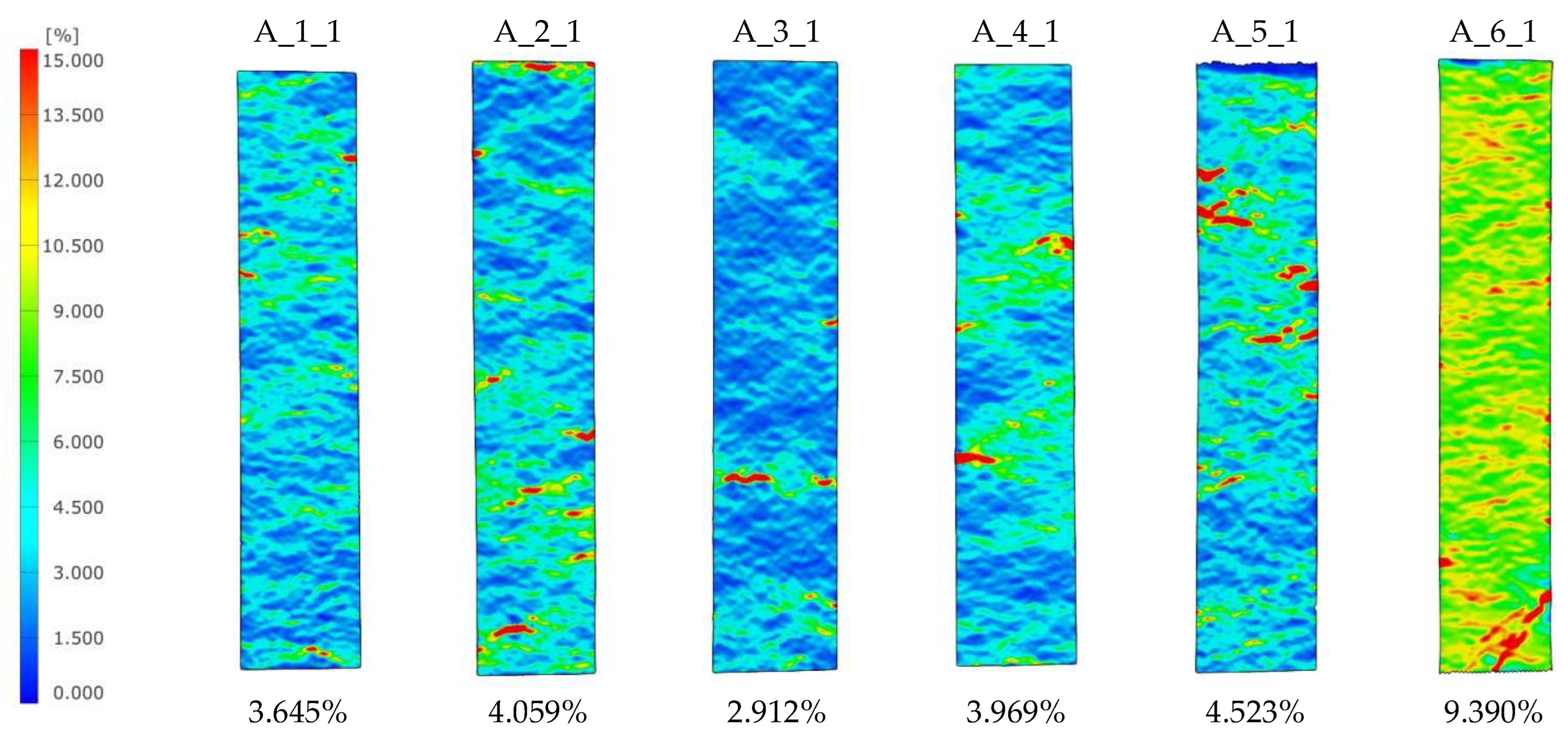

3.1. PC Tensile Tests

- When PC is manufactured in tape form and must be wound onto a spool. The tension force of the spool must not cause plastic deformation of the tape;

- PC is applied to the product, and the tension force must not exceed the limit for the formation of permanent deformations.

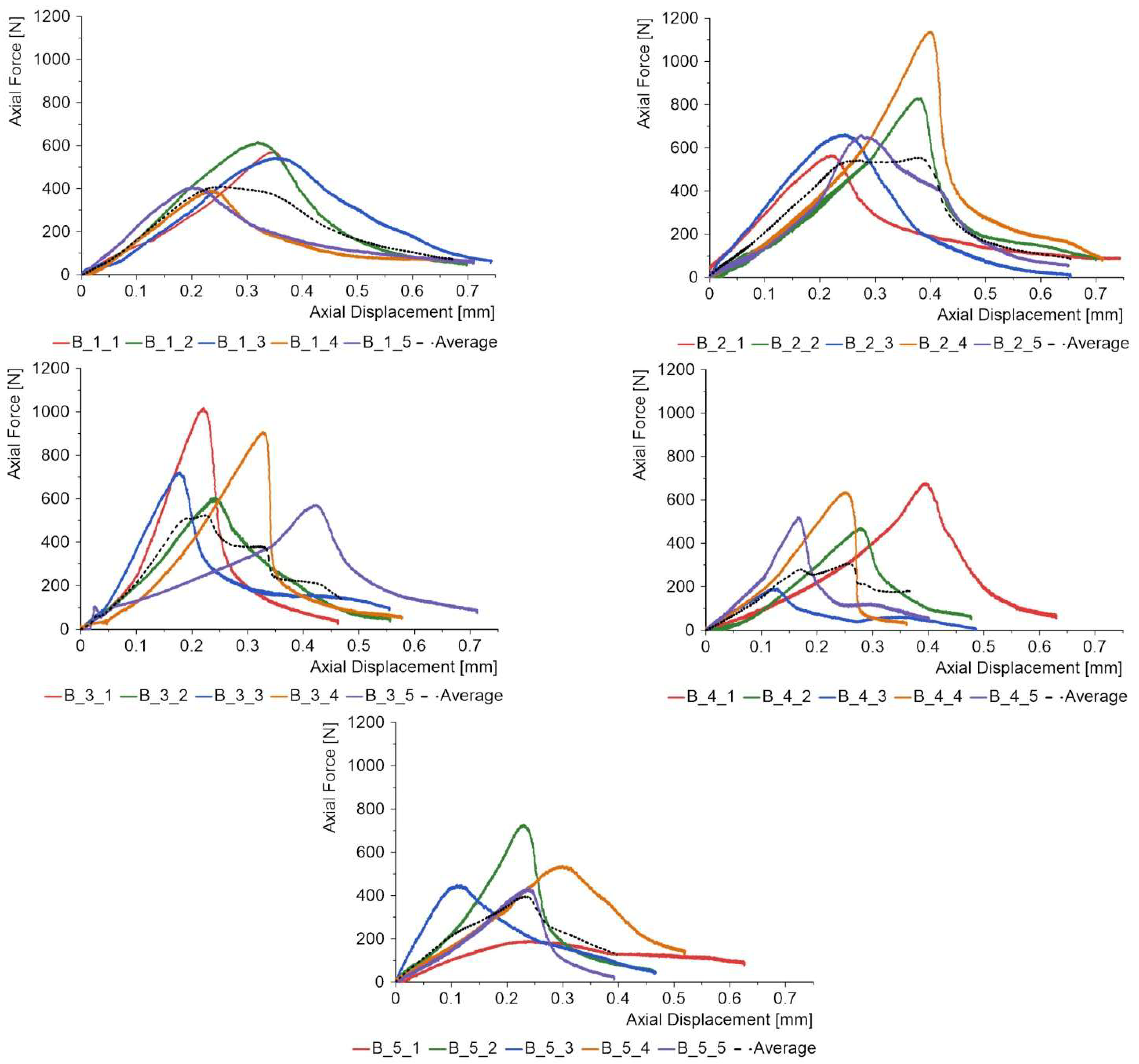

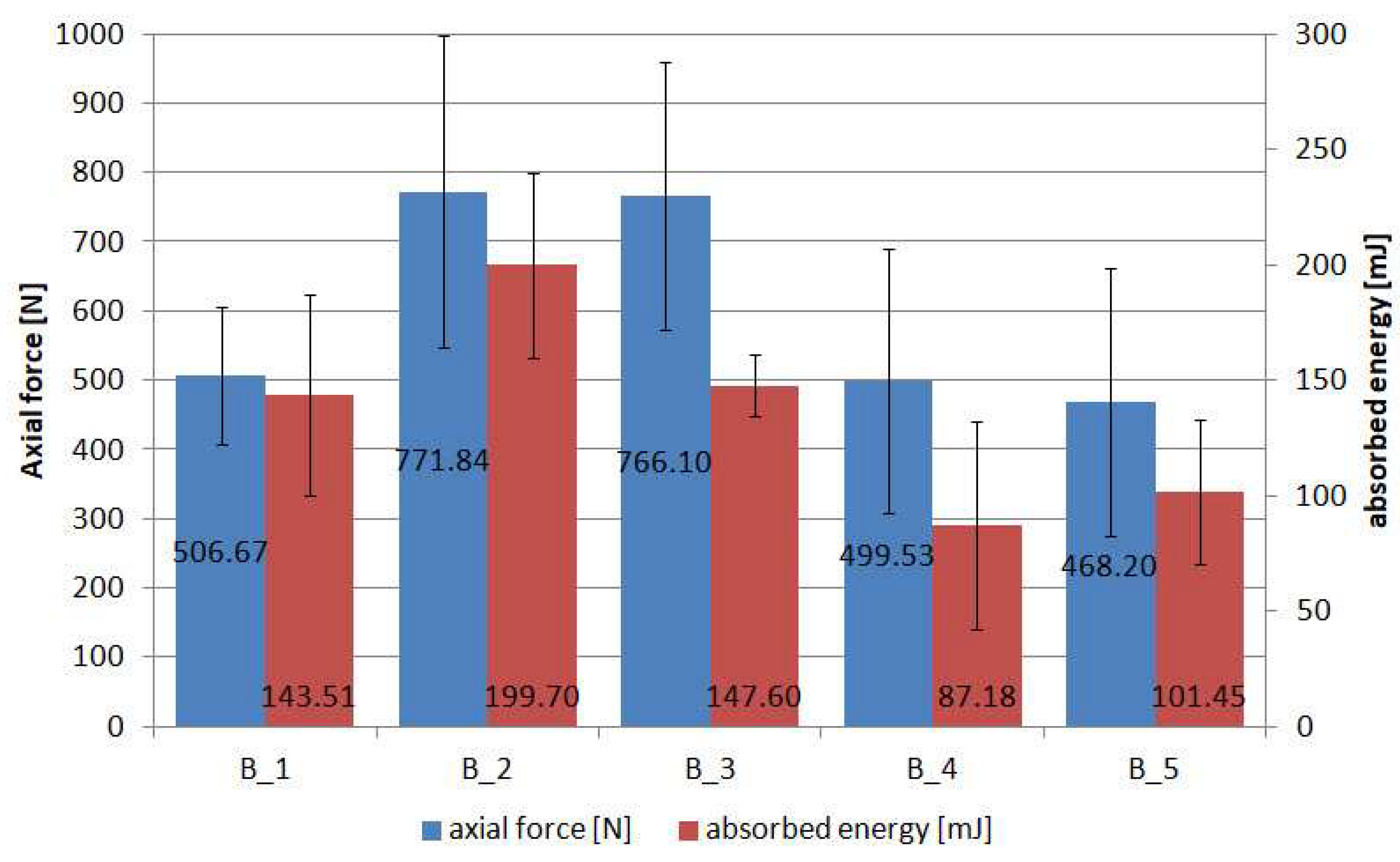

3.2. PC Adhesion Tests

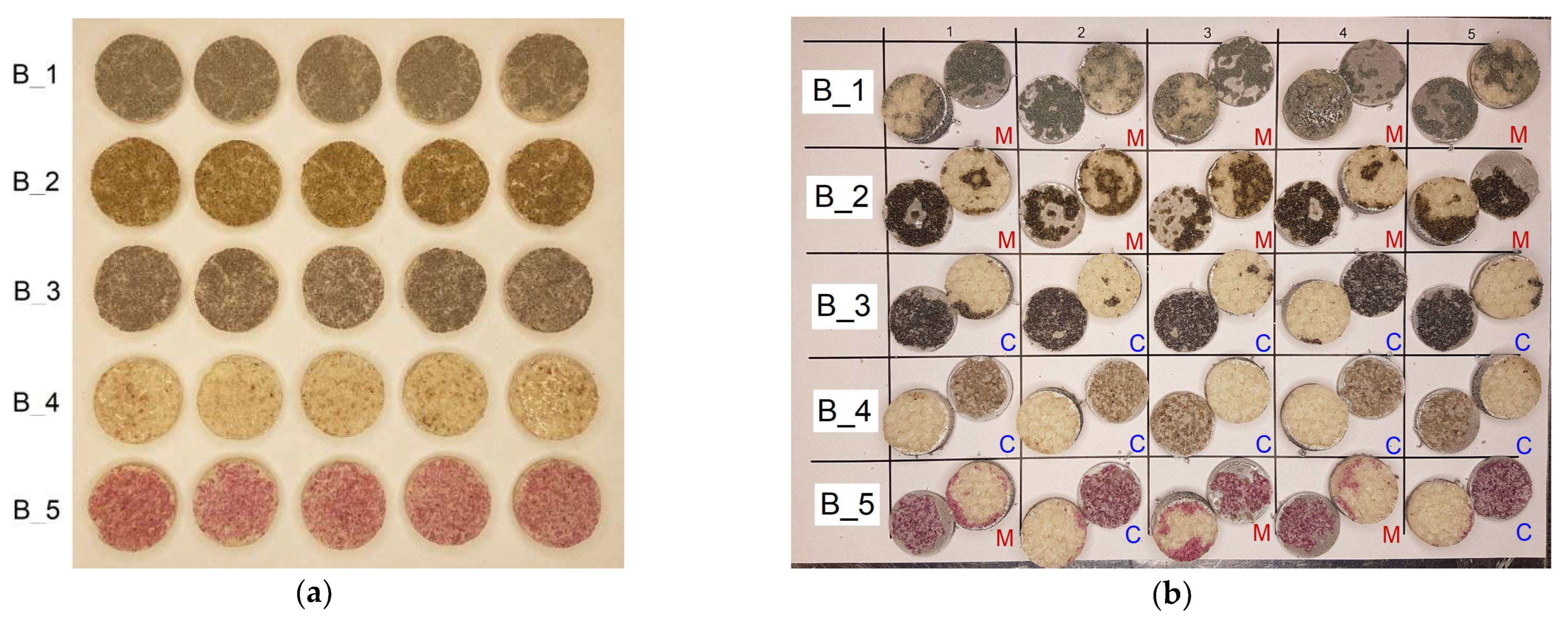

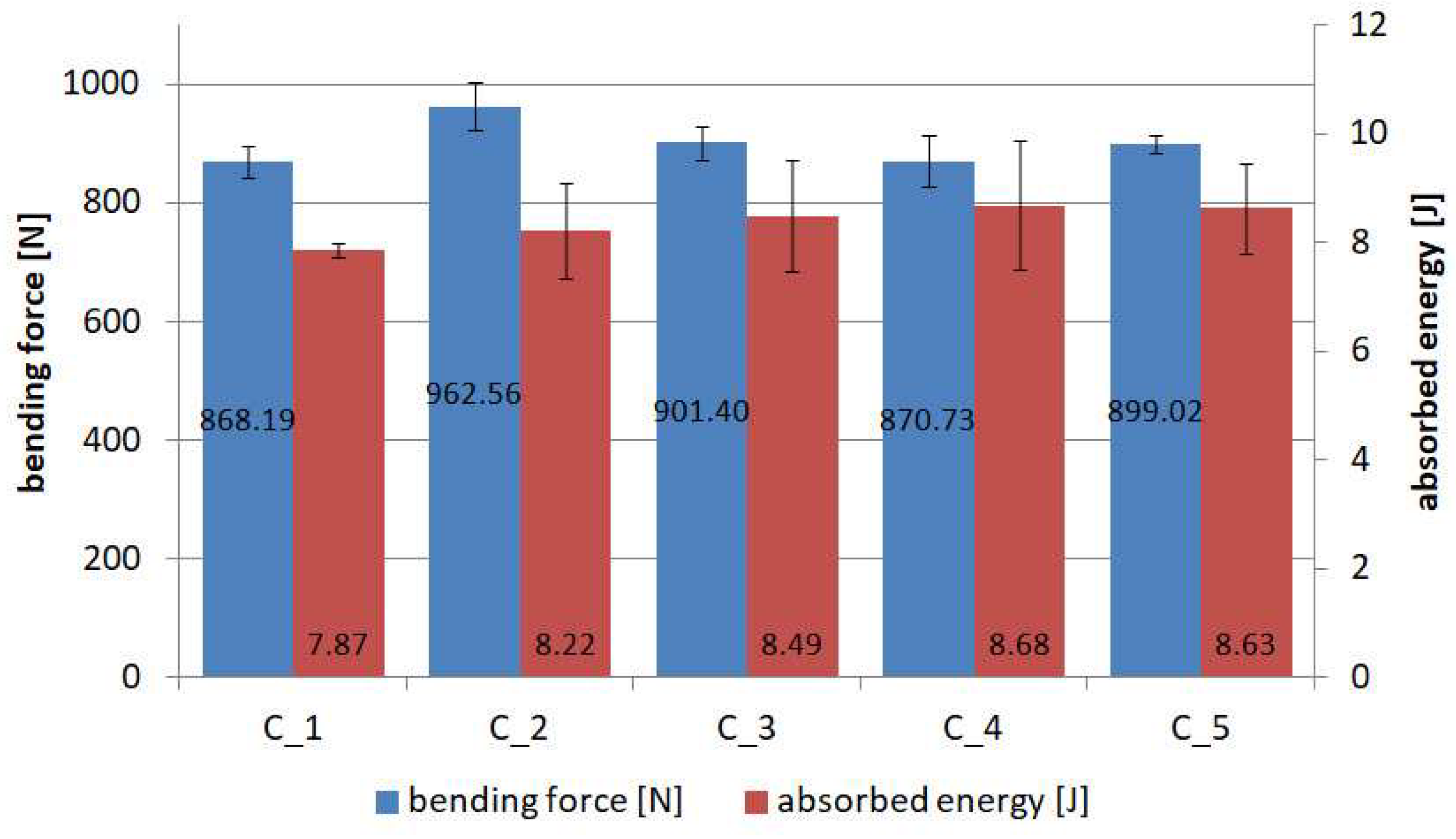

3.3. 3-PB Tests of PC “Sandwich” Composites

4. Conclusions

- The choice of gradation of the FL and the BL, as well as the proportion of thermoplastic material, has a significant impact on the final thickness and grammage of the PC. For the materials used in this work, PC thicknesses in the range 1.11 to 1.41 mm and grammages from 1.37 to 2.35 kg/m2 were obtained;

- Considering the failure force of a 30 mm wide PC, it is in the range of 24.61 N to 28.73 N. This is an important parameter from a technological point of view, e.g., when using winding where material tension must be ensured;

- The Young’s modulus, depending on the FL powders used, can vary between 38.58 MPa and 84.15 MPa, and the Poisson’s ratio varies from 0.26 to 0.34. This is important information that can be used to build a global numerical model in the future;

- The PC on the “sandwich” composite has satisfactory adhesion ranging from 0.95 MPa to 1.57 MPa, which allows it to be used in civil engineering;

- Three-point bending tests have shown that the one-sided application of PC results in a decrease in maximum force of approximately 9.77% compared to reference specimens without PC. This result was achieved for the C_1 batch with silicon carbide as the FL. The large advantages of using PC appear at the bending stage after the maximum force has been reached. PC makes the absorbed energy higher, and also the force drops by about 45% to 52% from the maximum value. For reference specimens, the decrease in force after the maximum value is as high as 69%;

- Pre-impregnated coatings made of powders with a variety of colours highlight the wide decorative possibilities of the products. PCs, therefore, have a high implementation potential.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRP | fibre-reinforced polymer |

| PC | pre-impregnated coating |

| FL | functional layer |

| BL | backing layer |

| 3-PB | three-point bending |

| DIC | digital image correlation |

| GFRP | glass fibre-reinforced polymer |

| CFRP | carbon fibre-reinforced polymer |

| UV | ultraviolet |

| UHMWPE | ultra-high-molecular-weight polyethylene |

| 7YSZ | 7% yttria-stabilised zirconia |

| APS | atmospheric plasma spray |

| TBC | thermal barrier coating |

| PVA | poly(vinyl alcohol) |

| APP | ammonium polyphosphate |

| SP | sepiolite nanofillers |

| PMC | polymer matrix composite |

| SEM | scanning electron microscope |

| MEKP | methyl ethyl ketone peroxides |

| %RSD | percent relative standard deviation |

Appendix A

References

- Mat Yazik, M.H.; Ismail, I. Aerospace Structures and Engines from Polymer Composites. In Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2025; pp. 349–383. [Google Scholar]

- Chellan, S.; Mondal, M.I.H.; Joseph, K. Basalt Fibres and Their Applications in the Automotive Industry. In Technical Organic and Inorganic Fibres from Natural Resources; Elsevier: Amsterdam, The Netherlands, 2025; pp. 599–623. [Google Scholar]

- Santulli, C. Evolution and Recent Advancements of Composite Materials in Marine Applications. In Applications of Composite Materials in Engineering; Elsevier: Amsterdam, The Netherlands, 2025; pp. 195–218. [Google Scholar]

- Tian, Y.; Li, S.; Yin, Z.-Y.; Senetakis, K. A Micromechanical Study on Sand − FRP Interface Subjected to Cyclic Loading. Compos. Struct. 2024, 346, 118452. [Google Scholar] [CrossRef]

- Xie, B.; Chen, S.; Xu, Z.; Wang, F.; Gao, Y.; Yu, Z. Distribution Characteristics of Fire Temperature Field under I-Type Composite Beam Bridge. J. Constr. Steel Res. 2025, 229, 109470. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Ngo, T.; Tran, P.; Mendis, P.; Zobec, M.; Aye, L. Fire Performance of Prefabricated Modular Units Using Organoclay/Glass Fibre Reinforced Polymer Composite. Constr. Build. Mater. 2016, 129, 204–215. [Google Scholar] [CrossRef]

- Yanes-Armas, S.; de Castro, J.; Keller, T. Long-Term Design of FRP-PUR Web-Core Sandwich Structures in Building Construction. Compos. Struct. 2017, 181, 214–228. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. An Influence of UV Ageing Process on Tensile Strength and Young’s Modulus of Polymeric Fiber Composite Materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012057. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Tran, P.; Ngo, T.D.; Tran, P.A.; Mendis, P. Experimental and Computational Investigations on Fire Resistance of GFRP Composite for Building Façade. Compos. Part B Eng. 2014, 62, 218–229. [Google Scholar] [CrossRef]

- Golewski, P.; Budka, M. The Influence of Flame Exposure and Solid Particle Erosion on Tensile Strength of CFRP Substrate with Manufactured Protective Coating. Materials 2024, 17, 1203. [Google Scholar] [CrossRef]

- Golewski, P.; Rusinek, A.; Sadowski, T. Material Characterization of PMC/TBC Composite under High Strain Rates and Elevated Temperatures. Materials 2020, 13, 167. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T.; Rusinek, A. The SHPB Tests for GFRP Composites Subjected to Three Levels of Strain Rates. Mater. Today Proc. 2021, 45, 4275–4279. [Google Scholar] [CrossRef]

- Khaneghahi, M.H.; Najafabadi, E.P.; Shoaei, P.; Oskouei, A.V. Effect of Intumescent Paint Coating on Mechanical Properties of FRP Bars at Elevated Temperature. Polym. Test. 2018, 71, 72–86. [Google Scholar] [CrossRef]

- Kim, Y.; Makarov, D.; Kashkarov, S.; Joseph, P.; Molkov, V. Modelling Heat Transfer in an Intumescent Paint and Its Effect on Fire Resistance of On-Board Hydrogen Storage. Int. J. Hydrogen Energy 2017, 42, 7297–7303. [Google Scholar] [CrossRef]

- Bozzoli, F.; Mocerino, A.; Rainieri, S.; Vocale, P. Inverse Heat Transfer Modeling Applied to the Estimation of the Apparent Thermal Conductivity of an Intumescent Fire Retardant Paint. Exp. Therm. Fluid Sci. 2018, 90, 143–152. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, P.; Craciun, E. Internal Structure Influence on the Impact Strength and Dynamic Fracture Toughness of Hybrid Polymer Matrix Composites with Integrated Elastomer Interlayers. Compos. Struct. 2021, 258, 113375. [Google Scholar] [CrossRef]

- Huang, W.; Wang, Z.; Xu, J.; Fan, X.; Wang, Y.; Zou, B.; Cao, X. Novel Thermal Protection Coating Based on Zr0.75Ce0.25O2/Phosphate Duplex System for Polyimide Matrix Composites Fabricated via a Combined Sol-Gel/Sealing Treatment Process. Corros. Sci. 2013, 74, 22–34. [Google Scholar] [CrossRef]

- Pomázi, Á.; Toldy, A. Multifunctional Gelcoats for Fiber Reinforced Composites. Coatings 2019, 9, 173. [Google Scholar] [CrossRef]

- Dhanya, T.M.; Yerramalli, C.S. Lightning Strike Effect on Carbon Fiber Reinforced Composites—Effect of Copper Mesh Protection. Mater. Today Commun. 2018, 16, 124–134. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. A Novel Application of Alumina Fiber Mats as TBC Protection for CFRP/Epoxy Laminates—Laboratory Tests and Numerical Modeling. J. Eur. Ceram. Soc. 2018, 38, 2920–2927. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. Description of Thermal Protection against Heat Transfer of Carbon Fiber Reinforced Plastics (CFRP) Coated by Stiffened Ceramic Mat (TBC). Compos. Struct. 2019, 229, 111489. [Google Scholar] [CrossRef]

- Sudhindra, S.; Kargar, F.; Balandin, A.A. Noncured Graphene Thermal Interface Materials for High-Power Electronics: Minimizing the Thermal Contact Resistance. Nanomaterials 2021, 11, 1699. [Google Scholar] [CrossRef]

- Wang, L.; Kong, J.; Chu, D.; Wang, Y.; Wang, T.; Liu, Z. Enhancing Ballistic Performance: Effect of Polyurea Coating on Backface Deformation of UHMWPE Laminates. Compos. Struct. 2025, 355, 118846. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Lu, L.; Guan, Y. Anti-Icing Polyurethane Coating on Glass Fiber-Reinforced Plastics Induced by Femtosecond Laser Texturing. Appl. Surf. Sci. 2024, 662, 160077. [Google Scholar] [CrossRef]

- Semmler, C.; Gyoktepeliler-Akin, E.; Killinger, A. Plasma Sprayed Ceramic Coatings for the Thermal Protection of Carbon Fiber Reinforced Plastics (CFRP): Thermal and Mechanical Properties of YSZ, Aluminum Titanate, Cordierite and Mullite Coatings. Surf. Coatings Technol. 2023, 462, 129509. [Google Scholar] [CrossRef]

- Meng, Q.; Li, Y.; Yu, X.; Gong, W. Microstructure and Properties of Al/FeCoNiCrMo Coatings Prepared by Different Plasma Spraying Currents on Carbon Fiber Reinforced Plastic Surfaces. Surf. Coatings Technol. 2024, 494, 131385. [Google Scholar] [CrossRef]

- Das, S.; Kumar, V.; Lee, J.; Yokozeki, T.; Okada, T. Thickness Threshold Study of Polyaniline-Based Lightning Strike Protection Coating for Carbon/Glass Fiber Reinforced Polymer Composites. Compos. Struct. 2022, 280, 114954. [Google Scholar] [CrossRef]

- Cilento, F.; Leone, C.; Genna, S.; Giordano, M.; Martone, A. Graphene NanoPlatelet-Based Coating as Thermal Protection from High-Power Radiative Fluxes. Compos. Struct. 2023, 319, 117157. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T.; Kneć, M.; Budka, M. The Effect of Thermal Aging Degradation of CFRP Composite on Its Mechanical Properties Using Destructive and Non-Destructive Methods and the DIC System. Polym. Test. 2023, 118, 107902. [Google Scholar] [CrossRef]

- Floch, L.; Da Cruz Chiochetta, B.; Ferry, L.; Perrin, D.; Ienny, P. Fire Protective Surface Coating Containing Nanoparticles for Marine Composite Laminates. J. Compos. Sci. 2021, 5, 6. [Google Scholar] [CrossRef]

- Demircan, G.; Kisa, M.; Ozen, M.; Acikgoz, A.; Işıker, Y.; Aytar, E. Nano-Gelcoat Application of Glass Fiber Reinforced Polymer Composites for Marine Application: Structural, Mechanical, and Thermal Analysis. Mar. Pollut. Bull. 2023, 194, 115412. [Google Scholar] [CrossRef] [PubMed]

- Demircan, G.; Ozen, M.; Kisa, M.; Acikgoz, A.; Işıker, Y. The Effect of Nano-Gelcoat on Freeze-Thaw Resistance of Glass Fiber-Reinforced Polymer Composite for Marine Applications. Ocean Eng. 2023, 269, 113589. [Google Scholar] [CrossRef]

- Scholz, S.; Kroll, L.; Schettler, F. Nanoparticle Reinforced Epoxy Gelcoats for Fiber-Plastic Composites under Multiple Load. Prog. Org. Coatings 2014, 77, 1129–1136. [Google Scholar] [CrossRef]

- Firdosh, S.; Narasimha Murthy, H.N.; Angadi, G.; Raghavendra, N. Investigation of Water Absorption Characteristics of Nano-Gelcoat for Marine Application. Prog. Org. Coatings 2018, 114, 173–187. [Google Scholar] [CrossRef]

- Pomázi, Á.; Toldy, A. Development of Fire Retardant Epoxy-Based Gelcoats for Carbon Fibre Reinforced Epoxy Resin Composites. Prog. Org. Coatings 2021, 151, 106015. [Google Scholar] [CrossRef]

- Rezzoug, A.; Abdi, S.; Kaci, A.; Yandouzi, M. Thermal Spray Metallisation of Carbon Fibre Reinforced Polymer Composites: Effect of Top Surface Modification on Coating Adhesion and Mechanical Properties. Surf. Coatings Technol. 2018, 333, 13–23. [Google Scholar] [CrossRef]

- Lopera-Valle, A.; McDonald, A. Flame-Sprayed Coatings as de-Icing Elements for Fiber-Reinforced Polymer Composite Structures: Modeling and Experimentation. Int. J. Heat Mass Transf. 2016, 97, 56–65. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.; Lee, J.; Lee, M.W. Thermal Barrier Coating for Carbon Fiber-Reinforced Composite Materials. Compos. Part B Eng. 2021, 225, 109308. [Google Scholar] [CrossRef]

- Lafabrier, A.; Fahs, A.; Louarn, G.; Aragon, E.; Chailan, J.F. Experimental Evidence of the Interface/Interphase Formation between Powder Coating and Composite Material. Prog. Org. Coatings 2014, 77, 1137–1144. [Google Scholar] [CrossRef]

- Kandola, B.K.; Luangtriratana, P. Evaluation of Thermal Barrier Effect of Ceramic Microparticulate Surface Coatings on Glass Fibre-Reinforced Epoxy Composites. Compos. Part B Eng. 2014, 66, 381–387. [Google Scholar] [CrossRef]

- Gonzalez, R.; McDonald, A.; Mertiny, P. Effect of Flame-Sprayed Al-12Si Coatings on the Failure Behaviour of Pressurized Fibre-Reinforced Composite Tubes. Polym. Test. 2013, 32, 1522–1528. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. Technological and Strength Aspects of Layers Made of Different Powders Laminated on a Polymer Matrix Composite Substrate. Molecules 2022, 27, 1168. [Google Scholar] [CrossRef] [PubMed]

- Szpoganicz, E.; Hübner, F.; Beier, U.; Geistbeck, M.; Ruckdäschel, H. The Effect of Prepreg Ply Thickness in Carbon Fiber Reinforced Composites on Intralaminar Toughness and Shear Strength in Cryogenic Environments for Liquid Hydrogen Storage Tanks. Compos. Part B Eng. 2025, 292, 112077. [Google Scholar] [CrossRef]

- Kumar, V.; Panda, S.K. Elasto-Plastic Constitutive Behavior Prediction and Uncertainty Quantification of Damaged Composite Structure Under High-Strain Rate Loading. J. Eng. Mater. Technol. 2024, 146, 041005. [Google Scholar] [CrossRef]

- Chróścielewski, J.; Ferenc, T.; Mikulski, T.; Miśkiewicz, M.; Pyrzowski, Ł. Numerical Modeling and Experimental Validation of Full-Scale Segment to Support Design of Novel GFRP Footbridge. Compos. Struct. 2019, 213, 299–307. [Google Scholar] [CrossRef]

- Silva, J.K.F.; Ribeiro, R.R.; Lameiras, R. de M. Evaluation of Production Quality and Mechanical Behavior of Low-Cost Shear Connectors Manufactured with Perforated GFRP Plates. Rev. IBRACON Estruturas e Mater. 2021, 14, 1–21. [Google Scholar] [CrossRef]

- Gombos, Z.J.; Summerscales, J. In-Mould Gel-Coating for Polymer Composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 203–210. [Google Scholar] [CrossRef]

- Sun, J.; Yamanaka, K.; Bernard, C.; Lei, Y.; Zhou, S.; Lin, H.; Ogawa, K.; Chiba, A. A Novel Two-Step Process for Enhancing Adhesion Strength of Cold-Spray Metallization of Carbon Fiber-Reinforced Plastics. Mater. Des. 2025, 249, 113568. [Google Scholar] [CrossRef]

- Souza, J.; Pires, L.; Silva, A.; Nascimento, M. Exploring the Impact of Cement Mortar Adhesion Strength in the Durability of Facade Systems. Buildings 2025, 15, 1499. [Google Scholar] [CrossRef]

| Batch Number | Batch 1 | Batch 2 | Batch 3 | Batch 4 | Batch 5 | Batch 1–5 |

|---|---|---|---|---|---|---|

| Type of FL powder | silicon carbide | glauconite | stainless-steel shot | quartz sand | chromium electro-corundum | white electro-corundum |

| FEPA-F granularity | F220 | F60 | F050 | F080 | F036 | F24 |

| Grain size [μm] | 58 | 260 | 336 | 185 | 525 | 745 |

| Density of powder material [g/cm3] | 3.21 | 2.5 | 7.8 | 2.65 | 3.95 | 3.95 |

| Batch Number | Batch 1 | Batch 2 | Batch 3 | Batch 4 | Batch 5 | Batch 6 |

|---|---|---|---|---|---|---|

| Type of FL powder | silicon carbide | glauconite | stainless-steel shot | quartz sand | chromium electro-corundum | - |

| PC grammage [kg/m2] | 1.37 | 1.62 | 2.35 | 1.97 | 1.98 | 0.25 |

| PC grammage [kg/m2] | 1.11 ± 0.08 | 1.19 ± 0.06 | 1.27 ± 0.06 | 1.11 ± 0.06 | 1.41 ± 0.05 | 0.29 ± 0.02 |

| Percentage of non-woven | 18.36 | 15.56 | 10.72 | 12.79 | 12.70 | 100 |

| Silicon Carbide | Glauconite | Stainless Steel Shot | Quartz Sand | Chromium Electro-Corundum | Ref. (Without PC) | |

|---|---|---|---|---|---|---|

| thickness [mm] | 5.26 ± 0.07 | 5.46 ± 0.06 | 5.66 ± 0.05 | 5.69 ± 0.09 | 5.77 ± 0.05 | 4.12 ± 0.03 |

| Batch 1 | Batch 2 | Batch 3 | Batch 4 | Batch 5 | Batch 6 | |

|---|---|---|---|---|---|---|

| a1 [kN/mm] | 15.26 | 19.5 | 14.42 | 27.88 | 14.62 | 3.08 |

| a2 [kN/mm2] | −3.50 | −4.6 | −2.58 | −13.40 | −2.79 | −0.0738 |

| a3 [kN/mm3] | 0.217 | 0.358 | 0.145 | 3.19 | 0.157 | - |

| a4 [kN/mm4] | - | - | - | −0.297 | - | - |

| coef. of det. | 0.999 | 0.999 | 1.000 | 0.998 | 0.999 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golewski, P.; Budka, M. Manufacturing Technology and Mechanical Properties of Novel Pre-Impregnated Coatings as Applied to FRP “Sandwich” Composites. Materials 2025, 18, 4725. https://doi.org/10.3390/ma18204725

Golewski P, Budka M. Manufacturing Technology and Mechanical Properties of Novel Pre-Impregnated Coatings as Applied to FRP “Sandwich” Composites. Materials. 2025; 18(20):4725. https://doi.org/10.3390/ma18204725

Chicago/Turabian StyleGolewski, Przemysław, and Michał Budka. 2025. "Manufacturing Technology and Mechanical Properties of Novel Pre-Impregnated Coatings as Applied to FRP “Sandwich” Composites" Materials 18, no. 20: 4725. https://doi.org/10.3390/ma18204725

APA StyleGolewski, P., & Budka, M. (2025). Manufacturing Technology and Mechanical Properties of Novel Pre-Impregnated Coatings as Applied to FRP “Sandwich” Composites. Materials, 18(20), 4725. https://doi.org/10.3390/ma18204725