Coaxial Laser Cladding of Novel Wear-Resistant Alloy Coatings on 60CrMnMo Steel Surface

Abstract

1. Introduction

2. Experimental Materials and Methods

3. Results and Discussion

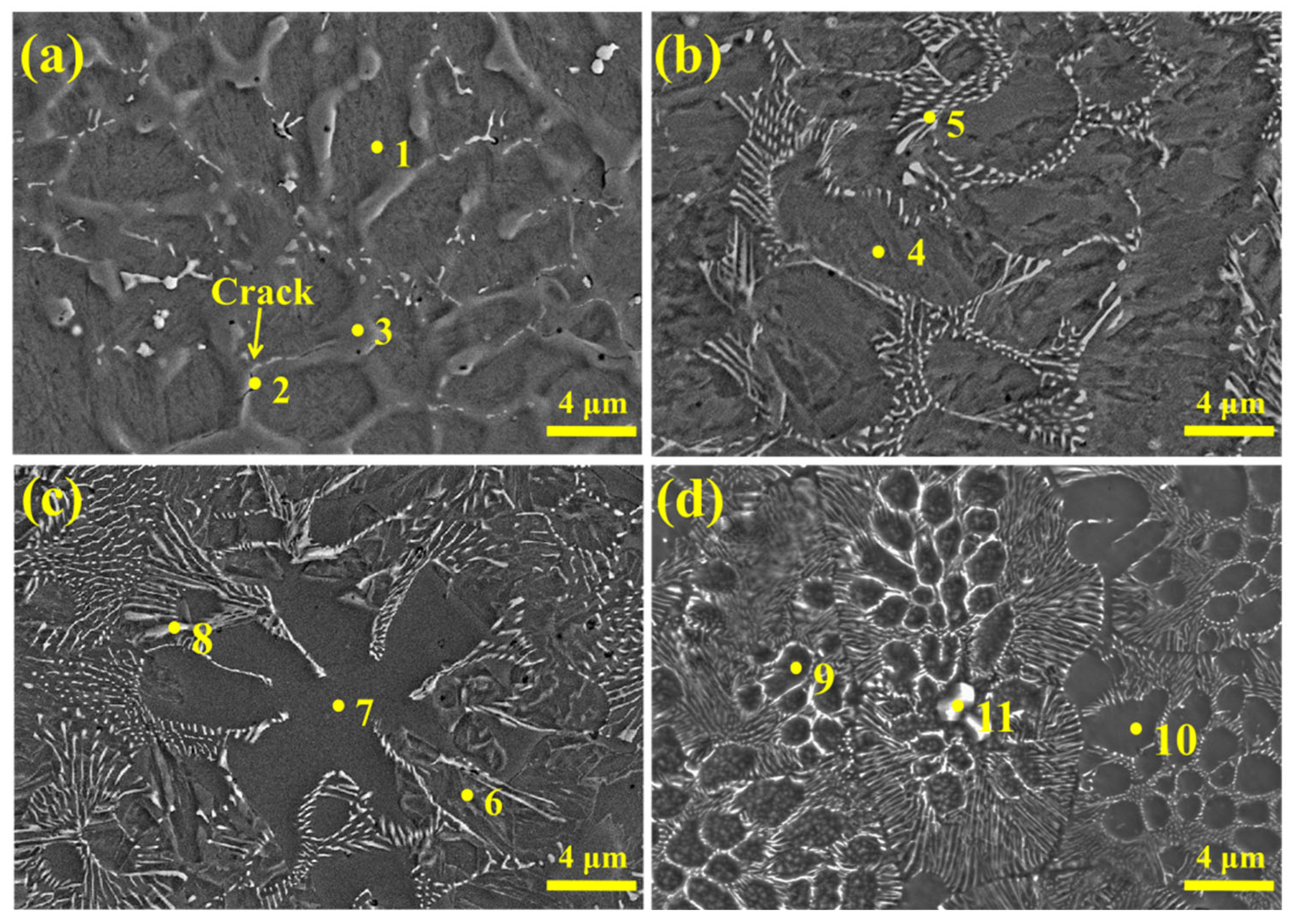

3.1. Morphology Analysis

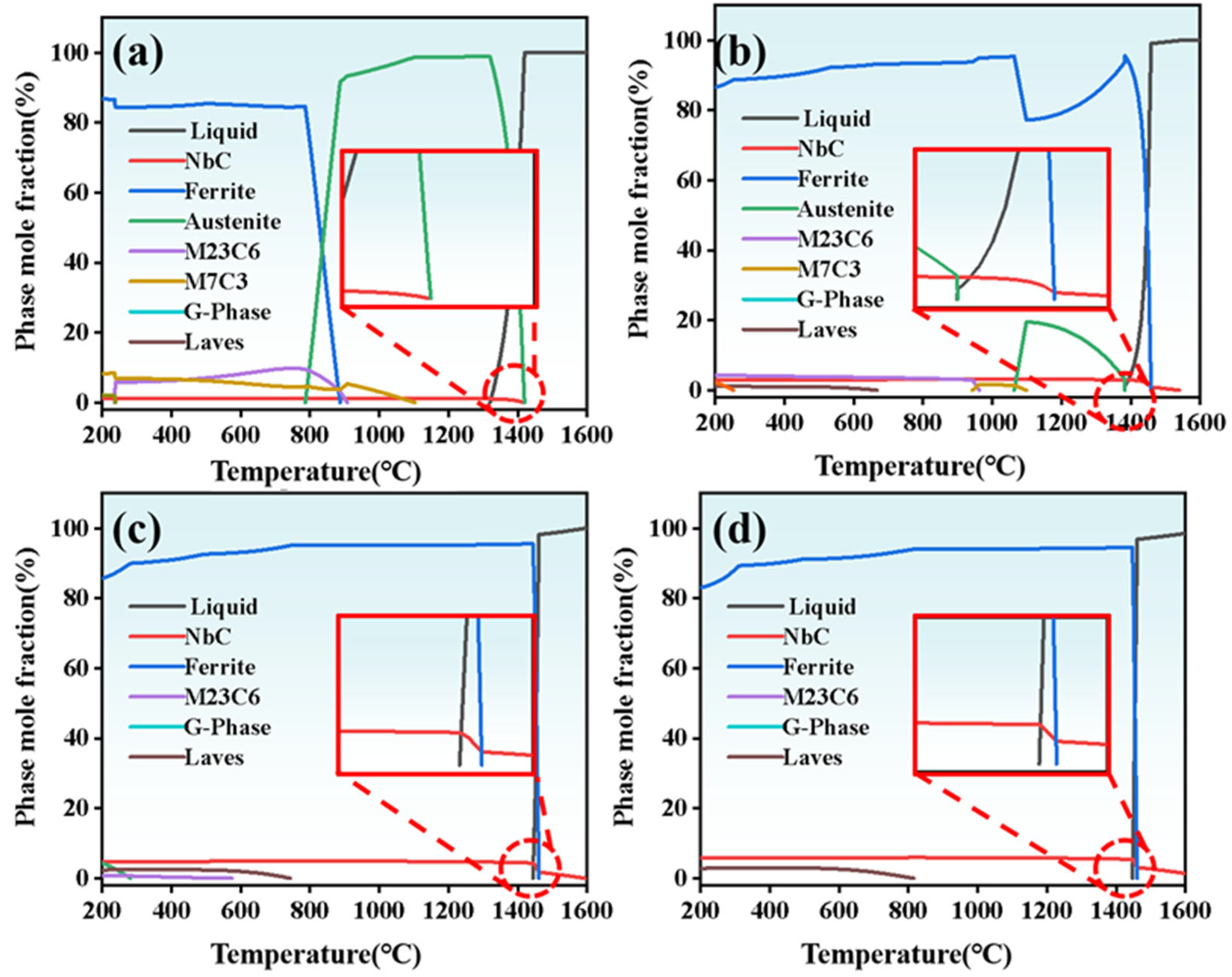

3.2. Phase Analysis

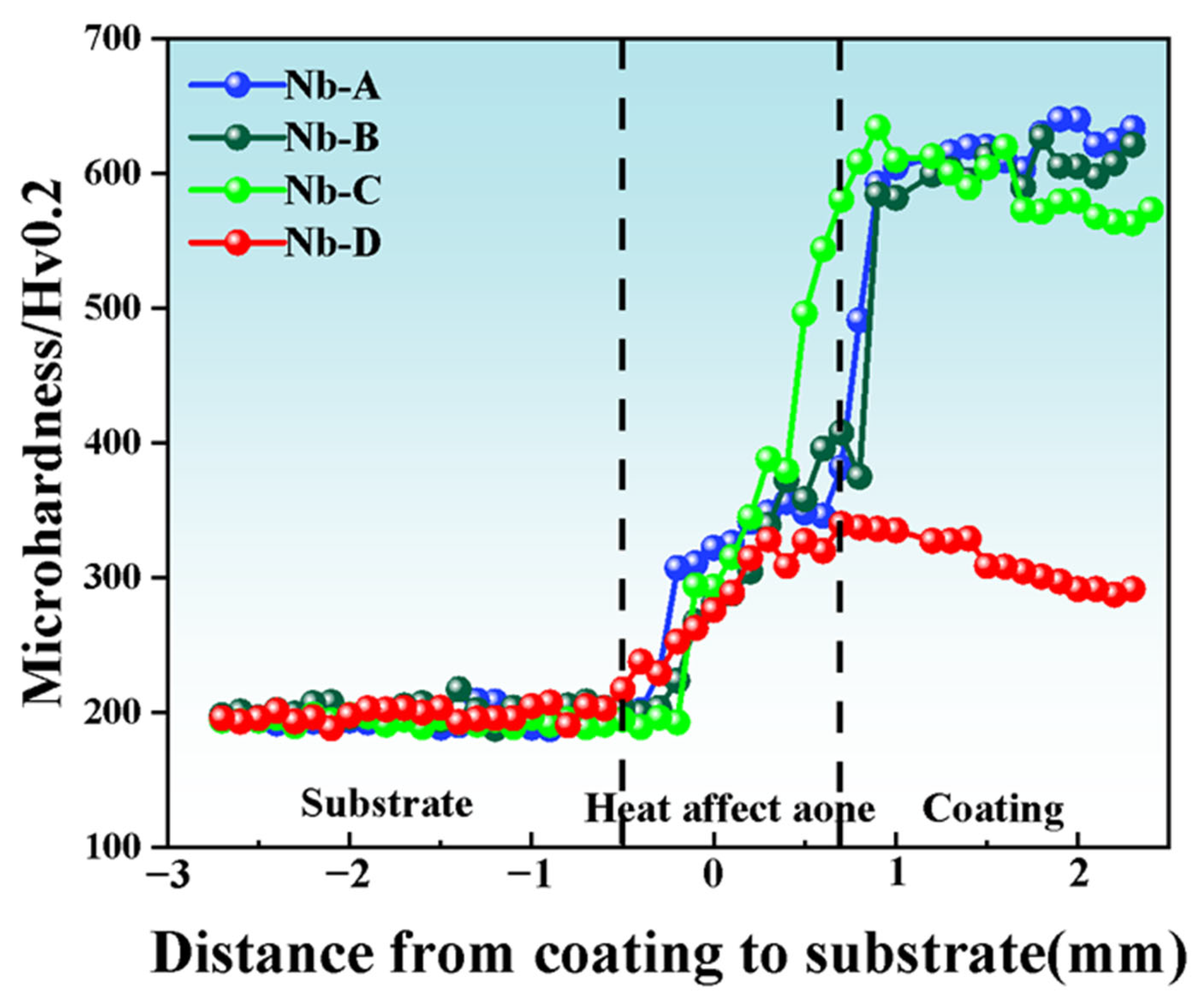

3.3. Mechanical Property

3.3.1. Hardness Characterization

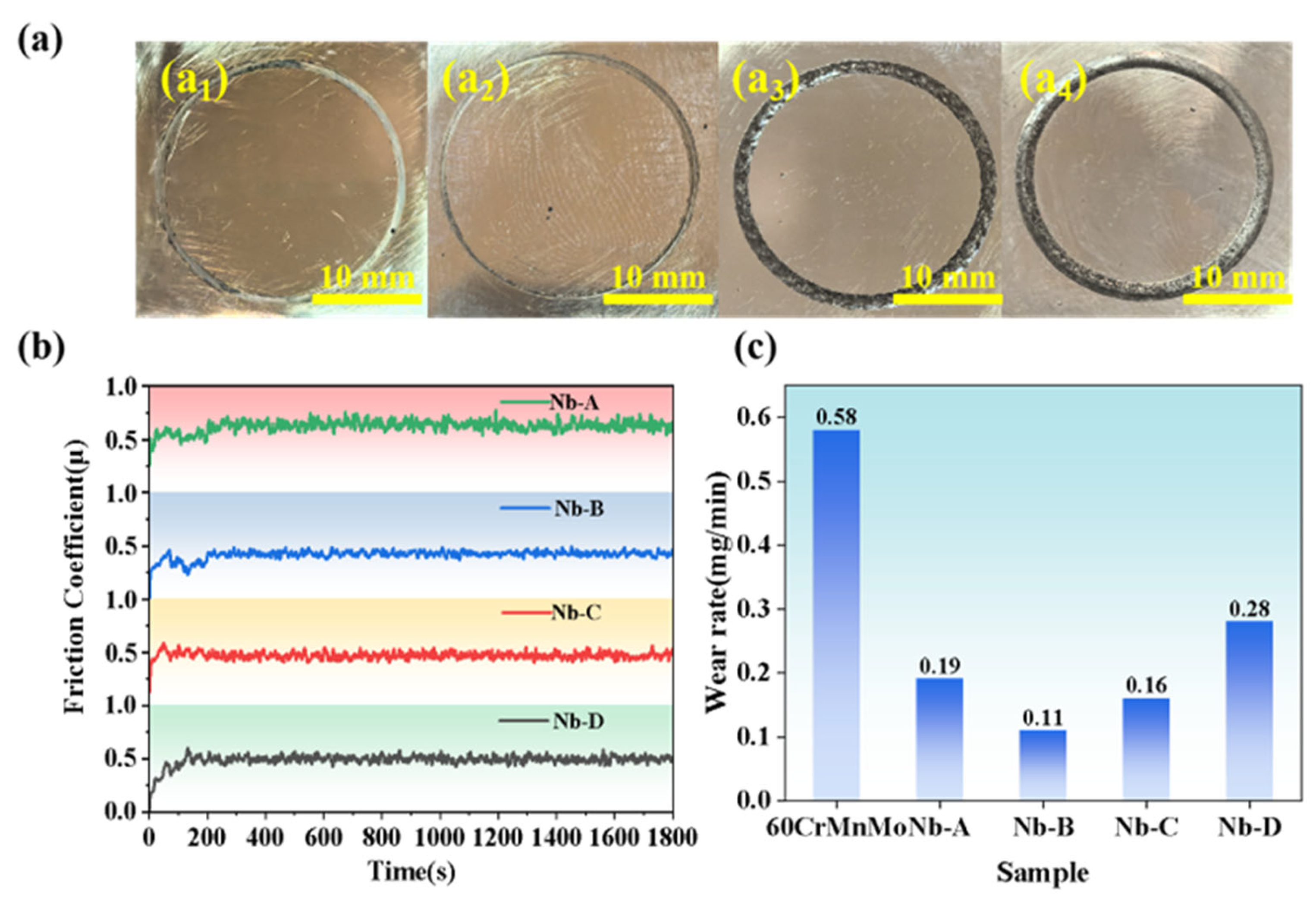

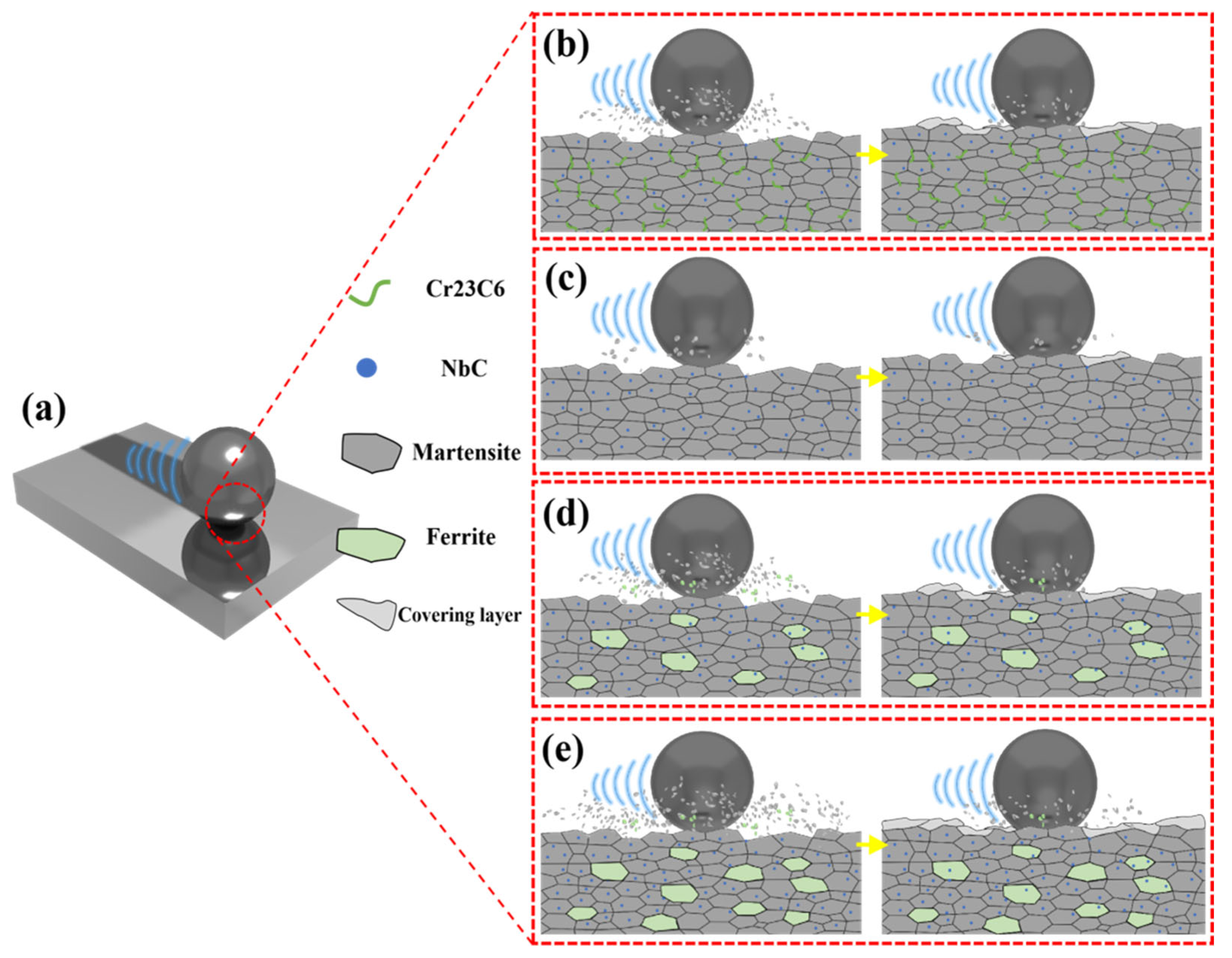

3.3.2. Wear Performance

3.3.3. Wear Track Morphology Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jhon, M.; Kuruveri, U.B.; Menezes, P.L. Laser Cladding-Based Surface Modification of Carbon Steel and High-Alloy Steel for Extreme Condition Applications. Coatings 2022, 12, 1444. [Google Scholar] [CrossRef]

- Wei, R.Z.; Mao, M.H.; Liang, J.G.; Zhao, C.J.; Ouyang, C.Y.; Bai, Q.F. Repair Feasibility and Performance Enhancement Analysis of Fe-Based Alloy Coating on Ductile Iron Surface by High-Speed Laser Cladding. Mater. Today Commun. 2024, 39, 108639. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Yu, T.B.; Sun, J.Y.; Zhang, Y.Y.; Sun, Z.Y.; Yu, C.; Yin, J.H. Investigation of Laser Cladding Using Inconel 625-Enhanced Fe-Based Coatings: Microstructure, Wear Behavior, and Corrosion Resistance Properties. Appl. Surf. Sci. 2025, 688, 162398. [Google Scholar] [CrossRef]

- Tang, J.L.; Wang, K.M.; Fu, H.G. Laser Cladding In Situ Carbide-Reinforced Iron-Based Alloy Coating: A Review. Metals 2024, 14, 1419. [Google Scholar] [CrossRef]

- Prakash, O.; Chandrakar, R.; Martin, L.; Verma, J.; Kumar, A.; Jaiswal, A. Laser Cladding Technology for High Entropy Alloys: Effect and Applications. Mater. Res. Express 2024, 11, 096510. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, G.Z.; Zhao, H.C.; Mou, H.L.; Xu, J.F.; Wang, W.Z.; Xing, Z.G.; Li, Y.; Guo, W.L.; Wang, H.D. Research Status and Prospect of Extreme High-Speed Laser Cladding Technology. Opt. Laser Technol. 2024, 168, 109800. [Google Scholar] [CrossRef]

- Wu, Q.L.; Long, W.M.; Zhang, L.; Zhao, H.W. A Review on Ceramic Coatings Prepared by Laser Cladding Technology. Opt. Laser Technol. 2024, 176, 110993. [Google Scholar] [CrossRef]

- Mukherjee, M. Wear Characteristics of Laser Cladded Surface Coating. In Tribology in Materials and Applications; Springer: Cham, Switzerland, 2024; pp. 189–210. [Google Scholar] [CrossRef]

- Raghuram, H.; Katsich, C.; Pichelbauer, K.; Koschatzky, K.; Gachot, C.; Cihak-Bayr, U. Design of Wear and Corrosion Resistant FeNi-Graphite Composites by Laser Cladding. Surf. Coat. Technol. 2019, 377, 124897. [Google Scholar] [CrossRef]

- Shang, F.M.; Xu, Z.; Chen, J.Z.; Lu, S.; Wang, S.L.; Jiang, X.W.; Dubovyi, O. Effect of Cr on Wear Resistance and Mechanism of Preset-Powder Laser Cladding T15 Alloy Steel Coating. J. Mater. Res. Technol. 2024, 29, 4991–4999. [Google Scholar] [CrossRef]

- Feng, Y.L.; Yao, C.W.; Shen, C.; Feng, Y.Q.; Feng, K.; Li, Z.G. Influence of In-Situ Synthesized Carboborides on Microstructure Evolution and the Wear Resistance of Laser Clad Fe-Base Composite Coatings. Mater. Charact. 2020, 164, 110326. [Google Scholar] [CrossRef]

- Chen, C.; Wang, J.F.; Ge, Y.Y.; Zhuang, M.H.; Ma, Z. Microstructure and Wear Resistance of High-Chromium Cast Iron with Multicomponent Carbide Coating via Laser Cladding. Coatings 2023, 13, 1474. [Google Scholar] [CrossRef]

- Chen, M.; Zhou, H.; Liu, X.; Feng, Z.; Xiao, X.; Weng, L.; Yang, Y.; Jiang, Y. Morphology and Wear Resistance of Laser-Clad Fe-Cr-Nb-C Alloy Coatings. Coatings 2025, 15, 1055. [Google Scholar] [CrossRef]

- Kivy, M.B.; Kriewall, C.S.; Zaeem, M.A. Formation of Chromium-Iron Carbide by Carbon Diffusion in AlXCoCrFeNiCu High-Entropy Alloys. Mater. Res. Lett. 2018, 6, 321–326. [Google Scholar] [CrossRef]

- Liu, J.B. Cracking Behavior of Two Kinds of Plasma Cladding Layers by Precursor Carbonization-Composition Process. Mater. Res.-Ibero-Am. J. 2013, 690–693, 2046–2050. [Google Scholar] [CrossRef]

- Liu, L.P.; Lin, Y.H.; Peng, L.S.; Kang, X.; Wang, X.L. Progress in Microstructure Design and Control of High-Hardness Fe-Based Alloy Coatings via Laser Cladding. Coatings 2024, 14, 1351. [Google Scholar] [CrossRef]

- Zhang, H.F.; Zhang, S.; Wu, H.; Wang, R.; Zhang, C.H.; Wu, C.L.; Chen, J.; Chen, H.T. Mechanical Properties and Corrosion Resistance of Laser Cladding Iron-Based Coatings with Two Types of NbC Reinforcement. Surf. Coat. Technol. 2024, 479, 130558. [Google Scholar] [CrossRef]

- Hu, Z.T.; Zhang, D.B.; Wu, D.S.; Zheng, X.Q.; Sun, J.; Geng, P.H.; Ma, N.S. Enhanced Mechanical Properties of Fe-Based Hardfacing Alloy with Al Additions Fabricated by Laser Cladding. Surf. Coat. Technol. 2024, 478, 130477. [Google Scholar] [CrossRef]

- Lian, G.; Yue, K.; Zeng, J.; Feng, M.; Lan, R.; Kong, L. Microstructures and Properties of NbC-Reinforced Ni-Based Coatings Synthesized In Situ by Ultrasonic Vibration-Assisted Laser Cladding. Materials 2023, 16, 1704. [Google Scholar] [CrossRef] [PubMed]

- Qi, K.; Yang, Y. Microstructure, wear, and corrosion resistance of Nb-modified magnetic field-assisted Co-based laser cladding layers. Surf. Coat. Technol. 2022, 434, 128195. [Google Scholar] [CrossRef]

- Chen, L.Y.; Yu, T.B.; Guan, C.; Zhao, Y. Microstructure and Properties of Metal Parts Remanufactured by Laser Cladding TiC and TiB2 Reinforced Fe-Based Coatings. Ceram. Int. 2024, 48, 14127–14140. [Google Scholar] [CrossRef]

- Yu, Y.Z.; Ding, W.K.; Wang, X.; Mo, D.L.; Chen, F. Study on Microstructure and Wear Resistance of Multi-Layer Laser Cladding Fe901 Coating on 65 Mn Steel. Materials 2025, 18, 3505. [Google Scholar] [CrossRef]

- Lee, D.; Yoon, G.Y.; Park, S.J.; Lee, J.S.; Heo, Y.U. M23C6 Formation and Its Role on the Brittle Fracture in an Austenitic Fe–Mn–Al–C Lightweight Alloy. J. Alloys Compd. 2024, 972, 172865. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, G.S.; Zhang, Z.J.; Wang, X.; Gao, L.; Song, X. Effect of niobium content on microstructure and wear and corrosion resistance of laser-clad FeCo0.5CrNi1.5B0.5Nbx coatings on ductile iron. Surf. Coat. Technol. 2024, 476, 130210. [Google Scholar] [CrossRef]

- Yuan, P.; Gu, D.D.; Dai, D.H. Particulate migration behavior and its mechanism during selective laser melting of TiC reinforced Al matrix nanocomposites. Mater. Des. 2015, 82, 46–55. [Google Scholar] [CrossRef]

- Kishida, K.; Ito, M.; Inui, H.; Heilmaier, M.; Eggeler, G. On the Inherent Strength of Cr23C6 with the Complex Face-Centered Cubic D84 Structure. Acta Mater. 2024, 263, 119518. [Google Scholar] [CrossRef]

- Wang, W.J.; Zhou, Y.N.; Ma, Y.Z.; Liu, K.J.; Wang, L.B.; Chen, K. The Ferrite Layer on the Surface of Carbon Steel Obtained by Precisely Designed Cooling Rate Heat Treatment and Its Microstructure Analysis. Coatings 2022, 12, 541. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, L.J.; Xu, Y.L.; Li, J.; Xiao, X.S.; Jiang, L.Z. Effect of Aluminum on Microstructure Mechanical Properties and Pitting Corrosion Resistance of Ultra-Pure 429 Ferritic Stainless Steels. Mater. Des. 2015, 65, 682–689. [Google Scholar] [CrossRef]

- Kan, W.H.; Albino, C.; Dis-da-Costa, D.; Dolman, K.; Lucey, T.; Tang, X.H.; Chang, L.; Proust, G.; Cairney, J. Microstructure Characterisation and Mechanical Properties of a Functionally-Graded NbC/High Chromium White Cast Iron Composite. Mater. Charact. 2018, 136, 196–205. [Google Scholar] [CrossRef]

- Haddad, F.; Amara, S.E.; Kesri, R. Liquidus Surface Projection of the Fe–Nb–C System in the Iron-Rich Corner. Metall. Mater. Trans. A 2008, 39, 1026–1033. [Google Scholar] [CrossRef]

- Cao, Y.B.; Zhi, S.X.; Qi, H.B.; Zhang, Y.; Qin, C.; Yang, S.P. Evolution Behavior of Ex-Situ NbC and Properties of Fe-Based Laser Clad Coating. Opt. Laser Technol. 2020, 124, 105999. [Google Scholar] [CrossRef]

- Perez, J.; Gutierrez, J.; Olaya, J.; Piamba, O.; Scotti, A. The Effect of Niobium Addition on the Operational and Metallurgical Behavior of Fe-Cr-C Hardfacing Deposited by Shielded Metal Arc Welding. J. Manuf. Mater. Process. 2024, 8, 38. [Google Scholar] [CrossRef]

- Ouyang, C.Y.; Wang, R.; Zhao, C.J.; Wei, R.Z.; Li, H.; Deng, R.; Bai, Q.F.; Liu, Y.L. Study on Ductile Iron Surface Laser Cladding Austenitic Stainless Steel Coating Heat Treatment to Enhance Wear Resistance. Tribol. Int. 2024, 191, 109202. [Google Scholar] [CrossRef]

| Element | Ni | C | Si | Mn | Cr | Mo | Fe |

| Composition(wt.%) | 1.5~2.0 | 0.55~0.65 | 0.2~0.4 | 0.6~1.0 | 0.7~1.0 | 0.1~0.3 | Bal. |

| Fe | Cr | Mn | Si | Mo | Al | Nb | C | |

| Nb-A | Bal. | 9.1 | 2.7 | 1.05 | 1.4 | 2.0 | 1 | 1.01 |

| Nb-B | Bal. | 9.1 | 2.7 | 1.05 | 1.4 | 2.0 | 3 | 1.01 |

| Nb-C | Bal. | 9.1 | 2.7 | 1.05 | 1.4 | 2.0 | 5 | 1.01 |

| Nb-D | Bal. | 9.1 | 2.7 | 1.05 | 1.4 | 2.0 | 6 | 1.01 |

| Point | C | Al | Cr | Mn | Nb | Mo | Fe | Type | |

| Nb-A | 1 | 6.87 | 1.86 | 5.74 | 1.51 | 0.65 | Bal. | Martensite | |

| 2 | 8.54 | 0.89 | 26.68 | 1.88 | Bal. | Chromium Carbon | |||

| 3 | 4.03 | 2.28 | 9.19 | 2.28 | 0.89 | Bal. | Primary Phase | ||

| Nb-B | 4 | 5.81 | 2.86 | 5.86 | 1.69 | Bal. | Martensite | ||

| 5 | 8.64 | 0.46 | 2.54 | 1.73 | 20.38 | 1.59 | Bal. | NbC | |

| Nb-C | 6 | 5.32 | 1.37 | 5.88 | 1.76 | Bal. | Martensite | ||

| 7 | 3.63 | 1.46 | 6.37 | 2.28 | Bal. | Ferrite | |||

| 8 | 8.34 | 0.47 | 2.71 | 1.79 | 30.45 | 1.47 | Bal. | NbC | |

| Nb-D | 9 | 4.61 | 1.74 | 7.05 | 2.22 | 1.33 | 0.95 | Bal. | Segregated Phase |

| 10 | 3.51 | 1.86 | 6.54 | 1.69 | Bal. | Ferrite | |||

| 11 | 10.89 | 0.04 | 1.42 | 73.5 | 1.94 | Bal. | NbC |

| Point | C | O | Al | Si | Cr | Mn | Fe | Ni | Nb | W |

| 1 | 5.19 | 19.04 | 1.31 | 0.36 | 5.31 | 1.83 | Bal. | 1.12 | 3.93 | 2 |

| 2 | 5.32 | 20.87 | 1.46 | 0.42 | 5.43 | 1.81 | Bal. | 0.87 | 2.47 | 1.9 |

| 3 | 9.63 | 21.78 | 1.13 | 0.39 | 6.72 | 1.51 | Bal. | 0.98 | 3.23 | 1.87 |

| 4 | 4.67 | 18.92 | 1.28 | 0.36 | 6.58 | 1.45 | Bal. | 0.93 | 5.41 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Weng, L.; Liu, X.; Feng, Z.; Xiao, X.; Zhou, H.; Zhang, X. Coaxial Laser Cladding of Novel Wear-Resistant Alloy Coatings on 60CrMnMo Steel Surface. Materials 2025, 18, 4696. https://doi.org/10.3390/ma18204696

Chen M, Weng L, Liu X, Feng Z, Xiao X, Zhou H, Zhang X. Coaxial Laser Cladding of Novel Wear-Resistant Alloy Coatings on 60CrMnMo Steel Surface. Materials. 2025; 18(20):4696. https://doi.org/10.3390/ma18204696

Chicago/Turabian StyleChen, Min, Liu Weng, Xuyang Liu, Zhongxue Feng, Xuan Xiao, Haoran Zhou, and Xuefeng Zhang. 2025. "Coaxial Laser Cladding of Novel Wear-Resistant Alloy Coatings on 60CrMnMo Steel Surface" Materials 18, no. 20: 4696. https://doi.org/10.3390/ma18204696

APA StyleChen, M., Weng, L., Liu, X., Feng, Z., Xiao, X., Zhou, H., & Zhang, X. (2025). Coaxial Laser Cladding of Novel Wear-Resistant Alloy Coatings on 60CrMnMo Steel Surface. Materials, 18(20), 4696. https://doi.org/10.3390/ma18204696