A Review of External Confinement Methods for Enhancing the Strength of Concrete Columns

Abstract

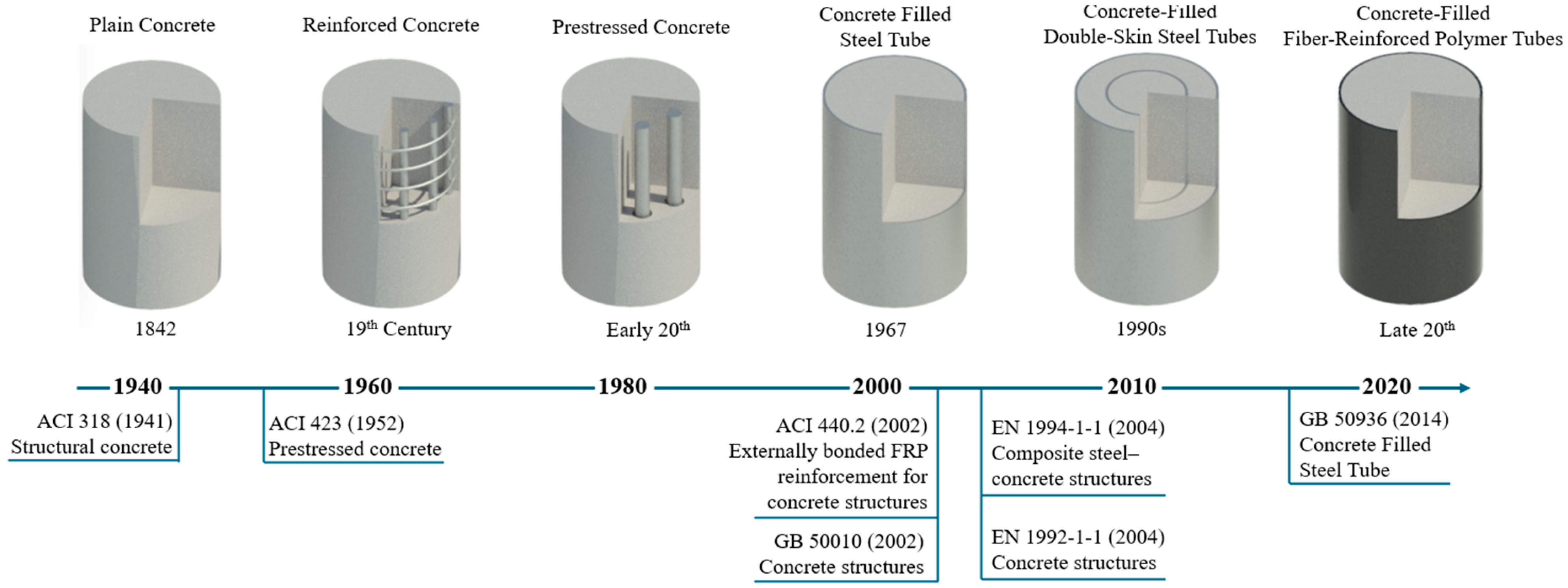

1. Introduction

| Criterion | Steel | Prestressed Concrete | CFST | CFFT |

| Structural performance | High | High | Very High | Very High |

| Construction time | Medium | Long | Short | Short |

| Labor cost | Medium | High | Medium | Medium |

| Material cost | Medium-High | High | Medium | High-Very High |

| Durability | Medium | Medium-High | High | Very High |

| Environmental resistance | Low (corrosion, humidity) | Medium | Medium-Low (outer steel exposed to environment—needs coating) | Excellent (FRP inert to chemicals, salts) |

| Waste/Pollution | Medium | Medium | Low (controlled production) | Very Low (precise, minimal waste) |

| Environmental impact | High (cutting, welding, paint fumes, noise) | Medium (pumps, post-tensioning, formwork removal) | Low (less noise, especially with prefab tubes) | Very Low (quiet installation, minimal waste, no welding or formwork) |

| Weight | High | High | High | Medium |

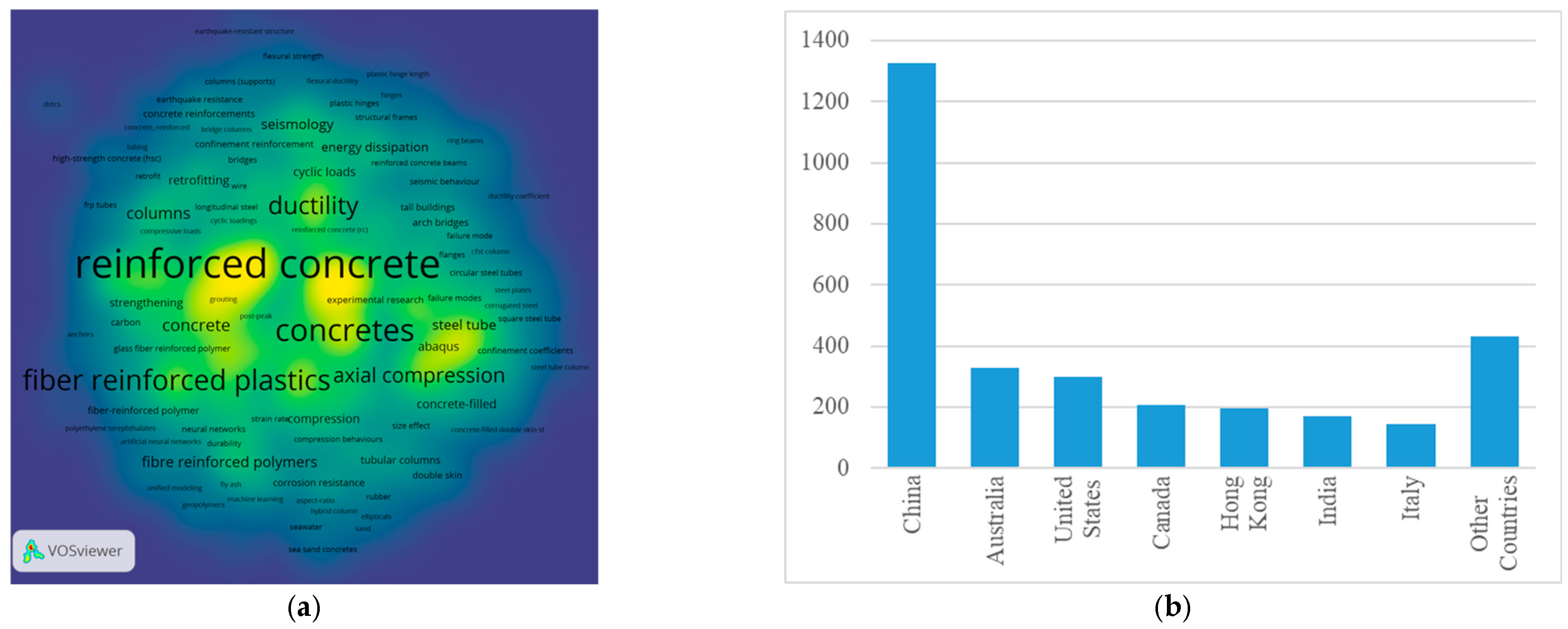

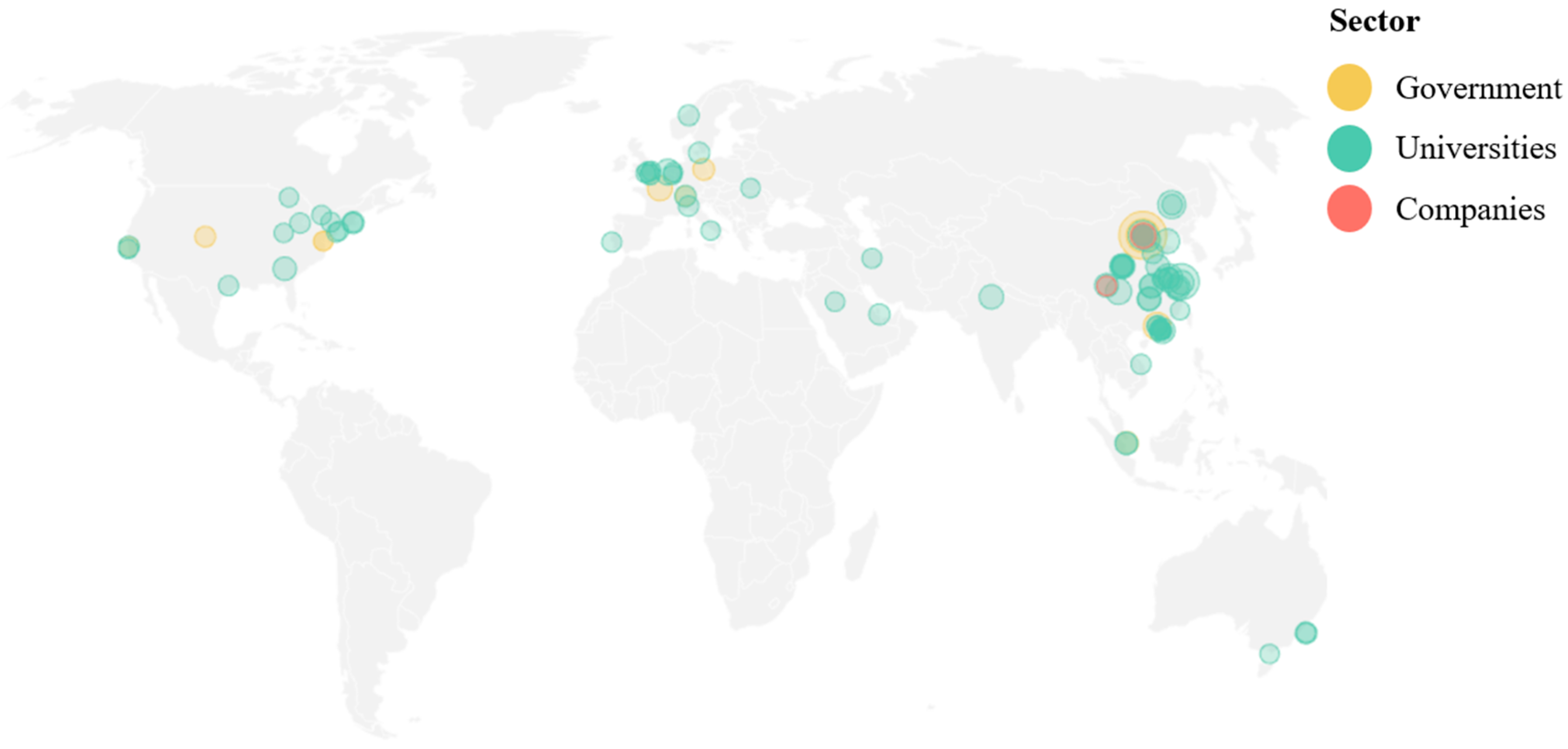

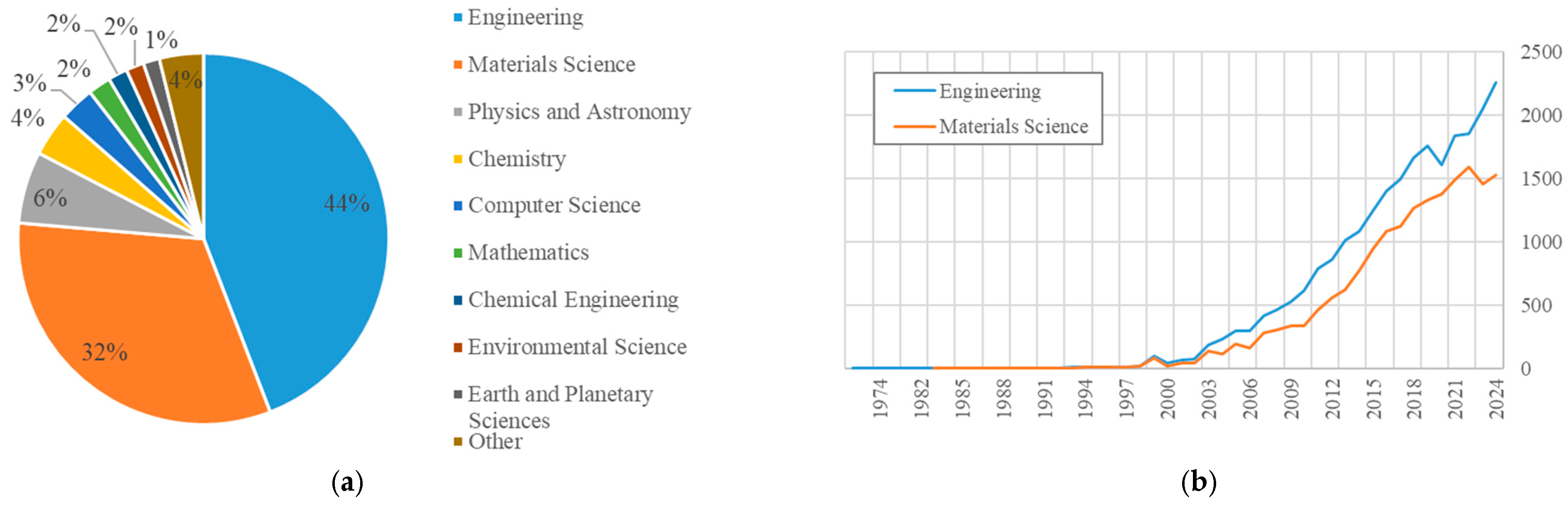

2. Scientometric Analysis of the Bibliometric Data

| Patents | Concrete-Filled Steel Tube (CFST) | Concrete-Filled Double-Skin Steel Tubes (CFDST) | Concrete-Filled Fiber-Reinforced Polymer Tubes (CFFT) | Concrete-Filled Fiber-Reinforced Polymer-Steel Composite Tube (CFCT) | Concrete Filled Tube (CFT) |

|---|---|---|---|---|---|

| Lens [34] | 42,812 | 3868 | 8818 | 5347 | 80,479 |

| Espacenet (EPO) [35] | 123,175 | 3493 | 5395 | 3102 | 208,439 |

| PatentScope (Wipo) [36] | 3330 | 5 | 7 | 2 | 4301 |

| Google Patents [37] | 125,048 | 124,755 | 70,142 | 41,518 | 125,048 |

3. Contemporary Methods of Strengthening Concrete Columns

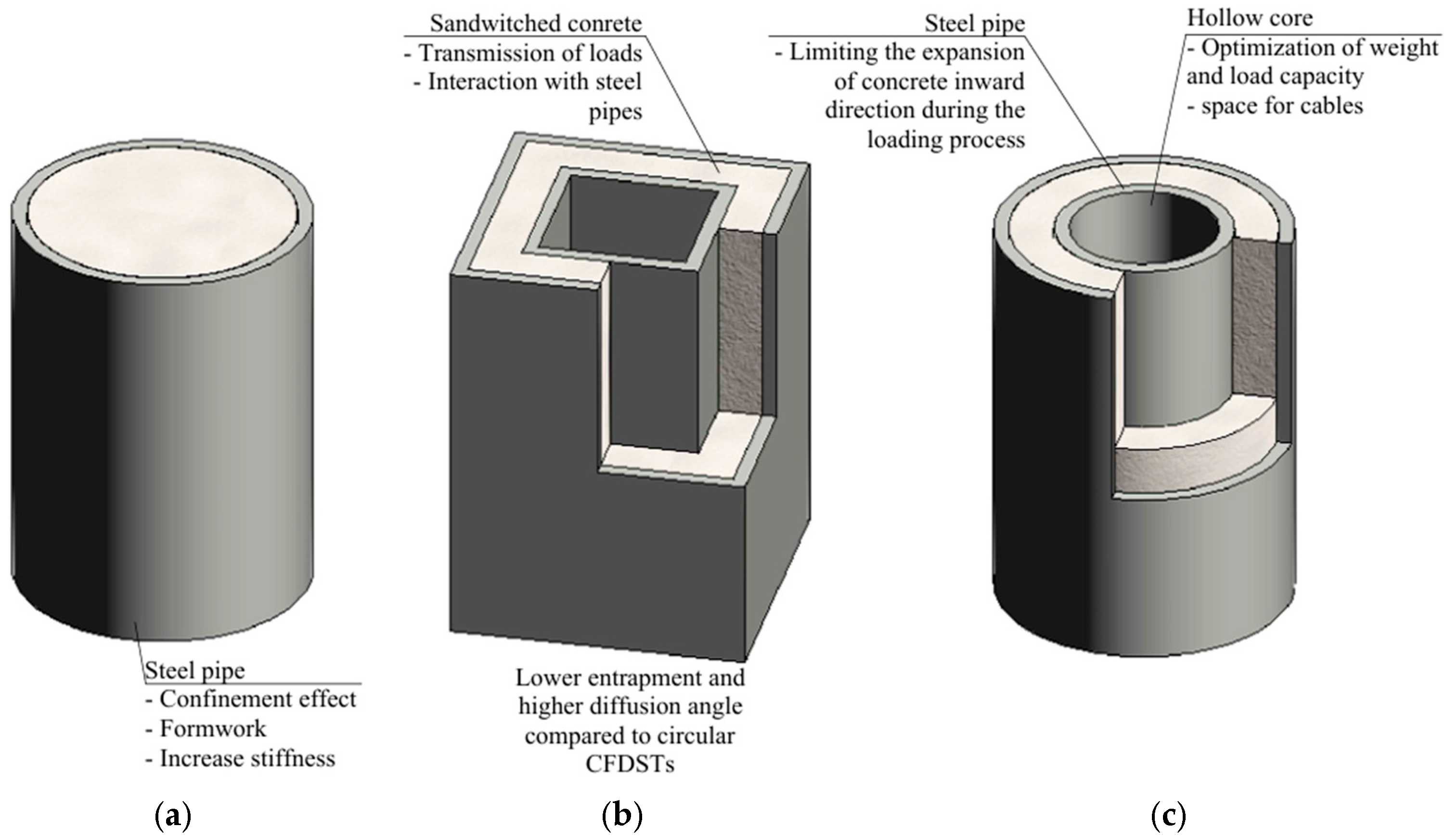

3.1. Concrete-Filled Steel Tube

3.2. Fiber Reinforced Polymer

3.3. Concrete-Filled Fiber-Reinforced Polymer

| Construction | Reference | The Main Conclusions |

|---|---|---|

| Square concrete-filled double skin steel tube (CFDST) | Y. Yang et al. [44] | Proposed design methods providing accurate and safe predictions |

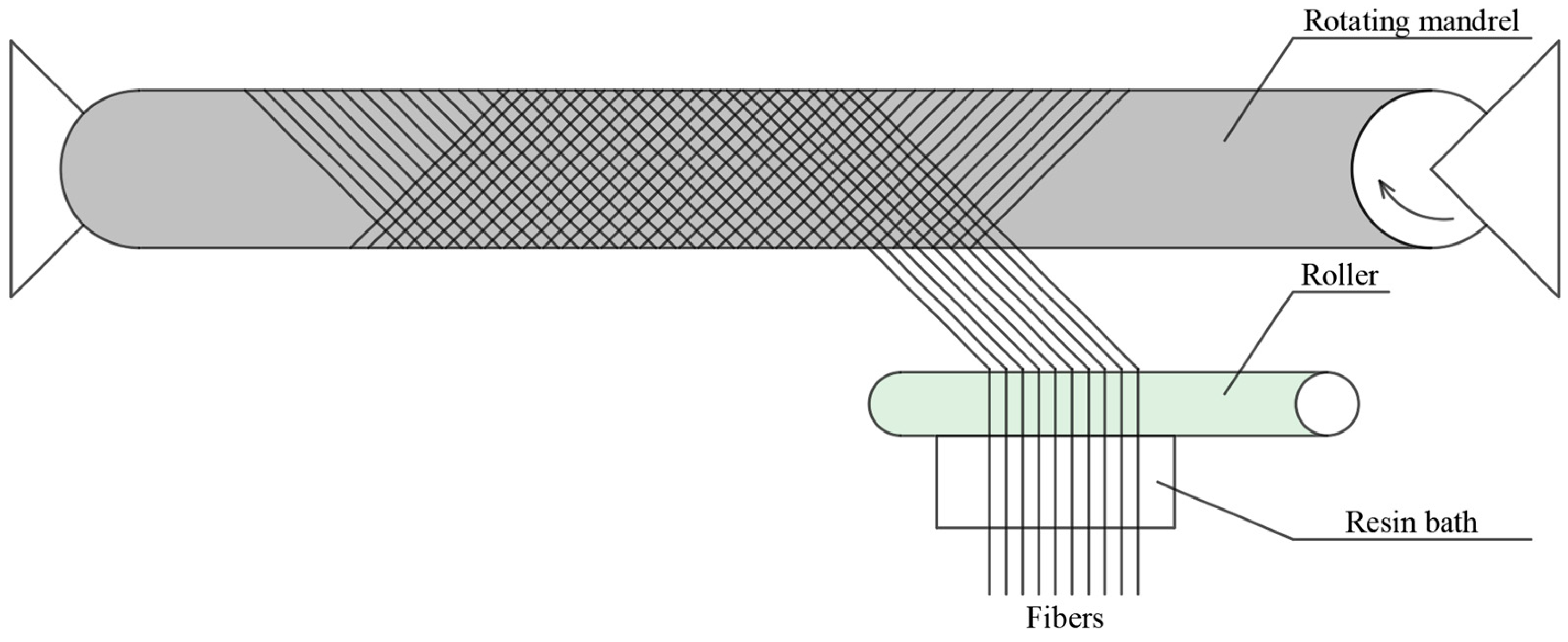

| Compressive behavior of CFFTs (HSCFFTs and UHSCFFTs) | T. Vincent and T. Ozbakkaloglu [64] | CFFTs filled with high- and ultra-high-strength concrete exhibit highly ductile behavior and significant strength gains after initial peak load; The FRP tube manufacturing method strongly affects the compressive performance, with automated filament winding producing better results compared to manual wet lay-up |

| Seismic behavior of square HSC-filled FRP tubes (HSCFFTs) | Y. Idris and T. Ozbakkaloglu [65] | Square HSCFFT columns demonstrate high inelastic deformation capacities under simulated seismic loading; Column deformability decreases with higher axial load levels and concrete strength, but increased confinement can mitigate this effect; Increasing the corner radius improves drift capacity up to a threshold, beyond which no further improvements are observed |

| Flexural behavior of concrete-filled FRP-steel composite circular tubes | Y. Wei et al. [66] | FRP enhances ultimate bearing capacity, introduces a hardening stage after steel yielding, and prevents “zero stiffness.”; The combination of various FRP types mitigates fracture failure by enabling sequential fiber rupture and altering failure modes |

| FRP Type and Layer | Layer Plain | Slenderness | (MPa) | (MPa) | Ultimate Strain (%) | Reference | |

|---|---|---|---|---|---|---|---|

| AFRP | 1 | 2 | 35.5 | 66.3 | 1.87 | 1.90 | [86] |

| 39.2 | 60.0 | 1.53 | 2.24 | [87] | |||

| PEN FRP 1 | 52.6 | 1.34 | 3.68 | ||||

| PET-900 FRP 2 | 48.0 | 1.22 | 4.89 | ||||

| PET-600 FRP 2 | 32.5 | 41.8 | 1.29 | 4.77 | |||

| GFRP | 35.2 | 63.8 | 1.81 | 1.97 | [88] | ||

| CFRP | 71.6 | 2.03 | 2.21 | ||||

| BFRP | 2 | 44.1 | 1.25 | 1.15 | |||

| CFRP + GFRP | 1 + 1 | 19.70 | 65.56 | 3.32 | 2.40 | [89] | |

| GFRP + CFRP | 1 + 1 | 44.34 | 2.25 | 1.76 | |||

| CFRP | 1 | 51.1 | 70.0 | 1.37 | 6.90 | [90] | |

| 36.0 | 41.8 | 1.16 | 2.90 | [91] | |||

| HM CFRP | 36.3 | 45.2 | 1.25 | 2.77 | |||

| GFRP | 33.1 | 42.0 | 1.27 | 1.29 | [92] | ||

| CFRP | 37.7 | 49.4 | 1.31 | 0.90 | |||

| JFRP 3 + BFRP | 2 + 2 | 22.8 | 38.5 | 1.69 | 1.80 | [93] | |

| BFRP | 2 | 31.0 | 1.36 | 1.60 | |||

| JFRP 3 | 27.7 | 1.22 | 1.48 |

| Type of Fiber | Elastic Modulus (GPa) | Ultimate Tensile Strain (%) | Tensile Strength (MPa) | Density (kg/m3) |

| Aramid | 70–179 | 2.50 | 2900–3450 | 1440–1470 |

| Carbon | 230–240 | 1.55 | 3700–3900 | 1800 |

| HM Carbon | 390–640 | 0.40 | 2600–4900 | 2000 |

| Glass | 65–72 | 1.93–2.12 | 1700–3400 | 2460–2580 |

| Basalt | 80–100 | 2.25–3.1 | 3300–4500 | 2600–2800 |

3.3.1. Size Effects in FRP-Wrapped Concrete Columns

| Fiber Type | Diameter (D) and Height (mm) | (mm) | Compressive Strength of Unconfined Concrete (MPa) | Compressive Strength of Strengthened Concrete (MPa) | References | ||

|---|---|---|---|---|---|---|---|

| CFRP | 100 × 200 | 0.167 | 0.00668 | 25.9 | 64.6 | 2.49 | [100] |

| 200 × 400 | 0.334 | 22.7 | 64.9 | 2.86 | |||

| 300 × 600 | 0.501 | 24.5 | 60.5 | 2.47 | |||

| AFRP | 70 × 100 | 0.0572 | 0.0033 | 29.4 | 41.8 | 1.45 | [103] |

| 0.0953 | 0.0054 | 49.64 | 1.72 | ||||

| 0.1907 | 0.0109 | 86.07 | 2.99 | ||||

| 105 × 315 | 0.0715 | 0.0027 | 28.8 | 41.2 | 1.43 | ||

| 0.143 | 0.0054 | 47.77 | 1.66 | ||||

| 0.286 | 0.0109 | 87.42 | 3.04 | ||||

| 194 × 582 | 0.1430 | 0.0029 | 24.0 | 33.84 | 1.18 | ||

| 0.2860 | 0.0059 | 43.9 | 1.52 | ||||

| 0.5720 | 0.0118 | 80.86 | 2.81 | ||||

| CFRP | 50 × 100 | 1 | 0.04 | 53.8 | 146.2 | 2.72 | [101] |

| 100 × 200 | 49.1 | 94.5 | 1.92 | ||||

| 2 | 0.08 | 146 | 2.97 | ||||

| 150 × 300 | 41.1 | 111.5 | 2.71 | ||||

| 1 | 0.04 | 76.4 | 1.86 |

| Fiber Type | Height (mm) | Diameter (mm) | Slenderness Ratio | Number of Layers of Composite | Compressive Strength of Unconfined Concrete (MPa) | Compressive Strength of Strengthened Concrete (MPa) | References | |

| GFRP | 300 | 150 | 2 | 2 | 30.6 | 89.5 | 2.92 | [104] |

| 450 | 3 | 91.2 | 2.98 | |||||

| 600 | 4 | 85.8 | 2.80 | |||||

| 750 | 5 | 30.4 | 87.6 | 2.89 | ||||

| 3 | 128.1 | 4.22 | ||||||

| 250 | 3 | 2 | 31.2 | 55.8 | 1.79 | |||

| CFRP | 600 | 150 | 4 | 2 | 28.2 | 57.4 | 2.04 | [94] |

| HM CFRP | 65.6 | 2.33 | ||||||

| GFRP | 35.8 | 1.27 | ||||||

| CFRP | 304 | 152 | 2 | 1 | 36 | 64 | 1.78 | [105] |

| 912 | 6 | 2 | 37 | 64 | 1.73 | |||

| GFRP | 304 | 2 | 3 | 36 | 90 | 2.50 | ||

| 902 | 6 | 37 | 87 | 2.35 |

3.3.2. Relationship Between CFRP Strengthening Effectiveness and Concrete Strength Class

3.3.3. Failure Modes of FRP Strengthened Columns

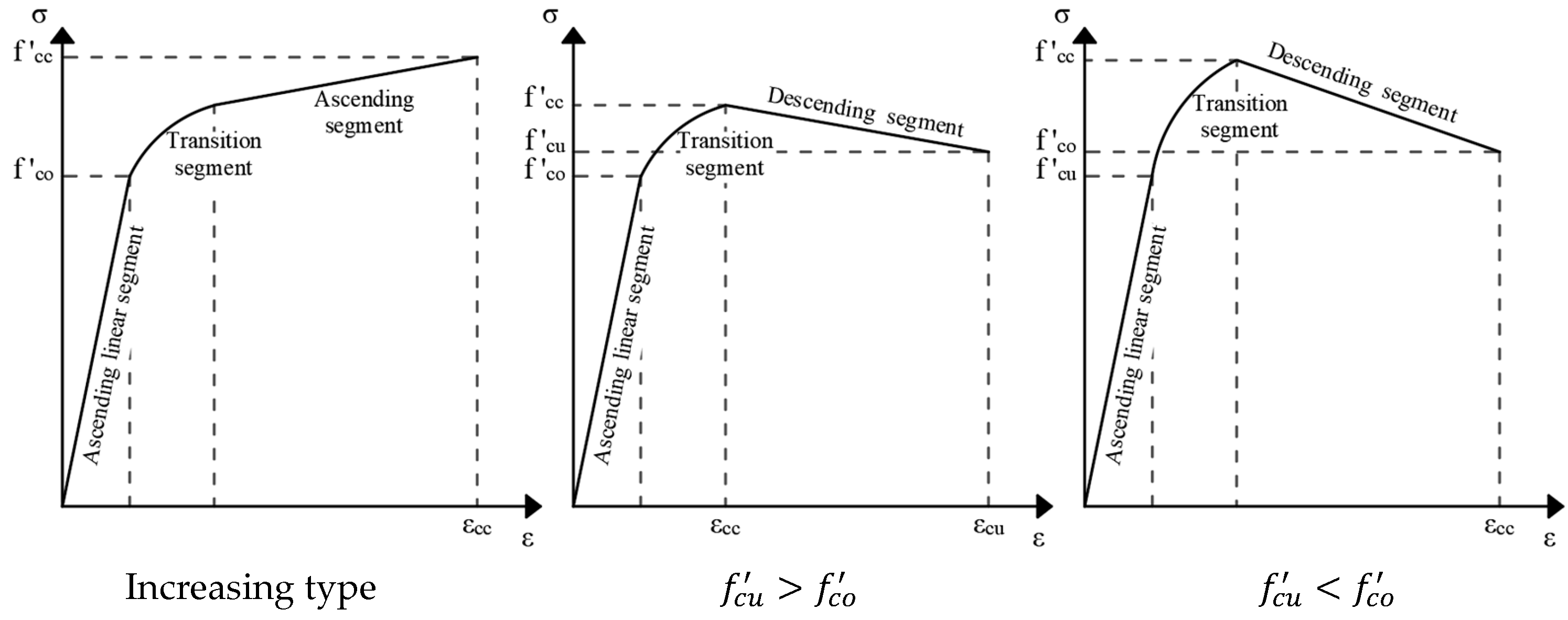

3.3.4. Load-Bearing Capacity Estimation

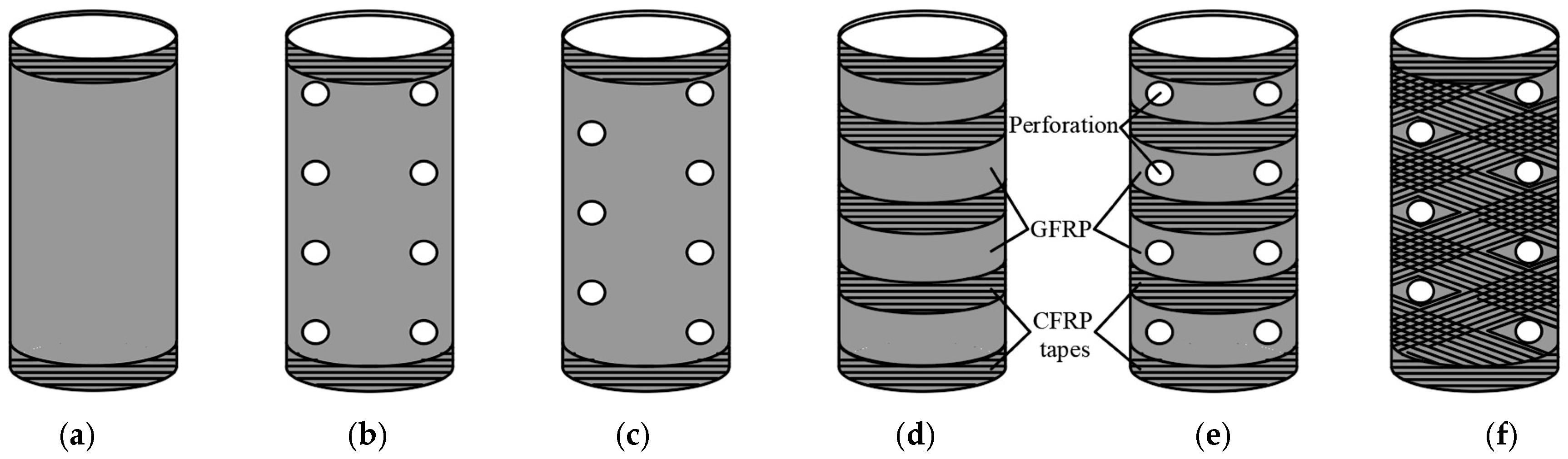

3.4. Perforated FRP Tubes

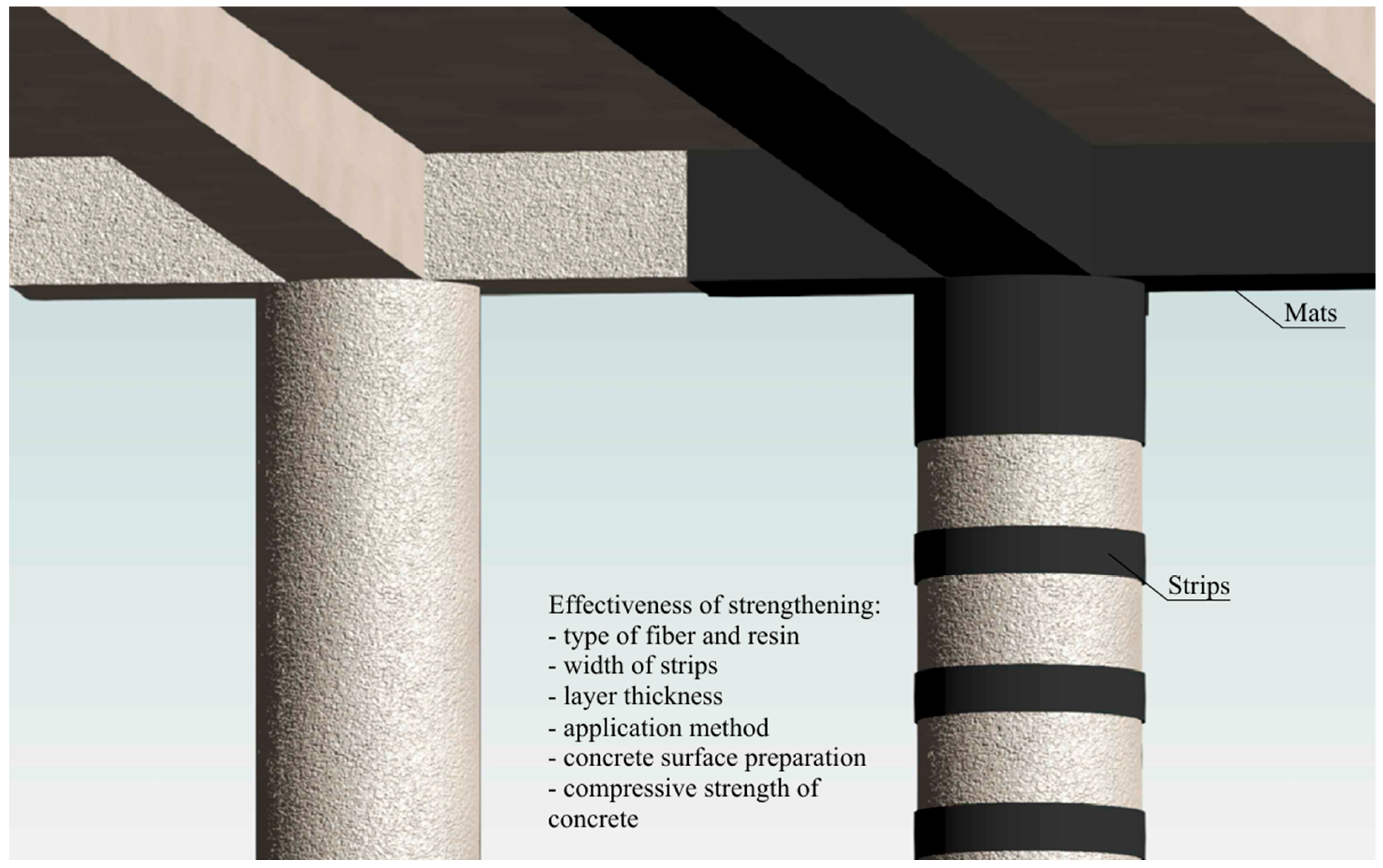

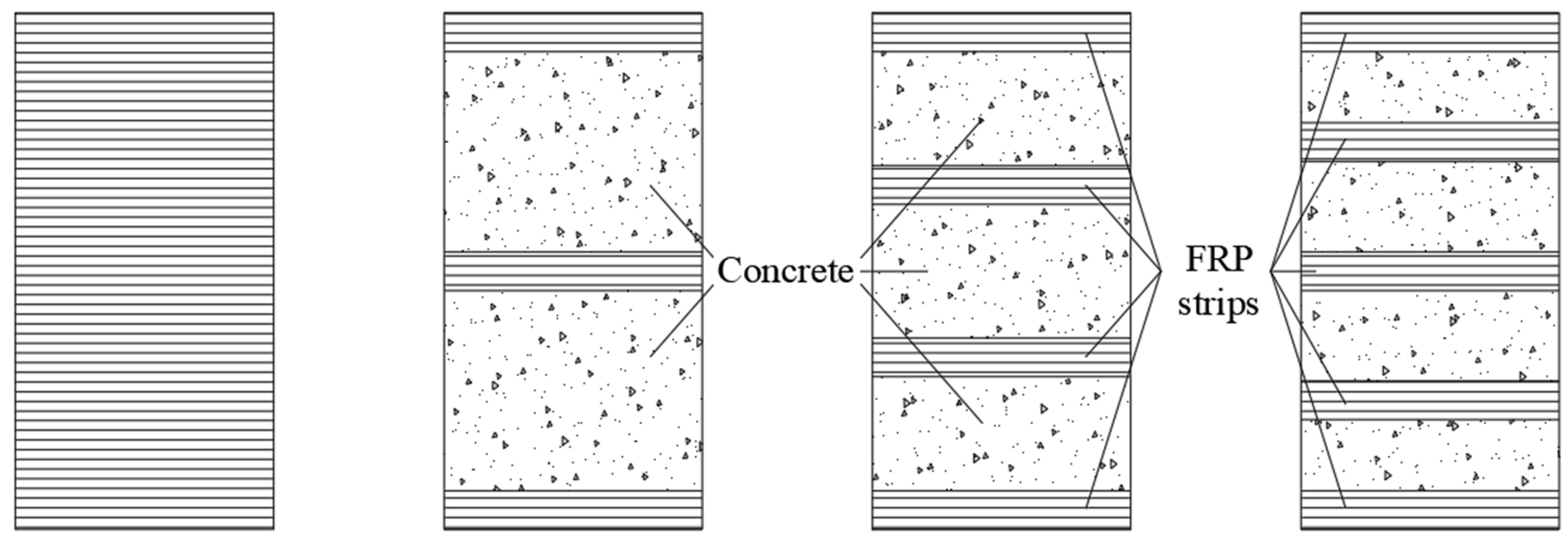

3.5. Strengthening of Concrete Columns by Strips

4. FRP Textiles and Their Application in Concrete Structures

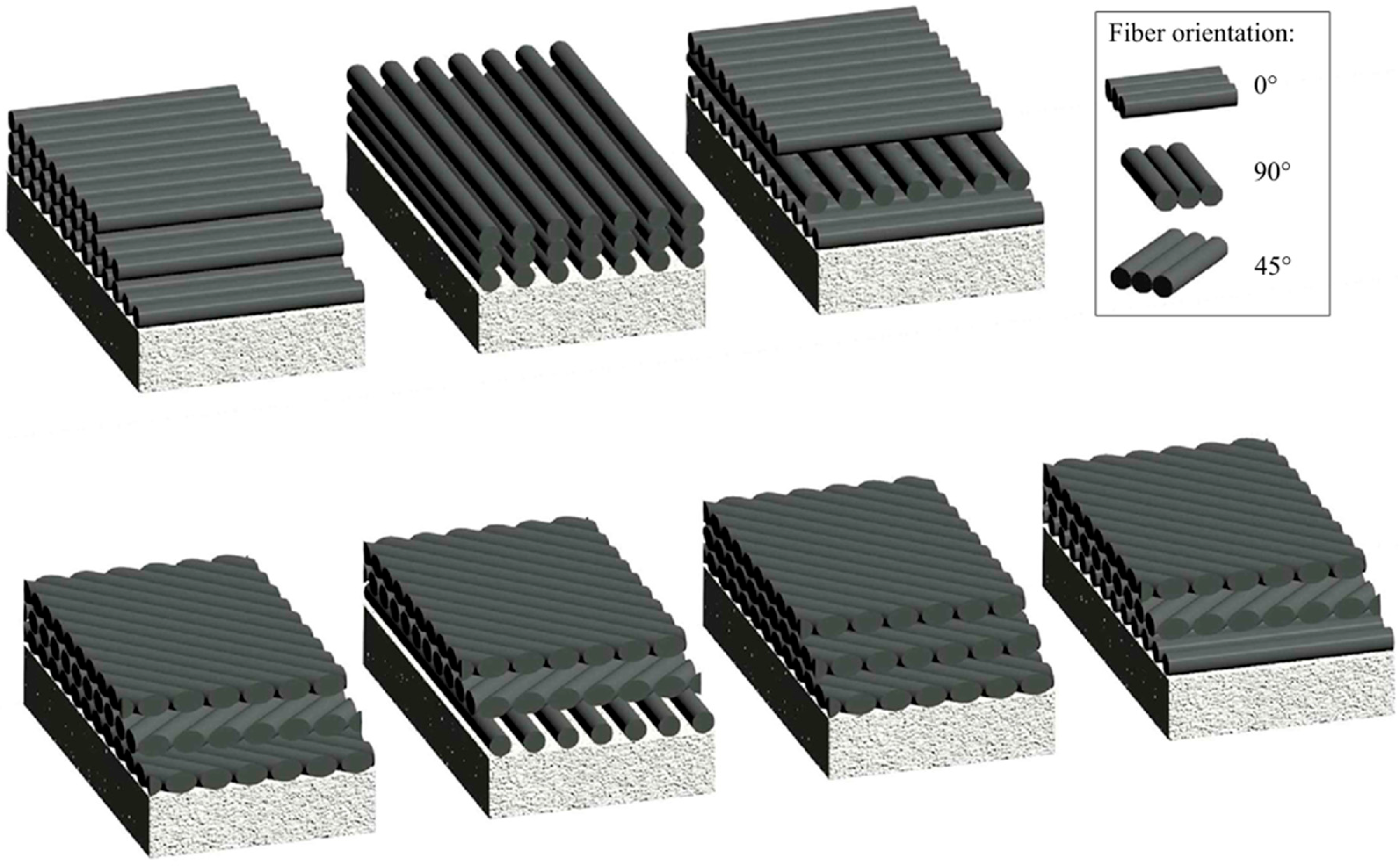

4.1. Orientation of Fibers

4.2. Lamination Process

4.3. Epoxy Resins

5. Research Gaps and Perspectives

- Can carbon fibers provide an effective alternative to traditional reinforcement in concrete columns?

- To what extent do the perforations provide effective bonding between the concrete core and the surrounding CFRP tube?

- How do the location and size of perforations influence the failure mechanism and its initiation?

- To what extent is it possible that the efficiency of the construction process be improved by using prefabricated CFRP reinforcement elements combined with self-compacting concrete?

| Selected Keywords | Number of Phrases | |

|---|---|---|

| Web of Science | Scopus | |

| Step 1 | ||

| Reinforcement/strengthening + concrete + CFRP/carbon fiber-reinforced polymer/fiber reinforced polymer/FRP + tube/circular column/hollow section | 23 | 357 |

| Step 2 | ||

| Reinforcement/strengthening + concrete + CFRP/carbon fiber-reinforced polymer/fiber reinforced polymer/FRP + tube/circular column/hollow section + perforation/perforated/hole/cutout | 0 | 1 |

| Step 3 | ||

| Reinforcement + concrete + CFRP + tube + perforated * | 1 | 0 |

6. Summary

- Material Selection: CFRP is the most effective in terms of mechanical performance and environmental resistance. For less demanding applications or cost-driven projects, GFRP or BFRP may be considered, acknowledging their limitations in durability and water absorption;

- Design Considerations: Engineers should ensure circumferential fiber orientation to maximize confinement. The number of FRP layers should be optimized, as increasing the number of layers does not necessarily result in proportional improvements in efficiency due to diminishing returns with each additional layer;

- Application Method: In retrofitting scenarios requiring minimal visual impact and greater protection against vandalism or mechanical damage, NSM is preferred over traditional EBR methods. For new constructions requiring both formwork and confinement, CFFT systems offer efficiency in terms of installation and performance.

- Durability and Fire Resistance: While FRP materials are corrosion-resistant, their performance in fire conditions is limited. Designers should include fire-resistant coatings or additives where required. In addition, attention should be paid to surface preparation and resin selection to ensure long-term bond integrity and structural performance;

- Sustainability and Recycling: Although current recycling methods for FRP are limited, engineers should consider hybrid composites or recyclable formulations when sustainability goals are prioritized.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFRP | Aramid Fiber-Reinforced Polymer |

| BFRP | Basalt Fiber-Reinforced Polymer |

| CFCR | Carbon Fiber Coated Reinforcement |

| CFCT | Concrete-Filled Fiber-Reinforced Polymer-Steel Composite Tube |

| CFDST | Concrete-Filled Double-Skin Steel Tubes |

| CFFTs | Concrete-Filled Fiber-Reinforced Polymer Tubes |

| CFRP | Carbon Fiber-Reinforced Polymers |

| CFST | Concrete-Filled Steel Tube |

| CFT | Concrete-Filled Tube |

| CNTF | Carbon Nanotube Fibers |

| EBR | Externally Bonded Reinforcement |

| FRP | Fiber-Reinforced Polymer |

| FTC | Freeze-Thaw Cycles |

| GFRP | Glass Fiber Reinforced Polymer |

| GFRP | Glass Fiber-Reinforced Polymer |

| HM CFRP | High-Modulus Carbon-Fiber-Reinforced Polymer |

| HSCFFT | High-Strength Concrete-Filled Fiber Reinforced Polymer |

| JFRP | Jute Fiber Reinforced Polymer |

| LCM | Liquid Composite Molding |

| LRS FRP | Large Rupture Strain Fiber-Reinforced Polymer |

| NSM | Near Surface Mounted |

| PEN FRP | Polyethylene Naphthalate Fiber-Reinforced Polymer |

| PET FRP | Polyethylene terephthalate Fiber-Reinforced Polymer |

| PVC | Polyvinyl Chloride |

| RTM | Resin Transfer Molding |

| SCC | Self-Compacting Concrete |

| SCRIMP | Seemann’s Composite Resin Infusion Molding Process |

| SMA | Shape Memory Alloy |

| SRIM | Structural Reaction Injection Molding |

| UHPC | Ultra-High Performance Concrete |

| UHSCFFT | Ultra-High-Strength Concrete Filled Fiber Reinforced Polymer |

Nomenclature

| Peak axial strain of confined concrete [-] | |

| Peak axial strain of unconfined concrete [-] | |

| Ultimate tensile strain of FRP [-] | |

| Effective tensile strain of FRP jacket at failure [-] | |

| Lateral strain (hoop strain) of the FRP jacket [-] | |

| Actual hoop strain of the FRP jacket at rupture [-] | |

| Ultimate Poisson’s ratio of FRP-confined concrete [-] | |

| Volumetric ratio of FRP strengthening [-] | |

| Lateral confining pressure applied by FRP jacket [MPa] | |

| Concrete strength factor [-] | |

| Diameter of the confined concrete core [mm] | |

| Young’s modulus of FRP fibers [MPa] | |

| Reference Young’s modulus used in empirical model [MPa] | |

| Confinement stiffness factor for FRP [MPa] | |

| Secant modulus of elasticity of unconfined concrete at peak stress [MPa] | |

| Confinement strength of FRP [MPa] | |

| Ultimate confined concrete strength [MPa] | |

| Compressive strength of unconfined concrete [MPa] | |

| Actual peak lateral confining pressure applied by FRP jacket [MPa] | |

| Nominal lateral confining stress [MPa] | |

| Threshold confining pressure [MPa] | |

| Strength enhancement coefficient [-] | |

| Coefficient of strain enhancement [-] | |

| Confinement stiffness [MPa] | |

| Radius of the confined concrete core [mm] | |

| Total thickness of the FRP jacket [mm] |

References

- Dan, M.B.; Přikryl, R.; Török, Á. Materials, Technologies and Practice in Historic Heritage Structures; Springer Netherlands: Dordrecht, The Netherlands, 2010; ISBN 978-90-481-2683-5. [Google Scholar]

- Goodnight, J.C.; Kowalsky, M.J.; Nau, J.M. Effect of Load History on Performance Limit States of Circular Bridge Columns. J. Bridg. Eng. 2013, 18, 1383–1396. [Google Scholar] [CrossRef]

- Dinges, T. The History of Prestressed Concrete: 1888 to 1963. Master’s Thesis, Kansas State University, Manhattan, KS, USA, 2009. [Google Scholar]

- Kim, T.-K.; Kim, S.-H.; Park, J.-S.; Park, H.-B. Experimental Evaluation of PSC Structures from FRP with a Prestressing Strengthening Method. Materials 2021, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- Hassanvand, P.; Rezaie, F.; Kioumarsi, M. Experimental Investigation of the Effect of Steel Fibers on the Flexural Behavior of Corroded Prestressed Reinforced Concrete Beams. Materials 2023, 16, 1629. [Google Scholar] [CrossRef] [PubMed]

- Schleiting, M.; Wetzel, A.; Bauer, A.; Frenck, J.-M.; Niendorf, T.; Middendorf, B. Potential of Fe-Mn-Al-Ni Shape Memory Alloys for Internal Prestressing of Ultra-High Performance Concrete. Materials 2023, 16, 3816. [Google Scholar] [CrossRef]

- Tomii, M.; Sakino, K. Experimental Studies on the Ultimate Moment of Concrete Filled Square Steel Tubular Beam-Columns. Trans. Archit. Inst. Japan 1979, 275, 55–65. [Google Scholar] [CrossRef]

- Hajjar, J.F.; Gourley, B.C. Representation of Concrete-Filled Steel Tube Cross-Section Strength. J. Struct. Eng. 1996, 122, 1327–1336. [Google Scholar] [CrossRef]

- Zhang, N.; Jiang, S.; Chen, X.; Bao, L.; Zhou, F.; Zhao, H.; Shi, G. Experimental Study on Seismic Behaviour of Thick-Flange Steel Beam to Square CFST Column Joints with Internal Diaphragms. Eng. Struct. 2024, 319, 118792. [Google Scholar] [CrossRef]

- Wang, Y.C. A Simple Method for Calculating the Fire Resistance of Concrete-Filled CHS Columns. J. Constr. Steel Res. 2000, 54, 365–386. [Google Scholar] [CrossRef]

- Espinos, A.; Romero, M.L.; Lam, D. Fire Performance of Innovative Steel-Concrete Composite Columns Using High Strength Steels. Thin-Walled Struct. 2016, 106, 113–128. [Google Scholar] [CrossRef]

- Sadeghian, P.; Fam, A. Improved Design-Oriented Confinement Models for FRP-Wrapped Concrete Cylinders Based on Statistical Analyses. Eng. Struct. 2015, 87, 162–182. [Google Scholar] [CrossRef]

- Keshtegar, B.; Sadeghian, P.; Gholampour, A.; Ozbakkaloglu, T. Nonlinear Modeling of Ultimate Strength and Strain of FRP-Confined Concrete Using Chaos Control Method. Compos. Struct. 2017, 163, 423–431. [Google Scholar] [CrossRef]

- Schué, F. FRP: Strengthened RC Structures. JG Teng, JF Chen, ST Smith and L Lam. John Wiley & Sons, Ltd, Chichester, UK, 2001. Pp 245, ISBN 0-471-48706-6. Polym. Int. 2004, 53, 232–233. [Google Scholar] [CrossRef]

- Ostrowski, K.; Dudek, M.; Sadowski, Ł. Compressive Behaviour of Concrete-Filled Carbon Fiber-Reinforced Polymer Steel Composite Tube Columns Made of High Performance Concrete. Compos. Struct. 2020, 234, 111668. [Google Scholar] [CrossRef]

- Xu, J.J.; Demartino, C.; Shan, B.; Heo, Y.A.; Xiao, Y. Experimental Investigation on Performance of Cantilever CFRP-Wrapped Circular RC Columns under Lateral Low-Velocity Impact. Compos. Struct. 2020, 242, 112143. [Google Scholar] [CrossRef]

- Hollaway, L. The Evolution of and the Way Forward for Advanced Polymer Composites in the Civil Infrastructure. Constr. Build. Mater. 2003, 17, 365–378. [Google Scholar] [CrossRef]

- Pessiki, S.; Harries, K.A.; Kestner, J.T.; Sause, R.; Ricles, J.M. Axial Behavior of Reinforced Concrete Columns Confined with FRP Jackets. J. Compos. Constr. 2001, 5, 237–245. [Google Scholar] [CrossRef]

- Li, G.; Maricherla, D.; Singh, K.; Pang, S.-S.; John, M. Effect of Fiber Orientation on the Structural Behavior of FRP Wrapped Concrete Cylinders. Compos. Struct. 2006, 74, 475–483. [Google Scholar] [CrossRef]

- ACI CODE-318-25; Building Code for Structural Concrete—Code Requirements and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2025.

- ACI-ASCE 423; Prestressed Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2017.

- ACI PRC-440.2-23; Design and Construction of Externally Bonded Fiber-Reinforced Polymer (FRP) Systems for Strengthening Concrete Structures—Guide. American Concrete Institute: Farmington Hills, MI, USA, 2023.

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

- EN 1994-1-1:2004; Eurocode 4: Design of Composite Steel and Concrete Structures Part 1-1: General Rules and Rules for Buildings. CEN: Brussels, Belgium, 2004.

- EN 1992-1-1:2023; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings, Bridges and Civil Engineering Structures. CEN: Brussels, Belgium, 2004.

- GB 50936-2014; Technical Code for Concrete Filled Steel Tubular Structures. China Architecture & Building Press: Beijing, China, 2014.

- Saadeh, M.; Irshidat, M.R. Recent Advances in Concrete-Filled Fiber-Reinforced Polymer Tubes: A Systematic Review and Future Directions. Innov. Infrastruct. Solut. 2024, 9, 1–26. [Google Scholar] [CrossRef]

- Hou, C.C.; Han, L.H. Life-Cycle Performance of Deteriorated Concrete-Filled Steel Tubular (CFST) Structures Subject to Lateral Impact. Thin-Walled Struct. 2018, 132, 362–374. [Google Scholar] [CrossRef]

- Zhang, S.; Miao, K.; Wei, Y.; Xu, X.; Luo, B.; Shi, W. Experimental and Theoretical Study of Concrete-Filled Steel Tube Columns Strengthened by FRP/Steel Strips Under Axial Compression. Int. J. Concr. Struct. Mater. 2023, 17, 1–22. [Google Scholar] [CrossRef]

- Villacreses, L.; Orellana-Alvear, B.; Pacurucu, N. Comparative Technical-Economic Study of a Reinforced Concrete Building and a Building with Prestressed Prefabricated Elements. Samborondón—Ecuador. Sustain. Constr. Era Fourth Ind. Revolut. 2023, 107, 130–139. [Google Scholar] [CrossRef]

- Manikanta Kopuri, N.A.G.K.; Priyadharshani, S.A. Influence of Concrete Type and Acidic Environment on the Behaviour of Concrete Filled Steel and FRP Tubes. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 2047–2064. [Google Scholar] [CrossRef]

- Scopus.Com. Available online: https://www.scopus.com/ (accessed on 28 April 2025).

- Where Are the Top-Ranked Institutions Located? Available online: https://www.scimagoir.com/institutionsmap.php?area=2205&top=100 (accessed on 28 April 2025).

- Lens.Org. Available online: https://www.lens.org/ (accessed on 28 April 2025).

- Espacenet. Available online: https://worldwide.espacenet.com/patent/ (accessed on 28 April 2025).

- Wipo Patentscope. Available online: https://www.wipo.int/en/web/patentscope (accessed on 28 April 2025).

- Google Patents. Available online: https://patents.google.com/ (accessed on 28 April 2025).

- Baig, M.N.; Fan, J.; Nie, J. Strength of Concrete Filled Steel Tubular Columns. Tsinghua Sci. Technol. 2006, 11, 657–666. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, J. Concrete-Filled Steel Tube Arch Bridges in China. Engineering 2018, 4, 143–155. [Google Scholar] [CrossRef]

- Craveiro, H.D.; Rahnavard, R.; Henriques, J.; Simões, R.A. Structural Fire Performance of Concrete-Filled Built-Up Cold-Formed Steel Columns. Materials 2022, 15, 2159. [Google Scholar] [CrossRef]

- Soltanalipour, M.; Ferrer, M.; Marimon, F.; Albareda, A.; Casafont, M.; Iglesias, G. Experimental Study on a Highly Efficient Shear Transfer System for Square CFST. J. Constr. Steel Res. 2023, 205, 107905. [Google Scholar] [CrossRef]

- Cheng, B.; Wang, W.; Li, J.; Huang, J.; Chen, H. Mechanical Properties of Full-Scale UHPC-Filled Steel Tube Composite Columns under Axial Load. Materials 2023, 16, 4860. [Google Scholar] [CrossRef]

- Li, F.; Hexiao, Y.; Gao, H.; Deng, K.; Jiang, Y. Axial Behavior of Reinforced UHPC-NSC Composite Column under Compression. Materials 2020, 13, 2905. [Google Scholar] [CrossRef]

- Yang, Y.-F.; Hou, C.; Meng, C.-Y.; Han, L.-H. Investigation on Square Concrete Filled Double-Skin Steel Tube (CFDST) Subjected to Local Bearing Force: Experiments. Thin-Walled Struct. 2015, 94, 394–409. [Google Scholar] [CrossRef]

- Ekmekyapar, T.; Ghanim Hasan, H. The Influence of the Inner Steel Tube on the Compression Behaviour of the Concrete Filled Double Skin Steel Tube (CFDST) Columns. Mar. Struct. 2019, 66, 197–212. [Google Scholar] [CrossRef]

- Tao, Z.; Han, L.-H.; Zhao, X.-L. Behaviour of Concrete-Filled Double Skin (CHS Inner and CHS Outer) Steel Tubular Stub Columns and Beam-Columns. J. Constr. Steel Res. 2004, 60, 1129–1158. [Google Scholar] [CrossRef]

- Tao, Z.; Hasan, M.M.; Han, D.; Qin, Q.; Abdul Ghafar, W. Study of the Axial Compressive Behaviour of Cross-Shaped CFST and ST Columns with Inner Changes. Buildings 2023, 13, 423. [Google Scholar] [CrossRef]

- Yang, Y.; Xue, J.; Liu, Z.; Wang, J.; Wang, X. Seismic Performance of Precast Frame with RC Beam and Spliced CFST Column under Cyclic Loading. Eng. Struct. 2025, 335, 120363. [Google Scholar] [CrossRef]

- Yang, Y.; Xue, J.; Liu, Z.; Wang, J.; Wang, X. Experimental and Numerical Study on Seismic Behavior of Spliced High-Strength Concrete-Filled Steel Tubular (CFST) Column to Precast RC Beam Frame. J. Build. Eng. 2025, 104, 112301. [Google Scholar] [CrossRef]

- Pan, X.; Wang, J.; Li, B. Seismic Performance and Fragility Evaluation of Assembly Blind-Bolt CFST Composite Frames under Mainshock-Aftershock Sequences. Structures 2025, 77, 108969. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Khan, Q.S.; Sheikh, M.N. Axial and Flexural Behavior of Unreinforced and FRP Bar Reinforced Circular Concrete Filled FRP Tube Columns. Constr. Build. Mater. 2016, 122, 43–53. [Google Scholar] [CrossRef]

- Abdallah, M.H.; Mohamed, H.M.; Masmoudi, R.; Moussa, A. Analytical Modeling of Moment-Curvature Behavior of Steel and CFRP RC Circular Confined Columns. Compos. Struct. 2018, 189, 473–487. [Google Scholar] [CrossRef]

- Breveglieri, M.; Barros, J.A.O.; Dalfré, G.M.; Aprile, A. A Parametric Study on the Effectiveness of the NSM Technique for the Flexural Strengthening of Continuous RC Slabs. Compos. Part B Eng. 2012, 43, 1970–1987. [Google Scholar] [CrossRef]

- Nabati, A.; Ghanbari-Ghazijahani, T. CFRP-Reinforced Circular Steel Tubes with Cutout under Axial Loading. J. Constr. Steel Res. 2020, 164, 105775. [Google Scholar] [CrossRef]

- Huang, C.; Shao, Y.; Ou, J.; Bi, X. Axial Compressive Behavior of Circular Concrete-Filled Steel Tubular Stubs Strengthened with CFRP Considering Preloading and Corrosion. Structures 2024, 62, 106281. [Google Scholar] [CrossRef]

- Martinez, J.L.; Ramalho Cyrino, J.C.; Vaz, M.A.; Hernández, I.D.; Zegarra, V.D.; Perrut, V.A.; Gomes de Paula, G. CFRP-Patch Repair Characterization for Compressive Capacity Recovery of Perforated Steel Tubular Members. J. Brazilian Soc. Mech. Sci. Eng. 2023, 45, 421. [Google Scholar] [CrossRef]

- Martinez, J.L.; Torres, V.Z.; Vaz, M.A.; Cyrino, J.C.R.; Hernández, I.D. Cohesive Failure Analysis of Carbon-Fiber Composite Patch Repair in Perforated Steel Tubular Elements. Int. J. Adhes. Adhes. 2024, 133, 103744. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, Z.; Wu, Z.; Liu, Y. Reinforcement Effect of Recycled CFRP on Cement-Based Composites: With a Comparison to Commercial Carbon Fiber Powder. Struct. Durab. Heal. Monit. 2024, 18, 409–423. [Google Scholar] [CrossRef]

- Jeong, J.; Oh, D.; Ju, Y.; Goh, M. Energy-Efficient Chemical Recycling of CFRP and Analysis of the Interfacial Shear Strength on Recovered Carbon Fiber. Waste Manag. 2024, 187, 134–144. [Google Scholar] [CrossRef]

- Wei, Y.; Hadigheh, S.A. Development of an Innovative Hybrid Thermo-Chemical Recycling Method for CFRP Waste Recovery. Compos. Part B Eng. 2023, 260, 110786. [Google Scholar] [CrossRef]

- Ostrowski, K.A.; Furtak, K. The Influence of Concrete Surface Preparation on the Effectiveness of Reinforcement Using Carbon Fibre-Reinforced Polymer in High-Performance, Self-Compacting, Fibre-Reinforced Concrete. Compos. Struct. 2021, 276, 114522. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, G.; Li, G. Performance of Circular Concrete-Filled Fiber-Reinforced Polymer-Steel Composite Tube Columns under Axial Compression. J. Reinf. Plast. Compos. 2014, 33, 1911–1928. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Aravinthan, T. Effect of Beam Orientation on the Static Behaviour of Phenolic Core Sandwich Composites with Different Shear Span-to-Depth Ratios. Compos. Struct. 2017, 168, 292–304. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkloglu, T. Axial Compressive Behavior of High- and Ultra High-Strength Concrete-Filled AFRP Tubes. Adv. Mater. Res. 2013, 671–674, 626–631. [Google Scholar] [CrossRef]

- Idris, Y.; Ozbakkloglu, T. Behavior of High-Strength Concrete-Filled FRP Tube Columns under Simulated Seismic Loading: An Experimental Study. Adv. Mater. Res. 2013, 743, 39–44. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, G.; Wu, Z.S.; Gu, D.S. Flexural Behavior of Concrete-Filled FRP-Steel Composite Circular Tubes. Adv. Mater. Res. 2011, 243–249, 1316–1320. [Google Scholar] [CrossRef]

- Wei, Y.; Bai, J.; Zhang, Y.; Miao, K.; Zheng, K. Compressive Performance of High-Strength Seawater and Sea Sand Concrete-Filled Circular FRP-Steel Composite Tube Columns. Eng. Struct. 2021, 240, 112357. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Y.; Miao, K.; Li, B. A Novel Seawater and Sea Sand Concrete-Filled FRP-Carbon Steel Composite Tube Column: Cyclic Axial Compression Behaviour and Modelling. Eng. Struct. 2022, 252, 113531. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Da Liang, S.; Xiao, S.-H.; Zeng, J.-J.; Sun, Y. Behavior of FRP-Confined Sea-Sand Concrete Columns with a Prefabricated Concrete-Filled FRP-Steel Core. Compos. Part C Open Access 2020, 2, 100042. [Google Scholar] [CrossRef]

- Yang, Z.-M.; Chen, J.; Wang, J.; Zeng, C.-Q. Axial Compressive Behavior of FRP-Confined Square CFST Columns Reinforced with Internal Latticed Steel Angles for Marine Structures. Eng. Struct. 2024, 319, 118847. [Google Scholar] [CrossRef]

- Cao, Q.; Lv, X.; Li, X.; Zhou, C.; Song, S. High Strength Expansive Concrete-Encased-Steel Filled Carbon Fiber Reinforced Polymer Tubes under Axial Monotonic and Cyclic Load. J. Compos. Mater. 2020, 54, 4557–4573. [Google Scholar] [CrossRef]

- Ms, R. Axial-Flexural Interaction of Square FRP Tube Columns In-Filled with Ultra—High Performance Concrete. Polym. Sci. 2017, 3, 1–12. [Google Scholar] [CrossRef]

- Huang, L.; Gao, C.; Yan, L.; Yu, T.; Kasal, B. Experimental and Numerical Studies of CFRP Tube and Steel Spiral Dual-Confined Concrete Composite Columns under Axial Impact Loading. Compos. Part B Eng. 2018, 152, 193–208. [Google Scholar] [CrossRef]

- Abdallah, M.; Hajiloo, H.; Braimah, A. Circular Concrete Columns Confined with GFRP Tubes under Repeated and Sequential Impact Loads. Eng. Struct. 2023, 280, 115725. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.; Chen, J.; GangaRao, H.; Liang, R.; Liu, W. Responses of Concrete-Filled FRP Tubular and Concrete-Filled FRP-Steel Double Skin Tubular Columns under Horizontal Impact. Thin-Walled Struct. 2020, 155, 106941. [Google Scholar] [CrossRef]

- Lanning, A.; Hain, A.; Zaghi, A.E.; Saiid Saiidi, M. Experimental Study on Hybrid Concrete-Filled Fiber Reinforced Polymer Tube (HCFFTs) Columns under Simulated Seismic Loading. Eng. Struct. 2022, 264, 114478. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Mathys, Z.; Gibson, A.G. Heat Release of Polymer Composites in Fire. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1040–1054. [Google Scholar] [CrossRef]

- Khalaf, S.; Abed, F.; El Refai, A.; Roshan, N.; Hajiloo, H. Circular RC Columns Wrapped with PBO-FRCM and CFRP Strengthening Systems in a Standard Fire. Fire Saf. J. 2025, 155, 104424. [Google Scholar] [CrossRef]

- Ji, G.; Li, G.; Li, X.; Pang, S.-S.; Jones, R. Experimental Study of FRP Tube Encased Concrete Cylinders Exposed to Fire. Compos. Struct. 2008, 85, 149–154. [Google Scholar] [CrossRef]

- Hassan, G.B.; Al-Kamaki, Y.S.S.; Mohammed, A.A.; AlSaad, A. Long-Term Exposure of RC Columns Immersed in Seawater or Crude Oil Confined with CFRP Fabrics under Monotonic or Cyclic Loading. Case Stud. Constr. Mater. 2023, 18, e01747. [Google Scholar] [CrossRef]

- Abadel, A.A.; Masmoudi, R.; Iqbal Khan, M. Axial Behavior of Square and Circular Concrete Columns Confined with CFRP Sheets under Elevated Temperatures: Comparison with Welded-Wire Mesh Steel Confinement. Structures 2022, 45, 126–144. [Google Scholar] [CrossRef]

- Dong, J.F.; Xu, Y.; Guan, Z.W.; Wang, Q.Y. Freeze-Thaw Behaviour of Basalt Fibre Reinforced Recycled Aggregate Concrete Filled CFRP Tube Specimens. Eng. Struct. 2022, 273, 115088. [Google Scholar] [CrossRef]

- Gu, Z.; Wei, C.; Wu, C.; Gao, D.; You, P.; Wei, D. Analysis of Eccentrically Loaded FRP Partially Wrapped Reinforced Concrete Columns Subjected to Combined Environmental Erosion. Eng. Struct. 2023, 280, 115720. [Google Scholar] [CrossRef]

- He, K.; Lin, Q.; Chen, Y.; Guo, Z. Compressive Behavior of Concrete-Filled GFRP Tubular Stub Columns after Being Subjected to Freeze-Thaw Cycles. Compos. Struct. 2021, 255, 112904. [Google Scholar] [CrossRef]

- Cruz, R.; Correia, L.; Cabral-Fonseca, S.; Sena-Cruz, J. Durability of Bond of EBR CFRP Laminates to Concrete under Real-Time Field Exposure and Laboratory Accelerated Ageing. Constr. Build. Mater. 2023, 377, 131047. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T. Compressive Behavior of Concrete-Filled FRP Tube Columns: Assessment of Critical Column Parameters. Eng. Struct. 2013, 51, 188–199. [Google Scholar] [CrossRef]

- Dai, J.-G.; Bai, Y.-L.; Teng, J.G. Behavior and Modeling of Concrete Confined with FRP Composites of Large Deformability. J. Compos. Constr. 2011, 15, 963–973. [Google Scholar] [CrossRef]

- Fallah Pour, A.; Ozbakkaloglu, T.; Vincent, T. Axial Compressive Behavior of Ultra-High-Strength Steel Fiber-Reinforced Concrete-Filled Fiber Reinforced Polymer (FRP) Tube Columns. Compos. Struct. 2021, 266, 113777. [Google Scholar] [CrossRef]

- Moretti, M.L.; Arvanitopoulos, E. Overlap Length for Confinement of Carbon and Glass FRP-Jacketed Concrete Columns. Compos. Struct. 2018, 195, 14–25. [Google Scholar] [CrossRef]

- Ostrowski, K.; Sikora, O.; Furtak, K. Ultimate Load-Bearing Capacity of Samples Made of Self-Compacting Concrete Placed inside Composite Pipes. Inżynieria I Bud. 2023, LXXIX, 604–607. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Vincent, T. Axial Compressive Behavior of Circular High-Strength Concrete-Filled FRP Tubes. J. Compos. Constr. 2014, 18, 173–178. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J.G. Analysis-Oriented Stress–Strain Models for FRP–Confined Concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef]

- Varma, D.A.; Joseph, L.; Madhavan, M.K.; Jayanarayanan, K.; Pegoretti, A. Strength, Durability and Finite Element Analysis of Hybrid Jute/Basalt Fiber Reinforced Polymer Confined Concrete Column under Axial Compression. Results Eng. 2024, 22, 102281. [Google Scholar] [CrossRef]

- da Silva, V.D.; Santos, J.M.C. Strengthening of Axially Loaded Concrete Cylinders by Surface Composites. Compos. Constr. 2001, 257–262. [Google Scholar]

- Hawileh, R.A.; Abu-Obeidah, A.; Abdalla, J.A.; Al-Tamimi, A. Temperature Effect on the Mechanical Properties of Carbon, Glass and Carbon–Glass FRP Laminates. Constr. Build. Mater. 2015, 75, 342–348. [Google Scholar] [CrossRef]

- Ostrowski, K.A.; Chastre, C.; Furtak, K.; Malazdrewicz, S. Consideration of Critical Parameters for Improving the Efficiency of Concrete Structures Reinforced with FRP. Materials 2022, 15, 2774. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; He, Y.; Huang, G.; Li, J.; Niu, Z.; Gao, B. A Review on Durability of Basalt Fiber Reinforced Concrete. Compos. Sci. Technol. 2022, 225, 109519. [Google Scholar] [CrossRef]

- He, B.; Wang, B.; Wang, Z.; Qi, S.; Tian, G.; Wu, D. Mechanical Properties of Hybrid Composites Reinforced by Carbon Fiber and High-Strength and High-Modulus Polyimide Fiber. Polymer 2020, 204, 122830. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Hoop Strains in FRP-Confined Concrete Columns: Experimental Observations. Mater. Struct. 2015, 48, 2839–2854. [Google Scholar] [CrossRef]

- Liang, M.; Wu, Z.-M.; Ueda, T.; Zheng, J.-J.; Akogbe, R. Experiment and Modeling on Axial Behavior of Carbon Fiber Reinforced Polymer Confined Concrete Cylinders with Different Sizes. J. Reinf. Plast. Compos. 2012, 31, 389–403. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Alsayed, S.H.; Iqbal, R.A. Experimental and Numerical Investigation of Size Effects in FRP-Wrapped Concrete Columns. Constr. Build. Mater. 2012, 29, 56–72. [Google Scholar] [CrossRef]

- Akogbe, R.-K.; Liang, M.; Wu, Z.-M. Size Effect of Axial Compressive Strength of CFRP Confined Concrete Cylinders. Int. J. Concr. Struct. Mater. 2011, 5, 49–55. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H. Size Effect of Concrete Short Columns Confined with Aramid FRP Jackets. J. Compos. Constr. 2011, 15, 535–544. [Google Scholar] [CrossRef]

- Silva, M.A.; Rodrigues, C.C. Size and Relative Stiffness Effects on Compressive Failure of Concrete Columns Wrapped with Glass FRP. J. Mater. Civ. Eng. 2006, 18, 334–342. [Google Scholar] [CrossRef]

- Thériault, M.; Neale, K.W.; Claude, S. Fiber-Reinforced Polymer-Confined Circular Concrete Columns: Investigation of Size and Slenderness Effects. J. Compos. Constr. 2004, 8, 323–331. [Google Scholar] [CrossRef]

- Rousakis, T.C.; Tepfers, R. Experimental Investigation of Concrete Cylinders Confined by Carbon FRP Sheets, under Monotonic and Cyclic Axial Compressive Load; Research Report, Chalmers University of Technology: Gothenburg, Sweden, 2001. [Google Scholar]

- Rousakis, T.; You, C.S.; De Lorenzis, L.; Tamužs, V.; Tepfers, R. Concrete Cylinders Confined by CFRP Sheets Subjected to Cyclic Axial Compressive Load. In Proceedings of the Fibre Reinforced Polymer Reinforcement for Reinforced Concrete Structures, Singapore, 8–10 July 2003; World Scientific Publishing Company: Singapore, 2003; pp. 571–580. [Google Scholar]

- Rousakis, T.; Tepfers, R. High-Strength Concrete Confined by High E-Modulus Carbon FRP Sheets, Subjected to Monotonic and Cyclic Axial Compressive Load. In Proceedings of the International Conference on “Composites in Constructions”, Rende, Italy, 16–19 September 2003; pp. 385–390. [Google Scholar]

- Xiao, Q.G.; Teng, J.G.; Yu, T. Behavior and Modeling of Confined High-Strength Concrete. J. Compos. Constr. 2010, 14, 249–259. [Google Scholar] [CrossRef]

- Choudhury, M.S.I.; Amin, A.F.M.S.; Islam, M.M.; Hasnat, A. Effect of Confining Pressure Distribution on the Dilation Behavior in FRP-Confined Plain Concrete Columns Using Stone, Brick and Recycled Aggregates. Constr. Build. Mater. 2016, 102, 541–551. [Google Scholar] [CrossRef]

- Liao, J.; Yang, K.Y.; Zeng, J.-J.; Quach, W.-M.; Ye, Y.-Y.; Zhang, L. Compressive Behavior of FRP-Confined Ultra-High Performance Concrete (UHPC) in Circular Columns. Eng. Struct. 2021, 249, 113246. [Google Scholar] [CrossRef]

- Li, W.; Li, W.; Lu, Y.; Hu, B.; Zhou, Y.; Wu, H.; Wang, P.; Ke, L.; Yu, J. Axial Compressive Behavior and Failure Mechanism of CFRP Partially Confined Ultra-High Performance Concrete (UHPC). Constr. Build. Mater. 2024, 426, 136104. [Google Scholar] [CrossRef]

- Ostrowski, K. Does the Carbon Fibre Coating Reinforcement Have an Influence on the Bearing Capacity of High-Performance Self-Compacting Fibre-Reinforced Concrete? Materials 2019, 12, 4054. [Google Scholar] [CrossRef]

- Rousakis, T.C.; Karabinis, A.I. Substandard Reinforced Concrete Members Subjected to Compression: FRP Confining Effects. Mater. Struct. 2008, 41, 1595–1611. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-Oriented Stress–Strain Model for FRP-Confined Concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C. Axial Compressive Behavior of FRP-Confined Concrete: Experimental Test Database and a New Design-Oriented Model. Compos. Part B Eng. 2013, 55, 607–634. [Google Scholar] [CrossRef]

- Wu, G.; Lü, Z.T.; Wu, Z.S. Strength and Ductility of Concrete Cylinders Confined with FRP Composites. Constr. Build. Mater. 2006, 20, 134–148. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Wei, Y. General Stress-Strain Model for Steel- and FRP-Confined Concrete. J. Compos. Constr. 2015, 19, 04014069. [Google Scholar] [CrossRef]

- Teng, J.G.; Huang, Y.L.; Lam, L.; Ye, L.P. Theoretical Model for Fiber-Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2007, 11, 201–210. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Hadi, M.N.S. Behaviour of Perforated GFRP Tubes under Axial Compression. Thin-Walled Struct. 2015, 95, 88–100. [Google Scholar] [CrossRef]

- Taheri-Behrooz, F.; Esmaeel, R.A.; Taheri, F. Response of Perforated Composite Tubes Subjected to Axial Compressive Loading. Thin-Walled Struct. 2012, 50, 174–181. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Hadi, M.N.S. Experimental Study on FRP Tube Reinforced Concrete Columns under Different Loading Conditions. J. Compos. Constr. 2016, 20, 04016034. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Wang, W.; Sheikh, M.N. Axial Compressive Behaviour of GFRP Tube Reinforced Concrete Columns. Constr. Build. Mater. 2015, 81, 198–207. [Google Scholar] [CrossRef]

- Jiang, H.; Ren, Y.; Liu, X.; Jin, Q. Enhancing Residual Energy-Absorption of Perforated CFRP Tube by a Critical Transition of Failure Mechanism. Compos. Struct. 2020, 253, 112811. [Google Scholar] [CrossRef]

- Liu, Q.; Liufu, K.; Cui, Z.; Li, J.; Fang, J.; Li, Q. Multiobjective Optimization of Perforated Square CFRP Tubes for Crashworthiness. Thin-Walled Struct. 2020, 149, 106628. [Google Scholar] [CrossRef]

- Ren, Y.; Ran, T.; Nie, L.; Jiang, H. Energy-Absorption Assessments of Perforated CFRP Tube Induced by Inward-Splaying Trigger with Different Trigger Radius. Thin-Walled Struct. 2021, 167, 108236. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, J.; Xu, X.; Wu, Y.; Li, Q. Load Bearing and Failure Characteristics of Perforated Square CFRP Tubes under Axial Crushing. Compos. Struct. 2017, 160, 23–35. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, Y.; Ren, Y. Controllable Energy-Absorption Behaviors of the Perforated CFRP Tube with an Adhesively Bonded CFRP Patch. Thin-Walled Struct. 2022, 181, 110015. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Guo, Y.-C.; Gao, W.-Y.; Chen, W.-P.; Li, L.-J. Stress-Strain Behavior of Concrete in Circular Concrete Columns Partially Wrapped with FRP Strips. Compos. Struct. 2018, 200, 810–828. [Google Scholar] [CrossRef]

- Zeng, J.; Guo, Y.; Li, L.; Chen, W. Behavior and Three-Dimensional Finite Element Modeling of Circular Concrete Columns Partially Wrapped with FRP Strips. Polymers 2018, 10, 253. [Google Scholar] [CrossRef]

- Khorramian, K.; Sadeghian, P. Hybrid System of Longitudinal CFRP Laminates and GFRP Wraps for Strengthening of Existing Circular Concrete Columns. Eng. Struct. 2021, 235, 112028. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Yu, Z.; Han, T.; Yuan, J. Behavior of BFRP Strips Confined PVC Tubes with Internal Fillers under Axial Compressive Load. J. Build. Eng. 2022, 58, 104999. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkaloglu, T. Influence of Fiber Orientation and Specimen End Condition on Axial Compressive Behavior of FRP-Confined Concrete. Constr. Build. Mater. 2013, 47, 814–826. [Google Scholar] [CrossRef]

- Na, L.; Yiyan, L.; Shan, L.; Lan, L. Slenderness Effects on Concrete-Filled Steel Tube Columns Confined with CFRP. J. Constr. Steel Res. 2018, 143, 110–118. [Google Scholar] [CrossRef]

- Kim, H.; Lee, K.H.; Lee, Y.H.; Lee, J. Axial Behavior of Concrete-filled Carbon Fiber-reinforced Polymer Composite Columns. Struct. Des. Tall Spec. Build. 2012, 21, 178–193. [Google Scholar] [CrossRef]

- Au, C.; Buyukozturk, O. Effect of Fiber Orientation and Ply Mix on Fiber Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2005, 9, 397–407. [Google Scholar] [CrossRef]

- Singh, K.K.; Shrivastava, R. Influence of Fiber Orientation on Thermo-Mechanical Response of Symmetric Glass/Epoxy Composite. J. Brazilian Soc. Mech. Sci. Eng. 2023, 45, 288. [Google Scholar] [CrossRef]

- Sadeghian, P.; Rahai, A.R.; Ehsani, M.R. Effect of Fiber Orientation on Nonlinear Behavior of CFRP Composites. J. Reinf. Plast. Compos. 2009, 28, 2261–2272. [Google Scholar] [CrossRef]

- Piekarczyk, J.; Piekarczyk, W.; Blazewicz, S. Compression Strength of Concrete Cylinders Reinforced with Carbon Fiber Laminate. Constr. Build. Mater. 2011, 25, 2365–2369. [Google Scholar] [CrossRef]

- Ellyin, F.; Kujawski, D. Tensile and Fatigue Behaviour of Glassfibre/Epoxy Laminates. Constr. Build. Mater. 1995, 9, 425–430. [Google Scholar] [CrossRef]

- Kulkarni, H.; Beardmore, P. Design Methodology for Automotive Components Using Continuous Fibre-Reinforced Composite Materials. Composites 1980, 11, 225–235. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 3rd ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis: New York, NY, USA, 2007; ISBN 978-0-8493-4205-9. [Google Scholar]

- Tyczynski, P.; Sliwa, R.E.; Ostrowski, R. Analysis of Possibilities for Modification of Drill Bit Geometrical Parameters Used to Drill Holes in Composite Materials of Various Composition. Aircr. Eng. Aerosp. Technol. 2015, 87, 120–130. [Google Scholar] [CrossRef]

- Tan, C.L.; Azmi, A.I.; Muhammad, N. Performance Evaluations of Carbon/Glass Hybrid Polymer Composites. Adv. Mater. Res. 2014, 980, 8–12. [Google Scholar] [CrossRef]

- Pawar, U.S.; Chavan, S.S.; Mohite, D.D. Synthesis of Glass FRP-Natural Fiber Hybrid Composites (NFHC) and Its Mechanical Characterization. Discov. Sustain. 2024, 5, 44. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2024, 16, 2. [Google Scholar] [CrossRef]

- Manimaran, R.; Jayakumar, I.; Mohammad Giyahudeen, R.; Narayanan, L. Mechanical Properties of Fly Ash Composites—A Review. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 887–893. [Google Scholar] [CrossRef]

- Hallonet, A.; Ferrier, E.; Michel, L.; Benmokrane, B. Durability and Tensile Characterization of Wet Lay-up Flax/Epoxy Composites Used for External Strengthening of RC Structures. Constr. Build. Mater. 2019, 205, 679–698. [Google Scholar] [CrossRef]

- Amirkhosravi, M.; Pishvar, M.; Altan, M.C. Improving Laminate Quality in Wet Lay-up/Vacuum Bag Processes by Magnet Assisted Composite Manufacturing (MACM). Compos. Part A Appl. Sci. Manuf. 2017, 98, 227–237. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Ahmad Thirmizir, M.Z.; Zainol Abidin, M.S.; Md Akil, H.; Omar, M.F.; Anjang Ab Rahman, A.; Nosbi, N.; Ab Ghafar, N. A Comparison Process Between Wet Lay-Up, Single Vacuum Bagging and Double Vacuum Bagging Toward Natural Fibre (Palm, Coconut and Kenaf) Reinforced Epoxy Composite Laminates. Fibers Polym. 2023, 24, 2107–2116. [Google Scholar] [CrossRef]

- Santhanakrishnan Balakrishnan, V.; Seidlitz, H. Potential Repair Techniques for Automotive Composites: A Review. Compos. Part B Eng. 2018, 145, 28–38. [Google Scholar] [CrossRef]

- Atas, C.; Akgun, Y.; Dagdelen, O.; Icten, B.M.; Sarikanat, M. An Experimental Investigation on the Low Velocity Impact Response of Composite Plates Repaired by VARIM and Hand Lay-up Processes. Compos. Struct. 2011, 93, 1178–1186. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Seible, F. Fiber Reinforced Composites—Advanced Materials for the Renewal of Civil Infrastructure. Appl. Compos. Mater. 2000, 7, 95–124. [Google Scholar] [CrossRef]

- Belingardi, G.; Cavatorta, M.P.; Salvatore Paolino, D. Repeated Impact Response of Hand Lay-up and Vacuum Infusion Thick Glass Reinforced Laminates. Int. J. Impact Eng. 2008, 35, 609–619. [Google Scholar] [CrossRef]

- Schechter, S.G.K.; Centea, T.; Nutt, S. Effects of Resin Distribution Patterns on Through-Thickness Air Removal in Vacuum-Bag-Only Prepregs. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105723. [Google Scholar] [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A State-of-the-Art Review: Near-Surface Mounted FRP Composites for Reinforced Concrete Structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar] [CrossRef]

- Szczech, D.; Krawczyk, Ł.; Kotynia, R. Flexural Strengthening of RC Beams with NSM CFRP Laminates. MATEC Web Conf. 2020, 323, 01010. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Teng, J.G. Near-Surface Mounted FRP Reinforcement: An Emerging Technique for Strengthening Structures. Compos. Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Di Ludovico, M.; Nigro, E.; Pecce, M.; Manfredi, G. Bond Efficiency of EBR and NSM FRP Systems for Strengthening Concrete Members. J. Compos. Constr. 2011, 15, 757–772. [Google Scholar] [CrossRef]

- Jeevan, N.; Keerthi Gowda, B.S.; Archana, D.P.; Razak, A.; Abbas, M.; Saleel, C.A. Experimental Study on Flexural Strengthening of RC Beams with NSM Technique by Different Orientation of CFRP Laminate. Ain. Shams Eng. J. 2023, 14, 101823. [Google Scholar] [CrossRef]

- Nurbaiah, M.N.; Hanizah, A.H.; Nursafarina, A.; Nur Ashikin, M. Flexural Behaviour of RC Beams Strengthened with Externally Bonded (EB) FRP Sheets or Near Surface Mounted (NSM) FRP Rods Method. In Proceedings of the 2010 International Conference on Science and Social Research (CSSR 2010), Kuala Lumpur, Malaysia, 5–7 December 2010; IEEE: New York, NY, USA; pp. 1232–1237. [Google Scholar]

- Barros, J.A.O.; Fortes, A.S. Flexural Strengthening of Concrete Beams with CFRP Laminates Bonded into Slits. Cem. Concr. Compos. 2005, 27, 471–480. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Dias, S.J.E.; Lima, J.L.T. Efficacy of CFRP-Based Techniques for the Flexural and Shear Strengthening of Concrete Beams. Cem. Concr. Compos. 2007, 29, 203–217. [Google Scholar] [CrossRef]

- Barros, J.; Sena-cruz, J.; Dias, S.; Ferreira, D.; Fortes, A. Near Surface Mounted CFRP-Based Technique for the Strengthening of Concrete Structures. Concrete 2004, 1–13. [Google Scholar]

- Triantafyllou, G.G.; Rousakis, T.C.; Karabinis, A.I. Effect of Patch Repair and Strengthening with EBR and NSM CFRP Laminates for RC Beams with Low, Medium and Heavy Corrosion. Compos. Part B Eng. 2018, 133, 101–111. [Google Scholar] [CrossRef]

- Sarasini, F.; Santulli, C. Vinylester Resins as a Matrix Material in Advanced Fibre-Reinforced Polymer (FRP) Composites. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Elsevier: Sawston, Cambridge, UK, 2013; pp. 69–87. ISBN 9780857094186. [Google Scholar]

- Fiore, V.; Valenza, A. Epoxy Resins as a Matrix Material in Advanced Fiber-Reinforced Polymer (FRP) Composites. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Elsevier: Sawston, Cambridge, UK, 2013; pp. 88–121. ISBN 9780857094186. [Google Scholar]

- Al-Rousan, R.Z.; AL-Tahat, M.F. Consequence of Surface Preparation Techniques on the Bond Behavior between Concrete and CFRP Composites. Constr. Build. Mater. 2019, 212, 362–374. [Google Scholar] [CrossRef]

- Szewczak, A. Influence of Epoxy Glue Modification on the Adhesion of CFRP Tapes to Concrete Surface. Materials 2021, 14, 6339. [Google Scholar] [CrossRef]

- Shin, J.; Lee, K.; Jung, Y.; Park, B.; Yang, S.J.; Kim, T.; Lee, S.B. Mechanical Properties and Epoxy Resin Infiltration Behavior of Carbon-Nanotube-Fiber-Based Single-Fiber Composites. Materials 2021, 14, 106. [Google Scholar] [CrossRef]

- Shakya, N.; Roux, J.A.; Jeswani, A.L. Effect of Resin Viscosity in Fiber Reinforcement Compaction in Resin Injection Pultrusion Process. Appl. Compos. Mater. 2013, 20, 1173–1193. [Google Scholar] [CrossRef]

- Web of Science. Available online: https://www.webofscience.com/wos/ (accessed on 18 April 2025).

| Laminate Type | FRP Layers | Concrete Surface Preparation Procedure | Compressive Strength of Unconfined Concrete (MPa) | Compressive Strength of Strengthened Concrete in Comparison to the Reference (%) | Ultimate Strain/Strain of Unconfined εcu/εco | Reference |

|---|---|---|---|---|---|---|

| CFRP | 1 | After formwork removal, the smooth concrete surface was thoroughly ground and a primer resin was applied [106] | 20.5 | +101.5 | 3.69 | [107] |

| 2 | +179.0 | 5.46 | ||||

| 3 | +207.8 | 5.46 | ||||

| 1 | 49.2 | +60.6 | 2.29 | |||

| 2 | +70.5 | 2.06 | ||||

| 3 | +104.5 | 3.65 | ||||

| 1 | 70.6 | +21.3 | 1.94 | [108] | ||

| 2 | +36.1 | 2.46 | ||||

| 3 | +59.1 | 3.58 | ||||

| 1 | 82.1 | +15.8 | 1.62 | |||

| 2 | +19.5 | 7.82 | ||||

| 3 | +49.0 | 3.04 | ||||

| 2 | CFRP as lost formwork | 36.4 | +66.5 | 6.4 | [86] | |

| 4 | 59.0 | +40.7 | 4.9 | |||

| 6 | 102.5 | +28.6 | 4.3 | |||

| 1 | 70.8 | +51.5 | 3.91 | [109] | ||

| 3 | +167.1 | 7.02 | ||||

| 5 | +149.9 | 7.13 | ||||

| 1 | 111.6 | +23.3 | 2.53 | |||

| 3 | +55.5 | 3.09 | ||||

| 5 | +94.6 | 4.65 | ||||

| 1 | Prior to the application of the primer, the concrete surfaces were dried, cleaned, and leveled | 24.5 1 | +56.1 | 2.4 | [110] | |

| 32.3 2 | +41.2 | 2.5 | ||||

| 36.2 3 | +18.4 | 2.5 | ||||

| 21.3 4 | +98.8 | 2.0 |

| Properties | Polyester Resin | Vinylester Resin | Epoxy Resin |

|---|---|---|---|

| Flexibility | Low | Medium | High |

| Production cost | Low | Medium | High |

| Chemical resistance | High | Very high | The highest |

| Curing process | Fast, high styrene emission | Similarly to polyester resin | Longer, more demanding |

| Main application | Transportation, construction materials | Energy and automotive industry | Industry: aerospace, construction and marine |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikora, O.; Ostrowski, K.A. A Review of External Confinement Methods for Enhancing the Strength of Concrete Columns. Materials 2025, 18, 3222. https://doi.org/10.3390/ma18143222

Sikora O, Ostrowski KA. A Review of External Confinement Methods for Enhancing the Strength of Concrete Columns. Materials. 2025; 18(14):3222. https://doi.org/10.3390/ma18143222

Chicago/Turabian StyleSikora, Oliwia, and Krzysztof Adam Ostrowski. 2025. "A Review of External Confinement Methods for Enhancing the Strength of Concrete Columns" Materials 18, no. 14: 3222. https://doi.org/10.3390/ma18143222

APA StyleSikora, O., & Ostrowski, K. A. (2025). A Review of External Confinement Methods for Enhancing the Strength of Concrete Columns. Materials, 18(14), 3222. https://doi.org/10.3390/ma18143222