Influence of a Biofiller, Polylactide, on the General Characteristics of Epoxy-Based Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

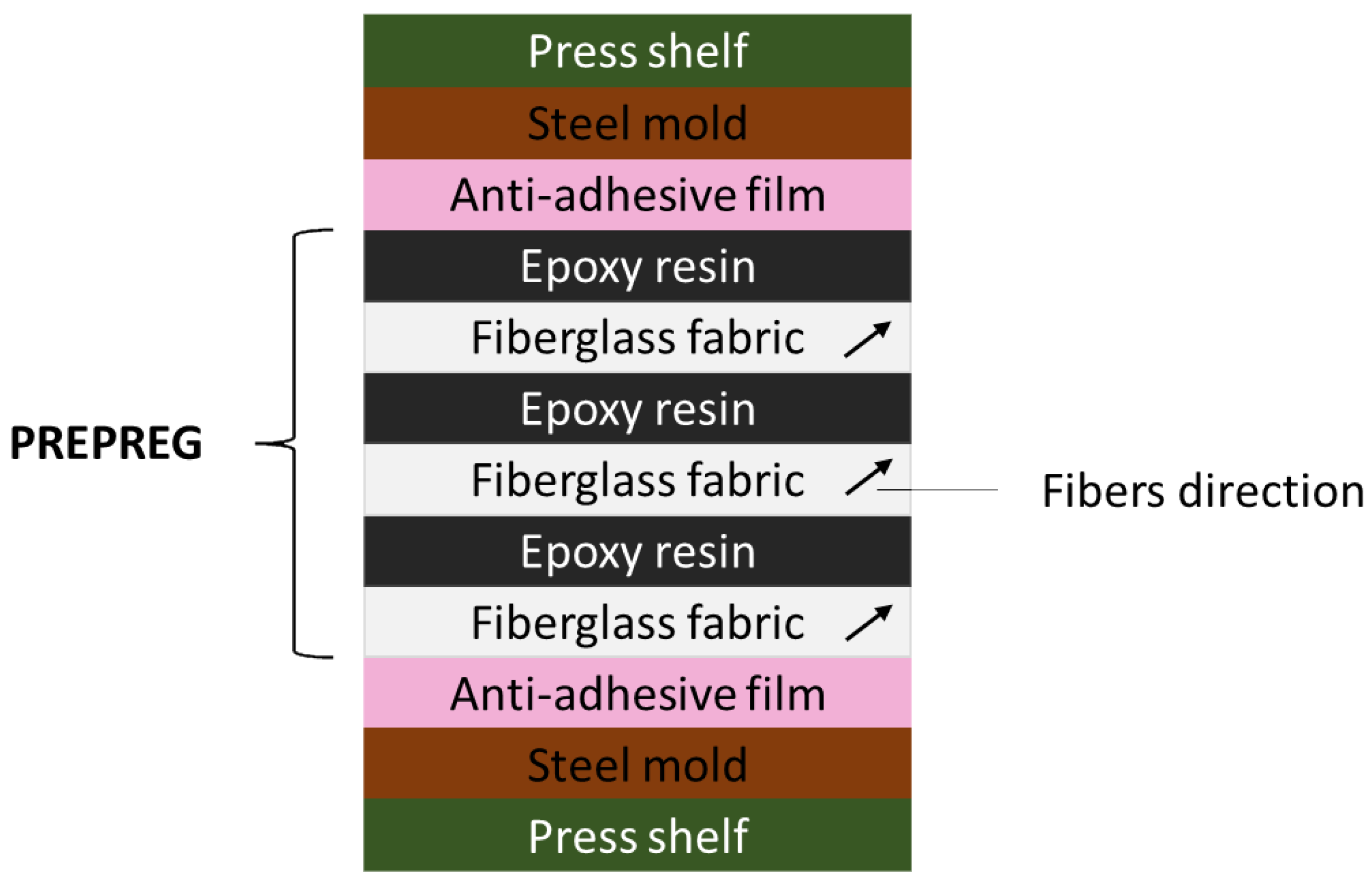

2.2. Manufacturing of Composites

2.3. Accelerated Aging Tests

2.4. Contact Angle Determination and Surface Energy Calculation

2.5. FTIR Spectroscopy

2.6. Color Change Analysis

2.7. Hardness Tests

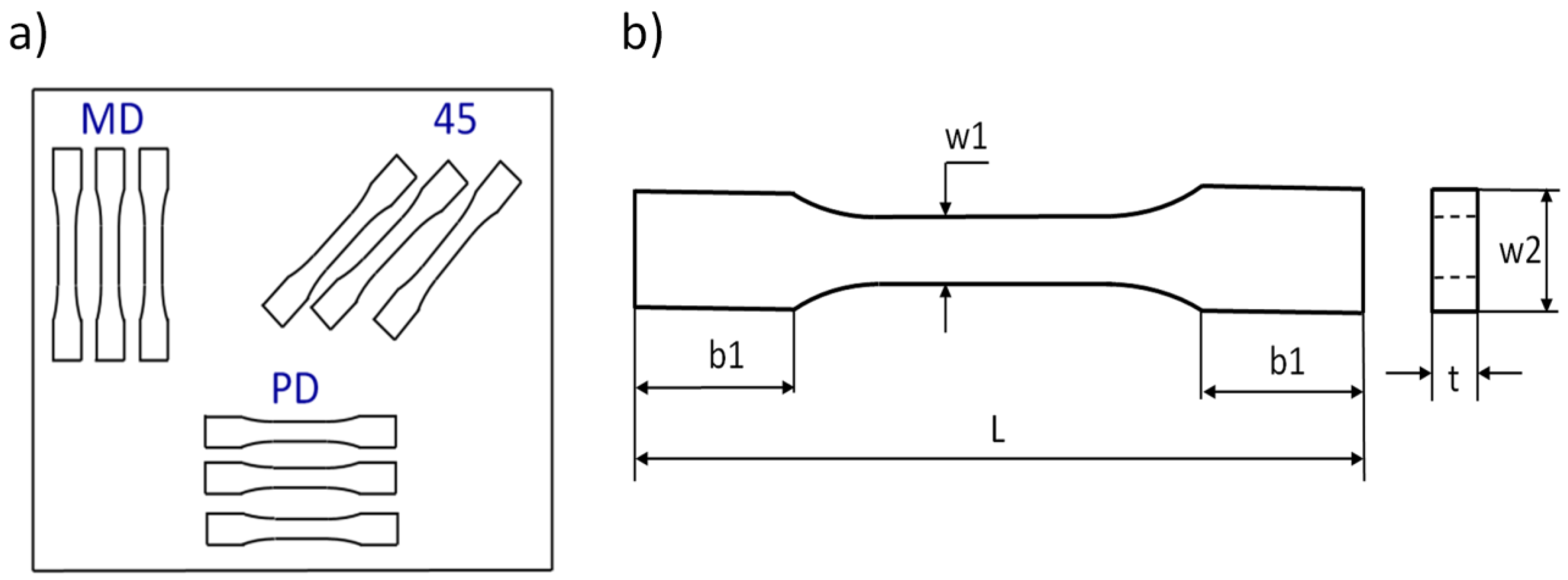

2.8. Tensile One-Directional Test

3. Results and Discussion

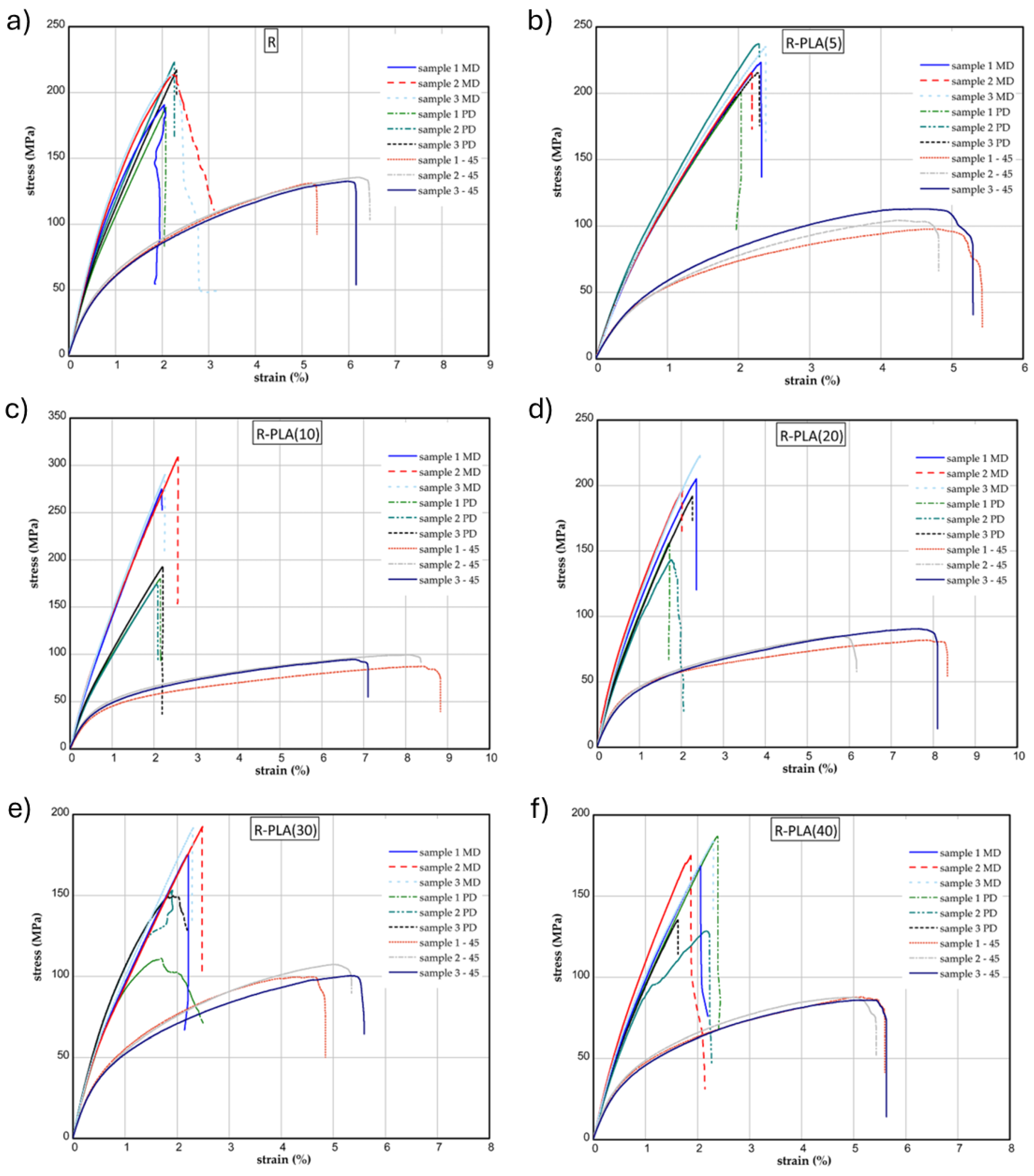

3.1. One-Directional Tensile Test before Aging

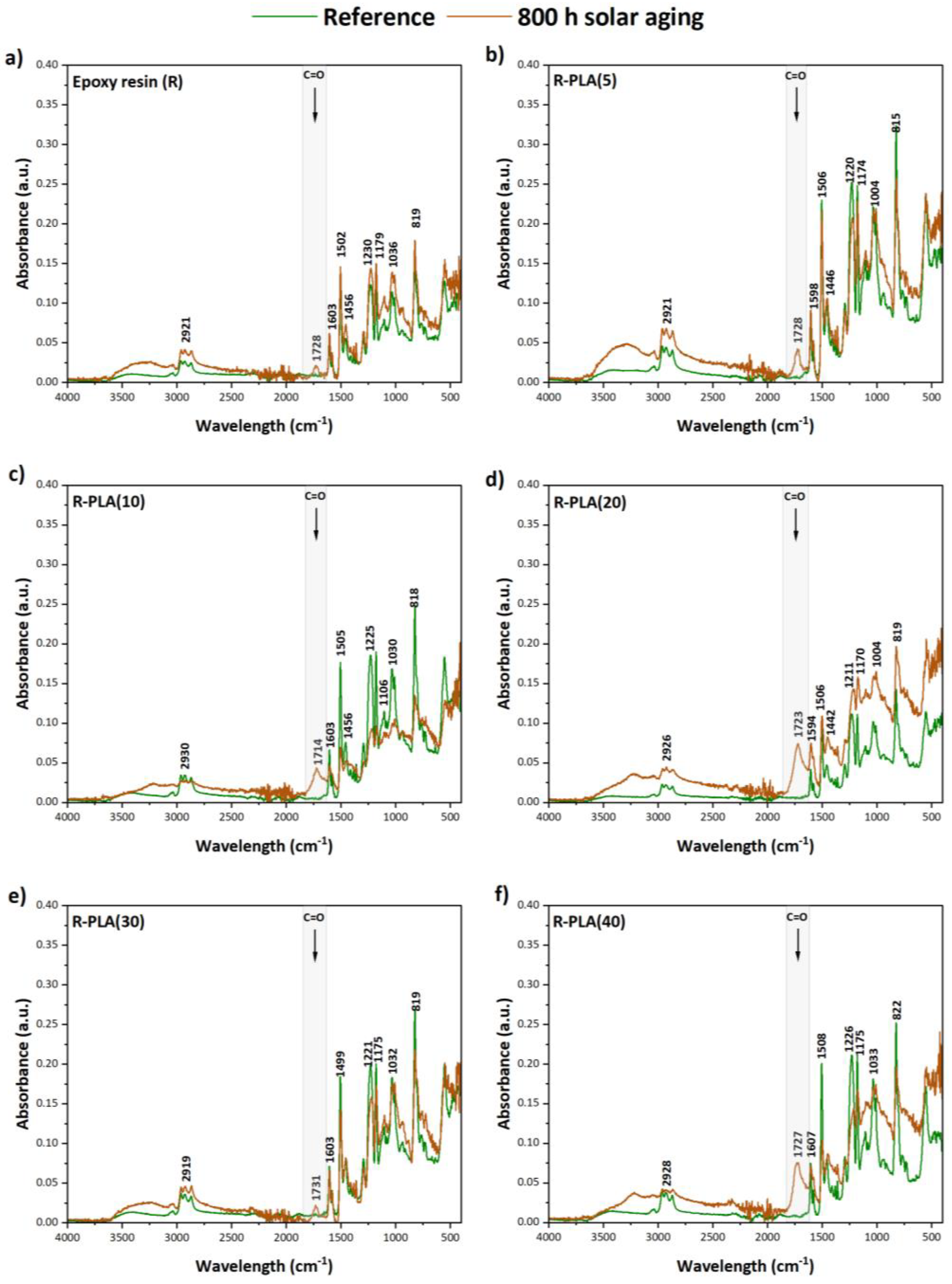

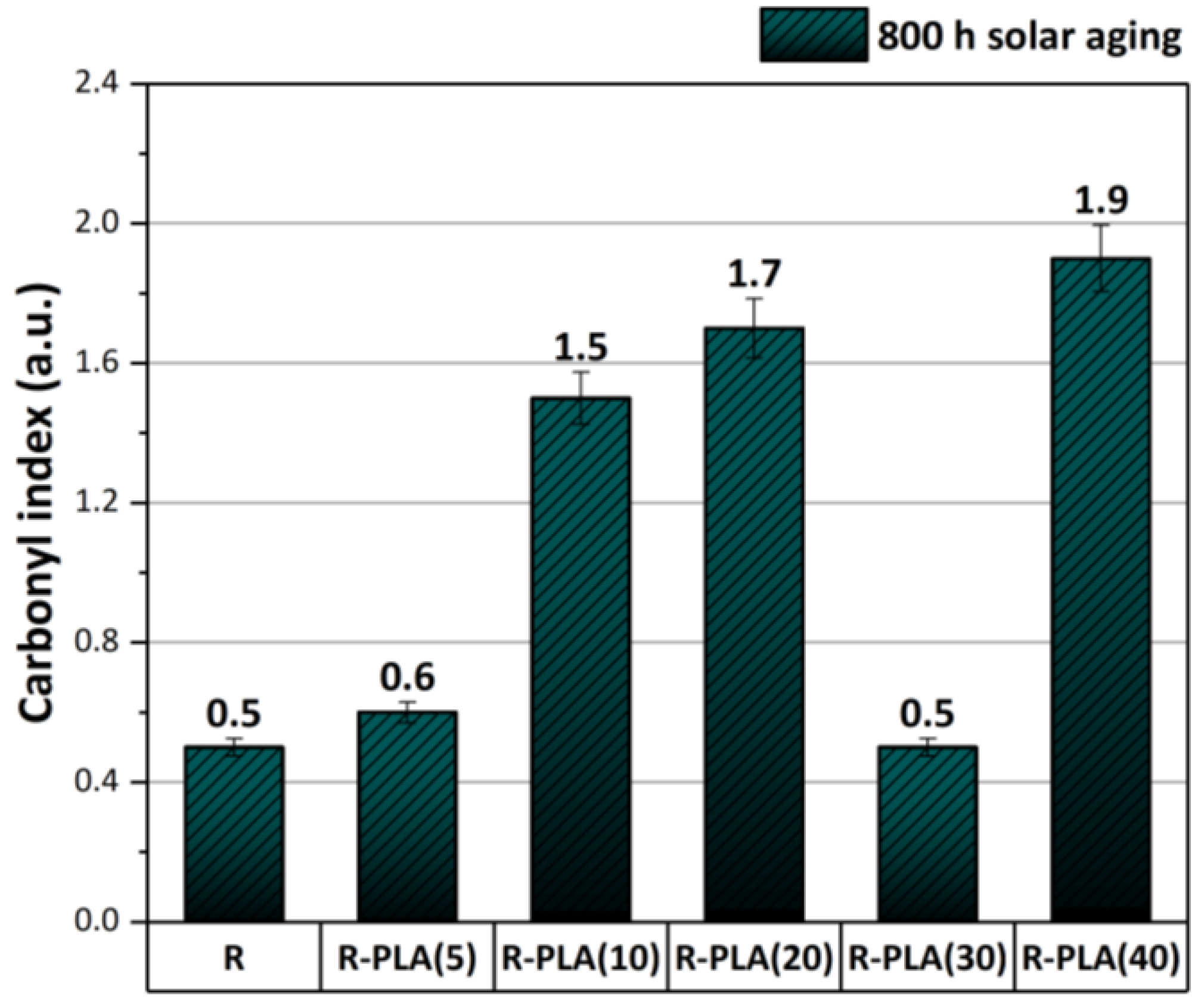

3.2. FTIR Spectroscopy

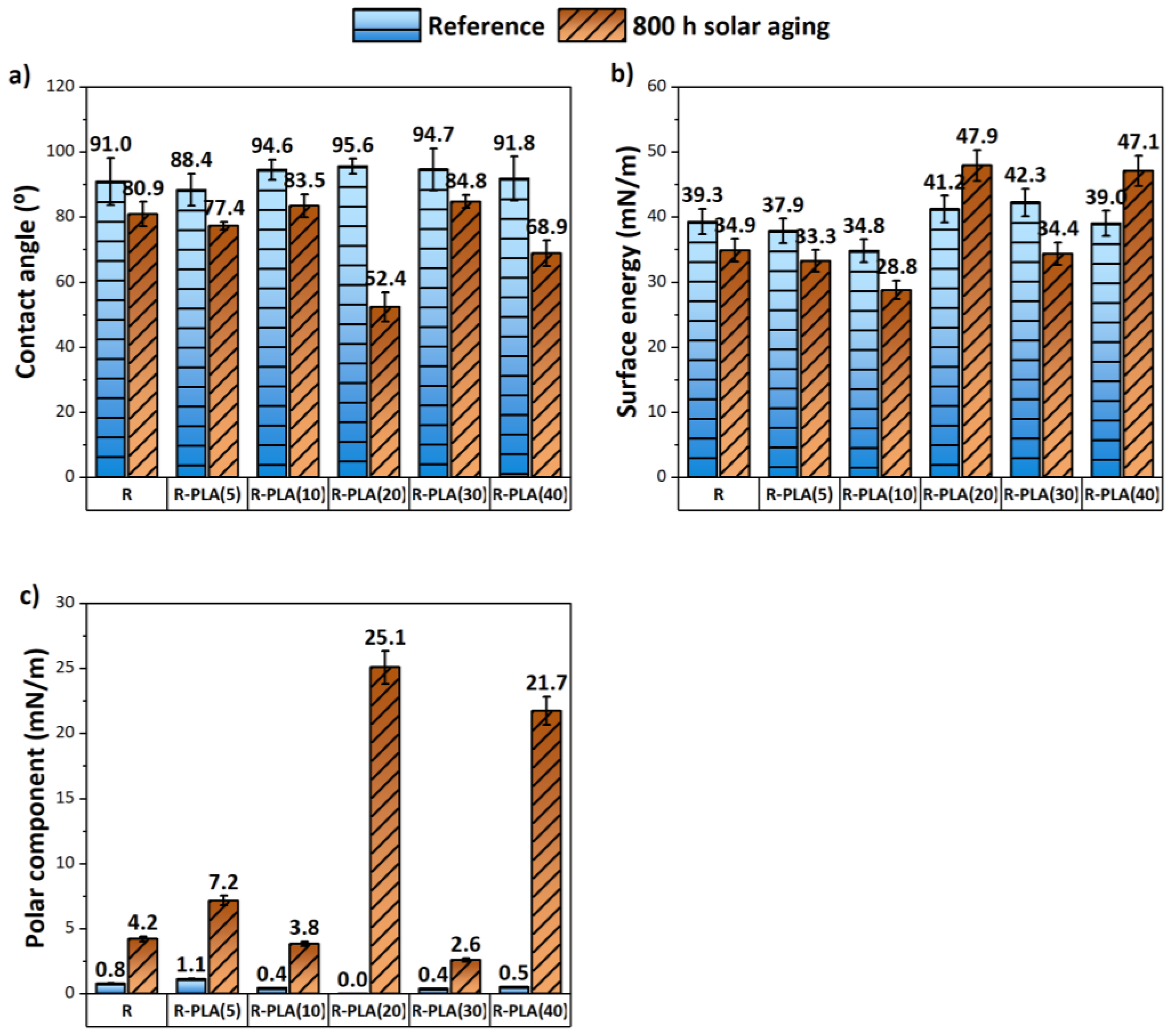

3.3. Contact Angle Determination and Surface Energy Calculation

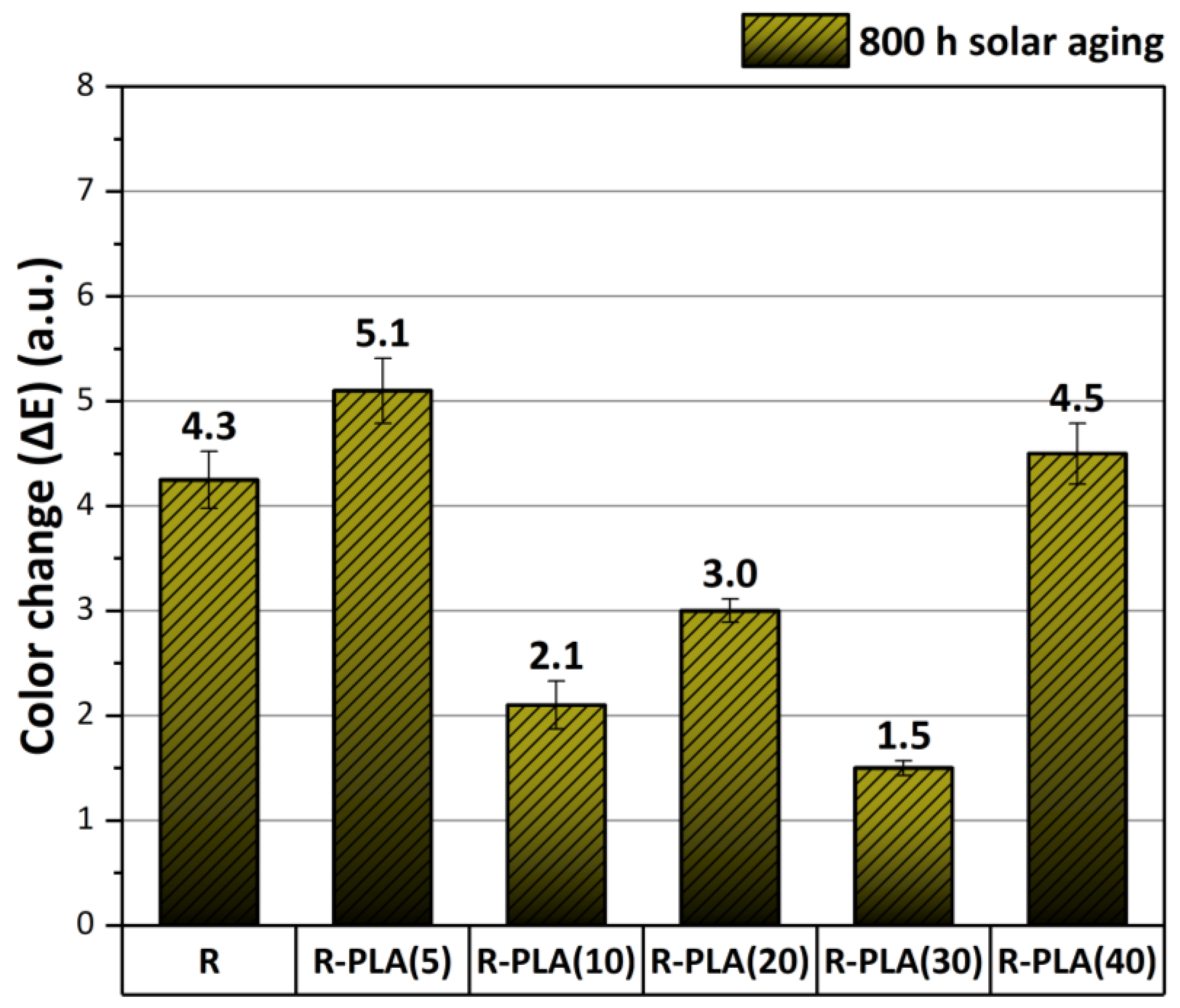

3.4. Color Change Analysis

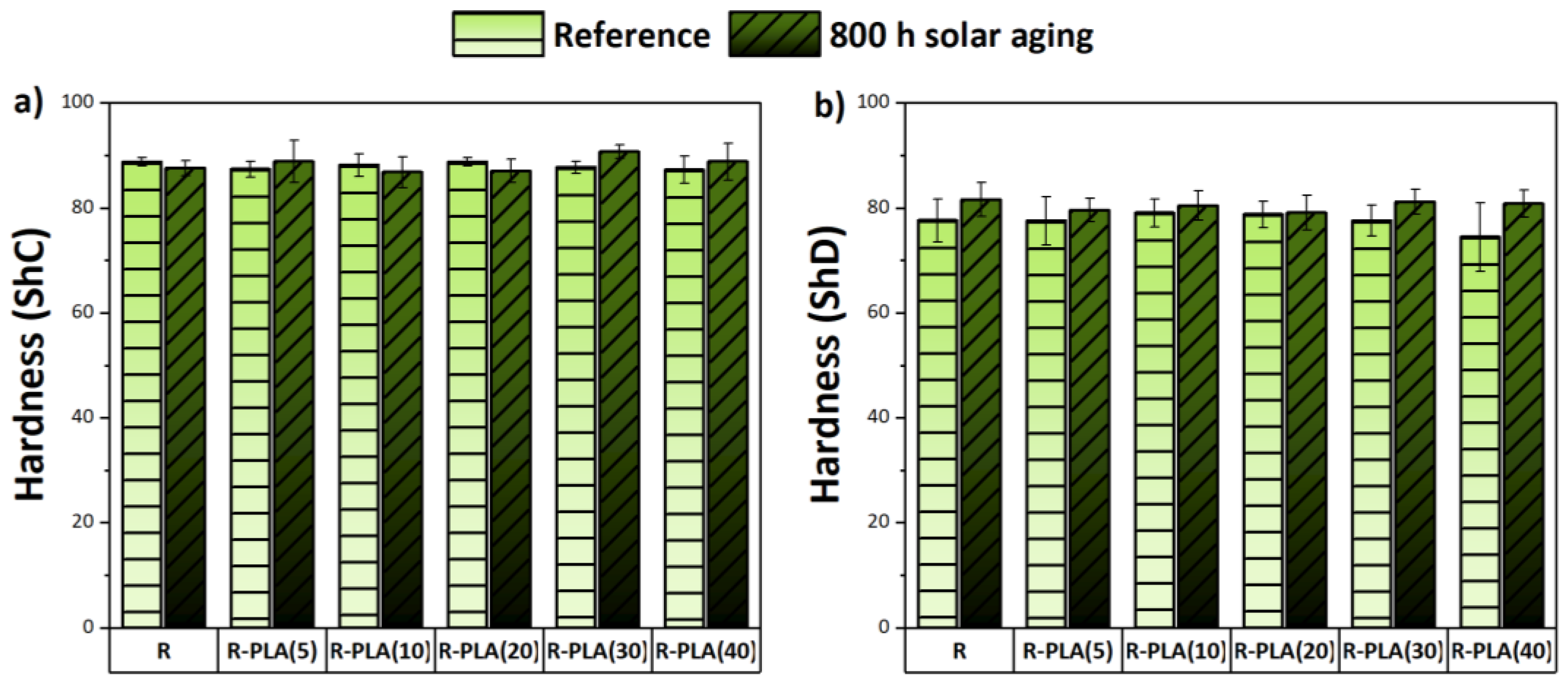

3.5. Hardness Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vieyra, H.; Molina-Romero, J.M.; de Calderón-Nájera, J.D.; Santana-Díaz, A. Engineering, Recyclable, and Biodegradable Plastics in the Automotive Industry: A Review. Polymers 2022, 14, 3412. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Liu, X.; Fan, L.; Jiang, Y.; Cao, L.; Tang, Z.; Zhu, J. Synthesis and properties of a bio-based epoxy resin with high epoxy value and low viscosity. ChemSusChem 2014, 7, 555–562. [Google Scholar] [CrossRef] [PubMed]

- Busiak, R.; Masek, A.; Węgier, A.; Rylski, A. Accelerated Aging of Epoxy Biocomposites Filled with Cellulose. Materials 2022, 15, 3256. [Google Scholar] [CrossRef] [PubMed]

- Selvam, V.; Kumar, M.S.C.; Vadivel, M. Mechanical properties of epoxy/chitosan biocomposites. Int. J. Chem. Sci. 2013, 11, 1103–1109. [Google Scholar]

- Atmakuri, A.; Palevicius, A.; Siddabathula, M.; Vilkauskas, A.; Janusas, G. Analysis of mechanical and wettability properties of natural fiber-reinforced epoxy hybrid composites. Polymers 2020, 12, 2827. [Google Scholar] [CrossRef] [PubMed]

- European Industry: Socio-Economic Value of Epoxy Resins. Available online: https://epoxy-europe.eu/ (accessed on 24 October 2023).

- Borah, N.; Karak, N. Green composites of bio-based epoxy and waste tea fiber as environmentally friendly structural materials. J. Macromol. Sci. Part A Pure Appl. Chem. 2023, 60, 217–229. [Google Scholar] [CrossRef]

- Revankar, S.; Banapurmath, N.R.; Sajjan, A.M.; Nimbagal, V.; Patil, A.Y.; Venkatesh, R.; Umarfarooq, M.A.; Vadlamudi, C.; Krishnappa, S. Epoxy-poly lactic acid blended composites reinforced with carbon fibres for engineering applications. Mater. Express 2022, 12, 1502–1511. [Google Scholar] [CrossRef]

- Shibata, M.; Nakai, K. Preparation and Properties of Biocomposites Composed of Bio-Based Epoxy Resin, Tannic Acid, and Microfibrillated Cellulose. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 425–433. [Google Scholar] [CrossRef]

- Nguyen, T.A. Biocomposites Developed with Litchi Peel Based on Epoxy Resin: Mechanical Properties and Flame Retardant. J. Chem. 2021, 2021, 3287733. [Google Scholar] [CrossRef]

- Srivastava, A.; Srivastava, A.K.; Singh, A.; Singh, P.; Verma, S.; Vats, M.; Sagadevan, S. Biopolymers as renewable polymeric materials for sustainable development—An overview. Polimery/Polymers 2022, 67, 185–196. [Google Scholar] [CrossRef]

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in applications and prospects of bioplastics and biopolymers: A review. Environ. Chem. Lett. 2022, 20, 379–395. [Google Scholar] [CrossRef] [PubMed]

- Amenorfe, L.P.; Agorku, E.S.; Sarpong, F.; Voegborlo, R.B. Innovative exploration of additive incorporated biopolymer-based composites. Sci. Afr. 2022, 17, e01359. [Google Scholar] [CrossRef]

- Perera, K.Y.; Jaiswal, A.K.; Jaiswal, S. Biopolymer-Based Sustainable Food Packaging Materials: Challenges, Solutions, and Applications. Foods 2023, 12, 2422. [Google Scholar] [CrossRef] [PubMed]

- Vijaya Kumar, N.; Banapurmath, N.R.; Ganachari, S.V.; Sajjan, A.M.; Patil, A.Y. Feasibility studies on bio composites using PLA and Epoxy for structural applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1070, 012048. [Google Scholar] [CrossRef]

- Chai, J.; Wang, G.; Li, B.; Wan, G.; Zhang, L.; Zhao, G. Strong and ductile poly (lactic acid) achieved by carbon dioxide treatment at room temperature. J. CO2 Util. 2019, 33, 292–302. [Google Scholar] [CrossRef]

- Jin, F.L.; Hu, R.R.; Park, S.J. Improvement of thermal behaviors of biodegradable poly(lactic acid) polymer: A review. Compos. Part B Eng. 2019, 164, 287–296. [Google Scholar] [CrossRef]

- Kiatiporntipthak, K.; Thajai, N.; Kanthiya, T.; Rachtanapun, P.; Leksawasdi, N.; Phimolsiripol, Y.; Rohindra, D.; Ruksiriwanich, W.; Sommano, S.R.; Jantanasakulwong, K. Reaction mechanism and mechanical property improvement of poly(lactic acid) reactive blending with epoxy resin. Polymers 2021, 13, 2429. [Google Scholar] [CrossRef]

- Wongjaiyen, T.; Brostow, W.; Chonkaew, W. Tensile properties and wear resistance of epoxy nanocomposites reinforced with cellulose nanofibers. Polym. Bull. 2018, 75, 2039–2051. [Google Scholar] [CrossRef]

- Urbaniak, M. Biokompozyty epoksydowe wzmacniane naturalnymi włóknami krótkimi oraz mikrowłóknami z łusek zbożowych. Inż. Mater. 2015, 1, 5–9. [Google Scholar] [CrossRef]

- Szatkowski, P.; Szatkowska, M.; Gralewski, J.; Czechowski, L.; Kedziora, S. Biocomposites with Epoxy Resin Matrix Modified with Ingredients of Natural Origin. Materials 2022, 15, 7167. [Google Scholar] [CrossRef]

- Koyuncu, M. Experimental investigation of epoxy matrix and pine sawdust reinforced wood-polymer composite materials. BioResources 2022, 17, 1161–1172. [Google Scholar] [CrossRef]

- Bisht, N.; Chandra Gope, P. Effect of rice husk (treated/untreated) and rice husk ash on fracture toughness of epoxy bio-composite. J. Mech. Behav. Mater. 2021, 29, 177–185. [Google Scholar] [CrossRef]

- Shah, A.H.; Li, X.; Xu, X.; Dayo, A.Q.; Liu, W.; Bai, J.; Wang, J. Evaluation of mechanical and thermal properties of modified epoxy resin by using acacia catechu particles. Mater. Chem. Phys. 2019, 225, 239–246. [Google Scholar] [CrossRef]

- Salasinska, K.; Barczewski, M.; Górny, R.; Kloziński, A. Evaluation of highly filled epoxy composites modified with walnut shell waste filler. Polym. Bull. 2018, 75, 2511–2528. [Google Scholar] [CrossRef]

- Ji, G.; Zhu, H.; Qi, C.; Zeng, M. Mechanism of Interactions of Eggshell Microparticles With Epoxy Resins. Polym. Eng. Sci. 2009, 49, 1383–1388. [Google Scholar] [CrossRef]

- Khan, F.M.; Shah, A.H.; Wang, S.; Mehmood, S.; Wang, J.; Liu, W.; Xu, X. A Comprehensive Review on Epoxy Biocomposites Based on Natural Fibers and Bio-fillers: Challenges, Recent Developments and Applications. Adv. Fiber Mater. 2022, 4, 683–704. [Google Scholar] [CrossRef]

- PN-EN ISO 105-J01; Tekstylia—Badania Odporności Wybarwień—Część J01: Ogólne Zasady Pomiaru Barwy Powierzchni. Polski Komitet Normalizacyjny: Warsaw, Poland, 2002.

- PN-EN ISO 868; Tworzywa Sztuczne i ebonit—Oznaczanie Twardości Metodą Wciskania z Zastosowaniem Twardościomierza (twardość metodą Shore’a). Polski Komitet Normalizacyjny: Warsaw, Poland, 2005.

- PN-EN ISO 527-1:2020-01; Tworzywa Sztuczne—Oznaczanie Właściwości Mechanicznych Przy Statycznym Rozciąganiu—Część 1: Zasady Ogólne. Polski Komitet Normalizacyjny: Warsaw, Poland, 2020.

- Ramírez-Herrera, C.A.; Cruz-Cruz, I.; Jiménez-Cedeño, I.H.; Martínez-Romero, O.; Elías-Zúñiga, A. Influence of the epoxy resin process parameters on the mechanical properties of produced bidirectional [±45°] carbon/epoxy woven composites. Polymers 2021, 13, 1273. [Google Scholar] [CrossRef]

- Heredia-Guerrero, J.A.; Benítez, J.J.; Domínguez, E.; Bayer, I.S.; Cingolani, R.; Athanassiou, A.; Heredia, A. Infrared and Raman spectroscopic features of plant cuticles: A review. Front. Plant Sci. 2014, 5, 1–14. [Google Scholar] [CrossRef]

- Nikafshar, S.; Zabihi, O.; Hamidi, S.; Moradi, Y.; Barzegar, S.; Ahmadi, M.; Naebe, M. A renewable bio-based epoxy resin with improved mechanical performance that can compete with DGEBA. RSC Adv. 2017, 7, 8694–8701. [Google Scholar] [CrossRef]

- González, M.G.; Cabanelas, J.C.; Baselga, J. 13-Applications of FTIR on Epoxy Resins—Identification, Monitoring the Curing Process, Phase Separation and Water Uptake. In Infrared Spectroscopy—Materials Science, Engineering and Technology; Theophanides, T., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 261–284. ISBN 978-953-51-0537-4. [Google Scholar]

- Yin, Q.; Yang, W.; Sun, C.; Di, M. Preparation and properties of lignin-epoxy resin composite. BioResources 2012, 7, 5737–5748. [Google Scholar] [CrossRef]

- Bednarczyk, P.; Irska, I.; Gziut, K.; Ossowicz-Rupniewska, P. Synthesis of epoxy methacrylate resin and coatings preparation by cationic and radical photocrosslinking. Molecules 2021, 26, 7663. [Google Scholar] [CrossRef] [PubMed]

| Mixture | Weight Composition [phr] | |

|---|---|---|

| Epoxy Resin (ASSET 1011) | Polylactide (PLA RXP 7501) | |

| 1 | 100 | - |

| 2 | 100 | 5 |

| 3 | 100 | 10 |

| 4 | 100 | 20 |

| 5 | 100 | 30 |

| 6 | 100 | 40 |

| Sample | Young’s Modulus [GPa] | Maximum Stress [MPa] | ||||

|---|---|---|---|---|---|---|

| MD | PD | 45 | MD | PD | 45 | |

| R | 16.11 ± 0.40 | 14.38 ± 0.74 | 9.74 ± 0.38 | 205.8 ± 13.2 | 209.6 ± 18.4 | 133.1 ± 2.2 |

| R-PLA(5) | 15.64 ± 0.45 | 14.98 ± 0.15 | 8.77 ± 0.31 | 218.0 ± 18.2 | 224.6 ± 9.9 | 105.0 ± 7.6 |

| R-PLA(10) | 17.25 ± 0.51 | 13.63 ± 0.59 | 8.64 ± 0.40 | 291.3 ± 16.9 | 182.2 ± 9.4 | 93.9 ± 6.2 |

| R-PLA(20) | 15.25 ± 1.63 | 12.82 ± 0.92 | 7.58 ± 0.50 | 208.3 ± 13.3 | 163.9 ± 25.1 | 85.7 ± 4.4 |

| R-PLA(30) | 13.35 ± 0.30 | 13.82 ± 0.64 | 8.93 ± 0.11 | 186.6 ± 9.5 | 138.0 ± 23.4 | 102.4 ± 4.2 |

| R-PLA(40) | 12.96 ± 0.65 | 12.20 ± 0.54 | 7.76 ± 0.23 | 176.0 ± 7.7 | 150.1 ± 32.0 | 87.1 ± 1.1 |

| Sample | Before Aging | After Solar Aging | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| R | 37.3 | −0.2 | 1.4 | 33.5 | 0.2 | 2.6 |

| R-PLA(5) | 38.9 | −0.3 | 1.5 | 37.2 | 0.5 | 4.9 |

| R-PLA(10) | 35.4 | −0.1 | 0.9 | 34.9 | 0.0 | 2.6 |

| R-PLA(20) | 36.2 | −0.4 | 1.1 | 36.6 | 0.4 | 3.8 |

| R-PLA(30) | 37.3 | −0.3 | 1.4 | 37.0 | 0.1 | 2.4 |

| R-PLA(40) | 38.5 | −0.5 | 1.4 | 39.1 | 0.4 | 4.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plota-Pietrzak, A.; Czechowski, L.; Masek, A. Influence of a Biofiller, Polylactide, on the General Characteristics of Epoxy-Based Materials. Materials 2024, 17, 1069. https://doi.org/10.3390/ma17051069

Plota-Pietrzak A, Czechowski L, Masek A. Influence of a Biofiller, Polylactide, on the General Characteristics of Epoxy-Based Materials. Materials. 2024; 17(5):1069. https://doi.org/10.3390/ma17051069

Chicago/Turabian StylePlota-Pietrzak, Angelika, Leszek Czechowski, and Anna Masek. 2024. "Influence of a Biofiller, Polylactide, on the General Characteristics of Epoxy-Based Materials" Materials 17, no. 5: 1069. https://doi.org/10.3390/ma17051069

APA StylePlota-Pietrzak, A., Czechowski, L., & Masek, A. (2024). Influence of a Biofiller, Polylactide, on the General Characteristics of Epoxy-Based Materials. Materials, 17(5), 1069. https://doi.org/10.3390/ma17051069