Abstract

A low-temperature sintering strategy was realized for preparing 0.21Bi(Ni0.5Ti0.5)O3-0.05BiFeO3-0.74Pb(Zr0.5Ti0.5)O3 (0.21BNT-0.05BF-0.74PZT) ceramics by conventional ceramic processing by adding low melting point BiFeO3 and additional sintering aid LiBO2. Pure perovskite 0.21BNT-0.05BF-0.74PZT ceramics are prepared at relatively low sintering temperatures, and their structure presents tetragonal distortion that is affected slightly by the sintering temperature. The 1030 °C sintered samples have high densification accompanied by relatively large grains. All ceramics have excellent dielectric performance with a relatively high temperature of dielectric constant maximum, and present an apparent relaxation characteristic. A narrow sintering temperature range exists in the 0.21BNT-0.05BF-0.74PZT system, and the 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics exhibit overall excellent electrical performance. The high-temperature conductivity can be attributed to the oxygen vacancies’ conduction produced by the evaporation of Pb and Bi during sintering revealed by energy dispersive X-ray measurement.

1. Introduction

Due to the rapid development of science and technology, high-Curie-temperature (TC) piezoelectric materials are required urgently because of the severe and harsh operation conditions in the application fields such as metallurgy, petroleum exploration, aeronautics and astronautics, and so on [1]. As piezoelectric ceramics are used extensively world-wide, Pb(Zr1−xTix)O3-based (PZT) ceramics cannot meet such strict application requirements since the commercially used PZT5H ceramics have just a typical TC of 193 °C [2]. The TC temperature is rather low for application in such circumstances since piezoelectric materials are faced with an obsession of depolarization and the safe working temperature is normally far less than their TC temperature [3,4]. Therefore, developing high-TC piezoelectric materials with a large energy density to replace the PZT-based piezoceramics has become an increasingly researched hotspot in recent years [5].

As well as consideration of the operating temperature, designing the composition is very important since electrical performance is determined mainly by the composition of the piezoelectric materials. Discovering the morphotropic phase boundary (MPB) is still an important strategy to develop novel piezoelectric materials since PZT exhibits enhanced electrical performance with composition approaching the MPB [6], which is also applicable to other ferroelectric systems [7]. The improved phase structure and physical properties are normally correlated with the coexistence of multiferroelectric phases, and further study has discovered intermediate bridge ferroelectric phases with lower symmetry [8,9].

Among versatile ferroelectrics, a LiNbO3 single crystal has a high TC of 1210 °C, but its piezoelectricity is too poor and crystal growth is complex and expensive. BiScO3 ceramics have a high production cost, and a Bi(Ni1/2Ti1/2)O3-based system has a difficult preparation process as discussed in our previous research [10]. The combination of Bi and (Ni1/2Ti1/2) induces our interest. Bi(Me)O3, where Me can be a single trivalent ion such as In, Yb, Sc, etc., can also be our considered complex ions combination such as Ni1/3Nb2/3, Zn1/2Ti1/2, Mg1/2Zr1/2, etc., and its complex perovskite solid solution with PbTiO3 was reported by Eitiel et al. [11]. Such a result promoted the research of similar systems, and MPB composition and excellent piezoelectricity in binary Bi(Ni1/2Zr1/2)O3-PbTiO3 and Bi(Ni0.5Ti0.5)O3-PbTiO3 were reported thereafter [12,13]. Then, ternary system BiScO3-Bi(Ni1/2Zr1/2)O3-PbTiO3 was reported by Zhao et al., which presents a rather large piezoelectric constant d33 of 480 pC/N and a high TC of 439 °C [14].

Based on these research studies, a pseudo-ternary system was constructed in this work, where Bi(Ni0.5Ti0.5)O3 (BNT) was selected as one end component, which has a perovskite structure with a B-site occupied by equivalent Ni2+ and Ti4+ ions [15], and Pb(Zr0.5Ti0.5)O3 was selected as another end component, which can stabilize the perovskite structure more effectively than PbTiO3. Ji et al. devised a pseudo-binary system xBi(Ni1/2Ti1/2)O3-(1−x)Pb(Zr1/2Ti1/2)O3 (xBNT-(1−x)PZT), in which preparation feasibility and MPB-dependent electrical properties were studied, and the 0.25BNT-0.75PZT ceramics presented excellent performance with d33 = 510 pC/N and TC = 227 °C [16], consistent with the design of this composition. The third end component selected was BiFeO3 (BF), substituting out BiScO3 due to the consideration of raw material cost. Furthermore, BF presents multiferroic performance with a high TC of 810 °C, which has large theoretical saturation polarization but cannot normally be acquired due to preparation difficulty and large leakage conductivity [17]. Although pure BF ceramics were hard to prepare, BF could facilitate ceramics preparation, promote grain growth and increase densification process due to its low melting point of 930 °C, and it had many application instances [18,19]. A similar sintering aid characteristic is used to facilitate the preparation of Bi(Ni0.5Ti0.5)O3-BiFeO3-Pb(Zr0.5Ti0.5)O3 (BNT-BF-PZT) ceramics in this work.

In materials science, composition, structure, performance and application have complicated mutual interactions [20], among which composition designing and ceramics processing are very important influencing factors. In this work, 0.21Bi(Ni0.5Ti0.5)O3-0.05BiFeO3-0.74Pb(Zr0.5Ti0.5)O3 (0.21BNT-0.05BF-0.74PZT) was chosen due to the comprehensive consideration of its performance and preparation feasibility based on the analysis of the reported ternary phase diagram and preliminary experimental study [13,16,21]. Among ceramics processing, sintering conditions are the most important factors since the phase structure, point defects, grain size, density, etc., are affected greatly by the sintering temperature and soaking time, especially for the difficult to prepare Pb- and Bi-containing ceramics [22]. Therefore, a low-temperature sintering strategy was realized due to the low melting point of BF [19] and PbO accompanied by the adding of an additional sintering aid, LiBO2 [23], and the systematic influences on structure, performance and conduction mechanism were studied in detail.

2. Experimental Procedure

0.21Bi(Ni0.5Ti0.5)O3-0.05BiFeO3-0.74Pb(Zr0.5Ti0.5)O3 (0.21BNT-0.05BF-0.74PZT) ceramics were prepared by conventional ceramic processing via low-temperature sintering technique with additional adding 0.5 wt% LiBO2 as sintering aid. Well-mixed stoichiometrically weighted raw materials of Bi2O3 (>99%), NiO (>99%), TiO2 (>98.5%), Fe2O3 (>99.9%), PbO (>99%) and ZrO2 (>99%) were calcined at 850 °C for 2 h to obtain perovskite structure 0.21BNT-0.05BF-0.74PZT precursor powder. Sintering aid was added into the well-ground precursor powder, then, pelletization with addition of 5 wt% polyvinyl alcohol aqueous solution and formed by cold-pressing at 300 MPa were undertaken. After separate debinding at 550 °C for 30 min, the green discs were sintered between 1010 °C and 1050 °C with 10 °C temperature interval covered by the calcined precursor powder. Detailed preparation procedure can be seen elsewhere for preparing the 0.55Bi(Ni0.5Ti0.5)O3-0.05BiFeO3-0.4PbTiO3 system [21].

Phase structure evolution of the polished 0.21BNT-0.05BF-0.74PZT ceramics was characterized by Rigaku D/max-2500/PC X-ray Diffractometer (XRD, Tokyo, Japan) in continuous scanning mode, where the measurement 2θ range was 10–80°, step interval was 0.02° and scanning speed was 4°/min. Ceramics’ free surface morphology was observed by JEOL JSM-IT100 InTouchScopeTM scanning electron microscope (SEM, Tokyo, Japan) using 800 °C thermal etched 30 min samples. Silver electrode was formed by firing silver paste at 810 °C for 10 min for electrical properties’ measurement. The dielectric performance–temperature relationship and impedance spectra at elevated temperatures were measured by Partulab HDMS-1000 connected with Microtest 6630-10 Precision LCR Meter (Wuhan, China). Piezoelectric constant and electromechanical coupling performance were measured by ZJ-3AN quasi-static d33 tester (Beijing, China) and TH2826 impedance analyzer (Changzhou, China), respectively, using room-temperature poled samples in silicone oil for 1 min [21].

3. Results and Discussion

3.1. Structure and Density Characterization

For the design of the composition in this work, as well as the consideration of MPB based on the phase diagram and preliminary experiment, Goldschmidt’s tolerance factor t is an important technique to check perovskite structural distortion and the stability of the ABO3 complex oxides as shown below [24]:

Using the revised effective ionic radii calculated by Shannon [25], the tolerance factor t can be calculated, where the ionic radii of Pb2+ in 12-CN (coordination number) is 1.49 Å, Ni2+ (6-CN) 0.69 Å, Ti4+ (6-CN) 0.605 Å, Fe3+ (6-CN, high spin state) 0.645 Å, Zr4+ (6-CN) 0.72 Å and O2- (6-CN) 1.4 Å. The dilemma is the ionic radius for Bi3+ just having maximum 8-CN with 1.17 Å. Via linear extrapolation of the ionic radius based on the relationship between the ionic radii and the coordination number, the predicted ionic radius for Bi3+ with 12-CN would be 2.06 Å. Then, the calculated t value range is 0.9643–1.0438 with Bi3+ in 8-CN to 12-CN. As the calculated t value approaches 1, it reveals the perovskite structure stability of the designed 0.21BNT-0.05BF-0.74PZT composition [24].

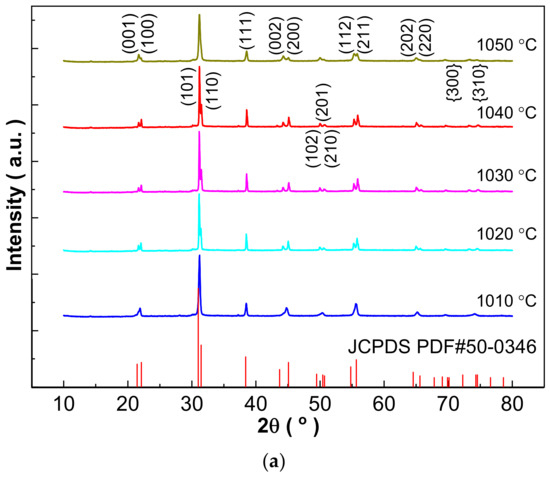

The successful design of the composition is further confirmed by XRD measurement as shown in Figure 1. A pure perovskite phase is obtained for all the 0.21BNT-0.05BF-0.74PZT ceramics sintered at relatively low sintering temperatures, and no impurity is detected within the XRD measurement limitation. In the enlarged XRD patterns shown in Figure 1b, it can be clearly seen that the phase structure evolution is induced by increasing the sintering temperature. Within the 2θ degree range of 42–60°, the {200}, {210} and {211} diffraction reflections show broadened singlet-like peaks for the 1010 °C sintered sample, showing a typical MPB composition characteristic [26]. For the 1020–1050 °C sintered ceramics, apparent splitting appears in the above three diffraction peaks accompanied by the change in diffraction peak intensity of the split peaks. The apparent splitting of the {211} diffraction reflection reveals the existence of rhombohedral distortion [26].

Figure 1.

(a) XRD patterns of low-temperature sintered 0.21BNT-0.05BF-0.74PZT ceramics sintered between 1010 °C and 1050 °C; (b) zoomed XRD patterns with 2θ being 42–60°; (c) Rietveld refinement of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics.

Since the major phase shows tetragonal symmetry, the phase structure of the 0.21BNT-0.05BF-0.74PZT ceramics is refined by the Rietveld method and indexed as a tetragonal phase (referred to JCPDS 50-0346). Figure 1c shows XRD Rietveld refinement using the 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics as an example. Based on this, lattice parameters were calculated and are shown in Table 1 combined with refinement parameters. All ceramics have excellent fitting accuracy since all fitting parameters are less than Rwp ≤ 6.12%, Rp ≤ 4.25%, and χ2 ≤ 5.770, showing high reliability of the Rietveld method. Table 2 shows density data, where theoretical density was calculated based on the XRD calculated cell volume and chemical formula weight, and bulk density was measured by Archimedes’ water immersion method [21]. The low-temperature sintering technique with the addition of LiBO2 is successful in this work since a large density can be obtained. Within the narrow sintering temperature range, the primary cell volume and relative density present a similar change trend, i.e., increasing first and then decreasing with an increasing sintering temperature. The best ceramics are prepared at a rather low sintering temperature of 1030 °C, and their density is 7.802 g/cm3 and relative density reaches 96.56%, satisfying the production and quality requirements of the electronic ceramic industry. The tetragonality factor c/a also exhibits an increasing first and then decreasing variation affected by sintering temperature, showing the change characteristic of tetragonal distortion [27].

Table 1.

Lattice constants with P4mm space group and fitting precision parameters of 0.21BNT-0.05BF-0.74PZT ceramics sintered at different temperatures refined by Rietveld method.

Table 2.

Cell volume, density and resistance of low-temperature sintered 0.21BNT-0.05BF-0.74PZT ceramics at several sintering temperatures.

3.2. SEM Observation

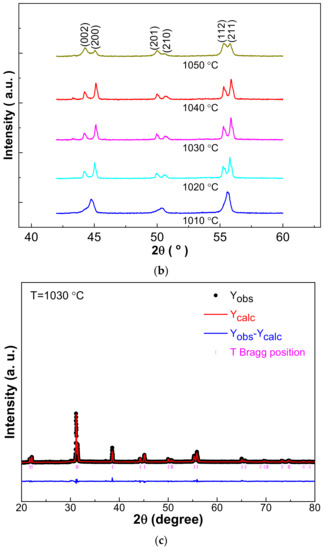

The largest densification of the 0.21BNT-0.05BF-0.74PZT ceramics sintered at 1030 °C is confirmed in Figure 2 by SEM observation accompanied by the corresponding grain size statistics. The free surface shows an obvious grain boundary, with clear grains and almost without visible pores, consistent with the high density. For the low-temperature sintered ceramics, no other characteristic grains appear, further showing the stability of the perovskite structure obtained in this work. Due to the low-temperature sintering technology, the solid-state sintering mechanism has a major effect in the ceramics’ densification process since most grains have a polyhedron shape with a large aspect ratio. The liquid phase sintering mechanism also contributes to the sintering process due to the low melting point of Pb and Bi oxides [18,19], and it produces relatively large grains with an average grain size of 11.74 μm. Due to the utilization of the low-temperature sintering technique, a large grain size appears in the 0.21BNT-0.05BF-0.74PZT ferroelectric ceramics, which can improve the ceramics’ quality and generate an extrinsic contribution to electrical performance [28].

Figure 2.

SEM image (a) and corresponding grain size distribution statistics based on two micrographs (b) of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics.

3.3. Resistance and Dielectric Performance

From Table 2 it can be seen that the resistivity of all of the low-temperature sintered 0.21BNT-0.05BF-0.74PZT ceramics is larger than 1011 Ω·cm, which is beneficial as it increases the dielectric breakdown strength and obtains large piezoelectricity due to increasing the poling electric field [29]. The resistivity versus the sintering temperature relationship also presents the largest value at the 1030 °C sintering temperature, which can be attributed to the largest relative density.

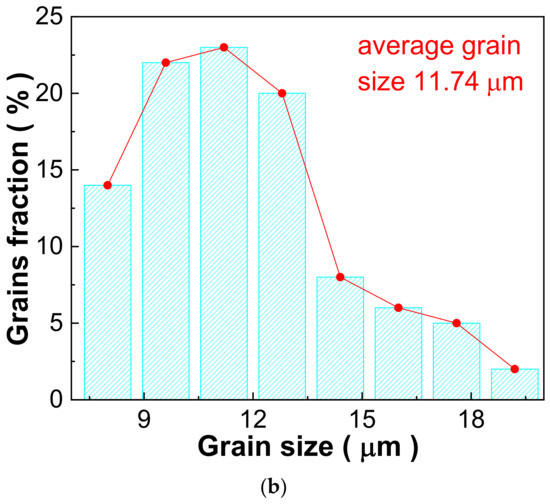

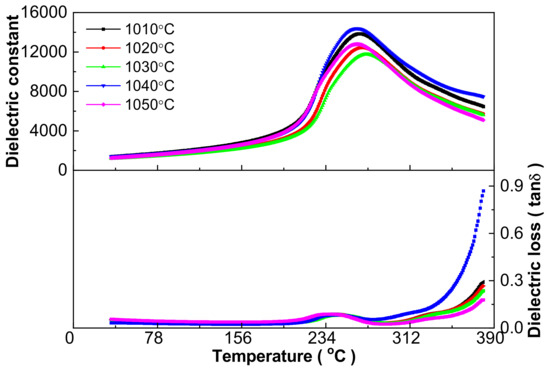

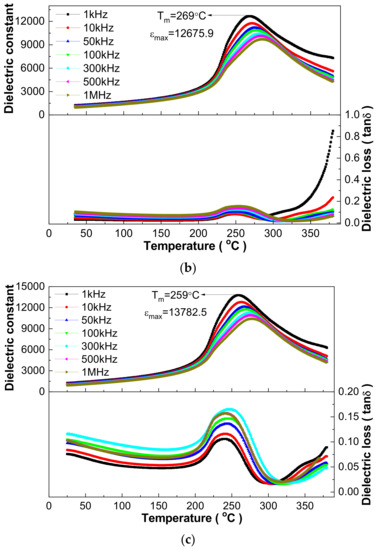

The influence of sintering temperature on the dielectric performance of the 0.21BNT-0.05BF-0.74PZT ceramics is shown in Figure 3. All curves present a similar shape, where broad dielectric constant-temperature curves accompanied by a sole wide dielectric peak can be attributed to the relaxor ferroelectric state to paraelectric phase transition. Important dielectric performance parameters are given in Table 3. With the increase in sintering temperature, the dielectric constant peak temperature (Tm) increases first and reaches a maximum value of 269 °C at the 1030 °C sintering temperature, and then declines with a variation of 10 °C in Tm, whereas the dielectric constant maximum value (εm) decreases first, then increases to a maximum value of 16,085.5 at the 1040 °C sintering temperature, and finally decreases again with a variation of 3409.6. Both maximum values appear at different sintering temperatures, which is also considered to relate to the relaxor ferroelectric characteristic [8].

Figure 3.

Dielectric performance versus temperature relationship at 1 kHz of 0.21BNT-0.05BF-0.74PZT ceramics sintered between 1010 and 1050 °C.

Table 3.

Important dielectric parameters of 0.21BNT-0.05BF-0.74PZT ceramics sintered at several temperatures.

The relaxor behavior is further shown with dielectric performance at different frequencies in Figure 4 using three samples as examples. Actually, all samples have apparent dielectric frequency dispersion, broad dielectric peaks and a diffused phase transition characteristic, i.e., presenting an obvious difference in the Tm and εm values at different frequencies, although detailed values show a difference for the ceramics sintered at different temperatures. Normally, dielectric loss exhibits a more apparent frequency dispersion, and the temperature of the loss tangent (tanδ) extremum value (Tm’) is lower than Tm for relaxor ferroelectrics [8]. The difference in the above two temperatures (Tm and Tm’) can be regarded as a signature of the degree of relaxor behavior. The unusual fast increase in dielectric loss above the Tm’ temperature (Figure 3 and Figure 4) can be attributed to the evaporation of Pb and Bi during sintering, although using the low-temperature sintering technique, which generates point defects, causes thermally activated lossy conduction and leads to an abnormal increase in dielectric loss [30] as shown below [29]:

Figure 4.

Typical dielectric performance–temperature curves measured at several frequencies upon heating of 0.21BNT-0.05BF-0.74PZT ceramics sintered at (a) 1010 °C; (b) 1030 °C and (c) 1050 °C.

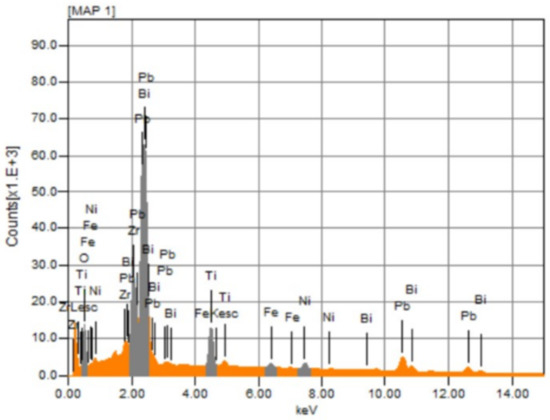

The evaporation of Pb and Bi was detected by energy dispersive X-ray (EDX) measurement as shown in Figure 5, Figures S1 and S2 and Table 4. Since the free surface of ceramics was used for the EDX measurement and the sample was thermally etched at 800 °C for 30 min, the atomic percentage of all metal elements was far less than the designed composition. Such a difference can be used to reveal the evaporation of metal elements, especially for Bi and Pb, during the sintering process. Although the evaporation of some metals during sintering is inevitable, the distribution of metal elements is rather homogeneous as shown in Figure S2, where the grain boundary presents higher sublimation capability due to the amorphous state or disordered arrangement of atoms [19].

Figure 5.

Typical EDX spectrum of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics.

Table 4.

Element type and corresponding atomic percentage of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics measured at different locations.

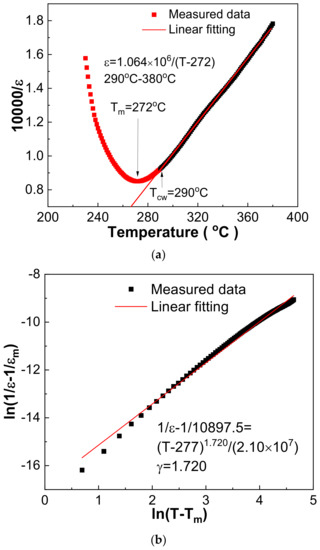

Dielectric response fitting using dielectric data above the Tm temperature provides an effective way to discriminate ferroelectrics’ type. Using the 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics as an example, the fitted Curie–Weiss law is ε = 1.064 × 106/(T − 272) and the fitted exponential law is 1/ε − 1/10897.5 = (T − 277)1.720/(2.10 × 107) (Figure 6) [31,32]. Combined with the data shown in Table 3, the fitted Curie–Weiss constant C of all samples has 105 magnitude order. Moreover, the C value presents a decreasing trend, the Curie–Weiss temperature increases first and then decreases, and the temperature above which the Curie–Weiss law can be obeyed (TCW) shows an increasing trend with increasing sintering temperature, i.e., the temperature difference of TCW-Tm is 11–27 °C for different samples. The fitted diffused coefficient γ increases first and reaches a maximum value of 1.733 for the 1040 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics, and then decreases slightly, revealing the change in the relaxation characteristic degree. All the fitted γ values are larger than 1.69 but less than 2. Based on these results, the 0.21BNT-0.05BF-0.74PZT samples present complicated dielectric response behavior, and can be regarded as displacive driven ferroelectric phase transition superimposed on obvious frequency dispersion [32]. Such a phase transition characteristic is normally related to the generation of polar nano-regions (PNRs) caused by local nano-sized nonuniformity of chemical composition, disordered distribution of cations at the A-site and B-site of the perovskite structure [33], and a randomly distributed strain field and electric field [34].

Figure 6.

Dielectric response fitting of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics using 10 kHz data. (a) Curie–Weiss law; (b) quadratic law.

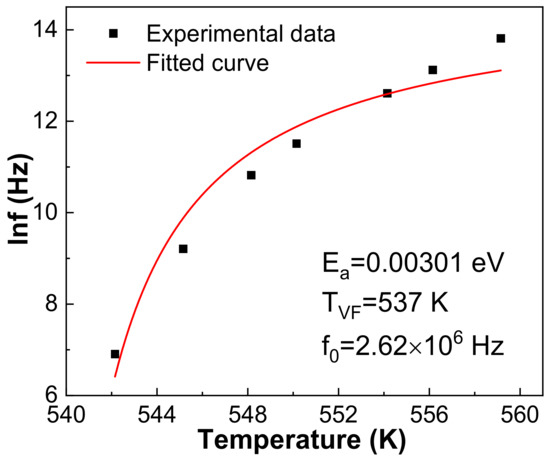

Vogel–Fulcher fitting provides another technique to research relaxation characteristic as shown in Figure 7, also using the 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics as an example. Based on the Vogel–Fulcher formula, f = f0exp[Ea/kB(T − TVF)], the fitting uses 1–1000 kHz data; therefore, the empirical relaxation strength ΔTres = Tm(1000 kHz) − Tm(1 kHz) can be used to describe the frequency dispersion degree [34]. The fitted parameters are f0 = 2.62 × 106 Hz, Ea = 0.00301 eV, TVF = 537 K and ΔTres = 17 K, respectively, presenting the appearance of composition-induced relaxor-like ferroelectrics. The average activation energy Ea = 0.00301 eV is comparable with the thermal excitation energy of kT, reflecting that the dipoles’ polarization orientation relates to the thermal excitation process [34]. The fitted Debye frequency f0 = 2.62 × 106 Hz is comparable to that of the Ba(Zr0.30Ti0.70)O3 ceramics, correlating with the complex microstructure and the generated point defects due to the evaporation of Pb and Bi during sintering [34].

Figure 7.

Vogel–Fulcher fitting of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT sample.

3.4. Piezoelectric Performance

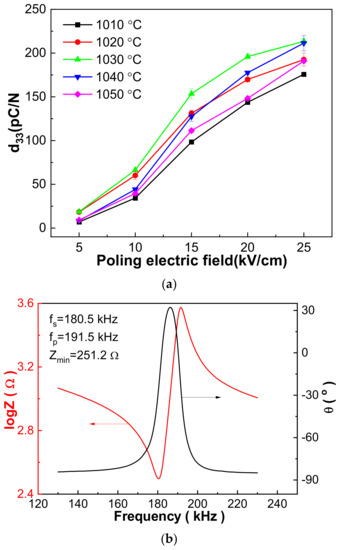

Figure 8 shows the piezoelectric performance of the 0.21BNT-0.05BF-0.74PZT samples. With the increase in the poling electric field, piezoelectric constant d33 increases rapidly, correlating with the easy switching of 180° domains under a high external electric field [5]. With the elevation of the sintering temperature, the d33 value increases first and then decreases. The 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics have the largest d33 value, being 213.4 pC/N, which is rather large considering the high Tm temperature. The 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics present explicit resonant and anti-resonant shape behavior poled at 25 kV/cm, whereas the maximum phase degree θ is just 34°, showing the possibility of increasing the poling electric field but constrained by the leakage current of the samples. Such a low θ value accompanied from the beginning by a rather low minus θ degree, i.e., nearly −90°, is usually observed in the (K1−xNax)NbO3-based lead-free piezoelectric ceramics, and the reason is difficult to explain [35]. Based on the resonant spectra, the mechanical quality factor Qm and electromechanical coupling coefficient Kp were calculated and are shown in Table 5. The 0.21BNT-0.05BF-0.74PZT ceramics exhibit an apparent soft piezoelectric materials characteristic due to the existence of a large quantity of point defects as discussed in defect Equations (1) and (2). Overall, the 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics have excellent electrical properties, where d33 = 213.4 pC/N, Kp = 37.7% and Qm = 27.3.

Figure 8.

(a) Poling electric-field-dependent piezoelectricity d33 of 0.21BNT-0.05BF-0.74PZT samples sintered at different temperatures; (b) impedance and phase degree versus frequency curves of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics poled at 25 kV/cm.

Table 5.

Kp and Qm values of 0.21BNT-0.05BF-0.74PZT ceramics sintered at different temperatures poled under 25 kV/cm.

3.5. Conduction Mechanism

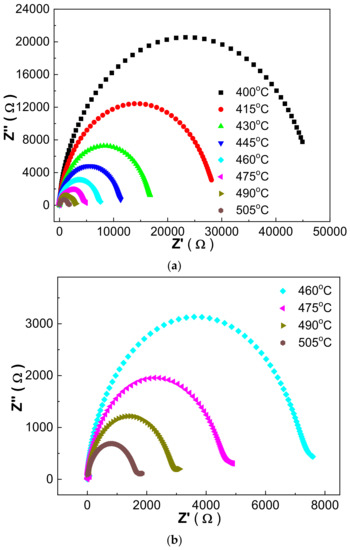

The impedance spectra and conduction mechanism were studied using the 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics as an example. The real part of impedance Z′ tends to decrease sharply before a certain frequency and then becomes stable, and the imaginary part of impedance Z″ normally presents a peak with the increase in frequency. With the increase in measurement temperature, both the Z′ and Z″ impedance values decrease, the Z″ peak frequency moves to a high frequency and the Z′’ peak broadens obviously.

Figure 9 shows Cole–Cole-like Z′-Z″ relationship curves based on the impedance measurement. At lower temperatures, the curves exhibit a straight line shape, whereas perfect Cole–Cole-shaped semi-circles are obtained at higher temperatures. The curve at different temperatures just presents a sole semi-circle, revealing the contribution of the grains’ conduction, and correlating with the thermally activated conduction of point defects generated as shown in defect Equations (1) and (2) [36].

Figure 9.

(a) Cole–Cole impedance spectra of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics measured within 400–505 °C; (b) enlarged Cole–Cole impedance spectra measured within 460–505 °C.

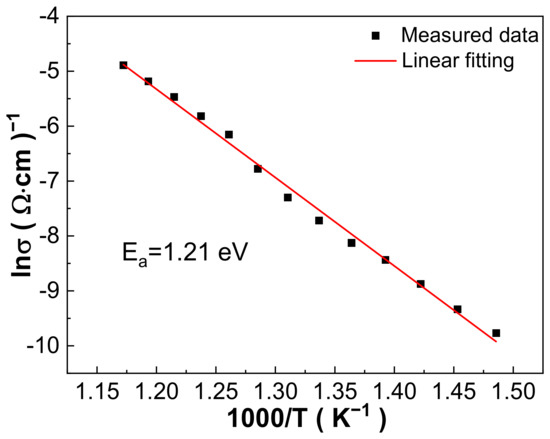

To reveal the type of point defects, the high-temperature conductivity was linearly fitting according to the Arrhenius law, based on which, the activation energy Ea of the sample was calculated and the point defects’ type could be determined. The sample’s conductivity was extrapolated from impedance spectra via formula σ = t/RS, in which t is the thickness of the sample, S is the sample’s area and R is the real part of the impedance at low frequencies. The calculated conductivity and liner fitting result are shown in Figure 10, where the fitting line matches well with the extrapolated data and shows the reliability of the Arrhenius law fitting. The fitted Ea = 1.21 eV, approaching close to 1 eV, shows that the oxygen vacancies produced by the evaporation of Pb and Bi during sintering as discussed in defect Equations (1) and (2) dominate the conduction process in the 0.21BNT-0.05BF-0.74PZT ceramics at high temperatures [37].

Figure 10.

Conductivity–temperature relationship of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics.

4. Conclusions

Pure perovskite 0.21BNT-0.05BF-0.74PZT ceramics were prepared by low-temperature sintering technology, which presents a narrow sintering temperature range, and the tetragonal distortion c/a increases first and then decreases with the increasing sintering temperature. Within the narrow sintering temperature range, the primary cell volume and relative density present parabolic curve-like change, and the best ceramics are prepared at a low sintering temperature of 1030 °C accompanied by large densification of 96.56% and rather uniform micromorphology. All of the sintered 0.21BNT-0.05BF-0.74PZT ceramics have resistivity larger than 1011 Ω·cm and excellent dielectric properties, where the highest Tm 269 °C and largest εm 16,085.5 are acquired at 1030 °C and 1040 °C sintering temperatures, respectively. The relaxation characteristic is confirmed by exponential law dielectric response fitting and Vogel–Fulcher fitting combined with dielectric frequency dispersion and diffused phase transition. The 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics have excellent electrical properties, in which Tm = 269 °C, d33 = 213.4 pC/N, Kp = 37.7% and Qm = 27.3. Oxygen vacancies produced due to the evaporation of Bi and Pb during sintering revealed by the EDX measurement perform a control function in the high-temperature grains’ conduction. The rather large piezoelectricity combined with a relatively high Tm temperature provides the prospect of their application in harsh operation temperature fields for the 0.21BNT-0.05BF-0.74PZT ceramics studied.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/ma16093459/s1, Figure S1: EDX spectra of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics at different locations; Figure S2: Element surface mapping of 1030 °C sintered 0.21BNT-0.05BF-0.74PZT ceramics at different locations.

Author Contributions

Conceptualization, B.F.; Supervision, B.F.; Methodology, J.S.; Formal analysis, S.W. and Q.W.; Investigation, W.W., S.W., J.S. and Q.W.; Data curation, W.W. and S.W.; Writing—original draft, S.W. and W.W.; Writing—review & editing, B.F. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank the Top-notch Academic Programs Project of Jiangsu Higher Education Institutions and the Priority Academic Program Development of Jiangsu Higher Education Institutions for their financial support.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data that support the findings of this study are included within the article and Supplementary File.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Damjanovic, D. Materials for high temperature piezoelectric transducers. Curr. Opin. Solid State Mater. Sci. 1998, 3, 469–473. [Google Scholar] [CrossRef]

- Gao, Z.; Lu, C.; Wang, Y.; Yang, S.; Yu, Y.; He, H. Super stable ferroelectrics with high Curie point. Sci. Rep. 2016, 6, 24139. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ma, H.; Yuan, G.; Luo, H.; Viehland, D. Heterogeneous domain configurations in ferroelectric crystals during thermal depolarization. J. Am. Ceram. Soc. 2017, 100, 1751–1759. [Google Scholar] [CrossRef]

- Hao, J.; Li, W.; Zhai, J.; Chen, H. Progress in high-strain perovskite piezoelectric ceramics. Mater. Sci. Eng. R 2019, 135, 1–57. [Google Scholar] [CrossRef]

- Ji, W.; Fang, B.; Zhao, X.; Zhang, S.; Lu, X.; Ding, J. Enhancing electrical properties of high-Curie temperature piezoelectric ceramics BNT-PZT and their mechanism. Curr. Appl. Phys. 2019, 19, 1367–1373. [Google Scholar] [CrossRef]

- Chen, L.; Liu, H.; Qi, H.; Chen, J. High-electromechanical performance for high-power piezoelectric applications: Fundamental, progress, and perspective. Prog. Mater. Sci. 2022, 127, 100944. [Google Scholar] [CrossRef]

- Li, F.; Lin, D.B.; Chen, Z.B.; Cheng, Z.X.; Wang, J.L.; Li, C.C.; Xu, Z.; Huang, Q.W.; Liao, X.Z.; Chen, L.Q.; et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 2018, 17, 349–356. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, S.; Gorzkowski, E.; Zhou, S.; Liu, W.; Li, F. Investigation of morphotropic phase boundaries in PIN-PSN-PT relaxor ferroelectric ternary systems with high Tr-t and Tc phase transition temperatures. J. Eur. Ceram. Soc. 2017, 37, 2813–2823. [Google Scholar] [CrossRef]

- Sato, Y.; Hirayama, T.; Ikuhara, Y. Monoclinic nanodomains in morphotropic phase boundary Pb(Mg1/3Nb2/3)O3-PbTiO3. App. Phys. Lett. 2014, 104, 082905. [Google Scholar] [CrossRef]

- Zhu, R.; Fang, B.; Zhang, S.; Lu, X.; Ding, J. Composition design of PMN-PH-PT piezoelectric ceramics for high-temperature actuator applications. Mater. Res. Express 2020, 7, 046304. [Google Scholar] [CrossRef]

- Eitel, R.E.; Randall, C.A.; Shrout, T.R.; Rehrig, P.W.; Hackenberger, W.; Park, S.-E. New high temperature morphotropic phase boundary piezoelectrics based on Bi(Me)O3-PbTiO3 ceramics. Jpn. J. Appl. Phys. 2001, 40, 5999–6002. [Google Scholar] [CrossRef]

- Wei, Y.; Bai, C.; Jin, C.; Zhu, W.; Jian, Z.; Nan, R.; Hu, L.; Dai, Z. Super short-range magnetic orderings in a multiferroic relaxor ceramic 0.41Bi(Ni1/2Zr1/2)O3-0.59PbTiO3. J. Mater. Sci. 2021, 56, 11838–11846. [Google Scholar] [CrossRef]

- Choi, S.M.; Stringer, C.J.; Shrout, T.R.; Randall, C.A. Structure and property investigation of a Bi-based perovskite solid solution: (1−x)Bi(Ni1/2Ti1/2)O3-xPbTiO3. J. Appl. Phys. 2005, 98, 034108. [Google Scholar] [CrossRef]

- Zhao, T.; Fei, C.; Pu, K.; Dai, X.; Song, J.; Wang, C.; Dong, S. Structure evolution and enhanced electrical performance for BiScO3-Bi(Ni1/2Zr1/2)O3-PbTiO3 solid solutions near the morphotropic phase boundary. J. Alloys Compd. 2021, 873, 159844. [Google Scholar] [CrossRef]

- Ansell, T.Y.; Cann, D.P.; Sapper, E.; Rödel, J. Thermal depolarization in the high-temperature ternary piezoelectric system xPbTiO3-yBiScO3-zBi(Ni1/2Ti1/2)O3. J. Am. Ceram. Soc. 2015, 98, 455–463. [Google Scholar] [CrossRef]

- Ji, W.; Feng, S.; Fang, B.; Zhao, X.; Zhang, S.; Ding, J.; Luo, H. Facile preparation and performance of novel high-TC xBi(Ni1/2Ti1/2)O3-(1−x)Pb(Zr1/2Ti1/2)O3 piezoceramics. Curr. Appl. Phys. 2018, 18, 289–296. [Google Scholar] [CrossRef]

- Zhai, L.; Shi, Y.G.; Gao, J.L.; Tang, S.L.; Du, Y.W. Ferroelectric and magnetic properties in high-pressure synthesized BiFeO3 compound. J. Alloys Compd. 2011, 509, 7591–7594. [Google Scholar] [CrossRef]

- Sun, X.; Chen, J.; Yu, R.; Xing, X.; Qiao, L.; Liu, G. BiFeO3-doped (Na0.5K0.5)NbO3 lead-free piezoelectric ceramics. Sci. Technol. Adv. Mater. 2008, 9, 025004. [Google Scholar] [CrossRef]

- Luo, F.; Guan, H.W.; Peng, R.; Jian, J.; Chen, J.G.; Cheng, J.R. Low-temperature sintering of BF-PT-BZ ternary solid solutions with enhanced piezoelectric properties. J. Am. Ceram. Soc. 2019, 102, 5958–5965. [Google Scholar] [CrossRef]

- Beuerlein, M.A.; Kumar, N.; Usher, T.-M.; Brown-Shaklee, H.J.; Raengthon, N.; Reaney, I.M.; Cann, D.P.; Jones, J.L.; Brennecka, G.L. Current understanding of structure-processing-property relationships in BaTiO3-Bi(M)O3 dielectrics. J. Am. Ceram. Soc. 2016, 99, 2849–2870. [Google Scholar] [CrossRef]

- Wang, S.; Fang, B.; Zhao, X.; Zhang, S.; Lu, X.; Ding, J. Phase formation and performance of high Curie temperature Bi(Ni0.5Ti0.5)O3-BiFeO3-PbTiO3 ceramics. Ferroelectrics 2022, 600, 105–123. [Google Scholar] [CrossRef]

- Chandrakala, E.; Praveen, J.P.; Hazra, B.K.; Das, D. Effect of sintering temperature on structural, dielectric, piezoelectric and ferroelectric properties of sol-gel derived BZT-BCT ceramics. Ceram. Int. 2016, 42, 4964–4977. [Google Scholar] [CrossRef]

- Ying, Y.; Xiong, X.; Wang, N.; Zheng, J.; Yu, J.; Li, W.; Qiao, L.; Cai, W.; Li, J.; Huang, H.; et al. Low temperature sintered MnZn ferrites for power applications at the frequency of 1 MHz. J. Eur. Ceram. Soc. 2021, 41, 5924–5930. [Google Scholar] [CrossRef]

- Lee, W.-C.; Huang, C.-Y.; Tsao, L.-K.; Wu, Y.-C. Chemical composition and tolerance factor at the morphotropic phase boundary in (Bi0.5Na0.5)TiO3-based piezoelectric ceramics. J. Eur. Ceram. Soc. 2009, 29, 1443–1448. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in Halides and chalcogenides. Acta Cryst. 1976, A32, 751–766. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, C.; Ji, Y.; He, L.; Ren, X. Designed morphotropic relaxor boundary ceramic exhibiting large electrostrain and negligible hysteresis. Acta Mater. 2021, 208, 116720. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Pande, D. Effect of stress induced monoclinic to tetragonal phase transformation in the multiferroic (1−x)BiFeO3-xPbTiO3 system on the width of the morphotropic phase boundary and the tetragonality. J. Appl. Phys. 2011, 110, 084105. [Google Scholar] [CrossRef]

- Tutuncu, G.; Fan, L.; Chen, J.; Xing, X.; Jones, J.L. Extensive domain wall motion and deaging resistance in morphotropic 0.55Bi(Ni1/2Ti1/2)O3-0.45PbTiO3 polycrystalline ferroelectrics. Appl. Phys. Lett. 2014, 104, 132907. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Bi, L.; Zheng, Q.; Fan, G.; Jie, W.; Lin, D. High energy storage density and discharging efficiency in La3+/Nb5+ co-substituted (Bi0.5Na0.5)0.94Ba0.06TiO3 ceramics. J. Eur. Ceram. Soc. 2019, 39, 3051–3056. [Google Scholar] [CrossRef]

- Wang, Y.; Jie, W.; Yang, C.; Wei, X.; Hao, J. Colossal permittivity materials as superior dielectrics for diverse applications. Adv. Funct. Mater. 2019, 29, 1808118. [Google Scholar] [CrossRef]

- Uchino, K.; Nomura, S. Critical exponents of the dielectric constants in diffused-phase-transition crystals. Ferroelectr. Lett. 1982, 44, 55–61. [Google Scholar] [CrossRef]

- Wei, X.; Feng, Y.; Yao, X. Dielectric relaxation behavior in barium stannate titanate ferroelectric ceramics with diffused phase transition. Appl. Phys. Lett. 2003, 83, 2031–2033. [Google Scholar]

- Shvartsman, V.V.; Kleemann, W.; Dec, J.; Xu, Z.; Lu, K.S.G. Diffuse phase transition in BaTi1−xSnxO3 ceramics: An intermediate state between ferroelectric and relaxor behavior. J. Appl. Phys. 2006, 99, 124111. [Google Scholar] [CrossRef]

- Tang, X.G.; Chew, K.-H.; Chan, H.L.W. Diffuse phase transition and dielectric tunability of Ba(ZryTi1-y)O3 relaxor ferroelectric ceramics. Acta Mater. 2004, 52, 5177–5183. [Google Scholar] [CrossRef]

- Zhou, Y.; Fang, B.; Zhang, S.; Lu, X.; Ding, J. Enhancing densification and electrical properties of KNN-based lead-free ceramics via two-step sintering. J. Korean Ceram. Soc. 2022, 59, 551–564. [Google Scholar] [CrossRef]

- Bhadauria, P.P.S.; Kolte, J. Impedance and AC conductivity analysis of La-substituted 0.67BiFeO3-0.33BaTiO3 solid solution. Appl. Phys. A 2022, 128, 465. [Google Scholar] [CrossRef]

- Pastor, M.; Bajpai, P.K.; Choudhary, R.N. Structural and electrical impedance study of Pb(Sr1/3Nb2/3)O3. J. Phys. Chem. Solids 2007, 68, 1914–1920. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).