Abstract

Energy storage and conversion are critical components of modern energy systems, enabling the integration of renewable energy sources and the optimization of energy use. These technologies play a key role in reducing greenhouse gas emissions and promoting sustainable development. Supercapacitors play a vital role in the development of energy storage systems due to their high power density, long life cycles, high stability, low manufacturing cost, fast charging-discharging capability and eco-friendly. Molybdenum disulfide (MoS2) has emerged as a promising material for supercapacitor electrodes due to its high surface area, excellent electrical conductivity, and good stability. Its unique layered structure also allows for efficient ion transport and storage, making it a potential candidate for high-performance energy storage devices. Additionally, research efforts have focused on improving synthesis methods and developing novel device architectures to enhance the performance of MoS2-based devices. This review article on MoS2 and MoS2-based nanocomposites provides a comprehensive overview of the recent advancements in the synthesis, properties, and applications of MoS2 and its nanocomposites in the field of supercapacitors. This article also highlights the challenges and future directions in this rapidly growing field.

1. Introduction

The global energy requirement is continuously on the rise because of the burgeoning population, expanding urban areas, and the growth of industries. This has led to a greater need for renewable energy sources and energy-efficient technologies to meet the demand while reducing carbon emissions. Non-renewable resources such as coal, oil, and natural gas are categorized as fossil fuels that took millions of years to form from the decomposed remains of dead animals and plants. These fuels are major sources of energy for electricity generation, transportation, and industrial processes, but their use contributes to climate change and environmental degradation. Fossil fuels still dominate the global energy mix and account for the majority of energy production in the world [1,2,3]. In addition to being finite resources that will eventually run out, fossil fuels also contribute to air pollution and climate change through the release of greenhouse gases during combustion. These negative impacts have spurred a global shift towards renewable energy sources. The sustainable and environmental advantages of renewable energy sources like solar, wind, and hydropower are causing them to gain more popularity [4,5].

Renewable energy sources provide several advantages, including decreasing the amount of greenhouse gas emissions, enhancing the quality of air, and generating employment opportunities in the clean energy industry. Additionally, renewable energy is often more cost-effective and sustainable in the long term compared to traditional fossil fuels [6]. With the increasing shift towards renewable sources of energy, energy storage is gaining more importance. The intermittent nature of wind and solar power underlines the amplified requirement for energy storage to balance out the supply and demand of energy and ensure the reliable and consistent availability of power [7]. Insufficient energy storage is a major challenge for renewable energy sources, as they are dependent on weather conditions. Developing cost-effective and efficient energy storage technologies is crucial to overcoming this challenge and making renewable energy more reliable and accessible [8]. Energy storage devices are designed to accumulate extra energy during periods of low consumption and restore it during periods of high demand. This process helps maintain a balanced grid and prevent power outages. This technology is becoming increasingly important as more renewable energy sources are added to the grid, which can be intermittent and unpredictable [9].

There are three types of energy storage devices: mechanical, electrical, and chemical. Flywheels and compressed air energy storage fall under the category of mechanical storage systems, while batteries and supercapacitors are classified as electrical storage systems [10]. Both batteries and capacitors are energy storage devices, but their energy densities and discharge rates differ. Batteries have a higher energy density and slower discharge rate, while capacitors have a lower energy density and faster discharge rate [11]. Batteries store the charges electrochemically. This means that they use chemical reactions to produce and store electrical energy, which can then be used to power various devices and equipment. Additionally, different types of batteries have varying capacities and lifetimes, making them suitable for different applications [12]. Capacitors store charges electrostatically and are commonly used in electronic circuits to smooth out voltage fluctuations and filter out unwanted signals [13]. They come in various sizes and types, including ceramic [14], electrolytic [15], and tantalum capacitors [16].

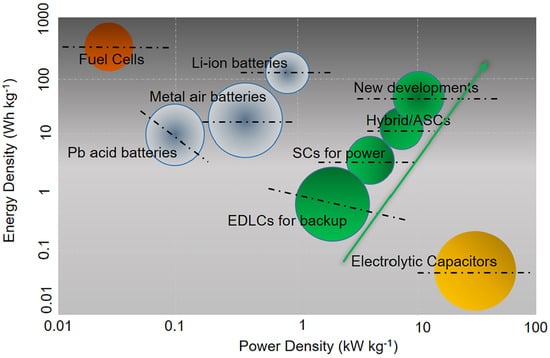

Supercapacitors are high-capacity electrochemical devices that store and release energy quickly. They have the ability to store and deliver much higher energy densities than conventional capacitors due to their unique electrode configurations. Supercapacitors typically have larger capacitance values compared to traditional capacitors, and their charge/discharge cycles are much faster. There are three types of supercapacitors, which are categorized as electrostatic double-layer capacitors, pseudo-capacitors, and hybrid capacitors. Electrostatic double-layer capacitors are the most common type of supercapacitor. They operate by separating positive and negative charges over two layers of electrically conducting material separated by a thin separator. This separation creates a high-capacity electrical field, which stores charge. Pseudo-capacitors, on the other hand, work by storing charge on the surface of a conducting material through a process called faradaic charge transfer. This type of supercapacitor has a higher energy density than electrostatic double-layer capacitors but typically has a lower power density. Hybrid capacitors, as the name suggests, combine the features of both electrostatic double-layer capacitors and pseudo-capacitors. By doing so, they are able to offer not only high energy density but also high power density. This makes them ideal for high-performance applications which require both high energy and power density [17]. The use of supercapacitors has been on the rise recently as they possess the capacity to quickly store and distribute energy, making them a suitable option for electric vehicles and sustainable energy setups. As the world shifts towards more sustainable forms of energy, the demand for supercapacitors is expected to continue to grow [18]. Supercapacitors have several advantages over traditional batteries, including faster charging times, longer lifetimes, and higher power densities. They are also more environmentally friendly, as they do not contain toxic chemicals or heavy metals [19]. In the energy storage industry, a Ragone plot is frequently utilized to assess the viability of various technologies by illustrating the compromise between power density and energy density. It compares the appropriateness of different energy storage systems for different applications. This plot (Figure 1) is also employed to gauge the potential of new materials and technologies in the field of energy storage [20].

Figure 1.

The Ragone plot displays the relationship between energy and power density of various energy storage devices. Adapted from [20]. Copyright 2020, Energy Reports.

Transition Metal Dichalcogenides (TMDs)

Transition metal dichalcogenides (TMDs) are a group of 2D materials that are made up of a transition metal atom like molybdenum or tungsten sandwiched between two layers of chalcogen atoms, such as sulfur or selenium. They display distinctive features in terms of their electrical, optical, and mechanical characteristics, which make them highly potential materials for applications in electronics [21], bio-applications [22], topological spintronics [23], optoelectronics [24], energy storage [25], and energy conversion devices [26]. Over the years, researchers have successfully synthesized stable TMDCs using a variety of methods like chemical vapor deposition (CVD), chemical exfoliation, and solvothermal synthesis. The utilization of these techniques permits the accurate manipulation of the size, morphology, and structure of the TMDs, ultimately influencing their characteristic traits [27]. TMDs like MoS2, WS2, MoSe2, and WSe2 have been extensively studied because of their extraordinary electronic, optical, and mechanical characteristics that are prominently displayed when their thickness is decreased to just a few layers [28]. TMDs have a layered crystal structure, with strong covalent bonds within the layers and weak van der Waals forces between the layers. This leads to a favorable relationship between surface area and volume, resulting in optimal mechanical flexibility. TMDs also have a direct bandgap, which makes them efficient light absorbers and emitters [29,30].

The edge locations exhibit a significant concentration of atoms that are unsaturated, thereby offering a greater number of active sites for chemical reactions. Additionally, the coordination of the edge atoms is different from that of the basal atoms, resulting in a different electronic environment. This causes the edge sites to have a different electrochemical potential, making them more active in redox reactions [31]. The fabrications of electrodes using TMDs are often optimized to incorporate the edge-exposed surface of these materials, as opposed to their basal planes. This strategy can enhance both their catalytic and electrochemical properties. The edge sites of TMDs possess higher reactivity and greater activity towards electrochemical reactions compared to the basal plane sites [32,33]. In recent years, there has been a noteworthy rise in the studies conducted on two-dimensional TMDs, particularly MoS2, with a focus on their electrochemical properties [34]. Molybdenum disulfide (MoS2) displays enormous potential in diverse electrochemical applications such as batteries [35], hydrogen evolution [36], supercapacitors [37], and sensors [38]. The unique atomic structure of MoS2, which consists of a layered structure of molybdenum and sulfur atoms, provides it with exceptional electro catalytic properties. MoS2-based electrochemical devices have shown remarkable performance in terms of rapid charge/discharge rates, high energy density, and extended life cycles. Researchers are also exploring the use of MoS2 in hybrid energy storage systems [39], ionic-liquid-based supercapacitors [40], and as a catalyst for water splitting [41] and carbon dioxide reduction [42].

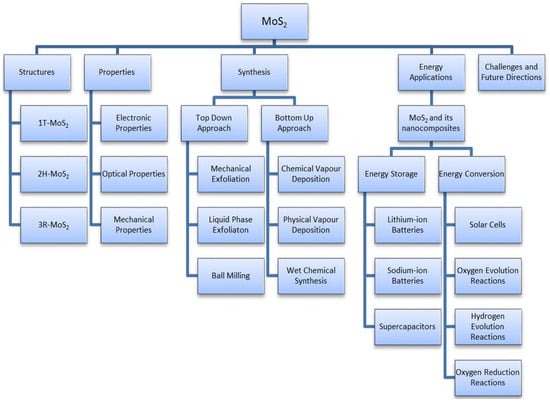

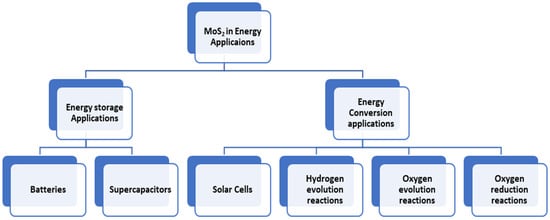

This article provides a general overview of the various 2D TMDs, focusing on their significant structure of MoS2. The mechanical, electrical, and optical properties of MoS2 and their impact on various applications are discussed in detail. Additionally, the paper systematically outlines the latest advancements in the methods used for their preparation and highlights their primary advantages and disadvantages. The main focus of this article is to explore the applications of MoS2 and its nanocomposites in energy storage and conversion techniques. In this study, we extensively evaluate the electrochemistry and capabilities of wearable and flexible supercapacitors based on MoS2, which have not been previously discussed in other review articles. Finally, we discussed the real-time challenges and the research gaps to improve the performance of MoS2 and its nanocomposites for potential applications in industries. The schematic representation of the overview of this review article is shown in Figure 2.

Figure 2.

Schematic representation of overview of this review article.

2. Structures, Properties and Synthesis of MoS2

2.1. Structure of MoS2

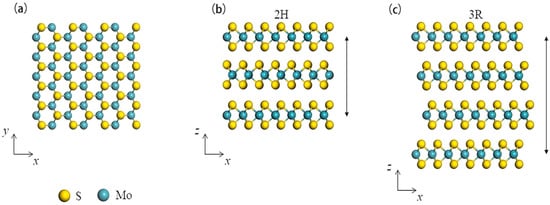

MoS2 is a unique material that exhibits different properties and applications depending on its structure and dimensions. The structure is composed of layers that are arranged in a hexagonal lattice made up of molybdenum atoms, with two sulfur atoms in between each layer. MoS2 has three polymorphic crystalline structures, which are 1T-MoS2, 2H-MoS2 and 3R-MoS2. 1T-MoS2 is the most thermodynamically stable polymorph of MoS2 at high temperatures. The Mo atoms are arranged in trigonal prismatic coordination, with a distorted octahedron formed by the six closest sulfur atoms. Its crystal structure is characterized by the existence of one type of sulfur atom in the lattice [43]. 2H-MoS2 is the most common form of MoS2 in nature. It has a hexagonal crystal structure, and each Mo atom is surrounded by six sulfur atoms forming a trigonal prism arrangement. Its unit cell consists of two different sulfur sites in the lattice [44]. 3R-MoS2 polymorph has a rhombohedral crystal structure (Figure 3) and is found at low temperatures. It has a lattice parameter that lies between the 1T and 2H structure and three different sulfur sites in the lattice [45].

Figure 3.

(a) Top view of monolayer MoS2 with stick and ball crystal structure, (b) Side view of multilayer MoS2 with 2H structure, (c) Side view of multilayer MoS2 with 3R structure. The arrow marks indicate the number of layers in a repeat unit. Adapted from [45]. Copyright 2019 Nano Energy.

One of the most common and stable phases of MoS2 is known as the 2H structure. This structure has a hexagonal lattice, which has two layers per unit cell. The adjacent layers are stacked in an ABA pattern, in which the middle layer is shifted slightly in relation to the top and bottom layers. This arrangement allows for strong interlayer interactions between the sulfur atoms, resulting in a stable crystalline structure [46]. The sulfur atoms from different atomic planes occupy the same positions relative to each other. The Mo-S bond in MoS2 is predominantly covalent in nature, meaning that the electrons are shared between the two atoms. This results in strong bonding between the Mo and S atoms within each sheet, contributing to the strong mechanical properties and thermal stability of the material. On the other hand, the layers of S atoms are coupled by van der Waals interactions, which are weaker and result from the temporary dipole moments that arise when the electron cloud around the atoms is slightly displaced [47]. The layered structure of MoS2 turns it into a perfect material for various applications, and its morphology can be controlled by different synthesis methods. MoS2 can be synthesized in various shapes and morphologies, including planar [48,49,50], nanoflowers [51], nanowires [52], nanotubes [53], nanoplatelets [54,55] and vertically aligned nanosheets [56]. Overall, the different structures of MoS2 offer a wide range of possibilities for scientific research and technological innovation.

2.2. Properties of MoS2

The properties of MoS2 play a crucial role in determining its suitability for energy storage applications. MoS2 possesses exceptional attributes, including high electrochemical activity, fast ion diffusion, and outstanding electrical conductivity, which make it a highly favored choice as an electrode in batteries and supercapacitors. The characteristics of MoS2 have a considerable impact on the utilization of energy storage in various applications, mainly because of its vast surface area that allows for a substantial active area for electrochemical reactions. Thus, the electrodes made of MoS2 possess a high capacitance and can conveniently accumulate a significant amount of charge, a crucial aspect for the superior functioning of energy storage devices. Another important property of MoS2 is its high mechanical strength and stability, which enables it to withstand repeated cycles of charge and discharge with minimal degradation. Additionally, MoS2 has good thermal stability and is capable of operating at high temperatures without compromising its performance, making it suitable for use in harsh environments. In addition, MoS2 has an electronic band structure that gives it a high electron affinity. This property makes it possible to achieve high energy storage density and excellent charge retention, which are essential for the development of high-performance energy storage devices [57,58,59].

2.2.1. Electronic Properties

The properties of multilayer MoS2 have been widely examined because of its impressive electronic and optical characteristics. Its band structure has been a focus of interest due to its potential use in optoelectronic devices. Studies have shown that multilayer MoS2 has an indirect band gap of 1.2 eV, indicating that the transfer of electrons from the valence to conduction bands necessitates a shift in momentum. However, the band gap increases as the number of layers in MoS2 decreases. MoS2 in a single-layer configuration, also known as monolayer MoS2, demonstrates a direct band gap measuring 1.8 eV. Moreover, the thickness-dependent band gap of MoS2 makes it possible to engineer its optical and electronic properties by controlling the number of layers and even stacking different materials on top of each other [60,61]. However, compared to silicon, which has a direct bandgap of 1.12 eV, MoS2 still falls short in terms of its ability to efficiently absorb and emit light in the visible spectrum [62]. The electronic characteristics of MoS2 can be significantly impacted by mechanical strain, which refers to the deformation caused by an applied force. Specifically, it can cause a change in the material’s band gap. For MoS2, this strain can shift its band gap from a direct one to an indirect one, thereby affecting its electronic properties in a significant way. Specifically, it can turn the material from a semiconductor into a metal, where there is no longer a band gap, and electrons can move freely across the material. This change in properties could have significant implications for the use of MoS2 in electronic devices, making it possible to tune its conductivity and optoelectronic properties through the application of strain. In addition to mechanical strain, other factors, such as electric fields and chemical doping, can also influence the electronic characteristics of MoS2 [63].

Monolayer MoS2 has become a noteworthy semiconductor material in recent times owing to its distinct characteristics. When this material is doped with chromium, copper, or scandium, it undergoes a transition to become an n-type semiconductor. On the other hand, doping with nickel or zinc causes monolayer MoS2 to become a p-type semiconductor. The ability to control the electrical properties of monolayer MoS2 through the process of doping opens up many potential applications in electronic devices. For example, n-type MoS2 can be used as a component in transistors, while p-type MoS2 can be used to create diodes [64]. The doping of Titanium in MoS2 can significantly alter its electronic properties, and the type of doping (interstitial or substitutional), as well as the doping concentration, play a crucial role in the resulting semiconductor behavior. Low levels of Ti doping lead to p-type behavior, while high levels result in n-type and, eventually, a ferromagnetic half-metal with spin polarization equal to one. These results may pave the way for the creation of advanced electronic gadgets that offer better performance and functionality [65].

2.2.2. Optical Properties

MoS2 is a semiconducting material that exhibits interesting optical properties. One of its notable characteristics is its absorption coefficient—a measure of how much light is absorbed as it passes through the material. The absorption coefficient of MoS2 was influenced by various factors, such as the chemical composition of the material, its thickness, and the wavelength of light being used. In the case of MoS2, its absorption coefficient is relatively large for wavelengths ranging from 400 nm to 500 nm [66]. The bandgap of bulk MoS2 changes when it is reduced to a few layers. This bandgap change in MoS2 enables the tunability of its photoresponsivity, specific detectivity, and response time. The photoresponsivity of MoS2-based devices is enhanced by the reduction in thickness due to quantum confinement effects. This confinement effect increases the electronic density of states in the bandgap, leading to an increase in light absorption and an increase in photoresponsivity. In addition to photoresponsivity, the specific detectivity of MoS2-based devices is improved by the increased surface area when reduced to a few layers, which improves the signal-to-noise ratio. The response time of MoS2-based devices is improved due to the reduction in thickness, which allows for faster carrier transport and recombination. Furthermore, the high mobility of charge carriers in MoS2 also contributes to its fast response time. Overall, the potential for MoS2 to be used in optoelectronics is very high due to its ability to have a tunable bandgap. This material has promising applications in photodetectors, solar cells, light-emitting diodes, and even optical switches and modulators [67].

The electronic and structural properties of MoS2 can be effectively assessed using its photoluminescence (PL) spectra. Any alterations in the material’s band gap, doping, or crystal structure can greatly impact its PL activity, making it a valuable tool for characterization. In pure MoS2, the band gap is estimated to be around 1.8 eV, resulting in an emission of around 670 nm. However, MoS2 can be doped with various elements, such as nitrogen or sulfur, which can alter the band structure and shift the emission peak. For example, nitrogen-doped MoS2 exhibits a blue-shifted PL peak due to a reduced band gap [68]. Moreover, the PL activity of MoS2 can also be affected by its structure. MoS2 can exist in different crystal forms, such as 1T or 2H, which have different electronic properties and, therefore, different PL activities. According to reports, the PL intensity of 1T-MoS2 is stronger as compared to 2H-MoS2 [69]. The addition of an H2O2 solution has been found to be an effective approach for enhancing the photoluminescence properties of monolayer MoS2. This is because H2O2 acts as a strong oxidizer that oxidizes the MoS2 surface without altering its crystalline structure [70]. Amani et al. attained an important improvement in the quality of MoS2 by using a chemical treatment of an organic super-acid, resulting in a quantum yield (QY) of 95%. This means that almost all of the absorbed energy is emitted as light, indicating a highly efficient process. It was noticed that the lifespan of MoS2 carriers is nearly 10.8 nanoseconds, making it a suitable material for utilization in advanced solar cells and high-performance lasers [71]. MoS2 exhibits exceptional electrical and optical characteristics, which make it a highly desirable substance for optoelectronic applications. However, the presence of defects has been a major obstacle to the realization of its full potential.

2.2.3. Mechanical Properties

The exclusive structure of Monolayer MoS2 contributes to its remarkable mechanical strength, which is similar to that of graphene, a two-dimensional material renowned for its exceptional strength. The Young’s modulus of a single layer of MoS2, which measures its stiffness and resistance to deformation, has been found to be 0.33 ± 0.07 TPa (terapascals). This is a remarkable value, particularly given that the Young’s modulus of steel, a material commonly used in construction, is only around 200 GPa (gigapascals). The lattice structure of MoS2 enables the material to withstand large amounts of stress without breaking or deforming [57]. One notable property of MoS2 is that it undergoes a transition from a bulk material to a two-dimensional (2D) material when its thickness is reduced to a single layer. This change is significant as the mechanical properties of MoS2 are affected: single-layered structures are more flexible than bulk materials. This is predominantly because of the interlayer interactions that exist in the bulk form of MoS2, resulting in a stiffer structure, whereas in the form of a single layer, the feeble van der Waals forces between layers enable increased flexibility [72].

One of the ways to alter the electronic characteristics of MoS2 is through mechanical strain. If mechanical stress is applied to MoS2, its band gap transforms from direct to indirect. This change in the band gap can result in new electronic and optical properties. Furthermore, when MoS2 is subjected to high strain values, it can undergo a structural deformation that can transform it from a semiconductor to a metal. This is because the deformation alters the Mo-S bonds and changes the electronic states of the material. Furthermore, the mechanical strain can also change the lattice symmetry, which influences the electronic properties of the material [73]. One of the significant differences between MoS2 monolayers and graphene is their thermal conductivity. MoS2 monolayers have a thermal conductivity of around 35 Wm−1 K−1, which is approximately 100 times lower than the thermal conductivity of graphene. This difference in thermal conductivity is attributed to the distinct atomic structure and electron configuration of the two materials. The lattice structure of graphene allows for the free flow of phonons, whereas MoS2 monolayers have a more complex lattice structure and exhibit phonon scattering [74].

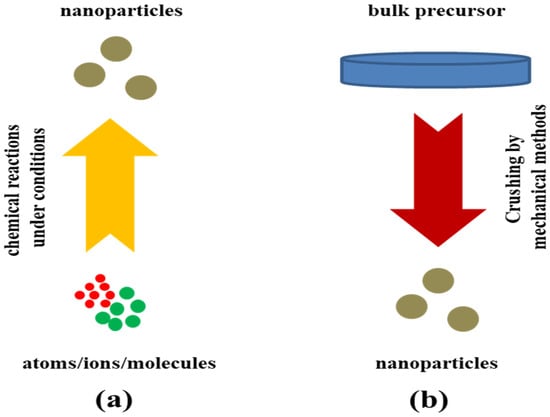

2.3. Synthesis Methods of MoS2

MoS2 has emerged as a potential material for advanced portable electronic gadgets like sensors, transistors, and photovoltaic cells in the future. To achieve the desired material features and uses, there are several techniques for synthesizing MoS2 and related composites that are more significant. The synthesis of MoS2 and its nanocomposites involves top-down and bottom-up methods for fabrication are shown in Figure 4. Chemical vapor deposition (CVD), liquid-chemical exfoliation, hydrothermal synthesis, solvothermal synthesis, and mechanical exfoliation are among the popular methods used for synthesis. The synthesis methodologies for MoS2 and its related composites are varied and provide researchers with a range of options for producing high-quality materials for a wide range of applications [75,76,77,78].

Figure 4.

Schematic representation of the (a) bottom-up approach and (b) top-down approach.

2.3.1. Top-Down Approaches

In the top-down method, MoS2 bulk crystal is carefully processed to produce MoS2 nanomaterials, which are commercially available. This downsizing process involves physical manipulation of the crystal to produce smaller particles with dimensions at the nanometer scale. This method is widely used in nanotechnology and is preferred for its ability to produce uniform and well-defined nanomaterials [79,80,81]. MoS2 nanosheets can be readily produced through the exfoliation technique owing to their layered structure and van der Waals forces. There are several exfoliation methods available for synthesizing these nanosheets, such as mechanical, chemical, electrochemical, and liquid-phase exfoliation [82,83,84,85]. Even though the top-down methods are uncomplicated to utilize, they are not successful in producing irregularly shaped and very minute particles. The primary disadvantage of this approach is the challenge of acquiring the appropriate shape and size of particles.

- (a)

- Mechanical Exfoliation

The mechanical exfoliation technique involves the removal of appropriate MoS2 flakes from the bulk crystal of MoS2 through the use of adhesive tape and then transferring them onto a specific substrate [86,87]. As there is no chemical reaction involved in the mechanical exfoliation of MoS2 from its bulk crystal, there will be no alteration in its structure. The exfoliation process yields single- or few-layer MoS2 nanosheets with various shapes and sizes after removing the scotch tape, leaving some MoS2 residues on the substrate. These nanosheets possess excellent quality, making them ideal for investigating the original material’s properties and device performance. Nevertheless, the yield of production is not high in this process, and it is challenging to regulate the particle size of the resulting MoS2 nanosheet [86,88,89]. A study was conducted to investigate the interlayer interactions in heterostructures of transition metal dichalcogenides. The study was successful in creating MoS2/WS2 and MoSe2/WSe2 heterostructures using a mechanical transfer technique after exfoliating the relevant crystals [90]. The field of 2D materials has witnessed a major advancement with the creation of an automated approach for exfoliating transition metal dichalcogenides (TMDs) into single-layer or few-layer forms. The technique hinges on deploying controlled normal and shear forces to detach a thin sample from bulk MoS2 or MoTe2 with the help of a parallel plate rheometer. This detached sample is subsequently affixed to the rheometer’s movable upper fixture through the application of blue dicing tape. The process of creating atomically thin films of specific materials can be initiated through a step-and-repeat exfoliation process by utilizing preprogrammed contact force and liftoff speed. This method results in the consistent formation of such MoS2 films [91]. The mechanical exfoliation method is simple, inexpensive, and does not require any special equipment, making it a popular technique for synthesizing high-quality MoS2 nanosheets. It can be further optimized by controlling the pressure, speed, and direction of the peeling process to obtain larger and more uniform MoS2 nanosheets.

- (b)

- Ball Milling

Ball milling is a mechanical method that involves the use of high-energy ball mills to reduce the size of the precursor materials. The ball milling process has been shown to be a favorable technique for the large-scale production of MoS2 nanosheets, as it offers several advantages, such as homogeneity of the final product, low cost, and ease of operation. The procedure can be readily expanded for large-scale manufacturing as well. Additionally, ball milling can be used to produce MoS2 nanosheets with varying thicknesses by simply adjusting the milling time and speed [92,93,94]. Cantarella et al. investigated commercial MoS2 nanopowders subjected to ball-milling for 20 and 40 h has revealed that the process has significantly enhanced the adsorption properties of the nanopowders. The researchers found that MoS2 ball-milled for 40 h showed an exceptional capability to remove methylene blue dye from aqueous solutions. It was able to adsorb all the dye present in just 20 min. This indicates that the milling process led to a considerable increase in the adsorption capacity of the nanopowders [95]. Kumar et al. reported that the ball-milling process was used to treat bulk MoS2, resulting in an improvement in the capacitive properties of the material. Specifically, the treated BL-MoS2 showed an increase in specific capacitance and energy density, making it highly suitable for use as an active component in supercapacitors [96]. The ultrasonic ball milling technology was utilized for the synthesis of materials like h-BN, graphene, MoS2, WS2, and BCN. The iron balls used for milling in this study had diameters ranging from 1.0 to 1.5 mm. The outcome achieved was more than 20% in terms of yield. The resulting materials had sizes ranging from 1 to 20 µm and had a thickness of approximately 1–3 nm [97]. Overall, the ball milling process is an effective and efficient method for synthesizing MoS2, producing uniform and highly crystalline particles that have potential applications in various fields.

- (c)

- Liquid phase Exfoliation

A popular technique for generating nanosheets and colloidal dispersions involves the use of liquid phase exfoliation (LPE) on layered materials, such as MoS2. In this method, the bulk material is dispersed in a solvent to form a suspension and then subjected to high-intensity sonication to break down the layered structure and produce nanosheets. The new approach to producing 2H-MoS2 nanosheets, which involves synthesizing two to seven layers, presents several advantages. These advantages include simplicity, effectiveness, environmental friendliness, and absence of contamination. One of the unique aspects of this technique is that no surfactants are required, which can be a common drawback of other methods. Additionally, the use of acetone as a solvent is a notable improvement over NMP, which is commonly used but has low volatility. This technique utilizes solvents that have surface energies that match well with the solid interface, making the synthesis more efficient. By using extended sonication times and low concentrations of bulk powder, the layers are effectively peeled off, and the dispersions remain stable [98,99]. Chlorophyll extracts have been found to be a highly effective exfoliating agent for producing a thin layer of MoS2/WS2 heterostructure. This novel method of synthesis has opened the door to exciting possibilities in the field of renewable energy. The MoS2/WS2 heterostructure produced through this method has proven to be an effective catalyst for the production of hydrogen, which is a vital ingredient in a range of clean energy applications [100]. The study examined the electrocatalytic performance of 2H-MoS2 nanosheets produced through LPE in N-dimethyl formamide, 1-methyl-2-pyrrolidinone, and formamide by examining their surface and interface functionalization. The findings indicated that MoS2 nanosheets produced in formamide were comparatively smaller in size and thickness but showed significantly better electrocatalytic activity when compared to those produced in the other two solvents [101]. One of the biggest challenges in energy research is finding electrode materials for sodium-ion batteries that are inexpensive but can store a large amount of energy. Fortunately, a solution has been found in the form of MoS2 nanosheets that are exfoliated in the liquid phase and reinforced with 20 wt% single-wall carbon nanotubes (SWNTs). When shaped into sodium-ion battery electrodes, these materials have impressive gravimetric, volumetric, and areal capacities [102]. The implementation of a partial etching approach has been suggested to be a highly effective method for modifying the thickness and lateral dimensions of MoS2 nanosheets, resulting in an increased percentage of edges. This technique has been found to significantly improve the production rate of monolayer MoS2 (20%) and WS2 (12%) nanosheets through LPE [103].

2.3.2. Bottom-Up Approaches

The bottom-up approach is an effective method for synthesizing MoS2 and other 2D materials. The bottom-up approach involves the fabrication of a material from its constituent atoms or molecules. In the case of MoS2, it involves the synthesis of Mo and S atoms or molecules, followed by their assembly into the final material. The synthesis process is controlled at the atomic and molecular level, which allows for precise control over the particle size and structure of the resulting MoS2 nanocrystals. Bottom-up synthesis methods are highly scalable, making it possible to produce large amounts of MoS2 with fewer impurities and defects at a relatively low cost. It requires less energy and fewer processing steps than top-down methods, making them a more energy-efficient and environmentally friendly approach. There are various methods for producing MoS2, such as chemical vapor deposition (CVD) and wet chemical synthesis [104].

- (a)

- Chemical Vapor Deposition (CVD)

The preferred method for synthesizing MoS2 is chemical vapor deposition (CVD) because it can produce films with large surface areas that have high crystallinity and purity [105]. CVD involves the deposition of MoS2 from precursor molecules in the gas phase onto a substrate. It utilizes various methods, including the sulfurization of Mo-based films, thermolysis of S and Mo precursors, and vaporization and decomposition of precursors that contain Mo and S atoms to produce a high-quality film. The thickness of the film can be easily adjusted by varying the duration of the deposition process [106,107,108,109]. The sulfurization of Mo-based films involves the deposition of Mo films followed by the introduction of sulfur gas. The sulfur atoms react with the Mo atoms to form MoS2. According to Hong et al., the vapor deposition of sulfurization of MoO3 precursor involves three main steps: the adsorption of sulfur on the MoO3 surface, the formation of an intermediate sulfur compound, and the final conversion to an MoS2 monolayer. The availability of sulfur atoms plays a crucial role in determining the growth rate of the MoS2 layer, whereas the quantity of sulfur precursor utilized in the reaction can regulate the thickness of the resulting MoS2 layer [110,111]. The oxygen content in the resultant material, specifically MoOxSy, led to a significant decrease in sheet conductivity. It is important to carefully control the synthesis conditions to minimize the presence of oxygen and other impurities in the material to ensure optimal conductivity and performance [112,113,114].

Rovira et al. reported that the CVD process had successfully synthesized MoS2 nanoribbons, where MoO3 nanoribbons were used as a template. Two distinct morphologies of MoS2 ribbons were obtained by altering the positioning of the crucibles. The first morphology consisted of dense, compact MoS2 ribbons, whereas the second morphology comprised ribbons with “thorns” caused by incomplete sulfurization [115]. A new technique called single-step vapor-phase sulfurization has been developed to cultivate uninterrupted films of monolayer MoS2. In a study conducted by Chiawchan et al., the process was carried out using MoO2 as the source material. The outcome demonstrated a noticeable pattern on the substrate surface, suggesting changes in the concentration-gradient of the Mo-source material throughout the growth phase [116]. The growth of an ordered array of MoS2 nanodots with lateral sizes ranging from approximately 100–250 nm has been reported through a thermal chemical vapor deposition process. The process was conducted directly onto SiO2 substrates at a relatively low temperature range of 510–560 °C. The results indicate that this CVD method can facilitate the growth of high-quality MoS2 nanodot arrays [117]. The integration of the wet synthesis and chemical vapor deposition technique is beneficial for producing MoS2 films of superior quality. To create MoS2 using the liquid precursor, the process requires transforming a sample coated with a solution of L-cysteine and sodium molybdate while being exposed to an argon gas flow at a temperature of 680 °C. This process results in the direct conversion of the coating into an MoS2 film on the substrate [118]. Moreover, the transferring process of prepared films can be quite complicated and may require specialized equipment and expertise. Additionally, achieving uniformity and controllability in the film deposition process can also be a challenge, leading to variability in the quality and properties of the resulting films.

- (b)

- Physical Vapor Deposition

Molecular beam epitaxy (MBE) is a highly advanced technology that has the ability to produce thin films of single-crystal semiconductors. However, its application is limited to the manufacture of two-dimensional (2D) materials [119]. Conversely, physical vapor deposition is not commonly employed for 2D material synthesis. Ti and MoS2 materials were employed in the preparation of an MoS2/Ti composite using direct current magnetron sputtering. The PVD process is an effective method for growing MoS2 at significantly lower temperatures, as low as 350 °C, in this particular study [120]. MoS2 can be directly grown on thermally grown silicon oxide and (002) graphite. The technique is based on sputtering and can be easily implemented for growing other TMDs [121]. The electronic and optoelectronic properties of MoS2(1−x)Se2x monolayer alloys can be studied through their growth with different edge orientations, specifically the Mo-zigzag and S-Se-zigzag edge orientations. It is possible to obtain these edge orientations by controlling the deposition temperature. Moreover, the remarkably large domain size of MoS2(1−x)Se2x monolayer alloys (x = 0.41–1) can pave the way for the development of high-quality films on a large scale [122]. The study of the early stages of growth of very thin Pd, Au, and Ag films on a single layer of MoS2 has uncovered different patterns of growth that were identified via atomic force microscopy. In particular, Pd develops an even layer of contact, whereas Au clusters into small nanostructures, and Ag takes on a scattered formation of islands on the MoS2 surface [123].

- (c)

- Wet Chemical Synthesis

Wet chemical synthesis is a commonly employed and economical method for producing few-layered MoS2 and related nanocomposites. It involves mixing reagents in a specific order and under certain conditions to control the chemical reactions and the resulting product. The reaction can occur at different temperatures and pressures, and various factors such as pH, concentration, and stirring rate can also affect the final product [124,125]. The hydro/solvothermal method has gained popularity in the hybridization of MoS2 with other functional nanomaterials because of its simple procedure, convenient handling, and economical reaction method. Additionally, this method allows for the creation of unique morphologies in metal oxides, hydroxides, and sulfides [126,127]. The ammonium heptamolybdate, MoO3, sodium molybdate, etc., are used as precursors for molybdenum and thiourea, sulfur powder, thioacetamide, etc., are used as precursors for sulfur in the preparation of MoS2 powder. The hydrothermal/solvothermal methods were widely used for synthesizing a variety of MoS2 powder with different structures and properties [128,129,130,131]. The synthesis of MoS2 nanosheets and their subsequent aggregation into various morphologies, such as nanotubes, nanoflowers and microspheres etc., holds great potential for applications in diverse fields, including catalysis, energy storage, and bio-imaging [132,133,134].

Luo et al. demonstrated that the preparation conditions of wrapped nano-sheet greatly affect its adsorption capacity. Specifically, a wrapped nano-sheet with a 3:1 ratio of S and Mo, hydrothermally treated at 240 °C for 37 h, exhibited the highest adsorption capacity. The gradual evolution of morphology from coral-like aggregates to flower-like spheres to wrapped nano-sheet structures is significant as it enables the production of three distinct morphologies that can cater to varying demands in various fields [135]. The production of MoS2 nanosheets has been accomplished effectively through an uncomplicated and environmentally friendly hydrothermal technique that utilizes l-cysteine and ammonium molybdenum hydrate. During the synthesis process, l-cysteine can serve a dual purpose as a sulfur source and as a capping agent [136]. MoS2 nanosheets with different layer thicknesses (bilayer, trilayer, quadrilayer, and more) and a combination of MoS2 quantum dot-nanosheets were produced using a hydrothermal process by controlling the amount of MoS2 and NaOH. NaOH serves as an agent for intercalating, and the fragmentation of nanosheets results in the production of quantum dots [137]. The study conducted by Cordeiro et al. highlights the possibility of utilizing microwave-assisted hydrothermal synthesis to cultivate MoS2 nanostructures on cellulose paper substrates. This development presents potential applications in the fields of electronics and sensors. The researchers investigated the influence of synthesis parameters like temperature and time on the quantity of MoS2 grown on cellulose fibers. The evaluation identified the existence of both metallic and semiconductor phases of the nanostructures [138]. Xuan et al. investigated the effect of reaction temperature (160–220 °C) and reaction time (6–14 h) on the microstructure and morphology of MoS2. The outcomes showed that as the reaction heat increased from 160 to 220 °C, the morphology of MoS2 transformed gradually from aggregated particles to flower-like spheres to a nanosheet structure. In contrast, the reaction time affected the restacking and refinement of the MoS2 crystal structure but did not have a significant impact on the morphology [139]. Duraisamy et al. described a straight forward hydrothermal method for creating a 3D network of metallic MoS2/MoO3 nanosheets. The study found that the resulting nanosheets exhibit not only the desired metallic MoS2 phase but also a significant density of active sites and a tuned electrical conductivity that contribute strongly to their catalytic activity and hydrogen evolution reaction [140]. The comparison of advantages and disadvantages of various synthesis methods are listed in Table 1.

Table 1.

Comparison of various synthesis methods of MoS2.

3. Energy Applications

MoS2 shows great potential for use in energy-related applications. However, further research and developments are necessary to address the scalability, stability, and cost-effectiveness challenges associated with its integration into the energy industry. We will categorize our conversation about energy applications into two primary domains, namely, the storage and conversion of energy. Ultimately, we will examine the challenges that MoS2 might encounter during its integration into the energy sector [141,142]. Various applications of MoS2 in energy storage and conversion fields are shown in Figure 5.

Figure 5.

Various applications of MoS2 in energy storage and energy conversion fields.

3.1. MoS2-Based Nanocomposites in Energy Applications

MoS2 composites have gained significant attention in recent years due to their unique properties that make them useful in energy applications. Here are some reasons why MoS2 composites are important in these applications:

- Improved conductivity: MoS2 composites offer improved electrical conductivity compared to pure MoS2, making them ideal for use in batteries, fuel cells, and other energy storage and conversion devices;

- Enhanced catalytic activity: MoS2 composites exhibit enhanced catalytic activity, which is useful in energy conversion processes like hydrogen evolution reaction (HER), oxygen reduction reaction (ORR), and carbon dioxide reduction reaction (CO2RR);

- Increased stability: MoS2 composites are more stable than pure MoS2 and other transition metal dichalcogenides (TMDs) under extreme conditions, such as high temperatures and corrosive environments. This makes them suitable for use in harsh industrial and energy-related applications;

- Reduced cost: MoS2 is a low-cost material, and its composites can be produced by simple, scalable processes, making them an economical option for energy applications.

In conclusion, MoS2 composites play a crucial role in energy production, storage, and conversion, making them highly useful in energy applications. With their exceptional properties, they have opened up new avenues for the development of highly efficient and sustainable energy technologies.

3.2. Energy Storage Applications

MoS2 is a potential material for energy storage applications due to its remarkable ability to store high amounts of energy and its extended lifespan. Its potential has been explored for its utilization in energy storage applications, specifically supercapacitors, sodium-ion batteries (SIBs) and lithium-ion batteries (LIBs). MoS2 nanosheets can also improve the overall performance of LIBs by improving their specific capacity and cycle life. MoS2 has displayed positive outcomes as a cathode material in SIBs concerning long cycle life and high energy density. Similarly, it has been observed that MoS2 carries a high surface area, excellent electrical conductivity, and exceptional electrochemical stability, making it an ideal electrode material for supercapacitors. Studies have revealed that MoS2-based supercapacitors exhibit better energy storage capacity than others, high power density, and long cycle life [143,144,145,146,147,148].

3.2.1. Li-Ion Batteries

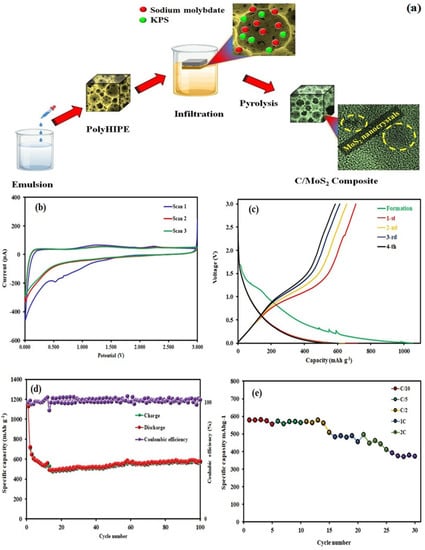

MoS2 has become a popular material for lithium-ion batteries (LIBs) in recent times. This is because it possesses distinctive characteristics that can enhance the performance and durability of the batteries. MoS2 acts as an anode or cathode in Li-ion batteries. It has a high inherent capacity for storing lithium ions, the ability to prevent lithium-ion insertion/extraction during charge cycles, and stability over long-time cycling. It has been shown that by incorporating MoS2 as an electrode into Li-ion batteries, the battery life can be increased due to the superior charge/discharge properties and stability of the MoS2 material [149]. Liu et al. introduced a new MoS2/C hybrid electrode for use as a Li-ion battery anode. This electrode exhibits impressive low-temperature performance, maintaining a stable discharge capacity of up to 854.3 mAh g−1 at −20 °C, which is equivalent to 72.8% of its room-temperature performance. Despite operating at a current density of 3 A g−1, this electrode continues to exhibit a capacity of 140.9 mAh g−1. The increased spacing between MoS2 layers promotes rapid Li+ diffusion, ultimately enhancing the kinetics of lithiation/delithiation and improving the performance rate at low temperatures [150]. Baheri et al. developed an innovative method to produce 1T/2H-MoS2 nanocrystals within N-doped nanoporous carbon shown in Figure 6. This process involves using a pyrolysis method of sodium molybdate and potassium persulfate within an acrylonitrile-based polymer base. As a result, the C-MoS2 composite showed exceptional battery performance, with a specific capacitance of 556 mAh g−1 at a current density of 0.2 A g−1 and maintained excellent stability even after undergoing 100 cycles [151]. A recent study has shown that a 3D bulky MoS2@C/RGO composite may offer significant benefits for the cycling performance and rate capability of Li-ion batteries. The synthesized nanocomposite demonstrated a comparable cycling performance of 1189 mAh g−1 after undergoing 100 charge/discharge cycles at 200 mA g−1, which was better than the control samples and earlier reports [152]. The composite also showcased a good rate capability, with 1211 mAh g−1 at a current density of 50 mA g−1 and even 726 mAh g−1 at a current density of 2000 mA g−1. Moreover, when tested in an MoS2-PDA-GO30//LiCoO2 full-cell configuration, this composite material exhibited a superior cycling capability of 890 mAh g−1, which is equivalent to 1750 Wh kg−1. Despite the challenges, MoS2 remains a promising electrode material for LIBs, and research efforts are ongoing to address its cycle stability issues [153]. The widespread use of MoS2 electrodes in LIBs could potentially lead to the development of more efficient and longer-lasting batteries, with significant implications for various industries and applications. Bozheyev et al. investigated the use of MoS2 nanopowder as an anode material in LIBs. The nanopowder was produced through a solid-state synthesis method (SHS). The electrochemical performance of this nanopowder was evaluated through a coin-type CR2032 cell. According to the findings, MoS2-NP displayed an initial charging ability of 567 mAh g−1 when subjected to a current density of 50 mAh g−1. This indicates that MoS2-NP could be a promising contender for a proficient anode substance in LIBs [154]. The study on MoS2 phase transformation and the incorporation of CNT additives in batteries have showcased promising results in the application of metal sulfide electrodes in high-energy-density batteries [155].

Figure 6.

(a) Schematic representation of the synthesis of C/MoS2 hybrid, (b) CV curves of C/MoS2 electrode at a scan rate of 1 mV s−1 within a potential window of 0.01–3.0 V, (c) GCD curves within a potential window of 0.01–3.0 V (vs. Li/Li+), (d) Cyclic performance of C/MoS2 electrode, and (e) Rate capability of C/MoS2 electrode. Adopted from [151]. Copyright 2023 Scientific Reports.

The MoS2 composite electrodes were prepared by a method of uniaxial cold-pressing, which involved the pressing of the materials under a high pressure of 3 tons. The composite electrodes contained 60 wt% MoS2, 10 wt% carbon black, and 30 wt% β-Li3PS4 solid electrolyte. The solid electrolyte used in these electrodes was β-Li3PS4, which has high ionic conductivity and stability in air. Solid-state lithium-ion batteries were utilized to assess the efficiency of these electrodes, with a Li-In alloy serving as the counter electrode. During the discharge process at a rate of 67 mA g−1 (C-10) within the voltage range of 0.01–3.0 V, the electrodes displayed an initial specific capacity of approximately 439 mAh g−1. The specific capacity retention was also outstanding, with 312 mAh g−1 obtained after undergoing 500 cycles [156]. MoS2 and its composites have garnered increasing attention as potential electrode materials in the field of battery technology. One key advantage is their larger interlayer spacing, which enables fast metallic ion diffusion compared to other materials. This is particularly useful for ions like Na+, Zn2+, and Mg2+, which are commonly used beyond LIBs. Furthermore, the usual abundance of molybdenum and sulfur means that MoS2-based electrodes can be produced at a relatively low cost compared to other materials [157]. Cha et al. demonstrated that the incorporation of MoS2 in Li metal batteries can effectively mitigate the issues of dendrite formation and electrolyte decomposition, which are notorious for causing safety hazards and performance degradation. MoS2 can be used as a protective coating for Li metal anodes to improve their cyclic stability and avoid the formation of lithium dendrites. The use of MoS2 as a separator modification can also improve the battery’s performance by enhancing the wettability of the electrolyte and decreasing the impedance. Moreover, the solid electrolyte interphase formed between MoS2 and Li metal can serve as a stable interfacial layer, reducing the risk of side reactions between the electrolyte and Li metal [158].

3.2.2. Sodium-Ion Batteries

Molybdenum-based materials have shown remarkable electrochemical properties and stability, making them a favorable choice for anode materials in sodium-ion batteries (SIBs). These materials have been researched in several different forms, like nanoparticles, flakes, and membranes. They have demonstrated encouraging outcomes regarding their ability to maintain capacity and stability during cycles. One of the key advantages of molybdenum-based materials is their ability to interact with sodium ions through various mechanisms, including alloying, intercalation, and conversion reactions. The unique Na-insertion properties of molybdenum-based materials can be attributed to the open framework of their crystal structure, which can accommodate large sodium ions and allow for reversible and sustainable storage [159]. A combination of two distinct 1T and 2H phases has been utilized to produce a dual-phase MoS2 (DP-MoS2). This electrode has displayed exceptional cycling stability, with a reversible capacity of 300 mAh g−1 after undergoing 200 cycles, as well as excellent rate capability with a capacity of ~220 mAh g−1 at 2 A g−1. These findings indicate that DP-MoS2 has the capability to be utilized in commercial devices, offering a fresh strategy to create metal chalcogenides for applications in storing electrochemical energy [160]. A thorough analysis of MoS2 in comparison with MoO2 indicates that MoS2 has the ability to store sodium through the insertion reaction due to its larger interlayer distance compared to MoO2. Furthermore, the weaker bonds of MoS2, as compared to MoO2, make the conversion reaction of sodium with MoS2 more favorable [161]. The MoS2/grapheme/chitosan electrode has demonstrated superior performance as an anode material for SIBs. After undergoing 200 charge/discharge cycles at a current density of 100 mA g−1, the electrode exhibited a high capacity retention of 527.3 mAh g−1. It also displayed excellent rate capability and maintained a high capacity of 439.1 mAh g−1 at 1 A g−1. Importantly, the MoS2/G/C electrode exhibited exceptional stability over a long cycle life span, making it a favorable material for high-performance SIBs [162]. MoS2@CNTs composite material has been found to exhibit remarkable performance as an anode material for SIBs. This composite material demonstrates a high rate of performance and can deliver 508, 418, 359, 305, 258, and 183 mAh g−1 at current densities of 0.1, 0.2, 0.5, 1, 2, and 5 A g−1, respectively. The remarkable cycling stability of this composite material allows it to retain 360 mAh g−1 after undergoing 400 charge/discharge cycles at 0.5 A g−1. The outstanding ability of MoS2@CNTs is attributed to the strong combination of the MoS2 and CNT components, which makes it highly robust [163].

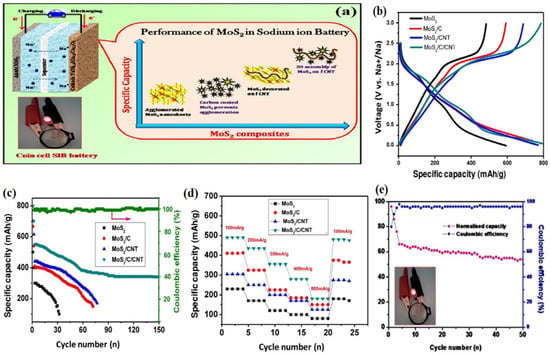

Ye et al. offer a different approach to enhancing the cycling performance of SIBs with respect to their reversible capacity. The remarkable performance of the Metal-semiconductor phase twinned hierarchical (MPTH) MoS2 electrode is ensured by expanding interlayers and preserving structural stability. It has been proven to deliver high reversible capacities of up to 200 mAh g−1 at a current density of 0.1 A g−1 for undergoing 200 cycles and an impressive 154 mAh g−1 at a current density of 1 A g−1 for undergoing 2450 cycles in the voltage range of 0.4–3.0 V. The electrode is capable of maintaining 6500 cycles when exposed to a current density of 2 A g−1, which results in 82.8% capacity retention from the second cycle. These findings exceed all previously recorded cycling performances of MoS2 by a significant margin [164]. A novel method for producing molecule-intercalated MoS2 with accurate interlayer spacing ranging from 0.62 to 1.24 nm has been suggested in a recent research study. This innovative technique allows for the fine-tuning of electrical conductivity, which ranges from 1.3 × 10−4 to 3.5 × 10−2 S cm−1, through incorporating guest molecules into MoS2. The synthesized MoS2 exhibits excellent sodium ion storage capacity, with the highest initial capacity of 465 mAh g−1 and retaining a capacity of 420 mAh g−1 after undergoing 600 charge/discharge cycles at a rate of 100 mA g−1. The better electronic conductivity and increased interlayer spacing collaborate to produce a synergistic impact that promotes the rapid movement of sodium ions and electrons. As a result, material usage is more efficient, and the outcomes are impressive [165]. Chothe et al. proposed a technique based on the solid-state method to generate ultrathin nanosheets of MoS2-graphene, which can be utilized in Na-ion batteries. During the galvanostatic study, the assembled Na-ion cell demonstrated a high specific capacity of 420 mAh g−1 at 50 mA g−1 and a capacity retention of 172 mAh g−1 at 200 mA g−1 after undergoing 200 cycles. This study highlights the potential of using hybrid materials in battery applications and demonstrates the importance of optimizing the electrode architecture for improved battery performance [166]. Halankar et al. developed an MoS2/C/CNT nanocomposite using a simple hydrothermal method shown in Figure 7. This composite material served as an electrode in SIB applications. The composite possesses excellent electronic conductivity and mechanical strength due to the presence of CNT, and at the same time, it effectively captures the polysulfide forms that occur during cycling. The full-cell SIB was developed using Na(Ni0.5Mn0.3Co0.2)O2 as a positive electrode and MoS2/C/CNT as a negative electrode. This battery demonstrated a specific capacitance of 96 mAh g−1 at a current density of 50 mA g−1 [167]. Researches on MoS2 in Na-ion batteries are still in its early stages, but there is potential for this material to show a significant role in the improvement of next-generation energy storage devices. Further investigation and optimization of the material’s properties and performance will be crucial for its successful integration into commercial Na-ion batteries.

Figure 7.

Electrochemical performance of MoS2, MoS2/C, MoS2/CNT, and MoS2/C/CNT electrodes in sodium-ion batteries: (a) schematic representation of the performance of MoS2 and its composites in sodium-ion batteries, (b) GCD characteristics of MoS2 and its composites at 50 mA g−1, (c) cyclic test of MoS2 and its composites at 50 mA g−1 (the green arrow indicates that MoS2/C, MoS2/CNT composite electrode have high cyclic stability), (d) cyclic rate of MoS2 and its composites at various current densities, and (e) cycling performance MoS2/C/CNT//Na(Ni0.5Mn0.3Co0.2)O2 full-cell at 50 mA g−1. Adopted from [167]. Copyright 2021 Carbon Trends.

3.2.3. Supercapacitors

MoS2 has a two-dimensional layered structure with remarkable electrochemical activity. This characteristic makes it an excellent option to serve as an electrode substance in supercapacitors, which require materials with high surface area and low resistance to store and release electrical energy quickly. Additionally, MoS2 has a high capacitance, which makes it an attractive option for supercapacitors, as increased capacitance typically leads to higher energy storage capacity.

- (a)

- 1T and 2H MoS2 Electrodes for Supercapacitors

The surface functionalization of 1T MoS2 nanosheets with NH2Ph ring, through the chemical reaction with iodobenzene, leads to the formation of Fc-1T MoS2, which exhibits improved electrocatalytic performance as compared to 1TMoS2. By adding NH2Ph ring functionality and 1T MoS2 phase, the charge density and electronic properties are improved, resulting in faster charge transport and greater charge storage capacity. Fc-1T MoS2 displays a significant specific capacitance of 501 F g−1 at 1 A g−1 while maintaining 76.32% capacitance retention even after 2000 cycles. This is 2.6 times greater than the bare 1T MoS2 nanosheets [168]. The latest combination of ammonium ion intercalation molybdenum disulfide (A-MoS2) with a considerable 1T proportion exhibits great potential in augmenting the functioning of energy storage devices, such as supercapacitors and batteries. Its substantial specific capacitance of 228 F g−1 at 5 mV s−1 indicates that A-MoS2 possesses a remarkable charge-storing capacity. Additionally, A-MoS2’s retention capability is also noteworthy, retaining 127 F g−1 at 80 mV s−1, which is vital for real-world usage [169]. Zarach et al. demonstrate the potential of Pt@1T/2H-MoS2 electrode material for energy storage applications, as it shows significantly improved specific capacitance and consistent coulombic efficiency during multiple charging and discharging cycles. The surface modification with Pt shows a crucial role in enhancing the material’s electrochemical properties by promoting the exfoliation process [170]. Shrivastav et al. synthesized 2H-MoS2 using a hydrothermal method [171]. At a scanning rate of 10 mv s−1, 2H MoS2 demonstrated a specific capacitance of 115.42 F g−1, and at a current density of 0.5 A g−1, it showed a specific capacitance of 57.69 F g−1. The 2H MoS2 also exhibited an electrochemical double-layer capacitive behavior with partial pseudo-capacitance. The retention of 71.5% of specific capacitance after 5000 CV cycles indicates good cyclic stability of the samples.

- (b)

- MoS2 with Graphene and Carbon-Based Nanocomposites

MoS2 with graphene-based nanocomposites have been researched as electrode materials for supercapacitors owing to their exceptional electrical conductivity and high surface area [172]. Moreover, the addition of carbon-based materials like carbon nanotubes or carbon black can enhance the electrochemical activities of the composite, improving the overall performance of the supercapacitor [173,174]. Ramakrishnan et al. developed an MoS2@rGO nanocomposite through a hydrothermal synthesis followed by an ultra-sonication method. This composite has been shown to be a profound candidate for sodium ion symmetric hybrid SCs. The electrode material was examined in a half-cell formation using metallic sodium and exhibited a high specific capacity of 226 F g−1 at a current density of 0.03 A g−1. In a full-cell configuration, the electrode exhibited a high capacitance of 55 F g−1 at a current density of 0.03 A g−1 [175]. Zhan et al. developed high-performance hybrid supercapacitors (HSCs) based on an interlayer-expanded MoS2/rGO nanocomposite. The sodium hybrid supercapacitor (Na-HSC) outperforms the lithium hybrid supercapacitor (Li-HSC) when combined with N-doped hierarchically porous 3D graphene (N-3DG). It displays remarkable performance, achieving an energy density of 140 Wh kg−1 at a power density of 630 W kg−1 and an energy density of 43 Wh kg−1 at an extremely high power density of 103 kW kg−1 (with a charge completed within 1.5 s). Furthermore, even after over 10,000 cycles, there is no apparent reduction in capacity [176]. Ji et al. synthesized an MoS2-reduced graphene oxide (rGO) in a sandwich structure through a solvent-free and one-step ball-milling process. The resulting MoS2-rGO nanocomposite sample exhibited exceptional electrochemical performance when used as an electrode material for supercapacitors. The composite demonstrated a high specific capacitance of 306 F g−1 at a current density of 0.5 A g−1, which was higher than that of pure MoS2. Additionally, the composite exhibited minimal discharge capacity decay after 100 cycles in li-ion batteries (0.2 A g−1) and 5000 cycles in supercapacitors (4 A g−1), demonstrating its excellent potential for long-term energy storage devices [177]. Quan et al. discovered a novel nanostructure composed of hollow carbon–MoS2–carbon, which has been synthesized using an l-cysteine-assisted hydrothermal method. The hollow nanoplate morphology of the material provided a high specific surface area of 543 m2 g−1 and a total pore volume of 0.677 cm3 g−1, with fairly small mesopores at approximately 5.3 nm. These properties make the hollow carbon–MoS2–carbon nanoplates ideal for use in supercapacitors. When tested in a symmetric supercapacitor, the material exhibited a specific capacitance of 248 F g−1 (0.12 F cm−2) at a constant current density of 0.1 A g−1 [178]. The MoS2/CNT composite is a highly effective material for producing high-performance supercapacitors. At a current density of 1 A g−1, the MoS2/CNT composite has a specific capacitance of 402 F g−1. This is an impressive result that indicates high energy storage capacity. Moreover, the composite maintains 81.9% capacitance retention after 10,000 continuous charge/discharge cycles at the same high current density, indicating excellent cycling stability [179].

Mahajan et al. successfully developed a high-performance supercapacitor using biocarbon-based MoS2 nanoparticles synthesized from date fruits. By converting agricultural biowaste into an easily affordable energy resource via the pyrolysis technique, the team has developed a carbon-based nanocomposite that exhibits a high specific capacitance of 945 F g−1 at a current density of 0.5 A g−1. This biocompatible Bio-C/MoS2 nanocomposite displayed an impressive reproducing stability of 92% even after 10,000 charge/discharge cycles. Furthermore, the Bio-C/MoS2 nanosphere demonstrated an exceptionally high power density of 3800–8000 W kg−1 and an energy density of 74.9–157 Wh kg−1, making it a promising material for high-performance energy devices [180]. Zhang et al. reported the successful development of a new hierarchically porous MoS2/C composite aerogel using a simple one-pot mass preparation method. The composite aerogel displays a high specific capacitance of 712.6 F g−1 at 1 A g−1 and a capacity retention rate of 97.3% after 13,000 cycles at 6 A g−1 when tested as a supercapacitor electrode [181].

- (c)

- MoS2 with Metal Oxide/Sulfide-Based Nanocomposites

The electrochemical performance of MoS2 is restricted by its low surface area and porosity. To enhance its performance, nanocomposites can be produced using metal oxides or sulfides, which have high surface areas and better ionic conductivity. The use of nanocomposites combining MoS2 with metal oxides or sulfides shows significant promise for improving the performance of supercapacitors. The study conducted on CoNi2S4 and an MoS2 nanocomposite fixed on porous graphene oxide yielded promising results in their potential as a high-performance substrate. The spongy nanocomposite showed a remarkable specific capacitance of 3268 F g−1 in a 3 M KOH solution at 1 A g−1. Furthermore, the CoNi2S4@MoS2@rGO electrode displayed an impressive 93.6% stability of its initial capacity after 3000 consecutive charge/discharge cycles at a current density of 10 A g−1. Moreover, the energy density of 41 Wh kg−1 and power density of 700 W kg−1 demonstrate the potential for this electrode to operate effectively under high power needs, indicating its wide-ranging applicability in supercapacitor applications [182]. The Bi2S3/MoS2 nanohybrid, which has a flower-like structure and contains high-quality heterostructures and 3D aisles, boasts exceptional electrochemical capabilities. This includes a high specific capacitance of 1258 F g−1 at 30 A g−1 and outstanding cycle stability of 92.65% after 5000 cycles at 10 A g−1 [183]. The prepared SnS2/MoS2 layered heterojunction has shown remarkable promise in terms of supercapacitor properties when compared with the sole SnS2. The specific capacitance achieved was a noteworthy 466.6 F g−1 at a current density of 1 A g−1, indicating a significant improvement. Furthermore, the experiment demonstrated impressive cycling stability, with 88.2% capacitance retention at a current density of 4 A g−1. The as-fabricated symmetric supercapacitor displayed an energy density of 115 Wh kg−1 at a power density of 2230 Wh kg−1, which demonstrates its high energy storage capacity in high power demand situations [184]. Govindan et al. highlighted the exceptional properties of CeO2/C/MoS2 hybrid for charge storage applications. The hybrid exhibited an outstanding specific capacitance of 1325.67 F g−1. This value is significantly higher than that of CeO2/C (727.49 F g−1) or MoS2 (300.33 F g−1) alone. Furthermore, the cyclic stability of the hybrid was excellent, as it showed a capacitance retention of 92.8% after 1000 charging/discharging cycles. The asymmetric supercapacitor (ASC) showed a remarkable electrochemical performance with a high specific capacitance of 110.55 F g−1, excellent cyclic stability (even after 1000 cycles) and a high energy density of 34.55 Wh kg−1 at a power density of 666.7 W kg−1 [185].

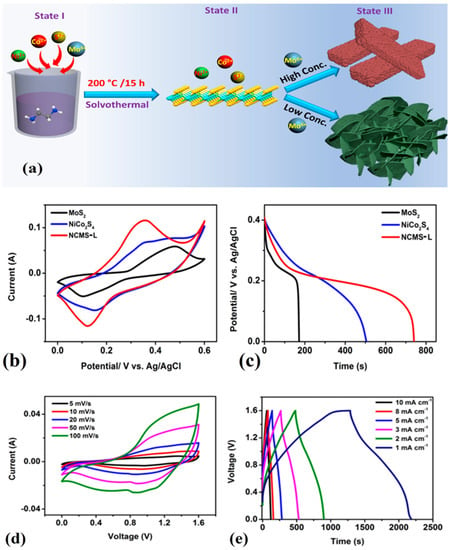

The preparation of an MoS2/Fe2O3/G composite heterostructure material through the hydrothermal method has enabled the development of a highly efficient electrode material for supercapacitor devices. The unique combination of MoS2, Fe2O3, and graphene has resulted in a significant increase in capacitance, with a value of 98.2 mAh g−1 at 1 A g−1. Importantly, the ASC device incorporating the MoS2/Fe2O3/G composite electrode has shown remarkable energy and power density of 46.8 Wh kg−1 and 750 W kg−1, respectively. Moreover, the impressive performance of the device is retained over a prolonged duration of usage with excellent capacity retention of up to 77% even after 10,000 cycles [77]. MnS/MoS2/Ni-Inverse opal structure nanocomposites were synthesized using the electrochemical deposition (ECD) technique. These specimens demonstrated exceptional specific capacitance values of 1880 F g−1 at a charge current density of 5 A g−1. Furthermore, the samples were subjected to 2000 cycles of cycle life testing, and even after this rigorous testing, they retained a respectable capacitance value of 76.6% of their initial value [186]. Tue et al. proposed a novel method to produce NiCo2S4/MoS2 composite with different morphologies (like sheet and rod shape) using a simple solvothermal method shown in Figure 8. The composite electrode in sheet-like morphology (NCMS-L) demonstrated remarkable performance, including outstanding coulombic efficiency, elevated specific capacitance, exceptional energy density, and good cyclic stability. Specifically, the electrode presented a capacity of 2594 F g−1 at a current density of 0.8 A g−1 after undergoing 45,000 charge and discharge cycles. Additionally, the hybrid supercapacitor device comprising NCMS-L and activated carbon achieved an energy density of 31.9 Wh kg−1 [187].

Figure 8.

(a) Schematic representation of the synthesis process of NiCo2S4/MoS2 composite (State I: shows the mixing of all precursors, State II: illustrates the formation of MoS2, State III: demonstrates the formation of NiCo2S4 over MoS2 with sheet- and rod-like morphologies), (b) Comparative CV curves of MoS2, NiCo2S4, and NCMS-L (NiCo2S4/MoS2 composite with sheet-like morphology) at a scan rate of 100 mV s−1, (c) Comparative GCD curves of MoS2, NiCo2S4, and NCMS-L at a current density of 1 mA g−1, (d) CV curves of the hybrid supercapacitor device of NCMS-L and activated carbon at various scan rates, (e) GCD curves of the hybrid supercapacitor device of NCMS-L and activated carbon at various current densities. Adopted from [187]. Copyright 2023 Nanomaterials.

- (d)

- MoS2 with Conducting polymer-based nanocomposites

In recent years, conducting polymers have gained increasing attention as electrode materials because of their numerous benefits. One of the most significant benefits of using conducting polymers is their low cost compared to traditional electrode materials such as metals. Additionally, conducting polymers possess high electrical conductivity, providing efficient transport of charge between the electrode/electrolyte interfaces. Chen et al. synthesized a hybrid electrode material, MoS2@PANI, by using a one-pot hydrothermal synthesis method. The resultant material had 25 wt% MoS2 and exhibited a high capacitance of 645 F g−1 at a current rate of 0.5 A g−1, which indicates maximum energy storage capacity. Additionally, this hybrid electrode material showed good cycling stability with a retention rate of 89% of its capacitance value after 2000 cycles at a current density of 10 A g−1 [188]. The CeO2/MoS2/PANI nanocomposite has demonstrated impressive electrochemical functionality, as evidenced by its specific capacitance values of 177 F g−1 at a scan rate of 5 mV s−1 and 62 F g−1 at a current density of 0.5 A g−1. This indicates its ability to store electrical charge efficiently. Additionally, the composite has exhibited excellent cyclic stability, with a capacitance retention rate of 98% after 2000 cycles at a current density of 5 A g−1, indicating its durability and long lifespan [189]. Ren et al. successfully developed MoS2/PANI nanocomposites with varying PANI loadings, using MoS2 nanosheets as the substrate. The composites with a 53 wt% PANI loading displayed the highest electro-capacitive property, resulting in exceptional electrochemical performance with a symmetric supercapacitor having an energy density of 35 Wh kg−1 and a power density of 335 W kg−1. Furthermore, the material demonstrated excellent cycling stability, showing 81% retention after 8000 cycles [190]. The preparation of a highly efficient MoS2/PANI/functionalized carbon cloth (MoS2/PANI/FCC) has been accomplished through a drop-casting method. This method allows for facile construction of the MoS2/PANI/FCC-based symmetric supercapacitor, which demonstrates a specific capacity of 72.8 F g−1 at 0.2 A g−1, based on the total mass of the two electrodes with a retention rate of 85% after 1000 cycles [191].

- (e)

- MoS2 based Flexible and wearable Supercapacitors

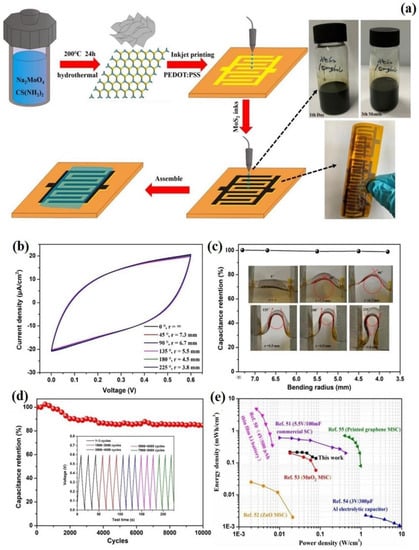

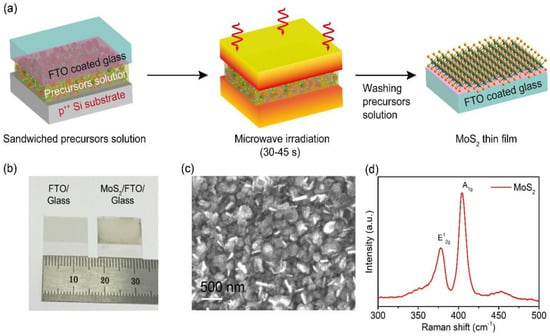

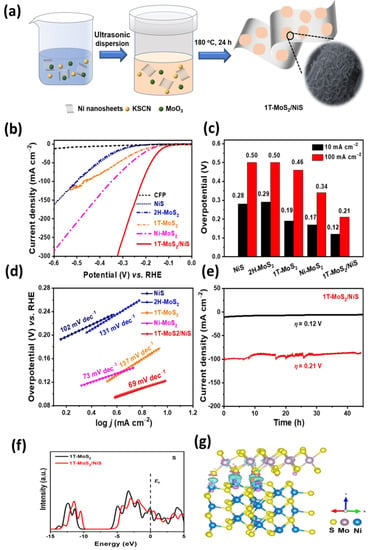

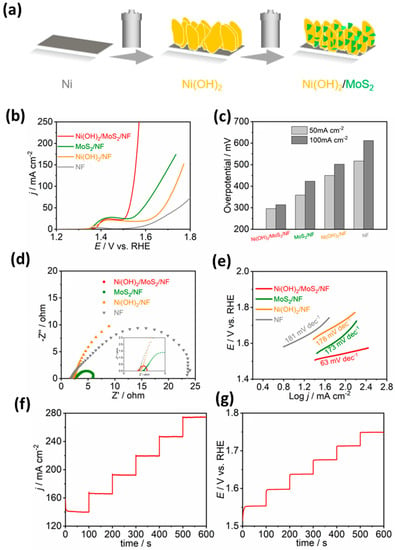

The emergence of wearable and flexible energy storage systems has revolutionized the field of wearable technology. These energy storage systems are designed to provide a reliable and sustainable source of power to wearable devices, including medical monitors, fitness trackers, and smartwatches. They are ultra-thin and flexible, which allows them to be integrated into the fabric of clothing or the band of a watch, making them easy to wear and practically invisible. The capability to deliver consistent and dependable power is a crucial factor for any wearable energy storage gadget. These devices must be able to store enough energy to last for an extended period, and they must also be capable of delivering a high current rate to meet the demands of different wearable devices. To achieve this level of performance, a variety of energy storage technologies are being researched, including batteries, supercapacitors, and hybrid systems that combine the best of both worlds [192,193,194]. Over the past few years, the wearable electronics industry has shown a remarkable interest in two-dimensional nanomaterials such as graphene, transition metal dichalcogenides (TMDs), and black phosphorus. This is because they possess distinctive features and benefits when compared to conventional materials [195,196,197,198,199,200,201]. One of the main benefits of these materials is their layer thickness, which is typically only a few atoms thick, making them ultra-thin and lightweight. In addition, the weak van der Waals force between layers enables simple exfoliation of these materials into thin layers, which enables the development of thin layers exhibiting distinct properties [202]. Due to its remarkable electrical conductivity, high surface area, and chemical stability, MoS2 has become a prominent contender as a material for flexible supercapacitor electrodes. When employed as an electrode material in flexible supercapacitors, MoS2 can improve their energy storage capacity, as well as their overall stability. The utilization of MoS2 in these capacitors shows great potential for next-generation energy storage devices that are lightweight, adaptable, and highly effective. Continued research into the fabrication and optimization of MoS2-based supercapacitors will be critical for realizing these capabilities and advancing the field of energy storage [203].