Abstract

Si3N4 ceramics with a microscale rice leaf structure (MRLS) and titanium alloy were connected via brazing, and the influence of the surface microstructure on the ceramic connection was analyzed. MRLS fabrication is an efficient and high-degree-of-freedom method that can be used to change a material’s surface morphology and wettability. The MRLS was obtained at a laser power of 110 W, with line spacings of 100 and 50 μm. The laser-treated surface included nanoparticles and micro particles, exhibiting a coral-like structure after agglomeration. When the MRLS was used to braze the titanium alloy, no defects were observed at the brazing interface, and the formation was excellent. Throughout the brazed joint, the MRLS remained intact and formed a strong metallurgical bond with the brazing filler metal. A finite element analysis was performed to study the cross-sectional morphology after joint fracture; from the load-time curve, it was found that the MRLS on the surface not only helped improve the mechanical occlusion and brazing area at the interface, but also helped generate compressive stress on the Si3N4 side. Crack propagation was hindered, thereby increasing the joint strength.

1. Introduction

Ceramics are widely used in aerospace, mechanical engineering, communications, electronics, and automobile fields; this is due to their incomparable high-temperature resistance, corrosion resistance, wear resistance, and unique electrical properties. Si3N4 ceramics exhibit high toughness, flexural strength, and excellent thermal insulation properties; their thermal expansion coefficient is close to that of steel and they are widely used in the field of structural ceramics [1,2,3]. However, the processability of Si3N4 is poor because of its high hardness and brittle texture. Further, it is difficult to directly process large-scale structural parts, significantly hindering its application. Therefore, the emergence of Si3N4-joining technology is expected to promote its development. Currently, there are many connection methods, including diffusion, brazing, reaction joining, etc. [4,5,6]. The direct brazing of ceramics involves the addition of active elements to the brazing filler, such that these elements react with the ceramic interface, thereby improving their wettability and producing a better joining effect [7,8].

Laser-induced periodic surface structures (LIPSSs) are important for fabricating surface microstructures [9,10,11,12]. LIPSSs are periodic nanostructures fabricated on the surface of metal materials using a pulsed laser to prepare micro/nano secondary surfaces with hydrophilic structures [13,14]. Chen et al. [15] used a laser to texture Ti3SiC2 ceramics to improve their wettability. After surface treatment, the wetting angle of the brazing filler on the ceramic was reduced from 59.6° to 25.7°, and the wettability was significantly improved. The brazing filler was uniformly filled into the machining groove, and the interface-forming effect was excellent. The surface microstructure morphology had a direct impact on wettability. With the change in the surface microstructure spacing, the wetting angle fluctuated [16]. Liu et al. [17] found that the Al–Si alloy had poor wettability on the surface of microgrooves and micropits, whereas the Al–Si alloy showed better wettability on the micro/nanoripple surface; this is attributed to the formation of micro/nano-layered patterns and the result is improved capillary action. Pardal et al. [18] performed spot welding on steel after forming a surface microstructure. Molten aluminum deeply penetrated the steel surface microstructure, and the maximum tensile shear strength of the joint increased by 25%. The machined surface microstructure played a role in homogenizing the nugget of the solder joint and improved the welding quality. Zhang et al. [19] fabricated a surface microstructure to achieve brazing between Al2O3 and stainless steel. The maximum joint strength reached 66 MPa, which was 2.7 times that of the untreated brazed joint. The spacing between the surface grooves affected the joint performance. When the groove spacing was large, the stress distribution in the brazing process improved, and it was difficult for the cracks to expand.

The difference in the coefficient of thermal expansion and elastic modulus of ceramic–metal materials leads to the generation and concentration of residual stress in brazed joints. Relieving this residual stress in ceramic–metal joints is one of the main research directions. Owing to the significant difference in base materials, the stress generated during the brazing process cannot be effectively relieved, and the maximum residual stress of the joint tends to concentrate on the base metal/brazing joint side, which has a higher elastic modulus. The performance of the obtained joint can be improved by adjusting the local stress via patterning. Song et al. [20] developed a new solder composed of AgCuTi powder, mixed with Si3N4 particles, and found that the dispersion distribution of Si3N4 particles reduced the mismatch in the thermal expansion coefficient and Young’s modulus between Si3N4 and TiAl base metals. Xiong et al. [21] introduced millimeter-scale periodic grooves on the C/C surface, which changed the stress distribution at the ceramic interface and increased the joint strength by 101.3%. LIPSS fabrication is an efficient and high-degree-of-freedom method that can be used to change the surface morphology and wettability of a material.

This study creatively used the microscale rice leaf structure (MRLS) in order to improve the ceramic–metal joint strength and stress. Based on the MRLS, Si3N4 ceramic and titanium alloy were joined by brazing, and the influence of the surface microstructure on the ceramic joining was analyzed.

2. Experimental Details

The Si3N4 ceramic was sintered by hot pressing, and the titanium alloy used was Ti6Al4V. The base materials were cut into small pieces of 15 × 15 × 4 mm3 using a diamond wire cutting machine, and the machined surfaces were polished. The braze filler should not only help complete the joining of Si3N4, but also meet the properties of high-temperature resistance and low activation; therefore, AgCuTi was selected as the braze filler.

2.1. Laser Surface Texture

The laser texture system was mainly composed of a femtosecond laser, a two-dimensional mobile working platform, a console, and an inert gas protection device. The average laser power was 110 W, the wavelength was 1064 nm, the focal diameter was 60 μm, the adjustable frequency range was 1–1000 kHz, and the pulse width range was 10–100 fs. Before processing, the Si3N4 ceramic was fixed onto a table and placed within the range of the galvanometer. A gas path was fixed on the mobile platform, and nitrogen was used as a protective gas at a flow rate of 10 cm3/s.

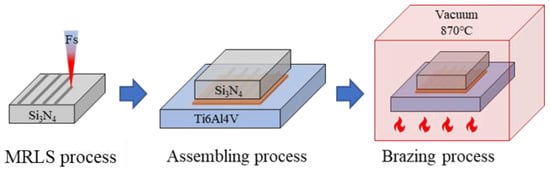

Figure 1 shows the laser scanning path. The scanning path was set along with the brazing direction, and the path was set to reciprocating to improve the processing efficiency. The distance between two adjacent paths was Δd. The optimal processing parameters were as follows: line spacings of 0.01 mm and 0.1 mm, frequency of 50 kHz, scan speed of 50 mm/s, pulse width of 50 fs, and duty cycle of 50%. The roughness was measured by an optical scanning 3D profiler (Sensofar S neox).

Figure 1.

Schematics of MRLS fabrication and brazing process.

2.2. Brazing and Performance Characterization

The samples to be brazed were assembled as shown in Figure 1, and then placed in a vacuum furnace. The operation program was set according to the brazing curve, and the temperature was increased to 800 °C at a rate of 10 °C/min and held for 5 min. The samples were then heated to a brazing temperature of 870 °C at a rate of 10 °C/min, held for 10 min, and finally cooled in a furnace. During the brazing process, the vacuum degree was maintained at 1~7 × 10−3 Pa. The shear strength was used to evaluate the mechanical properties of the joints.

3. Results and Discussion

3.1. Laser-Textured Surface Microstructure

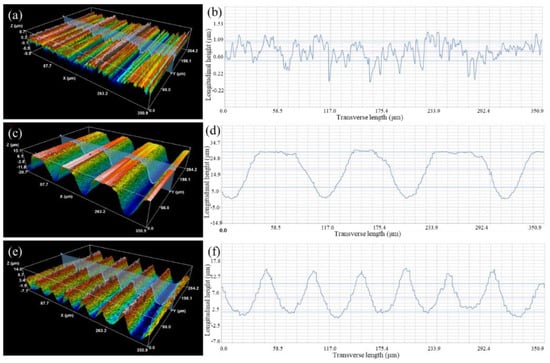

Figure 2 shows the three-dimensional morphology and roughness of the Si3N4 ceramic surface texture. The MRLS was obtained at a laser power of 110 W; line spacings of 100 μm (loose type) and 50 μm (dense type); and the corresponding trench structures were loose and dense, respectively.

Figure 2.

Surface profile shape curve of silicon nitride: (a,b) pristine surface; (c,d) loose surface; and (e,f) dense surface.

The surface of the pristine Si3N4 was relatively flat and had evident stripes with a small roughness (0.18 μm, as shown in Figure 2a). Figure 2b shows the loose groove-like texture on the surface after laser processing, with a line spacing of 100 μm. The grooves were large, the depth reached 35.79 μm, and the roughness increased to 9.83 μm. During laser texturing, the line spacing was larger than the width of a single ridge, and the micro–nano structures, formed on the previous path, were not etched in the next round of laser scanning. Figure 2c shows the formation of a dense, groove-like, textured surface with parallel, ridge-like protrusions, and the width of a single protrusion was approximately 100 μm. The center line of the ridge-like protrusion coincided with the scanning path of the laser, in which the tiny grooves and larger grooves constituted a “light trap” structure. During laser texturing, the Si3N4 surface quickly absorbed heat and melted, and small holes with large aspect ratios were thus formed. The pressure generated by the steam in the small holes squeezed the vaporized Si3N4 to move to both sides and form ridged protrusions after solidification (Figure 3f,i). The roughness was 3.71 μm, and the groove depth reached 21.11 μm.

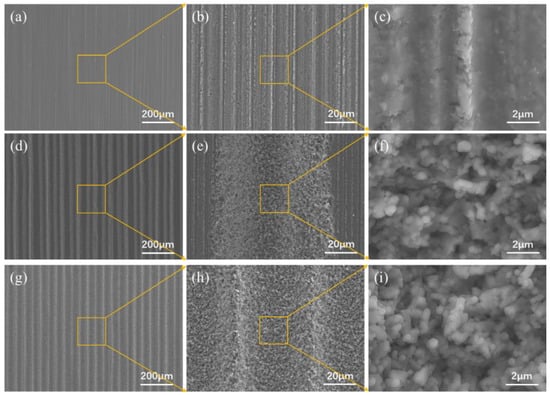

Figure 3.

MRLS microstructure of Si3N4: (a) pristine surface; (b) groove of pristine surface; (c) microstructure and roughness of pristine surface; (d) loose surface; (e) high magnification of loose surface after laser processing; (f) nanoparticles of loose surface; (g) dense surface; (h) high magnification of dense surface after laser processing; and (i) nanoparticles of loose surface.

As can be seen from the pristine Si3N4 shown in Figure 3a–c, its surface is relatively flat, with evident stripes, and small surface roughness; further, Figure 3b shows the microscopic topography formed on the loose groove-like surface. Laser-ablated Si3N4 has an affected width of approximately 40 μm. Figure 3c shows the profile curve of a single ridge and a small groove in the middle texture. The entire curve was regular, exhibiting a “V” shape. The height of the two upward growing columnar protrusions was 21.11 μm, and the gap was approximately 60 μm. The tiny grooves and larger width grooves constituted a light trap structure.

Groove structures of two different sizes were observed using SEM; Figure 3 shows the results. Owing to the induction mechanism (of ultra-short pulses) of the femtosecond laser, numerous nano-substructures, covering the entire surface of the microgrooves, appeared on the surface of the microscale grooves [22]. The nano-substructures were nanoparticles with sizes ranging from tens to hundreds of nanometers, exhibiting a coral-like structure after agglomeration. In the following brazing work, these nanoparticles were expected to provide a large number of nucleation sites for the solidification of the liquid solder, due to its high surface activity [23]. Notably, the nanoparticle cluster structure showed porous characteristics, which further improved the surface roughness of the hierarchical structure. In addition, the grooves were not very homogeneous, but the uniformity of the texture did not have an obvious effect on the wetting.

3.2. Performance Improvement of Brazed Joints by Textured Surfaces

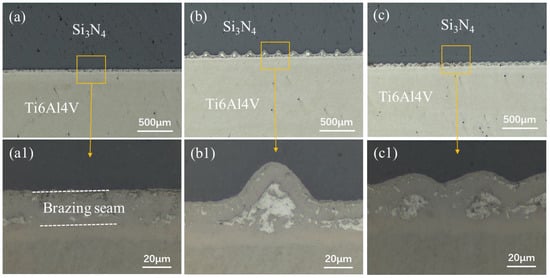

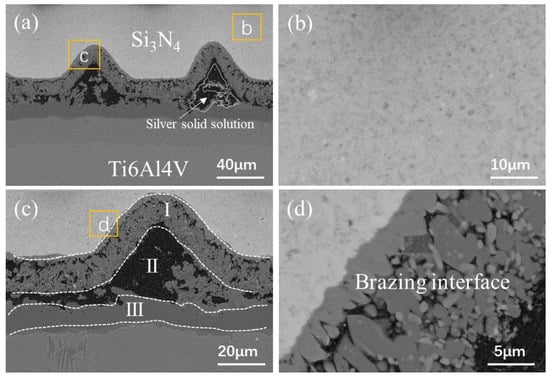

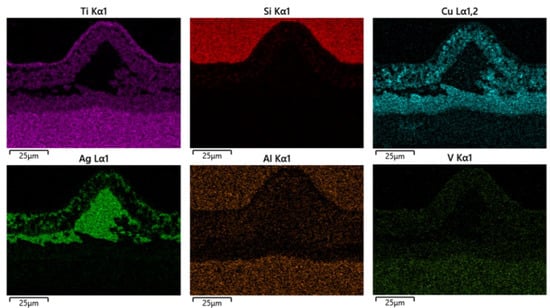

The MRLS was designed to improve the mechanical properties of Si3N4–titanium alloy joints and to reduce the joining defects. Figure 4 shows the typical interface structure of the joint obtained by brazing Si3N4 under a brazing temperature of 870 °C and a holding time of 10 min as the process parameters, and using MRLS to assist the AgCuTi braze filler. After brazing, there were no hole defects at the brazing interface, and the formation was good. Based on the microstructural distribution characteristics of the brazing seam interface, the interface of the brazed Si3N4–titanium alloy joint was divided into three regions: I, II, and III, and the overall width of the brazing seam was approximately 25 μm, as shown in Figure 5. Regions I and III have the same organization, which is the interfacial reaction region near Si3N4 and the titanium alloy; further, region II is the center region of the brazing seam. Throughout the brazed joint, the MRLS remained intact and formed strong metallurgical bonds with the brazing filler metal. An enlarged view of Region I shows that the central region of the brazing joint contains a gray matrix and white dotted phases; additionally, the gray phases were tightly connected to Si3N4 and facilitated by nanoparticles. Based on the elemental analysis (Figure 6), the white phase is Ti–Cu, and the white dotted phase is the silver solid solution.

Figure 4.

Interfacial microstructure of brazed joints of Si3N4–titanium alloys with different surface structures: (a,a1) pristine surface; (b,b1) loose surface; and (c,c1) dense surface.

Figure 5.

Brazing interface of the Si3N4–titanium alloy joint with a loose surface: (a) low-magnification microstructure; (b) the microstructure of Si3N4; (c) low-magnification microstructure (the black area shows holes that are not filled, which should contain the silver solid solution); and (d) brazing interface.

Figure 6.

Elemental mapping of Si3N4–titanium alloy joint with a loose surface.

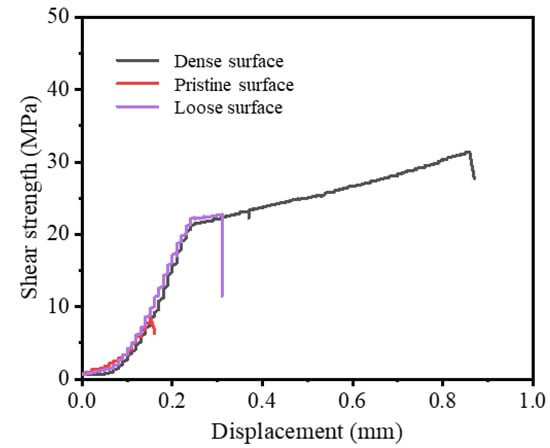

Figure 7 shows the force–displacement curves of the Si3N4–titanium alloy joints before and after the introduction of MRLS. The holding time was 10 min, the brazing temperature was 870 °C, and the room-temperature shear strength of the joint increased gradually. The maximum shear strength was only 10 MPa without the MRLS, and the joint strength improved significantly after the introduction of MRLS. When a dense structure was adopted, the strength increased by more than 300%. Interestingly, the displacement of the joint increased significantly during the shearing process with the introduction of the MRLS, indicating a considerable improvement in the impact resistance of the joint. Based on the texture characteristics of the MRLS, we believed that the large increase in shear displacement was attributed to the groove structure, which enhanced the mechanical interlocking ability between the brazing seam and Si3N4.

Figure 7.

Force–displacement curve of the brazed joint.

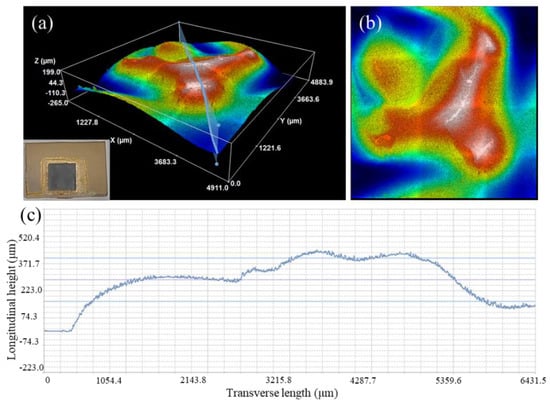

The above analysis showed that the shear strength of the brazed joints significantly improved after the introduction of the MRLS. When the AgCuTi filler was used for direct brazing, the joint broke on the Si3N4 side, indicating a high residual stress on this side after direct brazing, as shown in Figure 8. This was due to the significant differences in the thermal expansion coefficient between Si3N4 and the filler metal. At the same time, the shear strength of Si3N4 was low; therefore, it was damaged along the weak area under the action of an external force, resulting in a low shear strength of the joint.

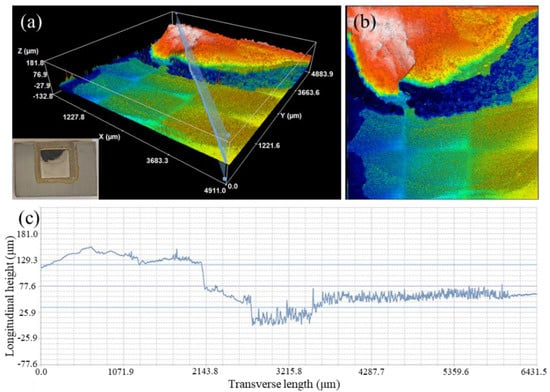

Figure 8.

Fracture morphology of the joint after direct brazing. (a) three-dimensional view of the fracture morphology, (b) top-view of the fracture morphology, (c) height profile on the cross-section in figure (a).

After the introduction of the MRLS, a small amount of AgCuTi remained on the fracture surface of the joint, indicating that a part of the brazed joint area was also fractured, as shown in Figure 9. The fracture path of the joint, after brazing with the MRLS, had changed significantly. The initial fracture position was still the edge position of Si3N4, near the interface. However, the crack no longer propagated only along the Si3N4 interior; instead, it passed through the interface reaction layer and the brazing seam area.

Figure 9.

Fracture morphologies of brazed joints after introducing the MRLS. (a) three-dimensional view of the fracture morphology, (b) top-view of the fracture morphology, (c) height profile on the cross-section in figure (a).

3.3. Simulation Analysis of Joint Residual Stress

To further verify the effect of the MRLS on the joint, the residual stress of the joint was simulated using ABAQUS software. The strengthening mechanisms of the joint were revealed by comparing the magnitude and distribution of the joint residual stress with and without the MRLS.

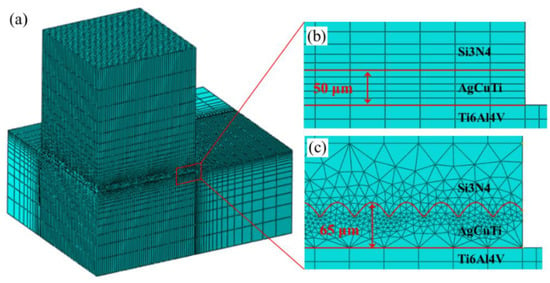

A finite element analysis (FEA) was performed according to the theory of thermoelasticity and plasticity. ABAQUS software was used to simulate the residual stress field of the brazed joint during cooling and the temperature was reduced from 870 °C to 20 °C. Since the static implicit analysis step was used to solve the problem, the simulation time had no effect on the simulation results. The grid division module used C3D8R cell type. The original sample had 133,740 cells and 143,027 nodes; the dense groove joint sample had 361,176 units and 472,474 nodes. It has been assumed that only elastic deformation occurred in Si3N4, and elastic–plastic deformation occurred in the brazing layer. The various performance parameters of materials required for the finite element calculation can be found in the literature [24,25,26]. To directly relate the residual stress to the shear strength, a finite element mesh was drawn with the size of the actual shear specimen. The sizes of the Si3N4 and titanium alloy were 5 × 5 × 3 mm3 and 15 × 10 × 3 mm3, respectively. In consideration of the distribution characteristics of the residual stress of the brazed joints, a nonuniform mesh division of the brazed joints was performed. The meshes in the area near the interface, between the brazed joint and the base metal, were relatively dense, which therefore improved the accuracy of the simulation results. Figure 10 shows these meshes.

Figure 10.

(a) Si3N4–titanium alloy joint model, (b) pristine surface, and (c) dense surface of the brazed joint.

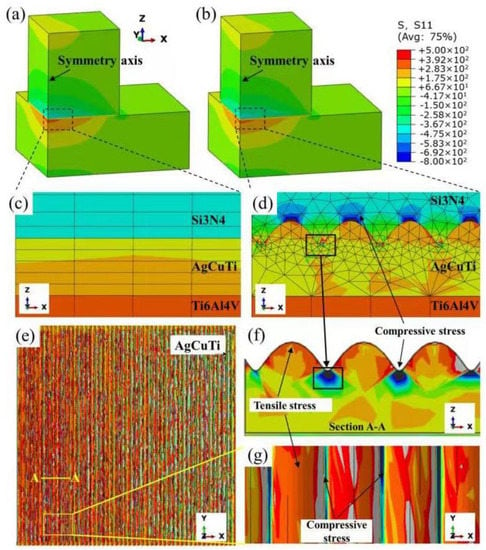

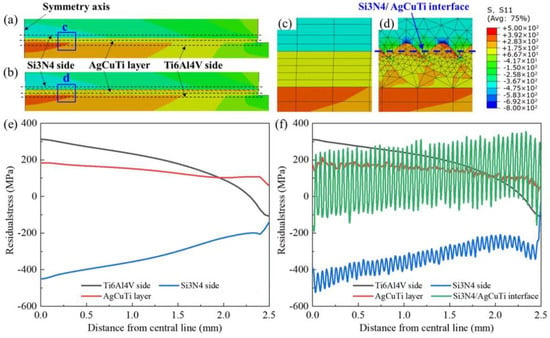

The initial condition considered for the finite element simulation was that the filler was a liquid before the temperature dropped to the solidification temperature of the brazing joint. Further, the residual thermal stress generated at this stage was not considered. Figure 11 shows the von Mises equivalent residual stress distribution of the brazed joint, and the corresponding residual stress distribution curve is shown in Figure 12.

Figure 11.

(a) Distribution cloud diagram of the residual stress τzx in the pristine surface, (b) dense surface joint, (c) pristine surface, (d) local enlarged view of the dense surface joint, (e) AgCuTi in the dense surface joint residual stress distribution, (f) corresponding local cross-section, and (g) surface stress state.

Figure 12.

(a) Pristine surface, (b) residual stress τzx results of the dense surface joint and the schematic of the extraction position, (c,d) partially enlarged views, (e) pristine surface, and (f) residual stress distribution curve of the dense surface joint.

For the joints directly brazed with AgCuTi, an evident stress concentration formed in the brazing seam, as shown in Figure 11 and Figure 12. There was also a stress concentration phenomenon at the corners of Si3N4; however, it was much lower than that of the brazing joint. These two locations in the joint are prone to the initiation and propagation of cracks. The internal stresses of the upper Si3N4 and lower titanium alloy were symmetrically distributed; however, the residual stress value of Si3N4 near the seam was higher. Therefore, it is more likely to break from Si3N4 when close to the brazing seam.

After the introduction of the MRLS, the stress of the joint did not increase; instead, a stress transition region was formed, which avoided any instantaneous change in stress and improved the toughness of the joint. In addition, although it was judged that the residual stress had not significantly improved on the whole, it was proven that the introduction of the MRLS structure did not damage the joint; therefore, the advantages of the MRLS structure outweigh the disadvantages.

The ceramic side of the joint was subjected to tensile and shear stresses that were directed toward the center, and the joint was also subjected to compressive and shear stresses. Si3N4 is prone to cracks under the composite state of tensile and shear stress. Therefore, cracks initiated near the brazing seam. During the crack propagation process, it was noted that the compressive stress hindered crack propagation. Combining the finite element analysis, cross-sectional topography after joint fracture, and load–time curve, it was found that the MRLS not only improved the mechanical and brazing area at the interface, but also produced a compressive stress on the ceramic side. This hindered the expansion of cracks, thereby playing a significant role in improving the joint strength.

4. Discussion

The MRLS design strategy was implemented in brazing in order to significantly increase joint strength. In this work, the groove array structure, which was fabricated by a femtosecond laser, was uniformly distributed on the Si3N4 surface, resulting in a significantly increased surface area. Under the action of laser ablation, a large number of nanoparticles were fully covered on the groove surface (see Figure 3). During brazing, these nanoparticles provide nucleation points for the solidification of the liquid solder, resulting in a dense interface connection (see Figure 5). This excellent interface connection, combined with mechanical interlocking, significantly improved the shear resistance of the joint. Residual stress was an unavoidable problem in brazing the connection, as this was derived from the huge physical differences (such as the linear expansion coefficient and elastic modulus), between the ceramics and metals. In severe cases, the ceramic side directly broke due to excessive internal stress (Figure 8). The introduction of a groove structure created a stress transition zone between the metal and ceramic. This, therefore, reduced the risk of direct fracture in the ceramic, thereby shifting the load capacity from brittle ceramics to the high-quality brazing seams (Figure 9). The finite element analysis showed that the periodicity of compressive stress along the interface further inhibited crack propagation. In summary, the MRLS induced a composite effect of dense interface, mechanical occlusion, and stress transition, which, taken together, promoted the bonding strength of the brazed joints.

5. Conclusions

- (1)

- The MRLS was obtained at a laser power of 110 W, with line spacings of 100 and 50 μm. A number of nanoparticles was formed during laser processing, with particle sizes ranging from tens to hundreds of nanometers, exhibiting a coral-like structure after agglomeration.

- (2)

- After brazing with the MRLS, there were no defects at the brazing interface, and the formation was good. The interface of the brazed Si3N4–titanium alloy joint was divided into three regions, and the central zone of the joint contained a gray Ti–Cu matrix, and a silver solid solution.

- (3)

- The joint strength was significantly improved with the implementation of the MRLS, and the displacement of the joints increased significantly during the shearing process. After brazing with the MRLS, the fracture path changed significantly, and the maximum shear strength reached about 35 MPa. The periodic microgrooves on the surface not only improved the mechanical occlusion and brazing area at the interface, but also generated compressive stress on the Si3N4 side.

Author Contributions

Conceptualization, J.-G.H.; methodology, S.-J.D.; software, Y.Z.; validation, J.-G.H. and Y.L.; formal analysis, S.-J.D.; investigation, S.-J.D.; resources, J.-G.H.; data curation, J.-G.H.; writing—original draft preparation, J.-G.H.; writing—review and editing, J.-Q.Y., L.-W.F. and W.-Q.G.; visualization, J.-Q.Y. and Y.T.; supervision, Y.-F.M. and M.H.; project administration, Y.-F.M. and M.H.; and funding acquisition, J.-G.H. and Y.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Instrument Developing Project of the Chinese Academy of Sciences, grant number YJKYYQ20200047, YJKYYQ20210028; the Science and Disruptive Technology Project of the Aerospace Information Research Institute, Chinese Academy of Sciences, grant number E2Z204010F; and the Shaanxi Provincial Key Research and Development Program, grant number 2018ZDZX01-03-01.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fünfschilling, S.; Fett, T.; Hoffmann, M.; Oberacker, R.; Schwind, T.; Wippler, J.; Böhlke, T.; Özcoban, H.; Schneider, G.; Becher, P.; et al. Mechanisms of toughening in silicon nitrides: The roles of crack bridging and microstructure. Acta Mater. 2011, 59, 3978–3989. [Google Scholar] [CrossRef]

- Petzow, G.; Herrmann, M. Silicon nitride ceramics. In High Performance Non-Oxide Ceramics II; Springer: Berlin/Heidelberg, Germany, 2002; pp. 47–167. [Google Scholar]

- Klemm, H. Silicon Nitride for High-Temperature Applications. J. Am. Ceram. Soc. 2010, 93, 1501–1522. [Google Scholar] [CrossRef]

- Loehman, R.E.; Tomsia, A.P.; Pask, J.A.; Johnson, S.M. Bonding Mechanisms in Silicon Nitride Brazing. J. Am. Ceram. Soc. 1990, 73, 552–558. [Google Scholar] [CrossRef]

- Guo, W.; Li, K.; Zhang, H.; Zhu, Y.; Shen, X.; Zhang, L.; Sun, H.; Zhong, S.; Long, W. Low residual stress C/C composite-titanium alloy joints brazed by foam interlayer. Ceram. Int. 2022, 48, 5260–5266. [Google Scholar] [CrossRef]

- Gui, X.; Zhang, M.; Xu, P.; Liu, G.; Guo, Q.; Zhang, X.; Meng, H.; Qiao, G. Experimental and theoretical study on air reaction wetting and brazing of Si3N4 ceramic by Ag-CuO filler metal: Performance and interfacial behavior. J. Eur. Ceram. Soc. 2022, 42, 432–441. [Google Scholar] [CrossRef]

- Blugan, G.; Kuebler, J.; Bissig, V.; Janczak-Rusch, J. Brazing of silicon nitride ceramic composite to steel using SiC-particle-reinforced active brazing alloy. Ceram. Int. 2007, 33, 1033–1039. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, H.; Ma, K.; Zhu, Y.; Zhang, H.; Qi, B.; Li, F.; Peng, P. Reactive brazing of silicon nitride to Invar alloy using Ni foam and AgCuTi intermediate layers. Ceram. Int. 2019, 45, 13979–13987. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, G.; Wu, S.; Alsaid, Y.; Zhao, W.; Yan, X.; Liu, L.; Zou, G.; Lv, J.; He, X.; et al. Solar anti-icing surface with enhanced condensate self-removing at extreme environmental conditions. Proc. Natl. Acad. Sci. USA 2021, 118, e2100978118. [Google Scholar] [CrossRef]

- Gurevich, E.L. Mechanisms of femtosecond LIPSS formation induced by periodic surface temperature modulation. Appl. Surf. Sci. 2016, 374, 56–60. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Krüger, J. Laser-induced periodic surface structures (LIPSS). In Handbook of Laser Micro-and Nano-Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–59. [Google Scholar]

- Zhang, D.; Liu, R.; Li, Z. Irregular LIPSS produced on metals by single linearly polarized femtosecond laser. Int. J. Extreme Manuf. 2021, 4, 015102. [Google Scholar] [CrossRef]

- Song, J.; Xu, W.; Feng, Z.; Liu, X.; Lu, Y.; Sun, J. Fabrication of Low-Adhesive Superhydrophobic Al Surfaces via Self-Assembled Primary Cell Assisted Etching. J. Dispers. Sci. Technol. 2013, 34, 908–913. [Google Scholar] [CrossRef]

- Martínez-Calderon, M.; Rodríguez, A.; Dias-Ponte, A.; Morant-Miñana, M.C.; Gómez-Aranzadi, M.; Olaizola, S.M. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl. Surf. Sci. 2016, 374, 81–89. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Fu, L.; Feng, M. Effects of surface microstructure on the active element content and wetting behavior of brazing filler metal during brazing Ti3SiC2 ceramic and Cu. Vacuum 2018, 156, 256–263. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Miao, L.; Fu, L. Effects of laser-textured surface pattern on the wetting behavior and composition optimization of brazing filler: Experimental study and numerical simulation. Appl. Phys. A 2019, 125, 879. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Li, Y.; Li, W.; Chen, J.; Shen, L.; Zhang, P.; Yu, Z. Wetting and spreading behaviors of Al-Si alloy on surface textured stainless steel by ultrafast laser. Appl. Surf. Sci. 2020, 520, 146316. [Google Scholar] [CrossRef]

- Pardal, G.; Meco, S.; Dunn, A.; Williams, S.; Ganguly, S.; Hand, D.P.; Wlodarczyk, K.L. Laser spot welding of laser textured steel to aluminum. J. Mater. Process. Technol. 2017, 241, 24–35. [Google Scholar] [CrossRef]

- Zhang, Y.; Zou, G.; Liu, L.; Wu, A.; Sun, Z.; Zhou, Y. Vacuum brazing of alumina to stainless steel using femtosecond laser patterned periodic surface structure. Mater. Sci. Eng. A 2016, 662, 178–184. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Wang, Y.F.; Feng, J.C. Effect of Si3N4-particles addition in Ag–Cu–Ti filler alloy on Si3N4/TiAl brazed joint. Mater. Sci. Eng. A 2011, 528, 5135–5140. [Google Scholar] [CrossRef]

- Xiong, J.; Li, J.; Zhang, F.; Lin, X.; Huang, W. Direct joining of 2D carbon/carbon composites to Ti–6Al–4V alloy with a rectangular wave interface. Mater. Sci. Eng. A 2008, 488, 205–213. [Google Scholar] [CrossRef]

- Fan, P.; Bai, B.; Zhong, M.; Zhang, H.; Long, J.; Han, J.; Wang, W.; Jin, G. General Strategy toward Dual-Scale-Controlled Metallic Micro–Nano Hybrid Structures with Ultralow Reflectance. ACS Nano 2017, 11, 7401–7408. [Google Scholar] [CrossRef]

- Tang, Y.; Li, G.; Pan, Y. Effects of TiO2 nanoparticles addition on microstructure, microhardness and tensile properties of Sn–3.0Ag–0.5Cu–xTiO2 composite solder. Mater. Des. 2014, 55, 574–582. [Google Scholar] [CrossRef]

- Wang, H.; Cao, J.; Feng, J. Brazing mechanism and infiltration strengthening of CC composites to TiAl alloys joint. Scr. Mater. 2010, 63, 859–862. [Google Scholar] [CrossRef]

- Wang, T.; Ivas, T.; Lee, W.; Leinenbach, C.; Zhang, J. Relief of the residual stresses in Si3N4/Invar joints by multi-layered braze structure—Experiments and simulation. Ceram. Int. 2016, 42, 7080–7087. [Google Scholar] [CrossRef]

- He, Y.; Zhang, J.; Pan, F.; Liu, C.; Li, X. Uncovering the critical factor in determining the residual stresses level in Si3N4–GM filler alloy–42CrMo joints by FEM analysis and experiments. Ceram. Int. 2013, 39, 709–718. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).