Abstract

A new non-dispersive, anti-washout grout consisting of ordinary Portland cement, slag, superplasticizer, and methylbenzyl cellulose is proposed herein for the treatment of open karst, jointed and fractured rock, open-work gravel, and permeable sediments. A series of laboratory experiments were performed to design an anti-wash out grout suitable for grout injection of coarse aggregates depicting partially and open-jointed saturated rock mass and grouting concrete aggregates for underwater construction. The Taguchi orthogonal array was used to obtain nine different grout mix ratios. A total of four variables were considered, each with three different levels of the water–cement ratio, slag, and dosage of additives such as the superplasticizer and methyl benzyl cellulose. The laboratory determination of grout characteristics recording of mini slump, temperature, pH, visual assessment of grout dispersion, bleeding, and initial setting time and as well as uniaxial compressive strengths and permeabilities of the hardened grout samples were tested. To evaluate the suitability of the grout mixes, an analysis of variance was used for factor analysis and Grey relational analysis (GRA) was used to determine the optimal grout mix design. Based on the GRA, the following levels of the factors afforded the best results: water level 1 (0.3%), SP level 3 (0.01%), methylbenzyl cellulose level 2 (0.002%), and slag level 3 (0.1%). This paper describes the research methodology, detailed research observations, and analyses involved in designing the appropriate concrete mix. Based on the conclusions, relevant commendations regarding the suitability of grout testing equipment and grout mix designs are presented.

1. Introduction

The present research deals with the investigation of formation of sinkholes near Jangseong limestone mine. However, the limestone formation, as evidenced in the mine providing raw material for manufacture of cement, is already karstic, containing partially infilled cavities and open voids in limestone.

As result of phased investigations comprised of satellite imagery, mapping of sinkholes, borehole drilling, and piezometric observations, it became evident that sinkholes are largely formed by aggressive groundwater movement dissolving limestone as it percolates along joints and fractures. Relatively high gradient in the groundwater table reflects significant water flow towards the nearby river. A numerical analysis modelling multiple level of limestone extraction in the mine indicated that the sinkholes are not directly related to the mining activity. Investigations into previous grouting treatment in the mine to reduce water inflow showed that the normal OPC cement grout was not effective, because this type of grout has long setting and hardening time and is also prone to dispersion and erosion.

Grouting is a geotechnical process that involves injecting a chemical grout to fill cracks or voids in the rock mass or coarse-grained soil. Cement is the most common and major ingredient in grouts. It is necessary to understand the rock conditions and properties before initiating grouting [1,2]. Both the soil formation and grout characteristics should be considered when choosing the grout. Therefore, permeability testing of the rock mass or soil must be performed. Furthermore, the rock cores and particle size distribution of soils must be analyzed. For long-term durability, the grout must have low sedimentation, resistance to wash out, good flow properties, early strength gain, and compatibility with the surrounding environment [3]. The most commonly used grout consists of cement and water, along with additives that improve workability and applicability. When the voids are large and easy to penetrate, fillers are used to increase the bulk of the grout mix. The filler properties also influence grout strength. Generally, grout strength is not a major concern provided the grout is not erodible and its strength is not significantly low (<8~12 MPa). Sand is a cheap filler but requires care to avoid segregation. Clays, including bentonite, can be used as grout fillers or as a grout on their own; however, clays are costly and require careful mixing and agitation prior to injection in order to maintain workability and have low compressive strength upon hardening.

A detailed literature review was carried out to determine the state of art development of non-dispersive grouts for use in void and cavity filling and use in underwater construction. Based on the previous examples and case histories, a series of laboratory grouting trials were performed to meet the non-dispersive grouts’ requirements.

The main grout parameters were selected using Taguchi orthogonal array to obtain nine different grout mix ratios. A total of four variables were considered, each with three different levels of the water–cement ratio, slag, and dosage of additives such as the superplasticizer and methyl benzyl cellulose. The laboratory determination of grout characteristics were based on recording of mini slump, temperature, pH, visual assessment of grout dispersion, bleeding, and initial setting time. Uniaxial compressive strengths and permeabilities of the hardened grout samples were evaluated as well. To evaluate the suitability of the grout mixes, an analysis of variance was used for factor analysis and Grey relational analysis (GRA) was used to determine the optimal grout mix design. Based on the GRA, the following levels of the factors afforded the best results: water level 1 (0.3%), SP level 3 (0.01%), methylbenzyl cellulose level 2 (0.002%), and slag level 3 (0.1%).

The laboratory testing of non-dispersive grout mixes led to an optimized, stable, non-dispersive and non-erodible grout mix with adequate workability and compressive strength requirements, which is proposed for field trials and use in underwater construction, filling of partially filled cavities and open voids, and treatment of jointed rock.

2. Literature Review

Li developed a new cementitious anti-washout grouting material (CIS), Cementitious grouts for Instant Sealing, which was prepared using ordinary Portland cement, water glass, and xanthan gum. The CIS grout offers the advantages of a short setting time, high early mechanical strength, high slurry viscosity, high slurry retention rate, and nontoxicity; the highest compressive strength achievable is 5 MPa. However, because of the low slump spread and setting time, long-distance pumping is not possible [4]. Jeff prepared anti-washout admixtures based on water-soluble polymers of various types for use in concrete placed underwater to minimize cement washout and ensure in-place concrete of satisfactory quality [5]. Cui made two anti-washout grouts using Portland cement, accelerating agents, and flocculating agents (cationic polyacrylamide, hydroxyethyl cellulose ether, underwater binder-II, and bentonite); two unnamed accelerating agents were also used. Two different grouts with a maximum slump spread of 60 mm were technically pumpable, featuring a maximum 28-day compressive strength of 13 MPa. This grout was developed to control water flow [6]. Various materials and admixtures have been introduced and used to control segregation and dispersion of cementitious materials. For instance, lignosulfonate was made in the 1920s and used as a concrete plasticizer biopolymer; lignite was established in the 1940s and used as a bentonite thinner biopolymer; Xanthan gum was introduced in the 1960s as a viscosity modifier biopolymer; melamine and naphthalene condensates were developed in 1962 and used as concrete superplasticizer synthetic polymers; cellulose ethers were introduced in the 1970s as water-retention agent biopolymers; vinylsulfonate copolymers were suggested in the 1980s and used as water-retention agents synthetic polymers; polycarboxylate copolymers were also put forward in the 1980s and used as concrete superplasticizer synthetic polymers; and polyaspartic acid was originated in the 1990s and used as a retarder biopolymer to increase the setting time of concretes and cementitious grouts [7]. Twenty different types of cellulose have been developed and used in various applications. In the construction field, cellulose has been used by various researchers for water retention, flowability, workability, strength, and non-dispersity. Hideo Tawara proposed an underwater, anti-washout, non-shrink grout using hydroxypropyl methylbenzyl cellulose [8]. Changmin initiated an anti-washout concrete mix for underwater use using methylbenzyl cellulose gum [9]. Bray tested cement additives for sealing gas channels and water wells [10]. Sahara used aggregates and methylbenzyl cellulose to reduce the flow of concrete [11]. In the present research, a wide-ranging DOE (design of experiments) study was adopted to develop a new type of cement-based, anti-washout grout. Tests were performed to study the effects of various constituents on the mini slump spread, permeability, compressive strength, pH, dispersion, and temperature. Grey relational analysis and the Taguchi design were used to obtain a simple and cost-effective method for the multiparametric optimization of cement grout mixes.

3. Grout Materials and Research Methodology

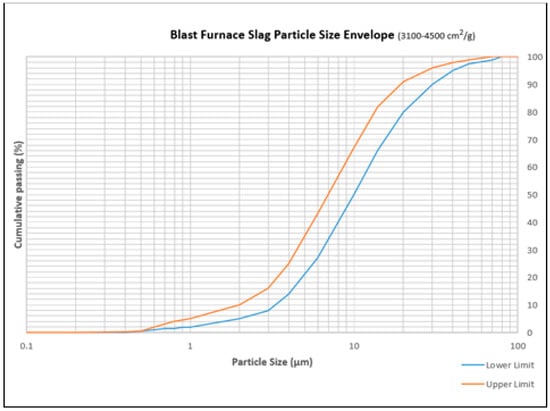

A new non-dispersive anti-washout grout consisting of ordinary Portland cement, slag, superplasticizer (Dongnam Flowmix 3000S, Bongam-dong, Korea), and VMA (methylbenzyl cellulose) is prepared. This grout is different from existing admixtures and viscosity modifiers such as micro-silica, nano-silica slurry, high molecular ethyl-enoxy derivate, natural polysaccaride, methyl cellulose, methyl propyl cellulose, and starch derivate. It is also different from other materials such as various types of accelerators, xanthan gum, clay, and HI-FA (High Performance and Multi-Functional Agent) materials. Blast furnace slag (BFS) is a calcium silicate based by-product produced from melted iron ore in the blast furnace. Typically, it is swiftly cooled to a glassy state and it is pulverized into various grades of fineness for the use as filler in the cementitious construction materials. BSF is widely used between 15–35% of cement content to control heat of hydration and for improvement in workability of cement without impairing its strength compressive strength. BSF has dormant hydraulic properties that allows its most communal application for being a cement additive and in concrete structures. This property allows its part in soil stabilization and in mortar for masonry. The chemical components of BSF are given in Table 1 and particle size distribution is given in Figure 1.

Table 1.

Chemical composition of BSF.

Figure 1.

Blast furnace slag (BSF) cumulative particle size distribution (3100–4500 cm2/g).

3.1. Selection of Target Permeability and Aggregates Size

The selection of the size of the aggregate was based on the permeabilities of jointed and open-jointed rocks. The permeabilities were 10−3 and 10−2 m/s, respectively. Therefore, 16-mm and 10-mm aggregates were selected for the open and jointed rocks, respectively. As depicted in Figure 2, sieve analysis was performed on 50% of each aggregate to confirm the average size of each aggregate. The results are listed in Table 2 and Table 3. After the sieve analysis, each aggregate was put into a model, as depicted in Figure 3.

Figure 2.

Sieve analysis for the aggregates.

Table 2.

Sieve analysis of coarse aggregate (16 mm).

Table 3.

Sieve analysis of fine aggregate (10 mm).

Figure 3.

Falling head permeability test equipment.

A falling head permeability test was performed, and permeability was determined using Equation (1). The permeabilities of the 16-mm and 10-mm aggregates were 10−2 and 10−3 m/s, respectively. It is necessary to determine permeability considering the actual rock/soil condition to ensure that aggregates with the appropriate permeability are used to design the most suitable grout in consideration of the actual conditions. After the target permeability was obtained, nine different grouts were designed and implemented using two types of aggregates in an underwater environment.

In the above-given equation, “k” is the coefficient of permeability (m/s), “a” is the diameter of the main model pipe (m), “L” is the total length of the sample present in the sample section (m), “A” is the cross-section of the sample (m), “t” is the time in which water drops from h1 height to h2 height, h1 and h2 are the water initial height and final height, respectively, and the log is base 10 logarithm.

3.2. Grout Preparation and Testing

To execute the grout, the following materials were used: superplasticizer, methylbenzyl cellulose-based viscosity modifying admixture, Portland cement, and water. To optimize the mixing ratios of the materials, the Taguchi orthogonal array was designed as in Table 4. Based on the Taguchi orthogonal array, nine grouts were prepared using the proportions listed in Table 5. The 28-day strength of each grout specimen and the target permeability of the aggregate were evaluated in an underwater environment. Subsequently, the mass permeability and strength were assessed. Using these outcomes, Grey relational analysis was used to obtain the most significant variables and optimal levels that improved the grout strength and other properties. The results were validated by directing assenting experiments that show good treaties with optimum design results.

Table 4.

Ratios of nine different grouts Taguchi orthogonal array L9 (4).

Table 5.

Mix proportions of the grouting materials.

Based on the Taguchi array, all grouts were first prepared and tested in the second phase, before implementing and testing them on the target aggregates. The following properties were checked: pH, temperature, bleeding, dispersion, mini slump spread, initial setting time, and compressive strength. For the pH and temperature, the OHAUS starter3100 (Seoul, Korea) was used immediately after preparation of each grout, as in Figure 4.

Figure 4.

OHAUS starter3100 for measuring pH and temperature.

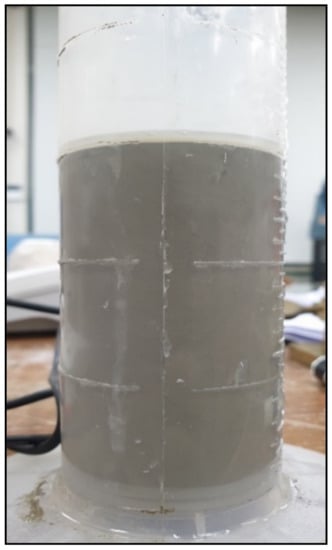

For the bleeding test, each grout mix was poured into a graduation cylinder. The bleeding percentage was measured 45 min later, as depicted in Figure 5.

Figure 5.

Method to test the bleeding of grout sample.

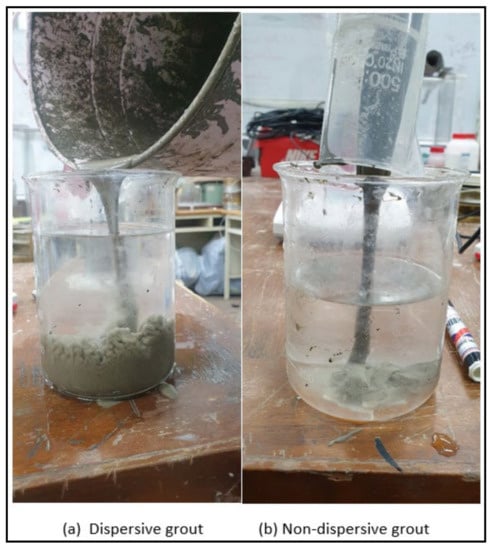

The dispersiveness of the grout samples was checked by pouring the grout into a water-filled beaker, as depicted in Figure 6.

Figure 6.

(a) Dispersive and (b) non-dispersive grouts testing.

Based on the standard 200 to 300 mm slump spread and the best flowable grout, for the mini slump spread, an open-ended flow cylinder with dimension of 75 mm × 150 mm was used to measure the spread of the grout [12]. The spread of the grout was measured along two directions, both perpendicular to each another, and the average of the spread was noted (see Figure 7).

Figure 7.

Mini slump spread measurement.

For the initial setting time, the Vicat apparatus (HD-102, Hyundai, Seoul, Korea) was used (as shown in Figure 8). The grout was tested after 1 h to obtain the results.

Figure 8.

Vicat apparatus for measuring initial setting time.

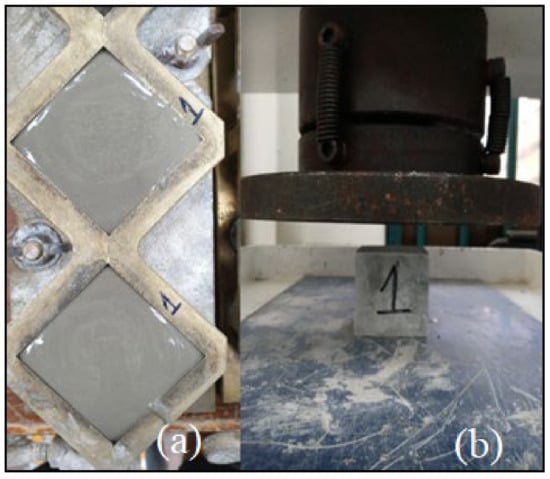

Compressive strength is an important factor. To test the compressive strength of the grout mixes, cubes samples were cast in bronze molds with dimensions of 50 × 50 × 50 mm3, as depicted in Figure 9. From the next day onward, the cubes were submerged in water for curing for 28 days. Thereafter, the mean strength values of the grouts were noted.

Figure 9.

(a) Grout casting in Bronze mold and (b) compression test.

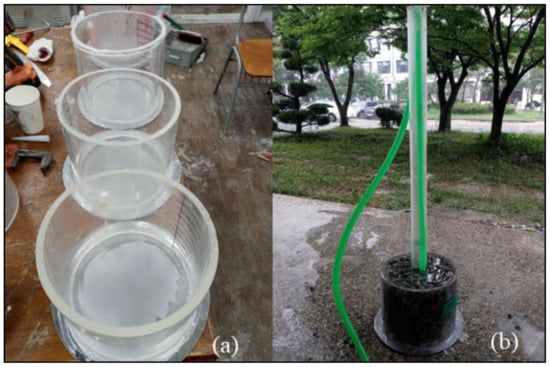

In the second phase of testing, each grout sample was added to the aggregate in the presence of water. Grout penetration was evaluated; after solidification, the sample was placed in water for seven days for curing, because a low 28-day strength was predicted based on ASTM D6103 [13]. Special molds with a diameter of 230 mm and length of 200 mm were prepared. The aggregate was placed into the molds after compaction. The molds were filled with water, and a 65-mm-diameter pipe was inserted through the aggregate to the base of the mold for injecting the grout, as shown in Figure 10.

Figure 10.

(a) Molds and (b) aggregate and water-filled mold.

Two samples of each grout type were prepared: one with the jointed rock permeability fine aggregate (10-mm) and the other with the open-jointed rock permeability coarse aggregate (16-mm). Thus, a total of 18 samples were prepared. After seven days of curing, the samples were dried, and a permeability test was performed. Each sample was placed underwater for one day at a maximum pressure of 1 MPa. Typically, pressure is maintained at 0.5 MPa, but it was increased to 1 MPa to reduce the test time from two days to one. Following a test as per the British standard BSEN 12390 [14], the maximum depth of the water penetration traces was measured. A sample of each grout mix was drilled, and two cylinders of each sample with fine and coarse aggregates were created using a rotary drill. A total of 36 samples were extracted, as depicted in Figure 11.

Figure 11.

(a) Samples for the mass strength, (b) test for permeability, (c) use of rotary drill to extract cylinders, and (d) extracted cylinders having 100 mm diameter and 200 mm length.

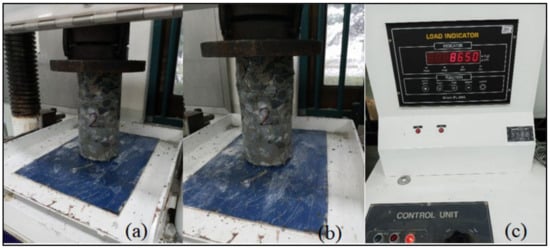

After the cylinders were prepared, their upper and lower faces were leveled using a precise core cutter, and 36 samples were tested in terms of their compressive strength (DYHU-100TC, Daeyeong Precision, Gunpo-si, Korea), as depicted in Figure 12. All the tests were performed as per the ASTM standard [15]. Each sample had a diameter of 100 mm and length of 200 mm.

Figure 12.

(a) Sample under compression, (b) failed sample, and (c) load indicator.

4. Use of Minitab and GRC Analysis for the Optimization, Results of Lab Experiments

4.1. Results of the Lab Experiments

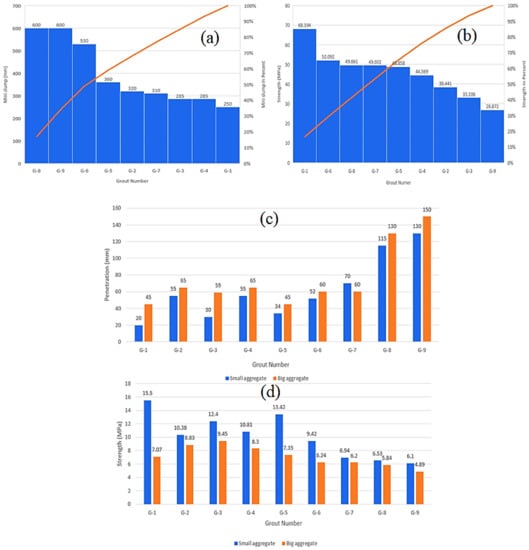

As discussed above, the following tests were performed on the cylinders with the coarse aggregates in the laboratory: mini slump spread (mm), initial setting time (min), dispersion (yes/no), bleeding (%), pH and temperature (°C), uniaxial compressive strength (UCS), for the cubes, and cylinders with fine and coarse aggregate. The results of these tests are listed in Table 6 and Figure 13.

Table 6.

Ratios of various constituents based on the Taguchi array.

Figure 13.

(a) Mini slump spread and (b) compressive strengths (MPa) of nine different grouts. (c) Mass permeability, water penetration depths, and (d) mass strengths of grout samples with fine and coarse aggregate.

Figure 13 depicts the histograms of mini slump spread, strength of the cubes, mass-strength of the samples with fine and coarse aggregates for nine different grout mixes, and water penetration depth. It revealed that Grout 1 exhibited the lowest mini slump spread, whereas Grouts 8 and 9 exhibited the highest mini slump spreads. The strength of Grout 1 was the highest, whereas Grout 9 had the lowest strength. Grout 1 had the lowest penetration depth of 20 mm for the fine aggregate, as compared with that of the coarse aggregates sample (45 mm). Grout 9 had the highest penetration depths of 130 and 150 mm for the fine and coarse aggregates, respectively.

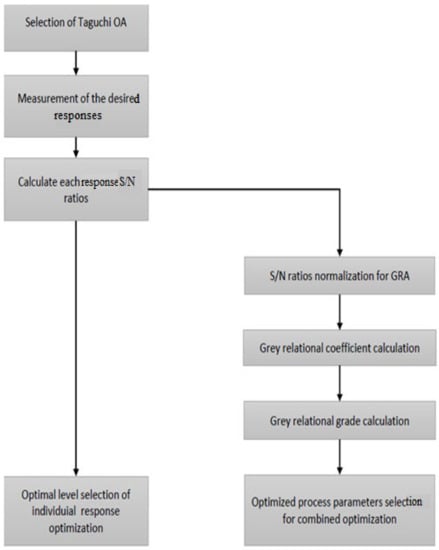

4.2. Use of Minitab and GRA

In this study, to obtain the design matrix, the Taguchi orthogonal array was used together with a restricted number of experiments for the parametric space. The experiments were performed based on the Taguchi orthogonal array design, which is used to optimize engineering problems. However, this process is suitable for single-parameter optimization [16]. Therefore, multiple responses cannot be addressed using the Taguchi method [17]. Consequently, researchers often use GRA with PCA for optimizing multiple responses instantaneously. This technique is different from the single-response optimization. This is an active statistical method and offers relatively effective results in obtaining a blend of parameters for the optimization of multiple responses. The concept of GRA-PCA is depicted in Figure 14.

Figure 14.

Concept of GRA-PCA.

The signal-to-noise (S/N) ratio for the larger the better criterion is calculated from Equation (2):

The S/N ratio for the smaller-the-better criterion is calculated from Equation (3), where x is the number of duplicates, and yij is the calculated observation:

The grouting process has multiple responses and the grouting quality depend strongly on optimizing all the responses instantaneously. GRA is commonly used by researchers, because statistical techniques can obtain better results for multiple-response optimizations [18]. In this study, the objectives were the maximization of the compressive strength and mini slump; therefore, a larger-the-better criterion is used for these excellence characteristics, and the regularized results are expressed using Equation (4):

However, bleeding, temperature, and initial setting time need to be minimized; to this end, the smaller-the-better criterion is used, as expressed in Equation (5):

where yj(q) is the Grey relational value, and max yi(q) and min yi(q) are the largest and smallest values of yj(q) for the observation of the qth response, respectively. The number of response variables was 4. The nine annotations of the trials are in sequence yi(q), j = 1, 2, …, 9.

A value of 1 is considered as the best normalized result; hence, the value of the normalized results is expected to be larger for accomplishing the best performance.

By calculating the Grey relational coefficients (GRC), data normalization is performed, which describes the relationship between desired and actual experimental normalized results.

For the expression of GRC, ξj(q) is determined as shown in Equation (6):

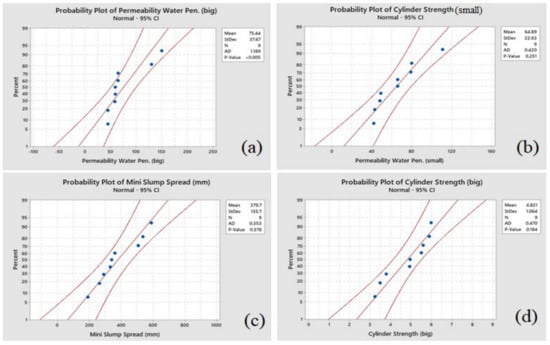

The distribution of the experimental data is measured using probability plots, as depicted in Figure 15 and Figure 16. The outlier detection from normality is evaluated using a powerful statistical tool called the Anderson Darling (ADT) test [19]. Figure 15 and Figure 16 depict that the experimental data for all responses are close to the fitted line, the ADT statistics are comparatively low, and the p-value of the test is more than 0.05. Hence, it is considered that the data follow a normal distribution. Further analyses and optimization can be performed using these results.

Figure 15.

Normal probability plot response for (a) initial setting time, (b) UCS of cubes (MPa), (c) bleeding %, (d) pH, (e) temperature (°C), and (f) permeability water penetration for fine aggregate sample.

Figure 16.

Normal probability plot for (a) permeability water penetration depth for coarse aggregates sample, (b) mass-cylinder strength with fine aggregates, (c) mini slump spread (mm), and (d) mass-cylinder strength with coarse aggregate.

In contrast, Δ0i(q)=│y*0(q) – y(q) represents the deviation sequence, which is the difference between the reference sequence y*0(q) and the comparability sequence y*j(q). The coefficient (ᶓ) takes values such as (0,1), which are set to 0.5 in this analysis [20].

The strength of the correlation between experimental runs is determined by the Grey relational grade (GRG), which is calculated using the mean weights of all the GRGs. (0,1) are the values between these GRG values.

Typically, a larger GRG for an experimental run is ideal, which demonstrates a strong correlation between the ideally normalized value and the corresponding experimental values.

When equal weights are chosen for the quality responses, Equation (7) is used to calculate the GRG [21]:

To study the main effects of the input parameters on individual responses, an analysis of variance (ANOVA) was performed at 95% confidence intervals.

For the mini slump, pH, bleeding, UCS of cubes, initial setting time, and compressive strength for the cylinders of coarse and fine aggregates, ANOVA results are listed in Table 7; a p-value less than 0.05 shows that the parameter is significant.

Table 7.

ANOVA results for mini slump, pH, bleeding, UCS of cubes, initial setting time, and compressive strength for the cylinders of coarse and fine aggregates.

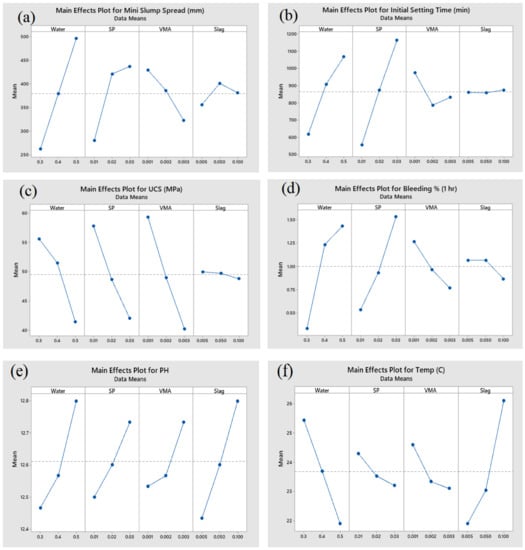

The mini slump spread was influenced the most by water (55.74%). When the water content increased or decreased, the mini slump spread also increased or decreased. The other influencing factors were SP (25.09%), VMA (11.65%), and slag (0.58%).

The initial setting time was affected the most by SP (59.95%), followed by water (32.81%), VMA (3.33%), and slag (0.04%). The UCS of the cubes was impacted the most by VMA (43.93%), followed by SP (29.84%), water (24.22%), and slag (0.18%). The significance order for bleeding was water (44.93%), SP (37.13%), VMA (9.28%), and slag (1.54%).

Furthermore, pH was affected the most by slag (38.22%), followed by water (31.51%), SP (15.44%), and VMA (11.34%). With regard to temperature, slag had the most significant impact (50.81%), followed by water (35.42%), VMA (6.38%), and SP (3.43%).

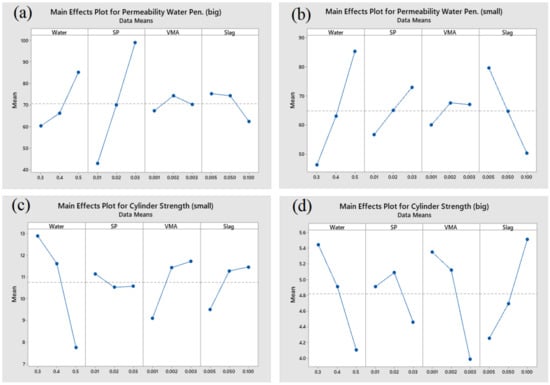

The permeability water penetration depth for the fine aggregate sample was influenced the most by water (55.69%), followed by slag (31.45%), SP (9.77%), and VMA (1.79%). The permeability water penetration depth for the coarse aggregates sample was influenced the most by SP (76.91%), followed by water (15.33%), slag (4.26%), and VMA (0.22%). The cylinder strength of the fine aggregates with lower permeability was influenced the most by water (62.91%), followed by VMA (16.26%), slag (8.80%), and SP (0.79%). Lastly, the cylinder strength of the coarse aggregates was impacted the most by VMA (31.04%), by water (29.84%), slag (26.64%), and SP (3.33%). The main effect plots are depicted in Figure 17 and Figure 18.

Figure 17.

Main effect of plots for (a) mini slump spread, (b) initial setting time, (c) UCS of cubes (MPa), (d) bleeding %, (e) pH, and (f) temperature.

Figure 18.

Main effect of plots for (a) permeability water penetration depth for coarse aggregate sample, (b) permeability water penetration depth for fine aggregate sample, (c) mass-cylinder strength with fine aggregate sample, and (d) mass-cylinder strength with coarse aggregate sample.

From the main effect plot for the mini slump, it can be concluded that there is a sharp increase in the slump when the water content increases. SP exhibits an almost identical trend.

Using the S/N ratio, each response is optimized. In this study, we used different objective functions for individual responses, such as maximization of the compressive strength, cylinder strengths for fine and coarse aggregates, and mini slump spread, and minimization of the temperature, pH, and penetration depth for fine and coarse aggregates samples. Therefore, the larger the better criterion is used for compressive strength, cylinder strengths for fine and coarse aggregates, and the mini slump spread, by using Equation (2). In contrast, the smaller-the-better criterion is used for temperature, pH, and penetration depth for fine and coarse aggregates samples, by using Equation (2).

Using these equations for the average S/N ratios of each response, optimal levels are obtained, as listed in Table 8. Good quality characteristics are represented by higher S/N ratios.

Table 8.

S/N ratios of response variables.

In Table 8, the highest S/N ratio of −24.94 is obtained for the mini slump spread, which designates that Grout 7 exhibited the optimized values for the mini slump spread. The ratio of −23.84 is obtained for the initial setting time, which specifies that Grout 5 had the optimized value for the initial setting time. Values of 37.41 and 13.48 for the UCS and bleeding, respectively, showed that Grout 1 produced the most optimized results. A bleeding value of 39.08 displays that Grout 6 exhibited the optimized value. With regard to temperature and water penetration depth, Grouts 9 and 3 showed the optimized results. For the cylinders with coarse and fine aggregates, Grouts 3 and 4 exhibited optimized levels, respectively.

All the steps involved in the multi-response optimization are depicted in Figure 14. The S/N ratios are normalized using Equations (4) and (5) and listed in Table 8 and Table 9. The Grey relational coefficient, listed in Table 10, was calculated using Equation (5). The response obtained via the GRC is listed in Table 11, which also shows the optimized levels of each factor.

Table 9.

Grey relational analysis for data normalization.

Table 10.

Grey relational coefficients.

Table 11.

Response table for average of GRG’s.

In Table 11, the optimized levels for the best grout are listed, where water level 1, SP level 3, VMA level 2, and level 3 for slag are the optimized levels. The mix design ratios are listed in Table 12. The results for the confirmatory optimal grout mix are listed in Table 13.

Table 12.

GRG optimal mix design.

Table 13.

Results for the confirmatory optimal grout.

5. Conclusions

In this study, laboratory experiments were performed to design a grout mix suitable for sealing underground water-filled karst cavities. The use of non-dispersible grout for filling karst cavities underwater is recommended to prevent grout washout under the flow of water. Many grout mixes, considering the target permeability of jointed rocks and open-jointed rocks, were tested, and the grout mix design suitable for implementation in actual environments was determined.

The key conclusions of this study on the optimal grout mix design can be summarized as follows:

- (1)

- This wide-ranging DOE study designed a new type of cement-based anti-washout grout. Laboratory tests were performed to study the effects of various constituents on mini slump spread, permeability, compressive strength, pH, dispersion, and temperature of the cement grout. The Grey relational analysis and Taguchi design of the joint experiments afforded a simple and cost-effective method for performing multiparametric optimization of cement grouts.

- (2)

- The main constituents of the proposed anti-washout grout as given in Table 12: (GRG Optimal Mix Design) are water, Portland cement, methylbenzyl cellulose, superplasticizer, and slag. The optimized proportions of these constituents for the best mini slump spread, yield stress, pH, dispersion, temperature, and permeability were as follows: 1% portion cement, 0.3% portion water, 0.1% portion slag, 0.03% portion SP, and 0.002% portion VMA. The optimized grout formula enabled strong anti-washout capacity, without dispersion, and a good setting time. Owing to the good fluidity of this mix using a low-pressure equipment, it can be used near and for deep subsurface targets.

- (3)

- Confirmatory experiments were performed to validate the results, which directed good agreement with the optimal grout mix. The optimized levels of mix constituents significantly increased the strength of the grout against water dilution, dispersion, segregation, and external bleeding. The addition of SP and methylbenzyl cellulose reduced the demand for water and helped to achieve a higher strength of 27 MPa, in addition to a low viscosity.

- (4)

- The results evidenced that Grey relational analysis is suitable for multi-objective optimization problems. Multi-objective ANOVA could obtain comparatively unimportant factors (p > 0.05) with respect to the prominent output responses. Some factors were insignificant for the rheological properties of the cement-based grout. Nevertheless, these insignificant factors can help adjust supplementary performances based on specific applications.

- (5)

- By determining the target permeability, as suggested in this research, researchers can optimize workability of grouts considering permeability and various hydraulic gradients in lab environments before using the grouts in the field.

- (6)

- The laboratory trials of the non-dispersive grout mixes presented in this paper were aimed to achieve an enhanced stable, non-dispersive and non-erodible grout mix with satisfactory workability and compressive strength properties. Site specific trials may be needed for further fine tuning of the proposed mix design, which is considered suitable for use in underwater construction, filling of partially filled cavities and open voids, and treatment of jointed rock.

Author Contributions

Conceptualization, K.B.; and H.-S.Y.; methodology, K.B.; software, J.-G.K. (Jong-Gwan Kim); validation, S.Q.B., J.-G.K. (Jong-Gwan Kim). and K.B.; formal analysis, K.B.; investigation, K.B.; resources, J.-G.K. (Jung-Gyu Kim); data curation, S.Q.B.; writing—original draft preparation, K.B.; writing—review and editing, S.Q.; visualization, S.Q.; supervision, H.-S.Y.; project administration, J.-G.K. (Jung-Gyu Kim).; funding acquisition, H.-S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- ASTM C109, Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens); American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2020.

- ASTM D 6103, Standard Test Method for Flow Consistency of Controlled Low Strength Material (CLSM); American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 1997.

- BSEN 12390, Testing Hardened Concrete. Making and Curing Specimens for Strength Tests; The British Standards Institution (BSI): London, UK, 2019.

- Bury, J.R.; Farzam, H. Laboratory evaluation of a unique anti-washout admixture in grouts. Spec. Publ. 1997, 173, 445–474. [Google Scholar]

- Cui, W.; Huang, J.; Song, H.; Xiao, M. Development of two new anti-washout grouting materials using multi-way ANOVA in conjunction with grey relational analysis. Constr. Build. Mater. 2017, 156, 184–198. [Google Scholar] [CrossRef]

- Eklund, D.; Stille, H. Penetrability due to filtration tendency of cement-based grouts. Tunn. Undergr. Space Technol. 2008, 23, 389–398. [Google Scholar] [CrossRef]

- Sahara, H.; Shoji, Y.; Hoshino, S.; Takeshita, H. Concrete Composition. Japan Patent No# JP2635884B2, 6 January 1992. [Google Scholar]

- Tawara, H.; Kamiya, K.; Inohana, H. Underwater Anti-Washout Non-Shrink Grout. Japan Patent No# JP2013249214A, 12 December 2013. [Google Scholar]

- Lang, A.; Plank, J. Optimization of comb-shaped polycarboxylate cement dispersants to achieve fast-flowing mortar and concrete. Appl. Polym. Sci. 2015, 132, 132–137. [Google Scholar] [CrossRef]

- Kim, U.G.; Cho, S.D.; Park, B.G.; Kim, J. Strength characteristics of the anti-washout grout mixed with coarse fill materials. J. Korean Geosynth. Soc. 2013, 12, 44–55. [Google Scholar] [CrossRef]

- Kurt, H.I.; Oduncuoglu, M.; Yilmaz, N.F.; Ergul, E.; Asmatulu, R. A Comparative Study on the Effect of Welding Parameters of Austenitic Stainless Steels Using Artificial Neural Network and Taguchi Approaches with ANOVA Analysis. Metals 2018, 8, 326. [Google Scholar] [CrossRef]

- Lombardi, G. The Role of Cohesion in Cement Grouting of Rock, 3rd ed.; Quinziéme Congres des Grands Barrages: Lausanne, Switzerland, 1985; pp. 33–60. [Google Scholar]

- Purwaningrum, Y.; Kusuma, P.L.T.; Darmawan, D. An Experimental Study on Effect of T-Joint’s Root Gap on Welding Properties. Appl. Mech. Mater. 2017, 863, 323–327. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Güllü, A. Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes 25. J. Clean. Prod. 2015, 91, 347–357. [Google Scholar] [CrossRef]

- Satheesh, M.A.; Pari, L. Antioxidant effect of Boerhavia diffusa leaves in tissue of alloxan induced diabetic rats. Indian J. Exp. Biol. 2004, 42, 989–992. [Google Scholar] [PubMed]

- Song, S.; Li, S.; Li, L.; Shi, S.; Zhou, Z.; Liu, Z.; Shang, C.; Sun, H. Model test study on vibration blasting of large cross-section tunnel with small clearance in horizontal stratified surrounding rock. Tunn. Undergr. Space Technol. 2019, 92, 103013. [Google Scholar] [CrossRef]

- Panda, S. Robust coordinated design of multiple and multi-type damping controller using differential evolution algorithm. Int. J. Electr. Power Energy Syst. 2011, 33, 1018–1030. [Google Scholar] [CrossRef]

- Stephens, M.A. EDF statistics for goodness of fit and some comparisons. J. Am. Stat. Assoc. 1974, 69, 730–737. [Google Scholar] [CrossRef]

- Wallner, M. Propagation of Sedimentation Stable Cement Pastes in Jointed Rock, 2nd ed.; Rock Mechanics and Waterways Construction; University of Aachen: Aachen, Germany, 1976; pp. 66–89. [Google Scholar]

- Bray, W.S.; Brandl, A. Use of Methylhydroxyethyl Cellulose as Cement Additive. U.S. Patent No# US8689870B2, 8 April 2014. [Google Scholar]

- Changmin, Z. Quick Coacervation Flocculant for Anti-Washout Concrete under Water. China Patent No# CN101289291A, 17 April 2007. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).