Microscale Cohesive-Friction-Based Finite Element Model for the Crack Opening Mechanism of Hooked-End Steel Fiber-Reinforced Concrete

Abstract

1. Introduction

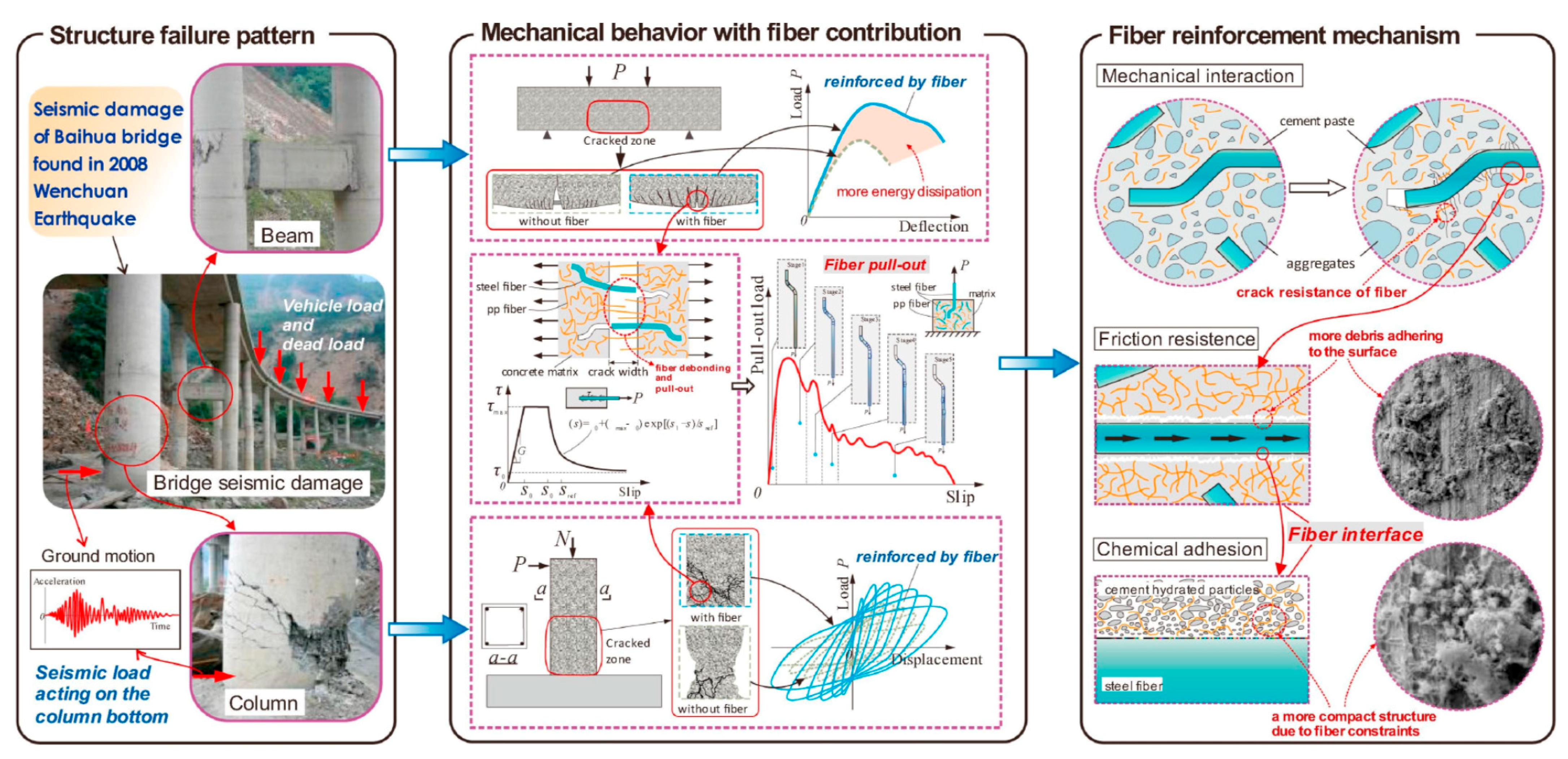

1.1. Background

1.2. Significance of the Study

1.3. Research Gap and Objectives

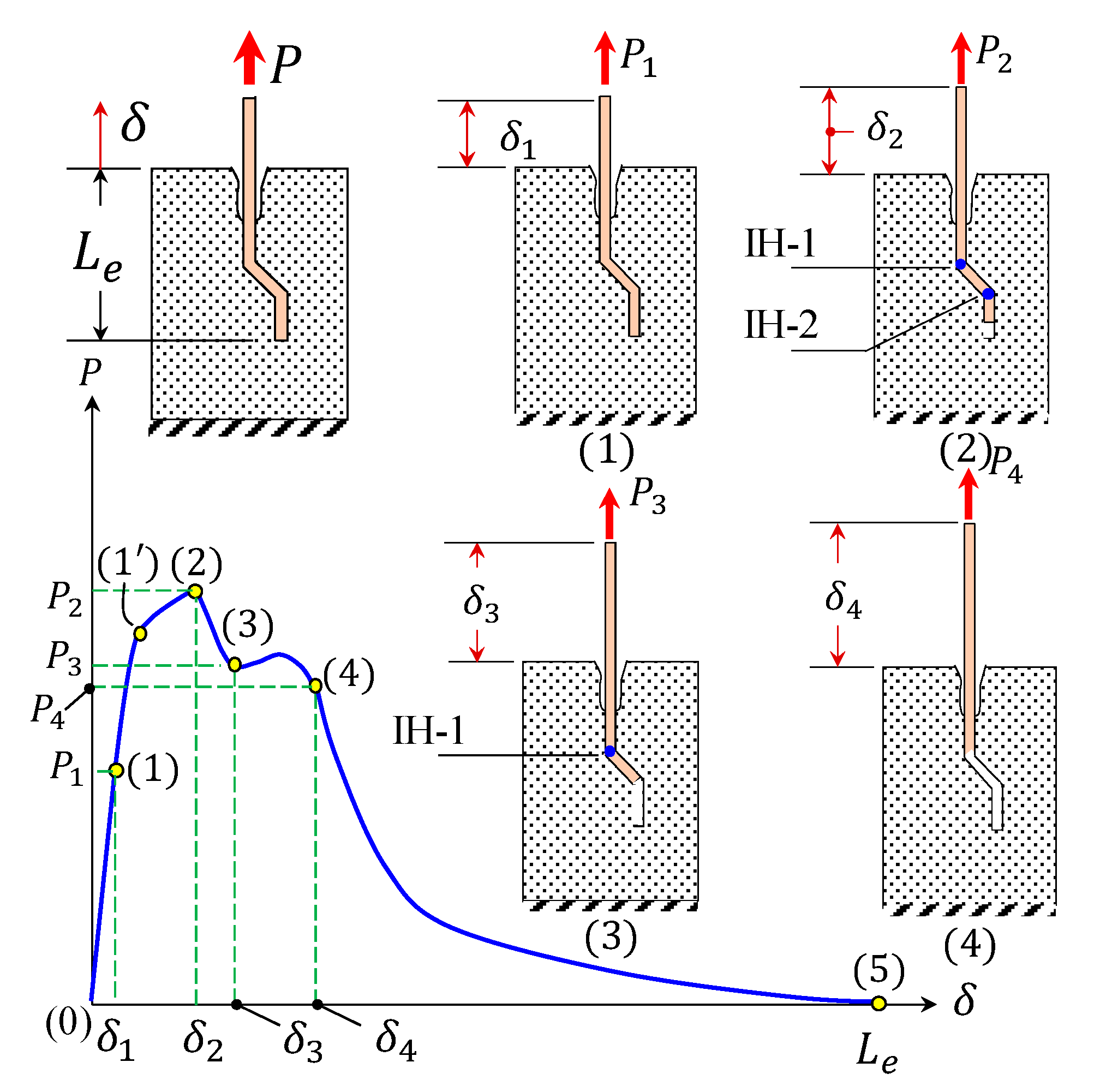

2. Pullout Response of Hooked-End Fibers

3. Finite Element Modeling

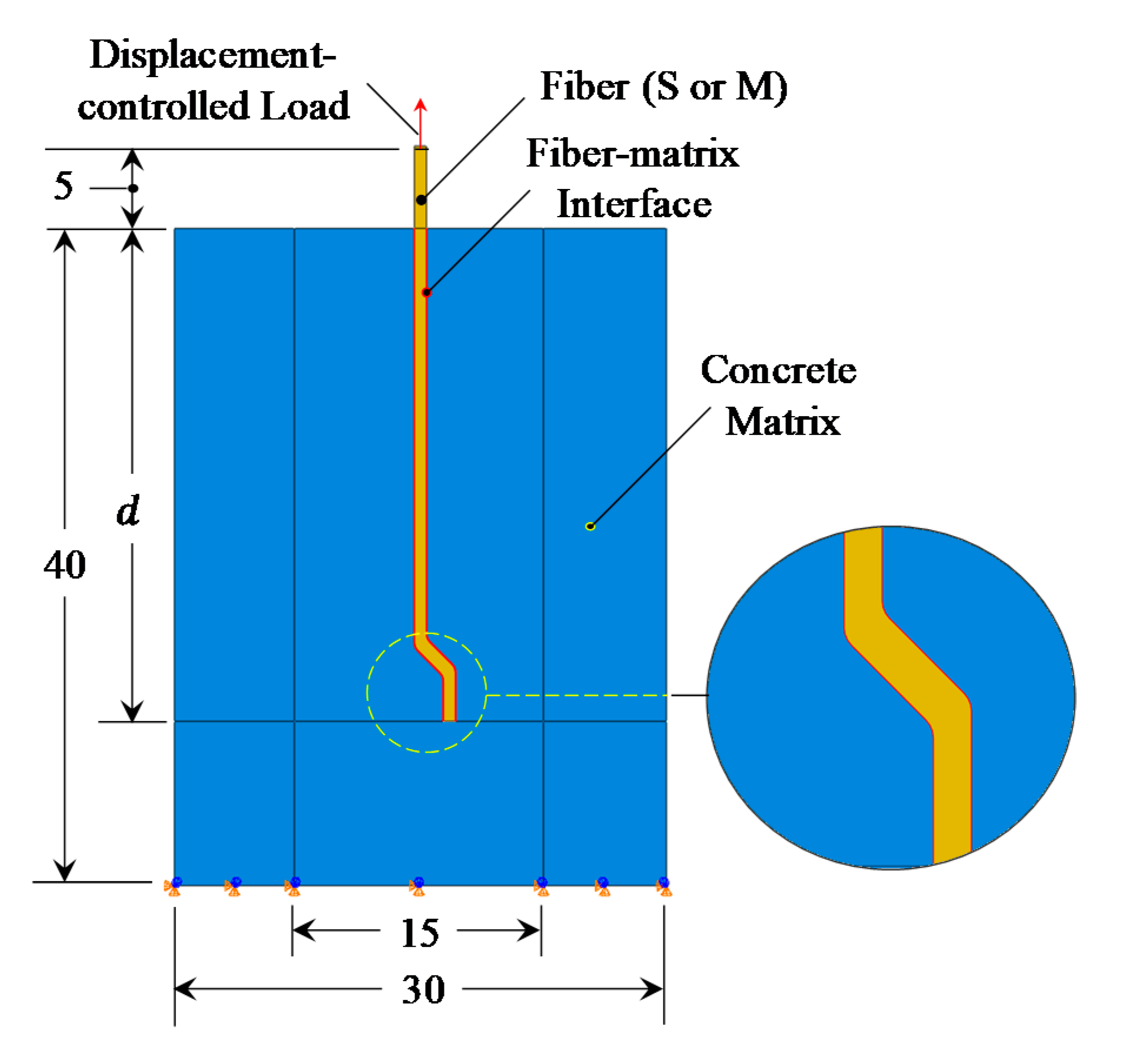

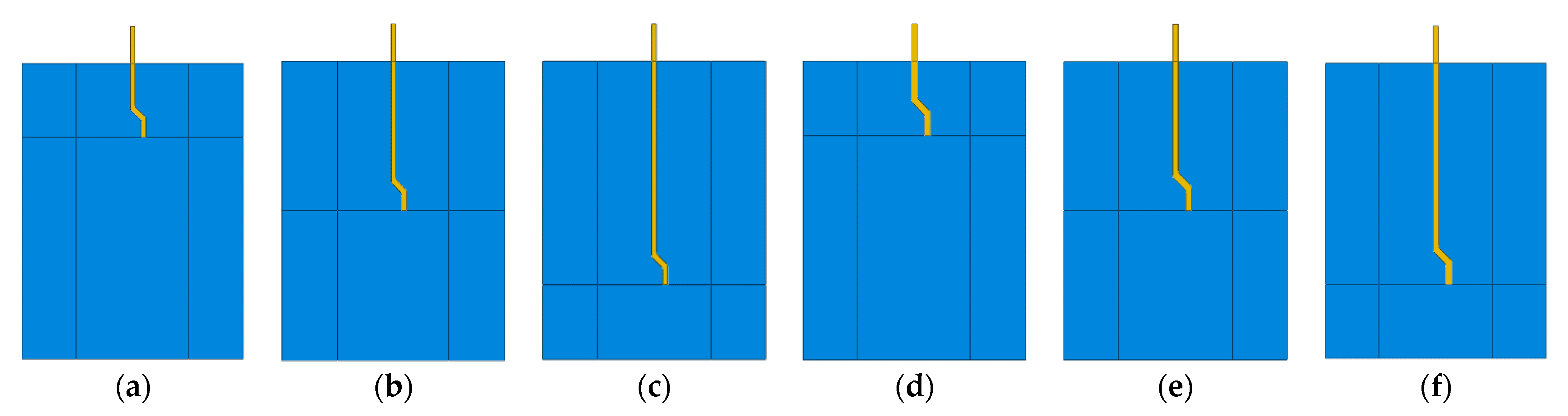

3.1. Geometry and Bond-Slip Model

3.2. Fiber–Matrix Interactions

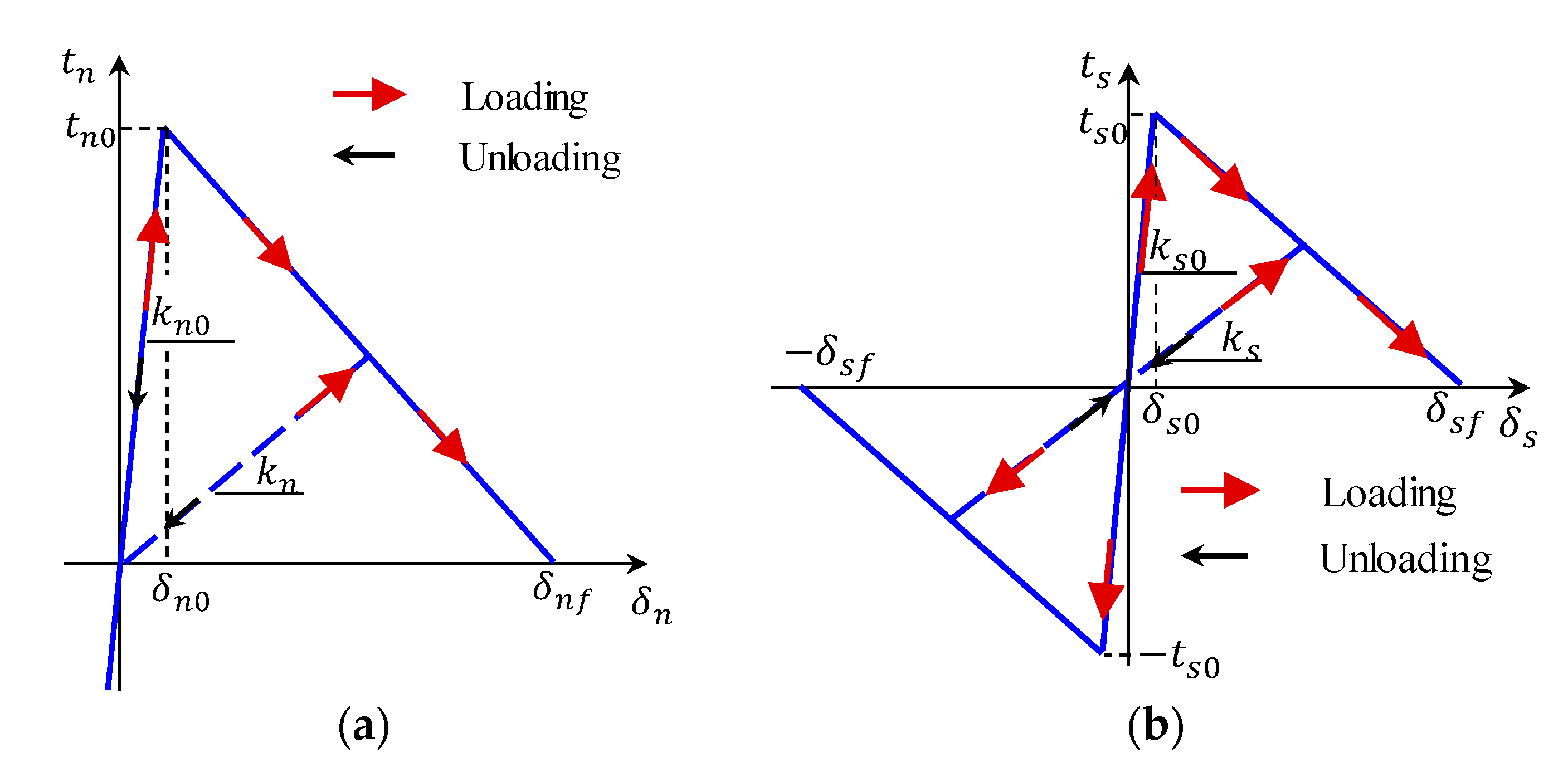

3.2.1. Traction–Separation Response

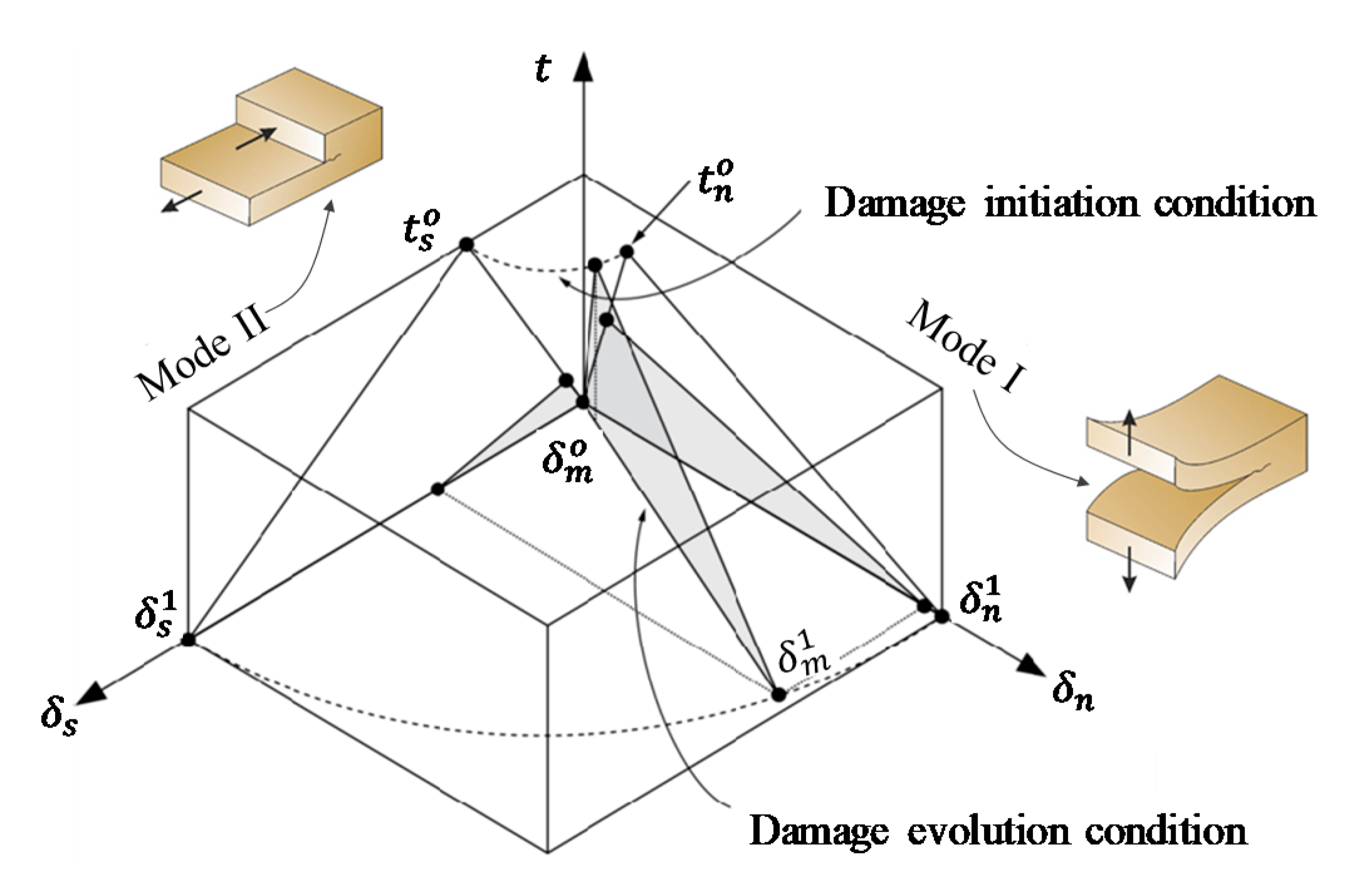

3.2.2. Damage Initiation and Evolution

3.3. Material Models

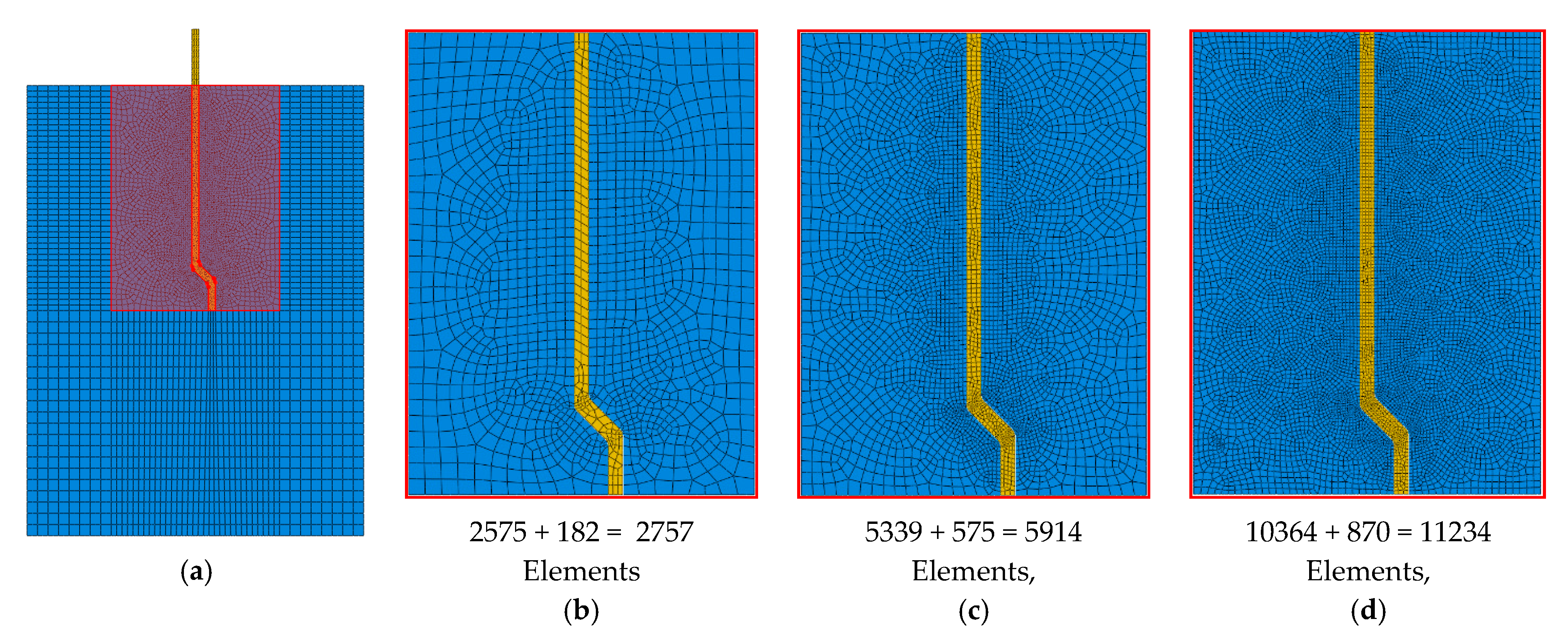

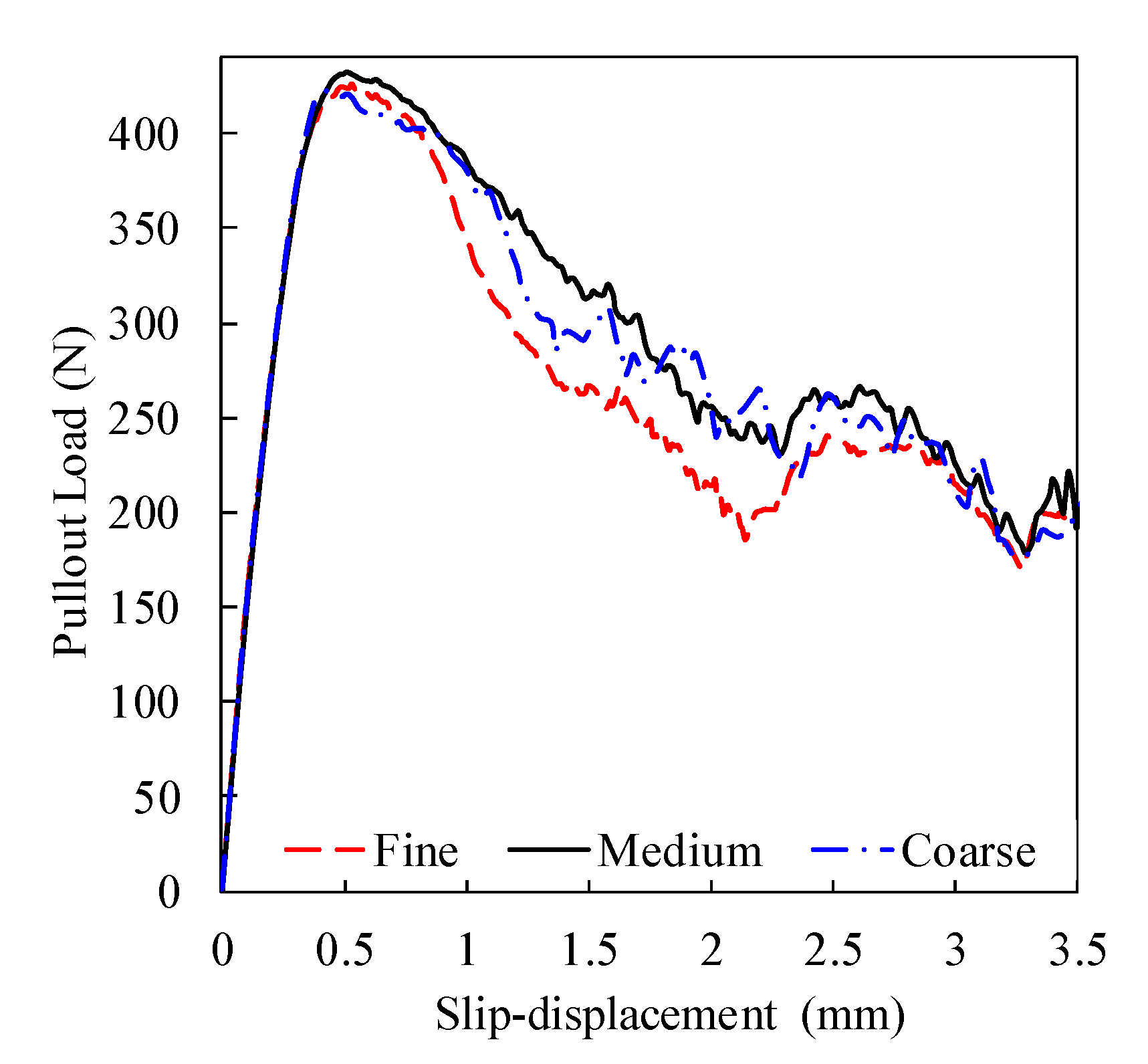

3.4. Mesh Sensitivity and Properties

4. Calibration of the FE Model

4.1. Materials

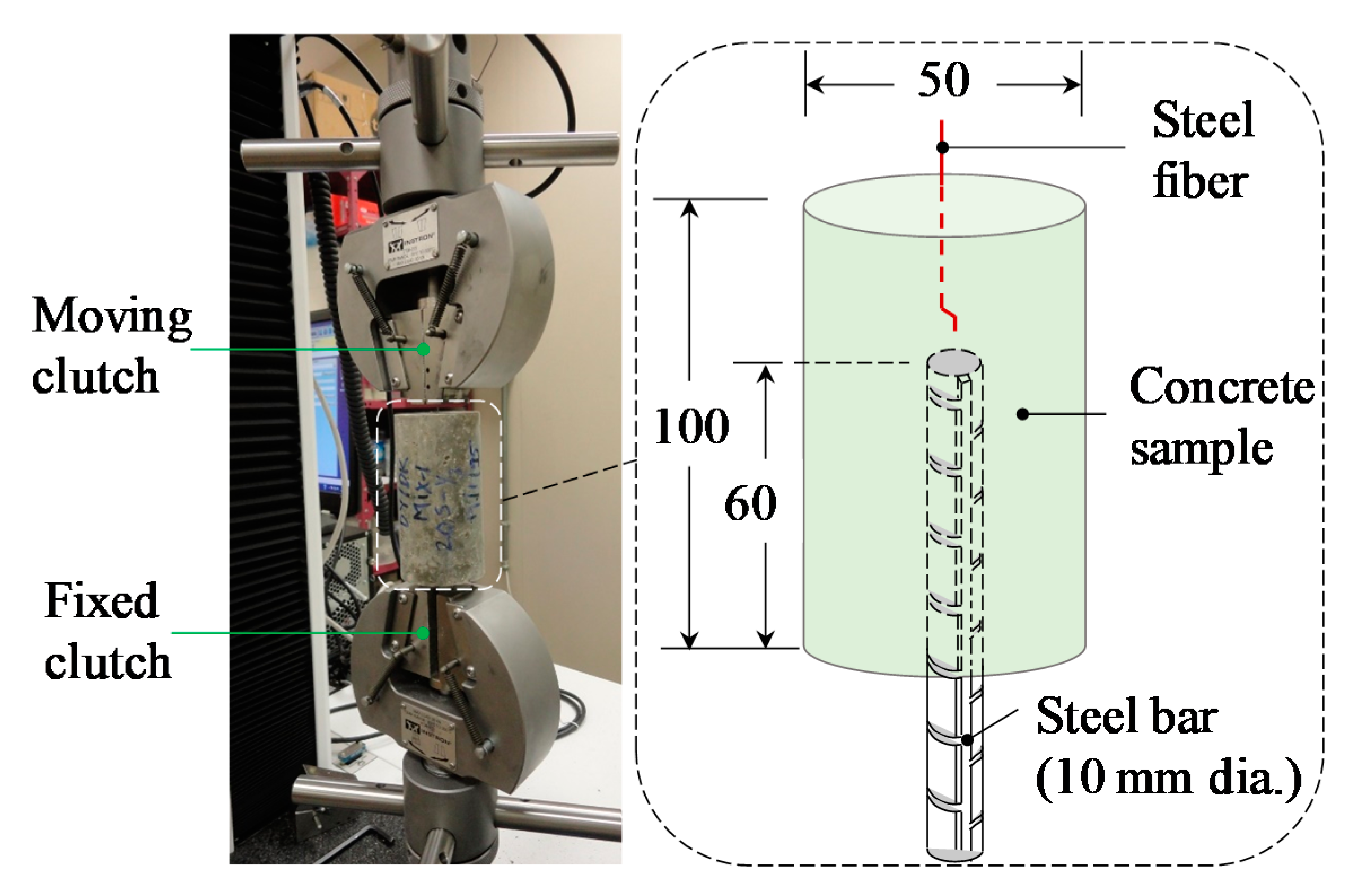

4.2. Method of Specimen Preparation and Testing

5. Results and Discussion

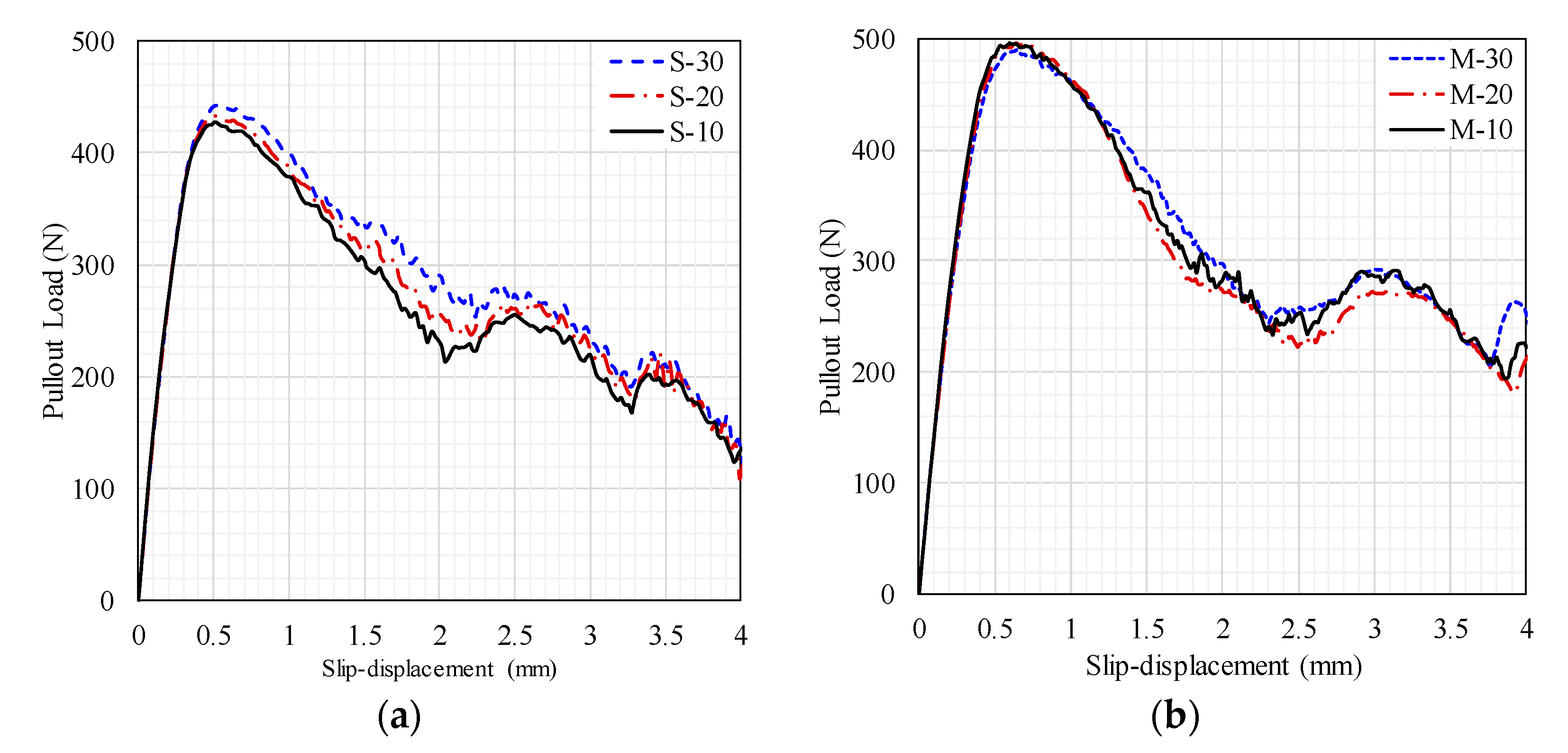

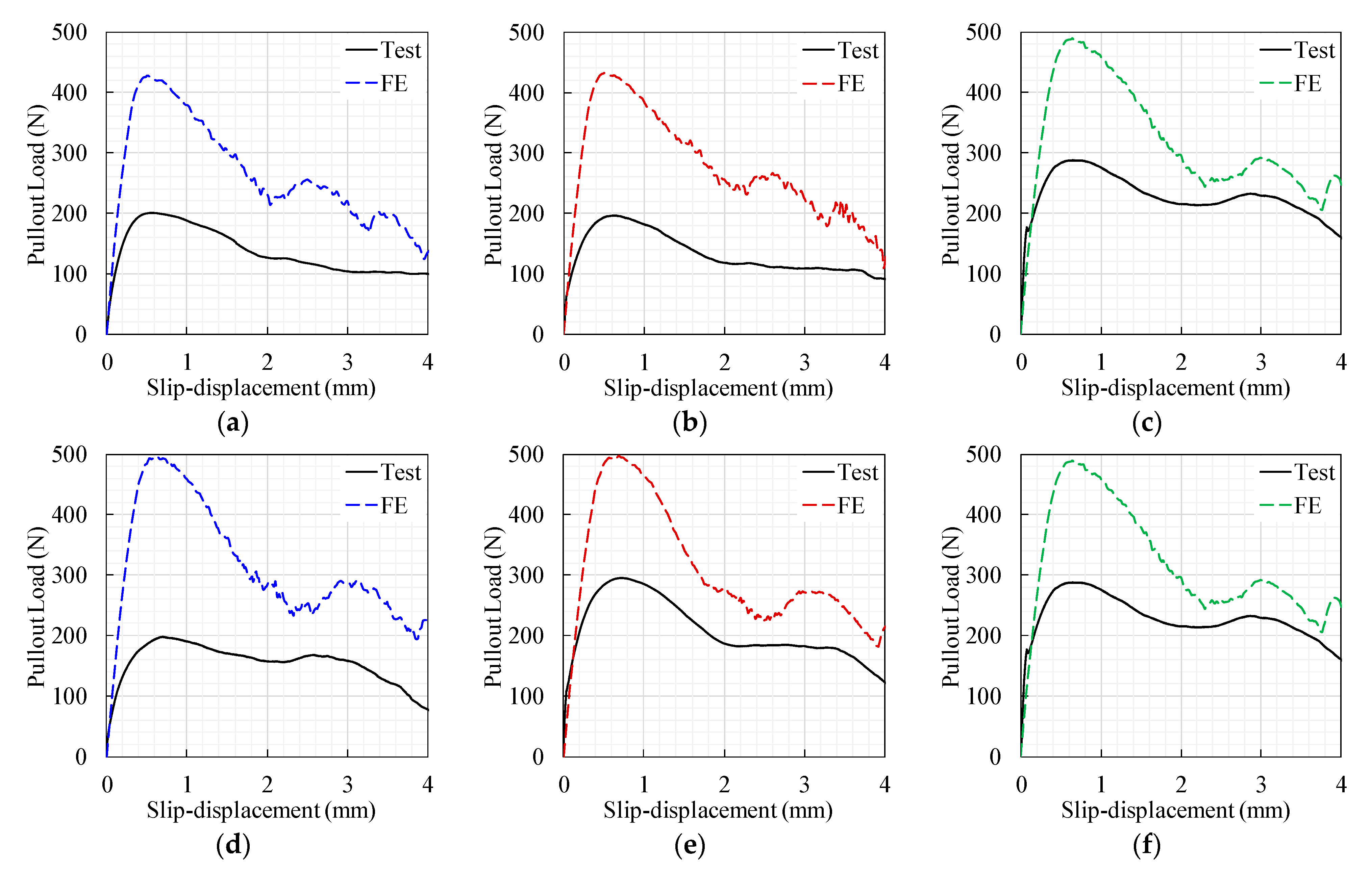

5.1. Load-Slip Curves

5.2. Fracture Pattern

6. Conclusions and Prospective Research

- The FE models’ results confirmed that the increased area of the fiber’s surface was able to enhance the fiber–matrix bond, resulting in higher pullout ultimate load and toughness.

- Increasing the fiber’s diameter could alter the mechanism of crack opening from loss of the fiber–matrix bond to that combined with matrix spalling. The latter mode of failure can neutralize the sensitivity of the complete pullout response of hooked-end steel fiber to embedment depth.

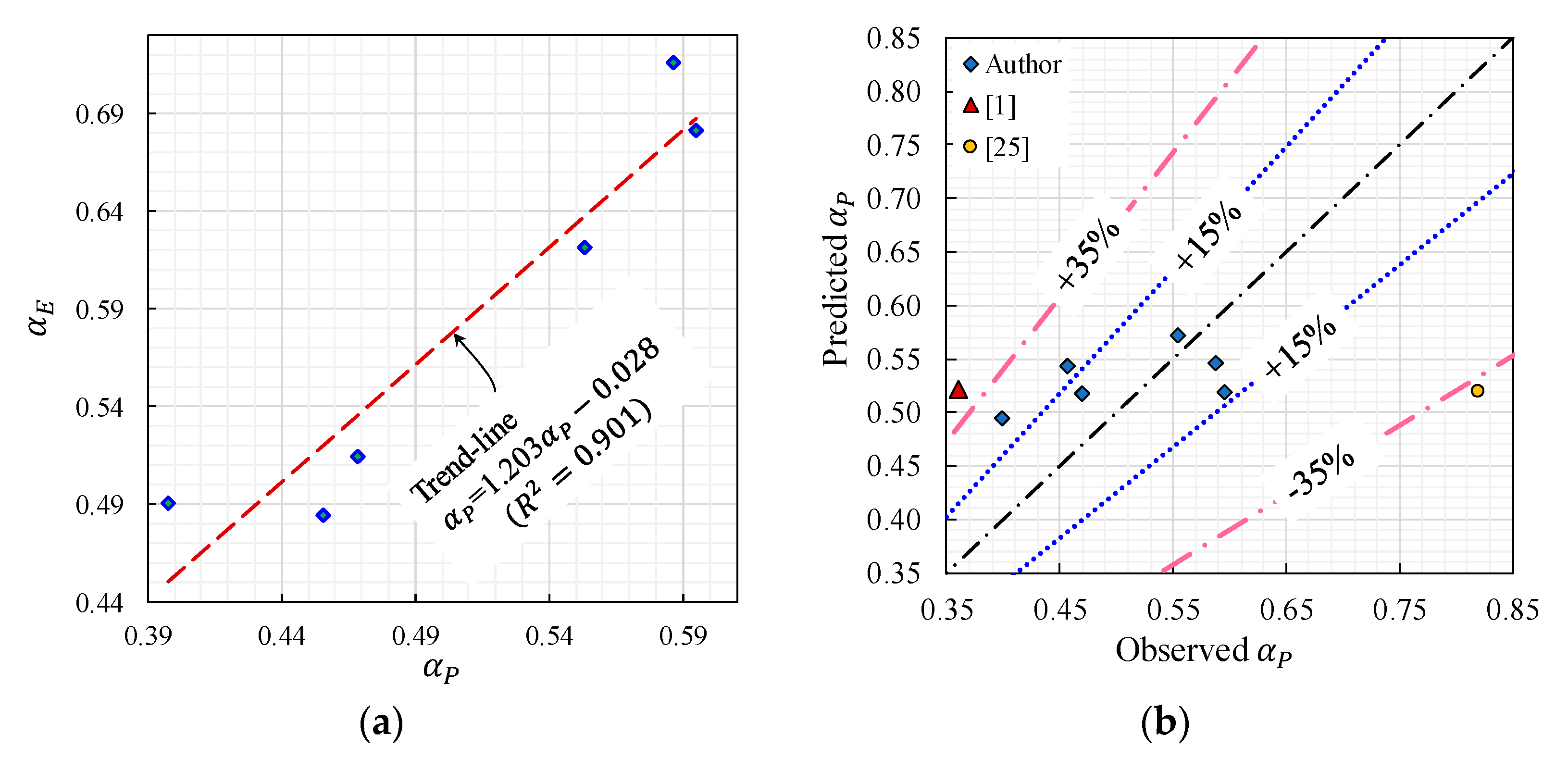

- Plane stress elements could model the entire behavioral constituents of a hooked-end steel fiber’s pullout response from the concrete matrix. However, the simplification of the spatial stress-dependence during the fiber’s pullout by plane one is likely to result in pullout load overestimation.

- The benefits of 2D modeling of the fiber’s pullout were discussed using the pullout load scaling-down modification factor able to be predicted given the fiber’s size and depth into the matrix.

- In the present study, the developed FE model was also capable of capturing the stress distribution and deformations during the crack opening of a SFRC; therefore, it provided confirmatory coincidence.

- Understanding the influence of concrete plasticity, shrinkage, and creep on deformed fibers’ pullout behavior.

- Insights into the effect of the matrix’s performance class (normal, high, and ultrahigh) on the fibers’ pullout behavior should be addressed. Moreover, deformed fibers’ pullout behavior under various confinement pressure and boundary conditions applied on the concrete surface has rarely been reported.

- A much broader understanding of the numerical solution scheme (i.e., implicit or explicit) on the FE model results’ stability and accuracy remains an open question.

- Simulation of the complete behavior of SFRC material under various loading conditions. This type of modeling could be performed by combining the influence of cracking and pullout of fibers. To approach this goal, a user subroutine needs to be written in ABAQUS® for the inclusion of various randomly oriented dosages of fibers in the concrete block.

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

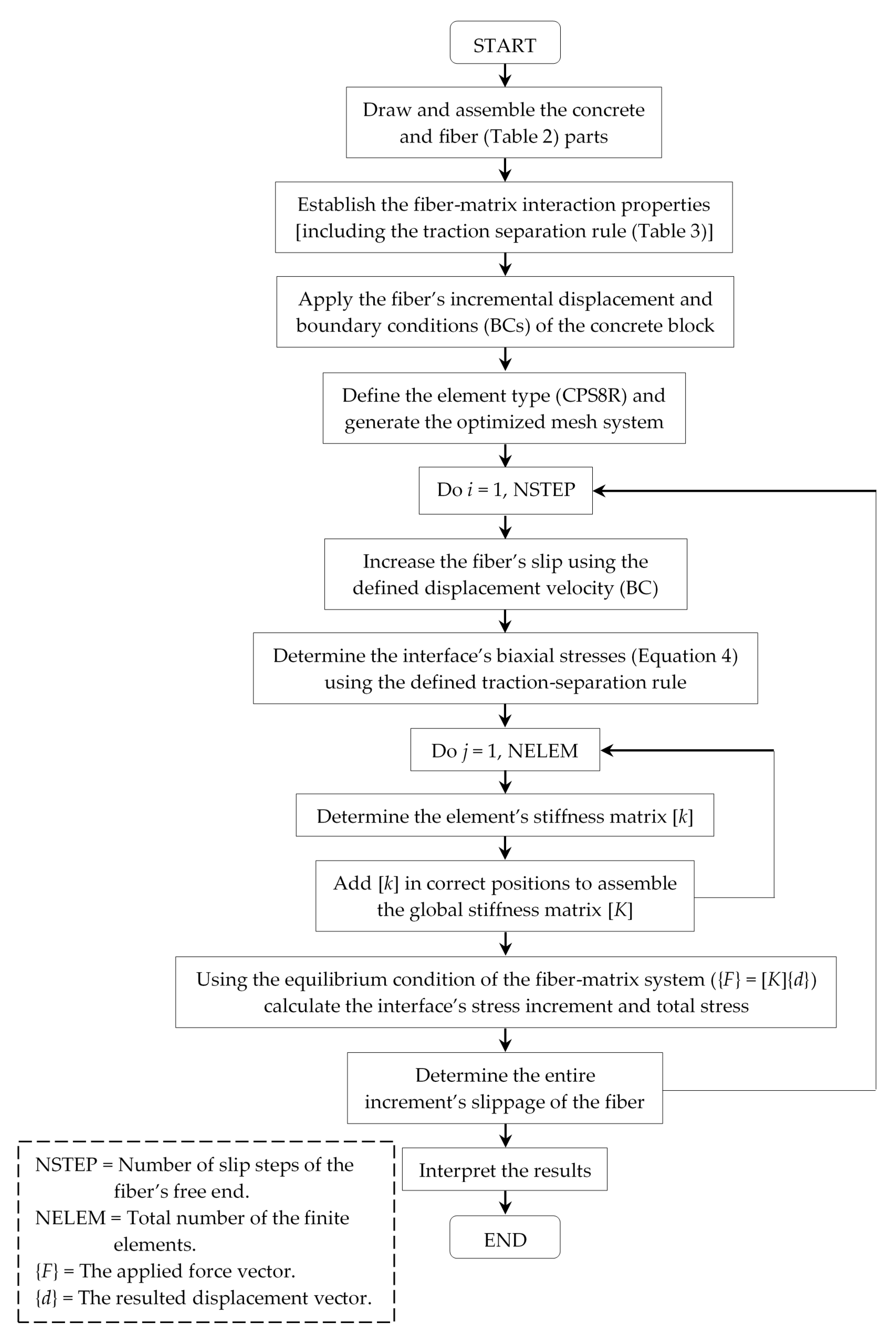

Appendix A. Flow Chart for the Developed Models

Appendix B. Keywords for “M10” Model

References

- Van der Aa, P.J. Biaxial Stresses in Steel Fibre Reinforced Concrete Modelling the Pull Out-Behaviour of a Single Steel Fibre Using FEM; Einhoven University of Technology: Eindhoven, The Netherlands, 2014. [Google Scholar]

- Wang, C.; Friedrich, L.F. Computational model of spalling and effective fibers on toughening in fiber reinforced composites at an early stage of crack formation. Lat. Am. J. Solids Struct. 2013, 10, 797–811. [Google Scholar] [CrossRef][Green Version]

- Han, J.; Zhao, M.; Chen, J.; Lan, X. Effects of steel fiber length and coarse aggregate maximum size on mechanical properties of steel fiber reinforced concrete. Constr. Build. Mater. 2019, 209, 577–591. [Google Scholar] [CrossRef]

- Tschegg, E.K. Biaxial Fracture Behaviour of Steel-Span and Steel-Fibre-Reinforced Concrete. J. Adv. Concr. Technol. 2009, 7, 229–238. [Google Scholar] [CrossRef]

- Ellis, B.D.; McDowell, D.L.; Zhou, M. Simulation of single fiber pullout response with account of fiber morphology. Cem. Concr. Compos. 2014, 48, 42–52. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Multi-scale investigation of microstructure, fiber pullout behavior, and mechanical properties of ultra-high performance concrete with nano-CaCO3 particles. Cem. Concr. Compos. 2018, 86, 255–265. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, C.; Wu, Z.; Ouyang, X.; Li, K. Numerical and analytical modeling of fiber-matrix bond behaviors of high performance cement composite. Cem. Concr. Res. 2019, 125, 105892. [Google Scholar] [CrossRef]

- Cunha, V.M.C.F.; Barros, J.A.O.; Sena-Cruz, J.M. Pullout behavior of steel fibers in self-compacting concrete. J. Mater. Civ. Eng. 2010, 22, 1–9. [Google Scholar] [CrossRef]

- Zhan, Y.; Bui, H.G.; Ninic, J.; Mohseni, S.A.; Meschke, G. Numerical modeling of steel fiber reinforced concrete on the meso-and macro-scale. Comput. Model. Concr. Struct. 2014, 579–586. [Google Scholar]

- Beghini, A.; Bažant, Z.P.; Zhou, Y.; Gouirand, O.; Caner, F.C. Microplane model M5f for multiaxial behavior and fracture of fiber-reinforced concrete. J. Eng. Mech. 2007, 133, 66–75. [Google Scholar] [CrossRef]

- Alwan, J.M.; Naaman, A.E.; Guerrero, P. Effect of mechanical clamping on the pullout response of hooked steel fibers embedded in cementitious matrices. Concr. Sci. Eng. 1999, 1, 15–25. [Google Scholar]

- Abdallah, S.; Fan, M.; Rees, D.W.A. Predicting pull-out behaviour of 4D/5D hooked end fibres embedded in normal-high strength concrete. Eng. Struct. 2018, 172, 967–980. [Google Scholar] [CrossRef]

- Maage, M. Interaction between steel fibers and cement based matrixes. Mater. Constr. 1977, 10, 297–301. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Iqbal Khan, M. Fiber–Matrix Interactions in Fiber-Reinforced Concrete: A Review. Arab. J. Sci. Eng. 2016, 41. [Google Scholar] [CrossRef]

- Xu, M.; Hallinan, B.; Wille, K. Effect of loading rates on pullout behavior of high strength steel fibers embedded in ultra-high performance concrete. Cem. Concr. Compos. 2016, 70, 98–109. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Marković, I. High-Performance Hybrid-Fibre Concrete: Development and Utilisation; IOS Press: Amsterdam, The Netherlands, 2006; ISBN 9040726213. [Google Scholar]

- Wu, Z.; Khayat, K.H.; Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC? Cem. Concr. Compos. 2018, 90, 193–201. [Google Scholar] [CrossRef]

- Cao, Y.Y.Y.; Yu, Q.L. Effect of inclination angle on hooked end steel fiber pullout behavior in ultra-high performance concrete. Compos. Struct. 2018, 201, 151–160. [Google Scholar] [CrossRef]

- Naaman, A.E. Engineered steel fibers with optimal properties for reinforcement of cement composites. J. Adv. Concr. Technol. 2003, 1, 241–252. [Google Scholar] [CrossRef]

- Chan, Y.-W.; Li, V.C. Effects of transition zone densification on fiber/cement paste bond strength improvement. Adv. Cem. Based Mater. 1997, 5, 8–17. [Google Scholar] [CrossRef]

- Deng, F.; Ding, X.; Chi, Y.; Xu, L.; Wang, L. The pull-out behavior of straight and hooked-end steel fiber from hybrid fiber reinforced cementitious composite: Experimental study and analytical modelling. Compos. Struct. 2018, 206, 693–712. [Google Scholar] [CrossRef]

- Oden, J.T.; Reddy, J.N. An Introduction to the Mathematical Theory of Finite Elements; Courier Corporation: Chelmsford, MA, USA, 2012; ISBN 0486142213. [Google Scholar]

- Brenner, S.; Scott, R. The Mathematical Theory of Finite Element Methods; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; Volume 15, ISBN 0387759336. [Google Scholar]

- Breitenbücher, R.; Meschke, G.; Song, F.; Zhan, Y. Experimental, analytical and numerical analysis of the pullout behaviour of steel fibres considering different fibre types, inclinations and concrete strengths. Struct. Concr. 2014, 15, 126–135. [Google Scholar] [CrossRef]

- Radtke, F.K.F.; Simone, A.; Sluys, L.J. A partition of unity finite element method for simulating non-linear debonding and matrix failure in thin fibre composites. Int. J. Numer. Methods Eng. 2011, 86, 453–476. [Google Scholar] [CrossRef]

- Georgiadi-Stefanidi, K.; Mistakidis, E.; Pantousa, D.; Zygomalas, M. Numerical modelling of the pull-out of hooked steel fibres from high-strength cementitious matrix, supplemented by experimental results. Constr. Build. Mater. 2010, 24, 2489–2506. [Google Scholar] [CrossRef]

- Guerrero, Z.; Patricia, A. Bond Stress-Slip Mechanisms in High-Performance Fiber-Reinforced Cement Composites; The University of Michigan: Ann Arbor, MI, USA, 1999. [Google Scholar]

- Li, C.Y.; Mobasher, B. Finite element simulations of fiber pullout toughening in fiber reinforced cement based composites. Adv. Cem. Based Mater. 1998, 7, 123–132. [Google Scholar] [CrossRef]

- Friedrich, L.F.; Wang, C. Continuous modeling technique of fiber pullout from a cement matrix with different interface mechanical properties using finite element program. Lat. Am. J. Solids Struct. 2016, 13, 1937–1953. [Google Scholar] [CrossRef]

- Cunha, V.M.C.F.; Barros, J.A.O.; Sena-Cruz, J. Pullout Behaviour of Hooked-End Steel Fibres in Self-Compacting Concrete; Universidade do Minho Departamento de Engenharia Civil (DEC): Braga, Portugal, 2007. [Google Scholar]

- Bruggeling, A.S.; Dicke, D.; Walraven, J.C.; Buist, W.; Gerritse, A.; Hartsuijker, C.; Pruijssers, A.F.; van der Veen, C. Theorie en Praktijk van het Gewapend Beton; Bakker Fonds: Amsterdam, The Netherlands, 1986. [Google Scholar]

- Davalos, J.F.; Chen, Y.; Ray, I. Numerical modeling for the interface bond of concrete and FRP bar. In Earth & Space 2008: Engineering, Science, Construction, and Operations in Challenging Environments; American Society of Civil Engineers: Reston, VA, USA, 2008; pp. 1–11. [Google Scholar]

- Dassault Systèmes, D.S. Abaqus Analysis User’s Guide; Technical Report Abaqus 6.14 Documentation; Simulia Corp.: Johnston, RI, USA, 2016. [Google Scholar]

- Needleman, A. A continuum Model for Void Nucleation by Inclusion Debonding. J. Appl. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Dahi Taleghani, A.; Ahmadi, M.; Olson, J.E. Secondary Fractures and Their Potential Impacts on Hydraulic Fractures Efficiency. In Proceedings of the ISRM International Conference for Effective and Sustainable Hydraulic Fracturing, Brisbane, Australia, 20–22 May 2013; International Society for Rock Mechanics and Rock Engineering: Lisbon, Portugal, 2013. [Google Scholar]

- Foraboschi, P. Analytical model to predict the lifetime of concrete members externally reinforced with FRP. Theor. Appl. Fract. Mech. 2015, 75, 137–145. [Google Scholar] [CrossRef]

- Foraboschi, P. Effectiveness of novel methods to increase the FRP-masonry bond capacity. Compos. Part B Eng. 2016, 107, 214–232. [Google Scholar] [CrossRef]

- Abbas, M.Y.; Khan, M.I. Fiber-Matrix Interfacial Behavior of Hooked-End Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2016, 28. [Google Scholar] [CrossRef]

- Inglis, H.M.; Kok, S. Pull-Out of Hooked End Steel Fibres: Experimental and Numerical Study; Hatfield: Pretoria, South Africa, 2014. [Google Scholar]

| Phase | Sub-Phase | Range in Figure 2 | Criterion | Description |

|---|---|---|---|---|

| Pure elastic | - | The hooked-end fiber acts as a straight one (deformed elastically) in this fully bonded phase, where the adhesive fiber–matrix governs the system. | ||

| Debonding | Incomplete debonded | Involves the fiber’s debonding process, and due to its deformability, this stage extended to (2), instead of in Figure 2, where the fiber’s lower end approaches the matrix’s first bend and plasticity begins. At the end of this phase, two inelastic hinges are formed (i.e., IH-1 and IH-2 in Figure 2). | ||

| Disappearance of IH-2 | The second inelastic hinge (IH-2) evanesces, as approaches , which notably reduces the pullout load (due to the decrease in the mechanical and frictional bonding). | |||

| Disappearance of IH-1 | In this sub-phase, the fiber’s first inelastic hinge (IH-1) fades out. Debonding is completed as . The slight load surge in this sub-phase is because the fiber travels through the second angle of the fiber–matrix interface. | |||

| Frictional slipping | - | The fiber becomes deformed-straight during this phase, where the Coulomb’s kinetic friction governs the fiber–matrix interactions. It is worth noting that a deformed fiber’s frictional abrasion is notably higher than that for a straight fiber [31]. |

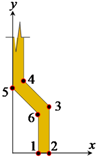

| Point | 1 | 2 | 3 | 4 | 5 | 6 |  |

| S-fiber | |||||||

| 1.473 | 2.098 | 2.098 | 0.625 | 0 | 1.473 | ||

| 0 | 0 | 2.721 | 4.194 | 3.752 | 2.279 | ||

| M-fiber | |||||||

| 1.768 | 2.518 | 2.518 | 0.750 | 0 | 1.768 | ||

| 0 | 0 | 3.265 | 5.033 | 4.503 | 2.735 | ||

| (N/mm3) | (MPa) | (mm) | |||||

|---|---|---|---|---|---|---|---|

| 11 | 0.7 | 0.5 | 6 | 0.05 | |||

| Model | Number of Nodes | Number of Elements | ||||

|---|---|---|---|---|---|---|

| Fiber | Matrix | Total | Fiber | Matrix | Total | |

| S-10 | 1936 | 11,009 | 12,945 | 585 | 3560 | 4145 |

| S-20 | 1971 | 16,525 | 8496 | 572 | 5360 | 5932 |

| S-30 | 2620 | 22,388 | 25,008 | 755 | 7275 | 8030 |

| M-10 | 1414 | 10,418 | 11,832 | 419 | 3365 | 3784 |

| M-20 | 2208 | 16,262 | 18,470 | 647 | 5271 | 5918 |

| M-30 | 3190 | 22,220 | 25,410 | 941 | 7215 | 8156 |

| Type | Diameter (mm) | Camber Length (mm) | Hook Length (mm) | Aspect Ratio | Hook’s Angle | Poisson’s Ratio | Elasticity Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| S-fiber | 0.625 | 2.0 | 2.5 | 80 | 45° | 0.3 | 210 | 1250 |

| M-fiber | 0.750 | 2.5 | 3.0 |

| Water | Cement | Aggregate | |

|---|---|---|---|

| Coarse | Fine | ||

| 157.5 | 350 | 1040 | 700 |

| Model | (mm) | (×10−3 J) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| FE | |||||||||

| S-10 | 427.91 | 200.46 | 0.47 | 0.50 | 0.56 | 1.12 | 1062.94 | 547.08 | 0.51 |

| S-20 | 432.47 | 197.14 | 0.46 | 0.51 | 0.64 | 1.26 | 1101.13 | 533.71 | 0.48 |

| S-30 | 442.42 | 244.72 | 0.55 | 0.52 | 0.73 | 1.41 | 1149.70 | 714.27 | 0.62 |

| M-10 | 495.53 | 197.16 | 0.40 | 0.60 | 0.70 | 1.18 | 1257.20 | 616.95 | 0.49 |

| M-20 | 496.50 | 295.44 | 0.60 | 0.69 | 0.74 | 1.07 | 1223.43 | 833.34 | 0.68 |

| M-30 | 489.58 | 287.15 | 0.59 | 0.65 | 0.65 | 1.00 | 1275.90 | 913.73 | 0.72 |

| Average | 464.07 | 237.01 | 0.51 | 0.58 | 0.67 | 1.17 | 1178.38 | 693.18 | 0.58 |

| Std. 1 | 33.07 | 45.83 | 0.08 | 0.08 | 0.07 | 0.15 | 87.03 | 155.77 | 0.10 |

| Min | 427.91 | 197.14 | 0.40 | 0.50 | 0.56 | 1.00 | 1062.94 | 533.71 | 0.48 |

| Max | 496.50 | 295.44 | 0.60 | 0.69 | 0.74 | 1.41 | 1275.90 | 913.73 | 0.72 |

| Range | 68.58 | 98.31 | 0.20 | 0.18 | 0.17 | 0.41 | 212.96 | 380.02 | 0.23 |

| (mm) | ||||||

|---|---|---|---|---|---|---|

| Author | 0.625 | 10 | 0.468 | 0.427 | 1.105 | 0.035 |

| 0.625 | 20 | 0.456 | 0.488 | 1.194 | 0.063 | |

| 0.625 | 30 | 0.553 | 0.557 | 1.034 | 0.013 | |

| 0.750 | 10 | 0.398 | 0.460 | 1.243 | 0.068 | |

| 0.750 | 20 | 0.595 | 0.525 | 0.874 | 0.053 | |

| 0.750 | 30 | 0.587 | 0.600 | 0.932 | 0.028 | |

| [1] | 0.900 | 30 | 0.360 | 0.457 | 1.450 | 0.115 |

| [25] | 0.750 | 20 | 0.820 | 0.820 | 0.634 | 0.212 |

| - | - | - | Average | 1.058 | 0.073 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, Y.M. Microscale Cohesive-Friction-Based Finite Element Model for the Crack Opening Mechanism of Hooked-End Steel Fiber-Reinforced Concrete. Materials 2021, 14, 669. https://doi.org/10.3390/ma14030669

Abbas YM. Microscale Cohesive-Friction-Based Finite Element Model for the Crack Opening Mechanism of Hooked-End Steel Fiber-Reinforced Concrete. Materials. 2021; 14(3):669. https://doi.org/10.3390/ma14030669

Chicago/Turabian StyleAbbas, Yassir M. 2021. "Microscale Cohesive-Friction-Based Finite Element Model for the Crack Opening Mechanism of Hooked-End Steel Fiber-Reinforced Concrete" Materials 14, no. 3: 669. https://doi.org/10.3390/ma14030669

APA StyleAbbas, Y. M. (2021). Microscale Cohesive-Friction-Based Finite Element Model for the Crack Opening Mechanism of Hooked-End Steel Fiber-Reinforced Concrete. Materials, 14(3), 669. https://doi.org/10.3390/ma14030669