Design and Evaluation of an Ultrahigh-Strength Coral Aggregate Concrete for Maritime and Reef Engineering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cementitious System

2.1.2. Aggregates

2.1.3. Artificial Seawater

2.2. Concrete Sample Preparation

- (1)

- All dry-mixing powders (binder particles, coral sand, and coral powder) were stirred for 3 min;

- (2)

- Water mixture was then added to the mixed dry materials, and the mixture was stirred for 5 min.

2.3. Experimental Methods

2.3.1. Strength Tests

2.3.2. Autogenous Shrinkage Test

- (1)

- The inner surfaces of the steel mold (100 mm × 100 mm × 550 mm) were smeared with grease. The Teflon sheets were placed to eliminate the friction between the inner surfaces of the steel mold and the concrete specimen;

- (2)

- Two steel target seats were mounted on the proper positions of the bottom surface of the steel mold. In this study, the distance of the two target seats was 455 mm. Standard targets were magnetically attached to the steel target seats;

- (3)

- The mixture was poured into the steel mold and encapsulated the steel target seats, guaranteeing that the target seats would deform simultaneously with the specimen. The thermocouples were embedded into the center of the specimen to isolate the autogenous shrinkage from the measured total deformation by monitoring the temperature changes within it;

- (4)

- The top surface of the specimen was sealed with two layers of polyethylene sheets to avoid the influence of exterior drying. The sensor support was fastened to the top of the steel mold. By regulating the fitting screw, the ECDS was mounted on a proper position;

- (5)

- In our measurements, the interval of data acquisition was 1 min;

2.3.3. Hydration Heat

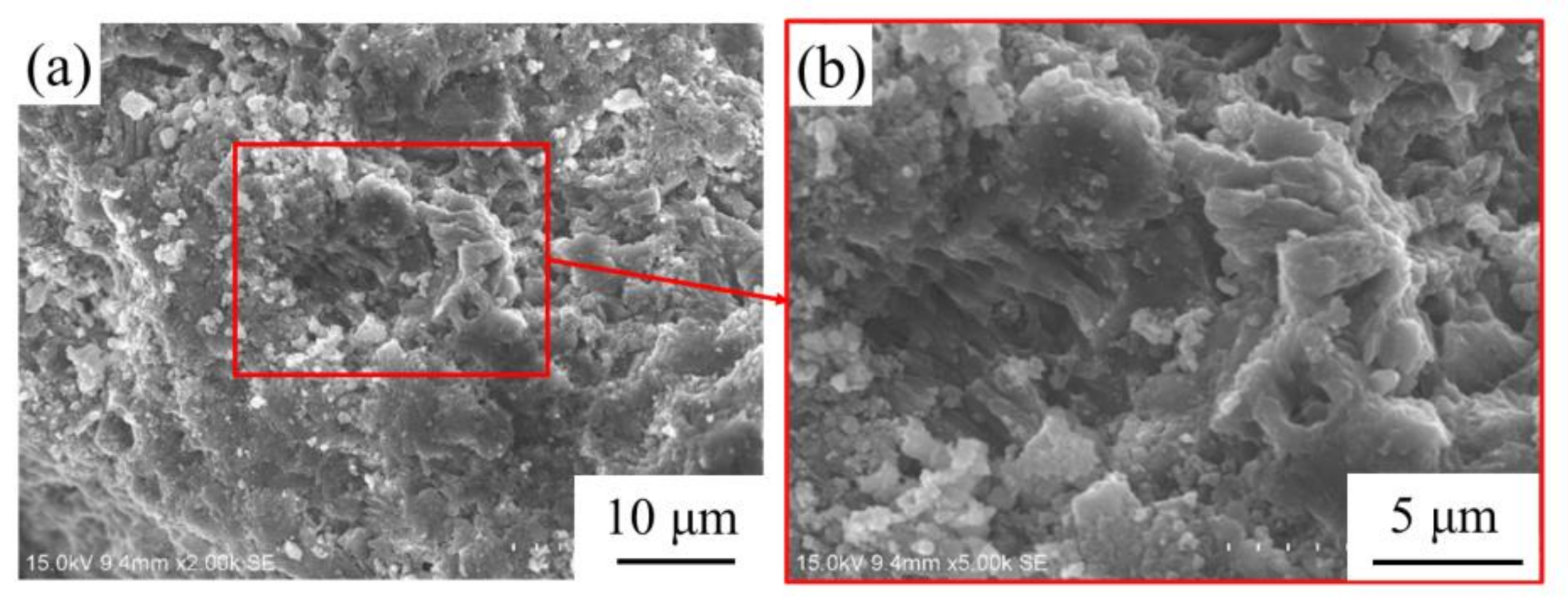

2.3.4. Scanning Electron Micrograph

2.3.5. X-ray Powder Diffraction

3. Results and Discussion

3.1. The Effect of a Single Binder on Mechanical Properties

3.2. The Influence of Multiple Combined Binders on Mechanical Properties

3.3. Microstructure Characterization and Performance Test of Optimized Concrete

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, Y.F. Mix Design and Property of Coral Aggregate Concrete; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2015. [Google Scholar]

- Narver, D.L. Good concrete made with coral and sea water. Civil Eng. 1954, 24, 49–52. [Google Scholar]

- Lorman, W.K. Characteristics of Coral Aggregate from Selected Loeations in the Pacific Ocean Area; USN Civil Engineering Laboratory: Philadelphia, PA, USA, 1958. [Google Scholar]

- Scholer, C.H. Examination and Study of Certain Structures in the Pacific Ocean Area; USN Civil Engineering Laboratory: Philadelphia, PA, USA, 1959. [Google Scholar]

- Lorman, W.K. Coral and Coral Concrete; USN Civil Engineering Laboratory: Philadelphia, PA, USA, 1960. [Google Scholar]

- Howdyshell, P.A. The Use of Coral as an Aggregate for Portland Cement Concrete Structures; Army Construction Engineering Research Laboratory: Champaign, IL, USA, 1974. [Google Scholar]

- United States Department of Defense. Tropical Engineering; UFC 4-023-03; United States Department of Defense: Virginia, VA, USA, 2009. [Google Scholar]

- Wang, Y.G. The Feasibility of Coral Concrete Application in the Port Industry. Port. Waterw. Eng. 1988, 9, 46–48. [Google Scholar]

- Lu, B.; Liang, Y.B. Experimental Research on Coral Sea Sand Concrete I. Mari. Sci. Bull. 1993, 5, 69–74. [Google Scholar]

- Lu, B.; Li, Q.G.; Huang, S.J. The research and practice of water—coral sand cement concrete, Guangdong Build. Guangdong Build. Mater. 1997, 4, 8–10. [Google Scholar]

- Chen, Z.L.; Sun, G.F.; Tang, Y.N.; Liu, Y.N. Study on Applications of Concretes from Coral Reef Sand Mixed with Seawater for Patching-up in Reef Engineering. Coas. Eng. 2008, 27, 60–69. [Google Scholar]

- Liu, J.M.; Ou, Z.W.; Peng, W.; Guo, T.; Deng, W.; Chen, Y.Z. Literature Review of Coral Concrete. Arab. J. Sci. Eng. 2018, 43, 1529–1541. [Google Scholar] [CrossRef]

- Li, L. Research on Basic Characteristics of Coral Concrete; Guangxi University: Guangxi, China, 2012. [Google Scholar]

- Han, C. Experimental Research on the Fundamental Mechanical Behavior of Seawater Coral Concrete; Guangxi University: Guangxi, China, 2011. [Google Scholar]

- Zhao, Y.L.; Han, C.; Zhang, S.Z.; Ge, R.D. Experimental study on the compression age strength of seawater coral concrete. Concrete 2011, 2, 43–45. [Google Scholar]

- Chen, F.X.; Zhang, G.Z.; Ding, S.; Qin, M.Q.; Liu, K.Y. Experimental Research on the Properties of Coral Concrete. China Concr. Cem. Product. 2016, 7, 16–21. [Google Scholar]

- Wang, L.; Fan, L. Strength Characteristic and Failure Pattern Analysis on Coral Debris Concrete. China Concr. Cem. Product. 2015, 1, 1–14. [Google Scholar]

- Chen, Z.L.; Tang, X.N.; Sun, G.F.; Liu, Y.L. Research on durability and application of seawater concrete. Ocean Eng. 2008, 26, 102–106. [Google Scholar]

- Chen, Z.L.; Chen, T.Y.; Qu, Z.M. A Feasibility study of the application for coral sand concrete. Ocean Eng. 1991, 9, 67–80. [Google Scholar]

- Arumugam, R.A.; Ramamurthy, K. Study of compressive strength characteristics of coral aggregate concrete. Mag. Concr. Res. 1996, 48, 141–148. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, Y.L.; Lv, H.B. Prospect on the properties and application situation of coral aggregate concrete. Concrete 2012, 2, 99–100. [Google Scholar]

- Pan, B.Z.; Wei, Z.B. Experimental Study on Effects to Coral Sand Concrete Compressive Strength of Raw Materials. Eng. Mech. 2015, 32, 221–225. [Google Scholar]

- Sun, X.; Wei, Z.B.; Gao, Y. Experimental Study on the Mixture Ratio of Coral Aggregate Concrete Mixed with Seawater. Sichuan Archit. 2016, 36, 204–206. [Google Scholar]

- Li, L.; Zhao, Y.L.; Lv, H.B.; Han, C. Coral aggregate pre-wet on the mechanical properties of concrete. Concrete 2011, 1, 85–86. [Google Scholar]

- Yoo, D.Y.; Banthia, N. Mechanical and structural behaviors of ultra-high-performance fiber-reinforced concrete subjected to impact and blast. Constr. Build. Mater. 2017, 149, 416–431. [Google Scholar] [CrossRef]

- Maya, L.F.; Graybeal, B. Experimental study of strand splice connections in UHPC for continuous precast prestressed concrete bridges. Eng. Struct. 2017, 133, 81–90. [Google Scholar] [CrossRef]

- Ghasemi, S.; Zohrevand, P.; Mirmiran, A.; Xiao, Y.L.; Mackie, K. A super lightweight UHPC-HSS deck panel for movable bridges. Eng. Struct. 2016, 113, 186–193. [Google Scholar] [CrossRef]

- Krauthammer, T. Recent observations on design and analysis of protective structures. Eng. Struct. 2017, 149, 78–90. [Google Scholar] [CrossRef]

- Wu, Z.M.; Shi, C.J.; He, W.; Wang, D.H. Static and dynamic compressive properties of ultra-high performance concrete (UHPC) with hybrid steel fiber reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef] [Green Version]

- Cwirzen, A.; Penttala, V.; Vornanen, C. Reactive powder based concretes: Mechanical properties, durability and hybrid use with OPC. Cem. Concr. Res. 2008, 38, 1217–1226. [Google Scholar] [CrossRef]

- Shen, W.G.; Liu, Y.; Cao, L.H.; Huo, X.J.; Yang, Z.G.; Zhou, C.C.; He, P.T.; Lu, Z.L. Mixing design and microstructure of ultra high strength concrete with manufactured sand. Constr. Build. Mater. 2017, 143, 312–321. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of Reactive Powder Concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Mehta, P.K. Pozzolanic and cementitious materials, Advances in Concrete Technology; Gordon and Breach: London, UK, 1996. [Google Scholar]

- Hassan, K.E.; Cabrera, J.G.; Maliehe, R.S. The effect of mineral admixtures on the properties of high-performance concrete. Cem. Concr. Compos. 2000, 22, 267–271. [Google Scholar] [CrossRef]

- Ministry of Construction of the People’s Republic of China. Reactive Powder Concrete: GB/T 31387-2015; China Building Industry Press: Beijing, China, 2016. [Google Scholar]

- Ministry of Construction of the People’s Republic of China. Ordinary Concrete Mechanics Performance Test Method: GB/T 50081-2002; China Building Industry Press: Beijing, China, 2003. [Google Scholar]

- State Bureau of Technical Supervision of the People’s Republic of China. Method of Testing Cements-Determination of Strength: GB/T 17671-1999; China Building Industry Press: Beijing, China, 1999. [Google Scholar]

- Jiang, C.H.; Yang, Y.; Wang, Y.; Zhou, Y.N.; Ma, C.C. Autogenous shrinkage of high performance concrete containing mineral admixtures under different curing temperatures. Constr. Build. Mater. 2014, 61, 260–269. [Google Scholar] [CrossRef]

- Snoeck, D.; Jensen, O.M.; De Belie, N. The influence of superabsorbent polymers on the autogenous shrinkage properties of cement pastes with supplementary cementitious materials. Cem. Concr. Res. 2015, 74, 59–67. [Google Scholar] [CrossRef]

- Mo, J.C.; Ou, Z.W.; Zhao, X.X.; Liu, J.M.; Wang, Y.H. Influence of superabsorbent polymer on shrinkage properties of reactive powder concrete blended with granulated blast furnace slag. Constr. Build. Mater. 2017, 146, 283–296. [Google Scholar] [CrossRef]

- Oertel, T.; Hutter, F.; Helbig, U.; Sextl, G. Amorphous silica in ultra-high performance concrete: First hour of hydration. Cem. Concr. Res. 2014, 58, 131–142. [Google Scholar] [CrossRef]

- Wang, X.P.; Shui, Z.H.; Yu, R.; Bao, M.; Wang, G.M. Effect of coral filler on the hydration and properties of calcium sulfoaluminate cement based materials. Constr. Build. Mater. 2017, 150, 459–466. [Google Scholar] [CrossRef]

- Peng, Y.; Jacobsen, S. Influence of water/cement ratio, admixtures and filler on sedimentation and bleeding of cement paste. Cem. Concr. Res. 2013, 54, 133–142. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K. Influence of water to cement ratio on the efficiency of internal curing of high-performance concrete. Constr. Build. Mater. 2017, 144, 311–316. [Google Scholar] [CrossRef]

- Tazawa, E.; Miyazawa, S. Influence of Cement and Admixture on Autogenous Shrinkage of Cement Paste. Cem. Concr. Res. 1995, 25, 281–287. [Google Scholar] [CrossRef]

- Sant, G.; Lothenbach, B.; Juilland, P.; Le Saout, G.; Weiss, J.; Scrivener, K. The origin of early age expansions induced in cementitious materials containing shrinkage reducing admixtures. Cem. Concr. Res. 2011, 41, 218–229. [Google Scholar] [CrossRef]

- Rostami, M.; Behfarnia, K. The effect of silica fume on durability of alkali activated slag concrete. Constr. Build. Mater. 2017, 134, 262–268. [Google Scholar] [CrossRef]

- Fan, X.M.; Fang, D.; Sun, M.Q.; Li, Z.Q. Piezoresistivity of Carbon Fiber Graphite Cement-Based Composites with CCCW. J. Wuhan Univ. Technol. 2011, 26, 340–344. [Google Scholar] [CrossRef]

- Siddique, R.; Jameel, A.; Singh, M.; Barnat-Hunek, D.; Kunal; Ait-Mokhtar, A.; Belarbi, R.; Rajor, A. Effect of bacteria on strength, permeation characteristics and micro-structure of silica fume concrete. Constr. Build. Mater. 2017, 142, 92–100. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Junaid, M.T.; Khennane, A.; Kayali, O.; Sadaoui, A.; Picard, D.; Fafard, M. Aspects of the deformational behaviour of alkali activated fly ash concrete at elevated temperatures. Cem. Concr. Res. 2014, 60, 24–29. [Google Scholar] [CrossRef]

- Hasan-Nattaj, F.; Nematzadeh, M. The effect of forta-ferro and steel fibers on mechanical properties of high-strength concrete with and without silica fume and nano-silica. Constr. Build. Mater. 2017, 137, 557–572. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Yang, K.H.; Ou, Z.W.; Xiao, H.B.; Mo, J.C.; Liu, J.M. Mechanism analysis and effect of cementitious capillary crystalline waterproofing materials on sulfur aluminate cement solidified soil. Rock Soil Mech. 2016, 37, 477–486. [Google Scholar]

- Liu, T.F. Analysis of Performance and Function of Composition of Cementitious Capillary Crystalline Waterproof Materials; Tsinghua University: Beijing, China, 2011. [Google Scholar]

- Fan, X.; Dong, X.; Sun, M.; Li, Z. Electrical characteristic and piezoresistivity of carbon fiber graphite cement-based composites containing CCCW. Acta Mater. Compos. Sin. 2009, 26, 138–142. [Google Scholar]

- Xiao, H.B.; Ou, Z.W.; Liu, J.M.; Yang, K.H. Optimization of Formula for the Rapid Curing Soil Stabilizer with Mixture Design. J. Logist. Eng. Univ. 2015, 31, 60–65. [Google Scholar]

- Yin, J.; Zhang, X.C.; Song, W.M.; Wu, H.; Chi, Y. Response analysis of pervious concrete aggregate gradation characteristics based on theory of mixture design. J. Build. Mater. 2013, 16, 846–852. [Google Scholar]

- Simsek, B.; Ic, Y.T.; Simsek, E.H.; Guvenc, A.B. Development of a graphical user interface for determining the optimal mixture parameters of normal weight concretes: A response surface methodology based quadratic programming approach. Chemom. Intell. Lab. Syst. 2014, 136, 1–9. [Google Scholar] [CrossRef]

- Jeirani, Z.; Jan, B.M.; Ali, B.S.; Noor, I.M.; Hwa, S.C.; Saphanuchart, W. The optimal mixture design of experiments: Alternative method in optimizing the aqueous phase composition of a microemulsion. Chemom. Intell. Lab. Syst. 2012, 112, 1–7. [Google Scholar] [CrossRef]

- Zaitri, R.; Bederina, M.; Bouziani, T.; Makhloufi, Z.; Hadjoudja, M. Development of high performances concrete based on the addition of grinded dune sand and limestone rock using the.mixture design modelling approach. Constr. Build. Mater. 2014, 60, 8–16. [Google Scholar] [CrossRef]

- Yolmeh, M.; Khomeiri, M.; Ahmadi, Z. Application of mixture design to introduce an optimum cell-free supernatant of multiple-strain mixture (MSM) for Lactobacillus against food-borne pathogens. Lwt Food Sci. Technol. 2017, 83, 298–304. [Google Scholar] [CrossRef]

- Jiang, Z.W.; Sun, Z.P.; Wang, P.M. Autogenous relative humidity change and autogenous shrinkage of high-performance cement pastes. Cem. Concr. Res. 2005, 35, 1539–1545. [Google Scholar] [CrossRef]

- Justs, J.; Wyrzykowski, M.; Bajare, D.; Lura, P. Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem. Concr. Res. 2015, 76, 82–90. [Google Scholar] [CrossRef]

- Liu, J.M.; Ou, Z.W.; Mo, J.C.; Chen, Y.Z.; Guo, T.; Deng, W. Effectiveness of Saturated Coral Aggregate and Shrinkage Reducing Admixture on the Autogenous Shrinkage of Ultrahigh Performance Concrete. Adv Mater Sci Eng 2017, 2017, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.R.; Kong, X.M.; Lu, Z.B.; Lu, Z.C.; Hou, S.S. Effects of the charge characteristics of polycarboxylate superplasticizers on the adsorption and the retardation in cement pastes. Cem. Concr. Res. 2015, 67, 184–196. [Google Scholar] [CrossRef]

- del Bosque, I.F.S.; Zhu, W.; Howind, T.; Matias, A.; de Rojas, M.I.S.; Medina, C. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.M.; Khayat, K.H.; Shi, C.J. Effect of nano-SiO2 particles and curing time on development of fiber-matrix bond properties and microstructure of ultra-high strength concrete. Cem. Concr. Res. 2017, 95, 247–256. [Google Scholar] [CrossRef] [Green Version]

- Schrofl, C.; Gruber, M.; Plank, J. Preferential adsorption of polycarboxylate superplasticizers on cement and silica fume in ultra-high performance concrete (UHPC). Cem. Concr. Res. 2012, 42, 1401–1408. [Google Scholar] [CrossRef]

- Bajja, Z.; Dridi, W.; Darquennes, A.; Bennacer, R.; Le Bescop, P.; Rahim, M. Influence of slurried silica fume on microstructure and tritiated water diffusivity of cement pastes. Constr. Build. Mater. 2017, 132, 85–93. [Google Scholar] [CrossRef]

- L’Hopital, E.; Lothenbach, B.; Le Saout, G.; Kulik, D.; Scrivener, K. Incorporation of aluminium in calcium-silicate-hydrates. Cem. Concr. Res. 2015, 75, 91–103. [Google Scholar] [CrossRef]

- Guo, B.L.; Sasaki, K.; Hirajima, T. Characterization of the intermediate in formation of selenate-substituted ettringite. Cem. Concr. Res. 2017, 99, 30–37. [Google Scholar] [CrossRef]

- Zhang, L.; Yamauchi, K.; Li, Z.J.; Zhang, X.X.; Ma, H.Y.; Ge, S.G. Novel understanding of calcium silicate hydrate from dilute hydration. Cem. Concr. Res. 2017, 99, 95–105. [Google Scholar] [CrossRef]

| Specimen | Binder (kg/m3) | Coarse Coral (kg/m3) | Coral Sand (kg/m3) | Simulated Seawater (kg/m3) | SP (kg/m3) | W/B | ||

|---|---|---|---|---|---|---|---|---|

| Cement (P.O 42.5R) | Slag | Fly Ash | ||||||

| S1 [1] | 416 | 80 | 72 | 660 | 990 | 160 | 8 | 0.3 |

| S2 [1] | 606 | 117 | 59 | 361 | 841 | 216 | 16 | 0.28 |

| S3 [1] | 786 | 151 | 71 | 302 | 705 | 252 | 20 | 0.25 |

| S4 [22] | 372 | 1147 NC | 678 | 228 | - | 0.6 | ||

| S5 [23] | 450 | 1020 | 320 | 228 | 21.6 | 0.5 | ||

| S6 [24] | 440 | 950 | 704 QS | 176 TW | 5.28 | 0.4 | ||

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | SO3 | Loss | |

|---|---|---|---|---|---|---|---|---|

| Cement (%) | 64.13 | 21.43 | 2.24 | 3.78 | 2.07 | 0.78 | 2.25 | 3.32 |

| Silica fume (%) | 0.52 | 94.51 | 0.61 | 0.22 | - | - | - | 4.14 |

| Detecting Items | Units | Detecting Results | Detecting Items | Units | Detecting Results |

|---|---|---|---|---|---|

| Moisture content | % | 0.2 | EC value | mS/cm | 0.140 |

| Organic matter | g/kg | 2.77 | Total nitrogen | g/kg | 0.174 |

| Available phosphorus | mg/kg | 6.8 | Total phosphorus | g/kg | 0.075 |

| pH | 9.3 | Total potassium | g/kg | 0.991 | |

| Bulk density | g/m3 | 1.137 | Available boron | mg/kg | 0.201 |

| Texture | Sand | Cation-exchange capacity | cmol/kg | 1.22 | |

| Available nitrogen | mg/kg | 12.0 | Available copper | mg/kg | 0.218 |

| Available potassium | mg/kg | 7.38 | Available zinc | mg/kg | 0.073 |

| Carbonate | g/kg | 987 | Available iron | mg/kg | 0.582 |

| Sample | Binder (Mass Fraction) | Coral Sand a | Coral Powder a | SP a | W/B | |

|---|---|---|---|---|---|---|

| Cement | Silica Fume | |||||

| S1 | 0.8 | 0.2 | 0.88 | 0.35 | 0.024 | 0.14 |

| Sample | Binder (Mass Fraction) | Coral Sand a | Coral Powder a | SP a | W/B | ||

|---|---|---|---|---|---|---|---|

| OPC | SF | CCCW | |||||

| S1 | 0.8 | 0.2 | - | 0.88 | 0.35 | 0.024 | 0.14 |

| S2 | 0.8 | 0.2 | - | 0.88 | 0.35 | 0.024 | 0.16 |

| S3 | 0.8 | 0.2 | - | 0.88 | 0.35 | 0.024 | 0.18 |

| S4 | 0.9 | 0.1 | - | 0.88 | 0.35 | 0.024 | 0.16 |

| S5 | 0.7 | 0.3 | - | 0.88 | 0.35 | 0.024 | 0.16 |

| S6 | 0.6 | 0.4 | - | 0.88 | 0.35 | 0.024 | 0.16 |

| S7 | 0.9 | - | 0.1 | 0.88 | 0.35 | 0.024 | 0.16 |

| S8 | 0.8 | - | 0.2 | 0.88 | 0.35 | 0.024 | 0.16 |

| S9 | 0.7 | - | 0.3 | 0.88 | 0.35 | 0.024 | 0.16 |

| Sample | Binder (Mass Fraction) | Coral Sand a | Coral Powder a | SP a | W/B | Y: Compressive Strength (MPa) | ||

|---|---|---|---|---|---|---|---|---|

| A: OPC | B: CCCW | C: SF | ||||||

| S1 | 0.70 | 0.10 | 0.20 | 0.88 | 0.35 | 0.024 | 0.16 | 114.21 |

| S2 | 0.60 | 0.15 | 0.25 | 0.88 | 0.35 | 0.024 | 0.16 | 108.04 |

| S3 | 0.65 | 0.1 | 0.25 | 0.88 | 0.35 | 0.024 | 0.16 | 100.42 |

| S4 | 0.59 | 0.19 | 0.22 | 0.88 | 0.35 | 0.024 | 0.16 | 100.66 |

| S5 | 0.63 | 0.16 | 0.20 | 0.88 | 0.35 | 0.024 | 0.16 | 105.43 |

| S6 | 0.7 | 0.15 | 0.15 | 0.88 | 0.35 | 0.024 | 0.16 | 115.51 |

| S7 | 0.66 | 0.13 | 0.21 | 0.88 | 0.35 | 0.024 | 0.16 | 103.82 |

| S8 | 0.55 | 0.2 | 0.25 | 0.88 | 0.35 | 0.024 | 0.16 | 88.58 |

| S9 | 0.66 | 0.16 | 0.18 | 0.88 | 0.35 | 0.024 | 0.16 | 104.22 |

| S10 | 0.70 | 0.10 | 0.20 | 0.88 | 0.35 | 0.024 | 0.16 | 114.21 |

| S11 | 0.62 | 0.20 | 0.18 | 0.88 | 0.35 | 0.024 | 0.16 | 104.62 |

| S12 | 0.63 | 0.16 | 0.20 | 0.88 | 0.35 | 0.024 | 0.16 | 105.43 |

| S13 | 0.65 | 0.20 | 0.15 | 0.88 | 0.35 | 0.024 | 0.16 | 108.64 |

| S14 | 0.63 | 0.16 | 0.21 | 0.88 | 0.35 | 0.024 | 0.16 | 105.43 |

| S15 | 0.70 | 0.15 | 0.15 | 0.88 | 0.35 | 0.024 | 0.16 | 115.51 |

| S16 | 0.60 | 0.15 | 0.25 | 0.88 | 0.35 | 0.024 | 0.16 | 108.04 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 703.45 | 9 | 78.16 | 276.45 | <0.0001 |

| Linear mixture | 457.24 | 2 | 228.62 | 808.61 | <0.0001 |

| AB | 0.095 | 1 | 0.095 | 0.34 | 0.5826 |

| AC | 1.76 | 1 | 1.76 | 6.21 | 0.0471 |

| BC | 0.12 | 1 | 0.12 | 0.41 | 0.5464 |

| ABC | 1.5 | 1 | 1.5 | 5.31 | 0.0608 |

| AB(A−B) | 9.69 | 1 | 9.69 | 34.27 | 0.0011 |

| AC(A−C) | 6.92 | 1 | 6.92 | 24.48 | 0.0026 |

| BC(B−C) | 2.71 | 1 | 2.71 | 9.59 | 0.0212 |

| Residual | 1.70 | 6 | 0.28 | - | - |

| Lack of Fit | 1.70 | 1 | 1.70 | - | - |

| Pure error | 0.000 | 5 | 0.000 | - | - |

| Cor total | 705.15 | 15 | - | - | - |

| Binder (Mass Fraction) | Coral Powder | Coral Sand a | W/B | SP a | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|---|---|---|---|

| OPC | CCCW | SF | ||||||

| 0.70 | 0.15 | 0.15 | 0.35 | 0.88 | 0.16 | 0.024 | 116.68 | 18.53 |

| 0.70 | 0.15 | 0.15 | 0.35 | 0.88 | 0.16 | 0.024 | 119.34 | 18.94 |

| 0.70 | 0.15 | 0.15 | 0.35 | 0.88 | 0.16 | 0.024 | 114.27 | 17.25 |

| Sample | Binder (Mass Fraction) | Quartz Powder a | Quartz Sand a | W/B | SP a | |

|---|---|---|---|---|---|---|

| Cement | Silica Fume | |||||

| Reactive powder concrete | 0.8 | 0.2 | 0.34 | 0.88 | 0.2 | 0.024 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Ju, B.; Xie, W.; Yu, H.; Xiao, H.; Dong, S.; Yang, W. Design and Evaluation of an Ultrahigh-Strength Coral Aggregate Concrete for Maritime and Reef Engineering. Materials 2021, 14, 5871. https://doi.org/10.3390/ma14195871

Liu J, Ju B, Xie W, Yu H, Xiao H, Dong S, Yang W. Design and Evaluation of an Ultrahigh-Strength Coral Aggregate Concrete for Maritime and Reef Engineering. Materials. 2021; 14(19):5871. https://doi.org/10.3390/ma14195871

Chicago/Turabian StyleLiu, Jinming, Boyu Ju, Wei Xie, Huang Yu, Haiying Xiao, Shanliang Dong, and Wenshu Yang. 2021. "Design and Evaluation of an Ultrahigh-Strength Coral Aggregate Concrete for Maritime and Reef Engineering" Materials 14, no. 19: 5871. https://doi.org/10.3390/ma14195871

APA StyleLiu, J., Ju, B., Xie, W., Yu, H., Xiao, H., Dong, S., & Yang, W. (2021). Design and Evaluation of an Ultrahigh-Strength Coral Aggregate Concrete for Maritime and Reef Engineering. Materials, 14(19), 5871. https://doi.org/10.3390/ma14195871