Towards Analysis and Optimization for Contact Zone Temperature Changes and Specific Wear Rate of Metal Matrix Composite Materials Produced from Recycled Waste

Abstract

:1. Introduction

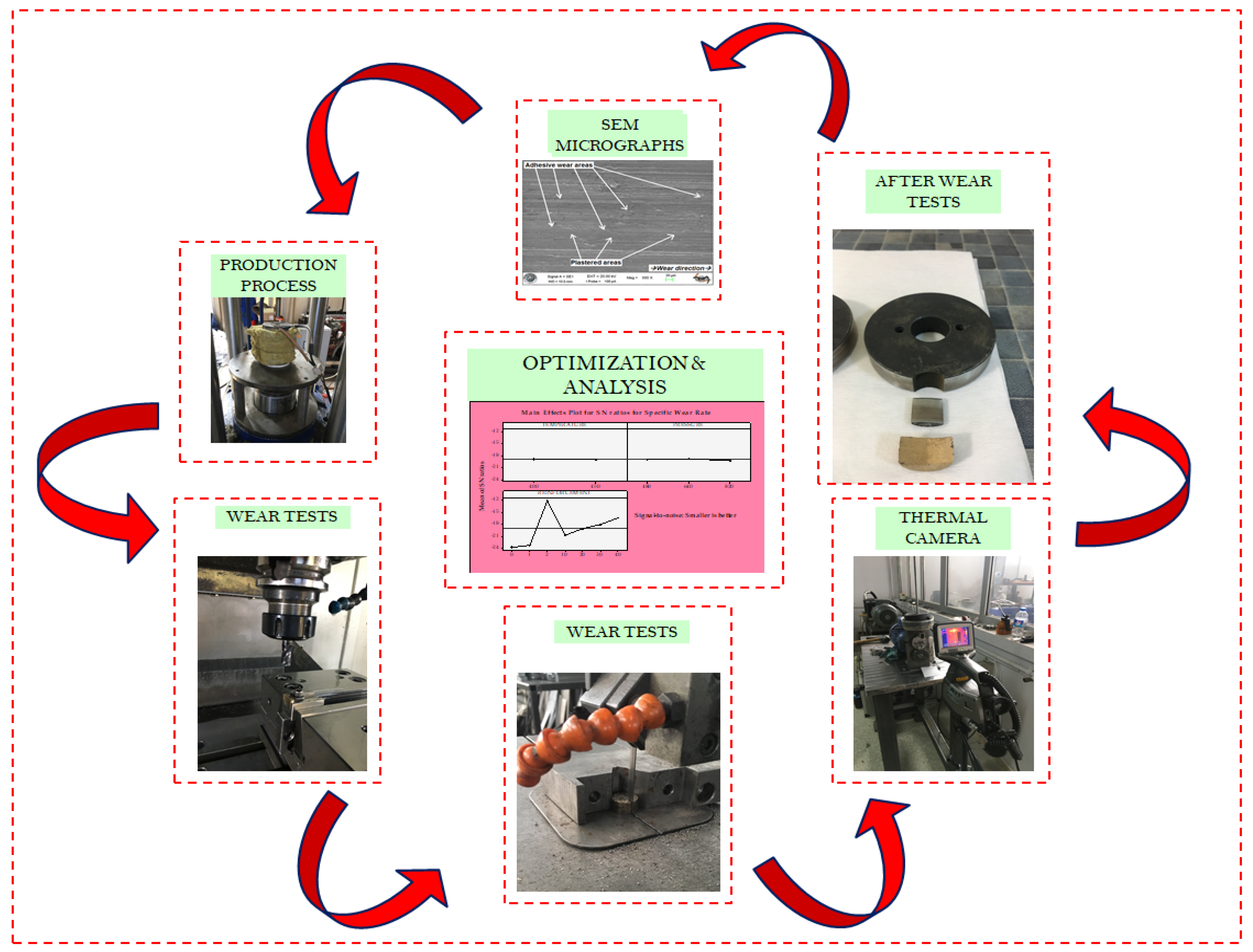

2. Materials and Methods

2.1. Composite Material Production Process

2.2. Wear Tests

2.3. Thermal Camera

2.4. Specific Wear Rate

3. Results and Discussion

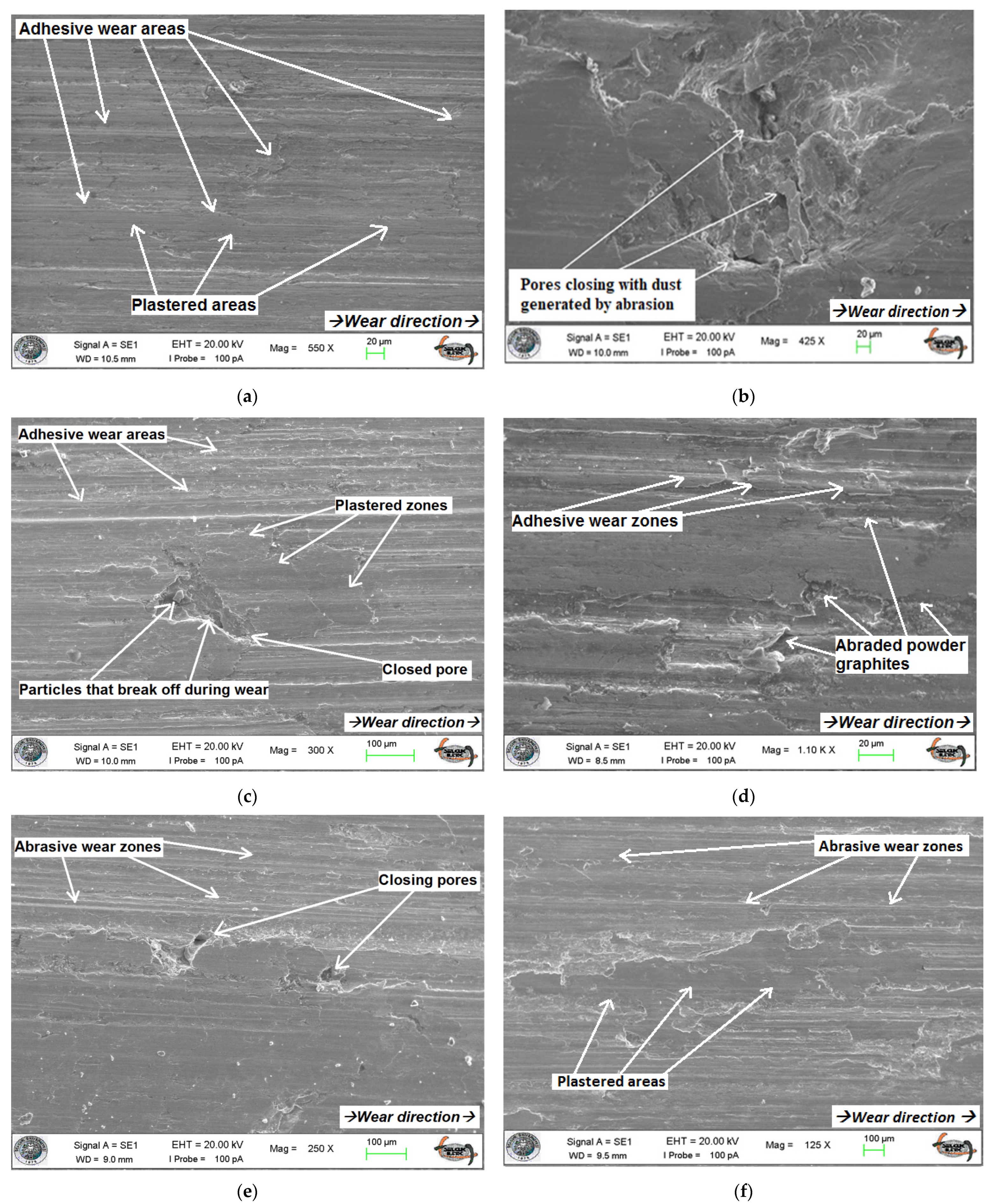

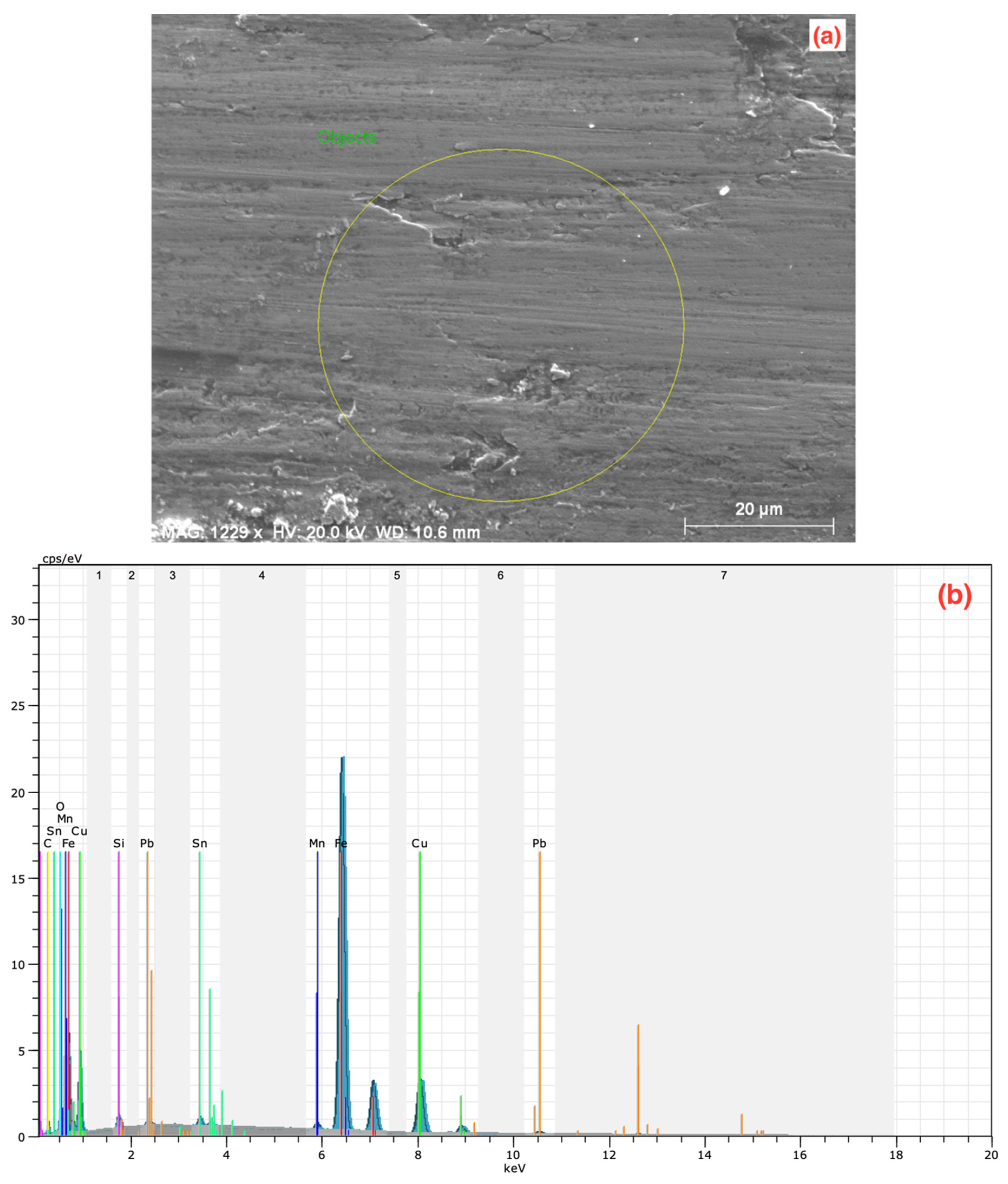

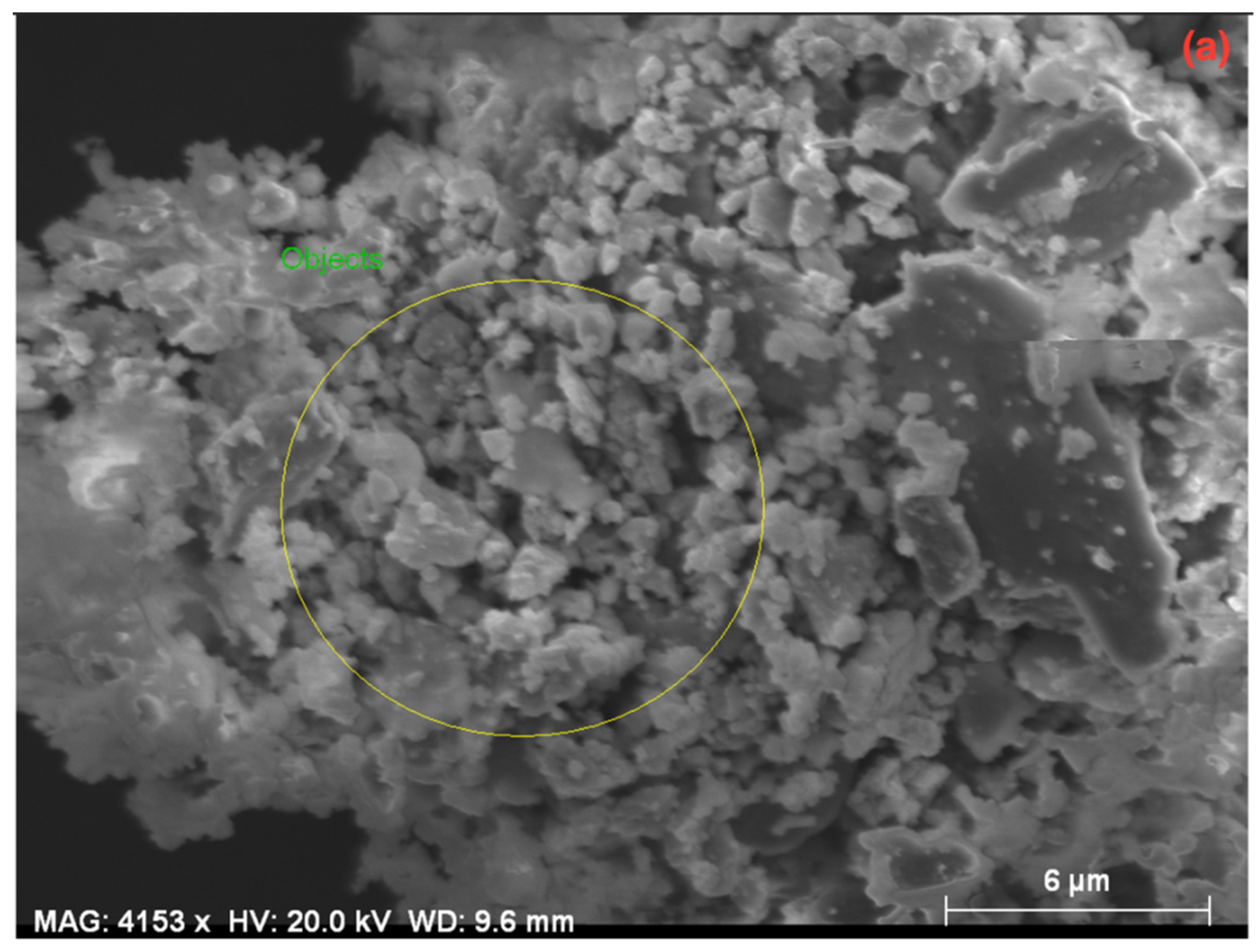

3.1. SEM Images/Microstructures

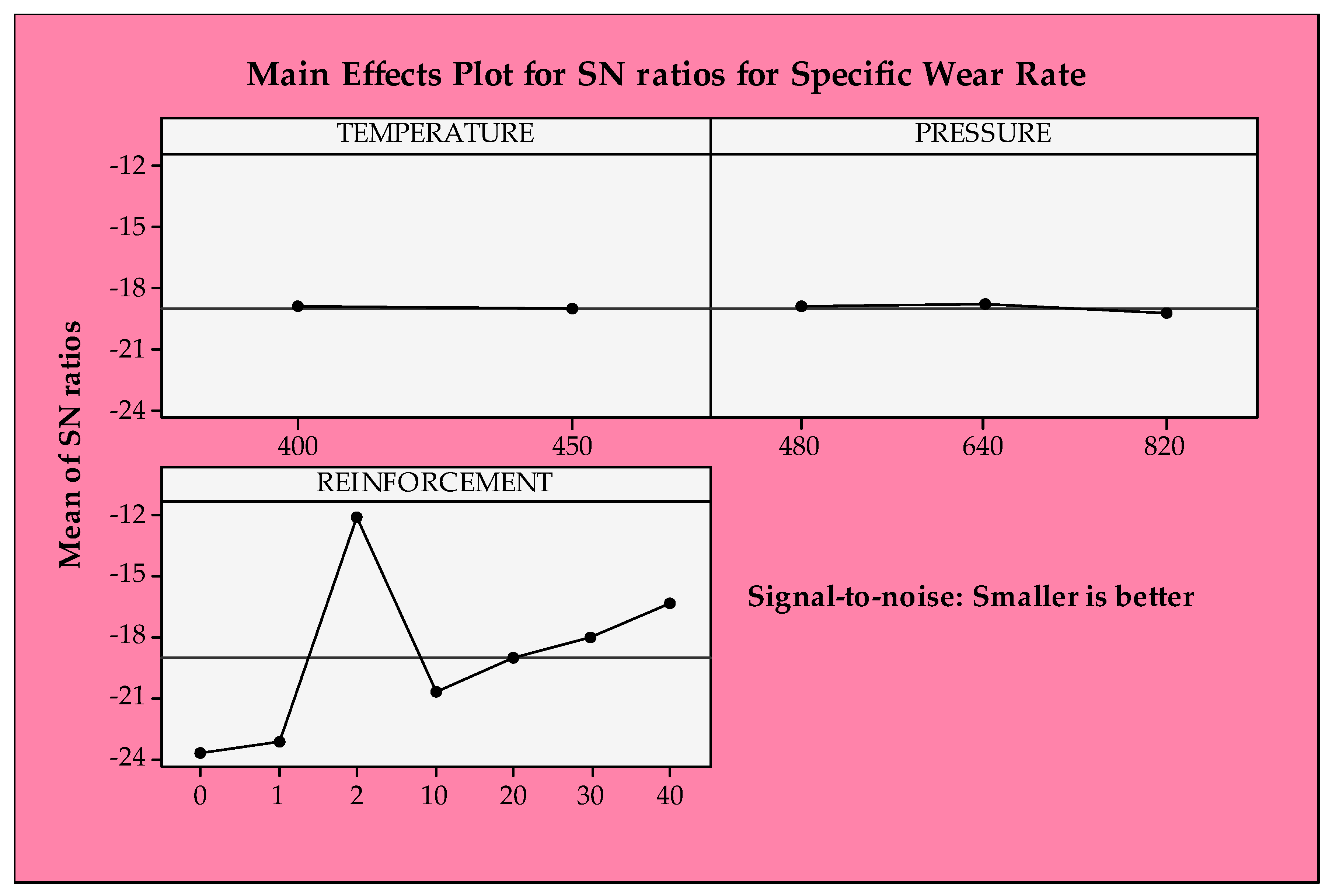

3.2. Interpretation of Experimental Results and Parameter Optimization for Specific Wear Rate

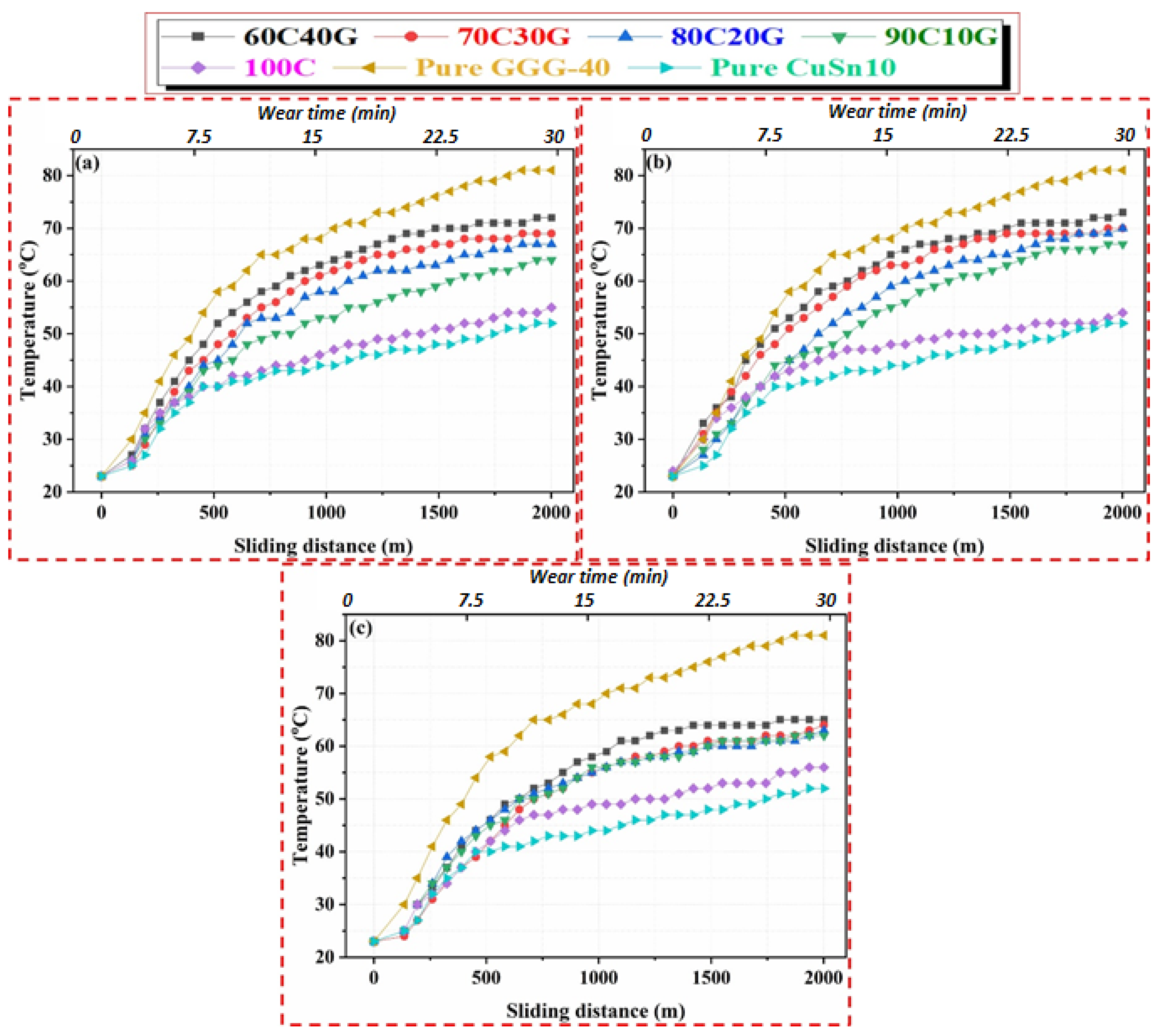

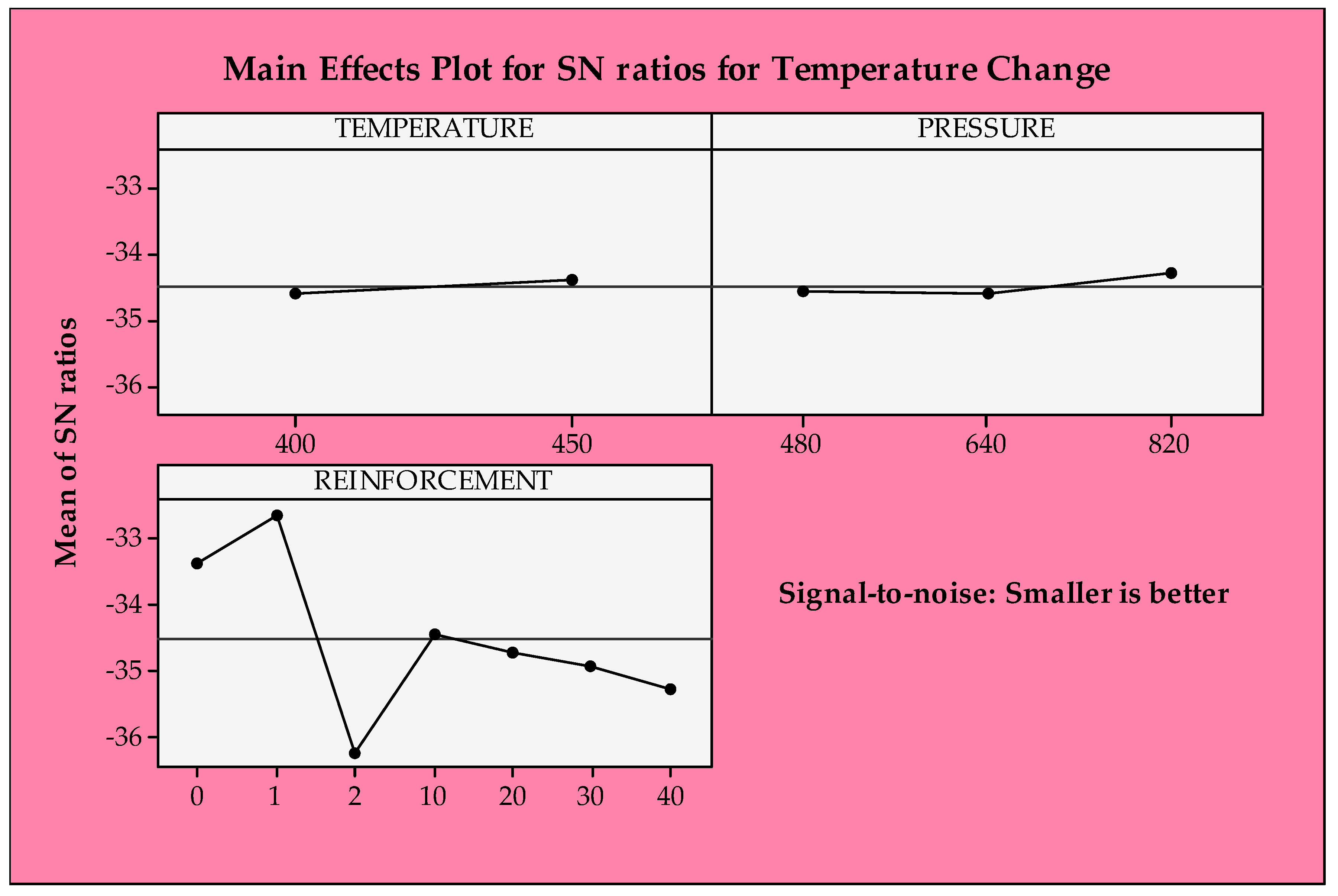

3.3. Interpretation of Experimental Results and Parameter Optimization for Temperature Change

3.4. ANOVA Evaluation for Temperature Change and Specific Wear Rate

4. Conclusions

- The SEM observations show that wear behavior changes depending on the reinforcement content in the MMC system. In the beginning, abrasive wear behavior is observed with decreasing reinforcement content; however, in the following process, the adhesive wear behavior occurs with elevated temperature.

- Considering both S/N ratio and ANOVA statistical analysis outcomes, it is seen that reinforcement is the most dominant production parameter on specific wear rate and temperature changes in the contact zone with 97.6 and 94.8 total percentage contributions, respectively. Plus, F values verify this situation (248.50 and 166.14, respectively).

- After the wear test, the maximum temperature is measured as 82 °C in a pure GGG-40 sample. However, the minimum temperature (52 °C) is observed in a pure CuSn10 specimen due to the higher thermal conductivity of the matrix phase. Naturally, an increment in reinforcement content elevates the temperature of the contact zone due to the increased friction coefficient induced by harder GGG-40 chips.

- A better structural integrity is achieved by increasing production temperature (from 400 to 450 °C) and production pressure (from 480 to 820 MPa). This achieved better structural integrity and increased the resistance to plastic deformation and made it difficult to erode the material from the surface during wear, causing an increase in temperature. On the temperature changes, it should be noted that temperature and pressure seem to be important, along with reinforcement, according to F values.

- According to the S/N ratio analyses for the specific wear rates, the first temperature level, 400 °C, and the middle range of pressure, 640 MPa, are the best conditions. Considering the influence of reinforcement content, it is observed that pure GGG-40 samples demonstrate the lowest specific wear rate compared to the other samples because the initial iron chips are harder than bronze chips. In addition, a gradually increased reinforcement ratio from 10 to 40 wt% improves wear rate characteristics. After this sample, the 60C40G composite produced with 450 °C and 480 MPa shows the lowest specific wear rate.

- As seen from the graphical, statistical, and optimization charts, production parameters exhibit unique importance, and have a determinative effect on the tribological properties. Hence, the selection and application of the proper production parameters are crucial points that should be considered, as they directly or indirectly influence the final product’s performance.

- The proposed method in this study offers an efficient way to manufacture Cu-based MMCs recycled from waste metallic chips.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharma, S.; Singh, J.; Gupta, M.K.; Mia, M.; Dwivedi, S.P.; Saxena, A.; Chattopadhyaya, S.; Singh, R.; Pimenov, D.Y.; Korkmaz, M.E. Investigation on mechanical, tribological and microstructural properties of Al–Mg–Si–T6/SiC/muscovite-hybrid metal-matrix composites for high strength applications. J. Mater. Res. Technol. 2021, 12, 1564–1581. [Google Scholar] [CrossRef]

- Salur, E.; Acarer, M.; Şavkliyildiz, İ. Improving mechanical properties of nano-sized TiC particle reinforced AA7075 Al alloy composites produced by ball milling and hot pressing. Mater. Today Commun. 2021, 27, 102202. [Google Scholar] [CrossRef]

- Aslan, A. Production of Metal Matrix Composites by Recycling of Waste Metal Chips and Their Mechanical Properties; Selçuk University: Konya, Turkey, 2014. [Google Scholar]

- Aslan, A.; Güneş, A.; Salur, E.; Şahin, Ö.S.; Karadağ, H.B.; Akdemir, A. Mechanical properties and microstructure of composites produced by recycling metal chips. Int. J. Miner. Metall. Mater. 2018, 25, 1070–1079. [Google Scholar] [CrossRef]

- Gronostajski, J.; Kaczmar, J.; Marciniak, H.; Matuszak, A. Direct recycling of aluminium chips into extruded products. J. Mater. Process. Technol. 1997, 64, 149–156. [Google Scholar] [CrossRef]

- Pul, M. Investigation of effects of MgO ratio on the surface quality and tool wear in turning Al–MgO composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 232, 2122–2131. [Google Scholar] [CrossRef]

- Şahin, Ö.S.; Güneş, A.; Aslan, A.; Salur, E.; Karadağ, H.B.; Akdemir, A. Low-Velocity Impact Behavior of Porous Metal Matrix Composites Produced by Recycling of Bronze and Iron Chips. Iran. J. Sci. Technol. Trans. Mech. Eng. 2017, 43, 53–60. [Google Scholar] [CrossRef]

- Wagiman, A.; Mustapa, M.S.; Asmawi, R.; Shamsudin, S.; Lajis, M.A.; Mutoh, Y. A review on direct hot extrusion technique in recycling of aluminium chips. Int. J. Adv. Manuf. Technol. 2020, 106, 641–653. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E.; Gunes, A.; Sahin, O.; Karadag, H.; Akdemir, A. The mechanical properties of composite materials recycled from waste metallic chips under different pressures. Int. J. Environ. Sci. Technol. 2019, 16, 5259–5266. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoglu, M.; Gunes, A.; Sahin, O.S. Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos. Part B Eng. 2019, 166, 401–413. [Google Scholar] [CrossRef]

- Kumar, J.; Singh, D.; Kalsi, N.S.; Sharma, S.; Pruncu, C.I.; Pimenov, D.Y.; Rao, K.V.; Kapłonek, W. Comparative study on the mechanical, tribological, morphological and structural properties of vortex casting processed, Al–SiC–Cr hybrid metal matrix composites for high strength wear-resistant applications: Fabrication and characterizations. J. Mater. Res. Technol. 2020, 9, 13607–13615. [Google Scholar] [CrossRef]

- Sap, E. Microstructural and mechanical properties of Cu-based Co-Mo-reinforced composites produced by the powder metallurgy method. J. Mater. Eng. Perform. 2020, 29, 8461–8472. [Google Scholar] [CrossRef]

- Şap, E. Investigation of Mechanical Properties of Cu/Mo-SiCp Composites Produced with P/M, and their Wear Behaviour with the Taguchi Method. Ceram. Int. 2021, 47, 25910–25920. [Google Scholar] [CrossRef]

- Şap, S.; Turgut, A.; Uzun, M. Investigation of microstructure and mechanical properties of Cu/Ti–B–SiCp hybrid composites. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- Cui, G.; Bi, Q.; Zhu, S.; Fu, L.; Yang, J.; Qiao, Z.; Liu, W. Synergistic effect of alumina and graphite on bronze matrix composites: Tribological behaviors in sea water. Wear 2013, 303, 216–224. [Google Scholar] [CrossRef]

- Gronostajski, J.; Marciniak, H.; Matuszak, A.; Samuel, M. Aluminium–ferro-chromium composites produced by recycling of chips. J. Mater. Process. Technol. 2001, 119, 251–256. [Google Scholar] [CrossRef]

- Chmura, W.; Gronostajski, Z. Bearing composites made from aluminium and aluminium bronze chips. J. Mater. Process. Technol. 2006, 178, 188–193. [Google Scholar] [CrossRef]

- de Paula Barbosa, A.; Bobrovnitchii, G.S.; Skury, A.L.D.; da Silva Guimarães, R.; Filgueira, M. Structure, microstructure and mechanical properties of PM Fe–Cu–Co alloys. Mater. Des. 2010, 31, 522–526. [Google Scholar] [CrossRef]

- Wu, S.; Ji, Z.; Zhang, T. Microstructure and mechanical properties of AZ31B magnesium alloy recycled by solid-state process from different size chips. J. Mater. Process. Technol. 2009, 209, 5319–5324. [Google Scholar] [CrossRef]

- Şap, E.; Usca, U.A.; Gupta, M.K.; Kuntoğlu, M. Tool wear and machinability investigations in dry turning of Cu/Mo-SiC p hybrid composites. Int. J. Adv. Manuf. Technol. 2021, 114, 379–396. [Google Scholar] [CrossRef]

- Şap, E.; Usca, Ü.A.; Gupta, M.K.; Kuntoğlu, M.; Sarıkaya, M.; Pimenov, D.Y.; Mia, M. Parametric optimization for improving the machining process of cu/mo-sicp composites produced by powder metallurgy. Materials 2021, 14, 1921. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Yue, H.; Guo, E.; Zhang, S.; Yao, L.; Lin, X.; Wang, B.; Guan, E. Tribological properties of copper matrix composites reinforced with homogeneously dispersed graphene nanosheets. J. Mater. Sci. Technol. 2018, 34, 1925–1931. [Google Scholar] [CrossRef]

- Kestursatya, M.; Kim, J.; Rohatgi, P. Wear performance of copper–graphite composite and a leaded copper alloy. Mater. Sci. Eng. A 2003, 339, 150–158. [Google Scholar] [CrossRef]

- Su, L.; Gao, F.; Han, X.; Fu, R.; Zhang, E. Tribological behavior of copper–graphite powder third body on copper-based friction materials. Tribol. Lett. 2015, 60, 1–12. [Google Scholar] [CrossRef]

- Young, R.J.; Kinloch, I.A.; Gong, L.; Novoselov, K.S. The mechanics of graphene nanocomposites: A review. Compos. Sci. Technol. 2012, 72, 1459–1476. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Şap, S.; Giasin, K.; Pimenov, D.Y. Tribological Aspects, Optimization and Analysis of Cu-B-CrC Composites Fabricated by Powder Metallurgy. Materials 2021, 14, 4217. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, Y.; Wang, J. Tribological behavior of Ti2SnC particulate reinforced copper matrix composites. Mater. Sci. Eng. A 2006, 422, 266–271. [Google Scholar] [CrossRef]

- Güneş, A.; Şahin, Ö.S.; Düzcükoğlu, H.; Salur, E.; Aslan, A.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y. Optimization Study on Surface Roughness and Tribological Behavior of Recycled Cast Iron Reinforced Bronze MMCs Produced by Hot Pressing. Materials 2021, 14, 3364. [Google Scholar] [CrossRef]

- Mai, Y.; Chen, F.; Lian, W.; Zhang, L.; Liu, C.; Jie, X. Preparation and tribological behavior of copper matrix composites reinforced with nickel nanoparticles anchored graphene nanosheets. J. Alloys Compd. 2018, 756, 1–7. [Google Scholar] [CrossRef]

- Ma, W.; Lu, J. Effect of sliding speed on surface modification and tribological behavior of copper–graphite composite. Tribol. Lett. 2011, 41, 363–370. [Google Scholar] [CrossRef]

- Senthil Kumar, P.; Manisekar, K.; Vettivel, S. Effect of extrusion on the microstructure and tribological behavior of copper–tin composites containing MoS2. Tribol. Trans. 2016, 59, 1016–1030. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Tribological behavior of microwave processed copper–nanographite composites. Tribol. Int. 2013, 57, 282–296. [Google Scholar] [CrossRef]

- Ünlü, B.S.; Atik, E. Evaluation of effect of alloy elements in copper based CuSn10 and CuZn30 bearings on tribological and mechanical properties. J. Alloys Compd. 2010, 489, 262–268. [Google Scholar] [CrossRef]

- Wang, Y.; Afsar, A.; Jang, J.; Han, K.; Song, J. Room temperature dry and lubricant wear behaviors of Al2O3f/SiCp/Al hybrid metal matrix composites. Wear 2010, 268, 863–870. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Mukund, K.; Ashwin, M.; Prabu, M. Dry sliding wear behavior of Al 2219/SiCp-Gr hybrid metal matrix composites. J. Mater. Eng. Perform. 2006, 15, 668–674. [Google Scholar] [CrossRef]

- Kozma, M. Friction and Wear of Aluminum Matrix Composites. In Proceedings of the National Tribology Conference, Galati, Romania, 24 September 2003; pp. 99–106. [Google Scholar]

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Sap, E.; Gupta, M.K. Investigations on tool wear, surface roughness, cutting temperature, and chip formation in machining of Cu-B-CrC composites. Int. J. Adv. Manuf. Technol. 2021, 1–15. [Google Scholar] [CrossRef]

- Martın, A.; Rodríguez, J.; Llorca, J. Temperature effects on the wear behavior of particulate reinforced Al-based composites. Wear 1999, 225, 615–620. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, D.S. Tribological properties of nickel-based self-lubricating composite at elevated temperature and counterface material selection. Wear 2008, 265, 533–539. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Tabandeh-Khorshid, M.; Omrani, E.; Lovell, M.R.; Menezes, P.L. Tribology of metal matrix composites. In Tribology for Scientists and Engineers; Springer: Berlin/Heidelberg, Germany, 2013; pp. 233–268. [Google Scholar]

- Baskaran, S.; Anandakrishnan, V.; Duraiselvam, M. Investigations on dry sliding wear behavior of in situ casted AA7075–TiC metal matrix composites by using Taguchi technique. Mater. Des. 2014, 60, 184–192. [Google Scholar] [CrossRef]

- Aslan, A. Optimization and analysis of process parameters for flank wear, cutting forces and vibration in turning of AISI 5140: A comprehensive study. Measurement 2020, 163, 107959. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Sağlam, H.; Pimenov, D.Y.; Giasin, K.; Mikolajczyk, T. Optimization and analysis of surface roughness, flank wear and 5 different sensorial data via Tool Condition Monitoring System in turning of AISI 5140. Sensors 2020, 20, 4377. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of progressive tool wear for determining of optimized machining parameters in turning. Measurement 2019, 140, 427–436. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Elayaperumal, A.; Issac, R.F. A statistical analysis of optimization of wear behaviour of Al-Al2O3 composites using Taguchi technique. Procedia Eng. 2013, 64, 973–982. [Google Scholar] [CrossRef] [Green Version]

- Sahin, Y. Optimization of testing parameters on the wear behaviour of metal matrix composites based on the Taguchi method. Mater. Sci. Eng. A 2005, 408, 1–8. [Google Scholar] [CrossRef]

- Stalin, B.; Kumar, P.R.; Ravichandran, M.; Saravanan, S. Optimization of wear parameters and their relative effects on stir cast AA6063-Si3N4 Composite. Mater. Res. Express 2018, 5, 106502. [Google Scholar] [CrossRef]

- Alagarsamy, S.; Ravichandran, M. Parametric studies on dry sliding wear behaviour of Al-7075 alloy matrix composite using S/N ratio and ANOVA analysis. Mater. Res. Express 2020, 7, 016557. [Google Scholar] [CrossRef] [Green Version]

- Stojanovic, B.; Blagojevic, J.; Babic, M.; Velickovic, S.; Miladinovic, S. Optimization of hybrid aluminum composites wear using Taguchi method and artificial neural network. Ind. Lubr. Tribol. 2017, 69, 1005–1015. [Google Scholar] [CrossRef]

- Chang, B.P.; Akil, H.M.; Nasir, R.B.; Khan, A. Optimization on wear performance of UHMWPE composites using response surface methodology. Tribol. Int. 2015, 88, 252–262. [Google Scholar] [CrossRef]

- Fung, C.-P. Manufacturing process optimization for wear property of fiber-reinforced polybutylene terephthalate composites with grey relational analysis. Wear 2003, 254, 298–306. [Google Scholar] [CrossRef]

- Gunes, A. Investigation of Wear Properties of Composite Materials Produced by Recycling of Cast Iron/Bronze. Ph.D. Thesis, Konya Technical University, Konya, Turkey, 2019. [Google Scholar]

- Aslan, A.; Sahin, O.S.; Salur, E.; Gunes, A.; Akdemir, A.; Karadag, H.B. A new method for recycling of metal chips. J. Selçuk Univ. Nat. Appl. Sci. 2015, 4, 1–12. [Google Scholar]

- Uzun, M.; Usca, U.A. Effect of Cr particulate reinforcements in different ratios on wear performance and mechanical properties of Cu matrix composites. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–9. [Google Scholar] [CrossRef]

- German, R.M. Powder Metallurgy and Particulate Materials Processing: The Processes, Materials, Products, Properties and Applications; Metal Powder Industries Federation Princeton: Princeton, NJ, USA, 2005. [Google Scholar]

- Aslan, A.; Salur, E.; Güneş, A.; Şahin, Ö.S.; Karadağ, H.B.; Akdemir, A. The Effect of Ultrasonic Cleaning Upon Mechanical Properties of Metal Matrix Composites. Trans. Indian Inst. Met. 2021, 74, 107–118. [Google Scholar] [CrossRef]

- Sukur, E.F.; Onal, G. Graphene nanoplatelet modified basalt/epoxy multi-scale composites with improved tribological performance. Wear 2020, 460, 203481. [Google Scholar] [CrossRef]

- Çuvalcı, H.; Celik, H.S. Investigation of the abrasive wear behaviour of ZA-27 alloy and CuSn10 bronze. J. Mater. Sci. 2011, 46, 4850–4857. [Google Scholar] [CrossRef]

- Jayashree, P.; Turani, S.; Straffelini, G. Effect of testing conditions on the dry sliding behavior of a Cu-Based refractory composite material. Tribol. Int. 2019, 140, 105850. [Google Scholar] [CrossRef]

- Tang, B.; Mo, J.; Xu, J.; Wu, Y.; Zhu, M.; Zhou, Z. Effect of perforated structure of friction block on the wear, thermal distribution and noise characteristics of railway brake systems. Wear 2019, 426, 1176–1186. [Google Scholar] [CrossRef]

- Abd El Aal, M.I.; Yoon, E.Y.; Kim, H.S. Recycling of AlSi8Cu3 alloy chips via high pressure torsion. Mater. Sci. Eng. A 2013, 560, 121–128. [Google Scholar] [CrossRef]

- Lyu, Y.; Bergseth, E.; Tu, M.; Olofsson, U. Effect of humidity on the tribological behaviour and airborne particle emissions of railway brake block materials. Tribol. Int. 2018, 118, 360–367. [Google Scholar] [CrossRef]

- Hutchings, I. Tribology: Friction and wear of engineering materials, 1992. Great Br. 1992, 13, 78–84. [Google Scholar]

- Deshpande, P.; Lin, R. Wear resistance of WC particle reinforced copper matrix composites and the effect of porosity. Mater. Sci. Eng. A 2006, 418, 137–145. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Fushchich, O.; Danyluk, S. The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper. Wear 2012, 290, 106–123. [Google Scholar] [CrossRef]

- Hwang, Y.-H.; Myung, B.-S.; Kim, H.-J. Study on frictional behavior of carbon nanotube thin films with respect to surface condition. Friction 2018, 6, 432–442. [Google Scholar] [CrossRef] [Green Version]

- Menezes, P.L.; Kailas, S.V. Influence of roughness parameters and surface texture on friction during sliding of pure lead over 080 M40 steel. Int. J. Adv. Manuf. Technol. 2009, 43, 731. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y.; Sun, Z.; Ji, Y. Corrosion resistance and tribological behavior of particles reinforced AZ31 magnesium matrix composites developed by friction stir processing. J. Mater. Res. Technol. 2021, 11, 1019–1030. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Mia, M.; Jamil, M.; Singla, A.K.; Bansal, A.; Pimenov, D.Y.; Kuntoğlu, M. Tribological performance based machinability investigations in cryogenic cooling assisted turning of α-β titanium alloy. Tribol. Int. 2021, 160, 107032. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | S | Mg | P | Cu | Sn | Zn | Pb |

|---|---|---|---|---|---|---|---|---|---|---|

| CuSn10 | - | - | - | - | - | - | 89.2 | 9.3 | 0.41 | 0.01 |

| GGG-40 | 3.4 | 2.5 | 0.13 | 0.01 | 0.046 | 0.08 | - | - | - | - |

| Specimen Code | Temperature (°C) | Pressure (MPa) | Mixture Weight Ratio (wt%) |

|---|---|---|---|

| 60C40G | 400, 450 | 480, 640, 820 | %60 CuSn10-%40 GGG-40 |

| 70C30G | 400, 450 | 480, 640, 820 | %70 CuSn10-%30 GGG-40 |

| 80C20G | 400, 450 | 480, 640, 820 | %80 CuSn10-%20 GGG-40 |

| 90C10G | 400, 450 | 480, 640, 820 | %90 CuSn10-%10 GGG-40 |

| 100C | 400, 450 | 480, 640, 820 | %100 CuSn10-%0 GGG-40 |

| Experiment Number | Specimen Code | Temperature T (°C) | Pressure P (MPa) | Reinforcement Ratio R (%wt.) | Temperature Change T (°C) | Specific Wear Rate SWR |

|---|---|---|---|---|---|---|

| 1 | 60C40G | 400 | 480 | 40 | 60.06 | 6.33 |

| 2 | 70C30G | 400 | 480 | 30 | 57.90 | 7.97 |

| 3 | 80C20G | 400 | 480 | 20 | 56.41 | 8.51 |

| 4 | 90C10G | 400 | 480 | 10 | 54.67 | 10.62 |

| 5 | 100C | 400 | 480 | 0 | 48.96 | 16.81 |

| 6 | 60C40G | 400 | 640 | 40 | 58.61 | 7.32 |

| 7 | 70C30G | 400 | 640 | 30 | 57.03 | 7.51 |

| 8 | 80C20G | 400 | 640 | 20 | 56.22 | 8.29 |

| 9 | 90C10G | 400 | 640 | 10 | 54.29 | 10.05 |

| 10 | 100C | 400 | 640 | 0 | 45.96 | 15.18 |

| 11 | 60C40G | 400 | 820 | 40 | 56.22 | 6.53 |

| 12 | 70C30G | 400 | 820 | 30 | 54.93 | 8.18 |

| 13 | 80C20G | 400 | 820 | 20 | 53.54 | 8.84 |

| 14 | 90C10G | 400 | 820 | 10 | 52.45 | 11.19 |

| 15 | 100C | 400 | 820 | 0 | 47.35 | 14.67 |

| 16 | 60C40G | 450 | 480 | 40 | 58.83 | 5.69 |

| 17 | 70C30G | 450 | 480 | 30 | 56.22 | 7.05 |

| 18 | 80C20G | 450 | 480 | 20 | 53.96 | 8.89 |

| 19 | 90C10G | 450 | 480 | 10 | 50.64 | 11.59 |

| 20 | 100C | 450 | 480 | 0 | 44.96 | 16.37 |

| 21 | 60C40G | 450 | 640 | 40 | 60.16 | 5.97 |

| 22 | 70C30G | 450 | 640 | 30 | 58.38 | 7.53 |

| 23 | 80C20G | 450 | 640 | 20 | 54.90 | 9.01 |

| 24 | 90C10G | 450 | 640 | 10 | 52.90 | 10.86 |

| 25 | 100C | 450 | 640 | 0 | 46 | 15.02 |

| 26 | 60C40G | 450 | 820 | 40 | 53.74 | 7.76 |

| 27 | 70C30G | 450 | 820 | 30 | 50.87 | 9.60 |

| 28 | 80C20G | 450 | 820 | 20 | 51.54 | 9.88 |

| 29 | 90C10G | 450 | 820 | 10 | 51.29 | 10.81 |

| 30 | 100C | 450 | 820 | 0 | 46.09 | 13.87 |

| 31 | Pure CuSn10 | 450 | 820 | * 1 | 42.83 | 14.29 |

| 32 | Pure GGG-40 | 450 | 820 | * 2 | 64.77 | 4.01 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value | Percent Contribution (%) |

|---|---|---|---|---|---|---|

| Specific Wear Rate | ||||||

| Temperature | 1 | 0.057 | 0.057 | 0.15 | 0.706 | 0.0001 |

| Pressure | 2 | 1.171 | 0.5856 | 1.49 | 0.241 | 0.2 |

| Reinforcement | 6 | 585.969 | 97.6615 | 248.50 | 0.000 | 97.6 |

| Residual error | 32 | 12.576 | 0.3930 | - | - | 2.2 |

| Total | 41 | 599.773 | - | - | - | 100 |

| Temperature Change | ||||||

| Temperature | 1 | 0.3886 | 0.38862 | 7.53 | 0.010 | 0.7 |

| Pressure | 2 | 0.7629 | 0.37143 | 7.39 | 0.002 | 1.4 |

| Reinforcement | 6 | 51.4356 | 8.57260 | 166.14 | 0.000 | 94.8 |

| Residual error | 32 | 1.6512 | 0.05160 | - | - | 3.1 |

| Total | 41 | 54.2382 | - | - | - | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Güneş, A.; Salur, E.; Aslan, A.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y.; Düzcükoğlu, H.; Şahin, Ö.S. Towards Analysis and Optimization for Contact Zone Temperature Changes and Specific Wear Rate of Metal Matrix Composite Materials Produced from Recycled Waste. Materials 2021, 14, 5145. https://doi.org/10.3390/ma14185145

Güneş A, Salur E, Aslan A, Kuntoğlu M, Giasin K, Pimenov DY, Düzcükoğlu H, Şahin ÖS. Towards Analysis and Optimization for Contact Zone Temperature Changes and Specific Wear Rate of Metal Matrix Composite Materials Produced from Recycled Waste. Materials. 2021; 14(18):5145. https://doi.org/10.3390/ma14185145

Chicago/Turabian StyleGüneş, Aydın, Emin Salur, Abdullah Aslan, Mustafa Kuntoğlu, Khaled Giasin, Danil Yurievich Pimenov, Hayrettin Düzcükoğlu, and Ömer Sinan Şahin. 2021. "Towards Analysis and Optimization for Contact Zone Temperature Changes and Specific Wear Rate of Metal Matrix Composite Materials Produced from Recycled Waste" Materials 14, no. 18: 5145. https://doi.org/10.3390/ma14185145

APA StyleGüneş, A., Salur, E., Aslan, A., Kuntoğlu, M., Giasin, K., Pimenov, D. Y., Düzcükoğlu, H., & Şahin, Ö. S. (2021). Towards Analysis and Optimization for Contact Zone Temperature Changes and Specific Wear Rate of Metal Matrix Composite Materials Produced from Recycled Waste. Materials, 14(18), 5145. https://doi.org/10.3390/ma14185145