Preheated (Heat-Assisted) Clinching Process for Al/CFRP Cross-Tension Specimens

Abstract

1. Introduction

2. Materials and Methods

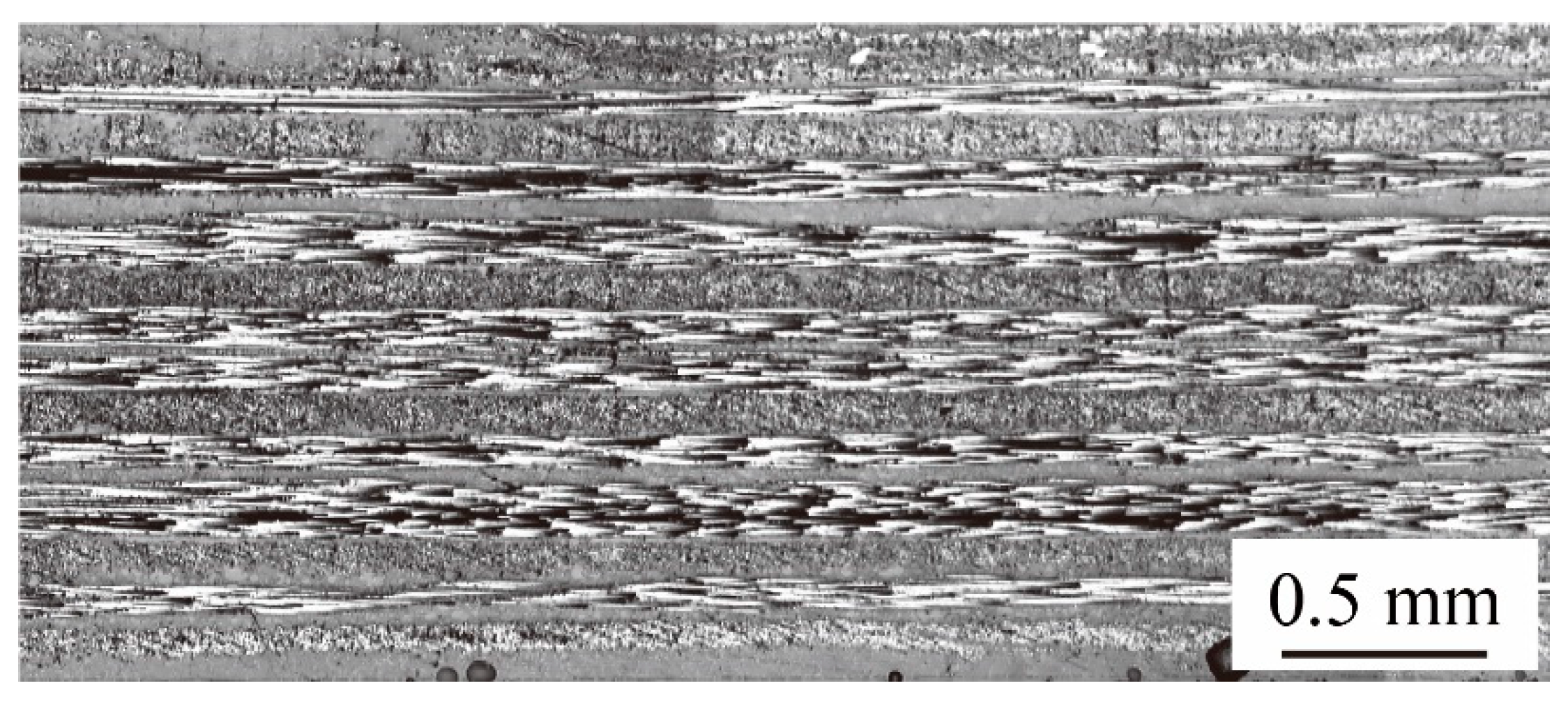

2.1. Materials

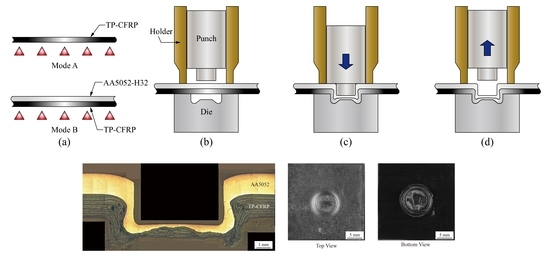

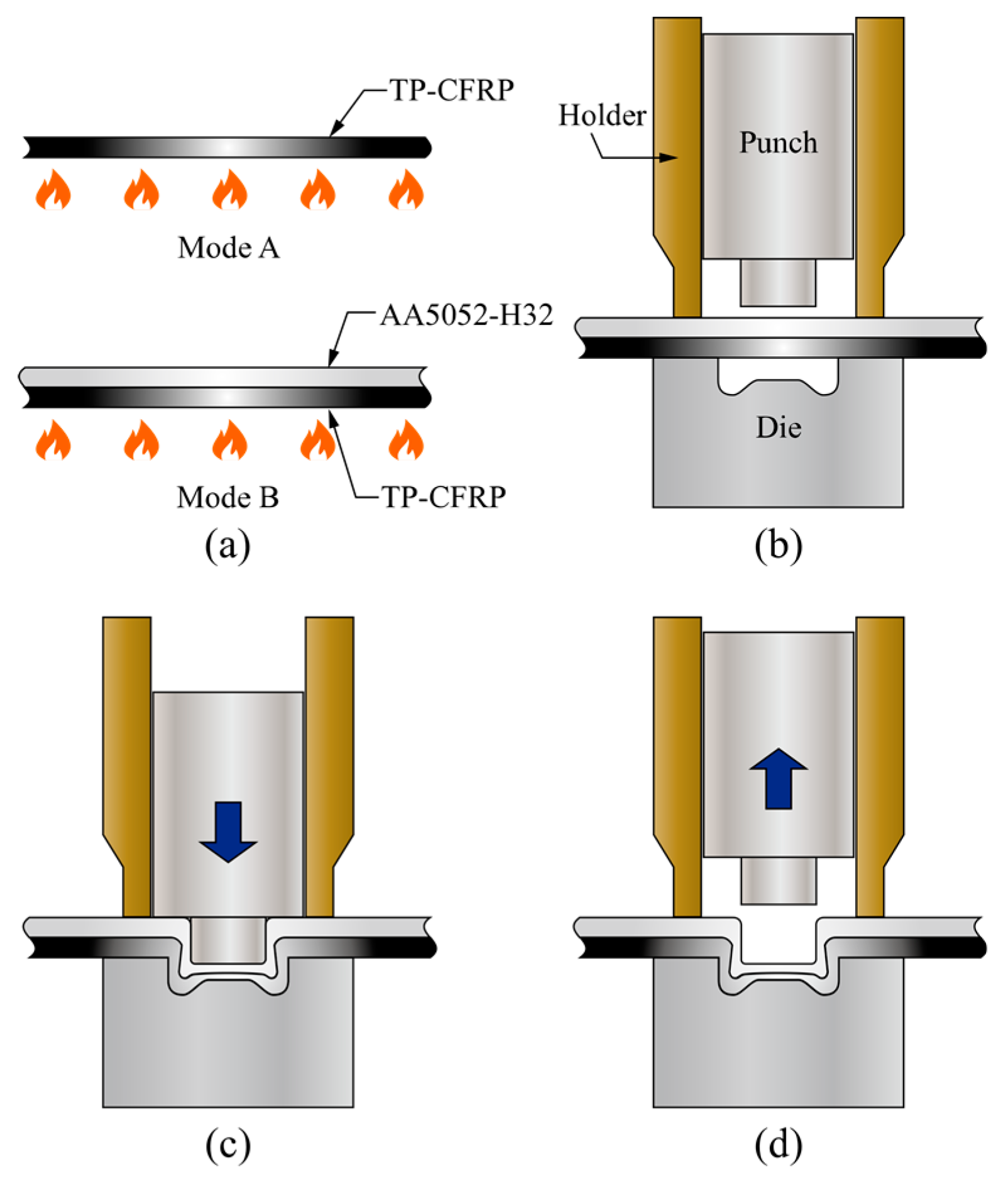

2.2. Preheated (Heat-Assisted) Clinching Process

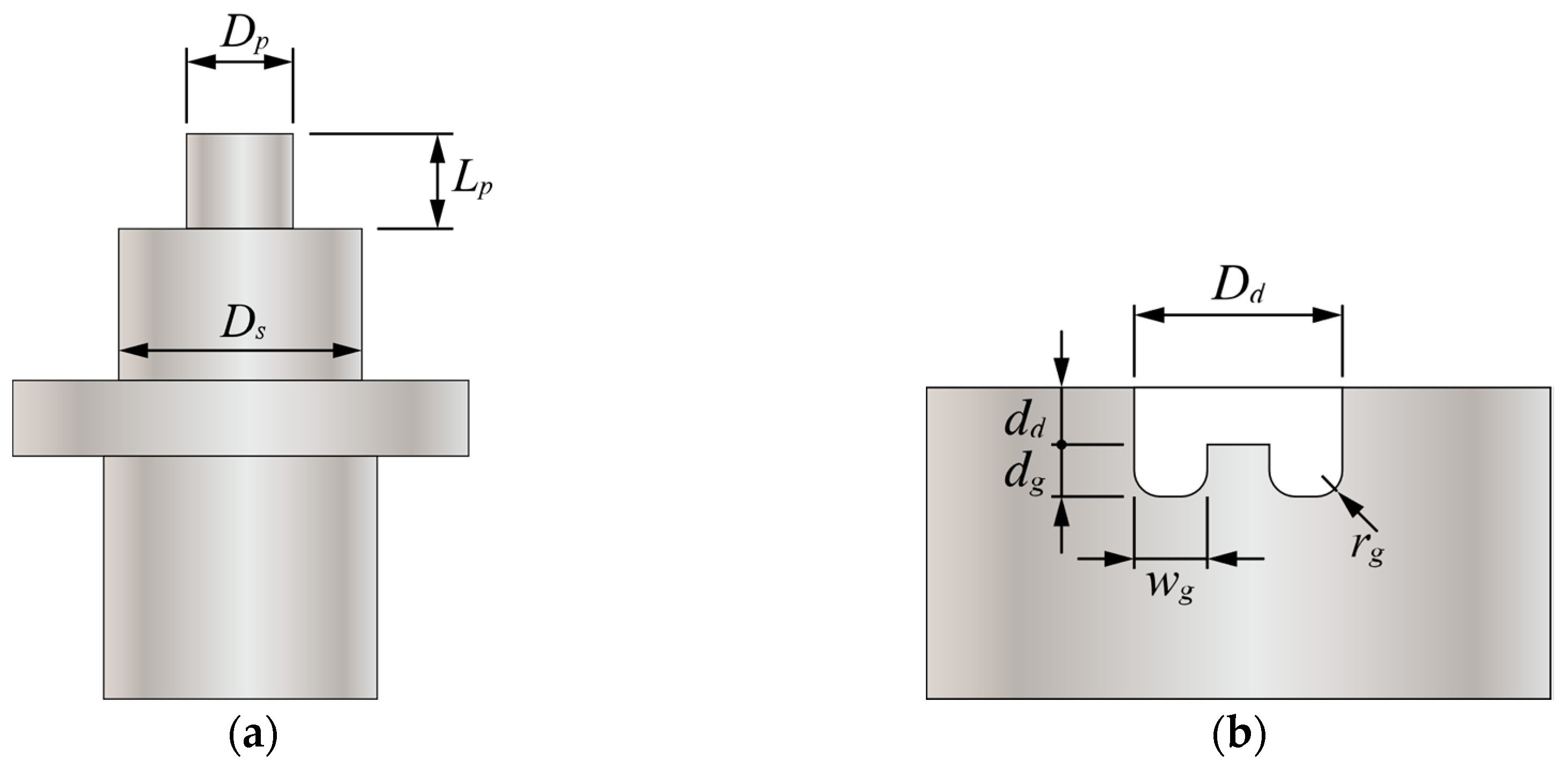

2.3. Punch and Die Designs

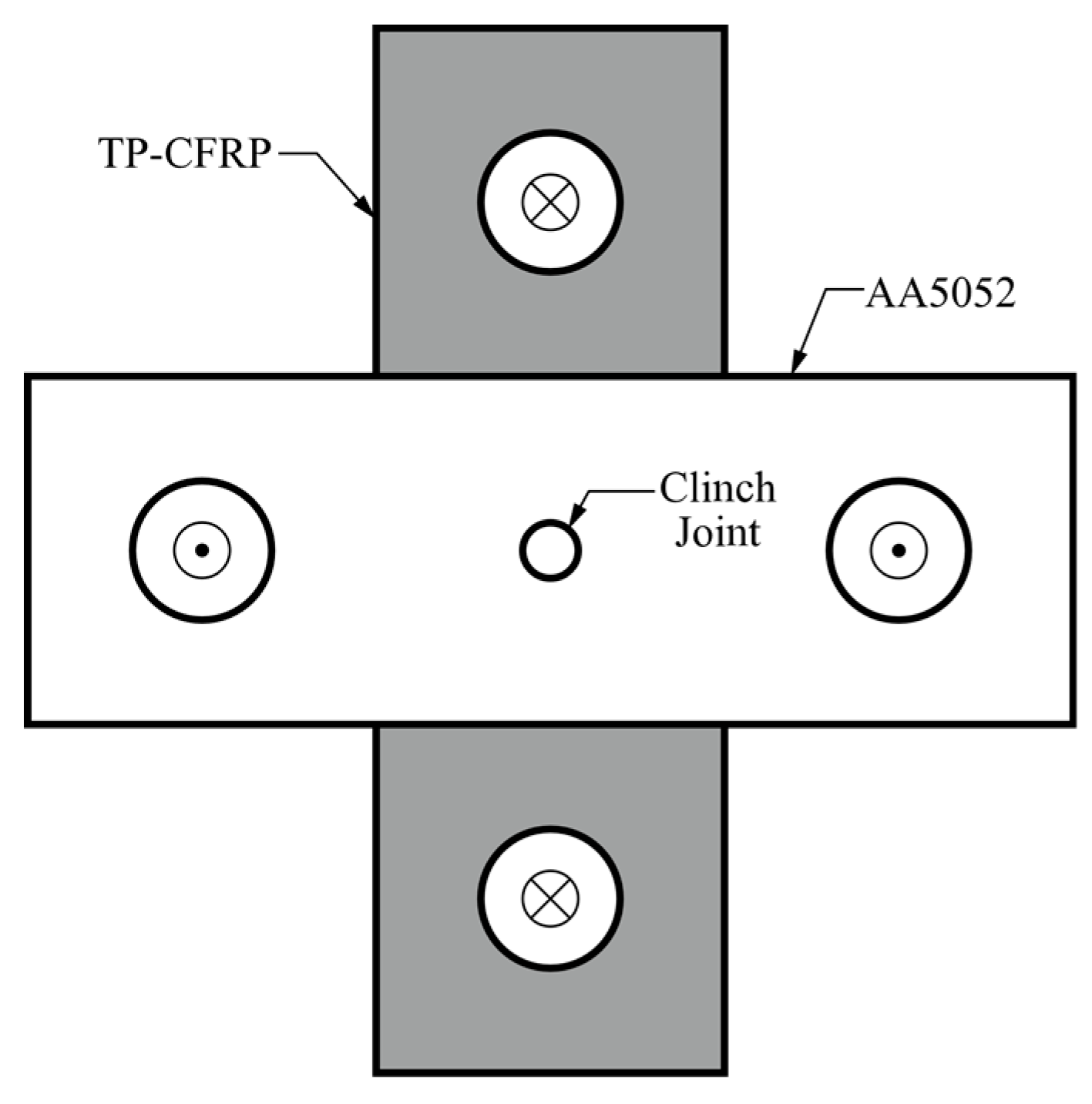

2.4. Specimen Design

2.5. Quasi-Static and Fatigue Tests

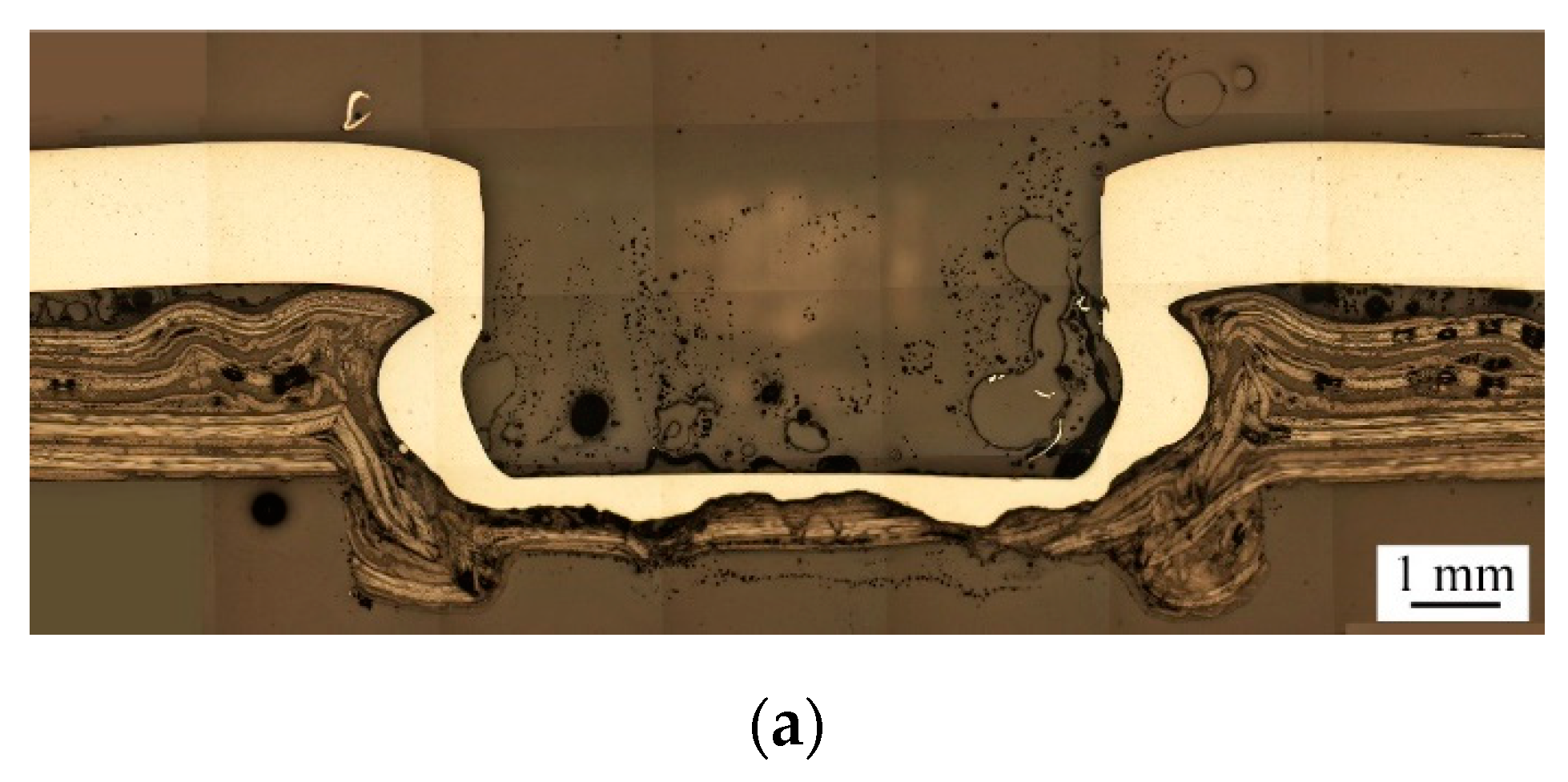

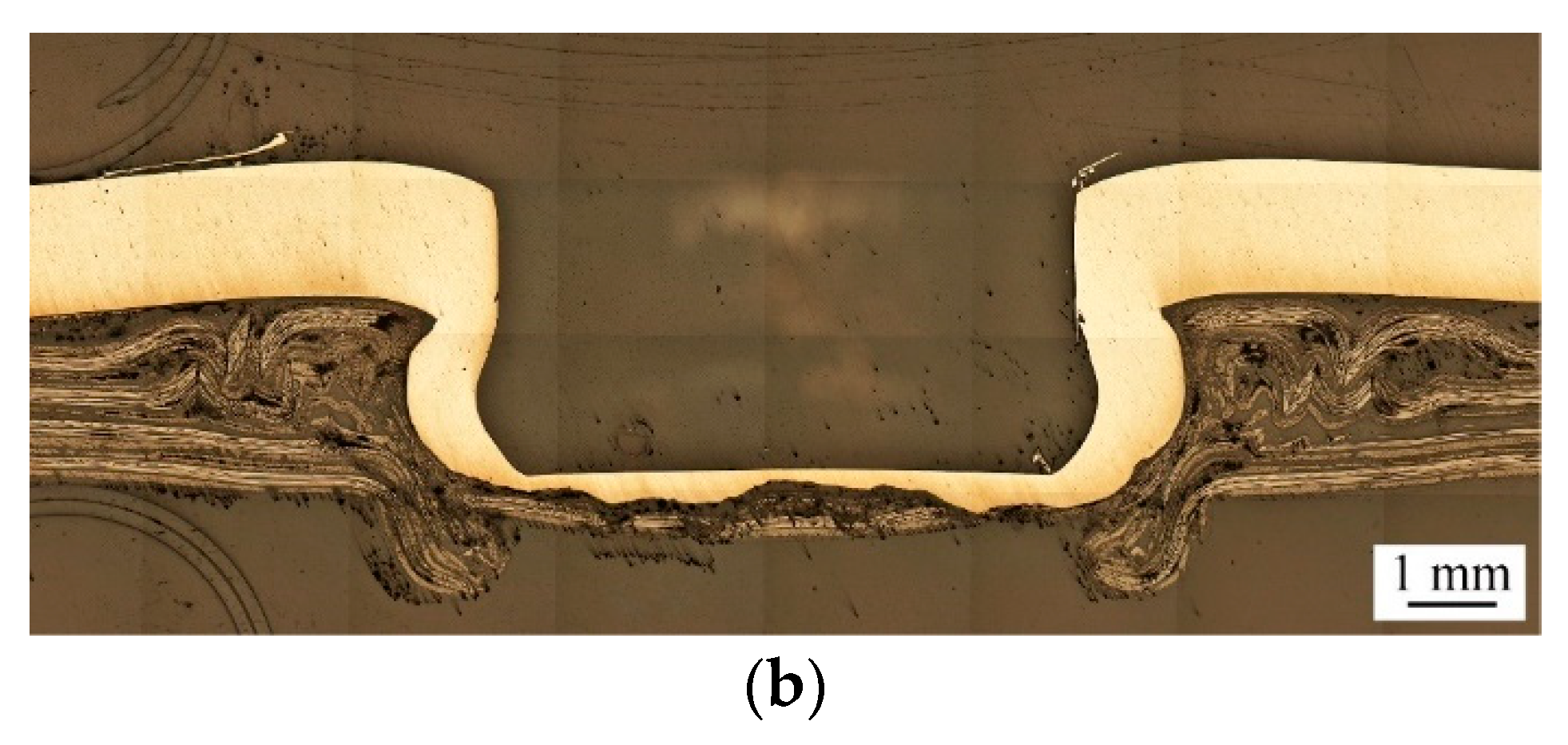

3. AA5052/TP-CFRP Clinch Joint

4. Results and Discussion

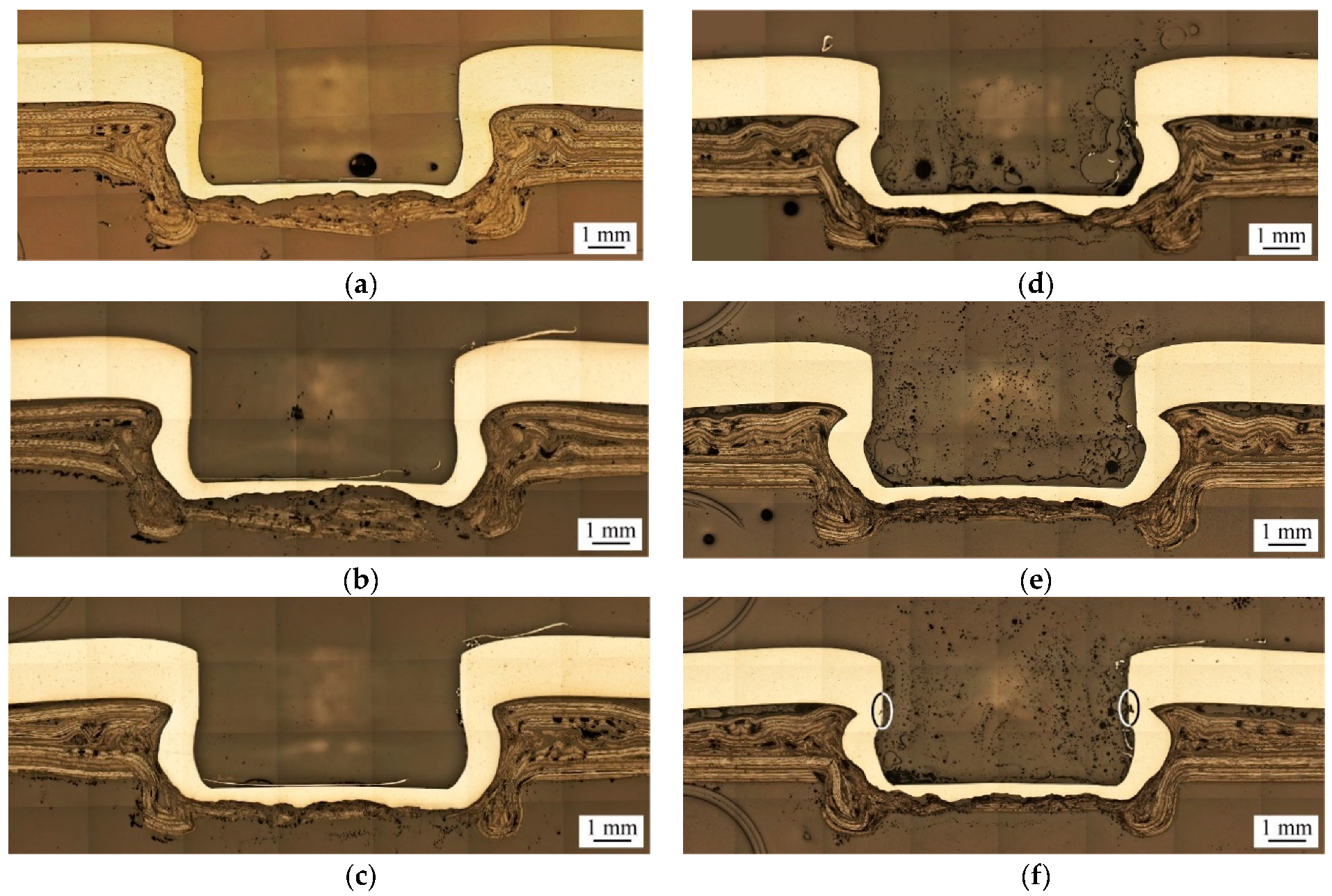

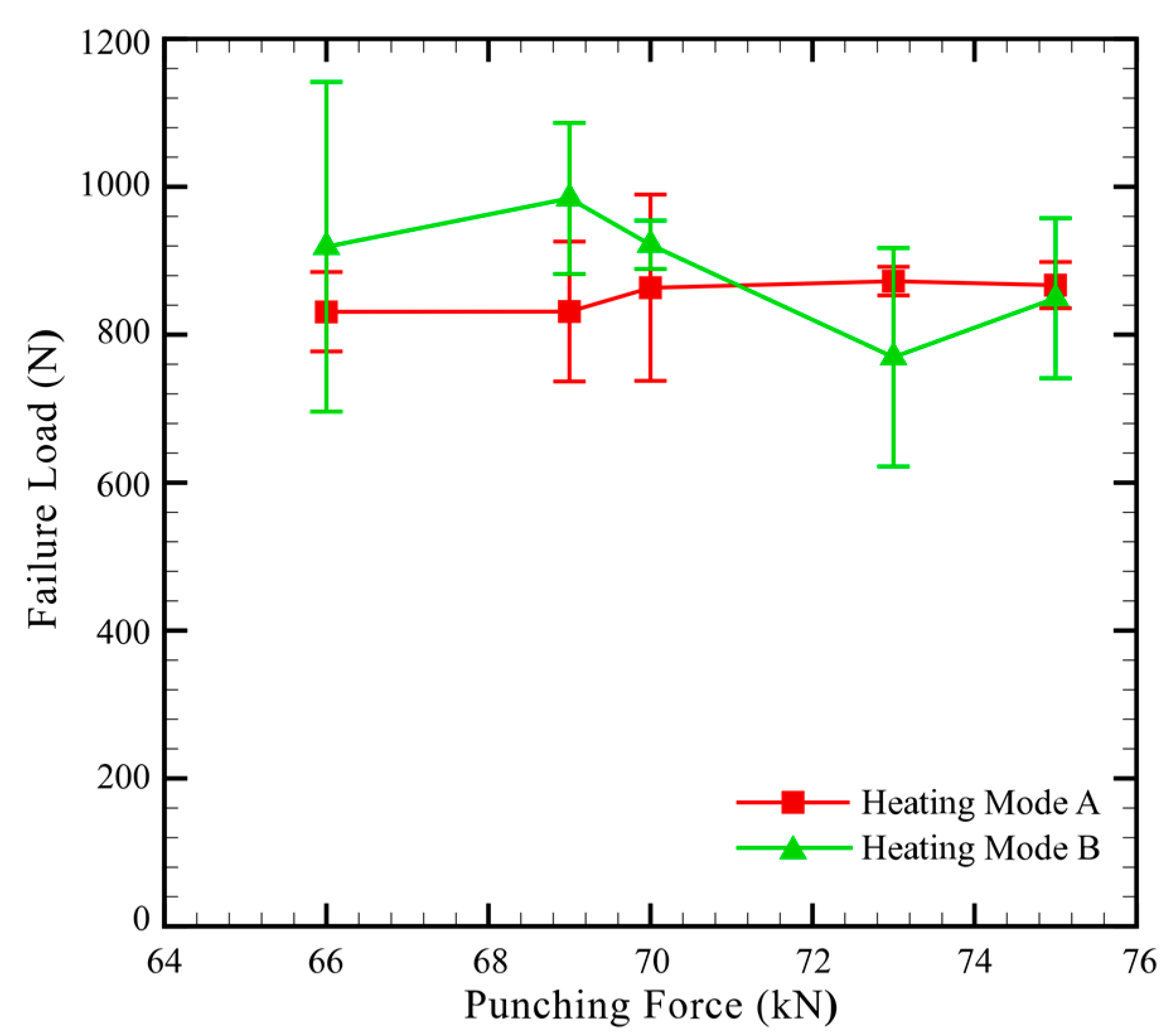

4.1. Heating Mode Effects

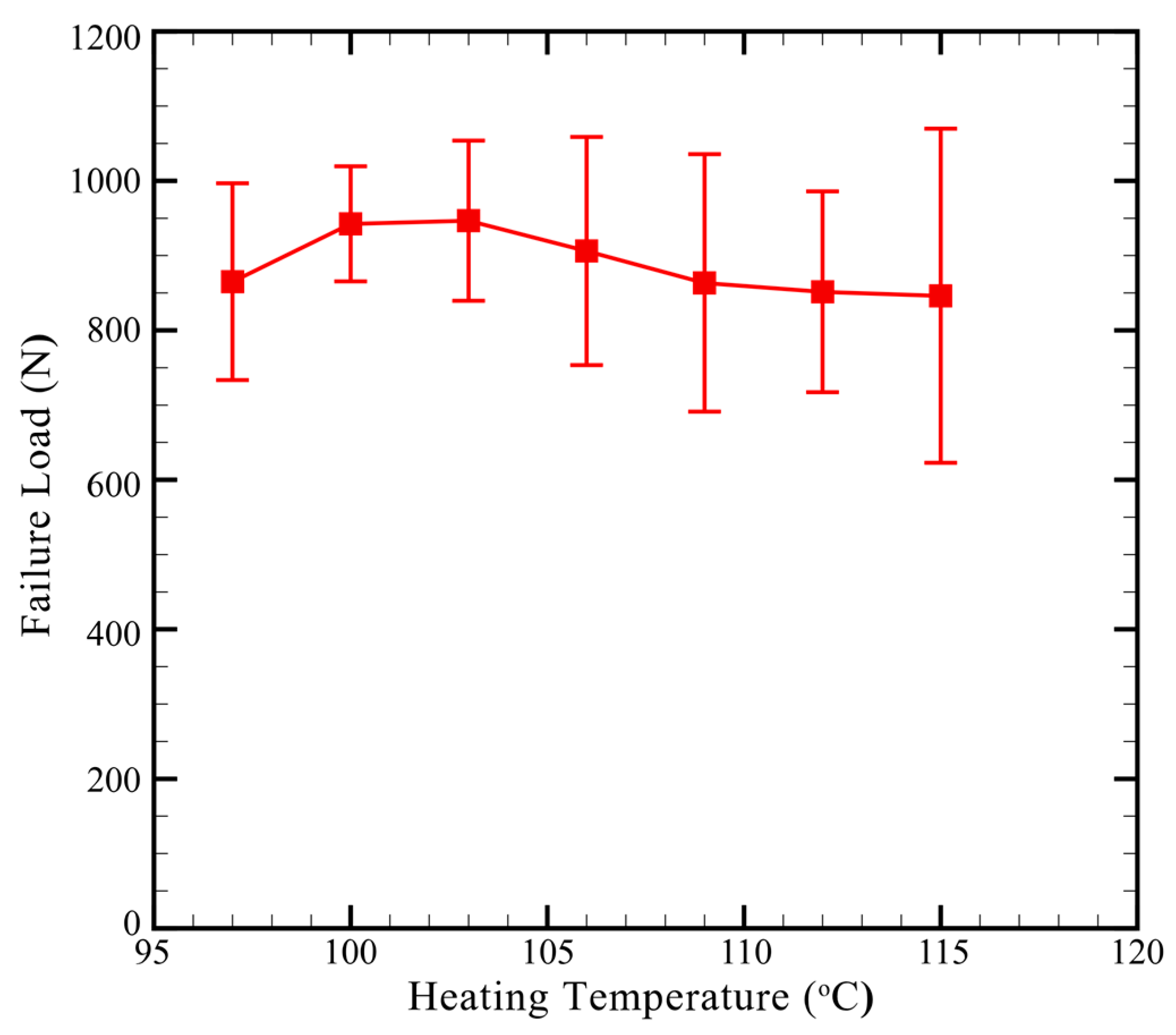

4.2. Heating Temperature Effects

4.3. Die Depth Effects

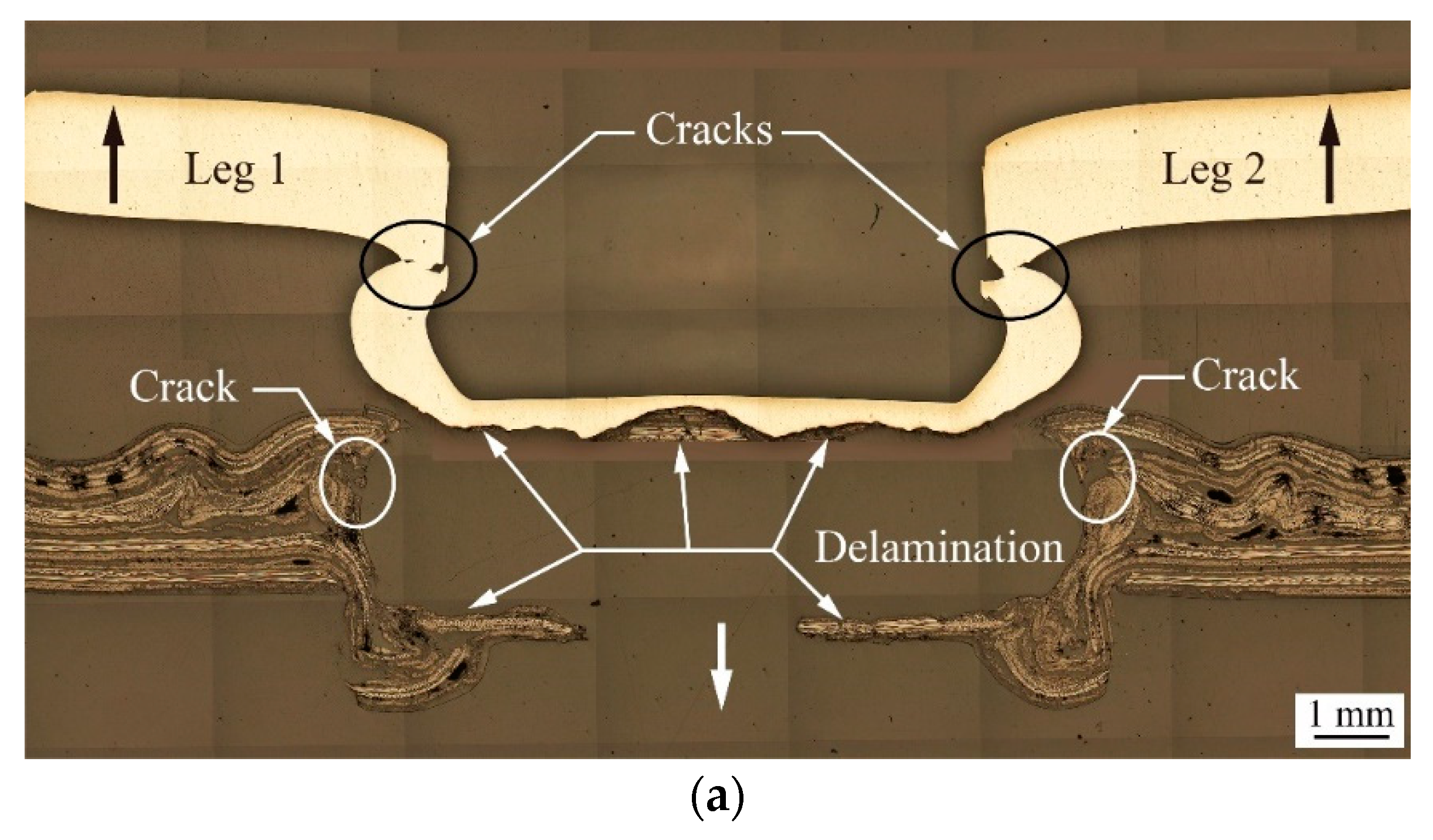

4.4. Fatigue Test Results

5. Conclusions

- Under Heating Mode A (preheating TP-CFRP), the increasing punching force within this range has insignificant effects on the joint geometry and provides nearly constant failure loads. However, under Heating Mode B (preheating AA5052 and TP-CFRP), the increasing punching force has significant effects on the joint geometry and provides the best results among all at the punch force of 69 kN.

- The increasing heating temperature improves the interlock but also enlarges the cracks near the necks; therefore, the failure load increases and then decreases due to the competitions between these geometric features.

- The decreasing die depth weakens the interlock; therefore, the clinch joints made by shallow die have poor failure loads.

- An appropriate setup for CT specimens, including Heating Mode B, a punching force of 69 kN, a heating temperature of 100 °C, Punch P1, and Die D1, was obtained for fatigue tests. The average failure load was 883 N.

- In fatigue tests, the fatigue behavior, failure mode, and fatigue data of clinch joints in CT specimens were obtained.

- The clinch joints in quasi-static tests all failed in the button separation failure mode, while those in fatigue tests all failed in the neck fracture failure mode.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Carle, D.; Blount, G. The suitability of aluminium as an alternative material for car bodies. Mater. Des. 1999, 20, 267–272. [Google Scholar] [CrossRef]

- Sakurai, T. The latest trends in aluminum alloy sheets for automotive body panels. Kobelco. Technol. Rev. 2008, 28, 22–28. [Google Scholar]

- Graf, M.; Sikora, S.P.; Roider, C.S. Macroscopic modeling of thin-walled aluminum-steel connections by flow drill screws. Thin Walled Struct. 2018, 130, 286–296. [Google Scholar] [CrossRef]

- Sun, X.; Khaleel, M.A. Performance optimization of self-piercing rivets through analytical rivet strength estimation. J. Manu. Process. 2005, 7, 83–93. [Google Scholar] [CrossRef]

- Sun, X.; Stephens, E.V.; Khaleel, M.A. Fatigue behaviors of self-piercing rivets joining similar and dissimilar sheet metals. Int. J. Fatigue 2007, 29, 370–386. [Google Scholar] [CrossRef]

- Tran, V.X.; Pan, J. Fatigue behavior of dissimilar spot friction welds in lap-shear and cross-tension specimens of aluminum and steel sheets. Int. J. Fatigue 2010, 32, 1167–1179. [Google Scholar] [CrossRef]

- Sun, Y.F.; Fujii, H.; Takaki, N.; Okitsu, Y. Microstructure and mechanical properties of dissimilar al alloy/steel joints prepared by a flat spot friction stir welding technique. Mater. Des. 2013, 47, 350–357. [Google Scholar] [CrossRef]

- Lin, P.C.; Liao, P.S.; Su, Z.M.; Aoh, J.N. Mechanical properties and failure modes of friction stir clinch joints between 6061-T6 aluminum and S45C steel sheets. In Proceedings of the 10th International Symposium of Friction Stir Welding, Beijing, China, 20–22 May 2014. [Google Scholar]

- Lee, C.J.; Kim, J.Y.; Lee, S.K.; Ko, D.C.; Kim, B.M. Parametric study on mechanical clinching process for joining aluminum alloy and high-strength steel sheets. J. Mech. Sci. Technol. 2010, 24, 123–126. [Google Scholar] [CrossRef]

- Abe, Y.; Mori, K.; Kato, T. Joining of high strength steel and aluminium alloy sheets by mechanical clinching with dies for control of metal flow. J. Mater. Process. Technol. 2012, 212, 884–889. [Google Scholar] [CrossRef]

- Ueda, M.; Miyake, S.; Hasegawa, H.; Hirano, Y. Instantaneous mechanical fastening of quasi-isotropic CFRP laminates by a self-piercing rivet. Compos. Struct. 2012, 94, 3388–3393. [Google Scholar] [CrossRef]

- Franco, G.D.; Fratini, L.; Pasta, A. Analysis of the mechanical performance of hybrid (SPR/bonded) single-lap joints between CFRP panels and aluminum blanks. Int. J. Adhes. Adhes. 2013, 41, 24–32. [Google Scholar] [CrossRef]

- Nagel, P.; Meschut, G. Flow drill screwing of fibre-reinforced plastic-metal composites without a pilot hole. Weld. World 2017, 61, 1057–1067. [Google Scholar] [CrossRef]

- Huang, Z.; Sugiyama, S.; Yanagimoto, J. Hybrid joining process for carbon fiber reinforced thermosetting plastic and metallic thin sheets by chemical bonding and plastic deformation. J. Mater. Process. Technol. 2013, 213, 1864–1874. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, C.J.; Kim, B.H.; Ahn, M.S.; Kim, B.M.; Ko, D.C. Effect of tool shape on hole clinching for CFRP with steel and aluminum alloy sheet. Key Eng. Mater. 2014, 622, 476–483. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, S.H.; Lee, J.M.; Kim, B.H.; Kim, B.M.; Ko, D.C. Design of hole-clinching process for joining CFRP and aluminum alloy sheet. Int. J. Precis. Eng. Manuf. 2014, 15, 1151–1157. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, S.H.; Lee, J.M.; Kim, B.H.; Kim, B.M.; Ko, D.C. Influence of tool shape on hole clinching for carbon fiber-reinforced plastic and SPRC440. Adv. Mech. Eng. 2014, 6, 1–12. [Google Scholar] [CrossRef]

- Lambiase, F. Mechanical behaviour of polymer-metal hybrid joints produced by clinching using different tools. Mater. Des. 2015, 87, 606–618. [Google Scholar] [CrossRef]

- Lambiase, F. Joinability of different thermoplastic polymers with aluminium AA6082 sheets by mechanical clinching. Int. J. Adv. Manuf. Technol. 2015, 80, 1995–2026. [Google Scholar] [CrossRef]

- Lambiase, F.; Ilio, A. Mechanical clinching of metal-polymer joints. J. Mater. Process. Technol. 2015, 215, 12–19. [Google Scholar] [CrossRef]

- Lambiase, F.; Ko, D.C. Feasibility of mechanical clinching for joining aluminum AA6082-T6 and carbon fiber reinforced polymer sheets. Mater. Des. 2016, 107, 341–352. [Google Scholar] [CrossRef]

- Lambiase, F.; Durante, M.; Ilio, A.D. Fast joining of aluminum sheets with glass fiber reinforced polymer (GFRP) by mechanical clinching. J. Mater. Process. Technol. 2016, 236, 241–251. [Google Scholar] [CrossRef]

- Lambiase, F.; Ko, D.C. Two-steps clinching of aluminum and carbon fiber reinforced polymer sheets. Compos. Struct. 2017, 164, 180–188. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A. Friction-assisted clinching of aluminum and CFRP sheets. J. Manuf. Process. 2018, 31, 812–822. [Google Scholar] [CrossRef]

- Lin, P.C.; Lin, J.W. Process Development of Dissimilar Clinch Joints in ALUMINUM 5052-H32 and Thermoplastic-CFRP Sheets; Technical Paper 2018-01-1232; SAE International: Warrendale, PA, USA, 3 April 2018. [Google Scholar] [CrossRef]

- Lin, P.C.; Lin, J.W.; Li, G.X. Clinching process for aluminum alloy and carbon fiber-reinforced thermoplastic sheets. Int. J. Adv. Manu. Technol. 2018, 97, 529–541. [Google Scholar] [CrossRef]

- Szlosarek, R.; Karall, T.; Enzinger, N.; Hahne, C.; Meyer, N.; Berger, A. Experimental and numerical investigations on the punching failure of carbon fiber-reinforced plastics. Mater. Test. 2016, 58, 617–621. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Buenoa, C.; Santos, J.F.D.; Huber, N.; Hage, E., Jr. On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater. Sci. Eng. A 2011, 528, 3841–3848. [Google Scholar] [CrossRef]

- Esteves, J.V.; Goushegir, S.M.; Santos, J.F.D.; Canto, L.B.; Hage, E.; Amancio-Filho, S.T., Jr. Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly (phenylene sulfide): Effects of process parameters on the microstructure and mechanical strength. Mater. Des. 2015, 66, 437–445. [Google Scholar] [CrossRef]

- Goushegir, S.M.; Santos, J.F.D.; Amancio-Filho, S.T. Failure and fracture micro-mechanisms in metal-composite single lap joints produced by welding-based joining techniques. Compos. Part A Appl. Sci. Manuf. 2016, 81, 121–128. [Google Scholar] [CrossRef]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer-joints. Materialwiss. Werkstofftech. 2007, 38, 934–938. [Google Scholar] [CrossRef]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic metal welding of aluminium sheets to carbon fibre reinforced thermoplastic composites. Adv. Eng. Mater. 2009, 11, 35–39. [Google Scholar] [CrossRef]

- Balle, F.; Huxhold, S.; Wagner, G.; Eifler, D. Damage monitoring of ultrasonically welded aluminum/cfrp-joints by electrical resistance measurements. Procedia Eng. 2011, 10, 433–438. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Katayama, S. Laser direct joining of CFRP to metal or engineering plastic. Trans. JWRI 2013, 42, 5–8. [Google Scholar]

- Katayama, S.; Kawahito, Y. Laser joining carbon fiber-reinforced plastic to stainless steel. Ind. Laser. Solut. 2014, 29, 22–24. [Google Scholar]

- Pramanik, A.; Basak, A.K.; Dong, Y.; Sarker, P.K.; Uddin, M.S.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys—A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- EuCIA: Carbon Composites in Automotive Structural Applications. Available online: http://www.eucia.eu/userfiles/files/Starke-Eucia%202016-V4-Druck%20b.pdf (accessed on 2 August 2020).

- Cao, K.; Wang, Y.; Wang, Y. Experimental investigation and modeling of the tension behavior of polycarbonate with temperature effects from low to high strain rates. Int. J. Solids Struct. 2014, 51, 2539–2548. [Google Scholar] [CrossRef]

- Recommended Practices for Resistance Welding; AWS Standard: AWS C1.1M/C1.1:2000; American Welding Society: Miami, FL, USA, 2000.

- Aerospace Material Specification; SAE Standard: AMS-W-6858A; SAE International: Warrendale, PA, USA, 2005.

| Material | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elongation (%) | Density () |

|---|---|---|---|---|

| AA5052-H32 | 70 | 193 | 12.0 | 2.68 |

| TP-CFRP | 250 | 4680 | 1.9 | 1.81 |

| Punch P1 | |||||

| 7.0 | 6.25 | 16.0 | |||

| Die D1 | |||||

| 10.0 | 0.7 | 0.5 | 1.5 | 1.5 | |

| Die D2 | |||||

| 10.0 | 0.4 | 0.5 | 1.5 | 1.5 | |

| Unit: mm | |||||

| Testing | Processes |

|---|---|

| Quasi-static Test |

|

| Fatigue Test |

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, P.-C.; Fang, J.-C.; Lin, J.-W.; Tran, X.V.; Ching, Y.-C. Preheated (Heat-Assisted) Clinching Process for Al/CFRP Cross-Tension Specimens. Materials 2020, 13, 4170. https://doi.org/10.3390/ma13184170

Lin P-C, Fang J-C, Lin J-W, Tran XV, Ching Y-C. Preheated (Heat-Assisted) Clinching Process for Al/CFRP Cross-Tension Specimens. Materials. 2020; 13(18):4170. https://doi.org/10.3390/ma13184170

Chicago/Turabian StyleLin, Pai-Chen, Jun-Chang Fang, Jia-Wei Lin, Xuan Van Tran, and Yern-Chee Ching. 2020. "Preheated (Heat-Assisted) Clinching Process for Al/CFRP Cross-Tension Specimens" Materials 13, no. 18: 4170. https://doi.org/10.3390/ma13184170

APA StyleLin, P.-C., Fang, J.-C., Lin, J.-W., Tran, X. V., & Ching, Y.-C. (2020). Preheated (Heat-Assisted) Clinching Process for Al/CFRP Cross-Tension Specimens. Materials, 13(18), 4170. https://doi.org/10.3390/ma13184170