Sliding Mode Control with Dynamical Correction for Time-Delay Piezoelectric Actuator Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. PEA Positioning System

2.1.1. Amplified Piezoelectric Actuator

2.1.2. Positioning Mechanism

2.1.3. Voltage Amplifier

2.1.4. Confocal Sensor

2.1.5. Control and Monitoring Hardware

- cRIO-9039 CompactRIO Controller, 1.91 GHz Quad-Core CPU, 2 GB DRAM, 16 GB Storage, and Kintex-7 325T FPGA, 8-Slot CompactRIO Controller,

- NI-9205 C Series Voltage Input Module, 32-Ch, +/−10V, 250 kS/s/ch, 16-bit,

- NI 9264, 16-Ch voltage, +/−10V, 16-bit, 25kS/s/ch AO module,

- NI-9401 5 V/TTL, 8 Bidirectional Channels, 100 ns C Series Digital Module.

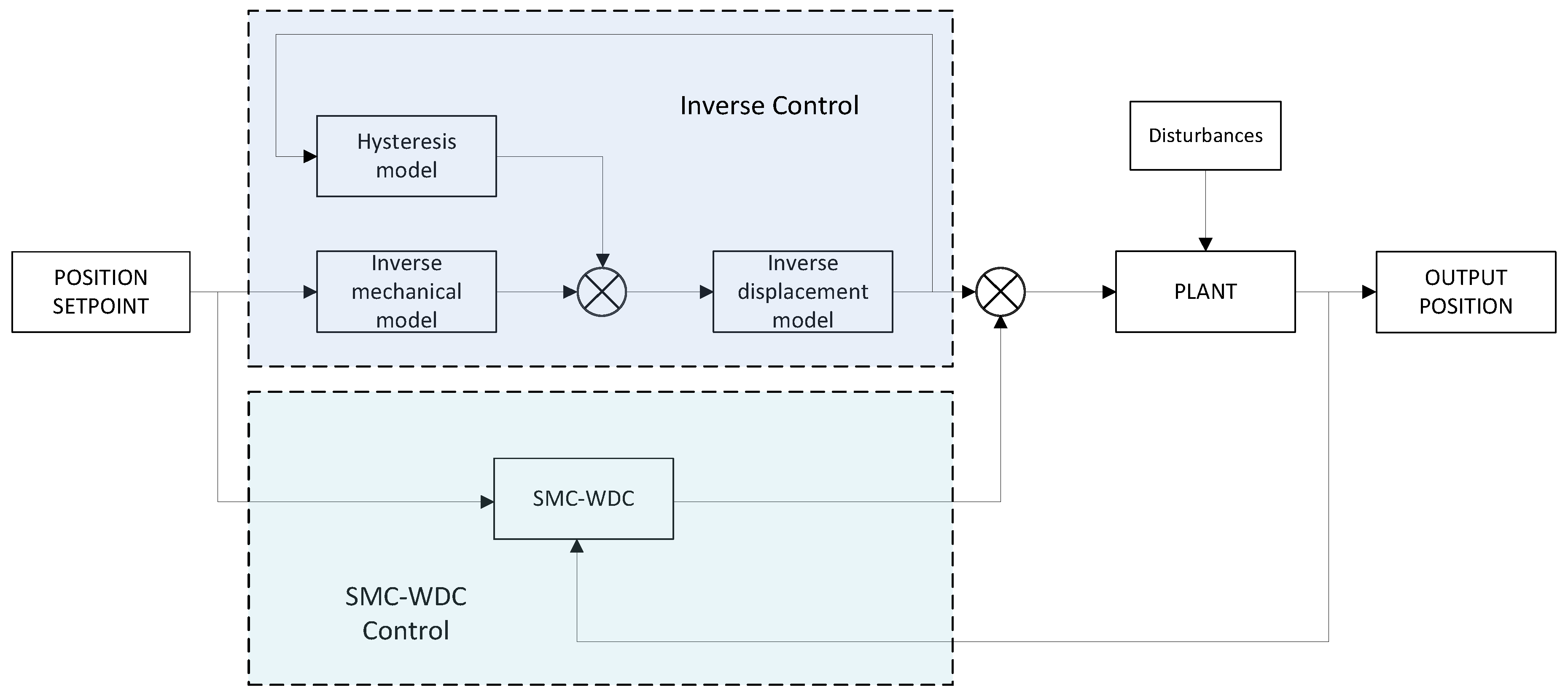

2.2. Control Strategy

2.2.1. Inverse Control

System Mathematical Model

Parameter Estimation

2.2.2. Sliding Mode Control with Dynamic Correction

Sliding Mode Control

SMC with Dynamical Correction

3. Results

3.1. Control Configuration

3.2. Ramp Signal Tracking Test

3.3. Sinusoidal Signal Tracking Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gu, G.Y.; Zhu, L.M.; Su, C.Y.; Ding, H.; Fatikow, S. Modeling and Control of Piezo-Actuated Nanopositioning Stages: A Survey. IEEE Trans. Autom. Sci. Eng. 2014, 13, 313–332. [Google Scholar] [CrossRef]

- Peng, J.; Chen, X. A Survey of Modeling and Control of Piezoelectric Actuators. Mod. Mech. Eng. 2013, 3, 1–20. [Google Scholar] [CrossRef]

- Zhang, Z.M.; An, Q.; Li, J.W.; Zhang, W.J. Piezoelectric friction-inertia actuator-A critical review and future perspective. Int. J. Adv. Manuf. Technol. 2012, 62, 669–685. [Google Scholar] [CrossRef]

- Stefanski, F.; Minorowicz, B.; Persson, J.; Plummer, A.; Bowen, C. Non-linear control of a hydraulic piezo-valve using a generalised Prandtl–Ishlinskii hysteresis model. Mech. Syst. Signal Process. 2017, 82, 412–431. [Google Scholar] [CrossRef]

- Chen, X.; Feng, Y.; Su, C.Y. Advanced Control for the XY-Table Driven by Piezo-Actuators; IFAC: Geneva, Switzerland, 2011; Volume 18, ISBN 9783902661937. [Google Scholar]

- Liu, P.; Yan, P.; Zhang, Z.; Leng, T. Modeling and control of a novel X–Y parallel piezoelectric-actuator driven nanopositioner. ISA Trans. 2015, 56, 145–154. [Google Scholar] [CrossRef]

- Mo, J.S.; Qiu, Z.C.; Wei, J.Y.; Zhang, X.M. Adaptive positioning control of an ultrasonic linear motor system. Robot. Comput. Integr. Manuf. 2017, 44, 156–173. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.J.; Hesselbach, J.; Kerle, H. Development of a two-degree-of-freedom piezoelectric rotary-linear actuator with high driving force and unlimited linear movement. Rev. Sci. Instrum. 2006, 77, 035112. [Google Scholar] [CrossRef]

- Pérez, N.; Buiochi, F.; Andrade, M.A.B.; Adamowski, J.C. Numerical characterization of piezoceramics using resonance curves. Materials 2016, 9, 71. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. Adaptive Sliding Mode Control With Perturbation Estimation and PID Sliding Surface for Motion Tracking of a Piezo-Driven Micromanipulator. IEEE Trans. Control Syst. Technol. 2010, 18, 798–810. [Google Scholar] [CrossRef]

- Ham, Y.B.; An, B.C.; Trimzi, M.A.; Lee, G.T.; Park, J.H.; Yun, S.N. An experimental study on the displacement amplification mechanism driven by piezoelectric actuators for jet dispenser. In Proceedings of the 2016 International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Paris, France, 18–22 July 2016; pp. 1–5. [Google Scholar]

- Popović, M.R.; Gorinevsky, D.M.; Goldenberg, A.A. Accurate positioning of devices with nonlinear friction using fuzzy logic pulse controller. Exp. Robot. IV 2005, 8, 331–342. [Google Scholar]

- Zhu, Z.; Zhou, X. A novel fractional order model for the dynamic hysteresis of piezoelectrically actuated fast tool servo. Materials 2012, 5, 2465–2485. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, F.; Li, H.; Du, Z.; Sun, L.; Dong, W. A friction-inertial-based rotary motor: Design, modelling and experiments. Materials 2018, 11, 918. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.F.; Li, J.; Zhang, Z.M.; Hu, X.H.; Zhang, W.J. Experimental comparison of five friction models on the same test-bed of the micro stick-slip motion system. Mech. Sci. 2015, 6, 15–28. [Google Scholar] [CrossRef]

- Song, X.; Duggen, L.; Lassen, B.; Mangeot, C. Modeling and identification of hysteresis with modified preisach model in piezoelectric actuator. In Proceedings of the 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Munich, Germany, 3–7 July 2017; pp. 1538–1543. [Google Scholar]

- Al Janaideh, M.; Davino, D.; Krejčí, P.; Visone, C. Comparison of Prandtl-Ishlinskiĭ and Preisach modeling for smart devices applications. Phys. B Condens. Matter 2015, 486, 155–159. [Google Scholar] [CrossRef]

- Liu, Y.-T.; Chang, K.-M.; Li, W.-Z. Model reference adaptive control for a piezo-positioning system. Precis. Eng. 2010, 34, 62–69. [Google Scholar] [CrossRef]

- Yang, C.; Chang, K. Adaptive Neural Network Control for Piezoelectric Hysteresis Compensation in A Positioning System. In Proceedings of the 2006 IEEE International Symposium on Industrial Electronics, Montreal, QC, Canada, 9–13 July 2006; Volume 2, pp. 829–834. [Google Scholar]

- Qin, Y.; Tian, Y.; Zhang, D.; Shirinzadeh, B.; Fatikow, S. A novel direct inverse modeling approach for hysteresis compensation of piezoelectric actuator in feedforward applications. IEEE ASME Trans. Mechatron. 2013, 18, 981–989. [Google Scholar] [CrossRef]

- Chen, X.; Hisayama, T. Adaptive sliding-mode position control for piezo-actuated stage. IEEE Trans. Ind. Electron. 2008, 55, 3927–3934. [Google Scholar] [CrossRef]

- Chuang, N.; Petersen, I.R. Robust H Infinity Control of Hysteresis in a Piezoelectric Stack Actuator; IFAC: Geneva, Switzerland, 2008; Volume 17, ISBN 9783902661005. [Google Scholar]

- Merry, R.J.E.; de Kleijn, N.C.T.; van de Molengraft, M.J.G.; Steinbuch, M. Using a walking piezo actuator to drive and control a high-precision stage. IEEE ASME Trans. Mechatron. 2009, 14, 21–31. [Google Scholar] [CrossRef]

- Huang, P.K.; Shieh, P.H.; Lin, F.J.; Shieh, H.J. Sliding-mode control for a two-dimensional piezo-positioning stage. IFAC Proc. Vol. 2005, 16, 263–268. [Google Scholar] [CrossRef]

- Chouza, A.; Barambones, O.; Calvo, I.; Velasco, J. Sliding Mode-Based Robust Control for Piezoelectric Actuators with Inverse Dynamics Estimation. Energies 2019, 12, 943. [Google Scholar] [CrossRef]

- Xu, Q. Continuous Integral Terminal Third-Order Sliding Mode Motion Control for Piezoelectric Nanopositioning System. IEEE ASME Trans. Mechatron. 2017, 22, 1828–1838. [Google Scholar] [CrossRef]

- Li, M.; Wang, Q.; Li, Y.; Jiang, Z. Modeling and Discrete-Time Terminal Sliding Mode Control of a DEAP Actuator with Rate-Dependent Hysteresis Nonlinearity. Appl. Sci. 2019, 9, 2625. [Google Scholar] [CrossRef]

- Truong, H.-V.-A.; Tran, D.-T.; Ahn, K.K. A Neural Network Based Sliding Mode Control for Tracking Performance with Parameters Variation of a 3-DOF Manipulator. Appl. Sci. 2019, 9, 2023. [Google Scholar] [CrossRef]

- Zhang, B.L.; Han, Q.L.; Zhang, X.M.; Yu, X. Sliding Mode Control With Mixed Current and Delayed States for Offshore Steel Jacket Platforms. IEEE Trans. Control Syst. Technol. 2014, 22, 1769–1783. [Google Scholar] [CrossRef]

- Ohtsuka, H.; Nakashima, Y.; Kouzawa, R.; Mizumoto, I.; Iwai, Z. Output Feedback Sliding Mode Control for Time Delay Systems. In Proceedings of the SICE-ICASE International Joint Conference, Busan, Korea, 18–21 October 2006; pp. 73–77. [Google Scholar]

- Shen, S.; Song, A.; Li, T. Predictor-Based Motion Tracking Control for Cloud Robotic Systems with Delayed Measurements. Electronics 2019, 8, 398. [Google Scholar] [CrossRef]

- Zhou, L.; She, J.; Zhang, X.-M.; Cao, Z.; Zhang, Z. Performance enhancement of repetitive-control systems and application to tracking control of chuck-workpiece systems. IEEE Trans. Ind. Electron. 2019, 1. [Google Scholar] [CrossRef]

- Li, J.; Tian, H. Position control of SMA actuator based on inverse empirical model and SMC-RBF compensation. Mech. Syst. Signal Process. 2018, 108, 203–215. [Google Scholar] [CrossRef]

- Liang, W.; Ma, J.; Ng, C.; Ren, Q.; Huang, S.; Tan, K.K. Optimal and intelligent motion control scheme for an Ultrasonic-Motor-Driven X-Y stage. Mechatronics 2019, 59, 127–139. [Google Scholar] [CrossRef]

- Thorlabs. Available online: https://www.thorlabs.com/ (accessed on 8 July 2019).

- Zhang, Y.; Xu, Q. Adaptive Sliding Mode Control With Parameter Estimation and Kalman Filter for Precision Motion Control of a Piezo-Driven Microgripper. IEEE Trans. Control Syst. Technol. 2016, 25, 1–8. [Google Scholar] [CrossRef]

| Constant | Value | Units |

|---|---|---|

| mEQ | 4.1 × 10−1 | kg |

| bEQ | 8.01 × 102 | Ns/m |

| bPAM | 1.50 × 10−12 | Ns/m |

| kEQ | 5.84 × 103 | N/m |

| kPAM | 5.23 × 103 | N/m |

| α | 4.5 × 10−1 | - |

| β | 4 × 10−1 | - |

| γ | 7.29 × 10−17 | - |

| Control | P | I | δ | η |

|---|---|---|---|---|

| PI | 70,000 | 10 | - | - |

| SMC-Sat | 6000 | 10 | 1 µm | 75 V |

| SMC-Hyp | 6000 | 5 | 1 µm | 75 V |

| SMC-WDC | 5000 | 0.0001 | 1 µm | 75 V |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velasco, J.; Barambones, O.; Calvo, I.; Zubia, J.; Saez de Ocariz, I.; Chouza, A. Sliding Mode Control with Dynamical Correction for Time-Delay Piezoelectric Actuator Systems. Materials 2020, 13, 132. https://doi.org/10.3390/ma13010132

Velasco J, Barambones O, Calvo I, Zubia J, Saez de Ocariz I, Chouza A. Sliding Mode Control with Dynamical Correction for Time-Delay Piezoelectric Actuator Systems. Materials. 2020; 13(1):132. https://doi.org/10.3390/ma13010132

Chicago/Turabian StyleVelasco, Javier, Oscar Barambones, Isidro Calvo, Joseba Zubia, Idurre Saez de Ocariz, and Ander Chouza. 2020. "Sliding Mode Control with Dynamical Correction for Time-Delay Piezoelectric Actuator Systems" Materials 13, no. 1: 132. https://doi.org/10.3390/ma13010132

APA StyleVelasco, J., Barambones, O., Calvo, I., Zubia, J., Saez de Ocariz, I., & Chouza, A. (2020). Sliding Mode Control with Dynamical Correction for Time-Delay Piezoelectric Actuator Systems. Materials, 13(1), 132. https://doi.org/10.3390/ma13010132