Abstract

Currently, the use of sensors and supporting technologies has become indispensable in the assessment of tribological behavioral patterns of composites. Furthermore, the current investigation focused on the assessment of the tribological behavior of the Al–SiCp composite for high-temperature applications. Moreover, the Al–SiCp composite was fabricated by adapting the liquid metallurgy route with varying weight percentages of SiCp (x = 3, 6, and 9). Density, hardness, and high-temperature wear tests were performed to evaluate the hardness and tribological characteristics and properties of modern-day advanced composites. Moreover, the inclusion of SiCp enhanced the advanced composite materials hardness from 60 HV to 110 HV due to a high degree of refinement of the α-phase. Subsequently, the fabricated samples’ wear behavior was assessed by varying the wear parameter viz. the applied load (20 N and 30 N) and sliding distance (250 m, 500 m, 750 m, and 1000 m) with the constant sliding velocity (0.45 m/s) for various temperatures (40 °C, 150 °C, and 250 °C). Moreover, the results revealed that the enhancement in the reinforcement percentage improves the wear resistance. Consequently, the wear rate decreased at 250 °C, possibly owing to the development of the oxide layers. Therefore, the occurrence of delamination and plastic deformation were evidenced in the wear-out surface, thereby depicting the prevalence of delamination and the abrasive wear-mechanism.

1. Introduction

Industry X.0 is pushing manufacturing and production businesses to move forward from conventional practices towards the use of progressive digital technologies to accomplish sustainable development. The emergence and advancement of day-to-day science and technology will augment the necessity for lightweight materials with unique characteristics compared to conventional materials. Aluminum-based alloys are used for fabricating automobile components like pistons, cylinder heads, cylinder blocks, among others, because of the alloys supreme specific strength and stiffness [1,2,3]. Furthermore, among the available Al alloys, Al–Si alloys exhibit various unique properties, including large strength-to-weight-rate, excellent castability, less thermal expansion, and high corrosion resistance. Moreover, such alloys exhibit weak wear-resistance that reduces their application in tribological environments (slippage under fretting, loading, degradation of material in sliding condition) [4,5,6,7]. This demand has prompted material researchers, product inventors, and manufacturers to explore the area of composite materials. Composite manufacturing was identified as the preeminent method to alter the required properties of the base material by adding suitable reinforcement particles. Amid the available composites, the metal matrix composite (MMC) has a comprehensive range of applications with the potential for use in the aerospace and automobile industries. The MMC is fabricated via various routes that include powder metallurgy, stir casting, squeeze casting, among others. In this work, the stir casting route was considered as the most economical method for the mass production of components [8,9,10,11,12]. These MMC’s are reinforced with several organic, carbides, and nitride-based materials that include graphite, graphene, silicon carbide, titanium nitride, among others, to enhance the performance of the base materials [13,14,15,16]. In general, these carbide-based ceramic particles are widely deployed as reinforcement agents to enhance the hardness and wear behavior of the Al MMC. In the existing literature, the carbide-based reinforcements are employed as agents to enhance the base material’s wear behavior. Moreover, the SiCp-based hybrid Al MMC was developed by Daniel [17] and his coworker to augment the high temperature wear performance of the Al alloy. Subsequently, the authors studied the wear parameters’ performance, including load velocity, sliding-distance, SiCp particle size, and temperature of the developed MMC. They found that increases in temperature decreased the wear resistance of the MMC. However, decreases in particle size and applied load showed an incremental trend in wear resistance. It was also found that the weight percentage of SiCp acted as a significant parameter in governing the wear behavior of MMC.

Smrutiranjan et al. [18] devised a stir casting scheme for fabricating an Al–SiCp composite with a constant wt.% of SiCp (7.5 wt.%). Moreover, they investigated the wear behavior of the composite with variations in environmental conditions that included dry, alkaline, and aqueous medium with varying wear parameters of applied load and speed. They observed that the wear rate increased with the increment in wear parameters under different environmental conditions and they concluded that the wear rate was maximum for the samples analyzed under an alkaline medium. Khan et al. [19] developed a SiCp reinforced Al MMC by adopting a stir casting scheme for assessing the wear characteristics of the developed MMC. Consequently, they observed that there was an increase in hardness and wear performance. However, the addition of SiCp showcased a declining trend in tensile and fatigue strength. They also revealed that the wear rate was minimal for Al MMC under saline and acidic mediums. Rouhi et al. [20] performed a comparative study to assess the wear characteristics of the hybrid-based MMC (SiCp and MoS2). Additionally, the experimental outcomes demonstrated that the inclusion of SiCp up to 10 vol.% and MoS2 up to 2 vol.% exhibited better wear resistance, thereby leading to a lower wear-rate.

Based on the exhaustive literature survey, it is evident that the inclusion of SiCp augments the base materials wear performance. However, there are only a few works on the wear behavior of composites under elevated temperatures. In this research, the Al MMC materials dry sliding wear characteristics were explored under distinct temperature ranges. There is a current need to explore the wear behavior of Al MMC under various environmental temperatures to develop a more comprehensive range of applications. Based on the facts above, the present work dealt with the fabrication of Al MMC under varying wt.% SiCp (0, 3, 6, and 9) and carried out a detail investigation of the wear behavior of developed composites under different environmental conditions.

2. Materials and Methods

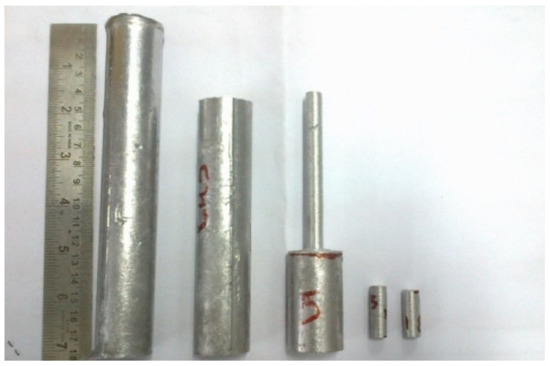

Hyper eutectic Al–Si alloy with 13.2% Si was melted in a graphite crucible in an electric resistance furnace and held at 850 °C for an hour to attain a homogeneous composition. After degassing with 1.0 wt.% solid hexachloroethane to remove porosity, the melt was stirred for 5 min at frequent intervals for an hour after adding preheated SiCp ceramic particles. Then the melt was poured into a cast-iron mold preheated at 300 °C. The cast samples were 160 mm long and 26 mm wide, and the percentage of SiCp varied from 2.0 to 6.0 wt.% is shown in Figure 1. The Al–SiCp composite specimens were cut into small pieces (10 mm × 100 mm) for metallography studies. The Keller’s reagent (2.5% HNO3, 1.5% HCl, 1% HF and 95% H2O) etchant was used in this study. The experimental composite specimens used in the present work were analyzed for composition using an optical emission spectrometer (OES) (Model ARL 3460 from Thermo Electron Corporation, Switzerland). Table 1 also shows the compositions of the Al–SiCp composites that were studied in the current research. The microstructural analysis was characterized using the DIC Leica optical microscopy (Model No: DM750M) and scanning electron microscopy (Hitachi SEM, NIT Trichy, Tamil Nadu, India). The current study added different levels of SiCp to the Al–Si alloy to understand the grain refining efficiency.

Figure 1.

Illustrating the cast samples of the developed metal matrix composite (MMC).

Table 1.

Chemical Analysis of Base Sample.

In the current study, different levels of SiCp could successfully suppress the formation of coarse dendritic α-Al grains into fine equiaxed grains. The grain refining efficiency of different levels of SiCp like x = 3.0, 6.0, and 9.0 wt.% was influenced by the formations of heterogeneous nucleation in the melt. The composite contained the fine SiCp particles during grain refinement with the Al–Si alloy; only SiCp particles acted as heterogeneous nucleating sites for the Al.

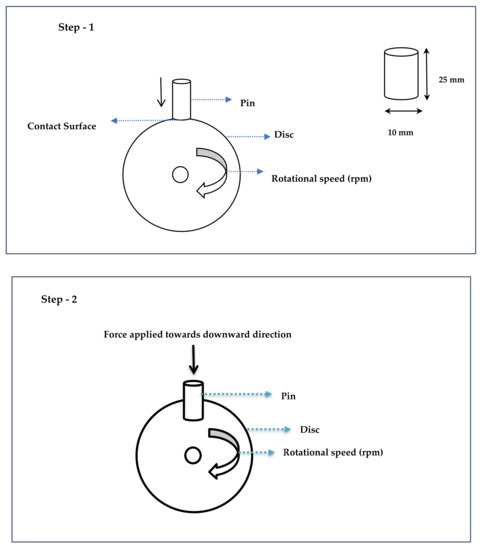

Figure 2 shows the precise control of temperature and load prediction during the wear tests performed by utilizing the pin on a disc machine, where step 1 is influenced by the pin and disc arrangement position for real brake pad application in any automobile. While testing the MMC sample, the pin is stationary when the disc is rotated during contact. The pin is moved in a downward direction towards the direction of rotation of the disc position in the step 2 position. When the contact of the pin moves toward the disc, an enormous amount of heat is produced due to friction. The pin creates a track diameter on the disc upon contact of the two mating parts, and it drives higher heat dissipation during the respective period. The load is also changed when the pin acts on the disc while testing the sample. The corresponding sensor is mounted on the bottom of the pin and disc location, and simultaneously the heat and load are continuously monitored using a temperature and load sensor. The predicted value of the temperature and load is recorded and then processed by the CPU, followed by presentation using the LabView software.

Figure 2.

Step 1–3 for temperature and load prediction using different sensors in the tribology test.

3. Material Characterization

The microhardness tests of the fabricated samples were performed using Vickers microhardness testing machine. The applied load during the test was 0.3 kg, with a dwell time of 15 s. The Vickers hardness number (VHN) was calculated from Equation (1).

where P = applied load, kgf, D = average length of diagonals, mm.

VHN = (1.854 P)/D2

The density tests were conducted using a sartorius electronic balance. High-temperature wear tests were performed on the casted sample pin on the disc apparatus that consisted of the loading panel and controller. The rotating disc was fabricated with carbon steel of diameter 80 mm and hardness of 200 HV. The samples were held stationary, and the required normal load was applied using a lever mechanism. The test was conducted at three different temperatures 40 °C, 150 °C, and 250 °C under two different loading conditions, i.e., 20 N and 30 N, at a fixed sliding velocity of 0.45 m/s. Wear loss of the specimen was measured at four different sliding distances, i.e., 250 m, 500 m, 750 m, and 1000 m. The pin height was kept at 25 mm, and the diameter was fixed at 8 mm. Wear rate was assessed by measuring the mass loss in the specimen after each wear test and the mass loss, Δm, in the specimen was measured using an electronic weighing machine having a least count of 0.1 mg. Wear rate, which relates to the mass loss (Δm) and sliding distance (L), was calculated using Equation (2),

W = Δm/L

4. Result and Discussion

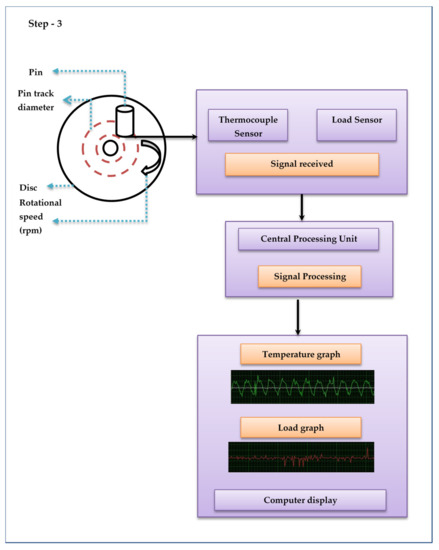

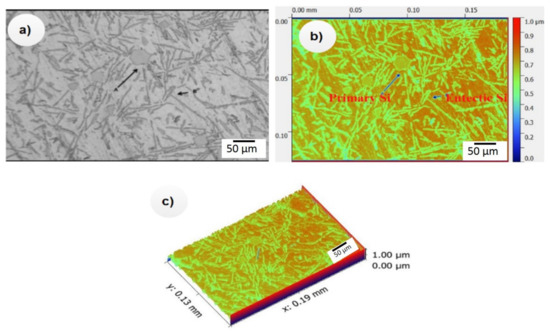

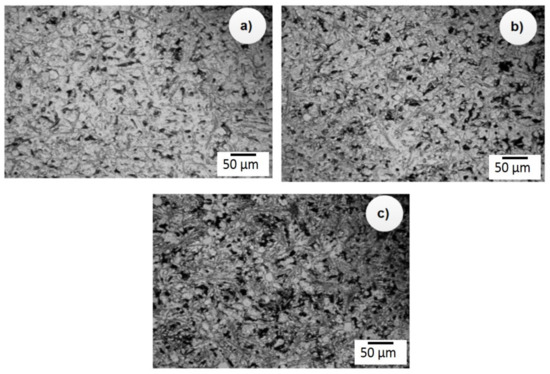

To understand the mechanism of grain refinement of Al/SiCp composites, the Al-13.2% Si alloy was modified with various levels of SiCp like 2.0 wt.%, 4.0 wt.%, and 6.0 wt.% and the melt was poured into a water-cooled water mold of 32 K/s cooling at 5 min holding. The higher cooling rate was chosen to observe the SiCp particles since a higher cooling rate allows the complete formation of SiCp fine particles in the Al/SiCp composites. The samples were subjected to DIC Leica optical microscopy (Figure 3) and SEM microanalysis (Figure 4) to observe the reaction of SiCp with the nucleation particles, which improves wear resistance under various environmental conditions.

Figure 3.

(a–c) Microstructure of the developed Al–Si alloys.

Figure 4.

Microstructure of (a) Al-13%Si-2%SiCp (b) Al-13%Si-4%SiCp (c) Al-13%Si-6%SiCp.

4.1. Microstructural Characterization

Figure 3a–c shows the microstructure of the developed Al–Si alloys. It could clearly show that the Al–Si alloy microstructure consisted of the eutectic mixture and primary Si. Figure 4a–c shows the microstructure of Al-13 wt.% of Si to which 2.0 wt.% SiCp, 4.0 wt.% SiCp and 6.0 wt.% SiCp, respectively, was added. The microstructure analysis also confirmed that the addition of SiCp refined the eutectic mixture from a coarser to a fine fibrous structure. However, we observed several unidentified needles, formed either by the cleaning of the extracted particle or from Al4C3 possibly formed along with the SiCp particles that reacted with the Al matrix. Generally, the Al4C3 was not easily identified, and Al4C3 is not easy to extract using any conventional procedure. In this study, we overcame the problem by developing a reclamation process that separated all the solid constituents such as reinforcement, reaction product, and insoluble metallic and non-metallic impurities in the composites melt. Using this technique, Al4C3 could be extracted even if it was formed in a small amount. However, the pits and porosities were not reflected in the density values because the density experiments were conducted in the unpolished samples. Moreover, the hardness results reflected only the surface and subsurface properties.

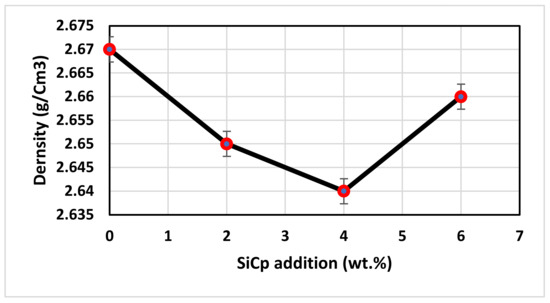

4.2. Density Analysis of the Developed Al MMC

The experimental results from the density analysis are shown in Figure 5 showing a slight increment in aluminum density with every addition of SiCp reinforcement. This increase in aluminum density was due to a higher density of the reinforced silicon carbide (3.21 g/cc). It could be noted from the plot that the density of unreinforced aluminum was near to 2.7 g/cc, which was similar to the actual density of the material that indicated poreless casting.

Figure 5.

Influence of SiCp on the Al–Si alloy density.

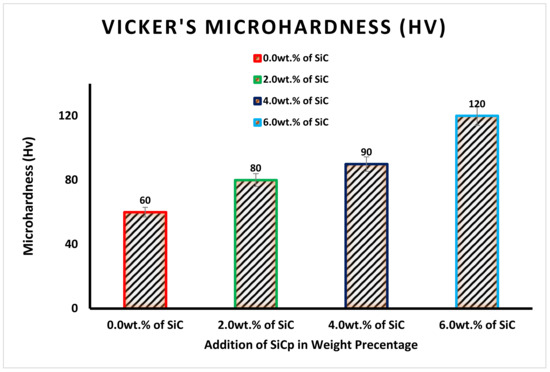

4.3. Hardness Analysis of the Developed Al MMC

Microhardness results of the unreinforced base alloy and SiCp reinforced composites are illustrated in Figure 6. The microhardness results indicated a positive trend from the addition of silicon carbide to the Al alloy resulting in increased hardness from 60 HV to 110 HV for 6% SiCp addition, which was about 57%. This increment in hardness was due to hindrance offered by the reinforced SiCp for dislocation motion during plastic deformation when the load was applied. This hindrance to dislocation motion under loading conditions results in an increased load requirement for plastic deformation that indicates the hardness increment [21,22].

Figure 6.

Influence of SiCp on Al–Si alloy microhardness.

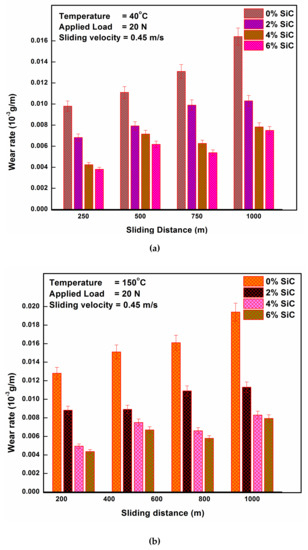

4.4. Wear Behavior of a Developed, Fabricated Composite at Adverse Loading Conditions:

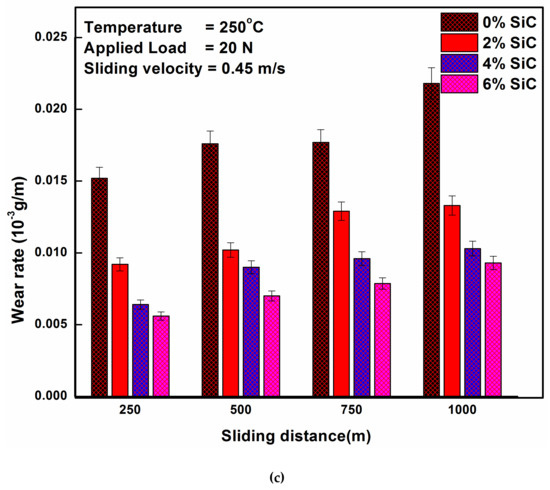

Wear rate observed while testing the aluminum alloy with different SiCp percentages for different sliding distances is given in Figure 7a. The temperature, load, and velocity were kept constant at 40 °C, 20 N, and 0.45 m/s, respectively. Figure 7b,c depict the wear rate for the same working conditions except for temperature, which was 150 °C and 250 °C, respectively. It is evident from Figure 7a–c that the inclusion of hard SiCp reinforcement into the soft aluminum matrix results in a decreased wear rate. That is, the wear-resistance capability of the aluminum increases with every addition of SiCp irrespective of the temperature at which the test is conducted. Moreover, this may be because the hardness of the aluminum increases with SiCp addition and it is a natural result that harder materials give higher resistance to wear. Since the load required for plastic deformation is higher for harder materials and hence the resistance to wear is also high. The wear rate increases with every increase in sliding distance, as a result of the increased temperature due to increased contact time with the counterpart [8,21,23].

Figure 7.

(a) Wear behavior of the Al MMC at 40 °C under a 20 N load, (b). Wear behavior of the Al MMC at 150 °C under a 20 N load, (c). Wear behavior of the Al MMC at 250 °C under a 20 N load.

This increased temperature softens the material resulting in more natural plastic deformation and, therefore, higher wear. Furthermore, the increase in the wear rate with sliding distance for unreinforced aluminum is higher than that of reinforced composites, which shows the capability of the developed MMC to withstand severe conditions [24].

While comparing Figure 7a–c, it is evident that the wear rate tends to increase with an increase in the temperature from room temperature (40 °C) to 250 °C. This outcome is because the increase in temperature softens the aluminum and reinforced composites, resulting in higher plastic deformation while sliding. Nevertheless, the increase in temperature causes a proportional increase in the wear rate [23,25].

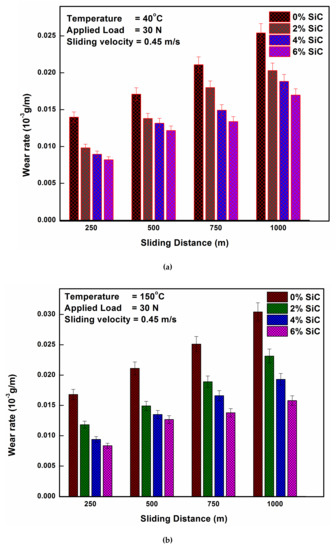

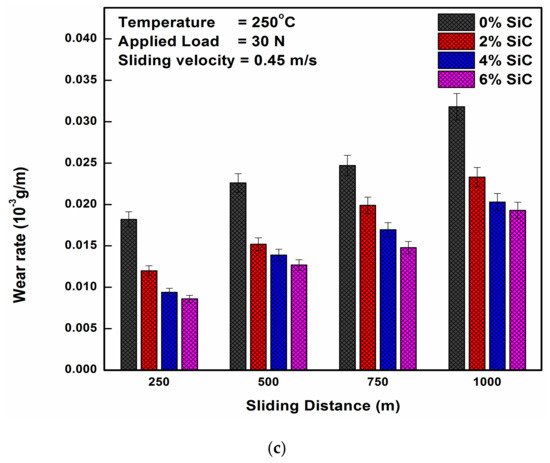

Figure 8a–c shows the wear rate of the base and reinforced aluminum under different loading conditions while the load applied is 30 N. Comparing Figure 7 and Figure 8, we observed that the rate of wear while sliding increases with an increase in the load from 20 N to 30 N. This increased wear rate at higher loading conditions was due to the increased contact load and the friction between the two sliding parts that tends to increase heat generation at the interface. Moreover, this generated heat results in the softening of the material and higher wear [26,27,28,29,30,31,32].

Figure 8.

(a) Wear behavior of the Al MMC at 40 °C under a 30 N load, (b). Wear behavior of the Al MMC at 150 °C under a 30 N load, (c). Wear behavior of the Al MMC at 250 °C under a 30 N load.

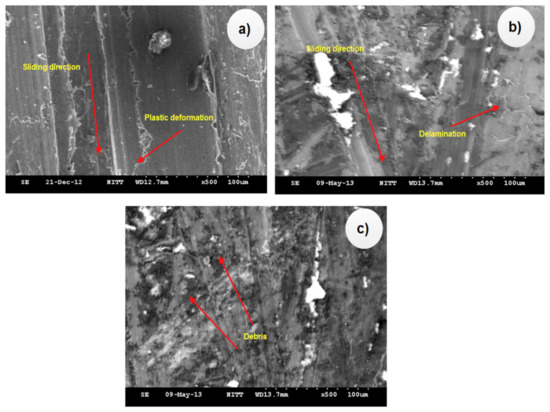

4.5. Worn Out Surface Morphology

Figure 9a–c shows the worn-out surface of the tested Al–Si alloy under varied applied loads of 0 N, 20 N (6 wt.% SiCp), and 30 N (6 wt.% SiCp), respectively. The analysis confirmed the occurrence of abrasion and delamination wear over the worn-out surfaces on the pure Al–Si alloy. The Al-13Si alloy with 6 wt.% SiCp under the 20 N and 30 N applied loads experienced the less abrasion, less debris, and delamination wear.

Figure 9.

(a) The worn-out surface of the Al–Si matrix, (b) 6 wt.% SiCp at an applied load of 20 N, (c) 6 wt.% SiCp at an applied load of 30 N.

5. Conclusions

SiCp reinforced Al MMC was successfully fabricated through a liquid metallurgy route. The influence of SiCp over the functional properties of the composite was studied. We investigated the worn-out surface morphology of the samples under wear conditions. The following observations were made:

- The addition of SiCp resulted in a drastic enhancement in hardness (~57%).

- Increments in SiCp wt.% showed increments in wear resistance.

- The occurrence of abrasion and delamination wear was observed on the worn-out surface.

- The developed MMC can be practically used in high-temperature sliding applications where higher wear resistance is required. Advanced technologies for tribology behavioral pattern analysis shall be considered in future works [33,34,35,36].

The technical merit of this work is summarized as follows:

- (a)

- The volumetric wear rate decreases with an increasing wt.% of SiCp, as well as a corresponding decrease in temperature.

- (b)

- The wear resistance decreases at a higher temperature while it drastically increases with an increase in the wt.% of SiCp.

- (c)

- The wear mechanism under the tested conditions was consistently adhesive in nature. The developed composite with a high wt.% of reinforcement agents exhibited abrasive wear mechanisms.

Author Contributions

Conceptualization, M.S. and S.K.S.; methodology, M.S., S.K.S.; software, K.S.; validation, M.S., S.K.S. and S.N.; formal analysis, S.N.; investigation, M.S., S.K.S., S.N.; resources, M.S. and S.K.S.; data curation, K.S.; writing—original draft preparation, M.S. and S.K.S.; writing—review and editing, K.S., S.N. and A.N.J.R.; visualization, S.N. and A.N.J.R.; supervision, A.N.J.R.; project administration, A.N.J.R.; funding acquisition, A.N.J.R.

Funding

This research was funded by the Research Start-up Fund Subsidized Project of Shantou University, China (No. NTF17016).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Prakash, K.S.; Moorthy, R.S.; Gopal, P.M.; Kavimani, V. Effect of Reinforcement, Compact Pressure and Hard Ceramic Coating on Aluminium Rock Dust Composite Performance. Int. J. Refract. Met. Hard Mater. 2016, 54, 223–229. [Google Scholar] [CrossRef]

- Kumarasamy, S.P.; Vijayananth, K.; Thankachan, T.; Muthukutti, G.P. Investigations on mechanical and machinability behavior of aluminum/flyash cenosphere/Gr hybrid composites processed through compocasting. J. Appl. Res. Technol. 2017, 15, 430–441. [Google Scholar] [CrossRef]

- Prakash, K.S.; Gopal, P.M.; Kavimani, V. Effect of rock dust, cenosphere and E-waste glass addition on mechanical, wear and machinability behaviour of Al 6061 hybrid composites. Indian J. Eng. Mater. Sci. 2017, 24, 270–282. [Google Scholar]

- Mahmoud, E.R.I.; Takahashi, M.; Shibayanagi, T.; Ikeuchi, K. Wear characteristics of surface-hybrid-MMCs layer fabricated on aluminum plate by friction stir processing. Wear 2010, 268, 1111–1121. [Google Scholar] [CrossRef]

- Afkham, Y.; Khosroshahi, R.A.; Rahimpour, S.; Aavani, C.; Brabazon, D.; Mousavian, R.T. Enhanced mechanical properties of in situ aluminium matrix composites reinforced by alumina nanoparticles. Arch. Civ. Mech. Eng. 2018, 18, 215–226. [Google Scholar] [CrossRef]

- Xu, J.; Qiu, R.; Lian, Z.; Yu, Z.; Yu, P.; Ren, W.; Yu, H. Wear and corrosion resistance of electroforming layer after WEDM for 7075 aluminum alloy. Mater. Res. Express. 2018, 5, 66502. [Google Scholar] [CrossRef]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Varol, T.; Canakci, A. Investigating the surface integrity of aluminium based composites machined by EDM. Def. Technol. 2018, 15, 338–343. [Google Scholar] [CrossRef]

- Prakash, K.S.; Kanagaraj, A.; Gopal, P.M. Dry sliding wear characterization of Al 6061/rock dust composite. Trans. Nonferrous Met. Soc. China 2015, 25, 3893–3903. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Pandian, M.A. Influence of r-GO addition on enhancement of corrosion and wear behavior of AZ31 MMC. Appl. Phys. A Mater. Sci. Process. 2017, 123. [Google Scholar] [CrossRef]

- Prakash, K.S.; Gopal, P.M.; Anburose, D.; Kavimani, V. Mechanical, corrosion and wear characteristics of powder metallurgy processed Ti-6Al-4V/B4C metal matrix composites. Ain Shams Eng. J. 2016. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Thankachan, T. Investigation of graphene-reinforced magnesium metal matrix composites processed through a solvent-based powder metallurgy route. Bull. Mater. Sci. 2019, 42, 39. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S. Tribological behaviour predictions of r-GO reinforced Mg composite using ANN coupled Taguchi approach. J. Phys. Chem. Solids. 2017, 110, 409–419. [Google Scholar] [CrossRef]

- Gopal, P.M.; Prakash, K.S.; Nagaraja, S.; Aravinth, N.K. Effect of weight fraction and particle size of CRT glass on the tribological behaviour of Mg-CRT-BN hybrid composites. Tribol. Int. 2017, 116, 338–350. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Rajesh, R.; Rammasamy, D.; Selvaraj, N.B.; Yang, T.; Prabakaran, B.; Jothi, S. Electrodeposition of r-GO/SiCp nano-composites on Magnesium and its Corrosion Behavior in Aqueous Electrolyte. Appl. Surf. Sci. 2016. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Gunashri, R.; Sathish, P. Progress in Organic Coatings Corrosion protection behaviour of r-GO/TiO2 hybrid composite coating on Magnesium substrate in 3.5 wt.% NaCl. Prog. Org. Coat. 2018, 125, 358–364. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Thankachan, T. Experimental investigations on wear and friction behaviour of SiCp@ r-GO reinforced Mg matrix composites produced through solvent-based powder metallurgy. Compos. Part B Eng. 2019, 162, 508–521. [Google Scholar] [CrossRef]

- Daniel, S.A.A.; Sakthivel, M.; Gopal, P.M.; Sudhagar, S. Study on tribological behaviour of Al/SiCp/MoS 2 hybrid metal matrix composites in high temperature environmental condition. Silicon 2018, 10, 2129–2139. [Google Scholar] [CrossRef]

- Pradhan, S.; Ghosh, S.; Barman, T.K.; Sahoo, P. Tribological behavior of Al-SiCp metal matrix composite under dry, aqueous and alkaline medium. Silicon 2017, 9, 923–931. [Google Scholar] [CrossRef]

- Khan, M.M.; Dixit, G. Evaluation of Microstructure, Mechanical, Thermal and Erosive Wear Behavior of Aluminum-Based Composites. Silicon 2019, 1–12. [Google Scholar] [CrossRef]

- Rouhi, M.; Moazami-Goudarzi, M.; Ardestani, M. Comparison of effect of SiCp and MoS2 on wear behavior of Al matrix composites. Trans. Nonferrous Met. Soc. China 2019, 29, 1169–1183. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. An investigation of mechanical properties and corrosion resistance of Al2618 alloy reinforced with Si3N4, AlN and ZrB2 composites. J. Alloy. Compd. 2015, 652, 244–249. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Thankachan, T. Surface characterization and specific wear rate prediction of r-GO/AZ31 composite under dry sliding wear condition. Surf. Interfaces 2017, 6, 143–153. [Google Scholar] [CrossRef]

- Rengasamy, N.V.; Rajkumar, M.; Senthil Kumaran, S. Mining environment applications on Al 4032 - Zrb2 and Tib2 in-situ composites. J. Alloy. Compd. 2016, 658, 757–773. [Google Scholar] [CrossRef]

- Rengasamy, N.V.; Rajkumar, M.; Senthil Kumaran, S. An analysis of mechanical properties and optimization of EDM process parameters of Al 4032 alloy reinforced with Zrb2 and Tib2 in-situ composites. J. Alloy. Compd. 2016, 662, 325–338. [Google Scholar] [CrossRef]

- Paranthaman, P.; Gopal, P.M.; Kumar, N.S. Characterization of Economical Aluminium MMC Reinforced with Weld Slag Particles. In Advances in Manufacturing Technology; Springer: Singapore, 2019; pp. 9–16. [Google Scholar]

- Kavimani, V.; Prakash, K.S.; Starvin, M.S.; Kalidas, B.; Viswamithran, V.; Arun, S.R. Tribo-Surface Characteristics and Wear Behaviour of SiCp@ r-GO/Mg Composite Worn under Varying Control Factor. Silicon 2019, 1–11. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. High temperature investigation on EDM process of Al 2618 alloy reinforced with Si3N4, ALN and ZrB2 in-situ composites. J. Alloy. Compd. 2016, 663, 755–768. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. An investigation of mechanical properties and material removal rate, tool wear rate in EDM machining process of AL2618 alloy reinforced with Si3N4, ALN and ZrB2 in-situ composites. J. Alloy. Compd. 2015, 650, 318–327. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. Wear behaviour of Al 261 8 alloy reinforced with Si3N4, AlN and ZrB2in situ composites at elevated temperatures. Alex. Eng. J. 2016, 55, 19–36. [Google Scholar]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. Aerospace application on Al 2618 with reinforced –Si3N4, ALN and ZrB2 in-situ composites in-situ composites. J. Alloy. Compd. 2016, 672, 238–250. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. An Optimization of Erosive Wear on AA 2618 Reinforced with SI3N4, AlN and ZrB2 In Situ Composites. Appl. Mech. Mater. 2016, 852, 452–458. [Google Scholar] [CrossRef]

- Selvaraj, S.K.; Nagarajan, M.K.; Kumaraswamidhas, L.A. An investigation of abrasive and erosion behaviour of AA 2618 reinforced with Si3N4, ALN and ZrB2 in-situ composites by using optimization techniques. Arch. Civ. Mech. Eng. 2017, 17, 43–54. [Google Scholar] [CrossRef]

- Dolata, A.J. Tribological Properties of AlSi12-Al2O3 Interpenetrating Composite Layers in Comparison with Unreinforced Matrix Alloy. Materials 2017, 10, 1045. [Google Scholar] [CrossRef] [PubMed]

- Toboła, D. Impact of Mechanical Processes as a Pre-Sulphonitriding Treatment on Tribology Properties of Selected P/M Tool Steels. Materials 2019, 12, 3431. [Google Scholar] [CrossRef] [PubMed]

- Lenart, A.; Pawlus, P.; Dzierwa, A. The Effect of Disc Surface Topography on the Dry Gross Fretting Wear of an Equal-Hardness Steel Pair. Materials 2019, 12, 3250. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, X.; Yang, S.; Hou, L.; Wei, Y.; Zhang, Z.; Yang, X. Investigation on Wear Behavior of Cryogenically Treated Ti-6Al-4V Titanium Alloy under Dry and Wet Conditions. Materials 2019, 12, 2850. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).