Abstract

Open cell foams consisting of Fe and Fe-Mn oxides are prepared from metallic Fe and Mn powder precursors by the replication method using porous polyurethane (PU) templates. First, reticulated PU templates are coated by slurry impregnation. The templates are then thermally removed at 260 °C and the debinded powders are sintered at 1000 °C under N2 atmosphere. The morphology, structure, and magnetic properties are studied by scanning electron microscopy, X-ray diffraction and vibrating sample magnetometry, respectively. The obtained Fe and Fe-Mn oxide foams possess both high surface area and homogeneous open-cell structure. Hematite (α-Fe2O3) foams are obtained from the metallic iron slurry independently of the N2 flow. In contrast, the microstructure of the FeMn-based oxide foams can be tailored by adjusting the N2 flow. While the main phases for a N2 flow rate of 180 L/h are α-Fe2O3 and FeMnO3, the predominant phase for high N2 flow rates (e.g., 650 L/h) is Fe2MnO4. Accordingly, a linear magnetization versus field behavior is observed for the hematite foams, while clear hysteresis loops are obtained for the Fe2MnO4 foams. Actually, the saturation magnetization of the foams containing Mn increases from 5 emu/g to 52 emu/g when the N2 flow rate (i.e., the amount of Fe2MnO4) is increased. The obtained foams are appealing for a wide range of applications, such as electromagnetic absorbers, catalysts supports, thermal and acoustic insulation systems or wirelessly magnetically-guided porous objects in fluids.

1. Introduction

Reticulated sponges made of polyurethane (PU) have been commercially available since the 1950s [1]. The first attempts to transfer porous templates into ceramic (i.e., oxide) foams by the powder slurry replication method date from early 1960s [2]. At present, the method has become widely available for many applications involving porous oxide materials: electromagnetic wave absorbers, gas sensors, catalysts, oil-water separators and lithium-ion batteries [3,4,5,6,7,8]. As a consequence, the polymeric sponge replication process has consolidated as a promising technique to create cellular oxide structures with 3D interconnected pores, characterized by high strength and high corrosion resistance in acid and alkaline media [9,10,11]. In the 1970s, metallic foams also started to be prepared by this method and they found applications such as battery electrodes, catalysts or filters [12,13,14]. Over the past ten years, the replication method has been extended to manufacture porous steels [15,16,17,18] and porous Cu-based [19] and Ti-based alloys [20,21].

While many studies have focused on metallic foams [15,16,17,18,19,20,21], fewer efforts have been devoted to synthesizing inorganic oxide foams through the polymer sponge replication process [22]. So far, to the best of our knowledge, the possibility to use this technique to produce oxide foams with magnetic properties has not been explored.

Manganese ferrite (MnFe2O4) is a well-known ceramic compound with electrically insulating and soft ferrimagnetic properties at room temperature. It has been widely used in the electronics industry to fabricate magnetic cores for read/write heads for high-speed tape or hard disk recording [23,24]. More recently, MnFe2O4 has emerged as a promising material to be used as a catalyst [25,26], in hydrogen production technologies [24] or for oil-water separation [7]. Diverse preparation techniques, such as high energy ball milling [24,27], co-precipitation [28,29] or sol-gel routes [30], have been used to obtain MnFe2O4 powders and nanoparticles. However, the preparation of porous MnFe2O4 remains challenging and rather elusive.

Meanwhile, magnetic foams made of Fe2O3, Fe3O4, Co or Ni are appealing since they combine the intrinsic properties of magnetic materials with the aforementioned advantages of the porous structures, constituting magnetic materials with high surface area, low density and high strength-to-weight ratio. For instance, ultralight Fe2O3/C foams produced using polyelectrolyte-grafted PU sponges [7] exhibit one of the highest oil-absorption capacities among the reported counterparts. Magnetic Fe3O4 nanoparticles/PU composites produced by in-situ blending methods have also been reported as good candidates for wastewater treatments, acting as carriers for immobilized microorganisms [30].

Therefore, the aim of the present work is to use the replication method to produce Fe and Fe-Mn oxides open-cell porous structures. The magnetic behavior of the foams is tuned, first, by the composition of the metallic slurry precursor and, secondly, by adjusting the N2 flow. The influence of the N2 flow and the Mn content, as well as the synergistic effect of porosity and magnetism are investigated.

2. Materials and Methods

Commercial Fe (97%) and Mn (99%) powders were used to coat a reticulated PU sponge by the impregnation method. First, the powders were mixed and mechanically milled in a planetary mill device (Fritsch Pulverisette 5, Fritsch, Idar-Oberstein, Germany) to reduce the powder size and to obtain the targeted composition, Fe or Fe-30Mn (Fe:Mn ratio of 70:30 nominal wt %). The raw powders were milled under Ar atmosphere with a ball-to-powder weight ratio of 10:1 at 300 rpm for 15 h. The particle size of the as-milled powders, calculated from a Scanning Electron Microscopy (SEM) image using the ImageJ software, was 10.8 ± 1.4 mm. To prepare the slurry, the milled powders were mixed with poly(ethylene glycol) (PEG) and distilled water. PEG acted as a binder and was used to control the slurry viscosity and to favor the adhesion of the powder particles to the sponge before sintering. The composition of the slurry is listed in Table 1. Subsequently, 1 cm3 of a commercial reticulated PU sponge, acting as organic template, was immersed into the slurry for 5 min to allow complete impregnation. The sponge was removed from the suspension and was squeezed to ensure that only a thin layer of slurry covered the skeleton of the PU template without blocking the pores. Then, the impregnated template was dried at room temperature for at least 12 h before sintering. Finally, the template was thermally removed at 260 °C and the debinded powders were sintered in a tubular furnace (Carbolite MTF 9/15, Parsons Lane, UK) at 1000 °C for 2 h under N2 flow ranging from 180 to 650 L/h.

Table 1.

Components and mass percentages of the slurry.

SEM observations were done on a Zeiss Merlin microscope (Carl Zeiss Microscopy, Jena, Germany) equipped with an energy dispersive X-ray (EDX) spectroscopy detector (Oxford Instruments, Abingdon, UK) for compositional analyses. X-ray diffraction (XRD) was carried out on a Philips X’Pert diffractometer (Philips, Amsterdam, The Netherlands) using Cu Kα radiation. The measurements were performed in the angular range 2θ = 30–100° with a step size of 0.026°. Furthermore, Rietveld refinement of the XRD patterns using the X’Pert HighScore Plus software (PANalytical, Almelo, The Netherlands) was carried out to determine the cell parameters and the percentage of the constituent phases.

Hysteresis loops were recorded at room temperature using a vibrating sample magnetometer (VSM) from MicroSense (LOT-QuantumDesign, Darmstadt, Germany), with a maximum applied magnetic field of 20 kOe.

3. Results and Discussion

3.1. Microstructure and Compositional Analyses

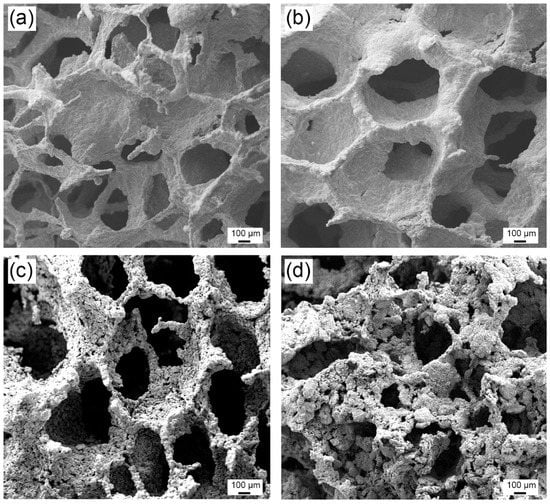

Figure 1 shows SEM images of the sintered open cell foams obtained by the replication process from Fe- (Figure 1a) and FeMn- (Figure 1b–d) containing slurries. At a first glance, a rather homogeneous pore distribution can be observed, with pore sizes of the order of 400 μm. Fully-compact pore walls were observed in the foams produced from the Fe- and FeMn-containing slurries obtained at the lowest N2 flow (Figure 1a,b); however, at larger N2 flows, the pore walls exhibit a nanoporous morphology although the distribution and the size of the big pores was not compromised. The composition of the foams obtained at different nitrogen flow rates, measured by energy-dispersive X-ray (EDX) analyses, is listed in Table 2. An O/Fe ratio of 1.56 is calculated for the foam produced from the Fe-containing slurry, suggesting the formation of Fe2O3. It is worth mentioning that no changes were observed in the foams produced under larger N2 flow (such as 350 L/h and 650 L/h) from the Fe-containing slurry in terms of pore morphology, integrity of the foam or chemical composition (not shown in the manuscript). However, the foams produced at open atmosphere were more powdery and brittle. In contrast, compositional changes were observed in the foams produced from the FeMn-containing slurry when changing the N2 flow. For the foam produced at 180 L/h, the O/Fe(Mn) ratio is 1.5 suggesting the formation of Fe2O3 or FeMnO3. Conversely, the O/Fe(Mn) ratio decreases to 1.38 and 1.27 as the N2 flow is increased to 350 L/h and 650 L/h, respectively, hence suggesting the formation of Fe3−x(Mn)xO4.

Figure 1.

(a) SEM image of a Fe-O foam prepared at a nitrogen flow rate of 180 L/min. SEM image of Fe-Mn-O foams prepared under a nitrogen flow rate of (b) 180 L/h, (c) 350 L/h and (d) 650 L/h.

Table 2.

Energy dispersive X-ray (EDX) composition of the foams produced from the Fe-containing slurry at a N2 flow of 180 L/h and from the FeMn-containing slurry at a N2 flow of 180, 350 and 650 L/h.

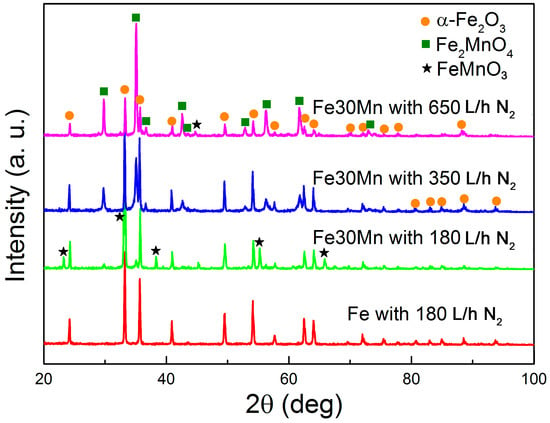

To shed light on the microstructure of the open-cell foams X-ray diffraction was carried out (Figure 2). As suggested by EDX analyses, the foams produced from the Fe-containing slurry consist of α-Fe2O3. In contrast, the XRD of the foams produced from the FeMn-containing slurry indicate a mixture of α-Fe2O3, FeMnO3 and Fe2MnO4 phases. Phase contributions and cell parameters estimated by Rietveld refinement are listed in Table 3. Sintering the FeMn-containing foams at higher N2 flow results in larger amounts of Fe2MnO4. As can be observed in Table 3, the amount of Fe2MnO4 increases from 8.5 to 74% when increasing the N2 flow from 180 to 650 L/h. Accordingly, the Fe2O3 phase percentage decreases from 60 to 26%. FeMnO3 only forms at a N2 flow of 180 L/h.

Figure 2.

X-ray diffraction (XRD) patterns of the Fe-O foam produced at N2 flow of 180 L/h and Fe-Mn-O foams produced at a N2 flow of 180 L/h, 350 L/h and 650 L/h.

Table 3.

Phase percentage and cell parameters (a and c) of the obtained foams.

3.2. Magnetic Properties

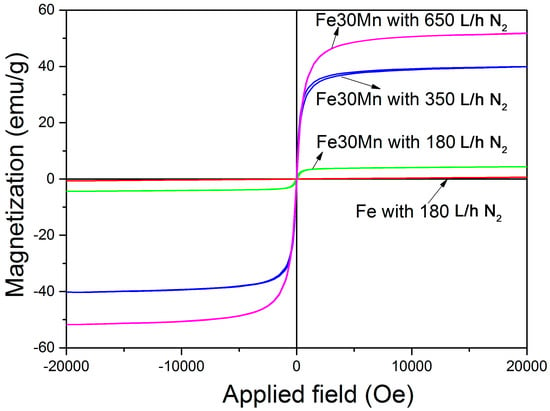

Figure 3 shows the hysteresis loops of the open-cell porous foams produced from the Fe- and FeMn-containing slurries at different nitrogen flow rates. A linear magnetization versus field behavior (reaching 0.6 emu/g for an applied field of 20 kOe) was observed in the Fe-O foams, in agreement with the reported behavior for antiferromagnetic α-Fe2O3. Clear hysteresis loops are observed in the FeMn-containing foams as a result of the ferrimagnetic character of the Fe2MnO4 phase, which exhibits a theoretical saturation magnetization, Ms, of 77 emu/g at room temperature [31]. The FeMnO3 phase is known to exhibit a weakly ferrimagnetic response with Ms ~ 0.23 emu/g [32]. Accordingly, the saturation magnetization of the FeMn-containing foams ranges from 5 emu/g to 52 emu/g depending on the N2 flow rate, i.e., the relative amount of FeMnO3 and Fe2MnO4 phases. For instance, an Ms value of 37.7 emu/g would be expected for the foam produced under a N2 flow of 350 L/h as it contains 49% of Fe2MnO4. The observed Ms in this case (40 emu/g) is in quite good agreement with the expected value. The foam produced under a N2 flow of 650 L/h has Ms = 52 emu/g which is also in good agreement with the theoretically calculated value (57 emu/g).

Figure 3.

Room temperature hysteresis loops of four kinds of open-cell porous foams produced from the Fe- and FeMn-containing slurries at different nitrogen flow rate.

4. Conclusions

Highly porous foams with homogeneous open-cell structure have been obtained by the replication process using polyurethane templates. The foams produced from the Fe-containing slurry consist of α-Fe2O3, independently of the N2 flow. In contrast, the phase composition of the foams produced from the FeMn-containing slurry can be tuned by adjusting the N2 flow. The main phases of the Fe-Mn-O foams sintered under a N2 flow of 180 L/h are α-Fe2O3 and FeMnO3 with minor content of Fe2MnO4. Increasing the N2 flow to 350 L/h results in a mixture of α-Fe2O3 and Fe2MnO4. The amount of manganese ferrite is further increased at a flow rate of 650 L/h. Hence, addition of Mn as well as the adjustment of the N2 flow allows tailoring the magnetic response of the foams from practically non-magnetic to soft ferrimagnetic. The magnetic behavior reported in this work for the Fe30Mn foams obtained at a N2 flow rate of 350 and 650 L/h could be of interest for a wide range of applications, such as electromagnetic absorbers, catalysts supports, thermal and acoustic insulation systems or wirelessly magnetically-guided porous objects in fluids.

Acknowledgments

This work has been partially funded by the 2017-SGR-292 project from the Generalitat de Catalunya, the MAT2014-57960-C3-1-R and MAT2017-86357-C3-1-R (co-financed by the Fondo Europeo de Desarrollo Regional, FEDER), from the Spanish Ministerio de Economía y Competitividad (MINECO) and the SPINPORICS 2014-Consolidator Grant (Agreement No. 648454) from the European Research Council. J.F. acknowledges the Juan de la Cierva Fellowship from MINECO (IJCI-2015-27030), E.P. is grateful to MINECO for the “Ramon y Cajal” contract (RYC-2012-10839) and Y.F. is grateful to the Chinese Scholarship Council for his PhD Grant.

Author Contributions

J.S. and J.F. conceived and designed the experiments; Y.F., S.S. and P.S. performed the experiments; E.P., J.F. and Y.F. analyzed the data; Y.F., J.F. and D.B. wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Seymour, R.B.; Kauffman, G.B. Polyurethanes: A Class of Modern Versatile Materials. J. Chem. Educ. 1992, 69, 909–910. [Google Scholar] [CrossRef]

- Karl, S.; Somers, A.V. Method of Making Porous Ceramic Articles. U.S. Patent 3,090,094 A, 21 May 1963. [Google Scholar]

- Park, K.Y.; Lee, S.E.; Kim, C.G.; Han, J.H. Fabrication and electromagnetic characteristics of electromagnetic wave absorbing sandwich structures. Compos. Sci. Technol. 2006, 66, 576–584. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, C.; Ma, C.Q.; Ren, W.C.; Cheng, H.M. Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef] [PubMed]

- Yavari, F.; Chen, Z.P.; Thomas, A.V.; Ren, W.C.; Cheng, H.M.; Koratkar, N. High sensitivity gas detection using a macroscopic three-dimensional graphene foam network. Sci. Rep. 2011, 1. [Google Scholar] [CrossRef] [PubMed]

- Buciuman, F.C.; Czarnetzki, B.K. Preparation and characterization of ceramic foam supported nanocrystalline zeolite catalysts. Catal. Today 2001, 69, 337–342. [Google Scholar] [CrossRef]

- Chen, N.; Pan, Q. Versatile fabrication of ultralight magnetic foams and application for oil-water separation. ACS Nano 2013, 7, 6875–6883. [Google Scholar] [CrossRef] [PubMed]

- Kang, E.; Jung, Y.S.; Cavanagh, A.S.; Kim, G.H.; George, S.M.; Dillon, A.C.; Kim, J.K.; Lee, J. Fe3O4 nanoparticles confined in mesocellular carbon foam for high performance anode materials for lithium-ion batteries. Adv. Funct. Mater. 2011, 21, 2430–2438. [Google Scholar] [CrossRef]

- Williams, E.J.A.E.; Evans, J.R.G. Expanded ceramic foam. J. Mater. Sci. 1996, 31, 559–563. [Google Scholar] [CrossRef]

- Wang, S.R.; Geng, H.R.; Hui, L.H.; Wang, Y.Z. Reticulated porous multiphase ceramics with improved compressive strength and fracture toughness. J. Mater. Eng. Perform. 2007, 16, 113–118. [Google Scholar] [CrossRef]

- Bhaduri, S.B. Science and technology of ceramic foams. Adv. Perform. Mater. 1994, 1, 205–220. [Google Scholar] [CrossRef]

- Arrance, F.C. Battery Electrode and Battery, and Process for Preparing Said Electrode. U.S. Patent 3,287,166 A, 22 November 1996. [Google Scholar]

- Antsiferov, V.N.; Makarov, A.M.; Khramtsov, V.D. High-porosity permeable cellular metals and alloys in catalytic processes of gas cleaning. Adv. Eng. Mater. 2005, 7, 77–91. [Google Scholar] [CrossRef]

- Roesler, J.F. Application of polyurethane foam filters for respirable dust separation. J. Air. Pollut. Control Assoc. 1996, 16, 30–34. [Google Scholar] [CrossRef]

- Haack, D.P.; Butcher, K.R.; Kim, T.; Lu, T.J. Novel Lightweight Metal Foam Heat Exchangers; Porvair Fuel Cell Technology, Inc.: Hendersonville, NC, USA, 2001. [Google Scholar]

- Quadbeck, P.; Stephani, G.; Kümmel, K.; Adler, J.; Standke, G. Synthesis and properties of open-celled metal foams. Mater. Sci. Forum 2007, 534–536, 1005–1008. [Google Scholar] [CrossRef]

- Quadbeck, P.; Kümmel, K.; Hauser, R.; Standke, G.; Adler, J.; Stephani, G. Open cell metal foams-application-oriented structure and material selection. In Proceedings of the International Conference on Cellular Materials, Dresden, Germany, 27–29 October 2010; pp. 279–288. [Google Scholar]

- Quadbeck, P.; Kümmel, K.; Hauser, R.; Standke, G.; Adler, J.; Stephani, G.; Kieback, B. Structural and material design of open-cell powder metallurgical foams. Adv. Eng. Mater. 2011, 13, 1024–1030. [Google Scholar] [CrossRef]

- Zhang, H.; Pinjala, D.; Joshi, Y.K.; Wong, T.N.; Toh, K.C.; Iyer, M.K. Fluid flow and heat transfer in liquid cooled foam heat sinks for electronic packages. IEEE Trans. Comp. Packag. Technol. 2005, 28, 272–280. [Google Scholar] [CrossRef]

- Li, J.P.; Li, S.H.; Groot, K.D.; Layrolle, P. Improvement of porous titanium with thicker struts. Key Eng. Mater. 2003, 240–242, 547–550. [Google Scholar] [CrossRef]

- Manonukul, A.; Tange, M.; Srikudvien, P. Rheological properties of commercially pure titanium slurry for metallic foam production using replica impregnation method. Powder Technol. 2014, 266, 129–134. [Google Scholar] [CrossRef]

- Biswas, P.; Ramavath, P.; Nair, C.M.; Suresh, M.B.; Ravi, N.; Johnson, R. Quasi-static compression behavior of nickel oxide, nickel oxide: Zirconia, nickel:zirconia and nickel foams. Ceram. Int. 2016, 42, 10572–10578. [Google Scholar] [CrossRef]

- Zuo, X.; Barbiellini, B.; Vittoria, C. Calculation of exchange constants in manganese ferrite (MnFe2O4). J. Magn. Magn. Mater. 2004, 272, 306–311. [Google Scholar] [CrossRef]

- Padella, F.; Alvani, C.; Barbera, A.L.; Ennas, G.; Liberatore, R.; Varsano, F. Mechanosynthesis and process characterization of nanostructured manganese ferrite. Mater. Chem. Phys. 2005, 90, 172–177. [Google Scholar] [CrossRef]

- Durán, F.G.; Barbero, B.P.; Cadús, L.E.; Rojas, C.; Centeno, M.A.; Odriozola, J.A. Manganese and iron oxides as combustion catalysts of volatile organic compounds. Appl. Catal. B 2009, 92, 194–201. [Google Scholar] [CrossRef]

- Quiroga, M.M.B.; Barbero, B.P.; Cadus, L.E. Synthesis of a catalyst of Mn–Fe–O by mechano-chemical reaction. Appl. Catal. A 2014, 474, 26–33. [Google Scholar] [CrossRef]

- Mahmoud, M.H.; Hamdeh, H.H.; Ho, J.C.; O’shea, M.J.; Walker, J.C. Mössbauer studies of manganese ferrite fine particles processed by ball-milling. J. Magn. Magn. Mater. 2000, 220, 139–146. [Google Scholar] [CrossRef]

- Amighian, J.; Mozaffari, M.; Nasr, B. Preparation of nano-sized manganese ferrite (MnFe2O4) via coprecipitation method. Phys. Status Solidi C 2006, 3, 3188–3192. [Google Scholar] [CrossRef]

- Baldi, M.; Escribano, V.S.; Amores, J.M.G.; Milella, F.; Busca, G. Characterization of manganese and iron oxides as combustion catalysts for propane and propene. Appl. Catal. B 1998, 17, L175–L182. [Google Scholar] [CrossRef]

- Kwon, W.H.; Kang, J.Y.; Lee, J.G.; Lee, S.W.; Chae, K.P. Synthesis and magnetic properties of Zn, Co and Ni substituted manganese ferrite powders by sol-gel method. J. Magn. 2010, 15, 159–164. [Google Scholar] [CrossRef]

- Rafique, M.Y.; Qing, P.L.; Javeb, Q.U.A.; Iqbal, M.Z.; Mei, Q.H.; Farooq, M.H.; Gang, G.Z.; Tanveer, M. Growth of monodisperse nanospheres of MnFe2O4 with enhanced magnetic and optical properties. Chin. Phys. B 2013, 22. [Google Scholar] [CrossRef]

- Rayaprol, S.; Kaushik, S.D.; Babu, P.D.; Siruguri, V. Structure and magnetism of FeMnO3. AIP Conf. Proc. 2013, 1512, 1132–1133. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).