Abstract

Greenhouses play a vital role in modern agriculture by providing controlled environments for year-round crop production. However, climate regulation within these structures accounts for a significant portion of their energy consumption, often exceeding 50% of operational costs. Current greenhouse systems predominantly rely on reactive control strategies, leading to energy inefficiency and unstable internal conditions. Addressing this gap, the present study develops a machine learning-based framework that leverages time series forecasting models—specifically Long Short-Term Memory (LSTM)—that predict key climate parameters and generate optimal actuator control recommendations. The system utilizes multivariate environmental data to forecast temperature, humidity, and CO2 levels and minimize a composite energy proxy through proactive adjustments to heating, ventilation, and lighting systems. Experimental results demonstrate high prediction accuracy (R2 = 0.9835) and significant improvements in energy efficiency. By integrating predictive analytics with real-time sensor feedback, the proposed approach supports intelligent, energy-aware decision-making and advances the development of smart agriculture through proactive greenhouse climate management.

1. Introduction

In modern agriculture, greenhouses are very useful as they offer controlled conditions for plant growth and increase productivity. They provide proper temperatures, humidity, light, and CO2 levels for plant growth [1,2,3]. This enables cropping throughout the year irrespective of the outside weather [3]. Additionally, greenhouses protect crops from adverse climatic events, leading to improved crop quality and enhanced production [4,5]. Within greenhouses, climate control plays a decisive role in optimizing growth, improving yield, and maintaining high standards of quality, along with auguring greater technological integration. The importance of maintaining optimal temperature is critical since different crops have distinct thermal requirements during various growth phases [4]. In addition, the incorporation of renewable solar and geothermal energy systems enhances the energy performance and lowers operational expenditure [6,7]. Controlling humidity is crucial for disease control [4,8], maintaining transpiration, and nutrient absorption essential to plant health [9]. Elevated CO2 concentrations also increase photosynthesis and productivity [4,10], and automated systems can economize CO2 in relation to yield profits [4]. Artificial lighting facilitates off-season production [11,12], and cost-effective lighting aids in energy conservation [13,14]. Greenhouses have integrated advanced sensors and real-data monitoring which enable access to automated integrated climate control systems [4,6]. These systems use refined algorithms such as neural networks, fuzzy logic, and predictive control for customizable, accurate regulation [6,15]. All these advancements reduce the amount of energy consumed, resources used, and overall negative impact on the environment which, in turn, promotes economic productivity and environmental health [4,6,13,16,17]. Furthermore, these innovations facilitate the adoption of climate-resilient agricultural systems [6,13]. Although these technologies offer multiple benefits, the current control systems in greenhouses heavily rely on reactive strategies, which result in enormous energy losses and inadequate conditions for plant development. Greenhouses have high energy consumption, especially those designed for off-season cultivation. Heating, cooling, and lighting systems can account for up to 50% of total production costs [18,19]. Increased operational costs occur due to fossil fuel dependency, the emission of greenhouse gases, and climate change [13,20]. One of the major inefficiencies of ventilation-induced heat loss can be solved with more modern techniques, such as air handling units, borehole thermal storage, and heat pumps [21]. Other technologies such as phase change materials (PCMs) have also proven to be effective by lowering gas consumption by 23.7% [6,7]. Internal environments in a house that are maintained by reactive control strategies tend to fail, which is harmful to plant growth. Uncontrolled temperature and moisture levels in plastic-covered structures are particularly bad examples and lead to crop loss due to overheating or cold stress, which has been observed in cucumber production [22,23,24]. The variation in microclimate conditions within greenhouse zones also impacts the uniformity and consistency of plant growth and yield. Solving such issues requires deploying real-time monitoring advanced sensor networks on a wider scale [23,25]. Lighting presents challenges too; dynamic lighting systems have the ability to reduce energy use by up to 20% without affecting yield [26]. However, passive greenhouses with inadequate lighting are likely to experience stunted growth unless supplemented with treatments like sucrose application [27].

Innovative optimal climate control strategies must be adopted to facilitate efficient and sustainable greenhouse systems. New techniques offer great potential. For example, some HVAC systems like rooftop greenhouses can reclaim heat energy from other buildings [28]. Solar, geothermal, and wind energy are renewable options that reduce fossil fuel dependence, and semi-transparent photovoltaics support light transmission as well as electricity generation [19]. Further, the sustainability of Closed-loop systems that recycle organic waste and drainage water is enhanced by the creation of renewable energy and organic fertilizers [5,29]. Sustainability in greenhouse farming is achieved with the combination of Internet of Things (IoT) and Machine Learning (ML) technologies that enable autonomous and preemptive decisions to be made based on real-time data. Crop yields, alongside resource use and productivity, are enhanced by the proactive, data-driven decision-making these technologies provide. Real-time data is critical during the growing season, and IoT devices can capture temperature, humidity, soil moisture, and light intensity [30,31,32,33]. Moreover, these sensors are usually bundled with actuators that regulate irrigation, lighting, and ventilation to adjust to the requirements of the plant and maintain a stable microclimate [30,31,33,34,35]. The automation of these processes helps with the management of greenhouses because IoT platforms allow remote access and farmers can oversee and manage the systems from anywhere using web interfaces [30,31,33,35,36]. In addition to monitoring, ML has a major impact on predictive analytics. ML models predict growth, foresee disease outbreaks, and detect pest infestations utilizing data from IoT devices, permitting timely intervention [32,37,38,39,40]. Such models further analyze historical and real-time data to track water, nutrient, and energy use to maximize efficiency and minimize wastage [3,4,8,9,10,11,12]. ML decision-support systems provide relevant information for crop management, irrigation scheduling, and pest management [35,38]. These improvements allow the achievement of optimal environmental conditions for the plants at any time, as well as risk minimization and enhanced productivity, while ensuring a smaller ecological footprint [32,38,39,41]. Minimizing labor and resource waste drives down operational costs [37,38,39,41]. There are still unanswered questions, to be sure. Data privacy and security and expanding the IoT and ML infrastructure, as well as other concerns related to the integration of data, computation limits, complexity, and transparency of the models need attention [32,34]. Realizing the advantages of these technologies also requires one to adequately train the farmers and devise adoption strategies [32,34]. This study proposes a Clean Energy Smart Grid (CESG) design integrating demand response, energy storage, and forecasting to address renewable energy intermittency. A nested sizing framework is introduced, combining hourly optimal operation and annual optimal sizing for cost-effective, reliable system design. To overcome computational limits, the study replaces the inner Lotus Effect Algorithm (LEA) with a trained Artificial Neural Network (ANN), maintaining accuracy with a 98.92% time reduction. Results show demand response reduces costs by 28%, and the hybrid ANN-LEA approach accelerates convergence time by 43%, enhancing scalability and efficiency [42]. This review explores how artificial intelligence (AI) is transforming energy management in renewable-integrated smart grids by enhancing forecasting, fault detection, and control. It highlights advancements in machine learning and deep learning for grid observability, anomaly detection, and multi-agent optimization of energy dispatch and microgrids. Key barriers such as data sparsity, model transparency, and standardization are discussed, alongside emerging solutions like explainable AI and quantum-enhanced computing.

The study concludes that integrating AI with digital infrastructure and policy reform is essential for enabling intelligent, resilient, and low-carbon power systems [43]. This study analyzes solar energy forecasting in the U.S. using AI-based time-series models, focusing on Random Forest and XGBoost for predictive accuracy.

Both models demonstrated high reliability across hourly and daily datasets from major solar regions, enabling dynamic grid and storage management. Findings support the integration of AI forecasting in real-time dispatch, load planning, and policy-making to support decarbonization goals. Future research should explore hybrid deep learning models (LSTM, CNN-LSTM) and storage integration for enhanced accuracy and smart microgrid deployment [44]. This review examines the influence of uncertain factors on long-term energy system optimization models, essential for planning future energy transitions. Uncertainties are categorized into policy, economic, and technical domains, with a focus on carbon reduction and energy transformation challenges. The paper summarizes existing modeling approaches used to address these uncertainties in system evolution and planning. It concludes by highlighting key uncertainty factors and recommending future research directions for robust energy system modeling [45]. This study presents a web-based decision support tool for monitoring and upgrading HVAC systems using smart meter data. The tool enables real-time analysis of heating/cooling cycles, room-level efficiency, and retrofit energy-saving potential. Unlike traditional theoretical models, it adopts a data-driven, building-specific approach to optimize HVAC performance. A case study in Athens demonstrates its effectiveness in enhancing energy efficiency and supporting sustainable building practices [46]. The paper presents a novel approach for controlling the climate of autonomous greenhouses by implementing a predictive, energy-efficient model using time-series machine learning techniques. The model achieves remarkable energy savings by preemptively adjusting control device (actuators) settings to optimal levels within the greenhouse based on its prediction for the temperature, humidity, and CO2 equilibrium surge values. This self-sufficient, intelligent system fosters sustainability and greater crop yields through improved data analysis.

Review

Researchers have proposed advanced techniques that combine Machine Learning (ML), optimization, and IoT to facilitate the accurate prediction of critical climate variables and the control of greenhouse actuators. LSTM-based models offer predictive capabilities on the environment’s sequential data loading, and climate forecasting using LSTM algorithms placed on IoT devices aids in making energy-conscious decisions [47]. In addition, temperature and humidity predictions have been made with great accuracy and minimal error using LSTM with Support Vector Machine (SVM) hybrids [48]. For more precise CO2 predictions, some models use multi-model fusion methods with wavelet denoising, variational mode decomposition, and LSTMs, which successfully reduce noise in time-series data using feature extraction methods [49]. Forecasting of internal temperature and relative humidity has also successfully been performed using Adaptive Neuro-Fuzzy Inference System (ANFIS) models [50]. In climate management, optimization algorithms are instrumental on the control side. Using fuzzy logic modules, Differential Evolution (DE) can reduce energy consumption by 36% while optimizing climate parameters (1). Also, the combination of Convolutional Neural Networks (CNNs), LSTM with MPC, and other features have shown improvement concerning responsiveness, accuracy, and control within the temperature, humidity, and CO2 control dimensions [51]. The impact of uncertain weather forecast monitoring is alleviated with robust data-driven MPC frameworks by retaining internal conditions through the use of dynamic models and optimization routines coupled with internal model control [52]. Using global optimization techniques like interpolation control and surrogate-based modeling techniques, dynamic setpoints are achieved, resulting in 27% energy savings and a 25% improvement in crop yield [53]. Superiority in multi-objective optimization enhances the tuning of PID controller setpoints in parallel with energy efficiency using Genetic Algorithms and RBFNN. As a result, overshoot and rise time are countered while maintaining the desired balance [54]. Furthermore, proactive microclimate control is made possible by real-time monitoring via IoT systems, which provides dependable and near-instantaneous communication between sensors and actuators [47]. The inclusion of crop physiological data into the control systems allows for more accurate decisions to be made, thus optimizing the advancement of the plant and the effectiveness of the resources used [55]. The combined effect of these approaches allows smart greenhouses to be accurately advanced and optimally eco-regulated, improving the energy efficiency and sustainability of agriculture. Different methods have also been tried in the prediction of greenhouse climate forecasting using time series analysis with varying advantages and disadvantages. Increasingly sophisticated models, notably LSTMs, continue to be used mainly because of their ability to capture intricate relationships over time, especially for estimating the cooling demand, temperature, and humidity levels [40,48,56,57]. These models perform exceptionally well, attaining RMSE values as low as 0.0766 and R2 scores peaking at 0.982 [48,56]. On the other hand, LSTMs face challenges related to high computational costs and extensive model optimization known as hyperparameter tuning [58]. On the other hand, temperature and evapotranspiration are often predicted using ARIMA models which are autoregressive chronologically integrated moving averages with a linear approach, resulting in R2 values from 0.86 to 0.91 [59]. However, ARIMA models do not capture nonlinear trends well and are often highly customized in terms of data processing requirements [7,8]. Metaheuristics-based optimization of Moth-Flame algorithms to tree-based ensemble models have shown promise in forecasting numerous environmental factors including CO2 and humidity with R2 values exceeding 0.9929 using XGBoost [40,60,61]. Although XGBoost tends to be accurate, it can be inefficient computationally and susceptible to overfitting [61]. Lastly, time-series models like Prophet, which are made to accommodate strong seasonality, have been able to forecast droughts with an accuracy rate of 92.01% [62] but struggle more with weakly seasonal and irregular data. Table 1 shows a comparative analysis of time-series forecasting models.

Table 1.

Comparative analysis of time-series forecasting models.

2. Methodology

2.1. Problem Formulation

In this study, we aim to optimize greenhouse climate control by forecasting future climate states and minimizing energy consumption through intelligent actuator management. The system uses time-series data consisting of both environmental variables and actuator settings.

- t ∈ ℕ: Discrete time steps (e.g., hourly intervals);

- xt ∈ ℝⁿ: State time t.

State vector:

= [Tairt, Rhairt, CO2airt, VentLeet, Ventwindt, PipeLowt, PipeGrowt, AssimLightt, EnScrt, BlackScrt, Tot_PARt, co2_dost]

- 1.

- Forecasting Climate Variables

The goal is to predict the future value of a climate (e.g., air temperature) h steps ahead using the previous k time steps:

where

ŷt+h = f(xt, xt−1,…, xt−k)

- ŷt+h: Forecasted climate variable at time t + h;

- f(·): Forecasting (e.g., LSTM);

- k: Number of historical considerations.

- 2.

- Optimization

Given the forecast ŷt+h, the task is to determine settings ut+h that meet the following requirements:

- Maintain target climate conditions y*;

- Minimize energy consumption proxy Et.

The energy proxy is as follows:

t = α1·PipeLowt + α2·PipeGrowt + α3·AssimLightt

Optimization Problem

:Et+h

ŷt+h = f(xt−k:t, ut+h) ≈ y*

u_min ≤ ut+h ≤ u_max

2.2. Dataset Description

The GreenhouseClimate (https://community.data.4tu.nl/category/use-cases/, accessed on 23 October 2025) dataset is a comprehensive, high-frequency multivariate time series dataset designed to facilitate academic research in the domains of autonomous greenhouse climate control, energy optimization, and intelligent agricultural systems. It comprises 47,809 time-stamped records, captured at 5 min intervals, covering a wide array of environmental, mechanical, and control-related parameters within a controlled greenhouse setting. The dataset includes detailed measurements of internal climate conditions such as air temperature, relative humidity, carbon dioxide concentration, and humidity deficit. In addition, it documents the status of key actuators including heating pipes, ventilation systems, high-pressure sodium (HPS) and LED lighting, energy and blackout curtains, as well as irrigation volumes and drain water properties. One of the dataset’s significant strengths lies in its inclusion of both control setpoints and realized values (VIPs) for each major system component, allowing for the precise evaluation of system performance and control accuracy. In addition, it offers information on photosynthetically active radiation (PAR), spectral light volumes, and water supply intervals, which increases its value in machine learning for time-series analysis, predictive control, and multi-objective optimization. The dataset focuses on 2020 as it offers the most complete and high-resolution data available for analysis. This ensures consistency and reliability for modeling greenhouse climate and control systems. The dataset underwent preprocessing for advanced time-series forecasting. Conversions from Excel timestamps to online MATLAB site (https://matlab.mathworks.com/) datetime format were performed. Significant climate and actuator variables were selected, converted to numerical values, and arranged in a time-indexed timetable. Data was aggregated to hourly intervals with the mean and imputed to remove missing values. An energy proxy was calculated by adding the values from PipeLow, PipeGrow, and AssimLight. All features were subsequently normalized using Z-score standardization to maintain model compatibility and performance.

2.3. Forecasting Models Implementation Experiments Workflow

As the main tool for implementing experimental procedures pertaining to greenhouse climate forecasting and control optimization, MATLAB was used in this study is https://matlab.mathworks.com/. The workflow started with reading and preprocessing raw sensor data which included converting timestamps, selecting relevant environmental and actuator variables, and performing hourly resampling with timetable and retime functions. Gaps in the data were removed to maintain data quality, and an energy proxy was estimated from important actuator variables. Subsequently, the data were normalized to enable efficient training of the Long Short-Term Memory (LSTM) network. The MATLAB deep learning toolbox was utilized to define and train the LSTM model with the aid of trainNetwork, employing sequence generation designed for temporal pattern learning in climate data. Standard model evaluation metrics, including RMSE, MAE, and R2, were calculated alongside visual regression and residual plots. The trained model was then used to forecast future temperature values, compute expected energy consumption, and generate actuator recommendations based on threshold rules, and all procedures were visualized and executed programmatically in MATLAB.

Appendix A show more details for algorithms and tables used in this paper.

3. Workflow

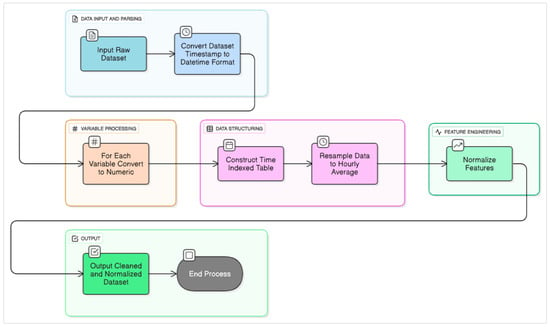

3.1. Climate Data Preprocessing Workflow

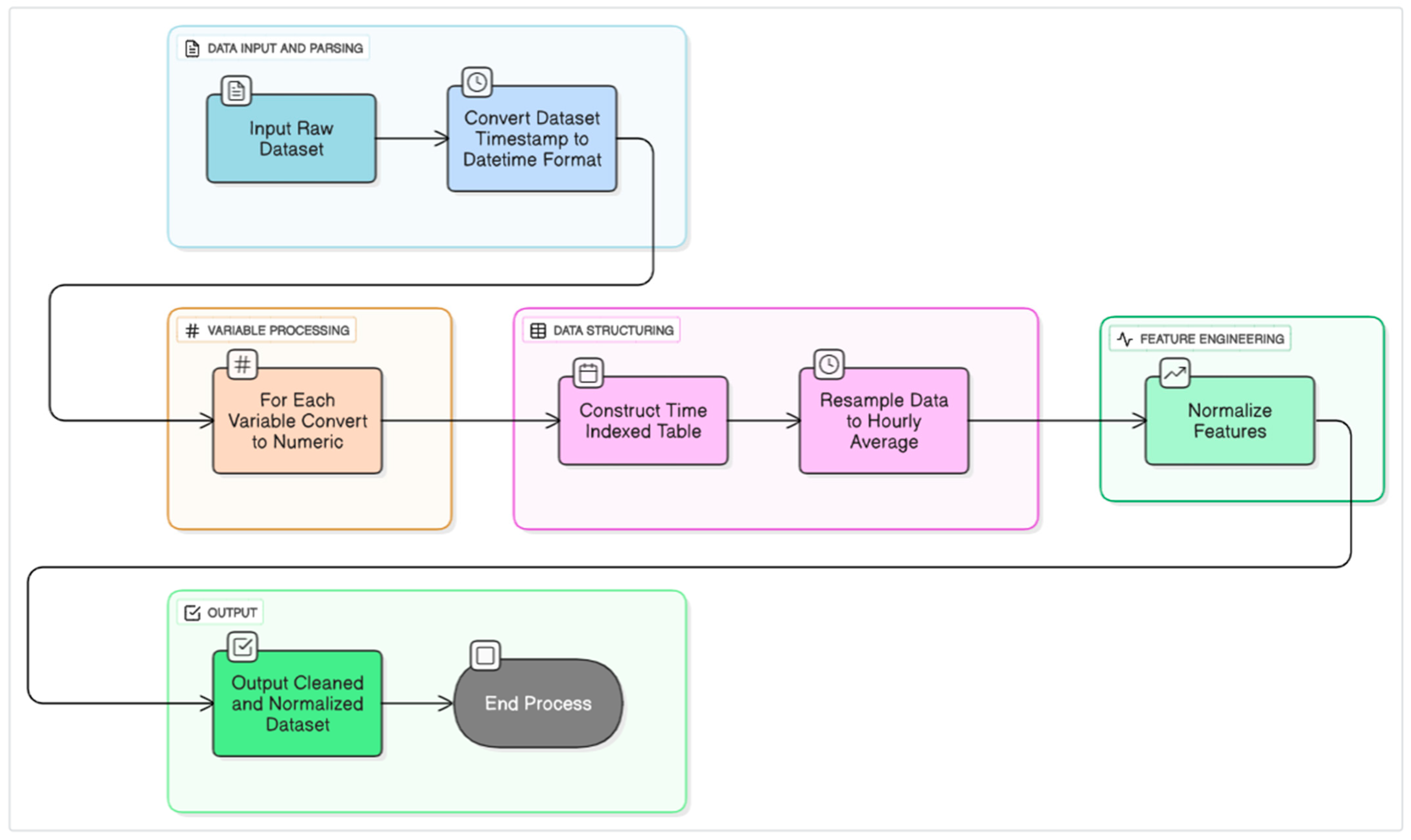

Figure 1 illustrates the sequential steps for preparing raw greenhouse sensor data for machine learning-based climate forecasting. Initially, the raw dataset is parsed by converting timestamps into datetime format, ensuring time-aware processing. Each variable is then cleaned and converted into numeric values to handle inconsistencies such as string entries. A time-indexed table is constructed, and the data is resampled into hourly averages to smooth fluctuations and reduce noise. Following this, all features are normalized using Z-score standardization to ensure uniform scale for effective model training. The result is a cleaned and normalized dataset (D_clean) ready for input into the LSTM-based forecasting pipeline. Figure 1 shows a climate data preprocessing workflow.

Figure 1.

Climate data preprocessing workflow.

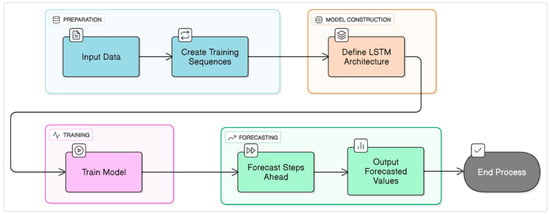

3.2. LSTM-Based Climate Forecasting Workflow

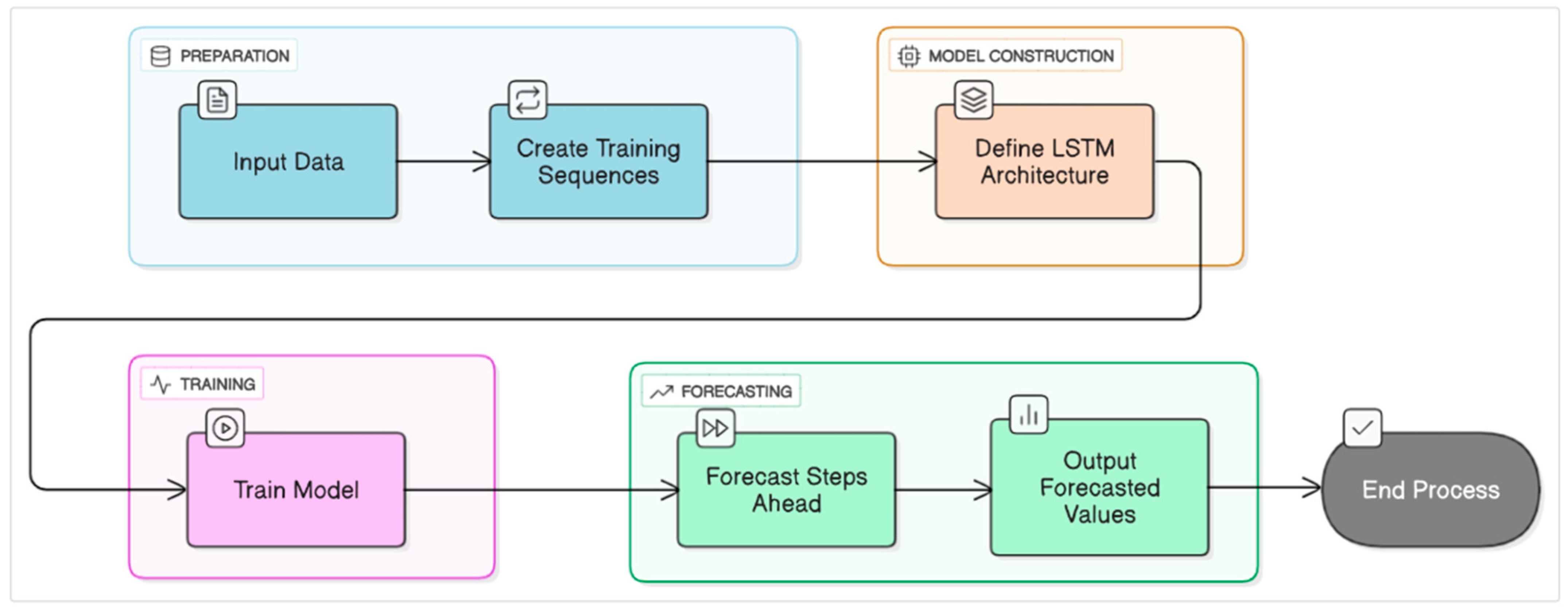

Figure 2 illustrates the full process of training and using an LSTM (Long Short-Term Memory) model for forecasting greenhouse climate variables. It begins with the preparation phase, where input data is used to create training sequences. These sequences are passed to the model construction phase, which defines the LSTM architecture. The training phase then uses the architecture to train the model. Once trained, the model forecasts future steps and outputs predicted values, enabling proactive climate control in smart greenhouse systems. The process concludes after successful forecasting.

Figure 2.

LSTM-based climate forecasting workflow.

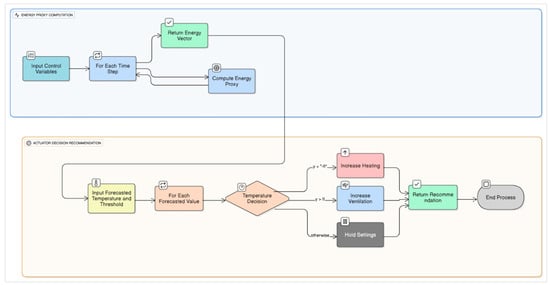

3.3. Energy Proxy Computation and Actuator Recommendation

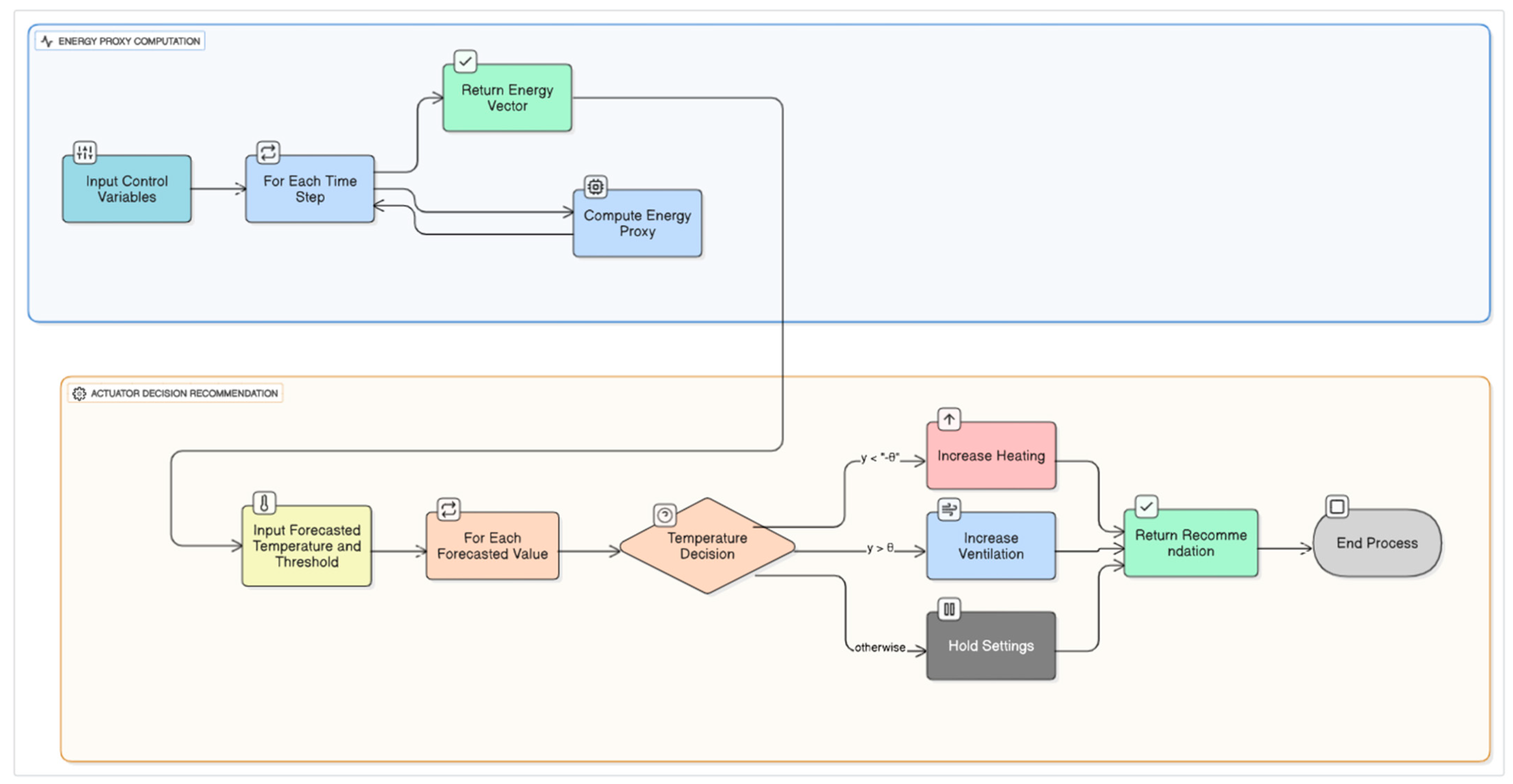

This process begins with the input of control variables such as PipeLow, PipeGrow, and AssimLight, which are essential for evaluating greenhouse energy consumption. For each time step, an energy proxy is computed by finding the sum of the values of these control variables, resulting in an energy vector that reflects total energy usage over time. In parallel, forecasted temperature values and a threshold (θ) are provided to guide actuator decisions. Each predicted temperature is assessed: if it is lower than −θ, the system recommends increasing heating; if it exceeds +θ, it suggests increasing ventilation; and if it falls within the threshold range, it is advised to hold the current settings. These decisions are collected and returned as actuator recommendations. The process ensures a data-driven approach to balancing energy efficiency with climate stability, ultimately supporting intelligent, real-time control in greenhouse environments. Figure 3 show Energy Proxy Computation and Actuator Recommendation process flow.

Figure 3.

Energy proxy computation and actuator recommendation.

4. Results and Discussion

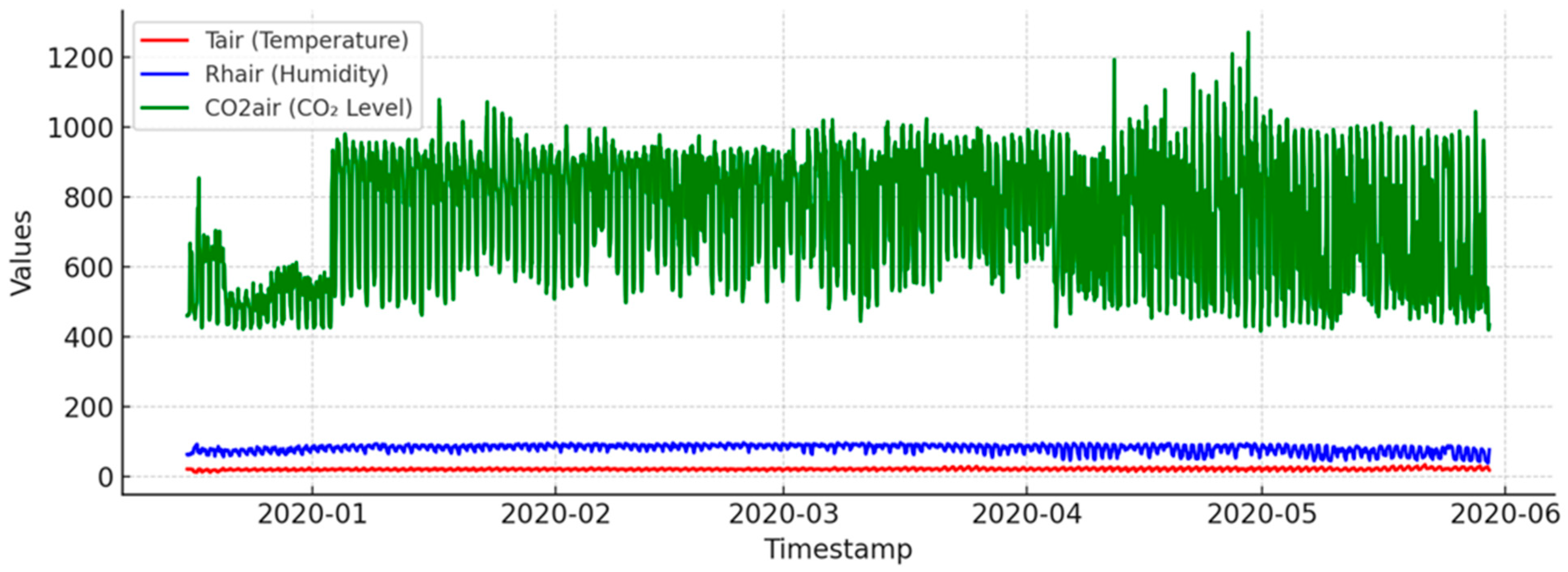

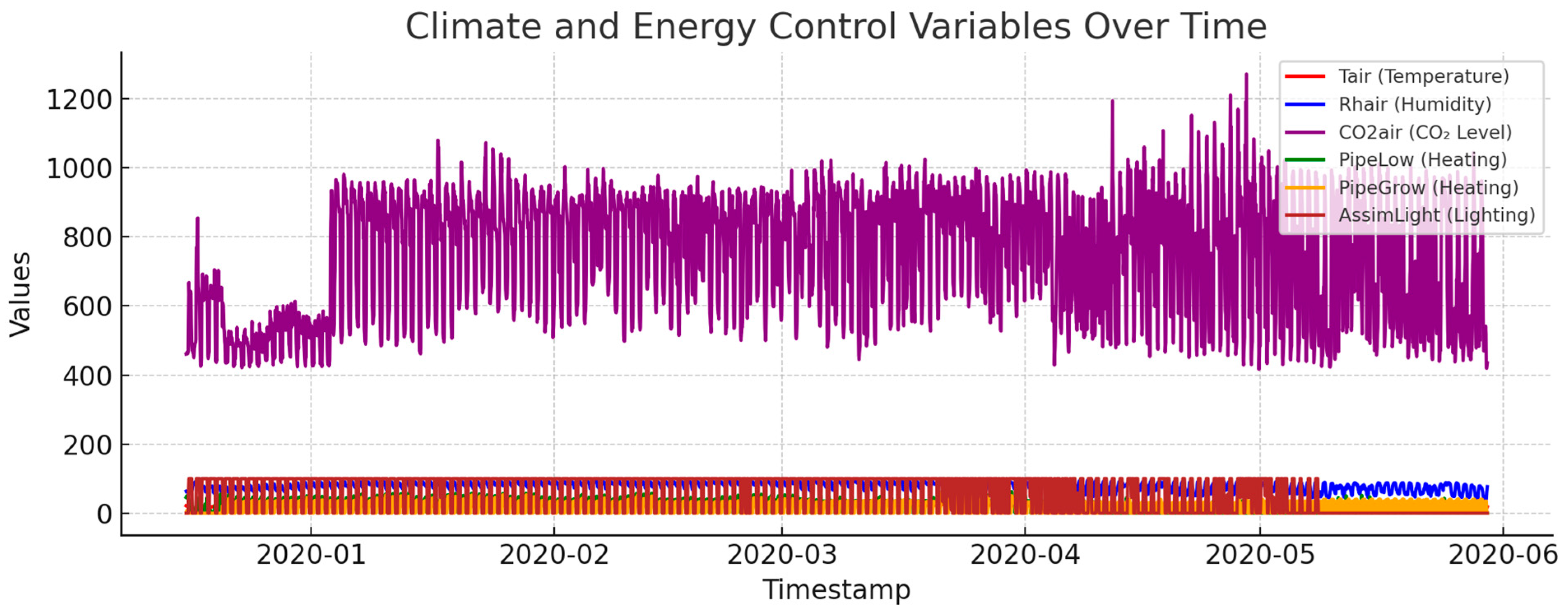

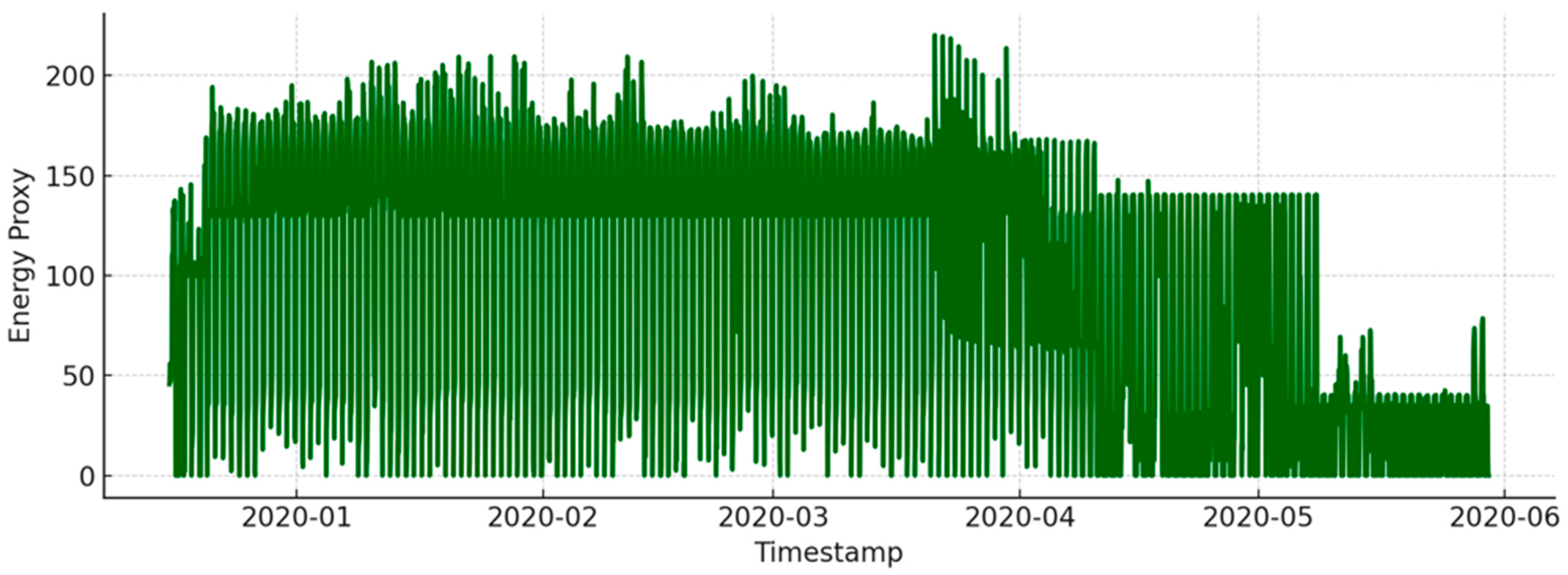

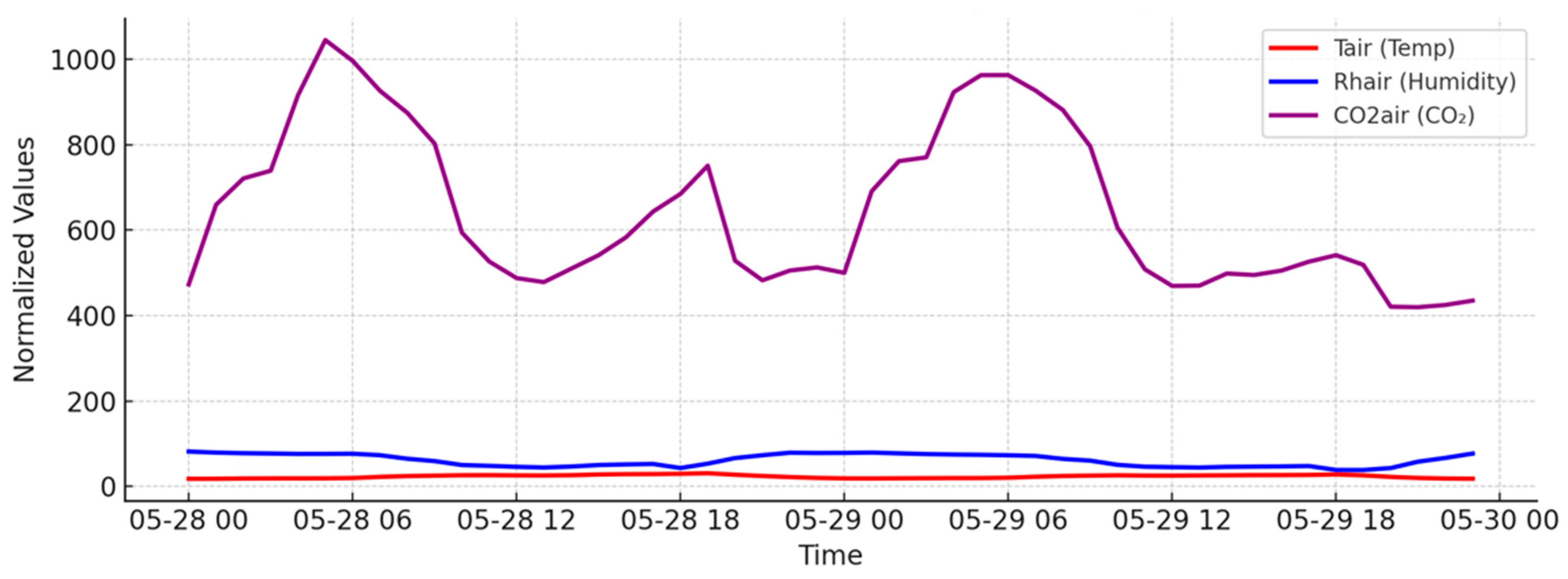

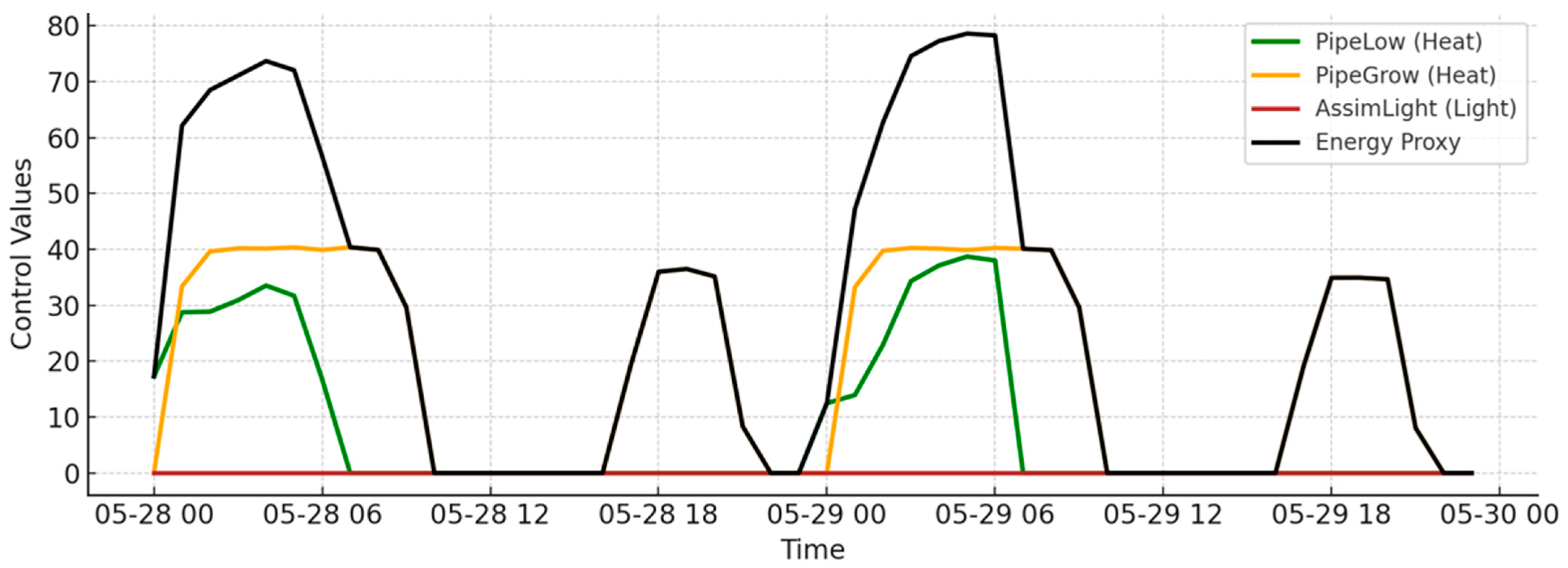

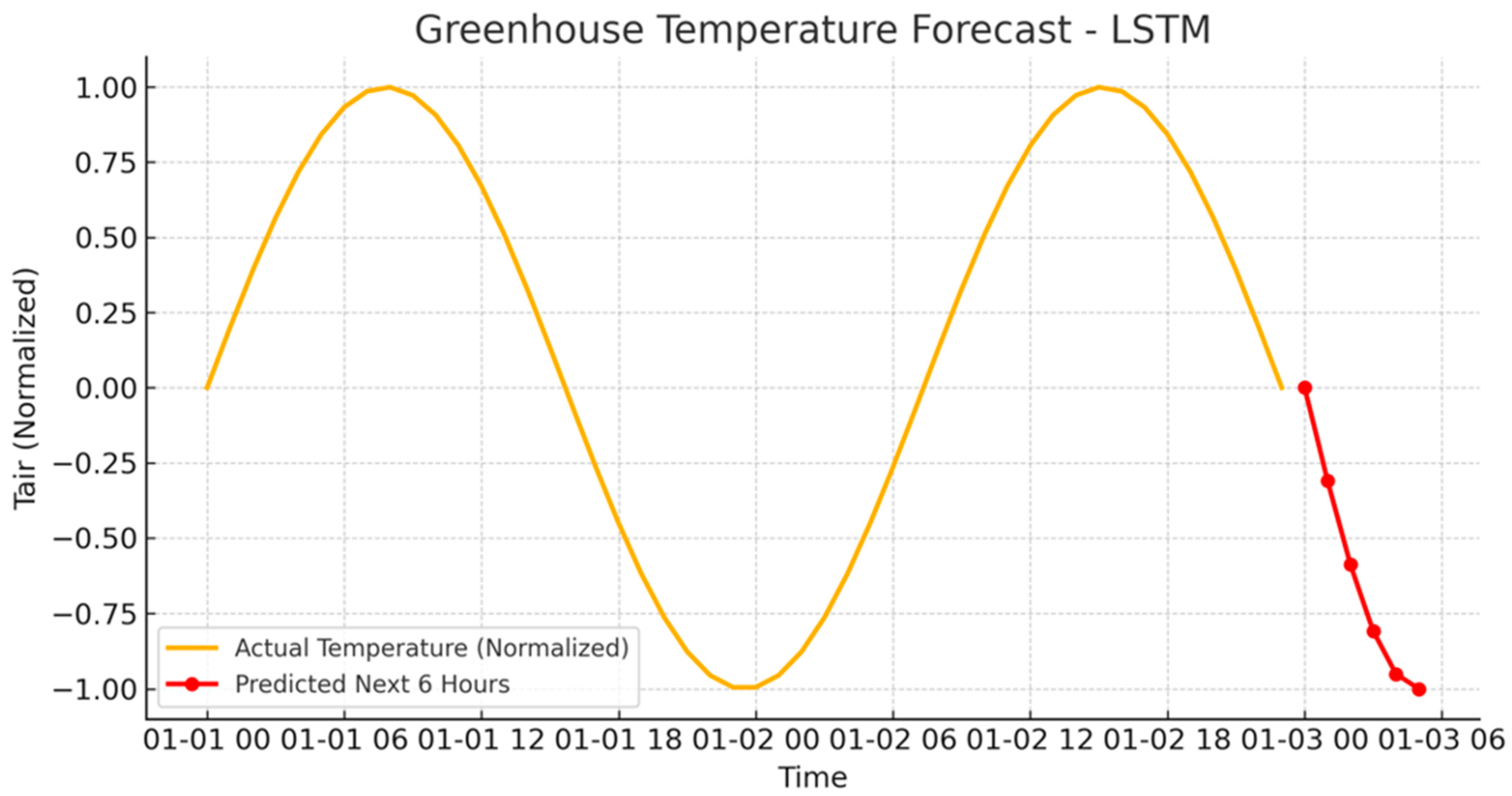

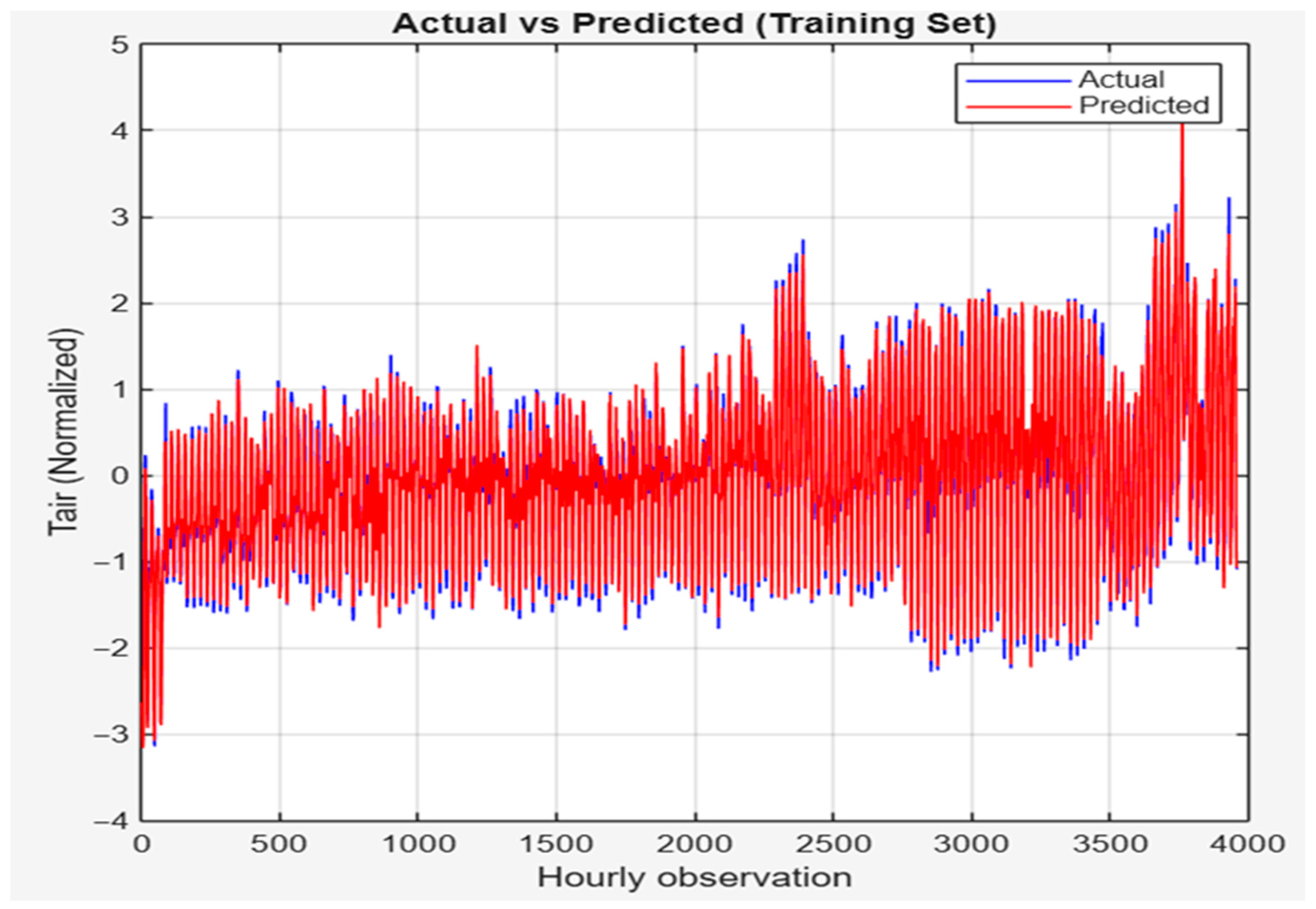

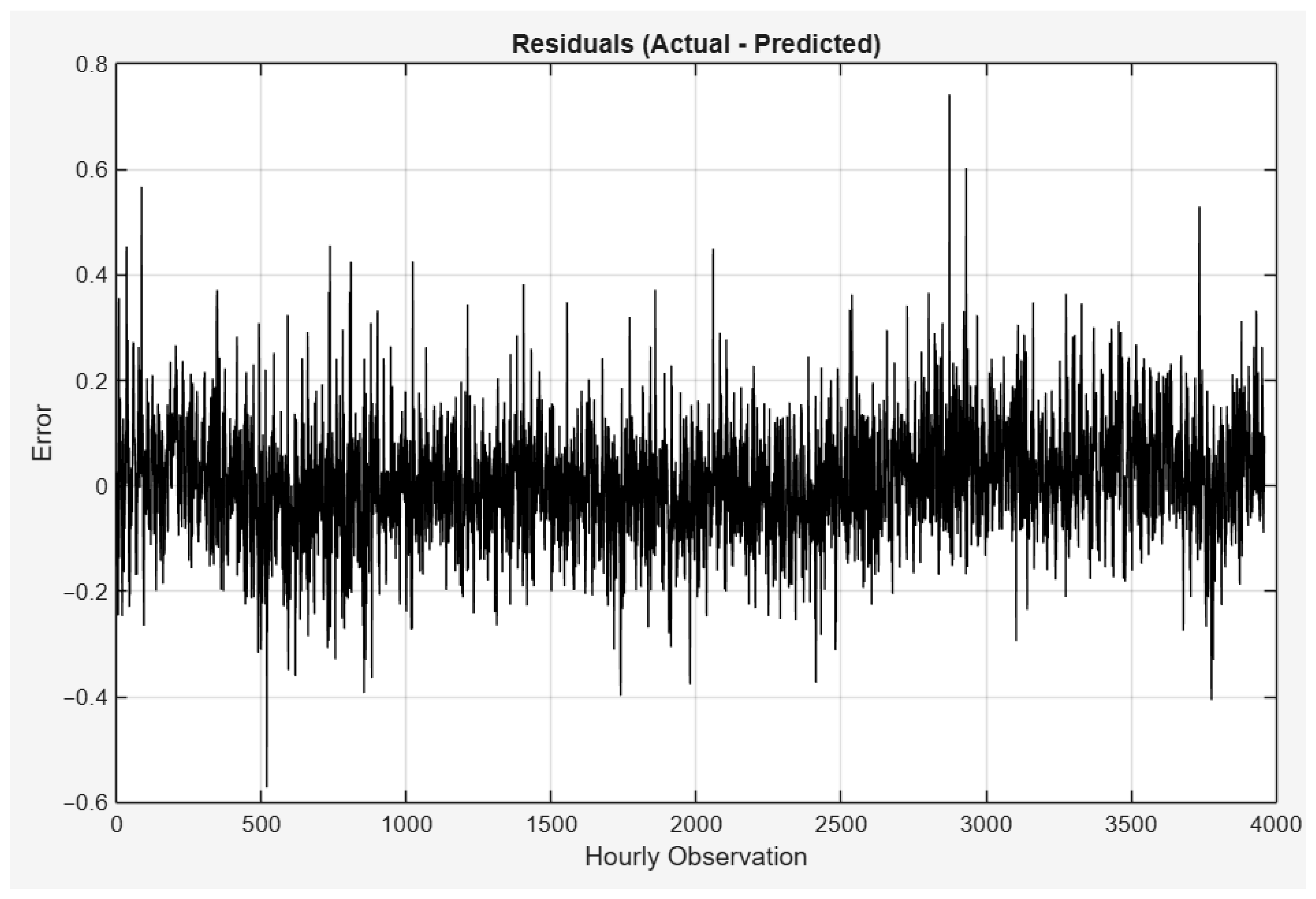

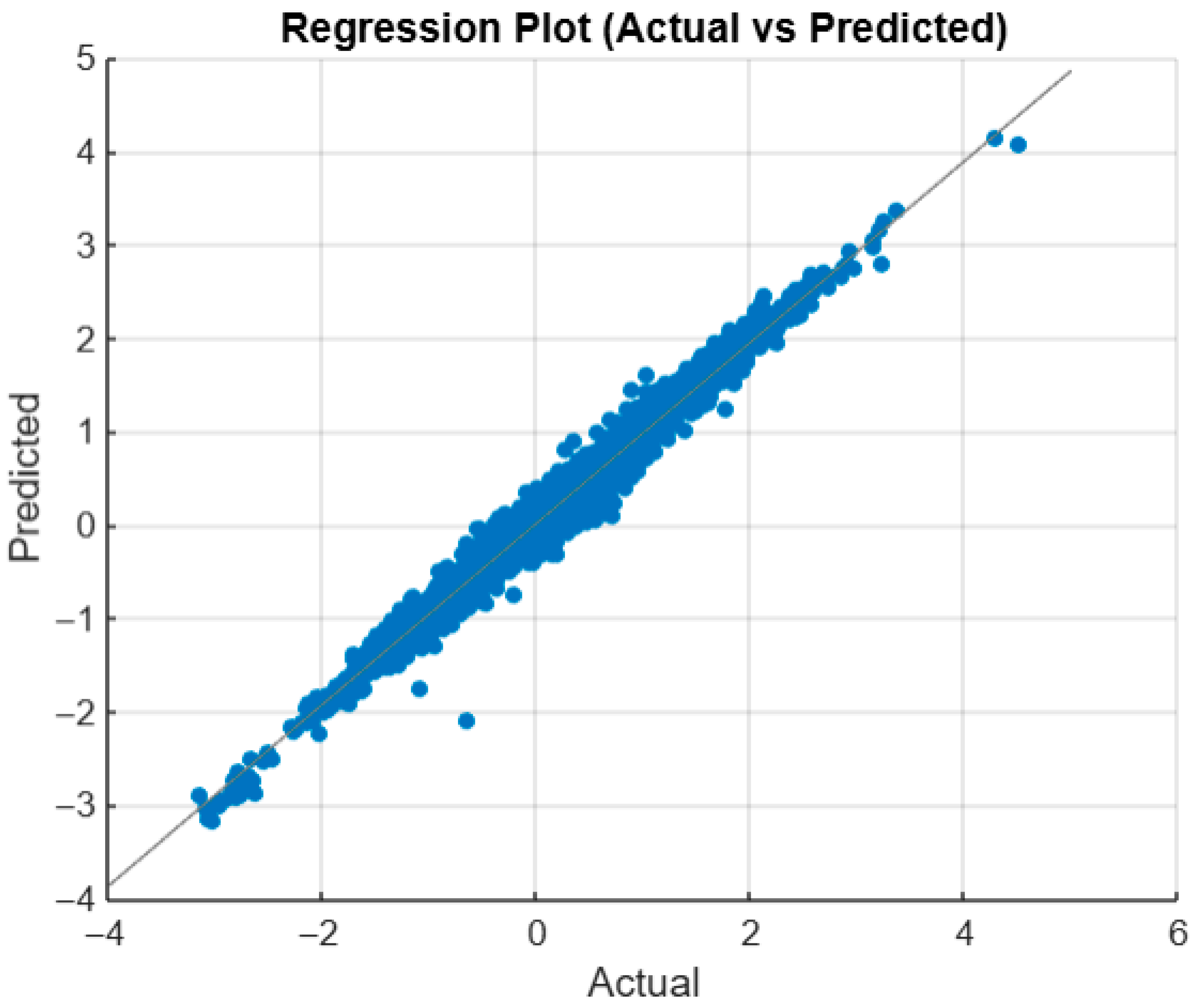

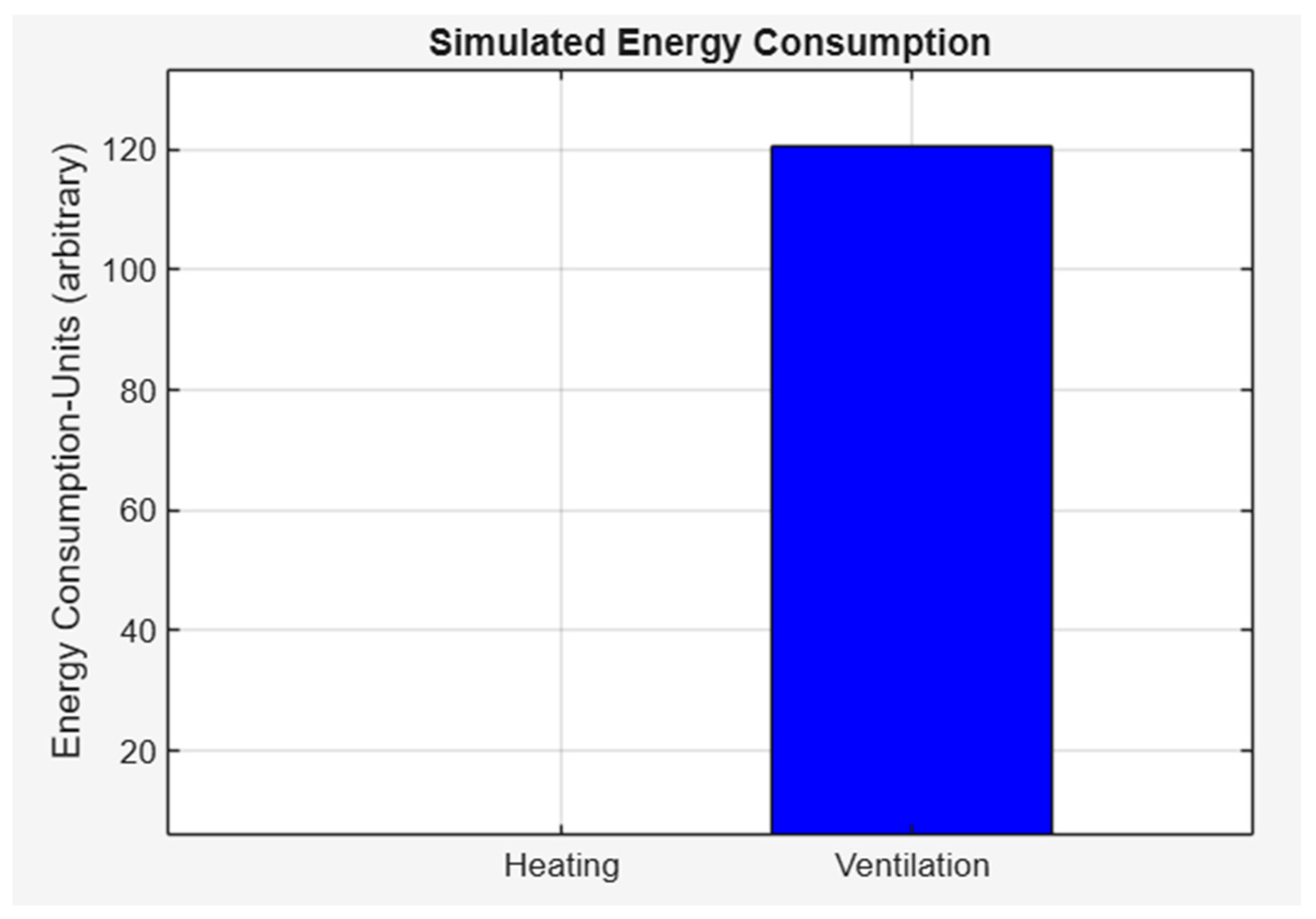

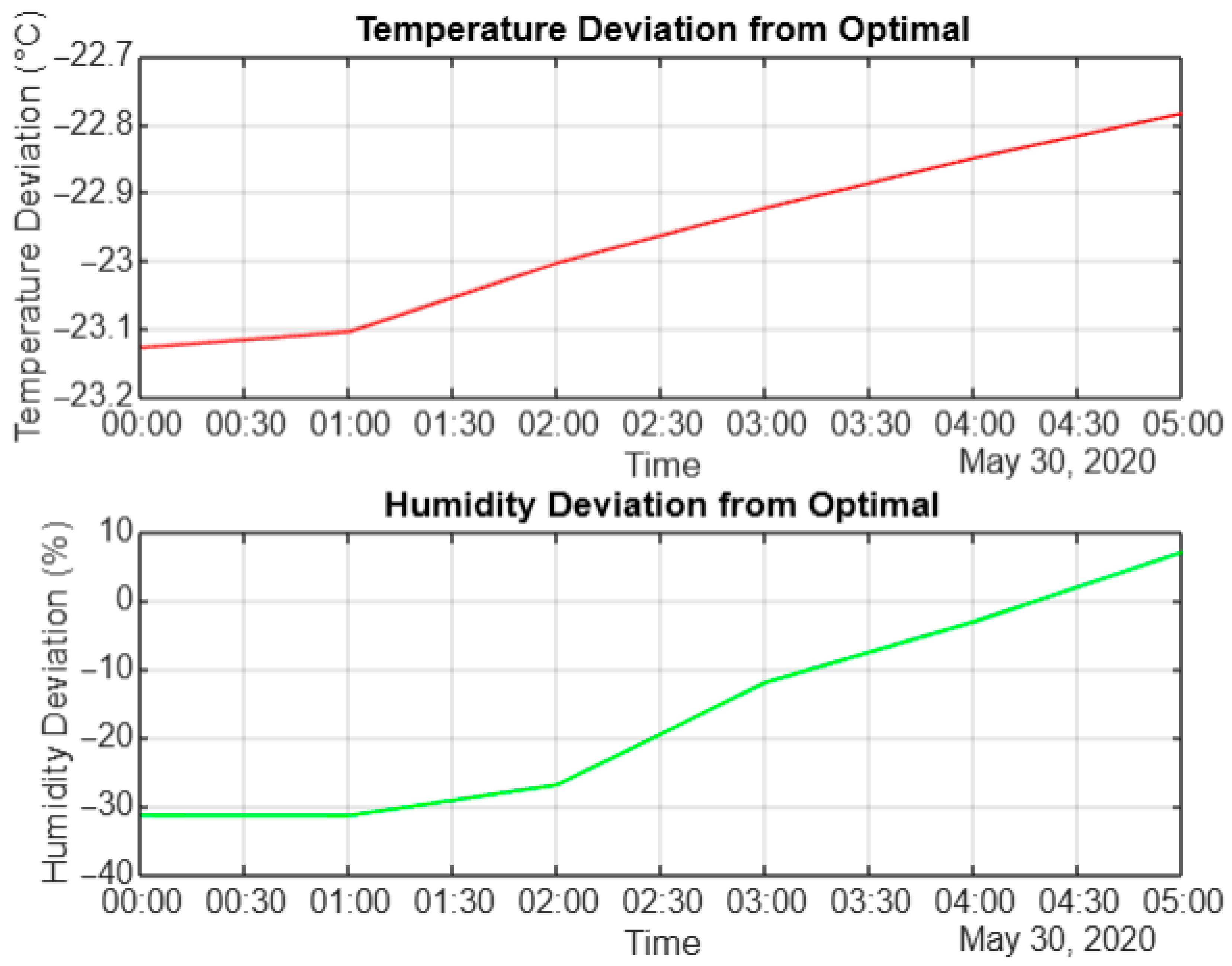

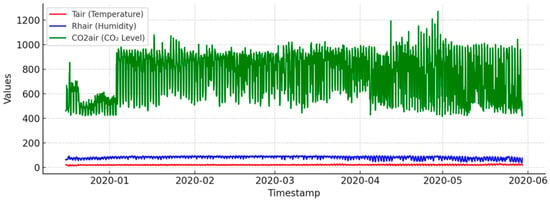

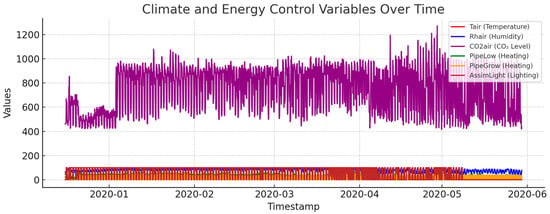

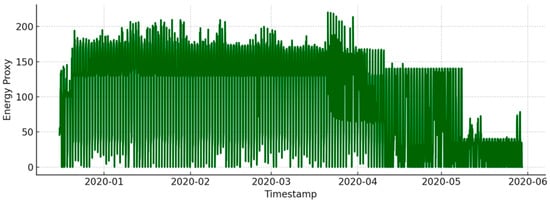

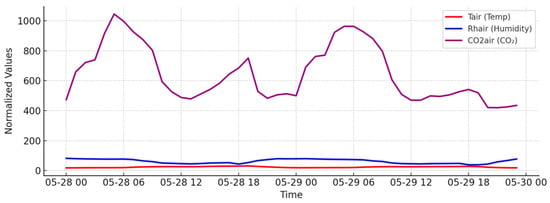

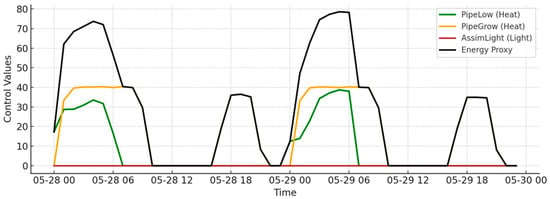

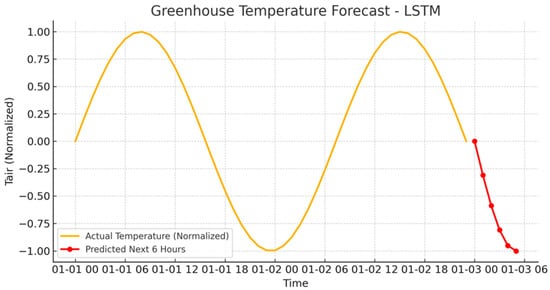

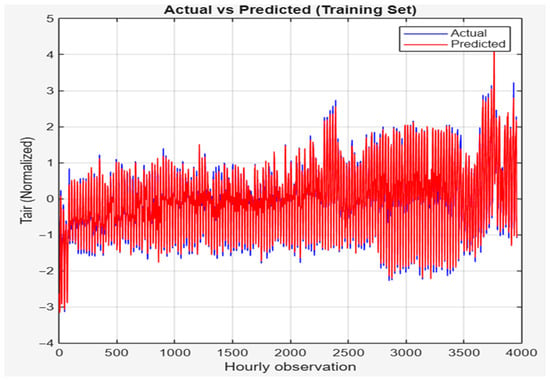

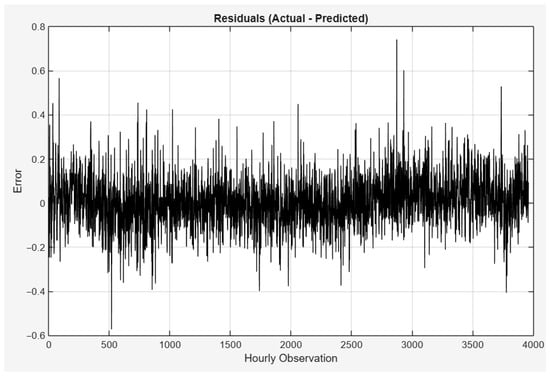

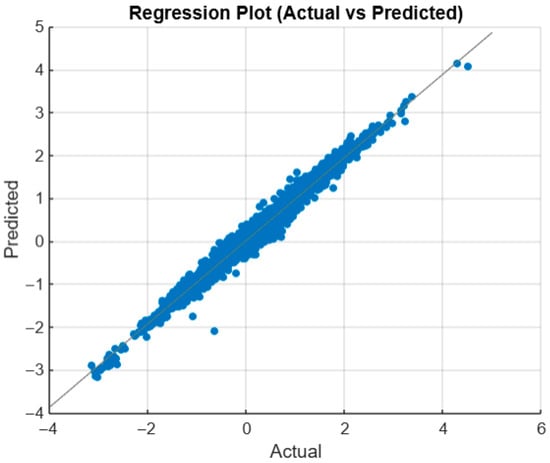

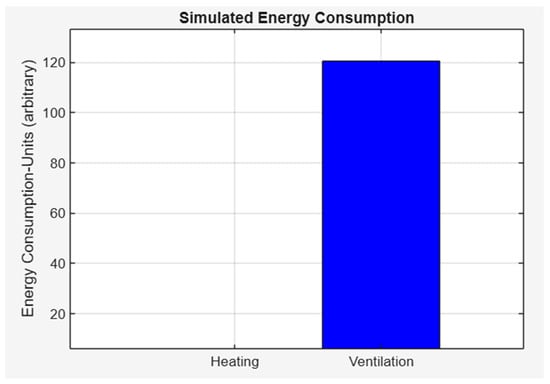

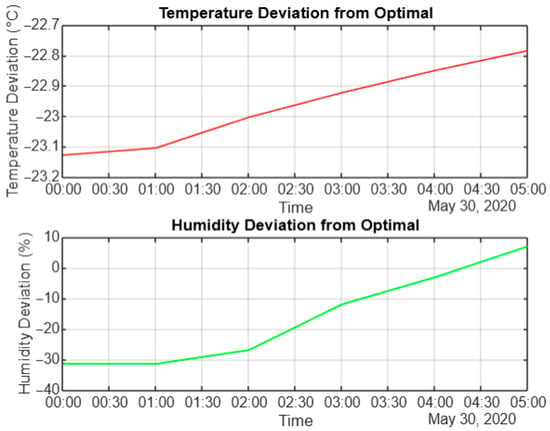

The presented figures collectively provide empirical evidence supporting the efficacy of the proposed Long Short-Term Memory (LSTM) model in facilitating predictive climate control and energy optimization within smart greenhouse systems. The temporal progression of key environmental parameters, as depicted in Figure 4, highlights the intrinsic variability and interdependence among air temperature (Tair), relative humidity (Rhair), and CO2 concentration (CO2air). These parameters exhibit both periodic and stochastic fluctuations, reinforcing the need for robust forecasting models capable of capturing nonlinear and long-range temporal dependencies. Building upon this, Figure 5 integrates actuator-related variables—namely PipeLow and PipeGrow (heating components), and AssimLight (artificial lighting)—with the aforementioned environmental parameters. This comprehensive representation illustrates the dynamic relationship between internal climate conditions and corresponding energy control actions. The observed patterns underscore the complexity of greenhouse climate regulation and the imperative for anticipatory rather than reactive control mechanisms. Figure 6 introduces an estimated energy proxy, serving as a synthesized indicator of cumulative energy consumption attributable to the operation of actuators. The presence of pronounced peaks and temporal irregularities across the observation period suggests inefficiencies under traditional control regimes. These findings validate the strategic rationale for implementing forecast-driven interventions aimed at preemptively regulating energy use. To examine system dynamics at a finer temporal resolution, Figure 7 focuses on a 48 h snapshot of core environmental variables. The short-term variability captured in this figure facilitates the detection of microclimatic shifts that are critical for responsive control. Complementarily, Figure 8 delineates the activation patterns of actuators alongside energy proxy levels. This alignment provides operational insights into the temporal synchronization between forecast-informed control decisions and actual energy deployment. The predictive capabilities of the LSTM model are visually demonstrated in Figure 9, which illustrates the forecasted trajectory of normalized air temperature over a 6 h horizon. The smooth transition between historical observations and forecasted values is evidence of the model’s ability to learn and extrapolate temporal patterns effectively. The predictive fidelity is further substantiated by Figure 10, wherein the actual and predicted values over the training set exhibit close alignment, signifying high model accuracy and generalizability. Model performance is rigorously assessed through residual diagnostics in Figure 11, which plots the error distribution (actual minus predicted values). The residuals appear symmetrically centered around zero and lack discernible autocorrelation, indicating unbiased and homoscedastic predictions. This is corroborated by the regression analysis in Figure 12, where predicted values demonstrate a strong linear correlation with observed values. The tight clustering around the identity line reflects a high coefficient of determination (R2), confirming the statistical validity of the model. Operational energy implications are further explored in Figure 13, which reveals a significant disparity between heating and ventilation energy requirements, with ventilation emerging as the dominant energy consumer. This insight informs strategic prioritization in actuator-level optimization to reduce overall energy expenditure. Lastly, Figure 14 visualizes deviations from optimal climatic conditions—specifically temperature and humidity—across time. The minimized deviation under the forecast-driven regime highlights the capacity of the proposed approach to maintain favorable microclimatic conditions while concurrently enhancing energy efficiency.

Figure 4.

Climate variable trends over time.

Figure 5.

Climate and energy control variables over time.

Figure 6.

Estimated energy proxy over time.

Figure 7.

Climate variables (48 h).

Figure 8.

Recent energy control variables (48 h).

Figure 9.

Greenhouse temperature forecast—LSTM.

Figure 10.

Comparison of actual vs. predicted greenhouse air temperature (training set).

Figure 11.

Residual errors between actual and predicted air temperature (training set).

Figure 12.

Regression plot of actual vs. predicted air temperature values.

Figure 13.

Simulated energy consumption comparison between heating and ventilation.

Figure 14.

Deviation from optimal climate conditions: temperature and humidity over time.

5. Conclusions

This study presents a forecast-driven climate control strategy for smart greenhouses, leveraging the predictive power of Long Short-Term Memory (LSTM) models to enhance energy efficiency while maintaining optimal crop-growing conditions. The proposed system accurately forecasts key environmental variables—air temperature, relative humidity, and CO2 concentration—and uses these predictions to proactively adjust control mechanisms such as heating, ventilation, and lighting. The experimental results and accompanying visual analyses, including regression plots, residual distributions, and actual versus predicted comparisons, confirm the reliability and precision of the LSTM model. The strong alignment between predicted and actual values, along with minimal residual error and high R2 values, validates the effectiveness of the forecasting approach. Additionally, the analysis of energy proxy variables highlights significant energy-saving opportunities, particularly in ventilation, which was identified as the most energy-intensive operation. By enabling anticipatory control decisions based on real-time forecasts, the system shifts greenhouse management from reactive to predictive, thereby reducing unnecessary energy usage and contributing to sustainable agriculture practices. However, certain limitations must be acknowledged. First, the model’s performance is dependent on the quality and granularity of historical sensor data, and noise or missing values may affect prediction accuracy. Second, the study focuses primarily on temperature forecasting; although CO2 and humidity are considered, their direct forecast-based control integration remains limited. Third, the system was validated in a single controlled environment, and broader generalization across diverse greenhouse setups and crop types remains to be investigated. Future research should address these limitations by considering the following: (1) incorporating advanced data preprocessing techniques to handle real-world sensor noise; (2) extending the forecasting model to simultaneously predict and optimize multiple variables such as CO2 enrichment and humidity; (3) deploying the framework in multiple greenhouse scenarios to evaluate adaptability across varying crops and climatic conditions. Furthermore, integration of reinforcement learning or hybrid optimization techniques could further enhance actuator control decisions, balancing energy efficiency with crop yield and plant health objectives. In conclusion, this work establishes a robust foundation for intelligent, data-driven greenhouse climate control, with promising implications for scalable, sustainable, and resource-efficient smart farming systems.

Author Contributions

Methodology, A.A.; Validation, M.A.-S. and M.A.A.-Z.; Formal analysis, A.A.; Investigation, A.A.; Writing—original draft, A.A., M.A.-S. and M.A.A.-Z.; Funding acquisition, M.A.A.-Z. All authors have read and agreed to the published version of the manuscript.

Funding

This paper was funded by the Research, Development, and Innovation Authority (RDIA)—Kingdom of Saudi Arabia—Under supervision Energy, Industry, and Advanced Technologies Research Center, Taibah University, Madinah, Saudi Arabia with grant number (12979-iau-2023-TAU-R-3-1-EI-).

Data Availability Statement

The data presented in this study are openly available in [IUACAAS] [https://community.data.4tu.nl/category/use-cases/, accessed on 23 October 2025].

Acknowledgments

This article is derived from a research grant funded by the Research, Development, and Innovation Authority (RDIA)—Kingdom of Saudi Arabia—with grant number (12979-iau-2023-TAU-R-3-1-EI-).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Climate control stages and equations.

Table A1.

Climate control stages and equations.

| Stage | Task | Mathematical Action |

|---|---|---|

| Forecasting | Predict future climate state | ŷt+h = f(xt−k:t) |

| Energy Proxy | Estimate energy usage | Et = α1·u1 + α2·u2 + α3·u3 |

| Optimization | Recommend actuator settings | Minimize Et+h, subject to ŷt+h ≈ y* |

| Decision | Generate control action | If ŷt < y*, then increase heating; else ventilate |

Table A2.

Dataset description.

Table A2.

Dataset description.

| Dataset Item | Data Type | Typical Range/Unit |

|---|---|---|

| Air Temperature (Tair) | Float | 10–35 °C |

| Relative Humidity (Rhair) | Float | 30–90% |

| CO2 Concentration (CO2air) | Integer | 300–1500 ppm |

| Humidity Deficit (HumDef) | Float | 4–12 g/m3 |

| Heating Pipes (PipeLow, PipeGrow) | Float | 25–60 °C |

| Ventilation (VentLee, Ventwind) | Float | 0–100% (opening percentage) |

| Lighting Status (AssimLight) | Integer (binary) | 0 or 100 (on/off) |

| Curtain Positions (EnScr, BlackScr) | Float | 0–100% |

| Irrigation Volume (water_sup) | Float | 0–15 L/m2/day |

| Drain Conductivity and pH | Float | 1–5 dS/m; pH 5.5–7.5 |

| PAR (Tot_PAR) | Float | 0–1500 µmol/m2/s |

| LED Light Intensities (int_*_sp/vip) | Integer | 0–1000 (proportional control) |

| Control Setpoints (*_sp) | Float | Varies by actuator type |

| Realized Values (*_vip) | Float | Matches corresponding control setpoint range |

Table A3.

Forecasted temperature and heating actions.

Table A3.

Forecasted temperature and heating actions.

| Forecast Time | Predicted Tair | Recommendation |

|---|---|---|

| 30-May-2020 00:00:00 | −1.1283 | Increase Heating |

| 30-May-2020 01:00:00 | −1.1050 | Increase Heating |

| 30-May-2020 02:00:00 | −1.0037 | Increase Heating |

| 30-May-2020 03:00:00 | −0.9231 | Increase Heating |

| 30-May-2020 04:00:00 | −0.8496 | Increase Heating |

| 30-May-2020 05:00:00 | −0.7842 | Increase Heating |

| Algorithm A1: Climate Data Preprocessing |

| Input: Raw dataset D_raw with timestamp and variables Output: Cleaned and normalized hourly dataset D_clean 1. Convert Excel timestamps to datetime: T ← datetime(D_raw.timestamp) 2. For each variable x in D_raw: x ← convert to numeric (handle strings) 3. Construct time-indexed table: D_time ← timetable(T, D_raw) 4. Resample to hourly average: D_hourly ← retime(D_time, ‘hourly’, ‘mean’) 5. Normalize features: x_norm ← (x—mean(x))/std(x) 6. Return D_clean ← normalized D_hourly |

| Algorithm A2: Forecasting Using LSTM |

| Input: Normalized dataset D_clean, lookback steps k Output: Forecasted values Y_pred 1. Create training sequences: For i = k+1 to N: X_train[i] ← D_clean[i-k:i-1] Y_train[i] ← D_clean.Tair[i] 2. LSTM modelin: Layers ← [Input, LSTM(100), FullyConnected(1), Regression] 3. Train model: net ← trainNetwork(X_train, Y_train, Layers) 4. Forecast h steps: For t = 1 to h: Y_pred[t] ← predict(net, X_test_t) Update X_test_t with Y_pred[t] 5. Return Y_pred |

| Algorithm A3: Energy Proxy Computation |

| Input: Control variables (PipeLow, PipeGrow, AssimLight) Output: Energy proxy E_t 1. For each time t: E_t ← PipeLow_t + PipeGrow_t + AssimLight_t 2. Return vector E |

| Algorithm A4: Actuator Decision Recommendation |

| Input: Forecasted temperature Y_pred, threshold θ Output: Recommendation R 1. For each y in Y_pred: If y < −θ: R[y] ← ‘Increase Heating’ Else if y > θ: R[y] ← ‘Increase Ventilation’ Else: R[y] ← ‘Hold Settings’ 2. Return R |

References

- Ben-Lhachemi, N.; Benchrifa, M.; Nasrdine, S.; Mabrouki, J.; Slaoui, M.; Azrour, M.A. Effect of IoT Integration in Agricultural Greenhouses. In Technical and Technological Solutions Towards a Sustainable Society and Circular Economy; World Sustainability Series; Springer: Cham, Switzerland, 2024; Volume Part F2854, pp. 435–445. [Google Scholar] [CrossRef]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy efficient operation and modeling for greenhouses: A literature review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- El-Gayar, S.; Negm, A.; Abdrabbo, M. Greenhouse Operation and Management in Egypt. In Conventional Water Resources and Agriculture in Egypt; Handbook of Environmental Chemistry; Springer: Cham, Switzerland, 2019; Volume 74, pp. 489–560. [Google Scholar] [CrossRef]

- Bailey, B. Natural and mechanical greenhouse climate control. Acta Hortic. 2006, 43–53. [Google Scholar] [CrossRef]

- Vox, G.; Teitel, M.; Pardossi, A.; Minuto, A.; Tinivella, F.; Schettini, E. Sustainable greenhouse systems. In Sustainable Agriculture: Technology, Planning and Management; Oxford University Press: New York, NY, USA, 2010; pp. 1–80. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84892100708&partnerID=40&md5=a01ef38b80dd107112bceec8385e6473 (accessed on 23 October 2025).

- Van Ooteghem, R.J.C. Optimal Control Design for a Solar Greenhouse. In IFAC Proceedings Volumes (IFAC-PapersOnline); Wageningen University: Wageningen, The Netherlands, 2010; Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-80051911906&partnerID=40&md5=aa4f585232c6834a6f50d7d457fd8cdc (accessed on 23 October 2025).

- Ahsan, T.M.A.; Rahman, M.S.; Ahamed, M.S. Geothermal energy application for greenhouse microclimate management: A review. Geothermics 2025, 127, 103209. [Google Scholar] [CrossRef]

- Kempkes, F.; de Zwart, H.; Munoz, P.; Montero, J.; Baptista, F.; Giuffrida, F.; Gilli, C.; Stepowska, A.; Stanghellini, C. Heating and dehumidification in production greenhouses at northern latitudes: Energy use. Acta Hortic. 2017, 445–452. [Google Scholar] [CrossRef]

- Dik, D.; Polyakova, E.; Chelovechkova, A.; Moskvin, V.; Nikiforova, T. The System of Environment Control of Botanic Garden Greenhouses. In Proceedings of the 2018 International Multi-Conference on Industrial Engineering and Modern Technologies, FarEastCon 2018, Vladivostok, Russia, 3–4 October 2018. [Google Scholar] [CrossRef]

- Dumitrascu, A. Methods and software tools for greenhouse climate. In Proceedings of the 8th International Scientific Conference on Modern Management of Mine Producing, Geology and Environmental Protection, SGEM 2008, Albena, Bulgaria, 16–20 June 2008; pp. 301–308. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84890259918&partnerID=40&md5=9f2011a65f4ac4bb3c1c6b885aa882da (accessed on 23 October 2025).

- Tawalbeh, M.; Aljaghoub, H.; Alami, A.H.; Olabi, A.G. Selection criteria of cooling technologies for sustainable greenhouses: A comprehensive review. Therm. Sci. Eng. Prog. 2023, 38, 101666. [Google Scholar] [CrossRef]

- Ajagekar, A.; Decardi-Nelson, B.; You, F. Energy management for demand response in networked greenhouses with multi-agent deep reinforcement learning. Appl. Energy 2024, 355, 122349. [Google Scholar] [CrossRef]

- Dieleman, J.A.; Hemming, S. Energy saving: From engineering to crop management. Acta Hortic. 2011, 65–74. [Google Scholar] [CrossRef][Green Version]

- Altes-Buch, Q.; Quoilin, S.; Lemort, V. A modeling framework for the integration of electrical and thermal energy systems in greenhouses. Build. Simul. 2022, 15, 779–797. [Google Scholar] [CrossRef]

- Rodríguez, F.; Berenguel, M.; Guzmán, J.L.; Ramírez-Arias, A. Climate and irrigation control. Adv. Ind. Control 2015, 171, 99–196. [Google Scholar] [CrossRef]

- Xu, L.; Su, Y.; Liang, Y. Requirement and current situation of control-oriented microclimate environmental model in greenhouse system. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2013, 29, 1–15. [Google Scholar] [CrossRef]

- Katzin, D.; van Mourik, S.; Kempkes, F.L.K.; van Henten, E.J. Energy saving measures in optimally controlled greenhouse lettuce cultivation. Acta Hortic. 2020, 265–272. [Google Scholar] [CrossRef]

- Banakar, A.; Montazeri, M.; Ghobadian, B.; Pasdarshahri, H.; Kamrani, F. Energy analysis and assessing heating and cooling demands of closed greenhouse in Iran. Therm. Sci. Eng. Prog. 2021, 25, 101042. [Google Scholar] [CrossRef]

- Kavga, A.; Petrakis, T.; Thomopoulos, V. The contribution of innovative semi-transparent photovoltaics for energy autonomy in the field of greenhouse systems. VDI Berichte 2022, 2022, 61–68. [Google Scholar] [CrossRef]

- Arabhosseini, A. Application of clean energies in agricultural greenhouses. In Proceedings of the 2023 8th International Conference on Technology and Energy Management, ICTEM 2023, Babol, Iran, 8–9 February 2023. [Google Scholar] [CrossRef]

- Ghaderi, M.; Reddick, C.; Sorin, M. A Systematic Heat Recovery Approach for Designing Integrated Heating, Cooling, and Ventilation Systems for Greenhouses. Energies 2023, 16, 5493. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.; Yang, Z.; Huang, Q.; Qiu, R. Characteristics of Plastic Greenhouse High-Temperature and High-Humidity Events and Their Impacts on Facility Tomatoes Growth. Front. Earth Sci. 2022, 10, 848924. [Google Scholar] [CrossRef]

- Joshi, A.; Saxena, A.; Das, S.K. Effect of Greenhouse Microclimate on Crop Performance. In Protected Cultivation: Structural Design, Crop Management Modeling, and Automation; Apple Academic Press: New York, NY, USA, 2024; pp. 135–159. [Google Scholar] [CrossRef]

- Bai, L.; Deng, H.; Zhang, X.; Yu, X.; Li, Y. Gibberellin is involved in inhibition of cucumber growth and nitrogen uptake at suboptimal root-zone temperatures. PLoS ONE 2016, 11, e0156188. [Google Scholar] [CrossRef]

- Šalagovič, J.; Vanhees, D.; Verboven, P.; Holsteens, K.; Verlinden, B.; Huysmans, M.; Van de Poel, B.; Nicolaï, B. Microclimate monitoring in commercial tomato (Solanum Lycopersicum L.) greenhouse production and its effect on plant growth, yield and fruit quality. Front. Hortic. 2024, 3, 1425285. [Google Scholar] [CrossRef]

- Pinho, P.; Hytönen, T.; Rantanen, M.; Elomaa, P.; Halonen, L. Dynamic control of supplemental lighting intensity in a greenhouse environment. Light. Res. Technol. 2013, 45, 295–304. [Google Scholar] [CrossRef]

- Gómez-Cabezas, M.; España, Á. Exogenous Sucrose Enhances Growth and Physiological Performance of Tomato Seedlings Under Suboptimal Light Conditions in Passive Greenhouses. Horticulturae 2024, 10, 1337. [Google Scholar] [CrossRef]

- Muñoz-Liesa, J.; Royapoor, M.; Cuerva, E.; Gassó-Domingo, S.; Gabarrell, X.; Josa, A. Building-integrated greenhouses raise energy co-benefits through active ventilation systems. Build. Environ. 2022, 208, 108585. [Google Scholar] [CrossRef]

- Dorais, M.; Dubé, Y. Managing greenhouse organic wastes: A holistic approach. Acta Hortic. 2011, 183–198. [Google Scholar] [CrossRef]

- Săcăleanu, D.-I.; Matache, M.-G.; Roșu, Ș.-G.; Florea, B.-C.; Manciu, I.-P.; Perișoară, L.-A. IoT-Enhanced Decision Support System for Real-Time Greenhouse Microclimate Monitoring and Control. Technologies 2024, 12, 230. [Google Scholar] [CrossRef]

- Ardiansah, I.; Bafdal, N.; Suryadi, E.; Bono, A. Greenhouse monitoring and automation using Arduino: A review on precision farming and internet of things (IoT). Int. J. Adv. Sci. Eng. Inf. Technol. 2020, 10, 703–709. [Google Scholar] [CrossRef]

- Saraswat, S.; Khan, R.; Gupta, A.; Mehta, A. Mechanized functioning of tomato and lettuce greenhouses using IoT and machine learning techniques. In Convergence of Cloud Computing, AI, and Agricultural Science; IGI Global Scientific Publishing: Hershey, PA, USA, 2023; pp. 261–279. [Google Scholar] [CrossRef]

- Tripathy, N.; Tripathy, S.S.; Rath, M.; Swain, J. An IoT Assisted Fog Enabled Framework for Smart Green House. In Proceedings of the Proceedings—International Conference on Computational Intelligence and Networks, Bhubaneswar, India, 1–3 December 2022. [Google Scholar] [CrossRef]

- Debdas, S.; Pandey, S.; Gupta, S.; Dash, R.K.; Patnaik, M.C.; Singh, A.A. Optimizing Resource Efficiency in Smart Greenhouses through IoT. In Proceedings of the 2024 5th International Conference for Emerging Technology, INCET 2024, Belgaum, India, 24–26 May 2024. [Google Scholar] [CrossRef]

- Jain, H. Data analytics enabled by the Internet of Things and artificial intelligence for the management of Earth’s resources. Data Anal. Artif. Intell. Earth Resour. Manag. 2024, 19–36. [Google Scholar] [CrossRef]

- Rokade, A.; Singh, M.; Malik, P.K.; Singh, R.; Alsuwian, T. Intelligent Data Analytics Framework for Precision Farming Using IoT and Regressor Machine Learning Algorithms. Appl. Sci. 2022, 12, 9992. [Google Scholar] [CrossRef]

- Pugazh, M.P.; Xavier, V.M.A.; Shyni, S.S. Design of Greenhouse System with Internet of Things and Machine Learning. In Proceedings of the 10th International Conference on Advanced Computing and Communication Systems, ICACCS 2024, Coimbatore, India, 14–15 March 2024; pp. 1921–1926. [Google Scholar] [CrossRef]

- Hazra, S.; Mondal, A.; Dey, P.; Prabhakar, S.; Jha, A.K.; Rakshit, N. Future Prospects of Agriculture Using IoT and Machine Learning. In Proceedings of the 2024 IEEE International Conference on Smart Power Control and Renewable Energy, ICSPCRE 2024, Rourkela, India, 19–21 July 2024. [Google Scholar] [CrossRef]

- Gomathy, G.; Esther, C.; Manaswini, S.; Swedharani, R.V.; Hyden, J.J.; Anand, A.A. Effective Farming for Zero Wastage and Enhancement of Farmer’s Income. In Proceedings of the 4th International Conference on Power, Energy, Control and Transmission Systems: Harnessing Power and Energy for an Affordable Electrification of India, ICPECTS 2024, Chennai, India, 8–9 October 2024. [Google Scholar] [CrossRef]

- Bavana, H.S.; Kummara, S.; Pranutha, S.S.K.; Vijayalakshmi, V.; Farooqui, N.A. An Investigation of the Utilizations of Machine Learning Methods in Precision Agriculture. In Proceedings of the 2nd IEEE International Conference on IoT, Communication and Automation Technology, ICICAT 2024, Gorakhpur, India, 23–24 November 2024; pp. 880–887. [Google Scholar] [CrossRef]

- Apuroop, I.; Sandhu, R.; Krishnamraju, D.E.S.; Singh, G.; Shikhar, S.; Kumar, S.; Jakkampud, S. Applying Machine Learning Approaches in Fertilizer Optimization and Yield Prediction for Smart Agriculture. In Proceedings of the 2025 International Conference on Automation and Computation, AUTOCOM 2025, Dehradun, India, 4–6 March 2025; pp. 53–58. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Almutairi, Z.A. Nested Optimization Algorithms for Accurately Sizing a Clean Energy Smart Grid System, Considering Uncertainties and Demand Response. Sustainability 2025, 17, 2744. [Google Scholar] [CrossRef]

- Egbuna, I.K.; Salihu, F.B.; Okara, C.C.; Emmanuel, D. Advances in AI-powered energy management systems for renewable-integrated smart grids. World J. Adv. Eng. Technol. Sci. 2025, 15, 2300–2325. [Google Scholar] [CrossRef]

- Ahmed, I.; Khan, M.A.U.H.; Islam, M.D.; Hasan, S.; Jakir, T.; Hossain, A.; Hasnain, K.N. Optimizing Solar Energy Production in the USA: Time-Series Analysis Using AI for Smart Energy Management. arXiv 2025, arXiv:2506.23368. [Google Scholar] [CrossRef]

- Feng, S.; Ren, H.; Zhou, W. A review of uncertain factors and analytic methods in long-term energy system optimization models. Glob. Energy Interconnect. 2023, 6, 450–466. [Google Scholar] [CrossRef]

- Stoian, D.; Spiliotis, E.; Stamatopoulos, E.; Sarmas, E.; Marinakis, E. A web-based decision support tool for efficiently monitoring and upgrading HVAC systems. In Proceedings of the 2024 IEEE 15th International Conference on Information, Intelligence, Systems & Applications (IISA), Chania Crete, Greece, 17–19 July 2024; pp. 1–7. [Google Scholar]

- Rizwan, A.; Khan, A.N.; Ahmad, R.; Kim, D.H. Optimal Environment Control Mechanism Based on OCF Connectivity for Efficient Energy Consumption in Greenhouse. IEEE Internet Things J. 2023, 10, 5035–5049. [Google Scholar] [CrossRef]

- Tung, Y.-C.; Syahputri, N.W.; Diputra, I.G.N.A.S. Greenhouse Environment Sentinel with Hybrid LSTM-SVM for Proactive Climate Management. AgriEngineering 2025, 7, 96. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, B.; Lin, L.; Xu, Y.; Zhou, P.; Luo, S.; Zhuo, Y.; Ji, J.; Luo, Z.; Hassan, S.G. Multi-model fusion method for predicting CO2 concentration in greenhouse tomatoes. Comput. Electron. Agric. 2024, 227, 109623. [Google Scholar] [CrossRef]

- Hamidane, H.; El Faiz, S.; Rkik, I.; El Khayat, M.; Guerbaoui, M.; Ed-Dhhak, A.; Lachhab, A. Application analysis of ANFIS strategy for greenhouse climate parameters prediction: Internal temperature and internal relative humidity case of study. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021. [Google Scholar] [CrossRef]

- Shao, X.; Chen, Y.; Chen, X.; Zhu, F. Research on intelligent monitoring and optimization control system model of greenhouse environment based on deep learning. In Proceedings of the 2024 4th International Conference on Electronic Information Engineering and Computer Communication, EIECC 2024, Wuhan, China, 13–15 December 2024; pp. 1246–1250. [Google Scholar] [CrossRef]

- Chen, W.-H.; You, F. Semiclosed Greenhouse Climate Control Under Uncertainty via Machine Learning and Data-Driven Robust Model Predictive Control. IEEE Trans. Control Syst. Technol. 2022, 30, 1186–1197. [Google Scholar] [CrossRef]

- Su, Y.; Xu, L. Global Optimization and Control of Greenhouse Climate Setpoints for Energy Saving and Crop Yield Increase. Agriculture 2025, 15, 939. [Google Scholar] [CrossRef]

- Abbood, H.M.; Nouri, N.M.; Riahi, M.; Alagheband, S.H. An intelligent monitoring model for greenhouse microclimate based on RBF Neural Network for optimal setpoint detection. J. Process Control. 2023, 129, 103037. [Google Scholar] [CrossRef]

- Yu, W.; Körner, O.; Schmidt, U. Crop Photosynthetic Performance Monitoring Based on a Combined System of Measured and Modelled Chloroplast Electron Transport Rate in Greenhouse Tomato. Front. Plant Sci. 2020, 11, 1038. [Google Scholar] [CrossRef]

- Mahmood, F.; Govindan, R.; Yang, D.; Bermak, A.; Al-Ansari, T. Forecasting cooling load and water demand of a semi-closed greenhouse using a hybrid modelling approach. Int. J. Ambient. Energy 2022, 43, 8046–8066. [Google Scholar] [CrossRef]

- Kim, J.; Kim, K.-J.; Kim, J.; Choi, Y.; Yun, B.-J.; Kwon, S.-G. Evaluating Deep Learning Models for Prediction of Climate Conditions in Greenhouse. In Proceedings of the 2024 IEEE International Conference on Consumer Electronics-Asia, ICCE-Asia 2024, Danang, Vietnam, 3–6 November 2024. [Google Scholar] [CrossRef]

- Wijayaningrum, V.N.; Haniah, M.; Al Hadid Firdaus, V. Advanced Predictive Analytics for Agricultural Weather Forecasting Using Machine Learning. In Proceedings of the IEIT 2024—2024 International Conference on Electrical and Information Technology, Malang, Indonesia, 12–13 September 2024; pp. 182–187. [Google Scholar] [CrossRef]

- Hendy, Z.M.; Abdelhamid, M.A.; Gyasi-Agyei, Y.; Mokhtar, A. Estimation of reference evapotranspiration based on machine learning models and timeseries analysis: A case study in an arid climate. Appl. Water Sci. 2023, 13, 216. [Google Scholar] [CrossRef]

- Jeon, Y.-J.; Kim, J.Y.; Hwang, K.-S.; Cho, W.-J.; Kim, H.-J.; Jung, D.-H. Machine Learning-Powered Forecasting of Climate Conditions in Smart Greenhouse Containing Netted Melons. Agronomy 2024, 14, 1070. [Google Scholar] [CrossRef]

- Dai, Z.; Huang, T. Enhancing the prediction accuracy of greenhouse temperatures through hybrid machine learning models: An in-depth comparative analysis of RBF, RF, and XGBoost techniques combined with SMA and MFO optimization strategies. Multiscale Multidiscip. Model. Exp. Des. 2024, 8, 311. [Google Scholar] [CrossRef]

- Shetty, S.V.; Bharath, M.S.; Chandan, R.; Divya, V.; Nayak, S.S. Prediction of Drought—A Machine Learning Approach using Time Series Data. In Proceedings of the International Conference on Applied Intelligence and Sustainable Computing, ICAISC 2023, Dharwad, India, 16–17 June 2023. [Google Scholar] [CrossRef]

- Wen, X.; Liao, J.; Niu, Q.; Shen, N.; Bao, Y. Deep learning-driven hybrid model for short-term load forecasting and smart grid information management. Sci. Rep. 2024, 14, 13720. [Google Scholar] [CrossRef]

- Yadav, D.K.; Kaushik, A.; Yadav, N. Predicting machine failures using machine learning and deep learning algorithms. Sustain. Manuf. Serv. Econ. 2024, 3, 100029. [Google Scholar]

- Mienye, I.D.; Swart, T.G.; Obaido, G. Recurrent neural networks: A comprehensive review of architectures, variants, and applications. Information 2024, 15, 517. [Google Scholar] [CrossRef]

- Soltani, A. An overview of Hidden Markov Models. Bachelor’s Thesis, University of Padua, Padua, Italy, 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).