Abstract

The gradual exhaustion of fossil fuel reserves, along with the adverse effects of their consumption on global climate, drives the need for research into alternative energy sources that can meet the growing demand in a sustainable and eco-friendly way. Among these, hydrogen stands out as one of the most promising options for the automotive sector, being the cleanest available fuel and capable of being produced from renewable resources. This paper reviews the existing literature on compression ignition engines operating in a dual-fuel configuration, where diesel serves as the ignition source and hydrogen is used to enhance the combustion process. The reviewed studies focus on engine systems with hydrogen injection into the intake manifold. The investigations analyzed the influence of hydrogen energy fraction on combustion characteristics, engine performance, combustion stability, and exhaust emissions in diesel/hydrogen dual-fuel engines operating under full or near-full-load conditions. The paper identifies the main challenges hindering the widespread and commercial application of hydrogen in diesel/hydrogen dual-fuel engines and discusses potential methods to overcome the existing barriers in this area.

1. Introduction

Currently, the global energy demand is predominantly met by fossil fuels. However, the inevitable depletion of these resources and the significant impact of their use on global climate change necessitate research into alternative fuels to ensure the growing energy demand is met in a renewable and environmentally sustainable manner. Previous studies have explored the use of alcohols [1,2], biogas [3,4], synthesis gas [5,6], natural gas [7,8], biodiesel [9,10], ammonia, and hydrogen [11,12] as partial replacements for conventional fuels. Among alternative fuels, hydrogen is regarded as one of the most promising options for the automotive sector, as it is the cleanest available and can be produced from renewable sources. Being a zero-emission fuel, it provides several advantages over other alternatives. The use of hydrogen in internal combustion engines can, on the one hand, significantly improve the environmental performance of the engine, but on the other hand, it may present numerous technical challenges during operation and may not be economically justified under current conditions. A fundamental obstacle to using hydrogen as a standalone fuel in piston engines is its low energy density. Although hydrogen has a very high gravimetric heating value of approximately 120 MJ/kg, under standard conditions it exists as a gas with a volumetric heating value of only about 10 MJ/m3. To fully utilize hydrogen’s energy potential, it must be converted into a liquid state. This requires compression to a pressure of approximately 70 MPa and cooling to a temperature of −253 °C. Such conditions introduce significant challenges related to hydrogen storage and transportation. Cryogenic tanks used for hydrogen storage must not only withstand high mechanical stresses and maintain extremely low temperatures, but also prevent uncontrolled leakage. Due to its physical properties, hydrogen has the ability to permeate through the walls of conventional containers. Nevertheless, hydrogen in its gaseous form can be used in internal combustion engines as a supplementary fuel that enhances the combustion process—particularly in cases involving alternative fuels that are otherwise difficult or inefficient to burn independently. The positive impact of hydrogen addition on combustion and emissions has been observed in both spark-ignition and compression-ignition engines. Conventional compression-ignition (CI) engines are widely used as primary power sources in vehicles around the world due to their high efficiency, robust construction, and versatility. Over the past several decades, the diesel engine has been recognized as one of the most efficient and reliable energy conversion technologies, finding widespread application as a primary power source in land transportation, commercial maritime operations, and stationary power generation systems [13]. Compression-ignition engines are the propulsion system of choice for heavy-duty transportation owing to their robustness and high torque characteristics. Nevertheless, the carbon content of fossil-derived diesel fuel renders these engines a substantial contributor to global greenhouse gas (GHG) emissions [14]. Retrofitting existing diesel engines to operate on alternative fuels, such as hydrogen, has the potential to substantially decrease dependence on fossil fuels and improve environmental sustainability [15].

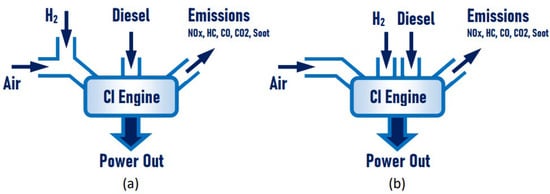

One of the main challenges in using hydrogen as a fuel in compression-ignition (CI) engines is their high compression ratio, which promotes uncontrolled ignition and the onset of knock combustion [16]. In CI engines, hydrogen is primarily utilized in dual-fuel systems based on Reactivity-Controlled Compression Ignition (RCCI) technology, which requires the use of a highly reactive fuel with good autoignition properties. In dual-fuel engines, hydrogen can be co-combusted with both conventional fuels, such as diesel, and alternative fuels, such as biodiesel. Depending on the system design, hydrogen in its gaseous form can be supplied to the intake manifold (PFI—port fuel injection) (Figure 1a), or directly into the combustion chamber (DI—direct injection) (Figure 1b), while the highly reactive fuel is injected directly into the combustion chamber [17,18]. The dose of the high-reactivity fuel is used to initiate the combustion process, and its quantity allows for control over the ignition delay of the air–fuel mixture.

Figure 1.

Schematic of a dual-fuel diesel engine with hydrogen port injection (PFI) (a) and direct in-cylinder (DI) hydrogen injection (b).

2. Methodology and Study Selection

This paper presents a literature review of compression ignition engines operating in dual-fuel mode, using diesel as the ignition fuel and hydrogen as a supplementary fuel to enhance the combustion process. The study examines the impact of the hydrogen energy fraction (HEF) on selected key engine performance indicators, including ignition delay (ID), combustion duration (CD), maximum in-cylinder pressure (pmax), maximum heat release rate (HRRmax), thermal efficiency (TE), specific energy consumption (SEC), coefficient of variation of indicated mean effective pressure (COVimep), and coefficient of variation of maximum in-cylinder pressure (COVpmax), as well as emissions of nitrogen oxides (NOx), hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2), Soot, and particulate matter (PM). The analysis does not evaluate absolute values of specific engine performance indicators; instead, it discusses relative percentage changes of these indicators compared to a reference diesel-only engine. Among the 13 studies selected for review, the hydrogen energy fraction (HEF) varied from 0 to 85%. The engines investigated employed port fuel injection (PFI) for hydrogen and were operated at constant engine speeds under full or near-full-load conditions.

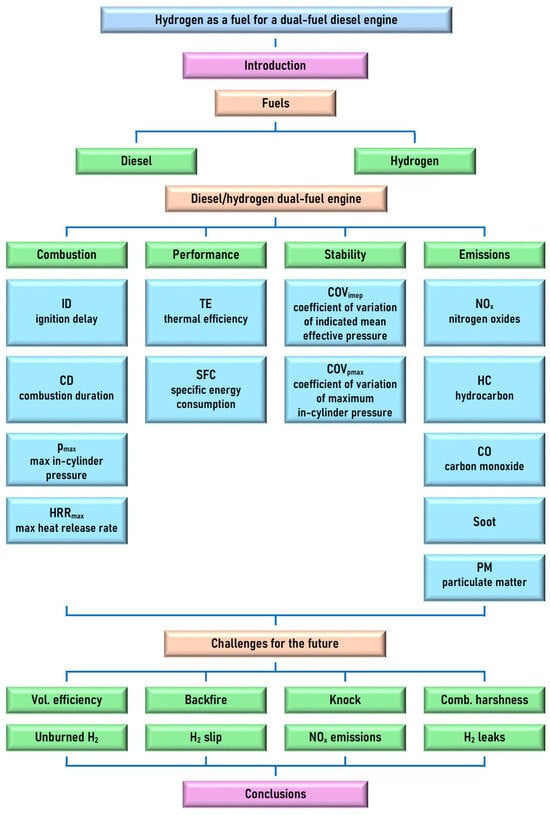

These studies highlight current achievements in combustion, performance, and emissions in specific diesel engines, typically focusing on selected benefits and occasionally noting some drawbacks. Challenges and proposed solutions for broader implementation are rarely discussed. This paper identifies the key challenges to widespread and commercial adoption of hydrogen in diesel/hydrogen dual-fuel engines and presents possible strategies to overcome existing barriers. The focus is placed on the most critical issues, such as decreases in volumetric efficiency, uncontrolled auto-ignition and backfires, engine knocking, combustion harshness, unburned H2 emissions under low-load conditions, H2 slip, excessive NOx emissions, and hydrogen storage and leakage. Figure 2 presents a schematic outline of the article’s structure.

Figure 2.

Schematic structure of the article.

3. Characteristics of Fuels

3.1. Diesel Fuel

In the studies carried out, diesel fuel was used as the baseline fuel. This fuel is widely applied in compression-ignition engines used in automotive vehicles, industrial machinery, and agricultural equipment. Diesel fuel is a multicomponent mixture of paraffinic, isoparaffinic, naphthenic, and aromatic hydrocarbons, primarily obtained through crude oil distillation and hydrocracking processes. The quality of diesel fuel is regulated by European legislation, in particular the EN 590:2013-12 standard [19], which specifies performance and environmental requirements for fuels intended for compression-ignition engines used in on-road vehicles. One of the key performance parameters of diesel fuel is the cetane number (CN), which defines its autoignition quality in the combustion chamber. According to current regulations, the minimum cetane number for diesel fuels marketed in the European Union is 51, which ensures proper combustion and engine operation [20]. Fuels with a lower cetane number may result in delayed ignition, reduced energy efficiency, and increased pollutant emissions. Another important parameter is the heating value, defined as the amount of thermal energy released during the complete combustion of a unit mass of fuel. The average lower heating value of diesel fuel is approximately 42.5 MJ/kg. Table 1 summarizes selected physico-chemical properties of diesel fuel, compiled from various literature sources, which are pertinent to the fueling of compression-ignition internal combustion engines.

Table 1.

Fundamental characteristics of diesel fuel.

3.2. Hydrogen (H2)

Hydrogen is the lightest and most plentiful element naturally occurring on Earth. Compared to other elements, it possesses many remarkable properties. During combustion in oxygen, hydrogen releases a large amount of energy. It has a high energy content per unit mass (approximately 120 MJ/kg), but its energy density per unit volume is low (about 10 MJ/m3) under standard temperature and atmospheric pressure conditions. The heating value of hydrogen is 2.5 times higher than that of diesel fuel. As an alternative fuel, hydrogen offers numerous advantages: it has a zero-emission profile, is renewable, generates fewer pollutants, enables clean combustion, and is non-toxic. Due to these benefits, hydrogen is considered a potential alternative fuel both in transportation and the energy sector. Hydrogen contains no carbon atoms, and its combustion product is solely water. The chemical reaction equation for hydrogen combustion in air is as follows [36,37]:

Hydrogen has a wide flammability range (4–75%), which allows the engine to operate under a broad range of excess air ratios, enabling ultra-lean combustion. Hydrogen combustion exhibits a very high flame propagation speed (up to 60 cm/s). Because hydrogen burns with a very fast flame speed, it enhances isochoric combustion, helping to improve how efficiently the fuel burns. Additionally, hydrogen of similar quality can produce more heat during combustion than diesel fuel.

Hydrogen is characterized by a very high diffusion coefficient in air (0.63 cm2/s), which is significantly higher than that of conventional fuels such as gasoline. This means that hydrogen molecules have a strong ability to rapidly disperse and mix with air molecules in the intake manifold and engine cylinder. As a result, good homogenization of the mixture is achieved, promoting the formation of a uniform fuel–air mixture.

As a fuel, hydrogen exhibits a very low ignition energy of approximately 0.02 mJ—several times lower than that of gasoline or natural gas. This implies that only a minimal spark, a hot surface, or even localized overheating of intake system components is sufficient to ignite the hydrogen–air mixture. At the same time, hydrogen has a high combustion velocity (exceeding 300 cm/s) and a wide flammability range (2–75 vol% in air). These properties cause the hydrogen flame to propagate easily and create a risk of flashback into the engine intake manifold.

Its high octane number (130) makes it an attractive fuel for spark-ignition engines; however, its low cetane number (5–10) limits its use as a sole fuel in compression-ignition engines. Table 2 presents eight selected physico-chemical properties of hydrogen, compiled from various studies in the literature, which are relevant for fueling internal combustion engines.

Table 2.

Fundamental characteristics of hydrogen [21,23,29,30,32,34,35].

Hydrogen can also serve as an excellent fuel for aviation applications and may, in the future, replace conventional aviation fuels, such as kerosene, which have been used for decades. However, at present, mainly due to the low energy density per unit volume of liquid hydrogen, which is much lower than that of kerosene, the use of this fuel in aircraft remains highly challenging [38].

3.3. Hydrogen Production

Hydrogen occurs on Earth in trace amounts (about 0.55 ppm), and therefore, for practical applications, it is most commonly produced through electrolysis, steam reforming of methane, coal gasification, or the conversion/oxidation of other hydrocarbons or biomass-derived products. A major drawback of using various hydrocarbons as substrates is the generation of large amounts of carbon dioxide, a pollutant contributing to environmental contamination. An alternative is the utilization of water splitting reactions powered by electricity in the electrolysis process. This method does not produce carbon dioxide, nitrogen oxides, or sulfur oxides. Currently, hydrogen is predominantly produced from fossil fuels such as crude oil, natural gas, and coal. The most commonly employed technologies include steam methane reforming, partial oxidation of hydrocarbons, and coal gasification. However, these technologies do not reduce the dependency of hydrogen production on fossil fuels. Water electrolysis is a sufficiently mature technology to be applied for industrial-scale hydrogen production. Although effective, the process requires significant amounts of electrical energy. This challenge can be addressed by utilizing electricity generated from wind turbines and solar panels. These technologies have reached a level of maturity enabling their successful application for industrial-scale electricity generation. Other approaches for hydrogen production include the use of electricity generated by hydroelectric or nuclear power plants (particularly during off-peak hours), thermal decomposition processes, photolysis, and thermochemical cycles.

The widespread use of hydrogen in dual-fuel diesel/hydrogen engines produced via water electrolysis powered by wind, solar, or hydro energy, i.e., from renewable energy sources may create a coherent, environmentally friendly, and efficient concept for reducing emissions in transportation. Hydrogen can serve as a bridge between renewable energy systems and the modernization of conventional propulsion technologies, enabling a gradual transition toward cleaner solutions without the need for a complete overhaul of the existing internal combustion engine infrastructure.

It should be noted that one of the key factors affecting the operation of dual-fuel diesel/hydrogen engines is the purity of H2. The presence of impurities in the produced hydrogen, such as CO, CO2, H2S, NH3, H2O, CH4, or particulate matter—can significantly deteriorate its fuel properties. These contaminants may reduce the calorific value of the combustible mixture, disrupt the combustion process, and negatively affect combustion stability, engine performance, and emissions. Furthermore, they can cause corrosion and degradation of intake system components. In [39], it was found that high-purity hydrogen (99.998%) improves engine performance parameters, including indicated power, torque, thermal efficiency, and specific fuel consumption.

4. The Impact of Hydrogen Energy Fraction on the Combustion Characteristics, Performance, Stability, and Emissions of a Diesel/Hydrogen Dual-Fuel Engine

For many years, research has been ongoing in both academic institutions and industrial laboratories on the effective, efficient, and—most importantly—environmentally friendly use of hydrogen in internal combustion engines, including compression ignition (CI) engines. The use of diesel/hydrogen dual-fuel engine technology appears to be a promising solution. Below, several examples of studies on co-combustion of diesel fuel with hydrogen in dual-fuel engines are presented, demonstrating current advancements in combustion, performance, and emissions of such engines. These studies generally focus on selected benefits and note some drawbacks of the approach, illustrating the potential of hydrogen utilization in specific diesel engines. Tsujimura and Suzuki [40] investigated the co-combustion of diesel fuel and hydrogen in a dual-fuel compression-ignition engine, aiming to develop a practical engine with enhanced efficiency and reduced emissions. The hydrogen energy fraction was varied from 0 to 73%. Their experiments demonstrated that adding hydrogen to a diesel engine could improve thermal efficiency, particularly under relatively high-load conditions. However, they also found that excessive hydrogen content may lead to premature ignition of the hydrogen–air mixture prior to diesel injection into the cylinder. Hydrogen combustion can be initiated due to its exceptionally low ignition energy (0.02 mJ), either as a result of accidental sparking or through contact with the hot surfaces of overheated components within the intake system.

The study by Jhang et al. [22] examined the effects of small hydrogen additions (0.6% and 1.2% v/v) on combustion and emissions in a conventional diesel engine. The results showed an increase in thermal efficiency and a decrease in specific fuel consumption with rising hydrogen content. Hydrogen addition also led to reductions in carbon dioxide (CO2) and carbon monoxide (CO) emissions, particularly at high loads. Unfortunately, under these conditions, hydrogen addition caused increased emissions of hydrocarbons (HC) and nitrogen oxides (NOx). Jamrozik et al. [24] conducted experimental research to evaluate the impact of hydrogen energy fraction up to 30%, on key engine performance parameters including cylinder pressure, pressure rise rate, heat release rate, ignition delay, and combustion duration. Increasing the hydrogen content to 30% led to higher maximum combustion pressure, heat release rate, and pressure rise rate. While hydrogen addition enhanced thermal efficiency, it adversely affected engine stability. Moreover, hydrogen significantly reduced Soot, CO, and CO2 emissions; however, it also resulted in increased HC and NOₓ emissions, highlighting a trade-off in its use as a fuel in compression-ignition engines. In another study, Duan et al. [21] investigated the combustion of diesel and hydrogen in a reactivity-controlled compression ignition (RCCI) dual-fuel engine. Their findings demonstrated that the diesel/hydrogen co-combustion approach can significantly enhance the engine’s thermal efficiency and combustion stability, while simultaneously reducing the cylinder pressure rise rate, NOx emissions, and Soot formation. Additionally, it was observed that increasing the fraction of the hydrogen-air mixture (50–90%) led to greater NOx reduction, as NOx emissions in H2/diesel RCCI combustion are primarily influenced by the homogeneity of the fuel–air mixture rather than the combustion rate. Zhou et al. [41] conducted experimental investigations on a dual-fuel diesel engine fueled with diesel and hydrogen under five different engine loads. The maximum hydrogen energy fraction reached 40% of the total fuel energy. They observed an improvement in engine efficiency; however, at high load and 30% hydrogen share, abnormal combustion occurred. At high loads, adding more than 30% hydrogen reduced CO, CO2, and particulate matter (PM) emissions but increased NOx emissions. Chintala and Subramanian [25] demonstrated that increasing the hydrogen energy fraction up to 18.2% in a dual-fuel diesel engine led to increased thermal efficiency and reduced emissions of hydrocarbons (HC), carbon monoxide (CO), and Soot. Unfortunately, NOx emissions increased significantly. Sharma and Dhar [27] examined combustion stability and the less commonly studied unregulated emissions in a dual-fuel engine co-firing diesel with 20% hydrogen. At 75% load, hydrogen addition resulted in an increased ignition delay and a shortened combustion duration, while having minimal impact on combustion stability. However, it contributed to a significant reduction in formaldehyde (CH2O), acetaldehyde (MeCHO), propylene (C3H6), ethylene (C2H4), and aromatic hydrocarbons (AHC). Dimitriou et al. [42] investigated the effect of hydrogen energy fraction on diesel engine performance and emissions while optimizing diesel pilot injection strategy and employing exhaust gas recirculation (EGR). At low loads, they applied very high hydrogen additions, reaching up to 85%, which, compared to diesel-only combustion, resulted in reduced CO, NOx, and Soot emissions. However, at medium loads, the high hydrogen addition caused an increase in NOx emissions. According to Li et al. [43], optimizing the diesel pilot injection strategy can enhance the overall performance of dual-fuel diesel engines. In compression-ignition engines, advancing the diesel injection timing has been shown to reduce brake specific fuel consumption and lower CO, HC, and Soot emissions. Concurrently, this adjustment can increase thermal efficiency, combustion pressure, heat release rate, cylinder temperature, and NOx emissions. According to the experimental and numerical studies conducted by Scrignoli et al. [44], a moderate hydrogen fraction in a dual-fuel diesel engine contributes to an improvement in the engine’s thermal efficiency, whereas higher hydrogen fractions, above 40%, pose significant challenges, leading to a decrease in indicated mean effective pressure (imep) and thermal efficiency (TE). Optimizing the diesel injection strategy may provide a solution to this issue. Juknelevicius et al. [45] conducted experiments on the co-combustion of biodiesel and hydrogen in a CI engine under various load conditions. They demonstrated that an increase in H2 content shortens ignition delay and combustion duration. Reductions in smoke emissions were achieved at the expense of increased NOx emissions. Similarly to the findings of Talibi et al. [28], it was confirmed that at low-load conditions, excessive hydrogen content (above 35%) can cause combustion instability manifested by knocking combustion. Nag et al. [29] investigated the impact of hydrogen addition on the performance of a dual-fuel compression-ignition engine equipped with exhaust gas recirculation (EGR). Experiments were conducted at engine loads of 25%, 50%, 75%, and 100%, with hydrogen energy fractions of 0%, 10%, and 30%. Significant emission reductions were achieved due to the synergistic effects of hydrogen addition and EGR, without a notable decline in thermal efficiency. At a 30% hydrogen energy fraction combined with 10% EGR, reductions were observed across all measured pollutants, including NOx, CO2, CO, total hydrocarbons (THC), and particulate matter (PM). Gültekin and Ciniviz [31] found that a hydrogen energy utilization rate of around 14% positively influences engine performance and emissions. Increasing hydrogen energy beyond 14% adversely affects engine performance and NO emissions. In the dual-fuel mode fueled by hydrogen and diesel, all emissions decreased except for NO emissions. Hamdan et al. [46] experimentally investigated the parameters of a dual-fuel compression ignition engine fueled with diesel and hydrogen, operating under variable speed and load conditions. The results showed that the engine’s thermal efficiency increases with the hydrogen content in the intake manifold. The impact of hydrogen addition on engine efficiency was more significant at low engine speeds and partial load conditions. While hydrogen incorporation led to increased NOx emissions—attributed to elevated combustion temperatures—it also resulted in a reduction in smoke emissions. Jhang et al. [47] investigated the impact of hydrogen addition to diesel fuel on the emissions of unconventional pollutants from a heavy-duty diesel engine. They analyzed emissions of unregulated carbonyl compounds such as formaldehyde, acetaldehyde, and acetone, as well as the ozone formation potential. The authors concluded that hydrogen could become a competitive biofuel for the transportation industry in the near future, allowing for the reduction of carbonyl emissions and lowering the risk of ozone formation in vehicle exhaust gases. Castro et al. [48] explored the potential for maximizing hydrogen content in a turbocharged four-cylinder diesel engine. They investigated the interplay between hydrogen flammability limits, knocking combustion, and hydrogen energy fraction. Experiments were conducted at three engine loads (30%, 60%, and 100%) while maintaining a constant engine speed. The results indicated a decrease in thermal efficiency with increasing hydrogen addition across all tested loads, which the authors attributed to steam formation during hydrogen combustion. In most cases, CO2 emissions decreased, whereas NO emissions varied with engine load; specifically, at low load, higher hydrogen shares resulted in reduced NO emissions. Additionally, smoke emissions were consistently reduced under all conditions. Liu et al. [49] investigated the potential for increasing the hydrogen fraction in a dual-fuel CI engine under various load conditions. They found that the higher the engine load, the lower the maximum hydrogen substitution ratio that could be applied in the dual-fuel engine. At 90% load, the maximum hydrogen fraction was determined to be 15%. At all load levels, increasing the hydrogen fraction resulted in higher in-cylinder pressure and peak heat release rate, as well as reduced brake specific fuel consumption and improved thermal efficiency. Operation at the highest load was associated with a reduction in CO2 emissions, accompanied by an increase in NOx emissions. Yilmaz [50] conducted experiments to investigate the effect of hydrogen enrichment of the combustible mixture within the cylinder on the combustion characteristics and performance of a turbocharged diesel engine with a low compression ratio. The addition of hydrogen resulted in increased cylinder pressure and heat release rate, leading to improved thermal efficiency of the engine. Gültekin [51] states that to achieve the maximum benefits of dual-fuel diesel/hydrogen operation in compression ignition engines, electronically controlled fueling systems should be employed, with settings appropriately optimized. Farzam et al. [14] conducted a detailed experimental study focusing on engine control parameters adjustable to accommodate operational changes induced by hydrogen introduction. These parameters included the start of diesel injection, intake manifold pressure, and exhaust gas recirculation (EGR) rate. By coordinating the control of intake air pressure, combustion phasing, and EGR rate, they successfully achieved a 40% hydrogen energy fraction while maintaining thermal efficiency and NOx emission levels comparable to those of conventional compression-ignition engines. Guan et al. [52] investigated the use of hydrogen as an additional fuel in a modern truck diesel engine, focusing on the effects of hydrogen addition up to 30% on engine performance and emissions. The tests were conducted without modifications to the engine controller, at engine speeds ranging from 1000 to 1400 rpm and torque levels from 10 to 75%. The study demonstrated a positive effect of hydrogen addition on the engine’s thermal efficiency and on CO2 and NOx emissions. Akhtar et al. [34] analyzed dual-fuel operation with hydrogen and diesel in a modern heavy-duty diesel engine using mathematical modeling. Parametric analyses were conducted over engine speeds ranging from 900 to 2200 rpm and hydrogen fractions from 0 to 17.5%. The results showed that the benefits of hydrogen enrichment are strongly dependent on engine speed. Optimal engine performance was achieved with a 17.5% hydrogen addition at 2200 rpm, although this increased NOx emissions due to higher combustion temperatures. According to the authors, these emissions can be mitigated through the use of EGR. Nag et al. [16] investigated dual-fuel combustion in a constant-speed compression-ignition engine fueled with diesel and hydrogen, focusing primarily on the effects of hydrogen addition on combustion characteristics, engine vibrations, and acoustic behavior. Liu et al. [53] examined a dual-fuel engine configuration in which both the pilot fuel (diesel) and the main fuel (hydrogen) were directly injected into the cylinder, enabling an increase in the hydrogen energy fraction of up to 90%. Table 3 summarizes key results from studies on diesel/hydrogen dual-fuel engines selected from the available literature, analyzing combustion, performance, stability, and exhaust emissions.

Table 3.

Literature review of CI engines with diesel/hydrogen dual-fuel mode (▲—increase, ▼—decrease).

4.1. Selected Parameters of Diesel/Hydrogen Dual-Fuel Engines

Table 4 presents the relative percentage changes of selected parameters of diesel/hydrogen dual-fuel engines with respect to a reference fuel, i.e., diesel. The table illustrates the effect of the hydrogen energy fraction (HEF) in the range of 2–85% on key indicators relevant to the operation of an internal combustion engine, such as ignition delay (ID), combustion duration (CD), maximum in-cylinder pressure (pmax), maximum heat release rate (HRRmax), thermal efficiency (TE), specific energy consumption (SEC), coefficient of variation of indicated mean effective pressure (COVimep), coefficient of variation of maximum in-cylinder pressure (COVpmax), nitrogen oxides (NOx), hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2), Soot, and particulate matter (PM) emissions.

Table 4.

Effect of hydrogen energy fraction (HEF) on selected parameter changes in diesel/hydrogen dual-fuel engines compared to diesel as the reference fuel.

Hydrogen energy fraction:

where is the mass in the diesel fuel supplied to the cylinder per cycle, is the mass in the hydrogen supplied to the intake manifold per cycle, and are lower heating value the diesel fuel and hydrogen.

Table 4 shows that out of the 13 cited studies, the vast majority, 11, focused on analyzing the effects of hydrogen addition up to 40% (HEF ≤ 40%) on selected parameters of diesel/hydrogen dual-fuel engines. Two studies investigated higher hydrogen fractions (HEF ≤ 85%).

4.2. Combustion Parameters of a Diesel/Hydrogen Dual-Fuel Engine

Combustion in a compression-ignition (CI) engine occurs in several distinct stages. The first is the ignition delay, representing the time required to establish favorable conditions for the autoignition of the fuel–air mixture. The quantity of mixture formed during this stage strongly influences the subsequent combustion phases. The second stage, premixed (kinetic) combustion, is characterized by a rapid heat release rate and high combustion speed, with its rate determined by the amount and quality of the mixture prepared during the ignition delay. The dominant phase in CI engine operation is diffusion combustion, governed by the mixing rate of injected fuel and air within the cylinder, and marked by a relatively low heat release rate. The final stage is late combustion, or afterburning, during which residual fuel combusts in the presence of a limited air supply. In diesel/hydrogen dual-fuel engines, premixing hydrogen with air before intake into the cylinder creates a more complex combustion process. The premixed hydrogen not only participates in the diffusion combustion of the diesel spray but can also burn through a premixed hydrogen–air flame. As a result, the presence of hydrogen can substantially alter the combustion characteristics and emission profile of the engine.

4.2.1. Ignition Delay (ID) and Combustion Duration (CD)

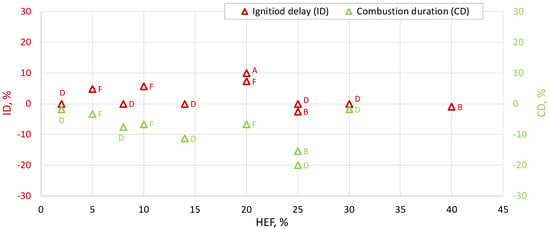

Ignition delay and combustion duration (covering both premixed and diffusion combustion phases) in a compression-ignition (CI) engine are most commonly defined in terms of the heat released during the combustion process. In this context, ignition delay is the time interval between the start of fuel injection into the cylinder and the onset of an irreversible, stable combustion process. It is generally accepted that combustion initiation occurs when 10% of the total heat release has been achieved [54,55]. An excessively long ignition delay is typically detrimental to engine operation, as it can lead to rapid pressure rises within the cylinder, resulting in increased mechanical stresses and elevated noise levels. According to Lotko [56], an excessively long ignition delay may not only reduce engine efficiency but also cause mechanical damage. Combustion duration is typically defined as the time interval between the release of 10% of the total heat (combustion start) and the release of 90% of the total heat (combustion end). According to Jamrozik et al. [24], shortening the combustion duration is essential as it reduces heat transfer to the cylinder and combustion chamber walls, thereby improving engine efficiency and decreasing specific fuel consumption. Moreover, it reduces the engine’s tendency toward knocking combustion and helps decrease unburned hydrocarbon emissions. Figure 3 illustrates the effect of hydrogen energy fraction (HEF) on the relative percentage changes in ignition delay (ID) and combustion duration (CD) in dual-fuel engines, based on data from the cited literature. The relative changes in ID and CD are referenced to the baseline case of pure diesel combustion (0% HEF). The analysis of ignition delay (ID) in diesel/hydrogen engines was addressed in four studies, for hydrogen fractions up to 40% (HEF ≤ 40%). Two of these studies reported an increase in ID, one reported a decrease, and in one study no effect of hydrogen addition on ID was observed. Changes in combustion duration (CD) were analyzed in three studies for HEF ≤ 30%, all of which indicated a reduction in combustion duration due to hydrogen addition. The literature predominantly reports an increase in ignition delay and a decrease in combustion duration with increasing hydrogen energy fraction. Maximum observed increases in ID reach approximately 10% [13], while reductions in CD of up to 20% have been documented [24]. The increase in ID can be attributed to hydrogen’s properties and its low tendency for autoignition (high autoignition temperature). The shortening of CD results from hydrogen’s very high flame velocity (Fv) and high diffusivity in air (Dair). Effective diffusion of H2 promotes the formation of a more homogeneous mixture with air and diesel fuel, initially in the intake manifold and subsequently within the engine cylinder. According to Farzam et al. [14], hydrogen combustion shortens the combustion duration, particularly at higher hydrogen energy fraction (HEF) levels. This effect is attributed to the high burning velocity of the premixed hydrogen–air flame and the increased formation of OH radicals during hydrogen combustion, which can promote the mixing-controlled combustion of the injected diesel fuel. Moreover, due to its low ignition energy, hydrogen addition can accelerate combustion even in very lean mixtures [33].

Figure 3.

Influence of hydrogen energy fraction (HEF) on relative changes in ignition delay (ID) and combustion duration (CD) in diesel/hydrogen dual-fuel engines (A [13], B [14], D [24], F [27]).

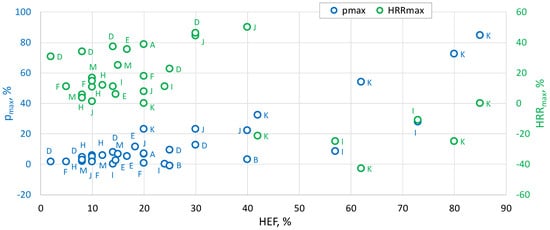

4.2.2. Maximum in-Cylinder Pressure (pmax) and Maximum Heat Release Rate (HRRmax)

Fuel combustion in compression ignition engines is accompanied by rapid increases in the maximum cylinder pressure (pmax). These pressure spikes cause undesirable vibrations and high noise levels, negatively affecting the engine’s structural components. Figure 4 illustrates the relative percentage changes in maximum cylinder pressure (pmax) resulting from an increase in hydrogen energy fraction (HEF) from 0 to 85% across multiple dual-fuel engines reported in the literature. For hydrogen fractions up to 40% (HEF ≤ 40%), out of 10 studies analyzing changes in maximum in-cylinder pressure (pmax), 9 reported an increase in this parameter, while one study observed no effect of hydrogen addition on engine pmax. Hydrogen fractions above 40% (HEF > 40%) were investigated in two studies, both of which reported an increase in pmax. In most cases, hydrogen addition caused an increase in the maximum cylinder pressure. The largest increases, relative to pure diesel operation, exceeded 80% [39]. Elevated pmax values are a consequence of increased ignition delay induced by the hydrogen addition. A longer ignition delay also means a prolonged period during which a homogeneous fuel-air mixture is formed and subsequently combusted. Moreover, the ignition delay shift moves the start of combustion closer to the top dead center (TDC) of the piston, where the charge is compressed to higher pressures. One of the key parameters used to analyze the combustion process inside a reciprocating engine cylinder is the heat release rate, which is determined based on the recorded cylinder pressure variations.

Figure 4.

Influence of hydrogen energy fraction (HEF) on relative changes in maximum in-cylinder pressure (pmax) and maximum heat release rate (HRRmax) in diesel/hydrogen dual-fuel engines (A [13], B [14], D [24], E [25], F [27], H [31], I [40], J [41], K [42], M [49]).

The heat release rate (HRR) reflects the intensity of the fuel oxidation reactions occurring in the cylinder and serves as an indicator of combustion efficiency as well as an indirect measure of exhaust emissions. The addition of hydrogen to diesel fuel in a compression-ignition engine significantly affects the characteristics and peak values of the heat release rate (HRR). Figure 4 illustrates the influence of hydrogen energy fraction on the relative changes in maximum HRR values for several engines examined in the selected literature. For hydrogen fractions up to 40% (HEF ≤ 40%), out of 9 studies analyzing changes in the peak heat release rate (HRRmax), 7 reported an increase in this parameter, while one study observed no effect of hydrogen addition on engine HRRmax. Hydrogen fractions above 40% (HEF > 40%) were investigated in two studies, both of which reported an increase in HRRmax. Experimental investigations have shown that increasing the hydrogen energy fraction to approximately 40% can increase the maximum HRR by up to around 50% [24,41]. According to Talibi et al. [28], this effect is attributed to the increased stoichiometry of the H2-air mixture inside the cylinder and the shifting of combustion and heat release closer to the top dead center (TDC) position. In the studies conducted by Gültekin and Ciniviz [31], at a hydrogen energy fraction of 12%, the peak heat release occurred closer to top dead center (TDC) compared to conventional diesel operation. This shift was identified as the primary cause of the increased combustion rate observed with hydrogen addition relative to pure diesel. However, increasing the hydrogen fraction beyond 40% resulted in a decrease in the maximum heat release rate (HRR) values. This phenomenon arises because, at such high hydrogen fractions, the kinetic phase of combustion is divided into two stages, each characterized by distinct HRR peaks. The first peak corresponds to the rapid combustion of the premixed mixture formed in the intake manifold immediately after the start of diesel injection and the onset of initial ignition sites. The second peak corresponds to the combustion of a homogeneous mixture of hydrogen, diesel fuel, and air prepared during the ignition delay period [24,37].

4.3. Performance of a Diesel/Hydrogen Dual-Fuel Engine

Thermal Efficiency (TE) and Specific Energy Consumption (SEC)

An objective comparative indicator for reciprocating engines is thermal efficiency (TE), which measures the effectiveness of converting the fuel’s thermal energy into mechanical work or useful energy.

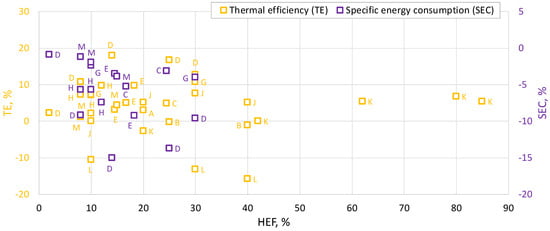

A parameter related to thermal efficiency (TE) is the specific energy consumption (SEC), which measures the amount of energy consumed to produce a unit of useful output. Unlike the specific fuel consumption used for single-fuel engines, the specific energy consumption indicator is more accurate because it accounts for the different energy values of the co-combusted fuels. Figure 5 presents the influence of hydrogen energy fraction (HEF) on the relative percentage changes in thermal efficiency (TE) and specific energy consumption (SEC) in dual-fuel engines, based on data reported in the referenced literature.

Figure 5.

Influence of hydrogen energy fraction (HEF) on relative changes in thermal efficiency (TE) and specific energy consumption (SEC) in diesel/hydrogen dual-fuel engines (A [13], B [14], C [15], D [24], E [25], G [29], H [31], J [41], K [42], L [48], M [49]).

For hydrogen fractions up to 40% (HEF ≤ 40%), out of 11 studies analyzing changes in thermal efficiency (TE), 8 reported an increase, 2 reported a decrease, and one study observed no effect of hydrogen addition on TE. Hydrogen fractions above 40% (HEF > 40%) were investigated in one study, which reported an increase in TE. Changes in specific energy consumption (SEC) were analyzed in five studies for HEF ≤ 30%, all of which indicated a decrease in this parameter.

The results indicate that, in most cases, hydrogen addition to diesel fuel had a positive effect on both TE and SEC. The highest improvement was observed at 14% HEF, with an 18% increase in thermal efficiency and a 15% reduction in energy consumption [24]. A notable decrease in efficiency was reported only in the study by Castro et al. [48], attributed to water vapor formation during hydrogen combustion. Since water absorbs energy from the combustion process, its presence reduces the indicated power output per cycle. Additionally, Köse and Ciniviz [33] suggested that efficiency losses at high hydrogen fractions may be associated with reduced volumetric efficiency, caused by partial displacement of intake air by hydrogen. Koten [57] demonstrated that hydrogen addition reduces specific fuel and energy consumption while increasing thermal efficiency, owing to hydrogen’s high flame speed and the formation of a more homogeneous mixture within the cylinder. This promotes more complete combustion of the air–hydrogen mixture. Similarly, Köse and Ciniviz [33] suggested that the improved thermal efficiency may result from enhanced combustion characteristics and the higher lower heating value (LHV) of hydrogen. Additionally, hydrogen’s flame speed is approximately nine times greater than that of diesel fuel. Consequently, during the overall combustion of diesel in the presence of hydrogen, the combustion process is faster and more complete, contributing to increased efficiency.

4.4. Stability of a Diesel/Hydrogen Dual-Fuel Engine

Coefficient of Variation of Indicated Mean Effective Pressure (COVimep) and Coefficient of Variation of Maximum in-Cylinder Pressure (COVpmax)

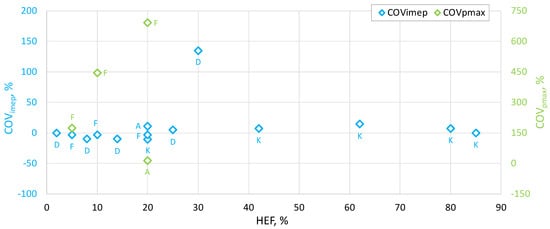

Engine stability is one of the key characteristics used to evaluate the performance of an internal combustion engine. Studies available in the literature commonly assess stability by referring to the coefficient of variation of indicated mean effective pressure (COVimep) and the coefficient of variation of maximum in-cylinder pressure (COVpmax).

It is generally accepted that an internal combustion engine operates stably if the cycle-to-cycle variability, defined by the coefficient of variation of indicated mean effective pressure (COVimep), does not exceed 5% [58].

A review of the literature reveals that only a small portion of studies include an analysis of the stability of dual-fuel engines. Figure 6 presents the relative changes in stability of diesel/hydrogen dual-fuel engines compared to the stability of engines fueled solely with diesel. For hydrogen fractions up to 40% (HEF ≤ 40%), out of four studies analyzing changes in COVimep, two reported a deterioration and two reported a slight improvement in engine stability due to hydrogen addition. Hydrogen fractions above 40% (HEF > 40%) were investigated in one study, which observed a slight increase in COVimep. Changes in COVpmax were analyzed in two studies for HEF ≤ 20%, with one reporting an increase and the other a decrease in the COVpmax coefficient.

Figure 6.

Influence of hydrogen energy fraction (HEF) on relative changes in coefficient of variation of indicated mean effective pressure (COVimep) and coefficient of variation of maximum in-cylinder pressure (COVpmax) in diesel/hydrogen dual-fuel engines (A [13], D [24], F [27], K [42].

As shown, the coefficient of variation of indicated mean effective pressure (COVimep) is more frequently used as a stability indicator. It can also be seen that for hydrogen energy fractions up to 85%, no significant deterioration in engine stability, measured by COVimep, was observed. Only in the study by Jamrozik et al. [24] was a marked increase in COVimep recorded at a hydrogen energy fraction (HEF) of 30%. According to the authors, the high hydrogen content in the fuel mixture caused premature ignitions in some cycles, leading to cycle irregularities and increased deviation from the mean cycle. Studies that use the coefficient of variation of maximum in-cylinder pressure (COVpmax) as a stability metric mainly indicate a deterioration in engine operation when diesel is supplemented with hydrogen, compared to pure diesel operation. Sharma and Dhar [27] attribute this to the unsuitable design of a serial production engine, originally intended solely for diesel fuel operation and not optimized for dual hydrogen-diesel fuel use.

4.5. Emissions of a Diesel/Hydrogen Dual-Fuel Engine

4.5.1. Nitrogen Oxides (NOx) and Hydrocarbon (HC) Emissions

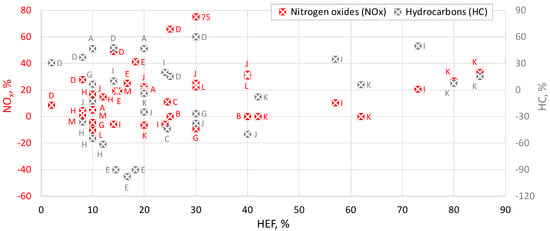

Nitrogen oxides (NOx) are compounds formed from various nitrogen and oxygen molecules. Exhaust NOx emissions primarily consist of nitric oxide (NO) and nitrogen dioxide (NO2), with NO accounting for over 90% of total NOx emissions from combustion processes, while NO2 comprises approximately 0.5–10% [59]. The formation of NOx is strongly influenced by factors such as cylinder temperature, oxygen concentration, and reaction duration. The introduction of hydrogen (H2) can either increase or decrease NOx formation depending on engine operating conditions and the amount of hydrogen supplied. Figure 7 illustrates the relative changes in NOx emissions from diesel/hydrogen dual-fuel engines as the hydrogen energy fraction increases up to 85%. For hydrogen fractions up to 40% (HEF ≤ 40%), out of 12 studies analyzing changes in NOx emissions, 8 reported an increase, 3 reported a decrease, and one study observed no effect of hydrogen addition on NOx emissions. Hydrogen fractions above 40% (HEF > 40%) were investigated in two studies, both of which reported an increase in NOx emissions.

Figure 7.

Influence of hydrogen energy fraction (HEF) on relative changes in nitrogen oxides (NOx) and hydrocarbon (HC) emissions in diesel/hydrogen dual-fuel engines (A [13], B [14], C [15], D [24], E [25], G [29], H [31], I [40], J [41], K [42], L [48], M [49]).

In most cases, the addition of hydrogen to diesel fuel results in increased NOx emissions in dual-fuel engines. Maximum increases can reach up to 60% compared to single-fuel engines fueled solely by diesel [24]. The primary reason for the increased NOx emissions in these cases is the higher combustion temperatures, which accelerate the Zeldovich mechanism reaction rates. Gültekin and Ciniviz [31] state that one of the major challenges in hydrogen-diesel dual-fuel engines is elevated NOx emissions because the increased hydrogen fraction raises cylinder temperatures above 2200 K. According to Köse and Ciniviz [33], higher NOx emissions are caused by peak combustion temperatures and the prolonged residence time of high-temperature gases within the cylinder. NOx emissions increase due to exceeding critical equivalence ratio thresholds. Both elevated temperature and increased availability of oxygen in the formed mixture contribute to higher NOx concentrations. Furthermore, hydrogen’s nearly threefold higher lower heating value (LHV) compared to diesel increases the peak cylinder temperature. Talibi et al. [28] observed that NOx emissions correlated with peak heat release rates and increased as the hydrogen concentration rose. However, some literature reports indicate a slight decrease in NOx emissions (approximately 10%) resulting from hydrogen addition in compression ignition engines, particularly for low hydrogen fractions not exceeding 30% [29,42,48]. This effect is explained by the reduced oxygen availability due to displacement of intake air by hydrogen.

One of the primary advantages of using hydrogen as an engine fuel is its remarkable capacity to reduce carbon-based exhaust pollutants such as hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2), and Soot. Hydrocarbons (HC) are organic compounds consisting of carbon (C) and hydrogen (H) atoms, representing the unburned fuel fraction within the engine cylinder. The source of hydrocarbon emissions is unburned fuel accumulating in crevices and gaps within the combustion chamber, where oxygen supply is insufficient. This so-called crevice effect is caused by gaps around piston rings, valves, and within the piston combustion chamber itself. Figure 7 presents the relative changes in HC emissions from diesel/hydrogen dual-fuel engines resulting from an increase in the hydrogen energy fraction up to 85%. For hydrogen fractions up to 40% (HEF ≤ 40%), out of 9 studies analyzing changes in HC emissions, 3 reported an increase and 6 reported a decrease in HC emissions from dual-fuel engines. Hydrogen fractions above 40% (HEF > 40%) were investigated in two studies, both of which indicated a tendency toward increased HC emissions.

It can be seen that there is no clear trend reflecting the influence of H2 on HC emissions from diesel/hydrogen engines. Some studies [13,24,40] report an increase in HC emissions up to 60%, whereas other research [25,31,41] observes a reduction in HC emissions reaching even 98%. Experiments involving substantial hydrogen shares, ranging from 57% to 85%, have shown that hydrogen addition can negatively impact HC emissions [40,42]. This increase in HC emissions is primarily attributed to reduced oxygen availability caused by a decline in the engine’s volumetric efficiency, resulting in incomplete fuel combustion. Conversely, reductions in HC emissions are mainly observed when hydrogen partially replaces diesel fuel—a carbon-free fuel—and due to hydrogen’s higher flame speed, which promotes more efficient diesel combustion [29,33,57].

4.5.2. Carbon Monoxide (CO) Carbon Dioxide (CO2) Emissions

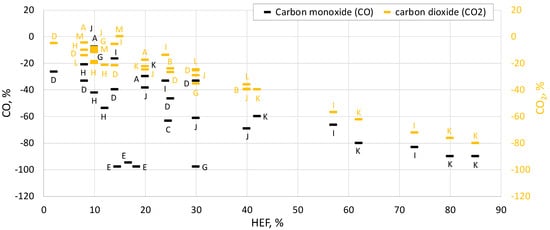

Carbon monoxide (CO) is produced by the partial oxidation of carbon-containing compounds and typically forms when there is insufficient oxygen to convert carbon fully into carbon dioxide (CO2). Depending on the availability of oxygen, CO generated during combustion can be further oxidized to CO2. Figure 8 illustrates the relative changes in CO and CO2 emissions from diesel/hydrogen dual-fuel engines compared to conventional diesel-only engines, for hydrogen energy fractions up to 85%. For hydrogen fractions up to 85% (HEF ≤ 85%), changes in CO emissions were analyzed in 11 studies, and changes in CO2 emissions were analyzed in 10 studies. All reported a decrease in emissions of these compounds from diesel/hydrogen dual-fuel engines.

Figure 8.

Influence of hydrogen energy fraction (HEF) on relative changes in carbon monoxide (CO) carbon dioxide (CO2) emissions in diesel/hydrogen dual-fuel engines (A [13], B [14], C [15], D [24], E [25], G [29], H [31], I [40], J [41], K [42], L [48], M [49]).

The literature-based emission results demonstrate reductions in CO and CO2 concentrations in all cases. Moreover, in most cases, an increasing hydrogen fraction corresponded to greater reductions in these compounds. Hydrogen fueling enabled CO reductions of up to 90–100%, for HEF ≤ 30% [25,29,42] and CO2 reductions of 70–80%, for HEF ≥ 73% [40,42]. The primary reason for this effect is the substitution of diesel with hydrogen, a fuel free of molecular carbon, which consequently lowers the carbon content within the combustion chamber. Similarly, Köse and Ciniviz [33] explain that the reduction in CO and CO2 emissions in hydrogen-powered dual-fuel engines stems from the absence of carbon in hydrogen fuel.

4.5.3. Soot and Particulate Matter (PM) Emissions

Soot is a fine particulate product of incomplete combustion of carbon-containing fuels. The main component of Soot is elemental carbon, but it may also contain organic compounds, heavy metals, and other contaminants. Soot formation primarily occurs under high-pressure combustion conditions with locally elevated temperatures and oxygen deficiency, which causes dehydrogenation and fuel breakdown, resulting in the creation of tiny carbon particles [13]. Soot is one of the main constituents of particulate matter (PM) emitted by internal combustion engines. In addition to Soot, PM may also include sulfur and nitrogen compounds, metals, and heavy hydrocarbons.

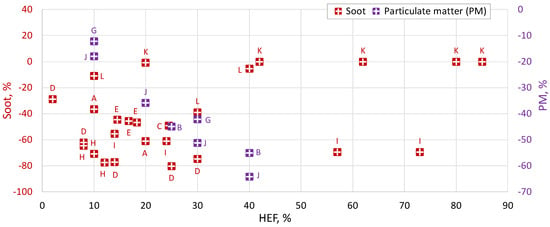

Replacing hydrocarbon fuels with hydrogen as a substitute must lead to a significant reduction in Soot and PM emissions. This is evident in Figure 9, which presents relative changes in Soot and PM emissions from diesel/hydrogen dual-fuel engines compared to engines fueled solely with diesel, based on selected studies available in the literature.

Figure 9.

Influence of hydrogen energy fraction (HEF) on relative changes in Soot and particulate matter (PM) emissions in diesel/hydrogen dual-fuel engines (A [13], B [14], C [15], D [24], E [25], G [29], H [31], I [40], J [41], K [42], L [48].

For HEF ≤ 85%, changes in Soot emissions were analyzed in 8 studies, and changes in particulate matter (PM) emissions were analyzed in 3 studies. All indicated a reduction in emissions of these species from diesel/hydrogen dual-fuel engines.

The cited works report reductions in Soot and PM emissions by approximately 80% [24,31] and 65% [41], respectively.

4.6. Summary of the Impact of H2 on a Dual-Fuel Diesel/Hydrogen Engine

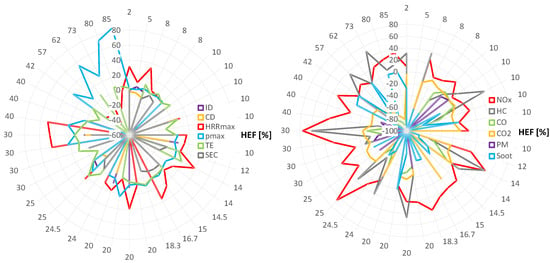

In summary, it can be concluded that hydrogen can serve as a valuable energy source for a compression ignition engine operating in dual-fuel mode. Published studies on the co-combustion of diesel and hydrogen in dual-fuel compression ignition engines indicate the feasibility of using significant hydrogen energy fractions, ranging from 2% to 85%. The addition of hydrogen to diesel in a dual-fuel CI engine has a substantial impact on combustion processes, engine performance, stability, and exhaust emissions. Figure 10 presents the consolidated results of the analyzed parameters of diesel/hydrogen dual-fuel engine operation, based on the conducted literature review.

Figure 10.

Influence of hydrogen energy fraction (HEF) on relative changes in selected operating parameters of a dual-fuel diesel/hydrogen engine.

Analyses indicate that increasing the hydrogen energy fraction (HEF) in a diesel/hydrogen dual-fuel engine leads to an increase in ignition delay (ID) and a decrease in combustion duration (CD). Available literature reports maximum ID increases of up to 10% (for HEF = 20%) and CD reductions of up to 20% (for HEF = 25%) compared to a diesel-only engine. Hydrogen addition to diesel in a CI engine also results in an increase in maximum in-cylinder pressure (pₘₐₓ), with the largest increases reaching 80% (for HEF = 85%) relative to a conventional diesel engine. Increasing HEF up to 40% causes an increase in peak heat release rate (HRRmax) by approximately 50% compared to a conventional engine.

Co-combustion of diesel with hydrogen in a dual-fuel CI engine positively affects thermal efficiency (TE) and specific energy consumption (SEC). Maximum TE increases and largest SEC reductions occurred for HEF = 14%, reaching 18% and 15%, respectively. Hydrogen addition is accompanied by an increase in nitrogen oxides (NOx) emissions in dual-fuel engine exhaust, with maximum increases of up to 75% (for HEF = 30%) compared to a diesel-only engine. For HEF ≤ 42%, there is no clear trend regarding the effect of H2 on hydrocarbon (HC) emissions from diesel/hydrogen engines. For HEF ≥ 57%, studies indicate a negative impact of H2 addition on HC emissions, with increases reaching up to 60%.

Increasing HEF results in more effective reduction of carbon monoxide (CO) and carbon dioxide (CO2) emissions in diesel/hydrogen dual-fuel engines. Hydrogen addition enabled CO reductions of up to 90–100% (for HEF ≤ 30%) and CO2 reductions of 70–80% (for HEF ≥ 73%) compared to conventional engines. Literature review also shows that hydrogen combustion in the cylinder of a dual-fuel diesel engine contributes to reductions in Soot and particulate matter (PM) emissions. Reductions in Soot and PM emissions can reach up to 80% (for HEF = 10–30%) and 65% (for HEF = 40%), respectively.

5. Challenges for the Future

The use of hydrogen in diesel/hydrogen dual-fuel engines can improve the combustion process, increasing process efficiency and positively impacting the environmental characteristics of compression ignition engines by reducing emissions of carbon-based compounds. However, there are many barriers to the practical use of hydrogen, related to certain characteristic properties of this gas. These include issues with fuel supply systems and a reduction in volumetric efficiency, premature ignition, combustion harshness, knocking combustion, unburned H2, excessive NOx emissions, as well as difficulties in storing and transporting liquid and gaseous hydrogen. These limitations may negatively affect both the performance and durability of hydrogen engines, as well as their widespread adoption. Overcoming these challenges is essential to maximize the greenhouse gas benefits offered by the dual-fuel approach and to enable the widespread and commercial use of hydrogen. As noted by Castro et al. [48], hydrogen can serve as a fuel for internal combustion engines; however, extensive research on their performance and emissions reveals persistent limitations, including diminished volumetric efficiency, pronounced susceptibility to knock, and decreased power density.

5.1. Decrease in Volumetric Efficiency

The supply of hydrogen to the intake manifold in dual-fuel mode is associated with a decrease in the engine’s volumetric efficiency due to the replacement of a significant portion of intake air by gaseous hydrogen. This issue is particularly pronounced at high hydrogen shares. According to Yilmaz [50], in a diesel/hydrogen engine with hydrogen supplied to the intake manifold, volumetric efficiency deteriorates, resulting in a loss of engine power. The amount of hydrogen should not be excessive, as it reduces the intake air volume. Nag et al. [29] also report that volumetric efficiency decreases in diesel/hydrogen engines compared to conventional diesel engines. Liu et al. [53] state that hydrogen displaces air during the intake stroke, reducing oxygen availability and thus requiring more compression work. This leads to a decrease in engine power density and volumetric efficiency. Gültekin and Ciniviz [31] demonstrated that increasing both the hydrogen energy fraction and the load in a dual-fuel engine leads to reduced volumetric efficiency. This reduction primarily results from excess hydrogen occupying cylinder volume, thereby limiting the intake of combustion air [31]. One way to overcome the reduction in volumetric efficiency is turbocharging, which increases the mass of air supplied to the engine [60]. Another approach is optimizing valve timing, specifically by increasing the intake valve opening duration. Proper valve timing enables better cylinder filling across various operating conditions, translating to power optimization and fuel savings [61]. Gültekin et al. [62] utilized adjustments in intake valve lift to improve the volumetric efficiency of the engine. They found that the drop in volumetric efficiency, which limits the increase of hydrogen energy fraction in dual-fuel mode, can be mitigated by increasing valve lift height. Another effective method could be the use of the second variant of the dual-fuel mode, involving direct injection of hydrogen into the cylinder. In this solution, hydrogen is injected during the compression stroke, with the valves closed, after the cylinders have been filled with air. Matthias et al. [63] report that employing direct hydrogen injection can increase volumetric efficiency while enabling precise stratification of the fuel–air mixture inside the engine cylinder. When analyzing the volumetric efficiency of diesel/hydrogen dual-fuel engines, multi-cylinder engines and uneven hydrogen dosing to individual cylinders must also be considered. According to Farzam and McTaggart-Cowan [64], inter-cylinder differences in combustion behavior can constrain the efficiency and overall utilization of hydrogen in these engines. Moreover, single-point injection systems—commonly applied in practice—may lead to deviations of up to ±25% in the fuel delivered to each cylinder, contingent upon injection velocity.

5.2. Uncontrolled Auto-Ignition and Backfires

In the analyzed dual-fuel configurations, gaseous hydrogen is supplied to the intake manifold, where it blends with air to form a homogeneous combustible mixture subsequently inducted into the cylinder during the intake stroke. Due to hydrogen’s inherently low ignition energy, rapid flame propagation, and wide flammability range, there exists a risk of premature combustion within the cylinder prior to diesel injection, manifesting as abnormal phenomena such as knocking and backfire. Backfiring, in particular, involves combustion within the intake manifold, which diminishes volumetric efficiency and, under extreme conditions, may lead to misfiring or total engine shutdown. Talibi et al. [28] reported periodic hydrogen auto-ignition prior to the onset of diesel injection when the hydrogen concentration in the intake air reached 20% v/v, attributing this phenomenon to localized hot spots within the cylinder. According to Yilmaz [50], although hydrogen offers notable advantages, it also presents operational challenges; due to its low minimum ignition energy, a homogeneous hydrogen–air mixture is highly susceptible to premature ignition, which can result in backfires. Xin et al. [65] highlight that the rapid and accurate detection of such events is crucial for effective control and management of hydrogen engines. In their study, they developed a backfire detection system utilizing pressure sensors mounted on the intake manifold. According to Yilmaz [50], one way to eliminate the backfire problem is direct hydrogen injection. Liu et al. [53] claim that direct hydrogen injection offers several improvements compared to manifold injection, including the elimination of backfires, as the injection occurs after the intake valve is closed. According to Dhyani and Subramanian [66], the application of exhaust gas recirculation (EGR) combined with water injection proved effective in controlling hydrogen combustion irregularities, particularly backfires.

5.3. Engine Knocking

Co-combustion of hydrogen in diesel engines may cause disturbances in the combustion process. In addition to uncontrolled auto-ignitions and backfires, knocking combustion can also occur [40]. Experimental results by Talibi et al. [28] showed that especially under low-load conditions, even a small hydrogen share can induce knocking. Research by Juknelevicius et al. [45] found that knocking combustion appeared when the hydrogen fraction exceeded 35%. Hosseini and Ahmadi [26] reported that under high-load conditions, the hydrogen amount capable of triggering knocking can be higher, reaching up to 70%. Verma et al. [15] demonstrated that hydrogen share in compression ignition engines is limited by knocking occurrence even at high loads. According to Nag et al. [16], the tendency for knocking in diesel/hydrogen engines decreases at low loads but increases at higher loads due to elevated gas temperatures in the cylinder and the formation of multiple local hot spots. Yilmaz [50] notes that in CI engines operating on hydrogen–diesel fuel, knocking combustion may arise, potentially causing severe damage to pistons, piston rings, and cylinder heads, as well as reducing overall engine performance. Several methods exist to avoid knocking in diesel/hydrogen dual-fuel engines. Chintala and Subramanian [25] prevented knocking by developing an appropriate diesel injection strategy and using water injection, which allowed increasing the hydrogen energy fraction from 18% to 36%. Zhou et al. [41] used charge dilution with N2 or CO2 (EGR) to suppress knocking combustion in dual-fuel diesel/hydrogen engines. An effective method to reduce hydrogen knocking combustion can be the co-combustion of hydrogen with another fuel characterized by a low flame speed and low reactivity [67]. Such a fuel could be ammonia. According to Ge et al. [68], the incorporation of ammonia into hydrogen fuel can modulate flame propagation and heat release dynamics, reducing the risk of knocking combustion and preserving the zero-emission performance of the system.

It should be noted, however, that the combustion of ammonia in a piston engine can result in the emission of unburned NH3, due to the fuel’s low reactivity and difficulty of ignition. Ammonia emissions from dual-fuel diesel/ammonia/hydrogen piston engines pose a range of negative environmental impacts. Although ammonia itself is neither a greenhouse gas nor an ozone-depleting substance, its presence in the atmosphere can cause several indirect but significant ecological effects, such as the formation of secondary aerosols and fine particulate matter, as well as acidification and eutrophication of ecosystems. In addition, ammonia is a toxic compound and poses a risk to human health.

5.4. Combustion Harshness

Another challenge associated with hydrogen combustion in dual-fuel CI engines is combustion harshness, which is typically assessed based on the pressure rise rate within the engine cylinder. This phenomenon can constitute a significant technical barrier and limit the effective utilization of hydrogen. Farzam et al. [14] demonstrated that such issues, including combustion harshness, can be alleviated through coordinated control of intake air pressure, diesel injection timing, and EGR rate, depending on the hydrogen energy fraction. In particular, by optimizing diesel injection timing and intake manifold pressure, the introduction of 20% EGR was shown to reduce the maximum pressure rise rate by up to 40% at high hydrogen shares, providing a practical strategy to mitigate combustion harshness.

5.5. Unburned H2 Emissions Under Low-Load Conditions

A significant issue when fueling an internal combustion engine with hydrogen is the excessive emission of unburned H2. Hydrogen acts as a potent indirect greenhouse gas, as it can influence the chemical composition of the atmosphere. This problem mainly concerns engines operating with lean mixtures under low-load conditions. According to Chen et al. [69], an increase in the air excess ratio intensifies the lean combustion conditions, leading to significant deterioration of in-cylinder combustion, a marked increase in unburned H2 emissions, and a sharp drop in exhaust gas temperature. Dimitriou et al. [30] suggest that a method to reduce the amount of unburned hydrogen at the engine outlet is exhaust gas recirculation (EGR) combined with various diesel injection strategies. Higher EGR rates elevate the intake charge temperature, thereby enhancing hydrogen combustion and improving fuel efficiency. Operating a dual-fuel engine at low load with a high EGR rate combined with slightly advanced main diesel injection can simultaneously reduce the most harmful emissions while improving overall engine efficiency [31].

5.6. H2 Slip

One of the challenges faced by hydrogen engines is the phenomenon known as H2 slip. It is related to the issue of unburned hydrogen but may occur under varying load conditions and, in particular, during combustion of large amounts of H2 in a non-homogeneous combustible mixture. The H2 slip problem mainly concerns engines with direct hydrogen injection, where improperly configured hydrogen injection can cause part of the fuel to enter areas inaccessible to the flame. Mohamed et al. [70] state that properly optimized direct H2 injection can effectively eliminate backfires as well as H2 slip. In engines with indirect hydrogen injection, the source of H2 slip is incomplete hydrogen combustion or valve overlap [71]. According to Farzam et al. [14], H2 slip can be mitigated through coordinated control of intake air pressure, diesel injection timing, and the EGR rate.

5.7. Excessive NOx Emissions

The main drawback associated with hydrogen combustion in diesel/hydrogen dual-fuel engines is the increased emission of NOx. Hamdan et al. [46] note that the use of hydrogen as a potential supplementary fuel to reduce the consumption of liquid diesel fuel is accompanied by the disadvantage of increased NOx emissions. Therefore, the need for NOx reduction techniques becomes increasingly important for engines operating on dual hydrogen-diesel fuel. Yilmaz [50] states that NOx emissions may increase when using hydrogen due to the high temperatures inside the cylinder. According to Nag et al. [29], an excellent NOx reduction technique is Exhaust Gas Recirculation (EGR), where part of the exhaust gases is mixed with fresh air and recirculated back into the combustion chamber. Farzam et al. [14] report that the introduction of EGR reduces NOx formation through two primary mechanisms. First, EGR dilutes the intake charge by replacing fresh air with gases such as CO2 and H2O, which possess higher heat absorption capacities, thereby lowering the combustion temperature for a given fuel quantity. Second, EGR decreases the oxygen concentration in the intake charge, a critical factor in NOx formation. Nag et al. [29] achieved significant NOx emission reductions from a diesel/hydrogen dual-fuel engine by applying EGR and exploiting the synergy between EGR and the hydrogen energy fraction. Verma et al. [15] found that EGR can enhance hydrogen utilization in dual-fuel engines, particularly under high-load conditions. Their study demonstrated that EGR reduces elevated NOx emissions from dual-fuel engines while maintaining thermal efficiency. According to Yilmaz [50], EGR can be used to control combustion temperatures and help address the issue of increased NOx emissions. However, it may unfortunately cause a reduction in oxygen concentration in the cylinder, which increases ignition delay and Soot emissions, and decreases the engine’s thermal efficiency. Another method for limiting NOx emissions from diesel/hydrogen dual-fuel engines is the optimization of hydrogen and diesel injection. Liu et al. [53] demonstrated that in the case of direct cylinder injection of diesel and hydrogen, a higher fraction of hydrogen energy leads to increased NOx emissions. However, variable direct hydrogen injection timings (delayed injection) allow NOx reduction even below the baseline diesel values. Tripathi et al. [72] presented numerical studies on optimizing diesel injection in a diesel/hydrogen engine and showed that optimized injection parameters positively affect NOx emissions. A common method for reducing NOx emissions by lowering cylinder temperatures in compression ignition engines, including diesel/hydrogen dual-fuel engines, is the injection of water vapor into the intake system or directly into the combustion chamber [73]. Another widely used NOx mitigation approach is Selective Catalytic Reduction (SCR) technology. SCR is an advanced active emission control method that converts nitrogen oxides (NOx) into diatomic nitrogen (N2) and water (H2O) in the presence of a catalyst. This conversion requires a reducing agent, typically ammonia or an ammonia solution. According to Farhan et al. [59], hydrogen, due to its clean and environmentally friendly characteristics, also represents a promising alternative to ammonia as a reducing agent in SCR systems.

5.8. Hydrogen Storage and Leakage

One of the drawbacks of hydrogen fuel is its high ability to penetrate metals due to the small size of the H2 molecule, which makes the storage and transportation of this gas a significant challenge. Hydrogen leaks and its emissions can indirectly contribute to climate warming and substantially undermine the predicted climate benefits of a hydrogen economy. According to Esquivel-Elizondo et al. [74], the largest ranges of estimated H2 emission rates are associated with its liquefaction (0.15–10%), transportation and handling of liquid hydrogen (2–20%), and liquid hydrogen refueling (2–15%). In the event of leakage, hydrogen disperses much faster than other fuels. A potential hazard related to hydrogen used as a vehicle fuel is its toxicity and explosiveness. Hydrogen ignition can occur due to issues in storage and transportation systems. Hydrogen is most commonly stored in pressure vessels. Due to hydrogen’s tendency to increase material brittleness, only a limited number of construction materials are suitable for storage tanks. Currently, the preferred solution is ultra-light composite materials capable of withstanding pressures of several hundred bar, which are employed in prototype vehicles such as cars and buses. Some tanks are designed for long-term storage, while others are optimized for continuous filling and discharge. At present, two main hydrogen storage approaches exist: physical storage—including high-pressure storage, cryogenic liquid storage, and cryogenic tanks—and chemical storage, which encompasses metal hydrides, liquid organic hydrogen carriers (LOHC), carbon nanotubes, and metal–organic frameworks (MOFs). According to Hren et al. [75], given current storage and transport technologies, gaseous hydrogen transported through pipelines appears to be the most environmentally favorable option, offering a lower energy footprint (38–85%) compared to other methods.

6. Conclusions and Future Research Directions

Hydrogen exhibits a range of distinctive characteristics that make it an attractive fuel option for both transportation and energy applications. Despite decades of research into hydrogen combustion, including its use in piston engines, there are still challenges regarding the optimization of combustion and the practical and commercial deployment of this gas. This work gathers and reviews numerous previously published studies focused on one specific approach to utilizing hydrogen in internal combustion engines: diesel/hydrogen dual-fuel technology. From the analysis of these studies, several key observations can be drawn:

- Hydrogen has the potential to serve as an effective energy source for compression ignition (CI) engines running in dual-fuel mode;

- Published studies on co-combustion of diesel fuel with hydrogen in dual-fuel CI engines indicate the possibility of using significant hydrogen energy fractions, ranging from 2% to 85%;

- Introducing hydrogen alongside diesel in dual-fuel CI engines markedly influences the combustion process, engine performance, operational stability, and exhaust emissions;

- Increasing the hydrogen energy fraction (HEF) in diesel/hydrogen dual-fuel engines results in longer ignition delays (ID) and shorter combustion durations (CD);

- Increasing hydrogen energy fraction to about 40% in a dual-fuel engine, compared to a conventional engine, results in an increase in maximum heat release rates (HRRmax);

- The combined combustion of diesel and hydrogen in dual-fuel CI engines positively influences thermal efficiency (TE) and specific energy consumption (SEC);

- Diesel/hydrogen dual-fuel engines maintained stable operation, with no significant increase in the coefficient of variation of indicated mean effective pressure (COVimep);

- In dual-fuel engines, hydrogen supplementation of diesel fuel elevates NOx emissions;

- For HEF ≤ 42%, there is no clear trend reflecting the impact of hydrogen on hydrocarbon (HC) emissions from diesel/hydrogen engines. However, above 57% hydrogen share, experiments indicate a negative effect of hydrogen addition on HC emissions;

- Increasing hydrogen share results in more effective reduction of carbon monoxide (CO) and carbon dioxide (CO2) concentrations in diesel/hydrogen dual-fuel engine exhaust;

- Hydrogen combustion in dual-fuel diesel engines contributes to Soot and particulate matter (PM) emission reductions.

For hydrogen to become a widely adopted fuel in internal combustion engines, including compression ignition engines, comprehensive research is required to optimize the combustion process and address challenges such as reduced volumetric efficiency, premature ignition, combustion harshness, and knocking. Furthermore, the implementation of reliable methods to limit excessive emissions of hydrogen (H2) and nitrogen oxides (NOx) is essential, alongside overcoming existing barriers related to hydrogen storage and transportation. It is also crucial to develop international regulations and standards governing the design, maintenance, and operation of hydrogen-related infrastructure and equipment. Ensuring consistency in robust technological solutions and safety requirements is necessary to enhance consumer confidence in hydrogen-powered engines.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Engine parameters | |

| CI | compression ignition |

| CR | compression ratio |

| SI | spark ignition |

| TDC | top dead center |

| n | engine speed |

| Combustion parameters | |

| CD | combustion duration |

| COVimep | coefficient of variation of indicated mean effective pressure |

| HRR | heat release rate |

| ID | ignition delay |

| imep | indicated mean effective pressure |

| p | pressure |

| PPR | peak pressure rise |

| SFC | specific energy consumption |

| TE | thermal efficiency |

| Fuel properties | |

| ρ | density |

| A/F | stoichiometric air/fuel ratio |

| C | carbon |

| CN | cetane number |

| Dair | diffusivity in air |

| Fv | flame velocity |

| H2 | hydrogen |

| HEF | hydrogen energy fraction |

| LFL | lower flammability limit |

| LHE | latent heat of evaporation |

| LHV | lower heating value |

| MIE | minimum ignition energy |

| N2 | nitrogen |

| O2 | oxygen |