Abstract

This article critically reviews advances and numerical modeling in absorbers and desorbers used in absorption refrigeration systems, emphasizing the applications, limitations, and future perspectives of computational fluid dynamics (CFD). This study’s main contribution lies in the detailed and critical analysis of the use of CFD in physical models of absorbers and generators of absorption chillers. In addition, several heat exchanger technologies, such as falling film, membranes, and bubbling, are addressed, highlighting CFD-based studies’ main findings and challenges. The article also explores the integration of artificial intelligence (AI) in CFD analyses, aiming to optimize modeling and system performance. It was found that the application of CFD analyses in absorbers and desorbers of absorption systems has proven to be an essential tool for developing and optimizing these systems. Finally, research gaps were identified, especially regarding the miniaturization and optimization of these exchangers, and directions for future studies are proposed.

1. Introduction

Recent efforts to implement more sustainable refrigeration systems have significantly increased, focusing on high efficiency and low energy consumption using natural refrigerants with low global warming potential. This trend is largely driven by global warming, which has increased energy consumption for cooling since 1990, exacerbated by the COVID-19 pandemic heightened demand for domestic cooling [1]. In this context, absorption refrigeration systems present a promising alternative. These systems offer several advantages, including adaptability to low-temperature heat sources, natural refrigerants with low global warming potential (GWP), a long service life, and their role as a key technology in reducing primary energy consumption and environmental impact [2].

Despite its significant potential, the commercial advancement of vapor absorption refrigeration technology faces two primary challenges: the large equipment volume and the high initial investment costs [3,4]. Numerous research initiatives are currently focused on developing strategies to optimize these systems and facilitate their miniaturization, making them economically competitive with traditional refrigeration systems [5,6]. Given the complex heat and mass transfer processes that occur in the absorbers and desorbers of absorption refrigeration systems, these components are recognized as critical for enhancing overall system performance [7]. This underscores the necessity of studying their behavior to optimize internal heat and mass transfer. Prioritizing research on advanced technologies related to operational modes, as well as the exploration of new fluids and innovative modeling approaches, is essential [8,9,10]. Specifically, adopting new or improved distribution methods and configurations for these components can significantly impact the performance of the entire system [4].

To achieve this improvement, it is essential to conduct tests on new geometries, parameters, and materials. From this perspective, the CFD numerical modeling approach offers an economical and accurate method for investigating machinery compared to conventional experimental research. It enables the analysis of aspects that are often impossible to verify experimentally, such as the equipment’s temperature field and mass fraction. It also facilitates examining and modifying computational domain conditions and operating parameters in comprehensive studies [11,12,13,14,15,16]. Although many studies have demonstrated the potential of CFD analysis methodologies for the sorption processes in absorption refrigeration systems, most of the reviews found in the literature do not focus on CFD simulations but instead on experimental or traditional numerical studies [4,13,17,18]. Amaris et al. [19], in their review paper, presented the main technologies used for absorbers but focused only on experimental studies. Similarly, Amaris and Bourouis [7] identified, summarized, and discussed only the experimental studies dealing with the boiling process in desorbers specifically for use in absorption heat pump technologies.

Integrating artificial intelligence (AI) techniques into CFD modeling represents a significant advancement, offering opportunities to enhance computational efficiency and simulation accuracy. Numerous studies have demonstrated AI’s potential to reduce computational costs [20,21,22]. Additionally, AI methodologies such as reinforcement learning have effectively optimized designs and control systems leveraging CFD outputs [23,24]. Adopting AI techniques in CFD analysis is becoming increasingly vital in the context of absorption refrigeration systems. These methods enhance the optimization and precision of simulations and present innovative solutions to the complex challenges inherent in these systems while maintaining lower computational costs [25,26,27]. Furthermore, reviews of the sorption elements in absorption chillers tend to focus on a single mode of operation of the exchangers or exchangers applied in areas other than refrigeration. Wen et al. [12] summarized previous studies on fluid flow and coupled heat and mass transfer in falling films for both dehumidification and absorption refrigeration systems. Mahamoudou et al. [28] reviewed analytical/numerical approaches to analyze thermal, mass, and hydrodynamic phenomena in falling film absorbers. Similarly, Zhao et al. [29] presented a review of computational studies on the impacts of falling film hydrodynamics and heat transfer performance in tube bundles. Zhai et al. [30] provided a review of various aspects of absorption cycles such as technological development, prospects, cycle configurations, working fluids, and current applications. This work, however, focused exclusively on membrane-based heat exchangers, such as the one presented by Sui and Wu [31] and Asfand and Bourouis [32].

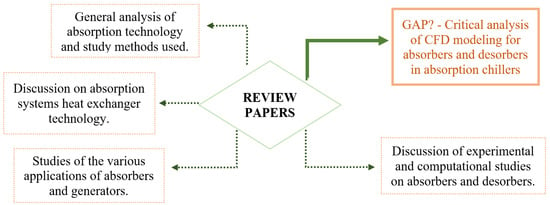

Figure 1 summarizes the main objectives of review papers on modeling the sorption elements over the last 5 years. As shown in Figure 1, several review papers on absorption refrigeration systems address thermodynamic analyses, experimental studies of absorption chillers, heat exchangers used, and applications of absorbers and generators. However, there is a gap in the performance of critical reviews that focus on applying CFD (Computational Fluid Dynamics) techniques in absorbers and desorbers. Additionally, there is a lack of specific studies on new heat exchanger technologies, such as the use of membranes and hybrid falling film systems, which have not yet been widely explored from the perspective of CFD techniques. Another relevant point is the widespread use of constant thermophysical properties in most studies, resulting in simplified models that limit applicability in real conditions, where properties vary significantly during the absorption and desorption processes. In the same context, the scarcity of research on new working fluids stands out, highlighting the need for reviews that consider more sustainable alternatives, such as ammonia-based mixtures or solutions with low toxicity and less environmental impact. In addition, there is an imbalance in the approach of studies, which often focus on absorbers, while generators, which are fundamental parts for the efficiency of systems, receive less attention. Finally, the importance of integrating artificial intelligence techniques with CFD is highlighted, aiming to increase the accuracy of simulations and reduce their computational costs. In this sense, this review study seeks to bring an innovative approach by exploring the application of CFD in absorbers and generators of absorption refrigeration systems, contributing to the advancement of this area of research. Despite the diversity of studies, there is still a need for a more specific review of CFD modeling for absorbers and desorbers used specifically in absorption refrigeration chillers.

Figure 1.

Summary of the main objectives of review articles on the sorption elements of absorption chillers over the last 5 years.

The primary objective of this article is to present a comprehensive review of the current state of CFD-based studies on absorbers and desorbers utilized in absorption refrigeration systems. This is achieved through a critical analysis of the most significant studies conducted over the past five years. The research encompasses key absorber and desorber technologies, essential heat and mass transfer mechanisms and models, and commonly used working fluids, as well as their implementation in the adopted tools. Additionally, it highlights the integration of AI with fluid dynamics analysis.

This work is organized into six sections. Section 1 presents the importance of CFD studies in sorption exchangers used in absorption chillers, highlighting the gaps identified in the review papers in the field. Section 2 outlines the search methodology. Section 3 focuses on the tools and models most commonly used in CFD analyses and examines the studies that identify the leading technologies employed as absorbers and desorbers. It also discusses the most common working fluids and details how their properties are incorporated into the fluid dynamics tools. Section 4 presents studies that have integrated fluid dynamics analysis with AI methods to enhance the modeling and optimization of this equipment. Section 5 offers a critical review of the current state of research and prospects for future work, emphasizing gaps in the literature. Finally, some conclusive remarks and brief recommendations for future work are put forward in Section 6.

2. State-of-the-Art Literature Survey

The search was conducted using the Scopus scientific repository, where relevant articles were explored. The primary keywords were combined using Boolean operators to identify the most pertinent manuscripts on the selected topic.

When accessing the repository, the search focused on the titles of the articles, keywords, and abstracts. Papers published within the last five years were selected. The initial search utilized the keywords “absorption or desorption” and “CFD” (QUERY 1), progressing with more specific keywords and narrowing the results to absorption chillers (QUERY 2). Finally, the keywords “absorber” and “desorber” were incorporated into the query to further refine the results to align with the specific objectives of our work (QUERY 3). The stratification of the results by document type is presented in Table 1, with Boolean operators indicated in the table legend.

Table 1.

Overview of the articles found according to the specified search queries.

3. Absorber and Desorber Technologies: CFD-Based Studies

Unlike experimental research, which demands significant time and financial resources, numerical simulations offer detailed insights into thermal and hydraulic behavior, enabling adjustments to operating conditions and design variables [31,33]. These methods have become increasingly popular for detailed flow analysis in cooling applications, particularly in absorption refrigeration. However, the accuracy of CFD solutions depends on the physical models representing real-world processes and the boundary conditions applied [34].

Various software packages are available for CFD analysis, each with unique advantages and limitations. Table 2 summarizes the advantages and disadvantages of the most used CFD software such as ANSYS/Fluent 14.0 in the field of absorption refrigeration. Research on the simulation of flow and heat and mass transfer in absorbers and desorbers of absorption chillers predominantly employs the commercial software ANSYS FLUENT 2024. However, studies also utilize ANSYS CFX 2023, COMSOL Multiphysics 6.3, and open-source software such as OpenFOAM-v2412.

Table 2.

General comparison of the CFD software used in the field of absorption refrigeration.

Table 2 also highlights the different characteristics found between commercial and open-source software. While commercial tools like ANSYS FLUENT and COMSOL Multiphysics offer comprehensive documentation and extensive technical support, they are costly and generally require substantial computational resources. On the other hand, open-source software such as OpenFOAM is more cost-effective and highly customizable but may require advanced programming knowledge from users. Furthermore, open-source software also lacks formal user support [38].

The selection of software is influenced by several factors, including cost, licensing restrictions, ease of use, implementation of properties, availability of solvers, pre- and post-processing tools, and technical support, among others. A critical consideration in this decision is whether to opt for open-source or commercial CFD software. Open-source software is often available at a lower cost, sometimes even free; nonetheless, it may lack technical support. In contrast, commercial packages typically provide comprehensive documentation and dedicated technical support for users [38].

Another difference is that in open-source CFD software, such as OpenFOAM, the material property library is often less extensive than in commercial software. While some community-developed libraries exist, they are limited compared to the comprehensive databases in commercial tools like ANSYS FLUENT/CFX or COMSOL Multiphysics. However, even commercial software often lacks specific information for certain fluids, particularly across a wide temperature range.

An approach for incorporating properties is through UDFs. UDFs are custom code snippets created by users to enhance model functionality, allowing them to extend the software’s capabilities beyond standard options. This enables the development of tailored calculation routines, custom boundary conditions, heat or mass sources, and more. Several studies, including those by Yang et al. [39], Sui et al. [40], Sui et al. [41], Turkmen and Atilgan [42], and Zhang et al. [43], have employed UDFs to dynamically update fluid properties in response to concentration and temperature variations during the absorption or desorption process.

Table 3 summarizes how the properties of the primary fluids used in absorption chillers are implemented in four different CFD software packages. Since ANSYS FLUENT and ANSYS CFX are tools from the same manufacturer, they share similar libraries and methods for inputting property values.

Table 3.

Means of implementing fluid properties in software.

In general, while there are studies in the literature that utilize CFD to investigate absorbers and desorbers, many of these studies fail to clarify how fluid properties were integrated into the software or the specific values employed. Furthermore, those studies that do provide these values typically rely on constant parameters. This lack of detail presents challenges in reproducing research related to the CFD technique and the application of absorbers and desorbers in absorption refrigeration systems.

Building on these limitations, recent research efforts have shifted toward enhancing absorption systems by exploring new exchanger technologies that can reduce both their size and cost. The complex simultaneous heat and mass transfer that occurs within these components demands exchanger geometries that, in some cases, lack optimization [4]. In this regard, strategies that aim at improving performance and miniaturizing these systems generally focus on enhancing the efficiency of heat and mass exchange within the solution [49].

The absorber is generally pointed out as the most critical component, significantly influencing both system performance and size [50]. Consequently, absorbers are the focus of extensive experimental and numerical investigations [17]. Additionally, there exists a body of research examining desorbers in different configurations as well [31].

The following subsections explore the sorption technologies utilized in both absorbers and desorbers, highlighting studies from the past five years. A table summarizes the types of equipment, fluid technologies, and objectives of the selected articles. Additionally, works using AI to optimize CFD analyses of sorption exchangers are highlighted. Finally, a table presents the software used by the authors, the transport phenomena models, basic configurations, and key results reported in the articles.

3.1. Absorber and Desorber Technologies

The following papers have used CFD to model multiphase flows, heat transfer, and mass transfer in absorbers and desorbers, focusing on falling film, bubble, and membrane technologies. These studies were analyzed to highlight the main contributions generated by computational analyses, providing a comprehensive overview of the advances and challenges faced in the field. By highlighting the contributions and limitations of these studies, we sought to better understand the crucial role of computational modeling in the optimization and development of these devices.

3.1.1. Falling Film

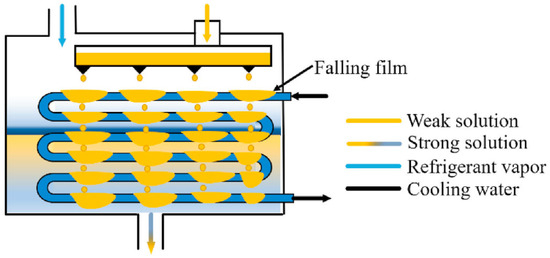

The absorption of water vapor by a falling film (Figure 2) is a configuration commonly found in absorbers today. Heat and mass transfer occur on the surface of the falling film, which is permeable to the refrigerant. This technology was initially studied for refrigeration applications and implemented by Ref. [51] in NH3-H2O absorbers.

Figure 2.

Schematic representation of the falling film absorption process in horizontal tubes. The weak solution enters the absorber and forms a uniform film as it flows down the tubes. The refrigerant vapor is absorbed into the film, resulting in a strong solution as it flows to the bottom of the system. The heat released during absorption is removed by cooling water circulating inside the tubes, enabling thermal control of the process [17].

Figure 2 illustrates falling film absorption in horizontal tubes, highlighting the flows and interactions involved. The weak solution (depicted in yellow), containing a low refrigerant concentration, enters the absorber at the top of the exchanger and flows over the set of tubes, forming a uniformly distributed film. Simultaneously, the refrigerant vapor (shown in light blue) enters the absorber (also from the top), which is absorbed into the weak solution film as it flows along the tube surfaces. During this process, the refrigerant concentration in the solution increases, turning it into a strong solution. Absorption occurs due to heat removal from the process, which is transferred to a cooling fluid (depicted in black) circulating inside the tubes. This thermal flow is essential for maintaining the efficiency of the absorption process.

Two-dimensional analyses are commonly employed to reduce the computational time of simulations. Shi et al. [52], for example, utilized the Lattice Boltzmann method (LBM) to model and simulate the distribution of wave velocity and energy during the liquid film falling process. This simulation assumed laminar flow with a semi-parabolic velocity distribution. In their study, a length of 1 m and an initial velocity of 0.1 m·s−1 were used for the falling film flow of H2O-LiBr. The results indicated that wave flow resulted in a modest enhancement of heat and mass transfer, with the local dimensionless numbers for mass (Sh) and heat (Nu) transfer increasing by factors of 4 and 2, respectively, compared to laminar flow.

In addition to considering laminar flow, another common simplification in studies within this field is the assumption of constant thermophysical properties of the fluid. In the study by Tahir et al. [53], for example, a 2D laminar numerical model was developed with constant properties and symmetrical flow. The authors analyzed the influence of liquid load in both drop and jet modes, as well as the concentration of the LiBr aqueous solution film. Two concentrations of LiBr solution were examined, 45% and 65%. The results indicated that the jet mode exhibited greater stability at concentrations above 65%, with a variation of ±0.5%, compared to lower concentrations. However, heat transfer was enhanced at lower concentrations due to reduced film thickness and thermal resistance, increased recirculation, and a higher velocity field.

The complexity of flow patterns in falling film absorbers and desorbers necessitates simplifying assumptions to achieve a closer representation of real equipment. To improve this accuracy, Subramaniam et al. [50] examined critical factors such as droplet formation and breakage, which often lead to oversimplified laminar flow models. They developed a two-dimensional model utilizing the VOF methodology in ANSYS FLUENT, indicating that flow patterns significantly influence absorption. The drop-by-drop flow mode facilitates the mixing of concentration profiles, thereby sustaining absorption. In contrast, the absence of mixing leads to a dramatic decrease in absorption after the initial stages.

New hybrid models have been developed to enhance the analysis of solution film characteristics. Vakilipour and Hekmatkhah [54] conducted a comprehensive examination of two-phase (gas–liquid) flows, both steady and unsteady, to investigate the absorption characteristics of the falling H2O-LiBr film. An arbitrary fully coupled Lagrangian–Eulerian interface tracking (ALE-IT) algorithm was developed to calculate transient heat and mass transfer, as well as the precise location of the absorption process. The energy and transport equations for chemical species were discretized implicitly and coupled with the flow equations of motion. This coupled solver enables accurate calculations of interfacial heat and mass transfer, allowing predictions of increased absorption from a falling corrugated film compared to a stable film. It was observed that cooling the wall temperature enhances the absorption rate, with the highest heat and mass transfer rates estimated across the interface at a Strouhal number of 0.03. The dynamic structures of interface instabilities, characterized by solitary and capillary waves, significantly influence the absorption rate. An increase in the rate was noted adjacent to capillary interface waves, while the absorbing flow was suppressed in the presence of solitary waves.

Zhang et al. [43] developed a hybrid multiphase model to analyze a liquid film flowing over a thin layer of compressed silicon carbide foam during a desorption process. This improved method combines the VOF and Euler–Euler models. Compared to the results obtained from liquid film flow over a rigid surface, the mass transfer performance is observed to degrade when the liquid film flows over a porous layer. This occurs because as the liquid flow rate in the porous medium increases, the slow species transport within the porous medium begins to have a considerable negative effect on the overall mass transfer performance. Furthermore, the desorption rate on the liquid side is significantly influenced by the properties of the porous layer due to flow resistance, revealing a non-linear relationship between the desorption rate and the liquid flow rate.

In addition to enhancing the understanding of flows in equipment utilizing falling film technology, several studies have explored alternative methods to improve the performance of falling film absorption, thereby increasing the efficiency of absorption systems. These investigations are typically conducted through experimental and numerical approaches. In the CFD analysis, Gao et al. [55] established a falling film absorption model for a H2O-LiBr solution, considering actual cooling water channels and tube wall thickness. They examined the impact of adding copper oxide nanoparticles (nano-CuO) on falling film absorption. A two-dimensional model was developed using COMSOL Multiphysics, which considers laminar flow, the physical transport of concentrated chemical species, and heat transfer in fluids. This model was applied to a falling film of LiBr solution flowing along a vertical copper wall under stationary conditions, utilizing the PAEDISO solver, which is less common in such analyses. The results indicated that the enhancement effect of nano-CuO was more pronounced at higher inlet temperatures and lower solution concentrations.

3.1.2. Bubble

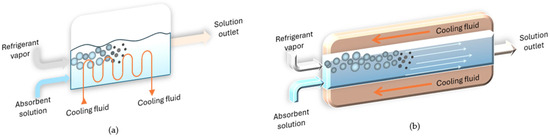

Bubble absorption and desorption technology is gaining prominence due to its effective heat and mass transfer performance, as well as its applicability in mobile devices [56,57]. In practice, two distinct operational scenarios exist, each characterized by significantly different bubble behavior. In the first scenario, illustrated in Figure 3a, the flow of bubbles occurs freely within a solution in a “pool-type” configuration. In this case, the absorbent solution and refrigerant vapor enter a reservoir resembling a pool, where bubbles disperse freely in the solution. The heat generated during absorption is removed by a cooling fluid that passes through a submerged tube within the reservoir. In the second scenario, shown in Figure 3b, the operation occurs in a shell-and-tube configuration. Here, the flow of bubbles is significantly influenced by the walls of the tubes, which act as structural barriers, altering the flow pattern and the interactions between the bubbles and the fluid. This configuration provides more controlled heat and mass transfer processes [57]. These different configurations directly affect process efficiency, as the interaction between the bubbles, the fluid, and structural surfaces varies depending on the operational environment.

Figure 3.

Schematic diagram of the bubble absorber in two distinct configurations: (a) pool-type configuration, where the absorbent solution and refrigerant vapor mix in a reservoir with free bubble flow and heat is removed by a cooling fluid passing through a submerged tube; (b) shell-and-tube configuration, where bubbles are generated inside the tubes and the cooling fluid flows externally to the tubes in the opposite direction.

The first type of exchanger was investigated by Panahizadeh et al. [58] in the desorption model, where they employed a two-phase Euler–Euler approach utilizing an extended boiling model from Rensselaer Polytechnic Institute alongside a κ-ε turbulence model. The numerical model was applied to three types of pipes: a bare pipe, a pipe with a notched fin, and a pipe with a low fin. The objective was to assess the impact of fin design on the boiling heat transfer rate within the absorption chiller generator and to compare the results with those from the bare tube. The findings indicated that the implementation of a tube with a notched fin or a low fin increases the rate of inhomogeneous nucleation, leading to earlier boiling compared to the bare tube, and reduces the thermal energy required in the generator of an absorption chiller.

The modeling of bubble exchangers featuring a shell-and-tube configuration is addressed in the studies conducted by Mohamed and Karimi [59] and Dong et al. [46]. The first study performed a CFD analysis of a shell-and-tube desorber with baffles to maximize heat exchange. The primary objective was to assess the optimal spacing of the baffles within the heat exchanger. Their findings indicated that reducing the baffle spacing resulted in an increased heat transfer coefficient, with a decrease from 137 mm to 101 mm leading to a 48% increase in the coefficient.

In the exchanger examined by Dong et al. [46], steam is injected into the LiBr solution through a hole at the bottom of the absorber, where bubbles are generated and subsequently rise through the solution, creating various flow regimes. The steam enters the solution due to a pressure differential, facilitating heat transfer to the cooling water outside the tube. A heat and mass transfer model incorporating composite heat exchange (both conduction and convection) was developed to explore this process under vacuum conditions. COMSOL Multiphysics was utilized to create an axisymmetric, two-dimensional model of the exchanger.

The results found by Dong et al. [46] revealed that enlarging the orifice diameter from 2 mm to 6 mm significantly improved the heat and mass transfer coefficients. Larger orifices produce larger bubbles, increasing the gas–liquid interface contact in the absorption process and promoting better convective heat and mass transfer. Similarly, increasing the bubble velocity from 0.1 m·s−1 to 0.5 m·s−1 yielded even more significant enhancements. This increasing bubble speed intensifies convection between phases, promoting a higher mass transfer rate. Conversely, raising the concentration of the solution from 50% to 60% reduced the heat and mass transfer coefficients. The increase in concentration alters the fluid properties, resulting in higher density, viscosity, and surface tension while simultaneously reducing thermal conductivity and specific heat. These changes impede mass transfer due to the increased inertial force and surface tension, which affect bubble size. Additionally, the increased concentration reduces the molecular spacing, thereby intensifying molecular interactions. This impedes thermal motion and consequently reduces both heat and mass transfer.

Lima et al. [11] conducted a two-dimensional numerical analysis using ANSYS-CFX to study an NH3-H2O bubble absorber. The equipment consisted of a plate heat exchanger with three channels, where the refrigerant vapor and solution flowed downwards in the central channel while the cooling water flowed upwards in the side channels. A single common inlet was considered for both flows to simplify the model, and it was analyzed as a distributed flow along the inlet. Additionally, the analysis neglected heat exchange by conduction. The results were compared with those in the literature and, despite simplifications, showed errors of less than 10%, except for the mass fraction of the solution. The parametric analysis revealed that a 10% increase in the ammonia mass fraction at the absorber’s inlet led to a 17.9% increase in the amount of ammonia present at the absorber’s outlet compared to its inlet value, while a 10% reduction in the ammonia mass fraction at the absorber’s inlet caused a 29.8% increase.

Understanding bubble behavior during the transfer process poses a significant challenge in this operational mode. Using the VOF model, some researchers have simulated absorbers and desorbers, achieving good results. Zapata et al. [60], for example, evaluated vapor bubble absorption in NH3-LiNO3 solution using an optimized CFD model ANSYS FLUENT. The results showed that the VOF and mixing models are suitable for predicting the absorption process in the bubble absorber, evaluated as a function of mesh density refinement. The absorbed flow estimated from the CFD model varied between 3.2 × 10 −3 kg·m−2·s−1 and 4.4 × 10−3 kg·m−2·s−1, while the solution-side heat transfer coefficient varied between 457 W·m−2·K−1 and 786 W·m−2·K−1.

In a related study, Zapata et al. [48] analyzed and validated a 3D CFD bubble absorber model in ANSYS FLUENT, developed to simulate the absorption process in a double vertical tube with the NH3-LiNO3 solution. They compared three multiphase models: the Volume of Fluid (VOF) model, which successfully converged in 4.5 h with a residual of 10−7; the mixture model, which failed to converge after 6 h; and the Eulerian model, which resulted in a divergent solution after 6 h of simulation. The results showed that the VOF coupled with the Realizable κ-epsilon mass transfer model offered the best performance, with errors of less than 10% when compared to the experimental data. The maximum absorption rate and heat transfer coefficient were 0.00441 kg·m2·s−1 and 786 W·m−2·K−1, respectively.

3.1.3. Membrane

In 1980, Zerweck obtained a patent for the membrane-based absorption cycle [61]. Following an extensive development period, membrane-based absorption technology has significantly advanced to meet diverse demands, including cooling, heating, and gas dehumidification, among others. An analysis of current development trends indicates that the membrane-based absorption cycle is an emerging technology that is attracting increasing attention from both researchers and industry. However, it faces certain challenges, including high costs and potential high-pressure losses, as well as the durability of the membrane, especially when used in salt-based working fluids [4,30].

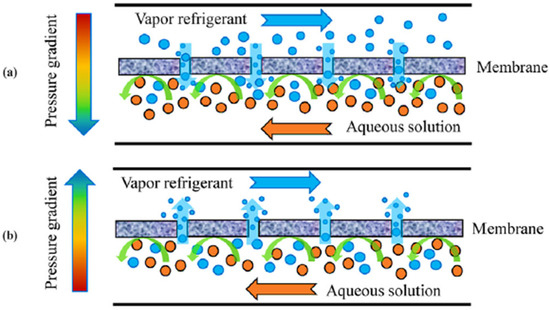

Membranes are widely utilized in the process industry due to their relative simplicity, reliability, high separation rates, large interfacial areas, and low energy consumption, which enhance heat and mass transfer. In the absorption cycle, the membrane serves as a barrier that permits the passage of small molecules, such as refrigerant vapor, while restricting larger molecules, such as absorbent molecules.

Figure 4 illustrates the schematic operation of membrane-based exchangers functioning in the absorption (Figure 4a) and desorption (Figure 4b) mode. In the absorption mode (a), refrigerant vapor flows through the membrane while the absorbent is retained in a narrow flow channel due to the selective permeation properties of the membrane. The absorbent solution flows through this channel, facilitating the entry of refrigerant vapor into the solution due to the partial pressure difference. In the desorption mode (b), the refrigerant vapor is extracted from the hot solution due to the difference in vapor pressure, even at low temperatures. Consequently, the desorption process occurs before the absorbent solution reaches its boiling point [43,62].

Figure 4.

Schematic diagrams of a membrane-based sorption exchanger operation in (a) absorption and (b) desorption modes. In the absorption mode (a), refrigerant vapor passes through the membrane due to a partial pressure difference. In the desorption mode (b), the process is reversed: refrigerant vapor is released from the heated solution due to the vapor pressure difference across the membrane [62].

Sui et al. [63] conducted a parametric study on H2O-LiBr absorbers with flat membranes using a 2D CFD model in ANSYS FLUENT to elucidate the impact of membrane parameters on the absorption process. The results indicate that membrane porosity is the most critical parameter influencing the absorption rate, surpassing the effects of membrane thickness and pore diameter. The optimal values recommended for membrane porosity, pore diameter, and thickness are 0.8, 1 μm, and 60 μm, respectively. Furthermore, the study demonstrates that a reinforcement structure with inclined grooves induces swirling of the solution, increasing the effective heat transfer area and significantly improving absorption performance at lower solution pressure drops. Among the proposed structures, the herringbone groove enhances the absorption rate by 1.62 times with a 19.01% solution pressure drop. In contrast, the inclined groove reinforcement achieves an improvement of 1.56 times in absorption rate and a pressure drop reduction of 20.77%.

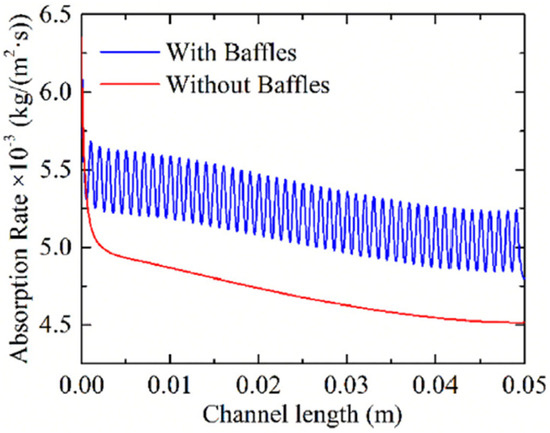

Sui et al. [40] conducted simulations in ANSYS FLUENT to study the effect of the design variables on the absorption process in an H2O-LiBr membrane absorber, employing UDFs to update fluid properties due to the lack of solution parameters in the CFD materials database. The study revealed that adding baffle modules at the solution channel inlets altered the entrance effects by disturbing the boundary layer, leading to a 20% increase in the absorption rate and a 230% improvement in volumetric cooling capacity. Figure 5 illustrates these effects, showing how the boundary layer disturbance at the channel entrance promotes a more significant mixing of the absorbent solution and enhances its interaction with the refrigerant vapor. This increase in the solution velocity improved the absorption performance, reducing the solution residence time within the channels and increasing the solution pressure drop. The study also determined that the optimal solution film thickness and velocity were 0.5 mm and 4.0 mm·s−1, respectively, balancing absorption efficiency with acceptable pressure drops.

Figure 5.

Comparison of absorption rates in an H2O-LiBr membrane absorber with and without baffles at the solution channel inlets. The presence of baffles disrupts the boundary layer, promoting greater mixing of the solution and interaction with the refrigerant vapor, resulting in a 20% increase in the absorption rate [40].

In a similar study, Sui et al. [41] applied the same principle to update the solution properties in the case of a microchannel membrane absorber. The findings suggest that the channel width has an insignificant impact on the heat and mass transfer behavior. Furthermore, the pressure drop increases by 16.6% as the solution channel width decreases from 1.8 mm to 1.0 mm. Finally, the implementation of groove structures at the bottom of the solution channel to generate a swirling effect allowed for a 13.17% reduction in pressure drop, accompanied by a 0.57% higher absorption rate.

Türkmen and Atilgan [42] also conducted CFD modeling in ANSYS FLUENT with the aid of UDFs for property integration. They investigated the optimization of membrane-based absorbers and desorbers in absorption refrigeration systems, considering various parameters such as the channel height, the solution inlet velocity, and the different solution pairs (H2O-LiBr, H2O-LiBr/LiNO3/LiI/LiCl, H2O-[EMIM][OAc], and H2O-LiCl). The results indicate that channels with a height of 0.5 mm performed best, while the liquid H2O-[EMIM][OAc] was the most efficient for absorption with an optimal inlet velocity of 0.027 m·s−1. In the desorption mode, the H2O-LiCl solution showed the best performance while H2O-[EMIM][OAc] exhibited the lowest pressure drop. Different microchannel structures were compared, demonstrating a significant increase in absorption rates at the cost of a greater pressure drop. The H2O-[EMIM][OAc] solution proved advantageous in terms of absorption rate and pressure drop, while the H2O-LiCl solution was advantageous for desorption rates. The authors recommend exploring more parameters and conducting three-dimensional analyses and experiments to determine the optimal conditions.

Medina-Caballero et al. [64] presented a numerical simulation of a membrane desorber utilizing an air gap membrane distillation configuration. The analysis was conducted using ANSYS FLUENT and involved a three-dimensional model. The maximum error in the simulated temperature was 11.9% compared to the experimental data. The results indicated a temperature difference of 288.15 K between the solution volume and the membrane interface. Additionally, stagnant areas within the solution channel resulted in velocity variations of five orders of magnitude compared to the midpoint of the channel. This poorly distributed flow created a “jet” effect within the solution channel, leading to an inhomogeneous concentration distribution at the membrane interface. Consequently, a concentration difference of up to 1.35% was observed between a point at the boundary of the membrane interface and a point located in the middle of the channel. Therefore, geometric modifications to the membrane desorber device could enhance the desorption rate.

3.2. General Discussion on the Different Sorption Exchanger Technologies

Table 4 summarizes the technologies discussed, including the research objectives and key characteristics of the studied equipment. Notably, there have been few studies in the last five years on absorber and desorber technologies for CFD-modeled absorption refrigeration systems. This gap highlights the urgent need for research to align with technological advancements and changing market demands.

Table 4.

Summary of the characteristics and objectives of research regarding absorbers and desorbers for absorption refrigeration systems.

Most studies on CFD for absorbers and desorbers focus on understanding flow phenomena, aiming for a comprehensive analysis of the key parameters that influence heat and mass transfer within the system. This focus ultimately seeks to enhance the COP while reducing the size and cost of the global system.

In the field of CFD modeling, conventional fluids, particularly the H2O-LiBr pair, dominate most studies. The prevalence of H2O-LiBr in CFD research can be attributed to several factors: its elevated thermal COP for positive cooling applications, simpler configuration [4], its favorable thermophysical properties, good chemical stability, an extensive property database, the availability and non-toxicity of water as a refrigerant, and the potential for specific applications [31,65]. Nevertheless, the literature highlights investigations into new working fluids, reflecting significant advancements in research and broadening the scope for optimization and innovation in absorption refrigeration systems.

Table 5 presents a summary of the primary software utilized by researchers in the studies covered by this present review, along with the transport phenomena models, information on fluid properties, basic configurations, and the key findings of the related studies, focusing on the last five years as the analysis period. For the articles cited in Table 5, unless otherwise specified in the models and complementary equations column, the governing equations used in the models are the continuity, momentum, and energy equations.

Table 5.

A summary of the software used, their properties, basic configurations, transport phenomena models applied to sorption, and the main conclusions from articles on modeling sorption exchangers with CFD over the past five years.

The CFD modeling of absorbers and desorbers has predominantly been conducted using ANSYS FLUENT in conjunction with the multiphase VOF model, often coupled with other solvers (Table 5). This preference arises from the software’s capability to accurately capture the dynamics of the vapor–liquid interface, where intense and simultaneous heat and mass exchange occurs. Effectively capturing the motions at this interface is essential for accurately simulating the heat and mass transfer behavior of the equipment.

Examining the basic configurations presented in Table 5, it is common to use a 2D model to represent the equipment. This approach can reduce the number of mesh cells by up to 98% compared to a 3D model, leading to significantly lower computational costs and execution time [50]. Due to its computational efficiency, the 2D model is particularly advantageous for conducting parametric studies with varying input conditions, and it was selected by 70% of the authors who performed CFD analyses of this equipment.

Although seldom utilized, 3D analysis provides a significantly larger surface area, particularly in the phase change region, where heat and mass transfer intensities are heightened. In certain scenarios, such as the simulation of falling films or flow in porous media, 2D simulations may fail to accurately represent the actual behavior of flow and mass transfer due to the complex dynamics involved [12,66].

While 2D simulations are limited in their ability to fully capture intricate dynamic flows, they have proven adequate for the hydrodynamic analysis of internal flows in heat and mass exchangers [50,67]. The decision between employing 2D and 3D models for the CFD analysis of absorbers and desorbers in absorption chillers depends on the specific objectives of the study. For rapid and less complex parametric investigations, where computational efficiency is imperative, the 2D model may be more appropriate. Conversely, for a comprehensive and precise understanding of heat and mass transfer phenomena, or when the geometry is particularly complex, the 3D model is favored.

Along with simplifying the model to 2D to reduce computational time and effort, authors often apply other conditions to the physical model of heat and mass transfer. This is due to the complexities of flow behavior during the absorption and desorption processes of binary fluids, making it challenging to simulate real-world flow conditions accurately.

Despite the popularity and usefulness of CFD, there are still specific challenges in this type of modeling in the context of absorption refrigeration. Table 6 summarizes the main challenges faced in the CFD modeling of sorption exchangers and the solutions proposed by some authors to overcome them. These solutions are typically presented as simplifying conditions that facilitate mathematical modeling and reduce computational time. For example, assuming uniform flow distribution or neglecting specific secondary effects are standard practices. In most cases, when appropriately applied, such simplifications do not significantly impact the underlying physics of the problem. However, further investigations are necessary to fully understand the effects of these assumptions on the final simulation outcomes.

Table 6.

Summary of the challenges, proposed solutions, and justifications found in research from the past 5 years regarding CFD models for sorption exchangers in absorption refrigeration.

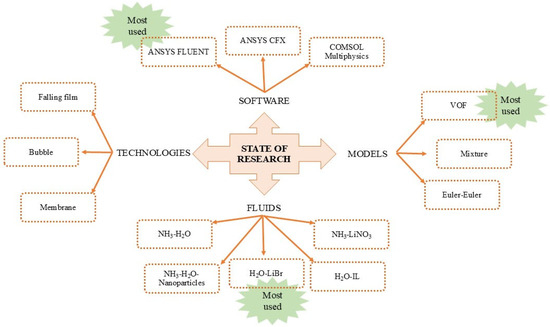

Figure 6 summarizes the main software, models, working fluids, and technologies of sorption heat exchangers used in the CFD analyses of absorbers and desorbers in absorption chillers over the past five years. Generally, the ANSYS FLUENT was the most used, with the VOF multiphase model being the most prevalent. The predominant working fluid was H2O-LiBr.

Figure 6.

Summarizing the key software, models, working fluids, and technologies of sorption heat exchangers.

4. Artificial Intelligence Techniques for CFD Analysis in Absorption Refrigeration Systems

Artificial intelligence (AI) integration is increasingly significant in CFD analysis, particularly in modeling absorption systems. AI techniques enhance the optimization and accuracy of simulations, providing innovative solutions to the complex challenges associated with these systems. AI is extensively employed to facilitate the resolution of advanced thermodynamic equations, which are often essential for accurately representing absorption systems’ behavior and extracting information about the system and equipment [69,70]. While not the sole approach, AI has been widely utilized to enhance the thermal performance of heat exchangers, including absorbers and desorbers. Table 7 presents several studies that have successfully employed various AI tools to optimize these systems. The table summarizes the objectives of each recently conducted study, which include improving thermal performance, identifying optimal operational parameters, and enhancing the accuracy of simulations.

Table 7.

Studies on the application of artificial intelligence in absorption systems.

Artificial intelligence (AI) has also been applied in modeling absorption systems using CFD, albeit on a smaller scale. With advancements in computing power, conducting more promising CFD simulations has become possible, allowing for more detailed predictions of flow behavior and heat and mass transfer, as well as preserving void spaces, velocity changes, and temperature variations [75]. However, low accuracy and high computational cost are significant limitations for developing CFD analyses. Machine learning techniques, such as Artificial Neural Networks (ANNs), can be an ally in these cases, as they often achieve results more quickly and have a greater capacity for generalization than traditional numerical methods [73,75,76]. This makes AI a potential ally in improving the efficiency and accuracy of CFD analyses.

Recently, some authors have used AI and CFD tools to facilitate simulations and reduce computational time. Dione et al. [77] combined a numerical model based on Monte Carlo ray tracing and a CFD model to evaluate the outlet temperature of a linear Fresnel reflector. The outlet temperature was used as input data for the thermodynamic simulation of the NH3-H2O absorption chiller model.

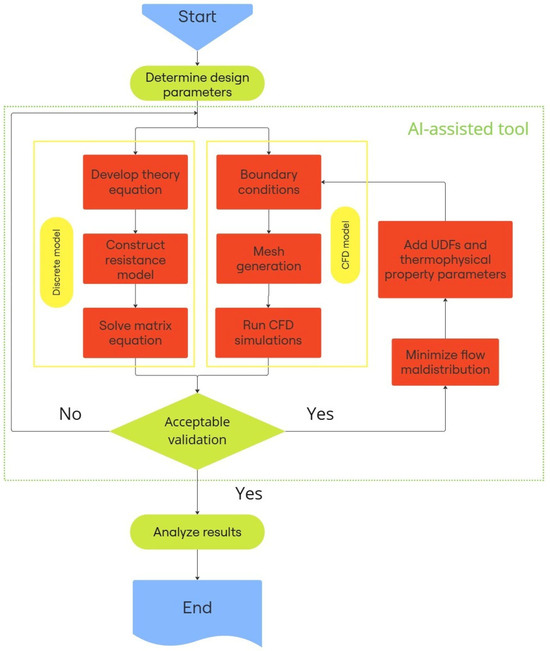

Sui, Sui, and Wu [26] conducted a multi-objective optimization study that combined machine learning and CFD models to maximize absorption rates while minimizing pressure drop in the solution. The absorber is based on a microchannel membrane with inclined grooves. The authors employed eight machine learning algorithms to identify the optimal ionic absorbent liquid. Sui and Wu [78] also developed an AI model to minimize flow maldistribution in membrane-based absorbers. The discrete model solves matrix equations using MATLAB to predict flow distribution in polymeric flat membrane absorbers (PFMAs). By integrating a genetic algorithm (GA) for design optimization, a uniform flow distribution in PFMAs is achieved. The results obtained from both the discrete model and the optimization model are validated through CFD simulations. Figure 7 shows the flowchart for the calculation process used by the authors, detailing steps such as the definition of design parameters, the processes involved in the discrete and CFD models, flow maldistribution corrections, and the validation and analysis of the final results.

Figure 7.

Flow chart for the optimization process used in this study, including the integration of discrete models, CFD simulations, and AI-assisted tools, adapted from Sui and Wu [78].

Indeed, AI is emerging as a powerful tool in CFD analyses, particularly in modeling absorption systems. Applying AI techniques, such as ANNs and machine learning algorithms, offers new opportunities to optimize simulations and enhance model accuracy, addressing complex and nonlinear challenges. Although the number of studies integrating CFD and AI remains relatively limited compared to the vast potential of these technologies, existing research has already demonstrated promising results. This innovative combination is a research area with significant potential for future exploration, highlighting a substantial gap that can be addressed with advancements in these methodologies.

5. Final Critical Considerations for the Application of CFD Modeling to Absorbers and Desorbers

Figure 8 illustrates the distribution of the articles cited in Table 4 based on the operating mode of the sorption exchanger. In general terms, the literature utilizing CFD analyses in the absorbers or desorbers of absorption chillers remains quite limited. Over the past five years, only 17 studies have been identified in this area.

Figure 8.

Summary of the number of articles that have studied sorption exchangers through CFD in the last 5 years and the exchanger technology used.

Research on the CFD analysis of absorbers has attracted more attention than that of desorbers, primarily due to the critical role that absorbers play in determining the efficiency and performance of absorption systems [7]. Absorbers’ heat and mass transfer characteristics are complex and diverse, requiring detailed studies to optimize performance. In contrast, desorbers typically exhibit more straightforward thermal processes, resulting in less emphasis on research in this area [79]. However, the desorber is also a crucial component for miniaturizing and enhancing system efficiency, especially for chillers that operate with the H2O-LiBr fluid pair, where the phase change occurring in the desorber is a typical problem of these systems, mainly due to the challenges related to the crystallization of lithium bromide. Therefore, it should be considered for future research, particularly in analyzing the technologies and fluids involved in desorption.

Most of these studies focus on absorbers, with falling film, membrane, and bubble technologies being the only ones reported (Figure 8). While it is common to find experimental and numerical works on sorption exchangers operating with spray technology, no CFD studies have been identified.

It is also observed that most research primarily investigates hydrodynamic behavior, focusing on the thickness, distribution, and velocity of the flow (Table 4). Consequently, generic models for heat and mass transfer are considered through the governing equations (Table 5). While hydrodynamic studies are fundamental and provide crucial insights into the performance of heat exchangers, there is a clear need for further investigations that consider the nuances of heat and mass transport. For instance, variations in the thermophysical properties of the solution, the effects of surface tension, and the characteristics of the exchanger surface, among others, should be examined. Such studies would contribute to more accurate and in-depth characterizations of heat and mass transfer, primarily aiding in the optimization of these systems.

Typically, articles that conduct a more in-depth study of heat and mass transfer and employ commercial software to solve the governing equations also include an external mass transfer model coupled with the internal models in the form of UDFs for mutual collaboration. However, in the studies presented here, the use of UDFs was limited to variations in fluid properties (Table 5). Moreover, even with the success achieved by applying multiphase models such as VOF and the mixture model, the complexity of interface phenomena is not yet fully understood. Further research is necessary to improve the accuracy in capturing interface dynamics.

Applying AI techniques, such as ANNs and machine learning algorithms, might help optimize simulations and enhance the accuracy of existing models. It is seen that the application of artificial intelligence in computational fluid dynamics modeling for absorbers and desorbers offers significant potential to address challenges related to complex absorption and desorption processes in absorption refrigeration systems. That is why integrating AI with physics-based CFD models (hybrid approaches) enhances accuracy while maintaining consistency with thermodynamic principles, as demonstrated in the literature [25]. Techniques such as ANNs, support vector machines, and genetic algorithms have proven effective. However, their performance depends on specific system characteristics, requiring customized optimization, as has been reported in various studies [23,73,80]. However, the training phase, especially for deep learning models [81], can be computationally demanding [73,74]. Lastly, thorough validation against experimental data or high-fidelity CFD results is critical to ensure the reliability of AI-based models. Establishing standardized benchmarks for comparing AI and traditional methods will be vital for guiding future research and fostering broader adoption in the industry [75].

Regarding the working fluids, more information about the properties of these fluids should be mentioned. Most studies consider the property value constant and use external references to validate the implementation of these data (Table 5). Providing the methods for implementing the properties would facilitate the inclusion of different materials with similar characteristics in future studies. These measures would allow for expanding research with equipment using new fluids, especially new environmentally friendly refrigerants and their combinations, in addition to the traditional H2O-LiBr working pair.

Regarding the future directions on the subject, it can be suggested that integrating physics-based and AI models offers a promising pathway for achieving higher accuracy while reducing computational demand. Another gap to fill is the investigation of innovative refrigerant mixtures with low environmental impact, extending the scope of current research.

6. Conclusions and Recommendations

The survey and discussion of the state of the art regarding the development and modeling in CFD of absorbers and desorbers in absorption chillers have been thoroughly studied and analyzed. A series of conclusions and recommendations on where studies should focus is presented as follows.

6.1. Conclusions

- It was found that the CFD techniques are essential for advancing the understanding of sorption processes, enabling detailed analysis of flow phenomena and the impact of operating parameters;

- AI integration—in particular, machine learning models—has shown potential for optimizing CFD simulations, reducing computational costs, and providing new insights into system behavior;

- Most studies have adopted the VOF method; however, when considering turbulence, the RNG κ-ε method is the most commonly used;

- The H2O-LiBr working fluid is the most extensively studied fluid for CFD-based studies on sorption exchangers for absorption refrigeration systems;

- The primary focus is optimizing absorption and desorption processes by enhancing exchangers and exploring new geometric configurations to improve the absorption or desorption flow of the binary fluid. Additionally, most research is aimed at understanding and enhancing the hydrodynamics of flows in heat and mass exchangers;

- Owing to its ease of implementation regarding flow characteristics, ANSYS FLUENT is widely used to simulate both the absorption and desorption processes, including those involving falling films, membranes, and bubbles. Furthermore, some researchers are developing proprietary codes to study the simultaneous transfer of heat and mass.

6.2. Recommendations

In general, it can be highlighted that, according to a critical review of the state of the art, the application of CFD analyses in the absorbers and desorbers of absorption systems has proven to be an essential tool for developing and optimizing these systems. Still, further investigations are needed to better characterize the flow regime and heat and mass transfer. Several recommendations for future work are suggested:

- ✓

- There is a significant need for the computational study of new technologies such as adiabatic absorbers and desorbers;

- ✓

- More CFD studies must be conducted with desorbers to explore and optimize the performance of these components. CFD modeling can help better understand the thermal phenomena and mass transfer occurring in the desorber, allowing for optimization of its performance and minimizing issues such as crystallization;

- ✓

- The role of new fluids in increasing absorption/desorption capacity is still an ongoing area of research, necessitating further studies in this field;

- ✓

- Potential research could be conducted to compare the behavior of absorption and desorption processes within heat exchangers by applying different multiphase and turbulence models. The goal would be to evaluate the models available in various software tools, identify any differences, and determine which model best represents real-world conditions;

- ✓

- The application of AI techniques, such as ANNs and machine learning algorithms, needs to be further explored, and also, the adaptation of CFD models for large-scale systems and the optimization of the results for industrial applications requires further investigation;

- ✓

- Advances have been evident in studies on the absorption process in absorbers and generators. However, gaps still need to be filled, such as models where thermophysical properties are varied, as well as a dynamic interface and more effective desorbent technology.

Author Contributions

Conceptualization, S.C.S.A., J.Â.P.d.C., A.A.V.O., G.d.N.P.L. and Á.A.S.L.; methodology, S.C.S.A., J.Â.P.d.C., A.A.V.O. and G.d.N.P.L.; formal analysis, S.C.S.A., J.Â.P.d.C., A.A.V.O., G.d.N.P.L., Á.A.S.L., H.C.N.S., P.S.A.M., I.C.d.S., A.M.d.A.C. and A.A.; investigation, S.C.S.A., J.Â.P.d.C., A.A.V.O., G.d.N.P.L., Á.A.S.L., H.C.N.S., P.S.A.M., I.C.d.S., A.M.d.A.C. and A.A.; resources, J.Â.P.d.C., A.A.V.O., G.d.N.P.L. and A.A.; data curation, J.Â.P.d.C., A.A.V.O., G.d.N.P.L. and A.A.; writing—original draft preparation, S.C.S.A.; writing—review and editing, S.C.S.A., J.Â.P.d.C., A.A.V.O., G.d.N.P.L., Á.A.S.L., H.C.N.S., P.S.A.M., I.C.d.S., A.M.d.A.C. and A.A.; visualization, S.C.S.A., J.Â.P.d.C., A.A.V.O., G.d.N.P.L., Á.A.S.L., H.C.N.S., P.S.A.M., I.C.d.S., A.M.d.A.C. and A.A.; supervision, J.Â.P.d.C., A.A.V.O., G.d.N.P.L. and A.A.; project administration, J.Â.P.d.C., A.A.V.O., G.d.N.P.L. and A.A.; funding acquisition, J.Â.P.d.C., A.A.V.O., G.d.N.P.L. and A.A. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The first author thanks CAPES for the financial support through the scholarship. The primary author also expresses gratitude to the Federal University of Pernambuco for her doctoral studies. Additionally, the first, second, third, and fifth authors extend their appreciation to the IFPE for its support in the development of this work. Both the second and third authors express their gratitude to the IFPE for the financial support through Call No. 43/2023/Propesq. The third author also thanks CNPq for productivity grant number 3303417/2022-6. Furthermore, the fourth author acknowledges CNPq for its support through post-doctoral grant number 200820/2022–2 under Call 26/2021, productivity grant number 303200/2023-5, and universal call grant number 422051/2023-3.

Conflicts of Interest

The authors declare no conflict of interest.

References

- IEA Cooling. Available online: www.iea.org/reports/cooling (accessed on 3 December 2022).

- Chakravarty, K.H.; Sadi, M.; Chakravarty, H.; Sulaiman Alsagri, A.; James Howard, T.; Arabkoohsar, A. A Review on Integration of Renewable Energy Processes in Vapor Absorption Chiller for Sustainable Cooling. Sustain. Energy Technol. Assess. 2022, 50, 101822. [Google Scholar] [CrossRef]

- Kaneesamkandi, Z.; Almujahid, A.; Salim, B. Selection of an Appropriate Solar Thermal Technology for Solar Vapor Absorption Cooling—An MADM Approach. Energies 2022, 15, 1882. [Google Scholar] [CrossRef]

- Altamirano, A.; Stutz, B.; Le Pierrès, N. Review of Small-Capacity Single-Stage Continuous Absorption Systems Operating on Binary Working Fluids for Cooling: Compact Exchanger Technologies. Int. J. Refrig. 2020, 114, 118–147. [Google Scholar] [CrossRef]

- Nikbakhti, R.; Wang, X.; Hussein, A.K.; Iranmanesh, A. Absorption Cooling Systems—Review of Various Techniques for Energy Performance Enhancement. Alex. Eng. J. 2020, 59, 707–738. [Google Scholar] [CrossRef]

- Zhai, C.; Wu, W. Energetic, Exergetic, Economic, and Environmental Analysis of Microchannel Membrane-Based Absorption Refrigeration System Driven by Various Energy Sources. Energy 2022, 239, 122193. [Google Scholar] [CrossRef]

- Amaris, C.; Bourouis, M. Boiling Process Assessment for Absorption Heat Pumps: A Review. Int. J. Heat Mass Transf. 2021, 179, 121723. [Google Scholar] [CrossRef]

- Altamirano, A.; Stutz, B.; Pierrès, N. Le Experimental Characterization of a Three-Dimensional-Printed Adiabatic Desorber for Absorption Chillers. Heat Transf. Eng. 2022, 43, 1867–1884. [Google Scholar] [CrossRef]

- Zhai, C.; Wu, W. Experimental Study on Heat/Mass Transfer and Pressure Drop of Plate Heat Exchanger Desorber for Compact and Efficient Absorption Cooling. Int. J. Refrig. 2023, 145, 243–255. [Google Scholar] [CrossRef]

- Ibarra-Bahena, J.; Dehesa-Carrasco, U.; Galindo-Luna, Y.R.; Medina-Caballero, I.L.; Rivera, W. Experimental Performance of a Membrane Desorber with a H2O/LiCl Mixture for Absorption Chiller Applications. Membranes 2022, 12, 1184. [Google Scholar] [CrossRef] [PubMed]

- Lima, A.A.S.; Ochoa, A.A.V.; Da Costa, J.A.P.; Henríquez, J.R. CFD Simulation of Heat and Mass Transfer in an Absorber That Uses the Pair Ammonia/Water as a Working Fluid. Int. J. Refrig. 2019, 98, 514–525. [Google Scholar] [CrossRef]

- Wen, T.; Lu, L.; Luo, Y. Review on the Fundamentals and Investigations of Falling Film Dehumidification/Absorption Refrigeration Based on CFD Technology. Int. J. Heat Mass Transf. 2021, 171, 121042. [Google Scholar] [CrossRef]

- Narváez-Romo, B.; Chhay, M.; Zavaleta-Aguilar, E.W.; Simões-Moreira, J.R. A Critical Review of Heat and Mass Transfer Correlations for LiBr-H2O and NH3-H2O Absorption Refrigeration Machines Using Falling Liquid Film Technology. Appl. Therm. Eng. 2017, 123, 1079–1095. [Google Scholar] [CrossRef]

- Wirtz, M.; Stutz, B.; Phan, H.T.; Boudehenn, F. Numerical Modeling of Falling-Film Plate Generator and Rectifier Designed for NH3—H2O Absorption Machines. Heat Mass Transf./Waerme-Stoffuebertragung 2022, 58, 431–446. [Google Scholar] [CrossRef]

- Wirtz, M.; Stutz, B.; Phan, H.T.; Boudehenn, F. Performance Improvement of NH3–H2O Absorption Chiller with a Combined Generator. Int. J. Refrig. 2022, 144, 331–341. [Google Scholar] [CrossRef]

- Tao, X.; Thanganadar, D.; Patchigolla, K. Compact Ammonia/Water Absorption Chiller of Different Cycle Configurations: Parametric Analysis Based on Heat Transfer Performance. Energies 2022, 15, 6511. [Google Scholar] [CrossRef]

- Sehgal, S.; Alvarado, J.L.; Hassan, I.G.; Kadam, S.T. A Comprehensive Review of Recent Developments in Falling-Film, Spray, Bubble and Microchannel Absorbers for Absorption Systems. Renew. Sustain. Energy Rev. 2021, 142, 110807. [Google Scholar] [CrossRef]

- Lima, A.A.S.; Leite, G.d.N.P.; Ochoa, A.A.V.; Dos Santos, C.A.C.; da Costa, J.A.P.; Michima, P.S.A.; Caldas, A.M.A. Absorption Refrigeration Systems Based on Ammonia as Refrigerant Using Different Absorbents: Review and Applications. Energies 2021, 14, 48. [Google Scholar] [CrossRef]

- Amaris, C.; Vallès, M.; Bourouis, M. Vapour Absorption Enhancement Using Passive Techniques for Absorption Cooling/Heating Technologies: A Review. Appl. Energy 2018, 231, 826–853. [Google Scholar] [CrossRef]

- Ghasem, N. Combining CFD and AI/ML Modeling to Improve the Performance of Polypropylene Fluidized Bed Reactors. Fluids 2024, 9, 298. [Google Scholar] [CrossRef]

- Li, H.; Spelman, D.; Sansalone, J. Coupling Computational Fluid Dynamics and Artificial Intelligence for Sustainable Urban Water Management and Treatment. Environ. Sci. Proc. 2022, 21, 87. [Google Scholar]

- Usman, A.; Rafiq, M.; Saeed, M.; Nauman, A.; Almqvist, A.; Liwicki, M. Machine Learning Computational Fluid Dynamics. In Proceedings of the 2021 Swedish Artificial Intelligence Society Workshop (SAIS), Luleå, Sweden, 14–15 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–4. [Google Scholar]

- Mao, R.; Zhang, M.; Wang, Y.; Li, H.; Xu, J.; Dong, X.; Zhang, Y.; Chen, Z.X. An Integrated Framework for Accelerating Reactive Flow Simulation Using GPU and Machine Learning Models. Proc. Combust. Inst. 2024, 40, 105512. [Google Scholar] [CrossRef]

- Ribeiro, M.D.; Rehman, A.; Ahmed, S.; Dengel, A. DeepCFD: Efficient Steady-State Laminar Flow Approximation with Deep Convolutional Neural Networks. arXiv 2021, arXiv:2004.08826. [Google Scholar]

- Panahizadeh, F.; Hamzehei, M.; Farzaneh-Gord, M.; Villa, A.A.O. Evaluation of Machine Learning-Based Applications in Forecasting the Performance of Single Effect Absorption Chiller Network. Therm. Sci. Eng. Progress. 2021, 26, 101087. [Google Scholar] [CrossRef]

- Sui, Z.; Sui, Y.; Wu, W. Multi-Objective Optimization of a Microchannel Membrane-Based Absorber with Inclined Grooves Based on CFD and Machine Learning. Energy 2022, 240, 122809. [Google Scholar] [CrossRef]

- May Tzuc, O.; Chan-González, J.J.; Castañeda-Robles, I.E.; Lezama-Zárraga, F.; Moheno-Barrueta, M.; Jiménez Torres, M.; Best, R. Multivariate Inverse Artificial Neural Network to Analyze and Improve the Mass Transfer of Ammonia in a Plate Heat Exchanger-Type Absorber with NH3/H2O for Solar Cooling Applications. Energy Explor. Exploit. 2022, 40, 1686–1711. [Google Scholar] [CrossRef]

- Mahamoudou, A.; Le Pierrès, N.; Ramousse, J. Review of Coupled Heat and Mass Transfer Studies in Falling Film Absorbers: Modeling, Experimental and Thermodynamic Approaches. Int. J. Refrig. 2022, 136, 229–244. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Qi, D.; Ji, W.T.; Jin, P.H.; Tao, W.Q. A Comprehensive Review on Computational Studies of Falling Film Hydrodynamics and Heat Transfer on the Horizontal Tube and Tube Bundle. Appl. Therm. Eng. 2022, 202, 117869. [Google Scholar] [CrossRef]

- Zhai, C.; Wu, W.; Coronas, A. Membrane-Based Absorption Cooling and Heating: Development and Perspectives. Renew. Energy 2021, 177, 663–688. [Google Scholar] [CrossRef]

- Sui, Z.; Wu, W. A Comprehensive Review of Membrane-Based Absorbers/Desorbers towards Compact and Efficient Absorption Refrigeration Systems. Renew. Energy 2022, 201, 563–593. [Google Scholar] [CrossRef]

- Asfand, F.; Bourouis, M. A Review of Membrane Contactors Applied in Absorption Refrigeration Systems. Renew. Sustain. Energy Rev. 2015, 45, 173–191. [Google Scholar] [CrossRef]

- Anderson, D.A.; Tannehill, J.C.; Pletcher, R.H.; Munipalli, R.; Shankar, V. Computational Fluid Mechanics and Heat Transfer, 4th ed.; CRC Press: New York, NY, USA, 2021. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; John Wiley & Sons Inc.: New York, NY, USA, 1995. [Google Scholar]

- Ansys Fluent Overview. Available online: https://www.ansys.com/products/fluids/ansys-fluent#tab1-1 (accessed on 4 April 2024).

- Ansys CFX Overview. Available online: https://www.ansys.com/products/fluids/ansys-cfx (accessed on 4 June 2024).

- OpenFOAM® Documentation. Available online: https://www.openfoam.com/documentation/overview (accessed on 11 September 2024).

- Medina, H.; Beechook, A.; Saul, J.; Porter, S.; Aleksandrova, S.; Benjamin, S. Open Source Computational Fluid Dynamics Using OpenFOAM. In Proceedings of the Royal Aeronautical Society, General Aviation Conference, London, UK, 9–10 June 2015. [Google Scholar]

- Yang, R.; Wang, Y.; Li, Y. Numerical Investigations on Flow Boiling Heat Transfer of Ammonia Water Binary Solution (NH3/H2O) in a Horizontal Microchannel. Int. J. Heat Mass Transf. 2021, 171, 121091. [Google Scholar] [CrossRef]

- Sui, Z.; Wu, W.; You, T.; Zheng, Z.; Leung, M. Performance Investigation and Enhancement of Membrane-Contactor Microchannel Absorber towards Compact Absorption Cooling. Int. J. Heat Mass Transf. 2021, 169, 120978. [Google Scholar] [CrossRef]

- Sui, Z.; Zhai, C.; Wu, W. Swirling Flow for Performance Improvement of a Microchannel Membrane-Based Absorber with Discrete Inclined Grooves. Int. J. Refrig. 2021, 130, 382–391. [Google Scholar] [CrossRef]

- Türkmen, U.; Atilgan, İ. Absorbsiyinlu Sogutma Sistemlerinde Mikro Kanallı Absorber ve Desorberin Sayısal Olarak Modellenmesi. J. Polytech. 2023, 27, 1823–1836. [Google Scholar] [CrossRef]

- Zhang, Z.; Hong, A.; Li, X.; Li, H.; Gao, X. Absorption and Desorption of Liquid Film Flowing over a Porous Layer. Int. Commun. Heat Mass Transf. 2019, 108, 104311. [Google Scholar] [CrossRef]

- Andersson, B.; Andersson, R.; Hakansson, L.; Mortensen, M.; Sudiyo, R.; Van Wachem, B. Computational Fluid Dynamics for Engineers; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- COMSOL Multiphysics Reference Manual. Available online: https://doc.comsol.com/5.4/doc/com.comsol.help.comsol/COMSOL_ReferenceManual.pdf (accessed on 14 October 2024).

- Dong, P.; Liu, G.; Liu, F.; Yan, G.; Wang, G. Effect of Structure and Operation Parameters on Heat and Mass Transfer Coefficients of Single-Bubble Absorption for Lithium Bromide Solution. Int. J. Heat Mass Transf. 2023, 201, 123587. [Google Scholar] [CrossRef]

- User Guide. Available online: https://www.openfoam.com/documentation/user-guide (accessed on 7 August 2024).

- Zapata, A.; Amaris, C.; Sagastume, A.; Rodríguez, A. CFD Modelling of the Ammonia Vapour Absorption in a Tubular Bubble Absorber with NH3/LiNO3. Case Stud. Therm. Eng. 2021, 27, 101311. [Google Scholar] [CrossRef]

- Altamirano, A.C. Development of a New Concept of Compact and Low-Cost Absorption Chillers: Application in Solar Cooling for Hot Climates; L’Université Savoie Mont Blanc: Chambéry, France, 2021. [Google Scholar]

- Subramaniam, V.; Chandrasekaran, S.; Garimella, S. A 2-D Numerical Analysis of Heat and Mass Transfer in Lithium Bromide-Water Falling Films and Droplets. Int. J. Heat Mass Transf. 2021, 177, 121518. [Google Scholar] [CrossRef]

- Keizer, C. Absorption Refrigeration Machines; Delft University of Technology: Delft, The Netherlands, 1982. [Google Scholar]

- Shi, Y.; Chen, G.; Wang, Q.; Chen, Q. Simulation on Falling Film Absorption Based on Lattice Boltzmann Method at Moderate Reynolds Number. Int. J. Heat Mass Transf. 2019, 128, 991–998. [Google Scholar] [CrossRef]

- Tahir, F.; Mabrouk, A.; Koç, M. CFD Analysis of Falling Film Hydrodynamics for a Lithium Bromide (LIBr) Solution over a Horizontal Tube. Energies 2020, 13, 307. [Google Scholar] [CrossRef]

- Vakilipour, S.; Hekmatkhah, R. Investigation of Water Vapour Absorption into Wavy Falling Films by Developing a Fully Coupled Interface Tracking Finite Volume Method. Int. J. Heat Mass Transf. 2022, 185, 122397. [Google Scholar] [CrossRef]

- Gao, H.; Mao, F.; Song, Y.; Hong, J.; Yan, Y. Effect of Adding Copper Oxide Nanoparticles on the Mass/Heat Transfer in Falling Film Absorption. Appl. Therm. Eng. 2020, 181, 115937. [Google Scholar] [CrossRef]

- Castro, J.; Oliet, C.; Rodríguez, I.; Oliva, A. Comparison of the Performance of Falling Film and Bubble Absorbers for Air-Cooled Absorption Systems. Int. J. Therm. Sci. 2009, 48, 1355–1366. [Google Scholar] [CrossRef]

- Wu, X.; Xu, S.; Jiang, M. Development of Bubble Absorption Refrigeration Technology: A Review. Renew. Sustain. Energy Rev. 2018, 82, 3468–3482. [Google Scholar] [CrossRef]

- Panahizadeh, F.; Hamzehei, M.; Farzaneh-Gord, M.; Villa, A.A.O. Numerical Study on Heat and Mass Transfer Behavior of Pool Boiling in LiBr/H2O Absorption Chiller Generator Considering Different Tube Surfaces. Therm. Sci. 2021, 25, 1599–1610. [Google Scholar] [CrossRef]

- Mohamed, S.A.; Karimi, N. Analysis and Optimization of Vapor Absorption Generator-Heat Exchanger Using Kern Method and Cfd. J. Therm. Eng. 2020, 6, 440–459. [Google Scholar] [CrossRef]

- Zapata, A.; Amaris, C.; Sagastume, A.; Rodríguez, A. Vapour Absorption Process in an NH3/LiNO3 Bubble Absorber Using an Optimized Cfd Model. Front. Heat Mass Transf. 2022, 19, 1–9. [Google Scholar] [CrossRef]

- Zerweck, K. Ein- oder mehrstufige Absorptions- oder Adsorptionsmaschine. Patent DE3009820A1, 19 March 1980. Available online: https://patents.google.com/patent/DE3009820A1/de (accessed on 20 December 2024).

- Ibarra-Bahena, J.; Raman, S.; Galindo-Luna, Y.R.; Rodríguez-Martínez, A.; Rivera, W. Role of Membrane Technology in Absorption Heat Pumps: A Comprehensive Review. Membranes 2020, 10, 216. [Google Scholar] [CrossRef] [PubMed]

- Sui, Z.; Zhai, C.; Wu, W. Parametric and Comparative Study on Enhanced Microchannel Membrane-Based Absorber Structures for Compact Absorption Refrigeration. Renew. Energy 2022, 187, 109–122. [Google Scholar] [CrossRef]

- Medina-Caballero, I.L.; Rivera, W.; Ituna-Yudonago, J.-F.; Ibarra-Bahena, J. Numerical Simulation of a Membrane Desorber with the H2O-LiBr Working Mixture for Absorption Cooling Systems. Therm. Sci. Eng. Progress. 2024, 48, 102399. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Yahiaoui, A.; Garkuwa, J.A.; Mansour, R.B.; Rehman, S. Solar Cooling with Absorption Chillers, Thermal Energy Storage, and Control Strategies: A Review. J. Energy Storage 2024, 97, 112762. [Google Scholar] [CrossRef]

- Wen, T.; Lu, L.; He, W.; Min, Y. Fundamentals and Applications of CFD Technology on Analyzing Falling Film Heat and Mass Exchangers: A Comprehensive Review. Appl. Energy 2020, 261, 114473. [Google Scholar] [CrossRef]

- Wang, Q.; Li, M.; Xu, W.; Yao, L.; Liu, X.; Su, D.; Wang, P. Review on Liquid Film Flow and Heat Transfer Characteristics Outside Horizontal Tube Falling Film Evaporator: Cfd Numerical Simulation. Int. J. Heat Mass Transf. 2020, 163, 120440. [Google Scholar] [CrossRef]

- Zhang, H.; Yin, D.; You, S.; Zheng, W.; Li, B.; Zhang, X. Numerical and Experimental Investigation on the Heat and Mass Transfer of Falling Film and Droplet Regimes in Horizontal Tubes LiBr-H2O Absorber. Appl. Therm. Eng. 2019, 146, 752–767. [Google Scholar] [CrossRef]

- Ahmed, R.; Mahadzir, S.; Erniza, B.; Rozali, N.; Biswas, K.; Matovu, F.; Ahmed, K. Artificial Intelligence Techniques in Refrigeration System Modelling and Optimization: A Multi-Disciplinary Review. Sustain. Energy Technol. Assess. 2021, 47, 101488. [Google Scholar] [CrossRef]

- Hosseini, P.; Nikbakht Naserabad, S.; Keshavarzzadeh, A.H.; Ansari, N. Artificial Intelligence-based Tri-objective Optimization of Different Demand Load Patterns on the Optimal Sizing of a Smart Educational Buildings. Int. J. Energy Res. 2022, 46, 21373–21396. [Google Scholar] [CrossRef]

- Sousa Alcântara, S.C.; Villa Ochoa, A.A.; da Costa, J.Â.P.; de Menezes, F.D.; de Novaes Pires Leite, G.; Arruda Michima, P.S.; da Silva Marques, A. Development of a Method for Predicting the Transient Behavior of an Absorption Chiller Using Artificial Intelligence Methods. Appl. Therm. Eng. 2023, 231, 120978. [Google Scholar] [CrossRef]

- Al-Rbaihat, R.; Alahmer, H.; Alahmer, A.; Altork, Y.; Al-Manea, A.; Awwad, K.Y.E. Energy and Exergy Analysis of a Subfreezing Evaporator Environment Ammonia-Water Absorption Refrigeration Cycle: Machine Learning and Parametric Optimization. Int. J. Refrig. 2023, 154, 182–204. [Google Scholar] [CrossRef]

- Ashouri, M.; Kheyrikoochaksarayee, N.; Chhokar, C.; Shabani, A.; Bahrami, M. A Big Data-Handling Machine Learning Model for Membrane-Based Absorber Reactors in Sorption Heat Transformers. Energy Convers. Manag. 2023, 292, 117376. [Google Scholar] [CrossRef]

- Zhai, C.; Sui, Y.; Wu, W. Machine Learning-Assisted Correlations of Heat/Mass Transfer and Pressure Drop of Microchannel Membrane-Based Desorber/Absorber for Compact Absorption Cycles. Int. J. Heat Mass Transf. 2023, 214, 124431. [Google Scholar] [CrossRef]

- Bard, A.; Qiu, Y.; Kharangate, C.R.; French, R. Consolidated Modeling and Prediction of Heat Transfer Coefficients for Saturated Flow Boiling in Mini/Micro-Channels Using Machine Learning Methods. Appl. Therm. Eng. 2022, 210, 118305. [Google Scholar] [CrossRef]

- Sundar, L.S.; Mewada, H.K.; Sangaraju, S. Experimental and Ensemble Machine Learning Analyses of Heat Transfer, Friction Factor and Thermal Performance Factor of RGO/Water Nanofluids in a Tube. Int. J. Thermofluids 2024, 21, 100557. [Google Scholar] [CrossRef]

- Dione, F.; Thiam, A.; Cisse, E.H.I.; Diouf, D.; Maiga, A.S. Theoretical Study of an NH3–H2O Absorption Chiller Powered by a Linear Fresnel System Modelled by Combining Ray Tracing and CFD. Results Eng. 2023, 20, 101410. [Google Scholar] [CrossRef]

- Sui, Z.; Wu, W. AI-Assisted Maldistribution Minimization of Membrane-Based Heat/Mass Exchangers for Compact Absorption Cooling. Energy 2023, 263, 125922. [Google Scholar] [CrossRef]

- Zhai, C.; Wu, W. Heat and Mass Transfer Performance Comparison of Various Absorbers/Desorbers towards Compact and Efficient Absorption Heat Pumps. Int. J. Refrig. 2021, 127, 203–220. [Google Scholar] [CrossRef]