A Greenhouse Profitability Model: The Effect of the Energy System

Abstract

1. Introduction

1.1. Scope

1.2. Recent Literature

2. Materials and Methods

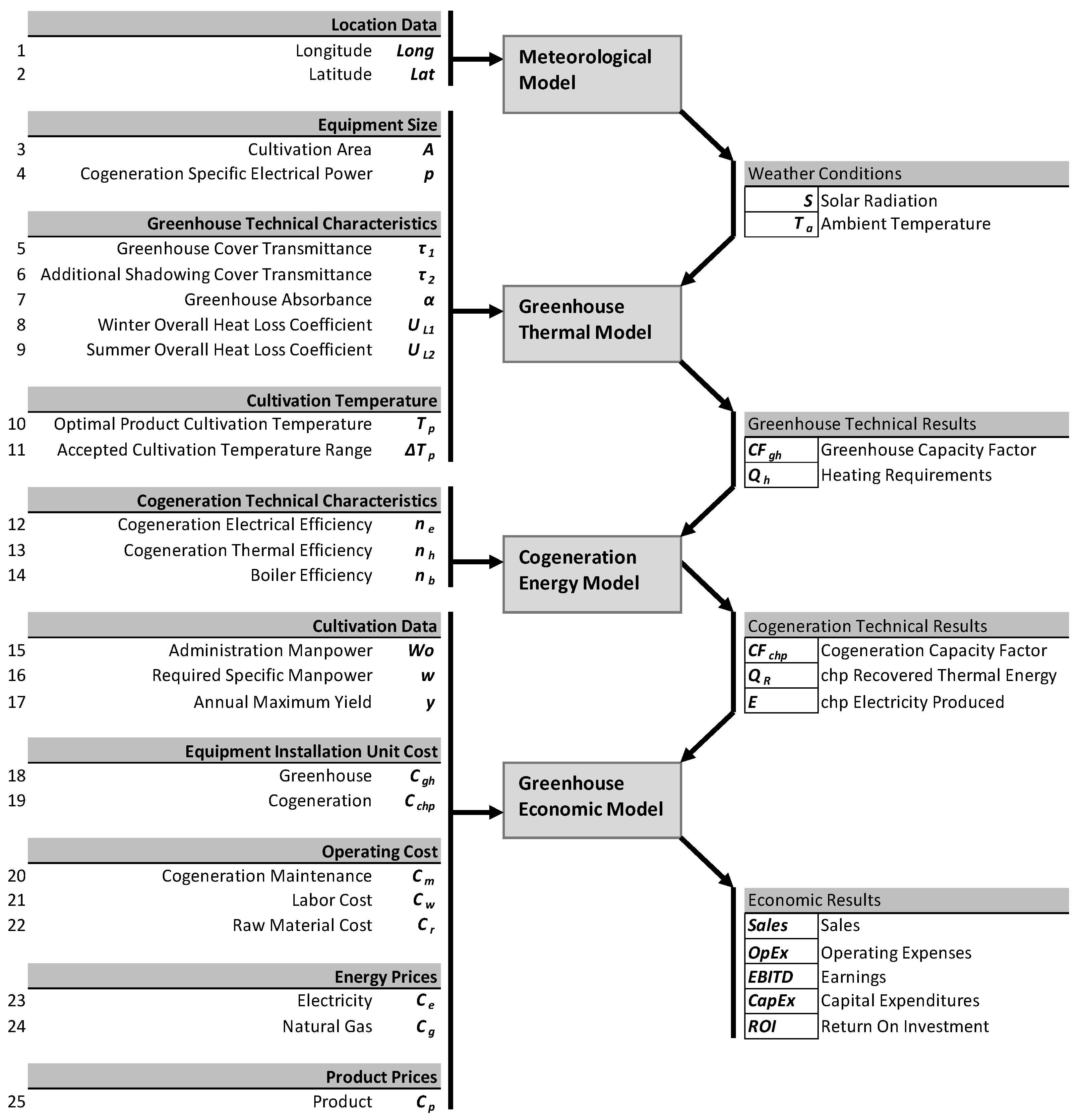

2.1. Mathematical Model

2.2. Greenhouse Technoeconomic Data

3. Results

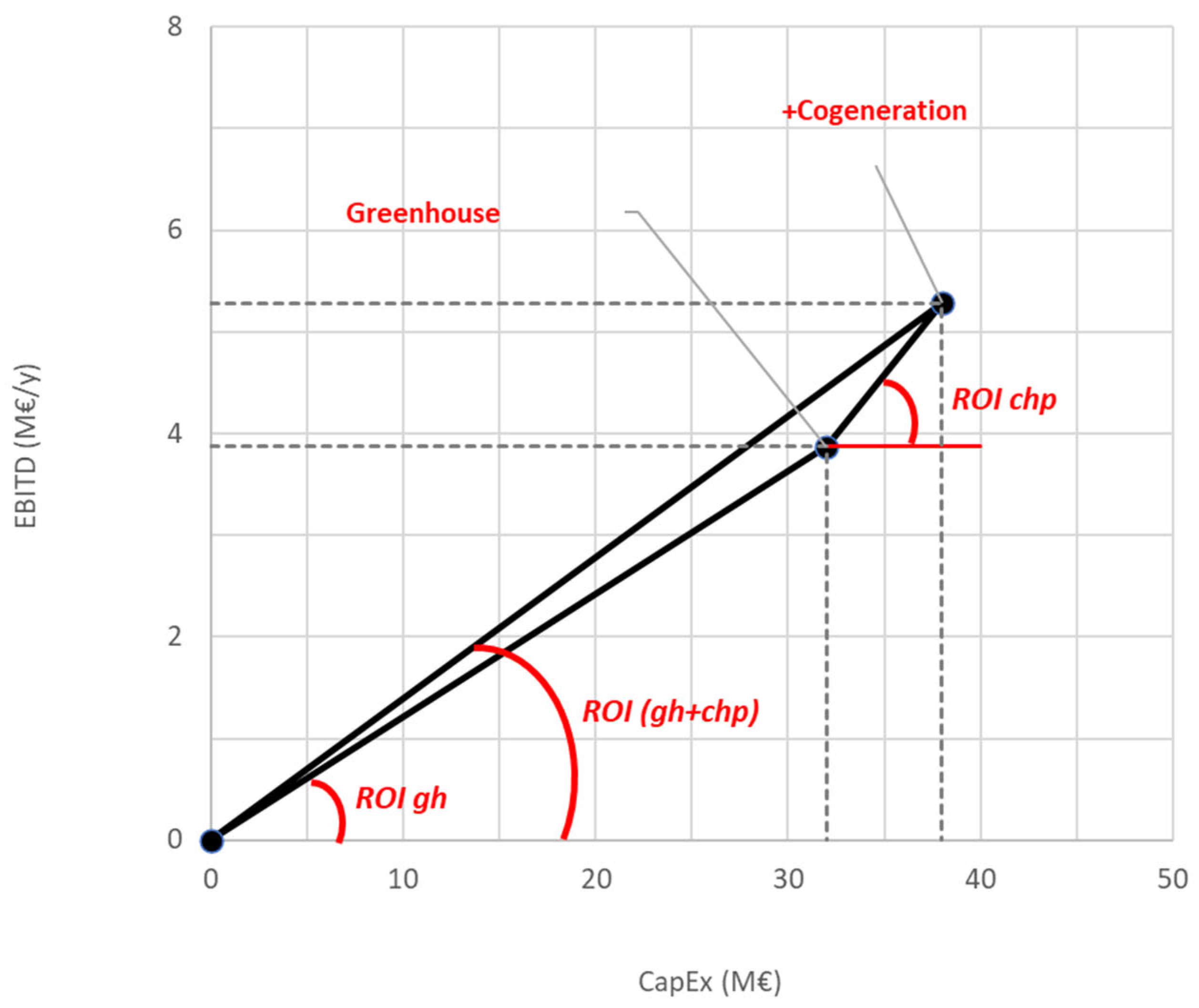

3.1. Base Case

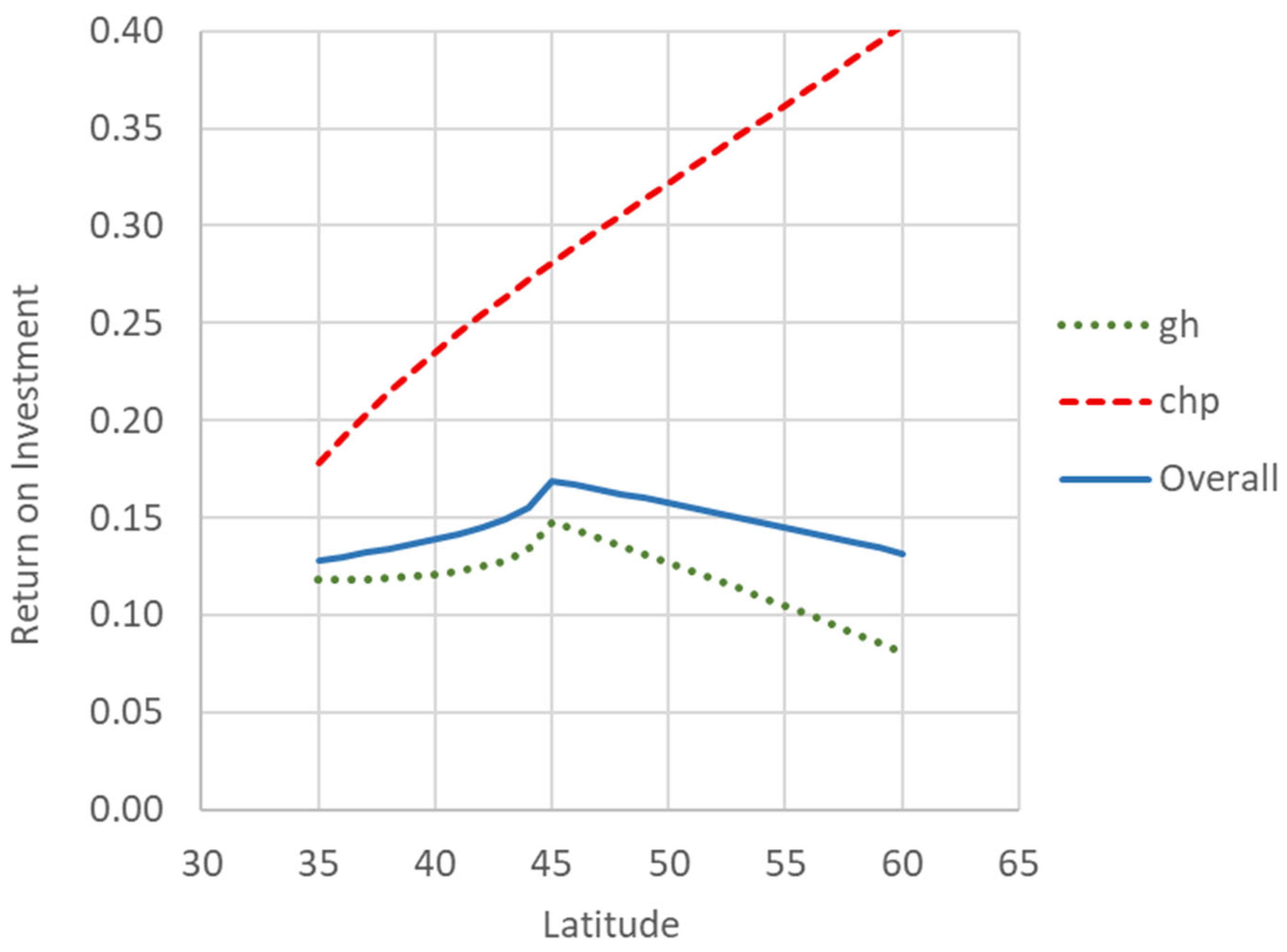

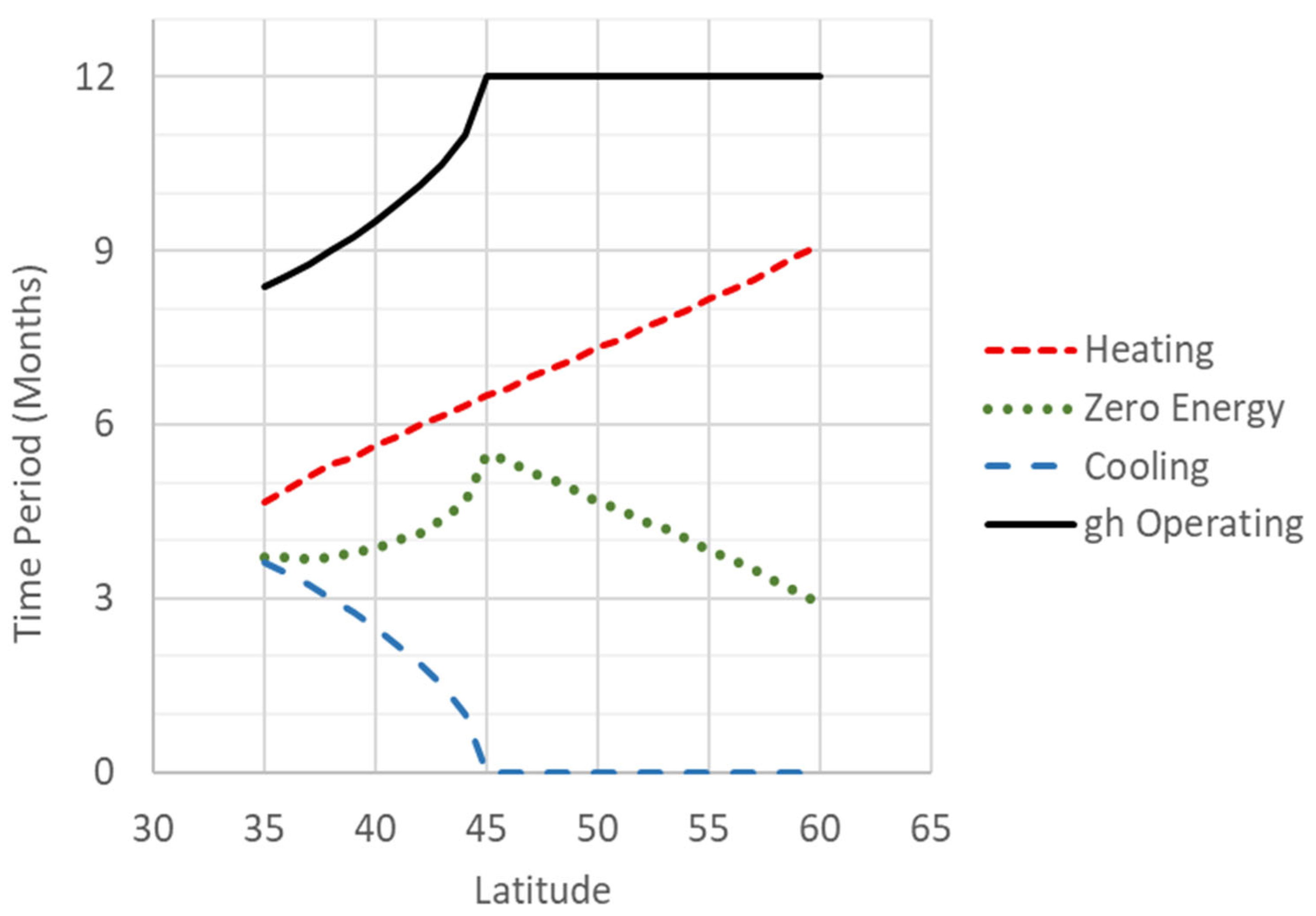

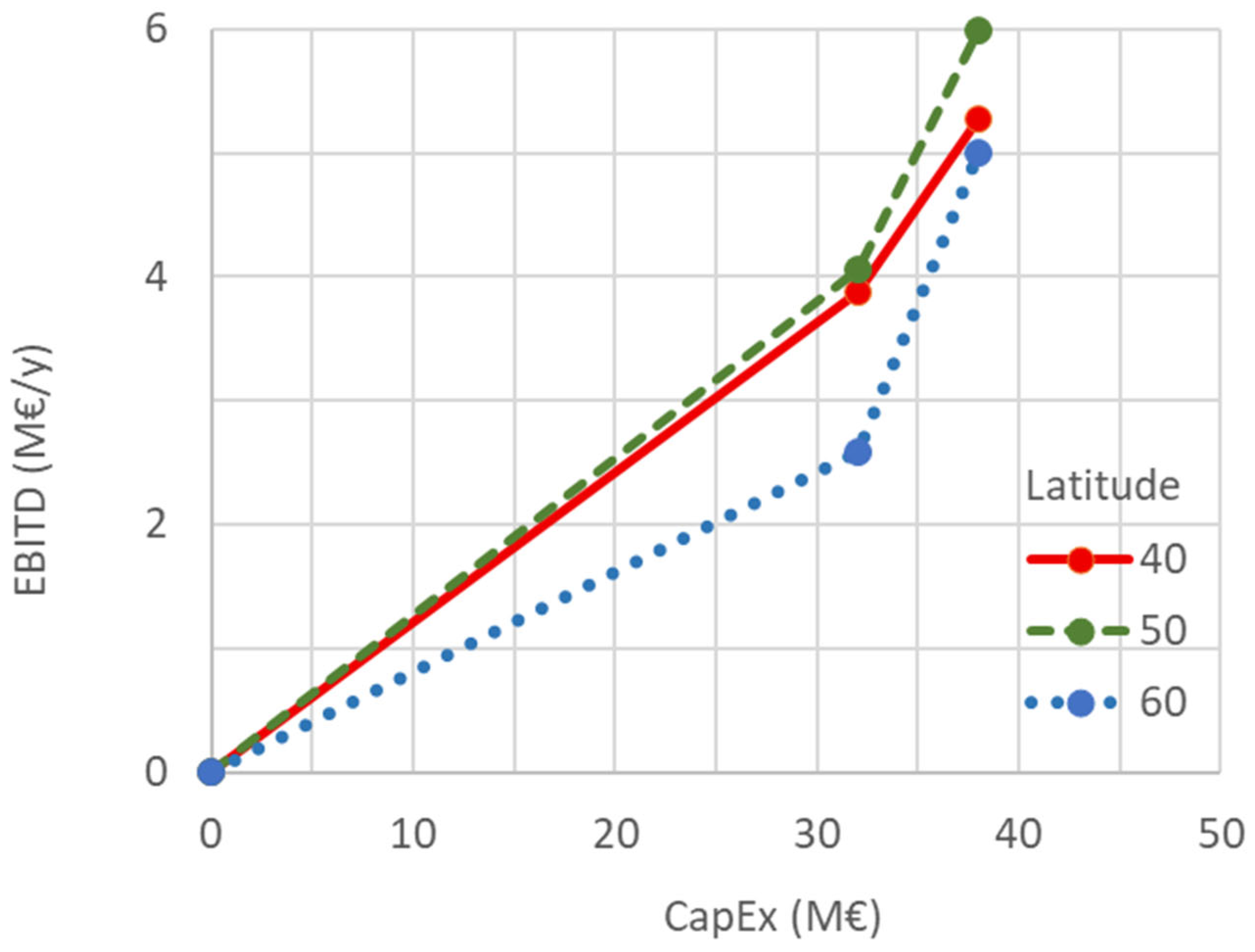

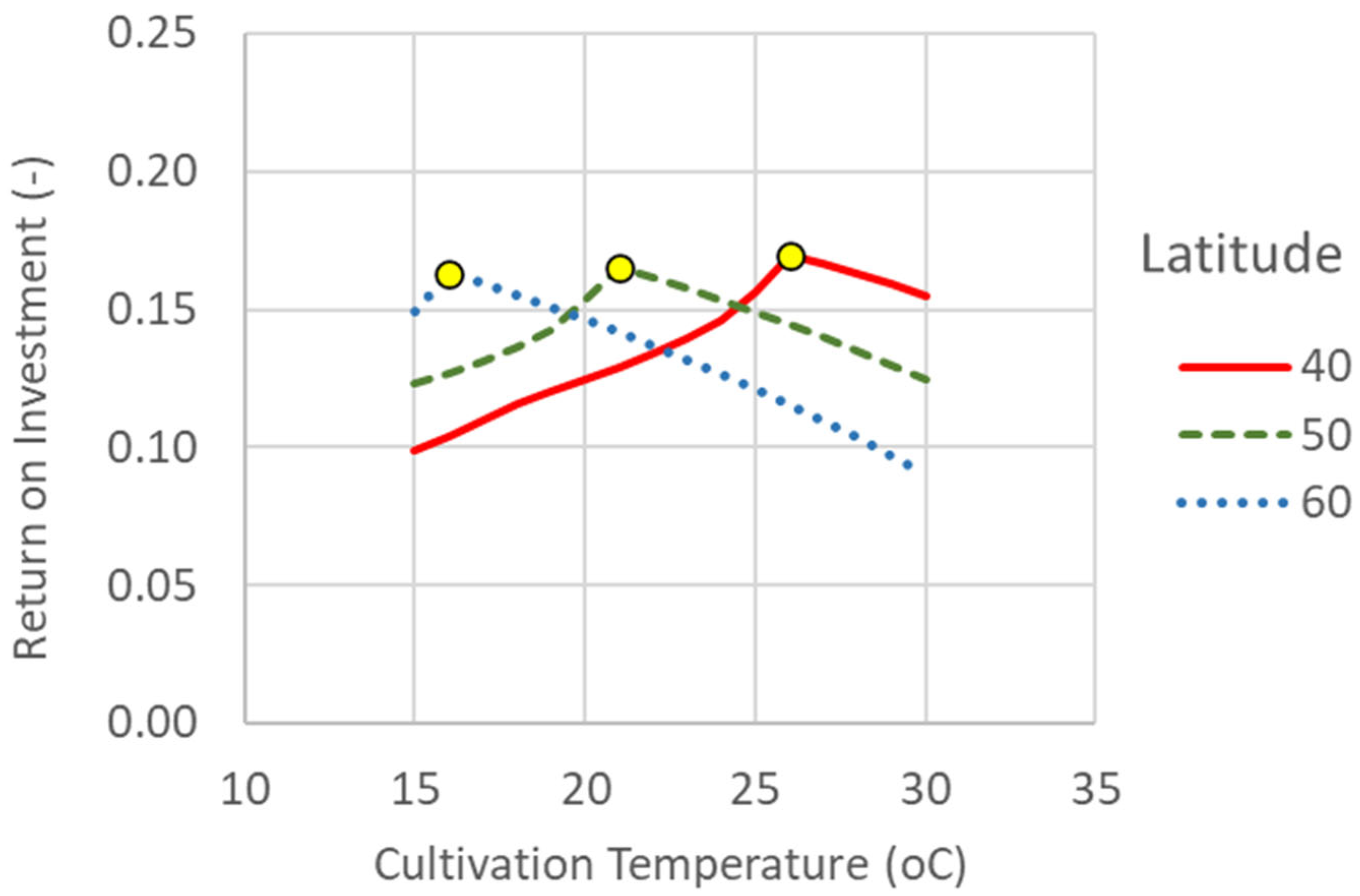

3.2. Latitude Effect

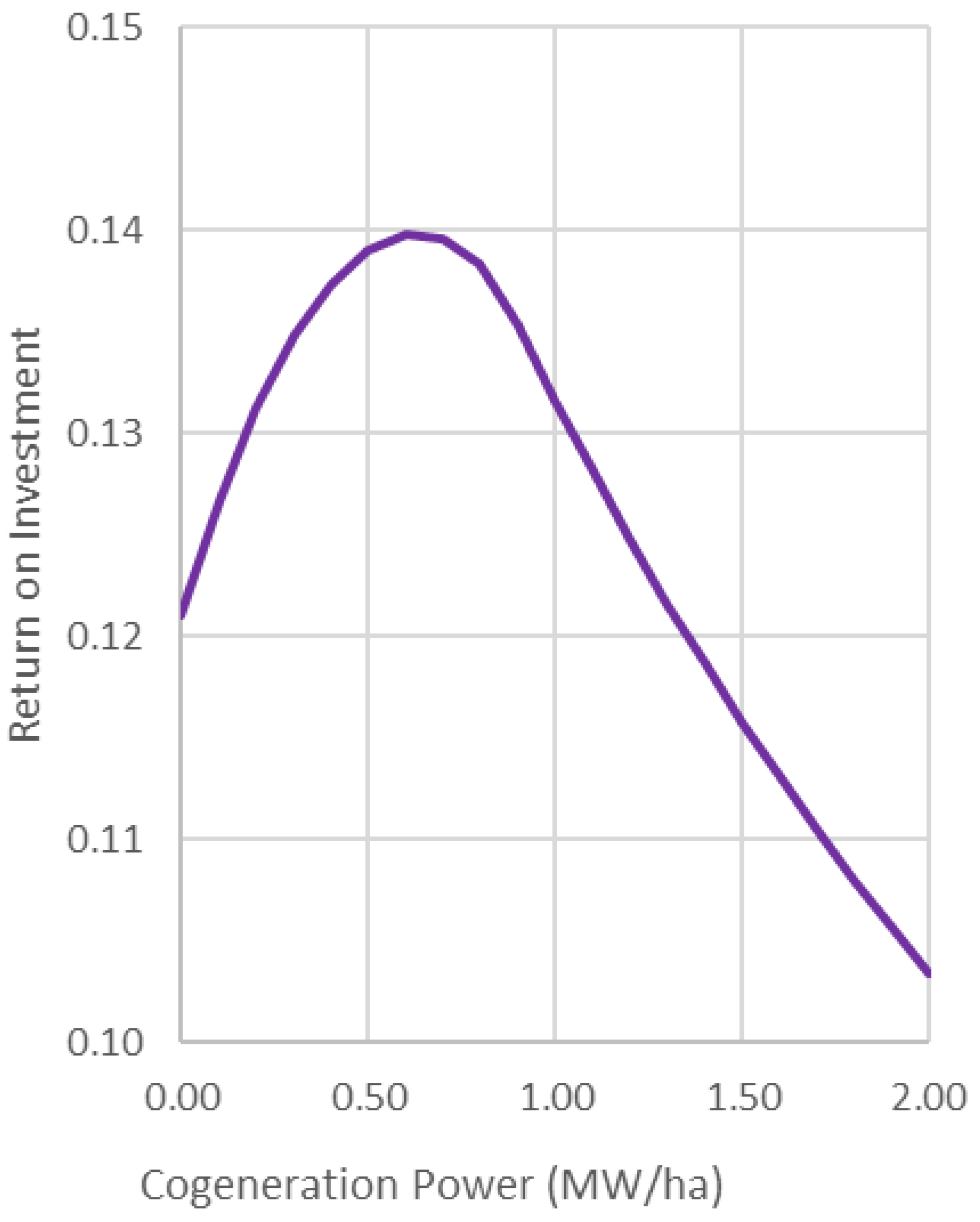

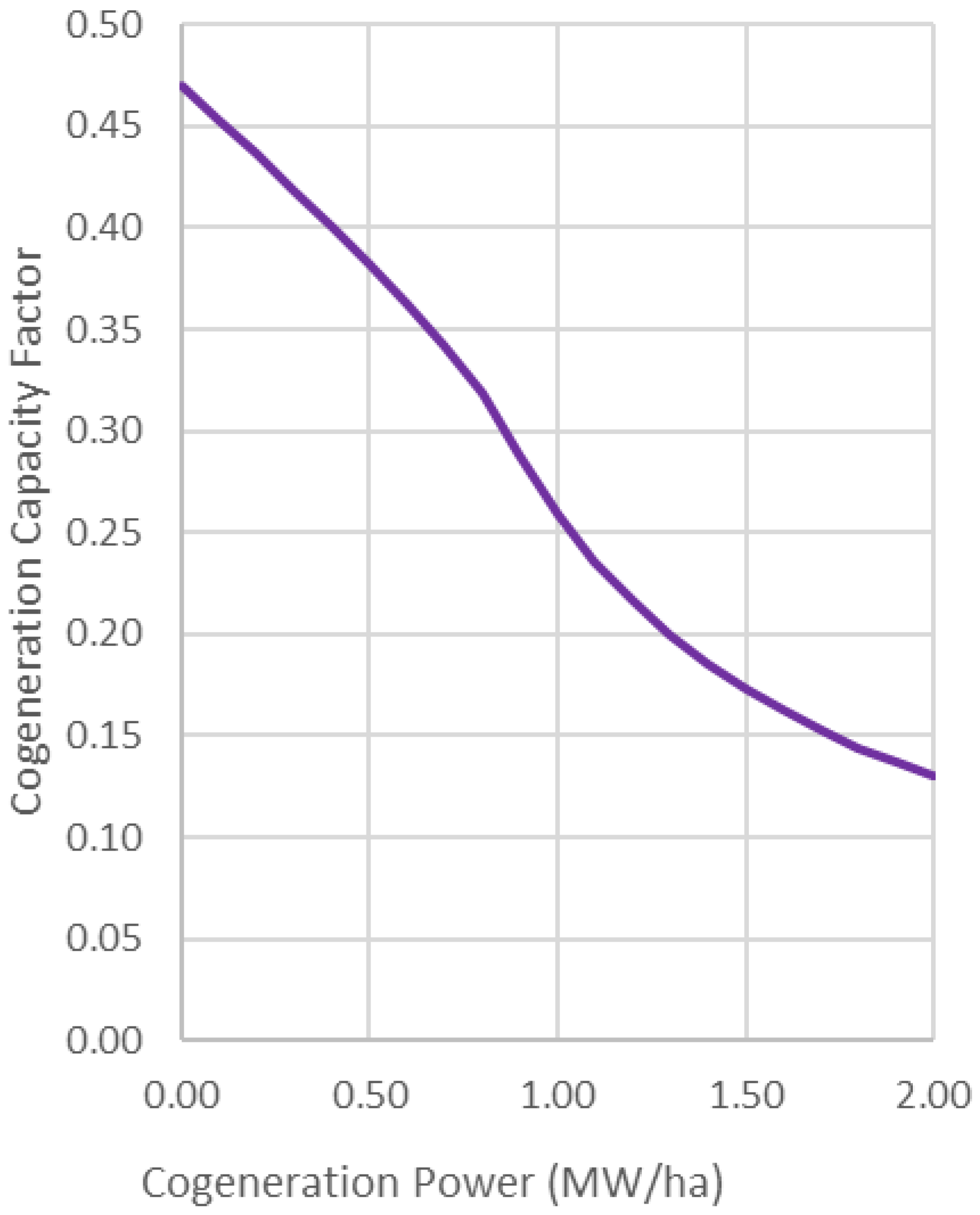

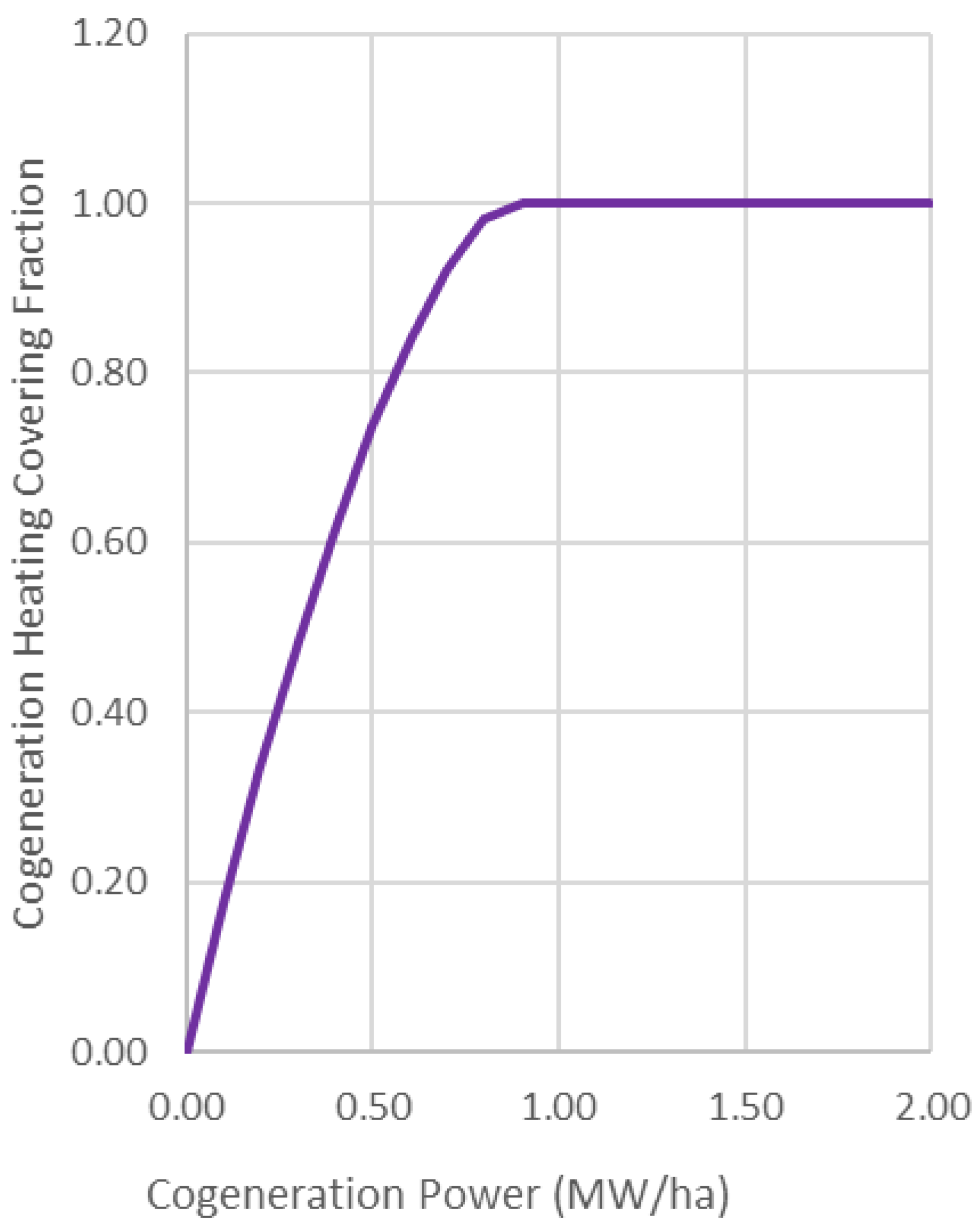

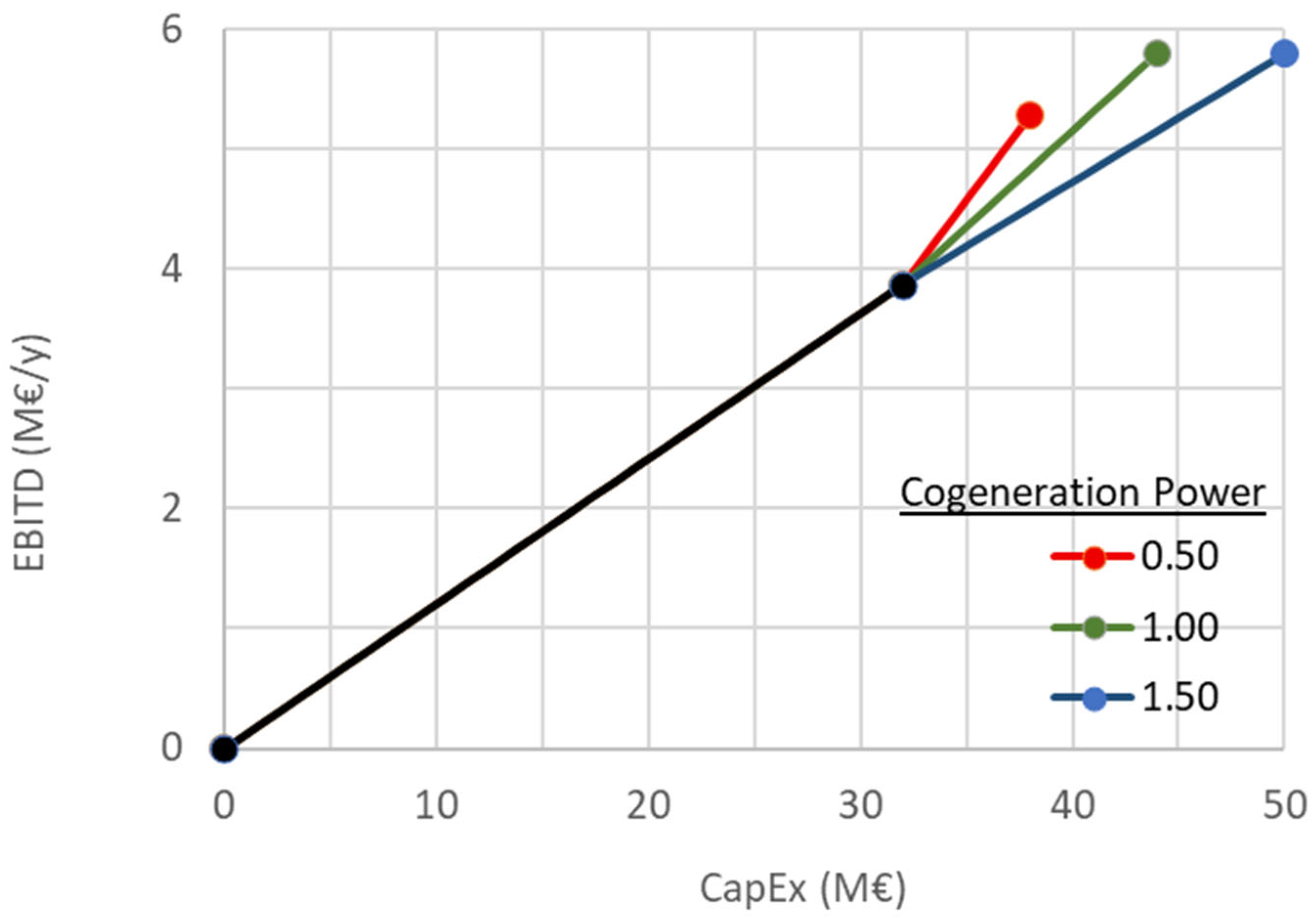

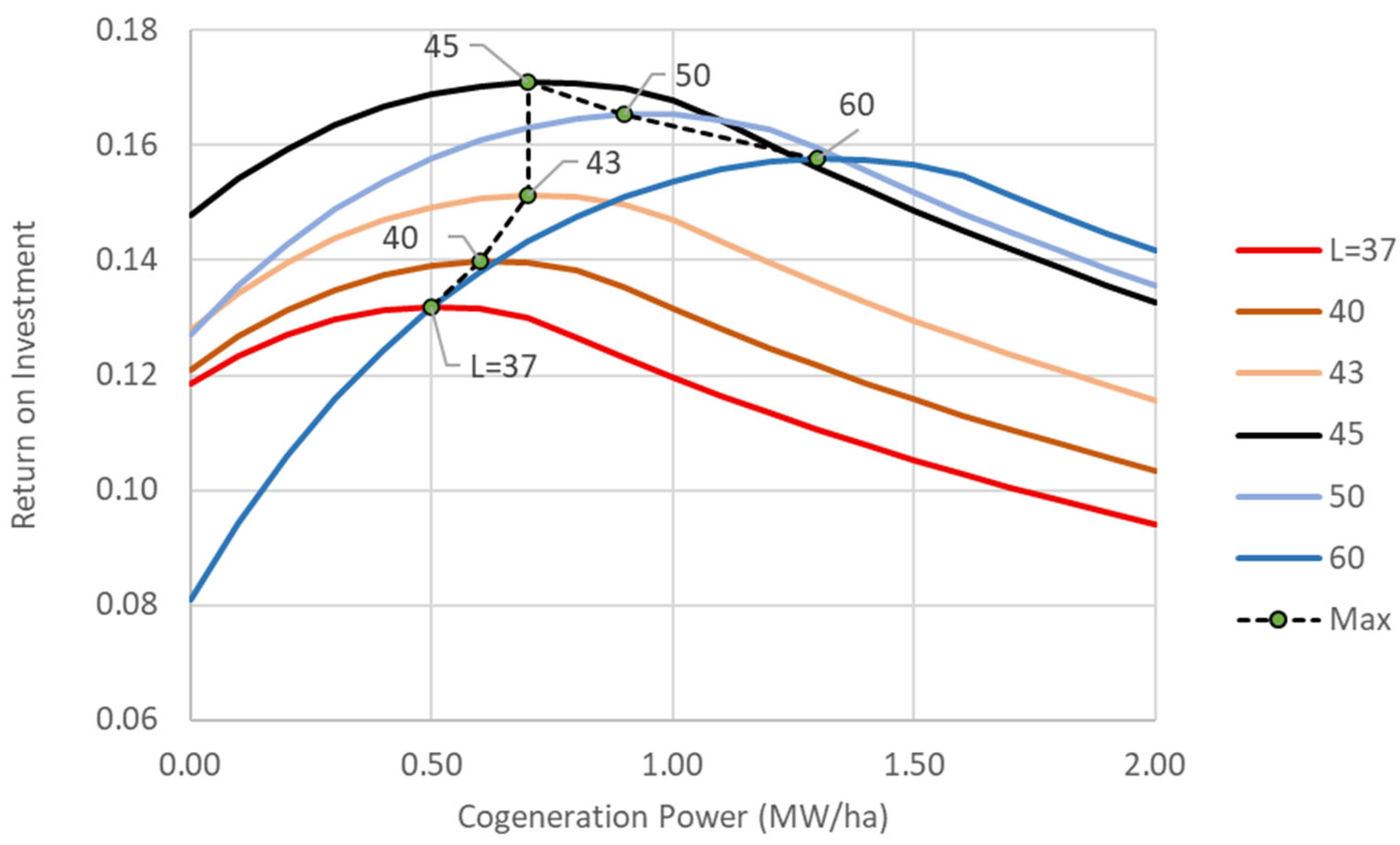

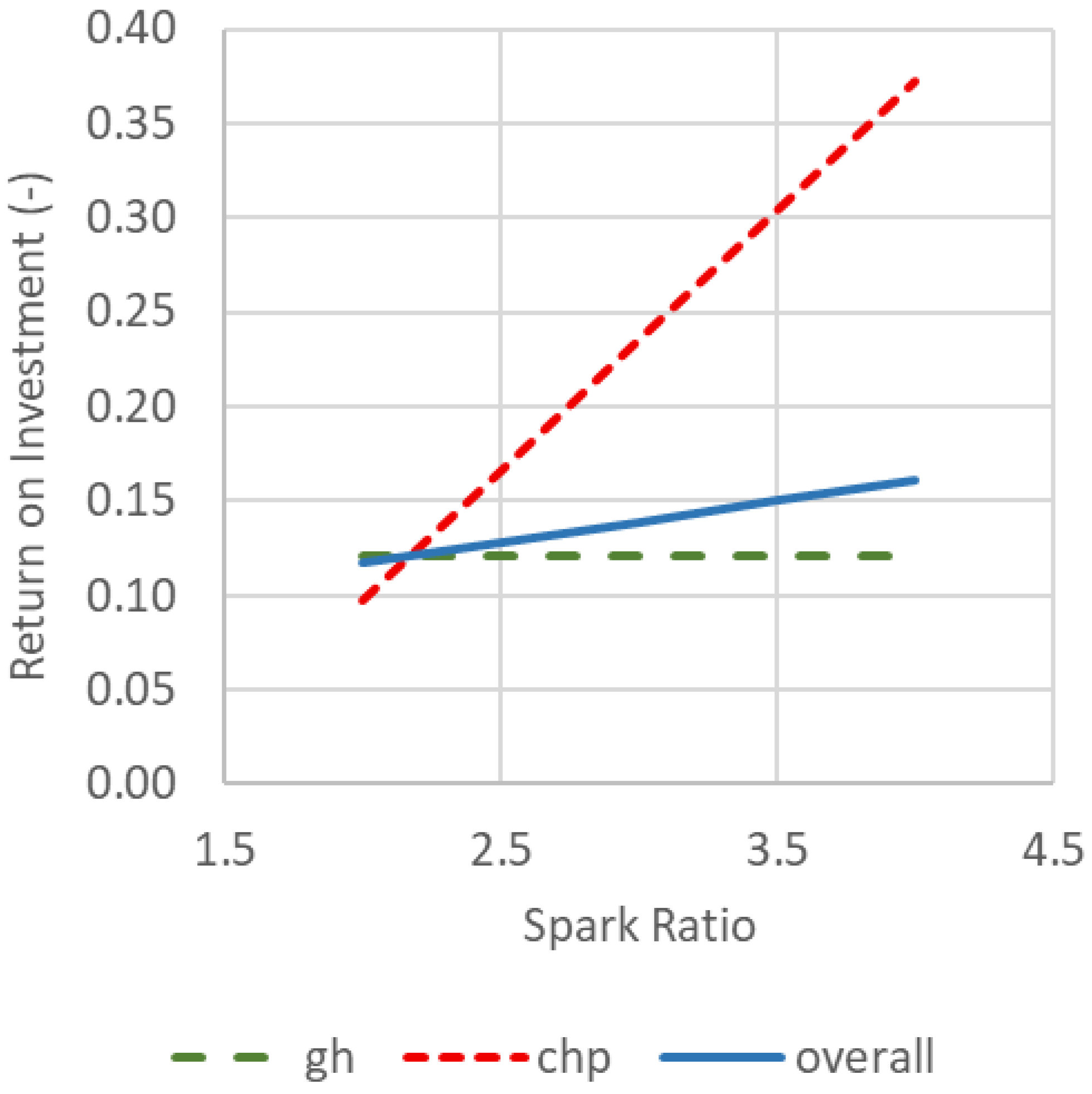

3.3. Cogeneration Size Effect

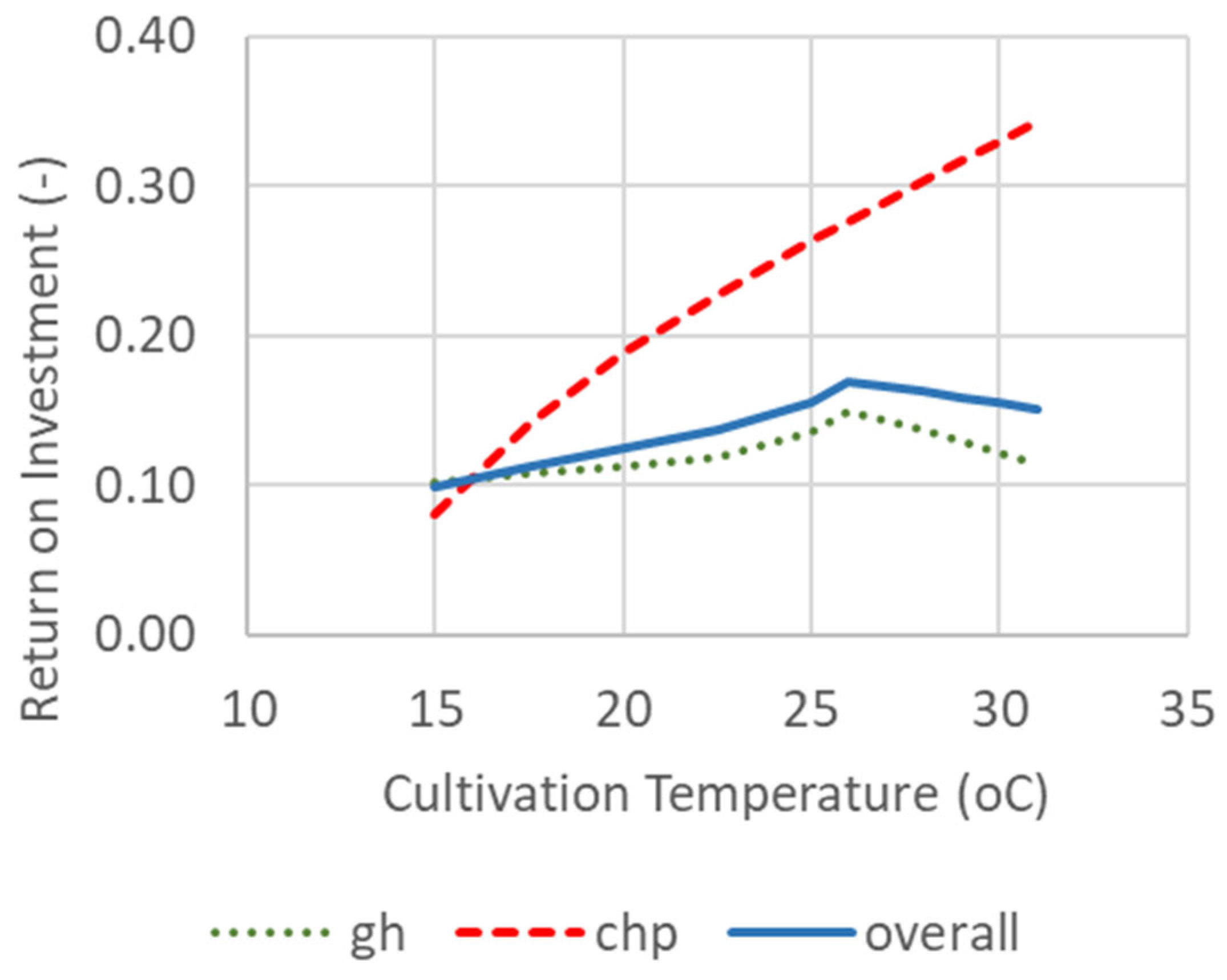

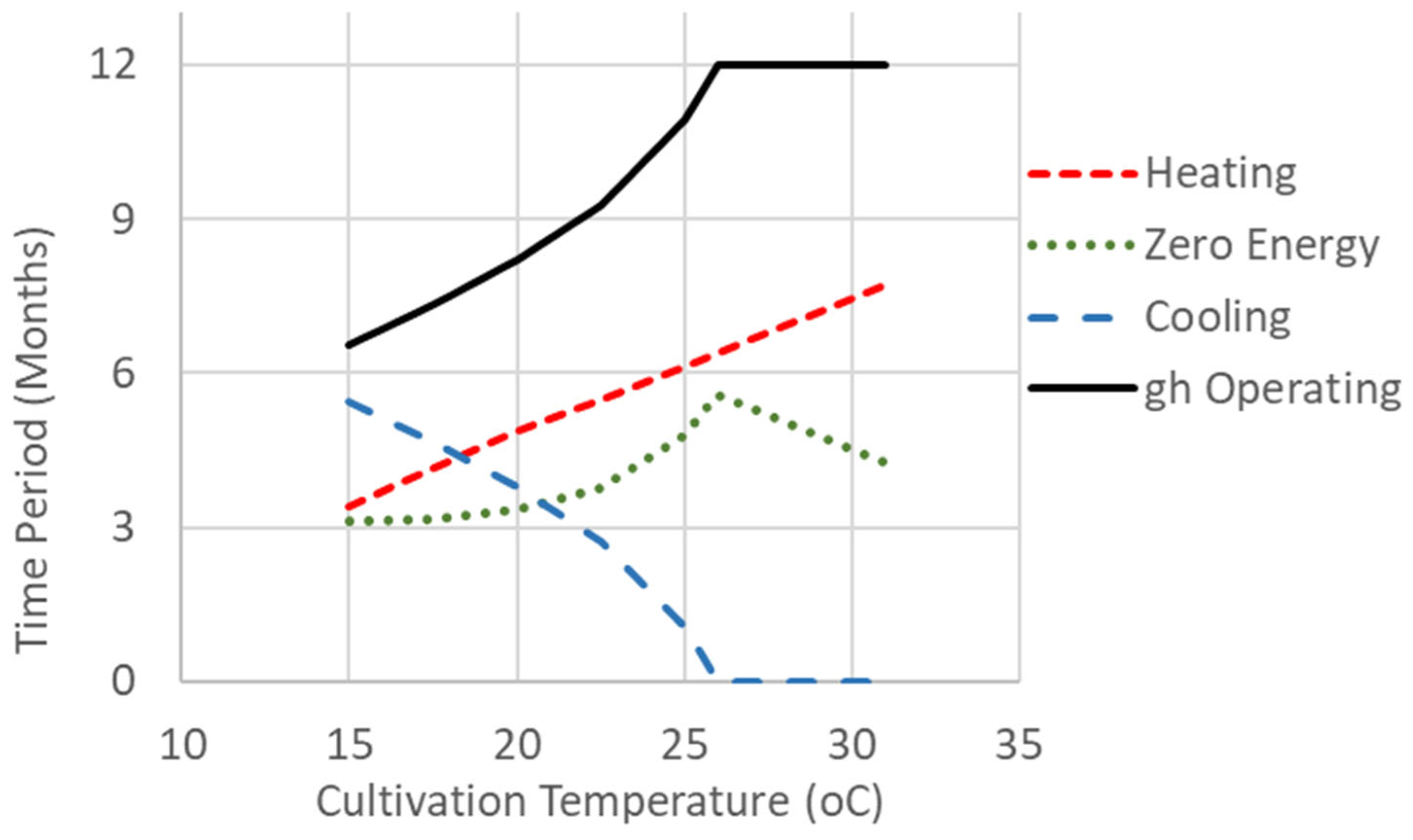

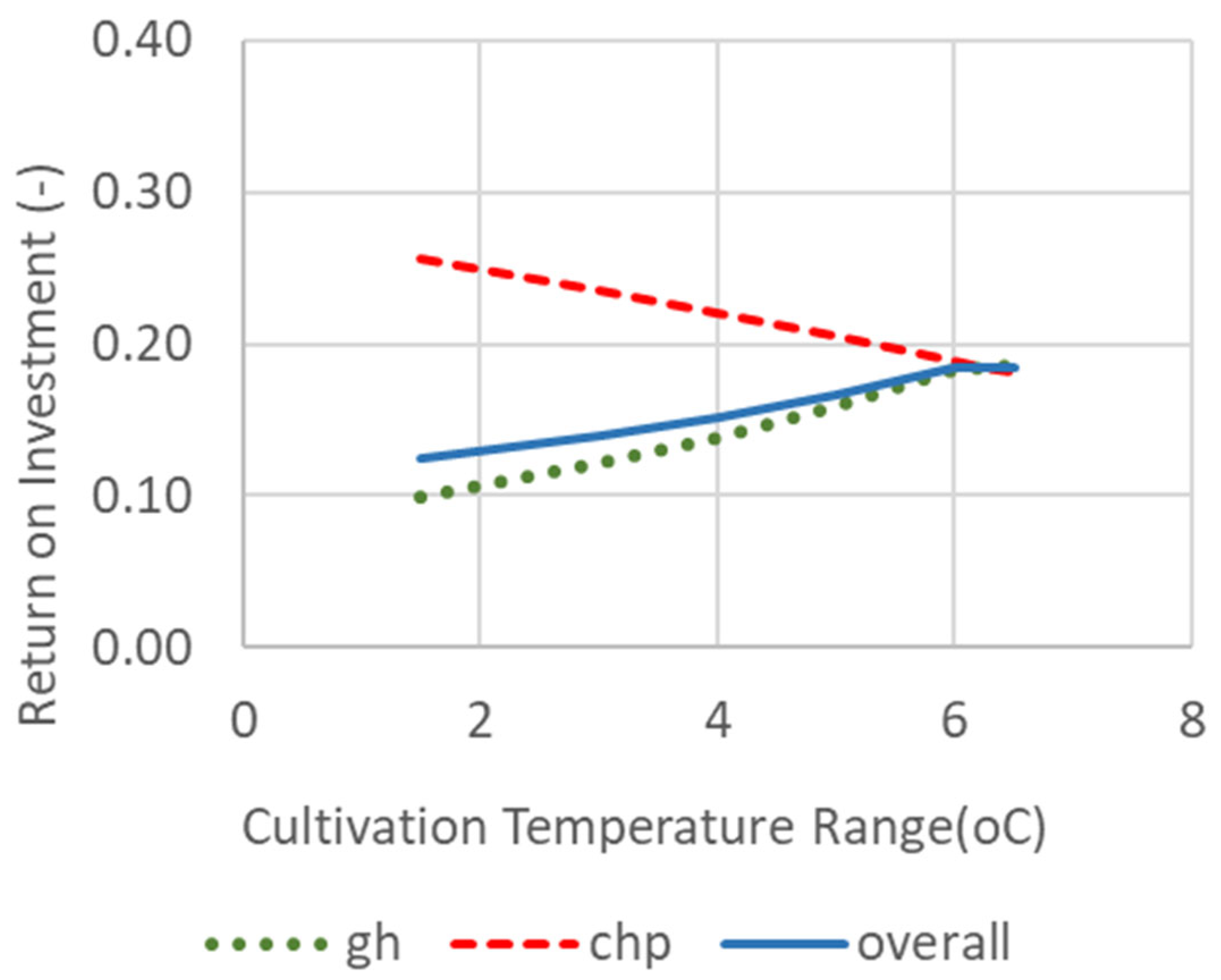

3.4. Cultivation Conditions Effect

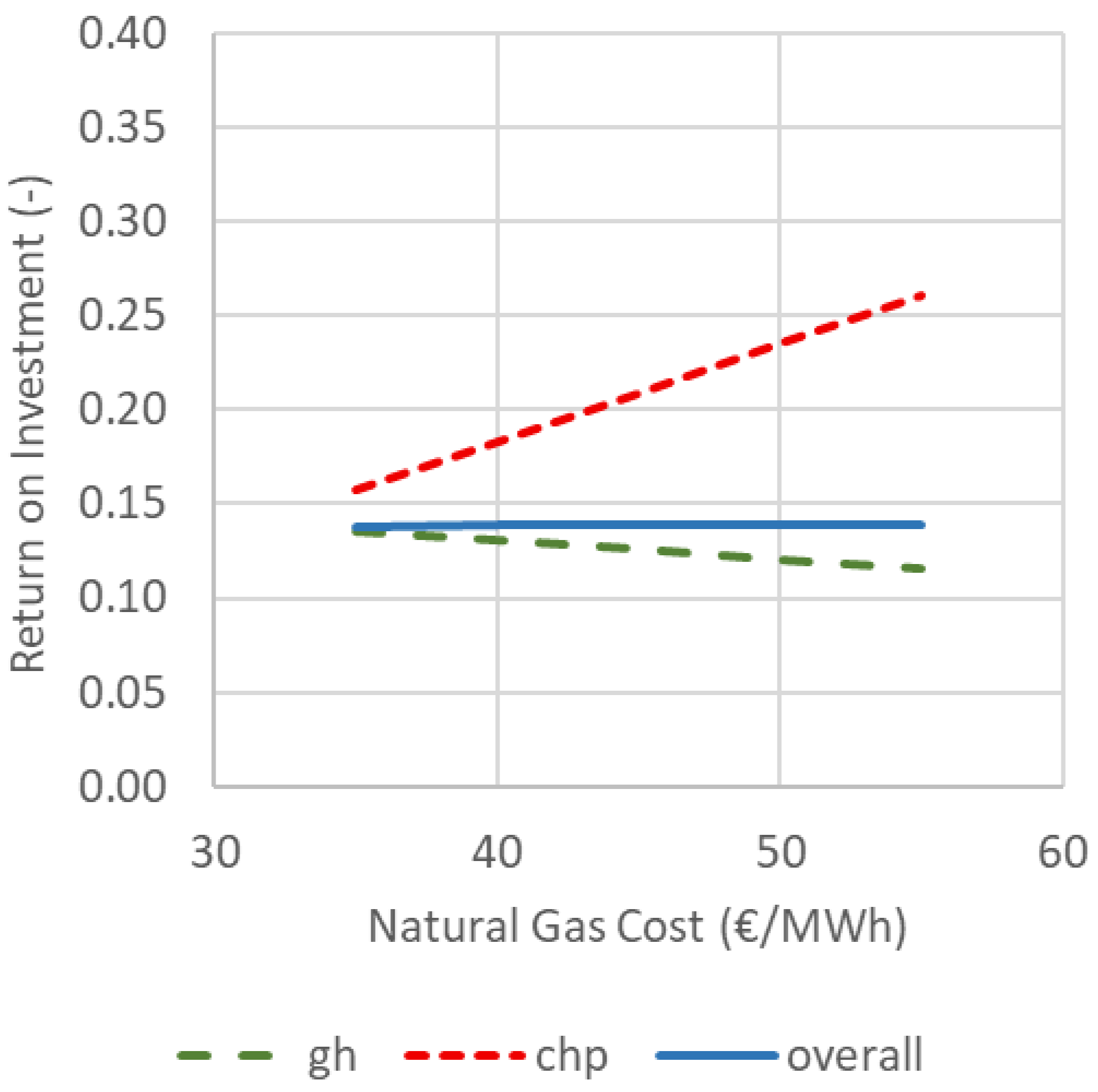

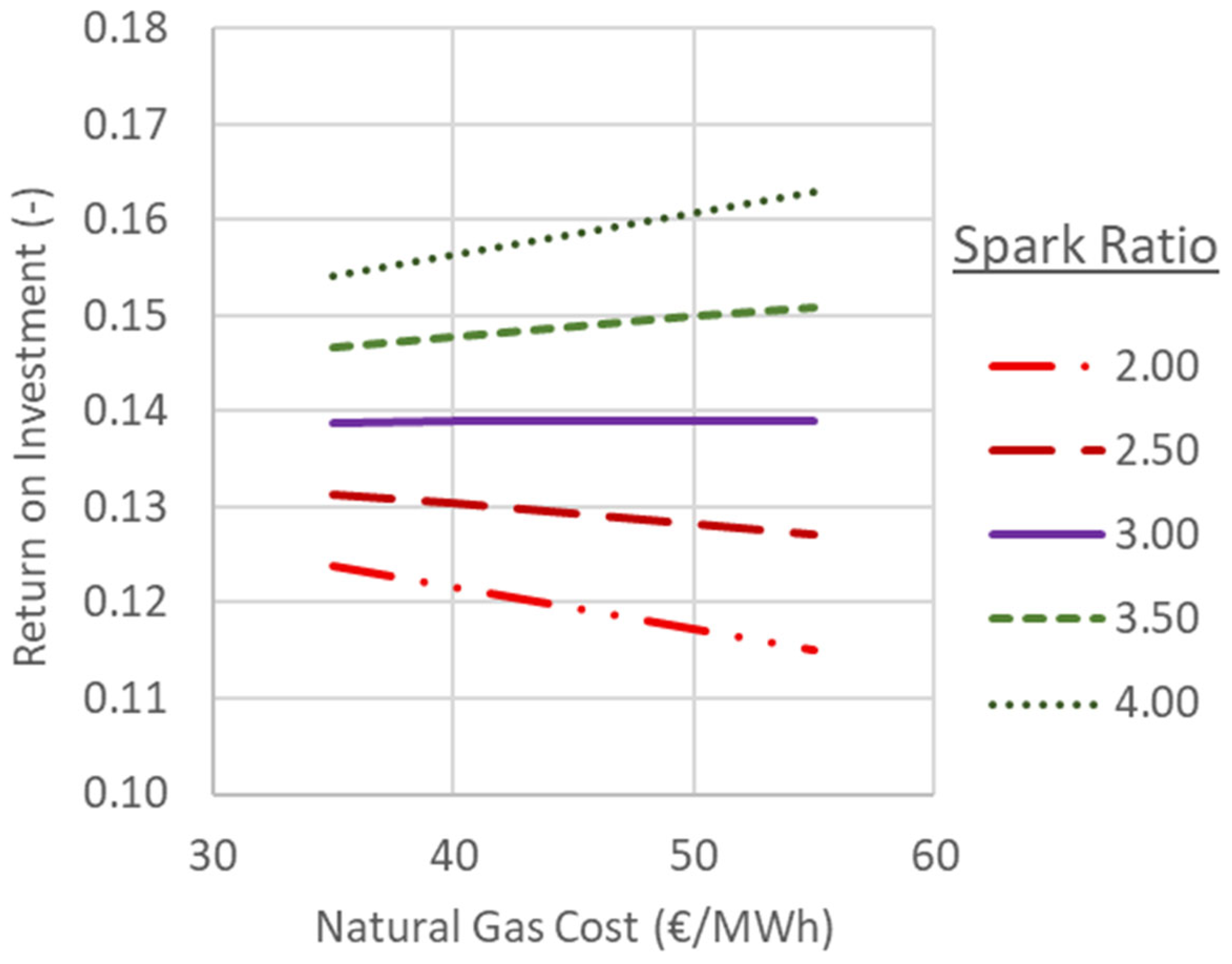

3.5. Energy Prices Effect

4. Discussion

4.1. Accuracy of Results and Model Validation

4.2. Literature Comparison

4.3. Assumptions and Limitations

5. Conclusions

- Profitability: Under baseline conditions, the system ROI was 14%, with CHP alone reaching 24%. Energy-related costs represented ~35% of operational expenses, making them the dominant economic factor.

- CHP sizing guidance: Recommended capacity ranges from 0.5 to 0.7 MW/ha in southern Europe (latitudes 37–45°) and 0.7–1.3 MW/ha in northern climates (45–60°), assuming Spark Ratio ≥ 3 and natural gas prices between 40 and 60 €/MWh.

- Latitude and cultivation temperature: CHP becomes more profitable in colder climates, but an inflection point appears when cooling demand drops, altering the system’s operational balance. Similar reversals were observed with increasing cultivation temperature ranges.

- Policy alignment: The results reinforce EU directives promoting efficient cogeneration (e.g., Energy Efficiency Directive (European Commission, [21]) and the Renewable Energy Directive (RED II) (European Commission, [22]) and suggest that predictable support mechanisms are essential for fostering long-term investment.

- Accessibility: Unlike many existing models, the proposed tool requires no commercial software or proprietary data. Its Excel-based structure makes it transparent, adaptable, and suitable for early-stage decision-making or policy planning across diverse geographic contexts.

- Renewable integration: Future versions of the model could include photovoltaic, geothermal, or biomass options to align with climate-neutral greenhouse strategies.

- CO2 enrichment: Incorporating scenarios for CO2 fertilization from CHP exhaust—common in tomato production—could improve yield estimation and ROI accuracy.

- Vertical farming adaptation: The model could be further adapted to evaluate energy and economic performance in stacked, controlled-environment agriculture systems.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kantor Management Consultants & Embassy of the Kingdom of The Netherlands. Greece-Market Special. Developments in the Greek Horticulture Sector: Greenhouses and Agro Logistics; Rijksdienst voor Ondernemend: The Hague, The Netherlands, 2015. [Google Scholar]

- Dimitropoulou, A.-M.N.; Maroulis, V.Z.; Giannini, E.N. A Simple and Effective Model for Predicting the Thermal Energy Requirements of Greenhouses in Europe. Energies 2023, 16, 6788. [Google Scholar] [CrossRef]

- Tataraki, K.; Giannini, E.; Kavvadias, K.; Maroulis, Z. Cogeneration Economics for Greenhouses in Europe. Energies 2020, 13, 3373. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in Greenhouses in the EU: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Tataraki, K.; Kavvadias, K.; Maroulis, Z. Combined Cooling, Heating and Power Systems in Greenhouses: Grassroots and Retrofit Design. Energy 2019, 189, 116283. [Google Scholar] [CrossRef]

- Seiler, J.C.; Pavlak, G.; Freihaut, J.D. Energy dispatch optimization at Controlled Environment Agriculture sites with CHP: How energy utilization, storage, and market exports impact operational costs. Energy Convers. Manag. 2025, 332, 119743. [Google Scholar] [CrossRef]

- Lahlou, F.-Z.; Mahmood, F.; Al-Ansari, T. Economic assessment of greenhouse and vertical farm production systems in arid regions: A case study of Qatar. Clean. Circ. Bioeconomy 2025, 12, 100151. [Google Scholar] [CrossRef]

- Compernolle, T.; Witters, N.; Van Passel, S.; Thewys, T. Analyzing a Self-Managed CHP System for Greenhouse Cultivation as a Profitable Way to Reduce CO2 Emissions. Energy 2011, 36, 1940–1947. [Google Scholar] [CrossRef]

- Kurklu, A. A Feasibility Study for Different Crops in a High-tech Greenhouse in Turkey. World J. Agric. Soil Sci. 2022, 8, 000688. Available online: https://irispublishers.com/wjass/pdf/WJASS.MS.ID.000688.pdf (accessed on 22 August 2025).

- Min, X.; Sok, J.; Elings, A.; Oude Lansink, A. Economic feasibility of glasshouse tomato production in China: A bio-economic stochastic modelling approach. NJAS Impact Agric. Life Sci. 2022, 94, 156–183. [Google Scholar] [CrossRef]

- Hopwood, W.; Lopez-Reyes, Z.; Bantan, A.; Vietti, C.; Al-Shahrani, D.; Al-Harbi, A.; Qaryouti, M.; Davies, P.; Tester, M.; Wing, R.; et al. Benchmarking Techno-Economic Performance of Greenhouses with Different Technology Levels in a Hot Humid Climate. Biosyst. Eng. 2024, 244, 177–199. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Taylor, L.; Tanino, K. Heating demand and economic feasibility analysis for year-round vegetable production in Canadian Prairie greenhouses. Inf. Process. Agric. 2019, 6, 81–90. [Google Scholar] [CrossRef]

- Michalis, E.; Giatra, C.-E.; Skordos, D.; Ragkos, A. Assessing the Different Economic Feasibility Scenarios of a Hydroponic Tomato Greenhouse Farm: A Case Study from Western Greece. Sustainability 2023, 15, 14233. [Google Scholar] [CrossRef]

- Folorunso, E.A.; Schmautz, Z.; Gebauer, R.; Mraz, J. The Economic Viability of Commercial-Scale Hydroponics: Nigeria as a Case Study. Heliyon 2023, 9, e18979. [Google Scholar] [CrossRef] [PubMed]

- FAO. Energy-Smart Food for People and Climate: Technical Paper. Food and Agriculture Organization of the United Nations: Rome, Italy, 2023. Available online: https://www.fao.org/3/i2454e/i2454e.pdf (accessed on 22 August 2025).

- Eurostat. Agriculture, Forestry and Fishery Statistics—2024 Edition. Publications Office of the European Union: Luxembourg, 2024. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agriculture,_forestry_and_fishery_statistics (accessed on 22 August 2025).

- Centrica Business Solutions. The Essential Guide to Combined Heat and Power. Centrica Business Solutions, UK. 2018. Available online: https://www.centricabusinesssolutions.com/sites/g/files/qehiga126/files/GDE%2001%20ENER-G%20Essential%20Guide%20to%20CHP_01_v5%20%281%29.pdf (accessed on 22 August 2025).

- Boyacı, S.; Kocięcka, J.; Jagosz, B.; Atılgan, A. Energy Efficiency in Greenhouses and Comparison of Energy Sources Used for Heating. Energies 2025, 18, 724. [Google Scholar] [CrossRef]

- Li, X.; Mupondwa, E.; Soolanayakanahally, R.; Stefner, C.; Pahari, S. Economic Feasibility of Using Willow and Poplar as Bioenergy Sources for Heating Small Greenhouses in Canadian Northern Communities. Biomass Bioenergy 2025, 197, 107822. [Google Scholar] [CrossRef]

- Torres, M.A.; Muñoz, D.; Burgos, C.; Casagrande, D.; Ortiz, J.; Reyes, H. Design and Performance Evaluation of a Photovoltaic Greenhouse as an Energy Hub with Battery Storage and an Electric Vehicle Charger. Sustainability 2024, 16, 981. [Google Scholar] [CrossRef]

- European Commission. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC. Off. J. Eur. Union L 2012, 315, 1–56. [Google Scholar]

- European Commission. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (recast). Off. J. Eur. Union L 2018, 328, 82–209. [Google Scholar]

| Study | Cultivation Type | Region/Climate | Metrics Used | Key Assumptions/Findings |

|---|---|---|---|---|

| Paris et al. [4] | General EU greenhouse sector | Northern vs. Southern Europe | Energy intensity | Large variation in heating demand; distinction between low- and high-energy systems |

| Tataraki et al. [3,5] | Tomato, cucumber greenhouses with CCHP | Greece, Europe | ROI, Energy costs | CCHP is profitable when Spark Ratio > 3; optimal CHP sizing is context-dependent |

| Seiler et al. [6] | Controlled environment agriculture with CHP and storage | US case study | Cost savings | Multi-objective optimization; CHP and storage reduce costs 7–12% |

| Lahlou et al. [7] | Tomato greenhouse vs. vertical farm | Qatar (arid climate) | Levelized production cost | Greenhouses are more cost-efficient; vertical farms save water |

| Compernolle et al. [8] | Tomato and lettuce | Belgium | NPV, CO2 savings | Self-managed CHP viable, lettuce: CHP system of 239 kW, tomato: 1.2 MW |

| Kurklu [9] | Multiple crops (tomato, strawberry, rose) (semi-closed, Venlo, and Gothic greenhouse) | Turkey | ROI, payback | Profitability is highly crop-dependent; electricity and financing dominate costs |

| Min et al. [10] | Cherry tomato (Venlo-type glasshouse) | China | NPV, IRR, payback | Wide regional variation in feasibility |

| Hopwood et al. [11] | Low- vs. high-tech greenhouses | Saudi Arabia (hot, humid climate) | Payback, productivity | High-tech closed systems: highest returns despite high Capex, Opex |

| Ahamed et al. [12] | Tomato, cucumber, pepper | Canada (cold climate) | NPV, net return | Tomatoes most profitable, and product prices in remote areas key driver |

| Michalis et al. [13] | Hydroponic tomato | Greece (Mediterranean climate) | NPV, IRR, payback | Baseline profitable (IRR 13%), sensitive to subsidies and prices |

| Folorunso et al. [14] | Hydroponic vegetables | Nigeria (tropical climate) | NPV, IRR | Medium-scale hydroponics more resilient to input cost fluctuations |

| Present study | Hydroponic tomatoes with CHP | Europe | ROI | Unified, spreadsheet-based model; integrates greenhouse and CHP, identifies optimum CHP sizing (0.5–1.5 MW/ha), Spark Ratio resilience, latitude/cultivation inflection points; transparent and easy-to-use |

| Location Data | ||||

|---|---|---|---|---|

| 1 | Longitude | Long | 23.0 | |

| 2 | Latitude | Lat | 40.0 | |

| Equipment Size | ||||

| 3 | Cultivation Area | A | 10.0 | ha |

| 4 | Cogeneration Specific Electrical Power | p | 0.50 | MW/ha |

| Greenhouse Technical Characteristics | ||||

| 5 | Greenhouse Cover Transmittance | τ1 | 0.75 | - |

| 6 | Additional Shadowing Cover Transmittance | τ2 | 0.40 | - |

| 7 | Greenhouse Absorbance | α | 0.40 | - |

| 8 | Winter Overall Heat Loss Coefficient | UL1 | 8.0 | W/m2/K |

| 9 | Summer Overall Heat Loss Coefficient | UL2 | 12.0 | W/m2/K |

| Cogeneration Technical Characteristics | ||||

| 10 | Cogeneration Electrical Efficiency | ne | 0.40 | - |

| 11 | Cogeneration Thermal Efficiency | nh | 0.50 | - |

| 12 | Boiler Efficiency | nb | 0.90 | - |

| Cultivation Temperature | ||||

| 13 | Optimal Product Cultivation Temperature | Tp | 23.0 | C |

| 14 | Accepted Cultivation Temperature Range | ΔTp | 3.0 | C |

| Cultivation Data | ||||

| 15 | Administration Manpower | Wo | 18.0 | persons |

| 16 | Required Specific Manpower | w | 8.0 | persons/ha |

| 17 | Annual Maximum Yield | y | 700 | t/ha |

| Equipment Installation Unit Cost | ||||

| 18 | Greenhouse | Cgh | 3.20 | M€/ha |

| 19 | Cogeneration | Cchp | 1.20 | M€/MW |

| Operating Cost | ||||

| 20 | Cogeneration Maintenance | Cm | 9.0 | €/MWh |

| 21 | Labor Cost | Cw | 15.0 | k€/y |

| 22 | Raw Material Cost | Cr | 0.30 | €/kg |

| Energy Prices | ||||

| 23 | Electricity | Ce | 150 | €/MWh |

| 24 | Natural Gas | Cg | 50 | €/MWh |

| Product Prices | ||||

| 25 | Product | Cp | 1.50 | €/kg |

| Economic Results | Total | Greenhouse | Cogeneration | ||

|---|---|---|---|---|---|

| Sales | Sales | 11.9 | 8.3 | 3.6 | M€/y |

| Operating Expenses | OpEx | 6.7 | 4.4 | 2.2 | M€/y |

| Earnings | EBITD | 5.3 | 3.9 | 1.4 | M€/y |

| Capital Expenditures | CapEx | 38.0 | 32.0 | 6.0 | M€ |

| Return On Investment | ROI | 13.9 | 12.1 | 23.5 | % |

| Cost Category | Cost (M€/y) | Cost (%OpEx) |

|---|---|---|

| Personnel | 1.22 | 27.5 |

| Raw Material | 1.66 | 37.4 |

| Energy | 1.56 | 35.1 |

| Operating Expenses (OpEx) | 4.44 | 100 |

| Cogeneration Contribution to Energy Cost | ||

| Energy Cost Covered by Cogeneration | 1.41 | M€/y |

| Energy Cost Reduction by Cogeneration | 90.5 | % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dimitropoulou, A.-M.N.; Giannini, E.N.; Maroulis, Z.B. A Greenhouse Profitability Model: The Effect of the Energy System. Energies 2025, 18, 4748. https://doi.org/10.3390/en18174748

Dimitropoulou A-MN, Giannini EN, Maroulis ZB. A Greenhouse Profitability Model: The Effect of the Energy System. Energies. 2025; 18(17):4748. https://doi.org/10.3390/en18174748

Chicago/Turabian StyleDimitropoulou, Anna-Maria N., Eugenia N. Giannini, and Zacharias B. Maroulis. 2025. "A Greenhouse Profitability Model: The Effect of the Energy System" Energies 18, no. 17: 4748. https://doi.org/10.3390/en18174748

APA StyleDimitropoulou, A.-M. N., Giannini, E. N., & Maroulis, Z. B. (2025). A Greenhouse Profitability Model: The Effect of the Energy System. Energies, 18(17), 4748. https://doi.org/10.3390/en18174748