Abstract

The search for low-emission fuels has increased interest in hydrotreated vegetable oil (HVO) as a renewable diesel substitute. This study examines the lubricity of HVO, diesel, and their blends using a four-ball tester, with scuffing load as the main evaluation criterion. Five fuel samples were tested: diesel, neat HVO, and blends containing 25%, 50%, and 75% HVO by volume. The results show that blending HVO with diesel improves lubricity at moderate concentrations, with the 25% HVO blend exhibiting the highest scuffing load. In contrast, neat HVO demonstrated significantly reduced lubricity—its scuffing load was 24% lower than diesel’s—confirming the negative impact of the absence of polar and aromatic compounds. The scuffing load did not decrease linearly with increasing HVO content, suggesting synergistic effects in certain blends. Viscosity increased with HVO content, but it did not directly correlate with improved lubricity. These findings indicate that chemical composition plays a dominant role over viscosity in determining lubricating performance. The study provides new insights into the tribological behavior of HVO–diesel blends and demonstrates that scuffing load testing offers a practical method for preliminary lubricity assessment of renewable fuels.

1. Introduction

The increasing demands for reducing greenhouse gas emissions and air pollutants pose a significant challenge to the transportation sector—particularly road transport—as it undergoes toward a gradual transition away from conventional fossil fuels. One potential solution supporting this transformation is the use of second-generation renewable fuels, including hydrotreated vegetable oil (HVO) [1,2,3].

HVO is produced through the hydrogenation of vegetable and animal fats, resulting in hydrocarbons with a molecular structure similar to that of conventional diesel fuel [4,5,6]. Unlike traditional biodiesel, HVO is characterized by superior performance and environmental properties [7,8,9]. These advantages are partly due to its favorable ignition characteristics, as indicated by the reported high cetane number (CN) values. The short ignition delay period—and consequently the high CN—is directly related to the composition of HVO, which consists exclusively of normal and iso-paraffins [10]. The absence of oxygen atoms in the molecular structure of HVO, combined with its excellent ignition quality, contributes to a higher heating value and lower emissions of particulate matter, carbon monoxide, and unburned hydrocarbons [11,12]. A key advantage of HVO is its ability to be produced from a wide range of waste-derived feedstocks, such as used cooking oil, which helps reduce the carbon footprint and limits competition with the food industry [13].

The complete replacement of diesel fuel with HVO in current transportation systems is often challenging due to both technical and economic factors. As a result, increasing attention is being given to the use of HVO–diesel blends, which allow for a gradual reduction in carbon dioxide emissions without requiring significant modifications to existing diesel engine designs [14,15].

One of the key fuel parameters that must be analyzed—particularly when evaluating the fueling of diesel engines with various fuel blends—is fuel lubricity. An adequate level of lubricity reduces wear on components of the fuel injection system, such as high-pressure pumps and injectors, by minimizing friction and the degradation of contact surfaces. High lubricity contributes to extended service life of the fuel system and lowers the risk of failures associated with excessive mechanical wear. These issues have been examined in greater detail in the authors’ previous studies [16,17,18].

Although the impact of using HVO on the performance parameters of compression ignition engines has been extensively investigated in numerous studies [19,20,21,22,23,24,25,26], most of this research has primarily focused on evaluating engine performance and the emissions of harmful exhaust components. The scope of these studies includes both the use of neat HVO and its blends with other fuels. However, relatively few studies on the application of HVO in compression ignition engines have concentrated on the analysis of the lubricity of this fuel and its blends with conventional diesel, based on experimental investigations. Some data regarding the lubricity characteristics of HVO and its blends with other fuels, including diesel fuel, can be found in studies such as [8,27,28,29].

Szeto and Leung [8] emphasized the impact of fuel lubricity on the efficiency and durability of precision pairs within engine fuel injection systems. They also concluded that neat hydrotreated fuels, including HVO, are unable to meet lubricity requirements without the use of friction modifiers, which form a protective layer at the contact surfaces of cooperating components within kinematic pairs. As the main reason for the reduced lubricity of HVO compared to conventional diesel fuel, the authors identified the absence of polar compounds containing oxygen and nitrogen, which are eliminated during the hydrogenation process of vegetable oil.

Fathurrahman et al. [27] investigated the effect of palm oil-based biodiesel on improving the lubricity of diesel fuel and HVO. Overall, the results of their study indicated that the addition of biodiesel to both diesel and HVO improved the lubricity of the resulting blends, with higher biodiesel volume fractions leading to greater enhancements in lubricity.

Zöldy [28] conducted a study on the lubricity characteristics of a ternary fuel blend consisting of diesel fuel, HVO, and butanol. The investigated blends included butanol and HVO volume fractions ranging from 2.5% to 10%. The results showed that changes in lubricity were not entirely consistent, with a general tendency toward decreased lubricity at higher butanol concentrations.

More detailed data on HVO and its blends with diesel fuel were presented in the work by Lapuerta et al. [29]. The study involved HVO, ultra-low sulfur diesel (ULSD), and their blends with HVO volume fractions ranging from 10% to 75%, with 10% being the lowest and 75% the highest concentration analyzed. The results showed that as the HVO content increased, the lubricity of the blend deteriorated significantly—especially in blends containing 40% HVO or more. The authors attributed the reduction in lubricity of HVO–ULSD blends to the removal of oxygen during the hydrogenation process of HVO and the absence of aromatic and olefinic compounds. This finding is further supported by studies reported in [30,31] in which the lubricity of various hydrocarbons was analyzed, confirming the positive impact of aromatic hydrocarbons on fuel lubricity.

The assessment of the tribological properties of fuels requires the use of appropriate testing methods, including laboratory tests, bench tests using components of the fuel supply system, and operational tests conducted after a specified vehicle mileage or engine runtime. The findings and observations regarding the lubricity of HVO—used either neat or in blends with other fuels, including diesel—presented by the authors of the previously cited studies [8,27,28,29] were based on the standardized High-Frequency Reciprocating Rig (HFRR) method, which is widely used for evaluating fuel lubricity. The requirements for this method are defined in standards such as [32,33].

In the HFRR method, the working element is a loaded steel ball. The ball, subjected to a specified load, is pressed against a stationary steel disc immersed in the test fuel. The ball is then set into a reciprocating motion with a defined stroke length and frequency. In this method, fuel lubricity is evaluated based on the diameter of the wear scar formed on the ball surface. The test procedure and the method for determining lubricity are described in the previously cited standards [32,33] as well as in the authors’ earlier works [16,18].

In addition to the widely used HFRR method, a variety of other laboratory techniques are available for evaluating the lubricity of fuels. These include, the Ball-on-Cylinder Lubricity Evaluator (BOCLE), Thornton Aviation Fuel Lubricity Evaluator (TAFLE), Ball-on-Three-Seats (BOTS), Cameron–Plint test (roller-on-plate), Scuffing Load BOCLE (SLBOCLE), Lucas dwell test, and Ball-on-Three-Discs (BOTD) and Vee Block Test [16,18,31,34,35]. However, to date, no published studies have reported the lubricity test results of HVO or its blends with diesel using these methods. The comparison of lubricity test methods is presented in Table 1.

Table 1.

Comparison of lubricity test methods.

As demonstrated in numerous prior studies [17,36,37,38,39,40,41,42,43], the four-ball tester—although originally developed for assessing the lubricating properties of oils—has proven to be a versatile and effective instrument for evaluating the lubricity of a wide range of liquid fuels. Its applicability in this context stems from several distinct advantages. Notably, the method offers a relatively simple experimental setup and procedure, which enhances reproducibility and operational convenience. Furthermore, the four-ball test is considerably more cost-effective than standardized methods such as the HFRR, making it particularly well-suited for preliminary screening and comparative analysis in early-stage research. In the context of our study, the use of the four-ball tester was especially justified given the exploratory nature of our work. This method allowed for the systematic and reliable comparison of the boundary lubrication performance of various HVO–diesel blends under controlled conditions. Importantly, the scuffing load parameter employed in our analysis provides a direct and meaningful measure of a fuel’s ability to maintain a boundary lubrication film under increasing mechanical load, which is a critical factor in assessing wear protection capabilities. It should be clearly acknowledged, however, that the four-ball tester is not a standardized method for assessing diesel fuel lubricity in regulatory or certification contexts. The HFRR method remains the industry benchmark for such purposes, as stipulated in applicable fuel standards. Nonetheless, within the defined and consistent framework of our experiments, the four-ball tester served as a robust and informative tool for comparative lubricity evaluation, complementing existing methods and contributing valuable insights into the tribological behavior of renewable fuel blends.

Kuszewski et al. [17] used a four-ball tester to study the lubricity of diesel–ethanol blends, adopting the scuffing load as the main lubricity evaluation criterion. Rahman et al. [36] also applied a four-ball tester to examine the tribological properties of first- and second-generation biofuels, conducting tests at a constant rotational speed and varying loads. Kumar et al. [37] investigated the lubricating properties of diesel–biodiesel blends using a four-ball tester, applying different loading conditions and sample temperatures. In their study, the coefficients of friction and wear scar diameters on the test balls were used as key indicators of lubricity. Yaqoob et al. [38,39] using a four-ball tester, evaluated the lubricity of pyrolysis oils derived from used automobile tires. In both studies, lubricity was assessed based on the measured coefficient of friction (COF) and wear scar diameters on the test balls.

Habibullah et al. [40] and Mosarof et al. [42], also employing a four-ball tester, focused on the lubricity of Calophyllum inophyllum biodiesel and its blends with diesel fuel [40], as well as blends of this biodiesel with both diesel and palm oil-based biodiesel [42]. In both cases, lubricity was evaluated based on the recorded COF and the diameter of wear scars on the test balls. Mujtaba et al. [41], in their research, assessed the effect of a 5% blend of palm and sesame oil-based biofuels, combined with alcohol and nanoparticles, on the tribological properties of lubricating oil. As in most of the previously cited studies, lubricity was evaluated using the COF and the wear scar diameter observed on the test balls.

Szymczyk et al. [43] investigated the effect of adding n-hexane to canola oil on its physicochemical and tribological properties in the context of its potential use as a diesel fuel additive. One part of the study involved testing the lubricating properties of canola oil and n-hexane blends using a four-ball tester. The authors used the scuffing load as the criterion for evaluating lubricity.

Given the very limited number of publications addressing the lubricating properties of HVO and its blends with conventional diesel fuel, the authors sought to fill this research gap. Notably, although the four-ball method has been used in previous studies involving various fuels, those studies typically evaluated lubricity based on the COF and the wear scar diameter on the test balls. In contrast to previous studies that mainly used wear scar diameter or coefficient of friction, the present study applies scuffing load as the main evaluation criterion for HVO and HVO–diesel blends. This approach focuses on the fuel’s ability to maintain boundary lubrication under increasing load, offering a direct and practical measure of its anti-wear performance.

2. Experimental Procedures

2.1. Characterization of Test Samples

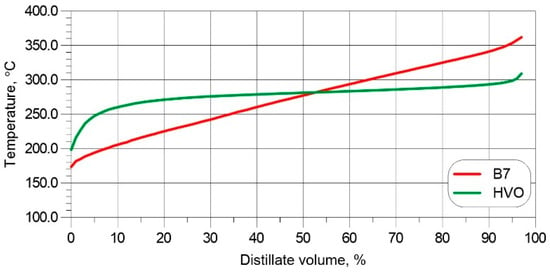

Lubricity measurements were carried out for five fuel samples. One of them was commercially available diesel fuel, labeled as B7 at European fuel stations, indicating that it may contain up to 7% by volume of fatty acid methyl ester (FAME). The second base fuel was HVO. The results of the basic physicochemical property measurements for both base fuels are summarized in Table 2, along with information on the analytical methods used. Additionally, the distillation curves for these fuels are presented in Figure 1.

Table 2.

Physicochemical characteristics of base fuels.

Figure 1.

Distillation curves of the tested fuels.

The other three fuel samples were created by blending HVO with B7 in volumetric ratios of 25%, 50%, and 75% HVO. Because of their chemical makeup—especially the fact that HVO is made up entirely of paraffinic hydrocarbons—these fuels mix very well. More detailed data on the properties of HVO–diesel blends at different ratios can be found in [29]. All blends were prepared at a consistent temperature of 22 ± 1 °C for both HVO and B7. The fuel blending temperature reflects typical laboratory conditions and was chosen to ensure full miscibility of the components. After blending, the samples were stored in sealed glass containers for at least 24 h at a controlled temperature of 22 ± 1 °C to ensure stability and repeatability of the fuel mixture composition. The names and mixing ratios of each sample, including the HVO–diesel blends, are shown in Table 3.

Table 3.

Fuel sample identifications.

2.2. Research Methodology and Data Acquisition

In this study, a four-ball tribometer of type T-02U was employed, consisting of a test unit along with an integrated measurement and control system. The mechanical assembly of the test unit includes the main frame, drive system, tribosystem loading mechanism, ball holder (chuck) and base structure. The tribosystem is composed of three fixed balls mounted in a ball pot, which are loaded against a fourth (upper) ball rotating at a specified speed. The upper ball is held in a precision chuck that ensures stable rotation during testing. The test specimens consisted of standardized bearing balls with a nominal diameter of 1/2 inch, manufactured from bearing-grade steel ŁH15 and hardened to a surface hardness of 60–65 HRC. Detailed specifications of the test balls are presented in Table 4. Table 4 summarizes the key technical specifications of the four-ball tester. The mechanical configuration allowed for a controlled, linear increase in load on the tribosystem throughout the test duration. The machine was operated using an asynchronous motor drive, a microprocessor-based controller, and a dedicated PC equipped with specialized control software (HFRPC – software version 2.14). A more detailed description of the four-ball tribometer used in this study available in [17,51].

Table 4.

Parameters of the test balls used in the study [43].

Lubrication tests were performed under a continuously increasing load. The spindle speed was maintained at 500 rpm, and the load was applied at a constant rate of 409 N/s. The initial temperature of the fuel sample at the start of each test was 60 ± 4 °C. The test parameters were selected based on previous studies [17,43] and allowed for the assessment of boundary film resistance under increasing load conditions. During the experiment, the friction torque (T), the linearly increasing load (F) applied to the tribosystem, and the COF were continuously monitored and recorded.

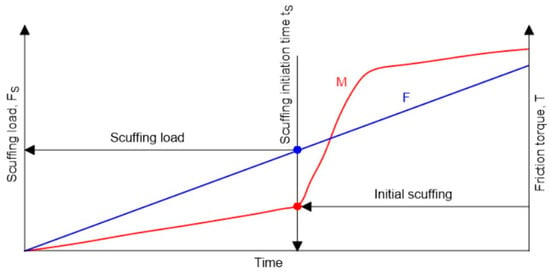

For each fuel sample, the lubricity test was conducted twice, and the recorded data were averaged. According to the adopted test methodology, the scuffing load (FS) was defined as the load corresponding to the point at which a sudden increase in T was observed. The analysis focused on the time interval during the test run in which this abrupt rise in T occurred. A schematic representation of the scuffing load identification procedure is shown in Figure 2. Consequently, all plots presented in the Section 3 were limited to the test run time interval from 0.8 to 2.0 s.

Figure 2.

Schematic diagram of scuffing load (FS) identification.

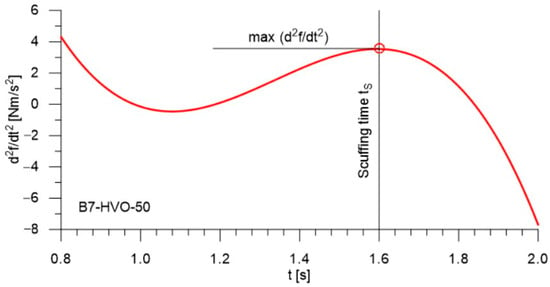

The measurement data were subsequently approximated using a linear function for the normal load applied to the friction node, and a fifth-degree polynomial for the COF and friction torque profiles. To clearly identify the time at which scuffing initiation occurred, the second derivative of the friction torque approximation function was calculated. The time corresponding to the local maximum of this second derivative was assumed to represent the point of scuffing initiation. The corresponding load value, denoted as FS, was then defined as the scuffing load. A graphical representation of scuffing time (tS) determination is shown in Figure 3.

Figure 3.

Schematic diagram of scuffing time (tS) identification, based on the example of the B7-HVO-50 sample.

Based on the determined scuffing time tS and the recorded data, the scuffing load FS was determined for each of the two tests conducted for each fuel sample. The absolute differences in FS values between the first and second test runs were then calculated, and their values—preceded by the ± symbol—were reported alongside the measured FS values. The determined scuffing loads were considered the primary criterion for evaluating the lubricity of the tested samples. Higher FS values indicated a greater ability to sustain the boundary lubrication film, and thus, better lubricating performance under boundary lubrication conditions.

3. Results and Discussion

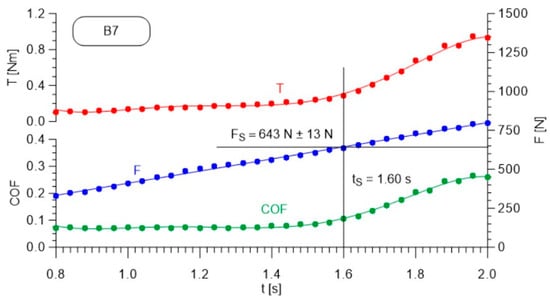

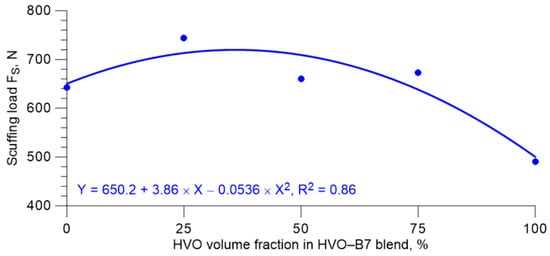

Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8 present the averaged courses of the tribosystem load F, friction torque T, and COF for the analyzed fuel samples, based on two test runs. In accordance with the methodology described in the previous section, the diagrams also indicate the scuffing load FS and the identified scuffing initiation time tS. Higher FS values reflect an enhanced ability to maintain the boundary lubrication film, which corresponds to improved lubricating performance under boundary lubrication conditions. To facilitate the analysis of the collected data, the measurement results are summarized in Table 5 and Figure 9, which presents the relationships between the scuffing load Fs and the volumetric fraction of HVO.

Figure 4.

Averaged profiles of the tribosystem load F, friction torque T, and COF for B7 fuel.

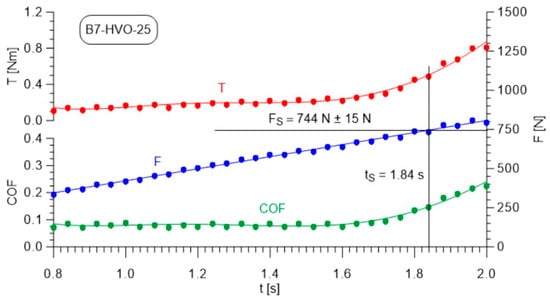

Figure 5.

Averaged profiles of the tribosystem load F, friction torque T, and COF for B7-HVO-25 fuel.

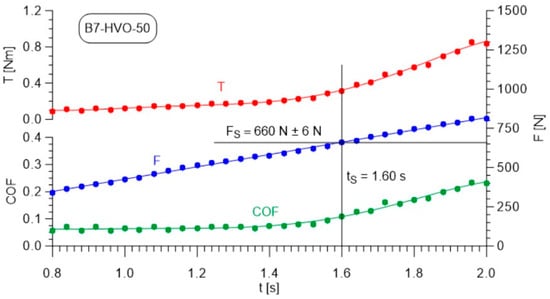

Figure 6.

Averaged profiles of the tribosystem load F, friction torque T, and COF for B7-HVO-50 fuel.

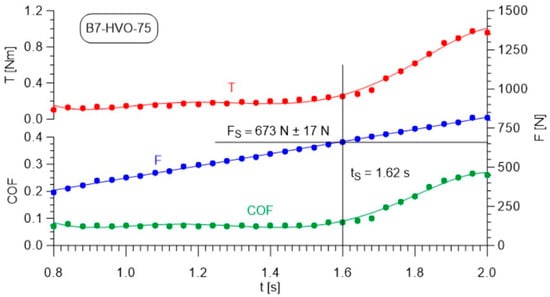

Figure 7.

Averaged profiles of the tribosystem load F, friction torque T, and COF for B7-HVO-75 fuel.

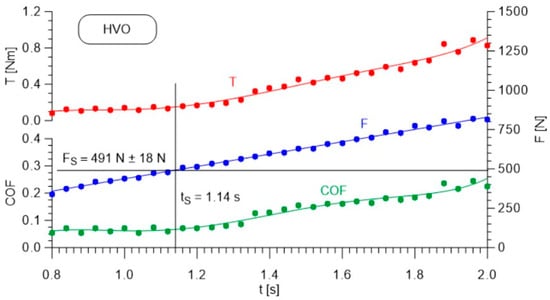

Figure 8.

Averaged profiles of the tribosystem load P, friction torque MT, and friction coefficient μ for HVO fuel.

Table 5.

Technical specifications of the four-ball tribometer [17].

Figure 9.

Effect of HVO volume fraction in the HVO–B7 blend on the scuffing load FS.

As shown in Figure 4, for diesel without the addition of HVO, the scuffing load in the tribosystem reached 643 N, with scuffing initiation occurring 1.60 s after the beginning of the test run. It should be noted that this value depends, among other factors, on the biodiesel content in the diesel and the presence of ring-structured hydrocarbons, which generally contribute to improved diesel lubricity. In one study [17], a slightly higher scuffing load (FS = 730 N) was reported for diesel containing a similar biodiesel content (6.70%) to that used in this study (6.79%). This difference may be attributed to a higher proportion of aromatic hydrocarbons.

As shown in Figure 5, the addition of 25 vol.% of HVO into B7 fuel resulted in an increase in the scuffing load in the tribosystem to 744 N. Consequently, the B7-HVO-25 sample demonstrated a better ability to form a boundary layer compared to the B7 sample. In this case, scuffing initiation also occurred slightly later—1.84 s after the start of the test run.

As shown in Figure 6 and Figure 7, further increasing the HVO content in the B7 blend resulted in clearly smaller increases in the scuffing load (FS) relative to B7—by 3% for B7-HVO-50 and 5% for B7-HVO-75—indicating a relatively minor, yet noticeable, improvement in lubricity. For all three fuels—B7, B7-HVO-50, and B7-HVO-75—the same scuffing initiation times were recorded: tS = 1.60 s, tS = 1.60 s, and tS = 1.62 s, respectively.

Figure 8 presents the data obtained for neat HVO. As shown, this fuel exhibited the lowest scuffing load (FS = 491 N). Therefore, the lubricity evaluation method based on the scuffing load also clearly confirmed the significantly poorer lubricating properties of this fuel compared to B7. In this respect, the findings align with the results obtained using the HFRR method, presented in [29], which also demonstrated noticeably lower lubricity of HVO relative to diesel. The inferior lubricity of HVO compared to diesel is attributed to the absence of aromatic and olefinic hydrocarbons in HVO, as well as the removal of oxygen during the hydrotreatment process. As shown in Table 5, HVO exhibited a 24% decrease in FS compared to B7, which, under continuously increasing load conditions in the friction node, also translated to the shortest time to scuffing initiation (tS = 1.14 s).

As shown in Figure 9, despite the well-documented inferior lubricity of neat HVO compared to conventional diesel, the scuffing load values observed in the present study did not decrease monotonically with increasing HVO content in the HVO–B7 blends. Instead, a non-linear trend was evident: FS initially increased with the addition of HVO, indicating a temporary improvement in lubricating performance. This behavior was likely due to synergistic effects between the additive components of B7 and moderate HVO concentrations, which may have stabilized the lubricating film during boundary lubrication. At higher HVO volume fractions, the scuffing load stabilized or slightly decreased, and for neat HVO, the lowest FS value was recorded, which aligned with its expected poor lubricity due to the absence of naturally lubricating compounds such as aromatic hydrocarbons or polar oxygenates.

As presented in Table 6, the observed decrease in the COF with increasing HVO content may be attributed to differences in chemical composition—particularly the absence of polar compounds and aromatic structures in HVO, which, in conventional fuels, tend to enhance the formation and adhesion of boundary lubrication layers on metal surfaces. Such polar components—such as esters, acids, or nitrogen-containing compounds—can adsorb onto sliding surfaces and contribute to reduced friction and wear under boundary lubrication conditions. In the four-ball tribosystem, where point contact dominates and high contact pressures are present, the presence of these adsorptive compounds is especially important for preventing metal-to-metal contact. The reduced ability to form such protective films in neat HVO might have resulted in lower interfacial shear resistance and faster breakdown of boundary lubrication, leading to earlier scuffing initiation. However, this effect did not translate into improved lubricity, as evidenced by the lower scuffing load and shorter scuffing time recorded for neat HVO. This trend is further supported by the kinematic viscosity data presented in Table 5. Although the viscosity of the fuel samples increased with higher HVO content—from 1.89 mm2/s for B7 to 2.07 mm2/s for HVO—this increase did not lead to better lubricating performance.

Table 6.

Measurement data recorded for the analyzed fuel samples.

Generally, higher viscosity can enhance the formation of a lubricating film and delay boundary lubrication failure. Nevertheless, in the case of neat HVO, the lower scuffing load and shorter scuffing time suggest that the chemical characteristics of the fuel played a more dominant role than viscosity in determining scuffing resistance. From the perspective of tribochemical reactions, the presence of aromatic and polar compounds in diesel fuel promotes the formation of a stable boundary film due to the ability of these molecules to adsorb onto metal surfaces. These compounds act as natural friction modifiers, stabilizing the lubricating layer and reducing direct metal-to-metal contact between sliding surfaces. In the case of HVO, which consists primarily of saturated straight-chain hydrocarbons, the ability to form such a film is limited. This may result in reduced lubricity despite comparable kinematic viscosity. This phenomenon indicates a partial decoupling between viscosity and lubricity, as also reported in Ref. [31]. It implies that while viscosity is a relevant parameter, it alone cannot compensate for the absence of specific molecular components that contribute to anti-wear properties in conventional diesel fuels.

4. Conclusions

The main findings of this study are as follows:

- Neat HVO demonstrated the lowest lubricity of all tested fuels, as shown by the lowest scuffing load and the shortest scuffing initiation time. This confirms its limited capacity to maintain boundary lubrication under increasing mechanical load.

- Blending HVO with diesel improved lubricity at moderate concentrations. The 25% HVO blend achieved the highest scuffing load and showed the most effective boundary layer performance.

- Increasing the HVO content beyond 25% led to diminishing returns in lubricity. Only slight improvements or even reductions were observed, indicating a non-linear relationship between HVO concentration and scuffing performance.

- The scuffing load method used in this study proved to be a practical and effective alternative to standard HFRR-based procedures for the comparative evaluation of lubricity in diesel fuels and renewable fuel blends.

- Although the kinematic viscosity of fuel samples increased with higher HVO content, this did not result in improved lubricity. This finding highlights that viscosity alone is insufficient to ensure boundary film stability in the absence of surface-active polar compounds. The lack of aromatic hydrocarbons in neat HVO also contributes to its inferior anti-wear properties.

This study adds to the limited research on the lubricating properties of HVO and its blends with diesel fuel. The scuffing load method proved to be a fast and cost-effective tool for preliminary evaluation of boundary lubrication performance. Further work will focus on detailed analysis of wear scars to better understand lubricity mechanisms, particularly in blended formulations.

Author Contributions

Conceptualization, H.K.; methodology, H.K., A.J. and D.S.; software, H.K., A.J.; validation, H.K.; formal analysis, H.K.; investigation, H.K., A.J. and D.S.; resources, H.K., A.J. and D.S.; data curation, H.K., A.J. and D.S.; writing—original draft preparation, H.K.; writing—review and editing, H.K., A.J. and D.S.; visualization, H.K.; supervision, H.K., A.J. and D.S.; All authors have read and agreed to the published version of the manuscript.

Funding

The research leading to these results has received funding from the commissioned task entitled “VIA CARPATIA Universities of Technology Network named after the President of the Republic of Poland Lech Kaczyński”, under the special purpose grant from the Minister of Science and Higher Education, contract No. MEiN/2022/DPI/2578 action entitled “In the neighborhood-inter-university research internships and study visits”.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HVO | Hydrotreated vegetable oil |

| CN | Cetane number |

| ULSD | Ultra-low sulfur diesel |

| HFRR | High-Frequency Reciprocating Rig |

| BOCLE | Ball-on-Cylinder Lubricity Evaluator |

| TAFLE | Thornton Aviation Fuel Lubricity Evaluator |

| BOTS | Ball-on-Three-Seats |

| SLBOCLE | Scuffing Load BOCLE |

| BOTD | Ball-on-Three-Discs |

| COF | Coefficient of friction |

| B7 | Diesel fuel with up to 7% (v/v) FAME, as per EN 590 |

| FAMEs | Fatty acid methyl esters |

| DCN | Derived cetane number |

| 2-EHN | 2-Ethylhexyl nitrate |

| HHV | Higher heating value |

| CFPP | Cold filter plugging point |

| WSD | Wear scar diameter |

| IBP | Initial boiling point |

| FBP | Final boiling point |

| T | Friction torque |

| F | Load of tribosystem |

| FS | Scuffing load |

| tS | Scuffing time |

References

- da Costa, G.A.A.; Mendes, A.B.; Silva, V.M.D. Decarbonization pathways in Brazilian maritime cabotage: A comparative analysis of very low sulfur fuel oil, marine diesel oil, and hydrogenated vegetable oil in carbon dioxide equivalent emissions. Lat. Am. Transp. Stud. 2024, 2, 100018. [Google Scholar] [CrossRef]

- Sonthalia, A.; Kumar, N. Hydroprocessed vegetable oil as a fuel for transportation sector: A review. J. Energy Inst. 2019, 92, 1–17. [Google Scholar] [CrossRef]

- Abrar, I.; Bhaskarwar, A.N. An overview of current trends and future scope for vegetable oil-based sustainable alternative fuels for compression ignition engines. In Second and Third Generation of Feedstocks: The Evolution of Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 531–556. [Google Scholar] [CrossRef]

- Huber, G.W.; O’cOnnor, P.; Corma, A. Processing biomass in conventional oil refineries: Production of high quality diesel by hydrotreating vegetable oils in heavy vacuum oil mixtures. Appl. Catal. A Gen. 2007, 329, 120–129. [Google Scholar] [CrossRef]

- Lorenzi, G.; Mignini, L.; Venezia, B.; Silva, C.; Santarelli, M. Integration of high-temperature electrolysis in an HVO production process using waste vegetable oil. Energy Procedia 2019, 158, 2005–2011. [Google Scholar] [CrossRef]

- Hilbers, T.J.; Sprakel, L.M.J.; van den Enk, L.B.J.; Zaalberg, B.; van den Berg, H.; van der Ham, L.G.J. Green Diesel from Hydrotreated Vegetable Oil Process Design Study. Chem. Eng. Technol. 2015, 38, 651–657. [Google Scholar] [CrossRef]

- Fathurrahman, N.A.; Ginanjar, K.; Devitasari, R.D.; Maslahat, M.; Anggarani, R.; Aisyah, L.; Soemanto, A.; Solikhah, M.D.; Thahar, A.; Wibowo, E.; et al. Long-term storage stability of incorporated hydrotreated vegetable oil (HVO) in biodiesel-diesel blends at highland and coastal areas. Fuel Commun. 2024, 18, 100107. [Google Scholar] [CrossRef]

- Szeto, W.; Leung, D.Y. Is hydrotreated vegetable oil a superior substitute for fossil diesel? A comprehensive review on physicochemical properties, engine performance and emissions. Fuel 2022, 327, 125065. [Google Scholar] [CrossRef]

- Pechout, M.; Kotek, M.; Jindra, P.; Macoun, D.; Hart, J.; Vojtisek-Lom, M. Comparison of hydrogenated vegetable oil and biodiesel effects on combustion, unregulated and regulated gaseous pollutants and DPF regeneration procedure in a Euro6 car. Sci. Total. Environ. 2019, 696, 133748. [Google Scholar] [CrossRef]

- Šimáček, P.; Kubička, D.; Šebor, G.; Pospíšil, M. Fuel properties of hydroprocessed rapeseed oil. Fuel 2010, 89, 611–615. [Google Scholar] [CrossRef]

- Bortel, I.; Vávra, J.; Takáts, M. Effect of HVO fuel mixtures on emissions and performance of a passenger car size diesel engine. enew. Energy 2019, 140, 680–691. [Google Scholar] [CrossRef]

- Bohl, T.; Smallbone, A.; Tian, G.; Roskilly, A.P. Particulate number and NOx trade-off comparisons between HVO and mineral diesel in HD applications. Fuel 2018, 215, 90–101. [Google Scholar] [CrossRef]

- Ajeeb, W.; Gomes, D.M.; Neto, R.C.; Baptista, P. Life cycle analysis of hydrotreated vegetable oils production based on green hydrogen and used cooking oils. Fuel 2025, 390, 134749. [Google Scholar] [CrossRef]

- Sihlovec, F.; Vrtiška, D.; Šimáček, P. The use of multivariate statistics and mathematically modeled IR spectra for determination of HVO content in diesel blends. Fuel 2024, 379, 132963. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Kousoulidou, M.; Clairotte, M.; Giechaskiel, B.; Nuottimäki, J.; Sarjovaara, T.; Lonza, L. Impact of HVO blends on modern diesel passenger cars emissions during real world operation. Fuel 2019, 235, 1427–1435. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jakubowski, M.; Jaworski, A.; Lubas, J.; Balawender, K. Effect of temperature on tribological properties of 1-butanol–diesel fuel blends—Preliminary experimental study using the HFRR method. Fuel 2021, 296, 120700. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Mądziel, M. Lubricity of Ethanol–Diesel Fuel Blends—Study with the Four-Ball Machine Method. Materials 2021, 14, 2492. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Ustrzycki, A. Lubricity of ethanol–diesel blends—Study with the HFRR method. Fuel 2017, 208, 491–498. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Natsios, I.; Katsaounis, D.; Samaras, Z.; Bezergianni, S.; Lehto, K. Evaluation of a Hydrotreated Vegetable Oil (HVO) and Effects on Emissions of a Passenger Car Diesel Engine. Front. Mech. Eng. 2018, 4, 368686. [Google Scholar] [CrossRef]

- Colangeli, C.; D’ambrosio, S.; Mancarella, A.; Marello, O.; Salamone, N.; American Society of Mechanical Engineers. Emissions, Performance and Vibro-Acoustic Analysis of a Compression-Ignition Engine Running on Hydrotreated Vegetable Oil (HVO), Proceedings of the ASME 2024 ICE Forward Conference, San Antonio, TX, USA, 20–23 October 2024; Internal Combustion Engine Division ICE: Washington, DC, USA, 2024. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Seljak, T.; Vihar, R.; Baškovič, U.Ž.; Dimaratos, A.; Bezergianni, S.; Samaras, Z.; Katrašnik, T. Improving PM-NOx trade-off with paraffinic fuels: A study towards diesel engine optimization with HVO. Fuel 2020, 265, 116921. [Google Scholar] [CrossRef]

- Tan, C.; Xu, H.; Shuai, S.-J.; Ghafourian, A.; Liu, D.; Tian, J. Investigation on Transient Emissions of a Turbocharged Diesel Engine Fuelled by HVO Blends. SAE Int. J. Engines 2013, 6, 1046–1058. [Google Scholar] [CrossRef]

- Hunicz, J.; Mikulski, M.; Shukla, P.C.; Gęca, M.S. Partially premixed combustion of hydrotreated vegetable oil in a diesel engine: Sensitivity to boost and exhaust gas recirculation. Fuel 2022, 307, 121910. [Google Scholar] [CrossRef]

- Bjørgen, K.O.P.; Emberson, D.R.; Løvås, T. Combustion and soot characteristics of hydrotreated vegetable oil compression-ignited spray flames. Fuel 2020, 266, 116942. [Google Scholar] [CrossRef]

- Pinto, G.; de Souza, T.; da Costa, R.; Roque, L.; Frez, G.; Vidigal, L.; Pérez-Rangel, N.; Coronado, C. Hydrogen and CNG dual-fuel operation of a 6-Cylinder CI engine fueled by HVO and diesel: Emissions, efficiency, and combustion analyses. Int. J. Hydrogen Energy 2025, 111, 407–432. [Google Scholar] [CrossRef]

- Zahos-Siagos, I.; Karonis, D. Exhaust Emissions and Physicochemical Properties of Hydrotreated Used Cooking Oils in Blends with Diesel Fuel. Int. J. Chem. Eng. 2018, 2018, 4308178. [Google Scholar] [CrossRef]

- Fathurrahman, N.A.; Auzani, A.S.; Zaelani, R.; Anggarani, R.; Aisyah, L.; Maymuchar; Wibowo, C.S. Lubricity Properties of Palm Oil Biodiesel Blends with Petroleum Diesel and Hydrogenated Vegetable Oil. Lubricants 2023, 11, 176. [Google Scholar] [CrossRef]

- Zöldy, M. Fuel Properties of Butanol—Hydrogenated Vegetable Oil Blends as a Diesel Extender Option for Internal Combustion Engines. Period. Polytech. Chem. Eng. 2020, 64, 205–212. [Google Scholar] [CrossRef]

- Lapuerta, M.; Villajos, M.; Agudelo, J.R.; Boehman, A.L. Key properties and blending strategies of hydrotreated vegetable oil as biofuel for diesel engines. Fuel Process. Technol. 2011, 92, 2406–2411. [Google Scholar] [CrossRef]

- Dodos, G.S.; Vassileiou, F.; Karonis, D.; Dodos, G.S.; Vassileiou, F.; Karonis, D. Lubricity of Diesel Fuel Hydrocarbons and Surrogate Fuels. SAE Tech. Pap. 2017, 1, 2292. [Google Scholar] [CrossRef]

- Hsieh, P.Y.; Bruno, T.J. A perspective on the origin of lubricity in petroleum distillate motor fuels. Fuel Process. Technol. 2015, 129, 52–60. [Google Scholar] [CrossRef]

- ISO 12156-1:2023; Diesel fuel—Assessment of Lubricity using the High-Frequency Reciprocating Rig (HFRR)—Part 1: Test Method. International Organization for Standardization (ISO): Geneva, Switzerland. Available online: https://www.iso.org/standard/85698.html (accessed on 3 May 2025).

- ASTM D6079; Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR). ASTM International: West Conshohocken, PA, USA. Available online: https://store.astm.org/d6079-18.html (accessed on 3 May 2025).

- Wojtyniak, M. Development of laboratory tests for diesel fuel lubricity evaluation. J. KONES 2005, 12, 375–382. [Google Scholar]

- Delgado, J.; Gadea, M.; Esarte, C.; Peláez, A. HFRR and SL-BOCLE Lubricity of Paraffinic Diesel Fuels Considering Different Origins and Final Formulations with Biodiesels and Additives. Energy Fuels 2020, 34, 2654–2664. [Google Scholar] [CrossRef]

- Rahman, M.; Rasul, M.; Hassan, N.M.S. Study on the Tribological Characteristics of Australian Native First Generation and Second Generation Biodiesel Fuel. Energies 2017, 10, 55. [Google Scholar] [CrossRef]

- Kumar, N.; Varun; Chauhan, S. Analysis of tribological performance of biodiesel. Proceedings of the Institution of Mechanical. Eng. Part J J. Eng. Tribol. 2014, 228, 797–807. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Jamil, M.A.; Rasheed, T.; Sher, F. An Experimental Investigation on Tribological Behaviour of Tire-Derived Pyrolysis Oil Blended with Biodiesel Fuel. Sustainability 2020, 12, 9975. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Sher, F.; Jamil, M.A.; Nuhanović, M.; Razmkhah, O.; Erten, B. Tribological Behaviour and Lubricating Mechanism of Tire Pyrolysis Oil. Coatings 2021, 11, 386. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Masum, B.M.; Arslan, A.; Gulzar, M. Friction and wear characteristics of Calophyllum inophyllum biodiesel. Ind. Crops Prod. 2015, 76, 188–197. [Google Scholar] [CrossRef]

- Mujtaba, M.; Kalam, M.; Masjuki, H.; Soudagar, M.E.M.; Khan, H.M.; Fayaz, H.; Farooq, M.; Gul, M.; Ahmed, W.; Ahmad, M.; et al. Effect of palm-sesame biodiesel fuels with alcoholic and nanoparticle additives on tribological characteristics of lubricating oil by four ball tribo-tester. Alex. Eng. J. 2021, 60, 4537–4546. [Google Scholar] [CrossRef]

- Mosarof, M.; Kalam, M.; Masjuki, H.; Alabdulkarem, A.; Habibullah, M.; Arslan, A.; Monirul, I. Assessment of friction and wear characteristics of Calophyllum inophyllum and palm biodiesel. Ind. Crop. Prod. 2016, 83, 470–483. [Google Scholar] [CrossRef]

- Szymczyk, K.; Zdziennicka, A.; Jańczuk, B.; Lubas, J.; Jaworski, A.; Kuszewski, H.; Woś, P.; Longwic, R.; Sander, P. n-hexane influence on canola oil adhesion and volumetric properties. Int. J. Adhes. Adhes. 2025, 140, 103990. [Google Scholar] [CrossRef]

- ISO 12185; Crude Petroleum, Petroleum Products and Related Products—Determination of Density—Laboratory Density Meter with an Oscillating U-Tube Sensor. International Organization for Standardization (ISO): Geneva, Switzerland, 2024.

- ISO 3104; Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. International Organization for Standardization (ISO): Geneva, Switzerland, 2023.

- ISO 1928; Coal and Coke—Determination of Gross Calorific Value. ISO: Geneva, Switzerland, 2020.

- ISO 2719; Petroleum Products and Lubricants—Determination of Flash Point—Pensky-Martens Closed Cup Method. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- EN 16329; Diesel and Domestic Heating Fuels—Determination of Cold Filter Plugging Point—Linear Cooling Bath Method. European Committee for Standardization (CEN): Brussels, Belgium, 2022.

- ISO 12937; Petroleum Products—Determination of Water—Coulometric Karl Fischer Titration Method. International Organization for Standardization (ISO): Geneva, Switzerland, 2000.

- ISO 3405; Petroleum and Related Products from Natural or Synthetic Sources—Determination of Distillation Characteristics at Atmospheric Pressure. International Organization for Standardization (ISO): Geneva, Switzerland, 2019.

- Szczerek, M.; Tuszynski, W. A method for testing lubricants under conditions of scuffing. Part I. Presentation of the method. Tribotest 2002, 8, 273–284. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).