Abstract

This paper studies the potential of utilizing cocoa residues to address energy demands in post-conflict regions of Colombia. Through a systematic review, the findings indicate that cocoa byproducts from 170 municipalities could produce enough biogas to power a population nearing one million inhabitants. Three main residues can be obtained from processing cocoa—mucilage, cocoa bean shells, and cocoa pod husks—which are analyzed and recognized as the most significant in terms of potential biogas yield. The review highlights a considerable gap in existing research regarding the specific characteristics of cocoa residues and their biogas production rates. Additionally, this study emphasizes the need to investigate pretreatment methods for these materials, particularly cocoa pod husks, as well as the critical impact of transportation logistics. It also suggests exploring integrated valorization strategies and various energy conversion pathways. Finally, the article emphasizes the importance of establishing markets and promoting new initiatives to effectively utilize this abundant amount of waste. The insights gained from this analysis are relevant to similar regions, not only across South America but also in any cocoa-producing area worldwide.

1. Introduction

Sustainable Development Goals (SDGs) are guidelines for improving global socioeconomic and environmental situations []. Specifically, SDG 7 encourages efforts to ensure access to affordable, reliable, sustainable, and modern energy for all []. In this context, there is a consequent need to develop new sources of energy. The production of fuels derived from biomass emerges as a promising alternative in the current global scenario []. The use of residues (i.e., agricultural and domestic) for energy production has gained traction due to its potential to minimize the environmental impact of energy production and the utilization of widespread resources such as these residues, with both factors becoming highly relevant for rural areas []. Biofuels are key for the transition from non-renewable to renewable resources []. Biorefinery processes, i.e., the sustainable method for producing biofuels and other bioproducts from biomass feedstock using different conversion technologies, are being transformed from concepts to reality [,] and constitute a fundamental step in the path to implementing a bioeconomy model [,].

Globally, agricultural residues are increasing and approximately one third of the food produced, i.e., 1.3 billion tons/year, is wasted during processing, distribution, and consumption []; however, that waste could be transformed into clean energy and a new revenue source [,]. The waste resulting from the agricultural industry represents 50% of the total weight of the fresh harvested product, which in energy terms is equivalent to 90 million tons of oil []. The growing world population demands a greater amount of energy [].

Agricultural residues are important in countries with an agricultural vocation, such as Colombia. According to the World Bank [], the agriculture in Colombia accounted for 7.6% of gross domestic product (GDP). Agricultural biomass encompasses both the food-based portion, i.e., oils and carbohydrates from crops like corn and sugarcane, and the non-food-based portion, from crops such as coffee leaves and cocoa pod husks (CPH) [,].

The United Nations Framework Convention on Climate Change (UNFCCC) noted that Colombian agriculture has been severely affected due to the armed conflict that has been going on for more than 50 years []. In August 2016, the two parties (i.e., government and guerilla) signed a peace agreement to end the oldest conflict in Latin America [], and one of the tools for its implementation is Decree 893 of 2017 []. In Decree 893, the country regions were prioritized (i.e., 16 regions and 170 municipalities) according to the criteria of (i) poverty levels, (ii) degree of affectation derived from the conflict, (iii) weakness of administrative institutions and management capacity, and (iv) illegal presence of crops and other illegitimate economies. Economic activities in prioritized post-conflict areas are highly dependent on agriculture []. After signing of the peace agreement, attention has been focused on the implementation of comprehensive rural reform [,] to prevent environmental problems such as deforestation, land use, and biodiversity preservation [,,,] and to reduce the economy’s dependence on the extractive sector [], therefore seeking to generate activities from agricultural and forest residues []. Colombia is the only country in the world where post-conflict strategies have been implemented amid armed confrontation and without peace negotiations having been completed []. Thus, the post-conflict scenario in Colombia envisions new opportunities for economic development in rural areas [,].

Cocoa, a perennial neotropical crop, is one of the most widely distributed and recognized products globally [], serving as the foundation for the thriving chocolate industry [,]. Worldwide, cocoa bean production is estimated at 4.9 million tons, with the market projecting a value of EUR 169 billion by 2026. The growth of confectionery products in Asian countries has led to an increasing demand for high-cocoa content products and organic chocolates. Colombia ranks among the top 10 cocoa producers [,,,], and in Latin America, the cocoa fermentation process has led to shorter production times and enhanced aroma quality.

Recently, efforts have been made to implement the criteria determined by the ISO 3410 Standard called: Sustainable and traceable cocoa, Part 1: Requirements for cocoa sustainability management systems [] for sustainable cocoa production as a differentiation strategy [].

Meanwhile, industrial waste from cocoa is estimated to be between 10 and 15 times the amount of cocoa produced, influenced by various factors such as weather conditions and species []. The main waste products resulting from cocoa industrialization include CPH, mucilage (CM), and cocoa bean shell (CBS) [], which remain underutilized. According to the Ministry of Agriculture and Rural Development [], in 2017, the total area cultivated for agro-industrial purposes in Colombia was 2 million hectareas, with cocoa cultivation accounting for 6.3%. In 2020, 65,170 tons of cocoa were produced and 11,150 tons were exported, representing approximately USD 27,942,058 or around 0.011% of the Colombian GDP. Cocoa is cultivated across 27 departments and 422 municipalities, involving 65,341 families [].

Planting, growing, and harvesting cocoa in post-conflict regions generates residues that are used in different ways. Among the alternative uses of agricultural residues are the production of direct heat [], biogas, and liquid biofuels []. The potential of biogas as a viable alternative energy source has been widely recognized globally, and the use of agricultural biomass for biogas production has increased in recent years []. Biogas is used for cooking and also provides health benefits compared to alternatives, such as burning cattle dung, leaves, and wood indoors []. Additionally, biogas is regarded as a climate-neutral fuel, as the carbon dioxide released during combustion is considered biogenic and, therefore, does not contribute to climate change [,]. There are thousands of centralized biogas plants in Europe that utilize manure and sludge from wastewater treatment plants, along with a wide range of easily digestible residues for heating and electricity generation []. Most of these facilities are based on anaerobic digestion (AD) or fermentation [,,]. Between 2009 and 2015, the number of biogas plants in Europe increased from 6000 to 17,000, with an annual growth rate of 9% []. Brazil and Mexico are the countries with the most advanced biogas facilities, followed by Colombia and Peru [].

The most recent research has expanded the technological opportunities to obtain biogas from new types of waste which, in addition to generating economic benefits, generates environmental, social, and health externalities [,,], and interest for industrial applications in the production of biogas using cocoa residues has grown in the last decade []; however, it has been little explored as a biological treatment of cocoa residues []. AD has benefits ranging from generating renewable energy and reducing greenhouse gas emissions to improving health/hygiene and the overall socio-economic status of rural communities in developing countries. It is probably the most important technology to provide clean and renewable energy to millions of people in rural areas of these countries [,]. On the other hand, [] mention that the technology generates income for impoverished countries.

This paper hypothesizes that cocoa waste is a significant resource in post-conflict regions of Colombia. It proposes a “waste factor” as a means to quantify this resource and explore the relationship between the amount of cocoa waste and the potential biogas yield.

The main objectives of this paper are as follows: (i) to explore the cocoa production in post-conflict regions in Colombia during the period 2007 to 2019, (ii) to examine the waste generated during cocoa production and, (iii) to investigate the potential to produce biogas through anaerobic digestion as a sustainable alternative to the use of fossil fuels. On the other hand, the paper shows data on the performance of waste in obtaining biogas and discusses the relationship between the volume of cocoa obtained and the waste generated through the so-called waste factor, a relationship shown in a few studies. The data presented can be extrapolated to any region in South America and globally where cocoa is planted, cultivated, and industrialized. The use of biogas or other biofuels in cocoa residues has been little explored [,]. In addition, in this study, the potential of the use of the cocoa residues in post-conflict areas in Colombia is addressed.

2. Materials and Methods

2.1. General Methodology for the Review

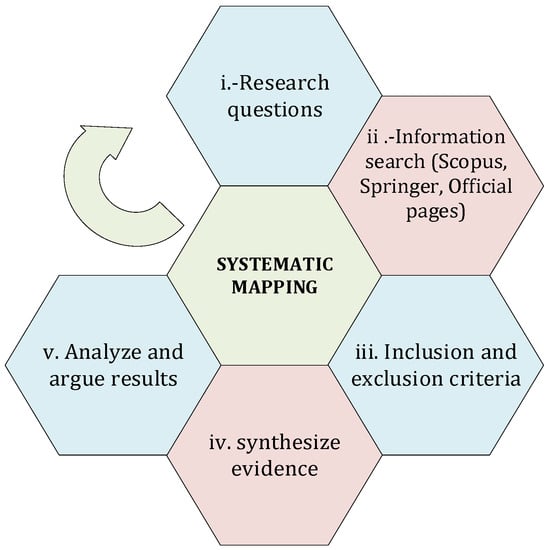

To conduct the review, a five-stage systematic mapping is illustrated in Figure 1. The steps are as follows. (i) Define the research questions. The following questions were defined: a. Which are the prioritized regions in the peace agreement in Colombia []? b. What is the historical production of cocoa in the prioritized regions []? c. How are the residues derived from cocoa cultivation produced []? d. What is the potential for biogas production using these residues, as well as their yield [,,,,,]? (ii) Information was obtained from the Scopus and Web of Science databases and the official websites of the Colombian Ministry of Agriculture (Agronet), the Agricultural Institute (ICA), the Colombia Fund for Peace, the Food and Agriculture Organization of the United Nations (FAO), the National Administrative Department of Statistics (DANE), and the National Institute of Health. In addition, the following keywords were analyzed: cocoa production in post-conflict regions, residues, biogas, and biogas yield. These terms were introduced into official databases and websites before mentioned. (iii) The inclusion and exclusion criteria were defined as the year of publication (2002 to 2019) and the type of publication (articles, books, book chapters). (iv) Documents that could answer the research questions related to the study topic were selected from the database. The information obtained from the documents was synthesized and displayed in figures or tables to demonstrate that the research questions were answered.

Figure 1.

Systematic mapping steps.

For research question (a) (What are the prioritized regions in the peace agreement in Colombia?), the information was summarized using a map of Colombia, where the prioritized regions are clearly observed. For question (b) (What is the historical production of cocoa in the prioritized regions?), the information that answers the question is shown using a bar graph of cocoa production in tons per year for each region. For question (c) (The production of waste derived from cocoa cultivation), after applying the respective calculations, a table is obtained that mentions the type of waste and the percentage that this waste represents in terms of the fruit and from there, the amount of waste generated for each ton of fruit is shown. Finally, to answer question (d) (The potential for biogas production that can be generated from waste), tables were raised that show the type of cocoa waste, the percentage that this type of waste represents in terms of the fruit, the tons of waste generated, and the potential for biogas production in cubic meters for each ton of waste. (v) In the Results and Discussion sections, the results are thoroughly analyzed and evaluated, culminating in the Conclusions.

2.2. Identification of Prioritized Regions

The first step of the specific methodology of this paper was to identify the prioritized regions in Colombia. In this case, according to the Decree 893 of 2017 [], a document issued by the Presidency of the Republic of Colombia, in which the post-conflict regions in Colombia were prioritized, was used in this research. This document defined the prioritized regions that have a Territorial Development Plan (PDET), an instrument created to accelerate the implementation and have the necessary resources defined in the peace agreement [].

2.3. The Cocoa Production in the Prioritized Regions

The second step of the methodology was to study cocoa production in the selected regions. Cocoa production quantities were obtained from the information reported by the Ministry of Agriculture of Colombia in the open-access database Agronet1 for production, planted area, harvested area, and crop yield during the period from 2007 to 2019. All municipalities in the prioritized areas were studied, culminating in a comprehensive total of 170 municipalities.

To perform searches related to cocoa production in the post-conflict regions of Colombia, different databases containing information on agricultural production in Colombia were located. The databases included as possible sources of information are mentioned as the System for Rural Agricultural Planning (SIPRA) [], Agricultural Library of Colombia (BAC) [], and Agronet [] (the information and communication network of the Colombian agricultural sector) [].

To select the appropriate database, the comparison method of information retrieval systems was applied. In their work, Ritchie et al. mention that the recovery search results in databases and other information retrieval systems also support database comparison methodologies []. The authors’ methodology mentions two parameters in the selection of databases: (i) relevance and agreement between evaluators (design) and (ii) statistical validation of the data []. In the authors’ research, statistical tests were used to determine the significance of their results; the test chosen depends on the nature of the data.

The design required the following first steps. The level of agreement of three reviewers of the data obtained needed to be quantified [] considering the timeliness of the data (years) and how the data are presented (disaggregation, level of detail in terms of departments, municipalities, cities). Regarding the timeliness of the data (year), the SIPRA page presented data up to 2017, the BAC page data up to 2018, and only Agronet showed data up to 2019, so at this point, the best selection is Agronet. Regarding how the data are presented, SIPRA shows studies on cocoa production in the form of bulletins without specifying production at the departmental level and BAC shows newsletters with cocoa production data only from certain departments and regions, among which are not all of the post-conflict regions that this study considers. Agronet provides information in two sections: (1) the statistical information section breaks down topics such as agriculture, livestock, and trade and (2) in the agricultural section, information related to agricultural production is shown by crop type, period year (from 2007 to 2019), product (e.g., coffee, cocoa, others), and department.

The Agronet database has the parameters of relevance and agreement between evaluators, and the statistical validation or data quality. Agronet database is subjected to validation. Stokes et al. mentioned the following: Agronet database uses statistical tests to determinate the significance of the results, and the chosen test depends on the nature of the data []. On the Agronet website, it is mentioned that the database can be subject to the Friedman test to identify the differences between other databases in terms of precision, novelty, and availability. Deka et al. [] mentioned that the ANOVA and Tukey’s HSD tests are used to evaluate the difference between the mean of relevant/stable results. Sewell et al. [] mentioned that SIPRA and BAC do not have information about the reports of statistical validation.

Regarding the information given above, it suggests that Agronet is the best database to consider for the present study. On the other hand, it was found that according to [], Agronet is recognized as an efficient tool by all policy makers from all government levels, technicians, academics, union leaders, and general citizens. Also, it is considered a reference for most of the actors of the Colombian agricultural and academic sectors.

2.4. The Residues Derived from Cocoa Industrialization in the Prioritized Regions

Once information regarding cocoa production was obtained in the prioritized areas in Colombia, a calculation of the total quantities of residues was performed. For the calculation of residues generated during the cacao industrialization, the residue index (RPR), i.e., the ratio of the residue produced to the main product, was used, according to Equation (1) [,]:

〖Residues〗_crop (ton) =〖Product〗_crop (ton)∗Residue index(RPR)

The energy production generated from residues is limited by their moisture content, which is usually in the range of between 60% and 80%, and the feasibility of the technology being applied []; a dry mass of the residues was obtained using Equation (2):

where ms is the dry mass, mh is the wet mass, and %H is the percentage of moisture of the residue under study [].

% ms = %mh∗((100−%H))/100

All of the data from the equations were obtained from different references according to the general methodology of Figure 1.

2.5. Potential of Biogas Production Using Residues from Cocoa Industrialization in the Prioritized Regions

Once the total quantity of residues is obtained, the following step is to study the potential of biogas production. In this case and taking into account the general methodology illustrated in Figure 1, a review of the literature was carried out using the Scopus and Web of Science databases; the keywords cocoa, biogas, and production were introduced, words that allowed us to answer the research questions posed (stage I of the MS systematic mapping). A total of 35 articles were obtained in Scopus and 37 documents from the Web of Science (stage II of the MS) to identify a. technologies to produce biofuels, with emphasis on the production of biogas from cocoa crop residues; b. the most widespread technologies used for the pretreatment of cocoa crop residues; and c. the information necessary to calculate the potential for biofuel production using the quantities of waste generated in post-conflict regions (stage III of the MS). Therefore, in each case, the biogas/biofuel production performance (i.e., L of fuel/kg of waste) and operating conditions were identified, then the evidence was synthesized (stage IV of the MS) to finally analyze the potential of biogas in the post-conflict rural areas in Colombia and to discuss the obtained results (stage V of the MS).

3. Results and Discussion

3.1. Identification of Prioritized Regions Subsection

Decree 893 of 2017 considered the following criteria for the prioritization of regions: a. high levels of poverty (i.e., extreme poverty and unmet needs); b. degree of affectation derived from the conflict; c. weak administrative institutions and management capacity; and d. the presence of crops for illicit use and other illegitimate economies []. The multidimensional poverty index is ranked as 72.8%, in contrast with 49.0% for the national level []. It is mentioned that in prioritized or post-conflict regions, strategies to reduce poverty must include the social and productive inclusion of the population.

The concept of post-conflict not only recognizes the absence of conflict but also the transition to lasting peace, which influences social cohesion and increases the potential to improve the use of natural resources, the consolidation of peace allows for better functioning of the sustainable land use systems including agriculture and the cultivation of regional products [,]. Multidimensional poverty is greater in post-conflict regions of Colombia than in those where access to land and crops are adequate; poverty resulting from conflict undermines social trust and cohesion [].

Moreover, 67.0% of the prioritized regions have between a very high and high incidence of armed conflict, and 94.2% of the illicit crops are concentrated here. During 2015, those regions, according to the comprehensive municipal performance evaluation score, had average efficiency and efficacy components of 56.4 and 66.1 in comparison to the national scores of 59.8 and 75.3 []. In terms of economy, agriculture is the third largest sector of all economic activity after social services and mining [,].

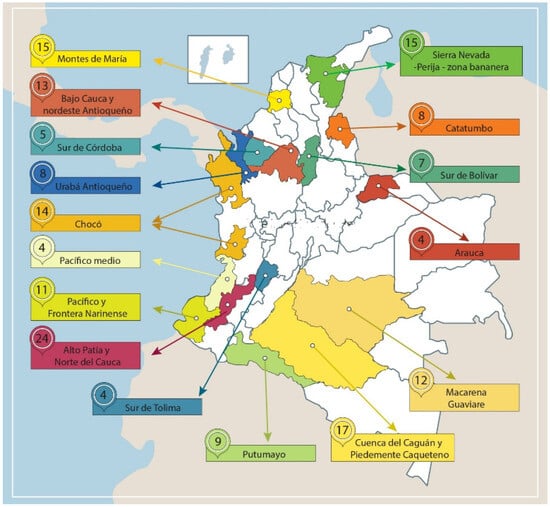

As a result, 16 subregions with a total of 170 municipalities were prioritized that respond to similar levels of development, history, and economic activities and are home to 6.8 million inhabitants, with 56% living in rural areas]. Thus, the prioritized regions are presented in Figure 2.

Figure 2.

Prioritized regions in Colombia post-conflict.

3.2. Cocoa Production in the Prioritized Regions

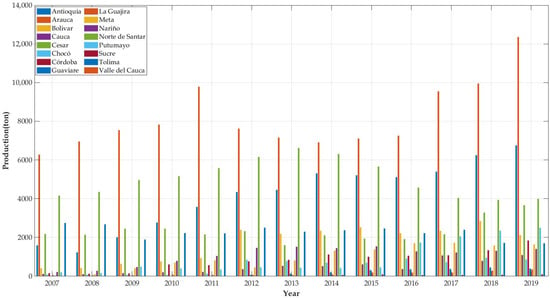

According to the specific methodology of this study and as shown in Section 2.1, studies of the total cocoa production from the years 2007 to 2019 were obtained for the 170 prioritized post-conflict municipalities (www.agronet.gov.co, accessed on 8 April 2025) []. The results show a 123% increase in production, from 18,260 tons in 2007 to 40,740 tons in 2019.

Yearly regionalized production is presented in Figure 3, where it can be observed that the departments of Arauca, Antioquia, Norte de Santander, Cesar, and Tolima have the highest cocoa production during the analyzed period. Arauca was the department with the highest production, with 6270 tons in 2007 and 12,360 tons in 2019, whereas Norte de Santander had 4160 tons in 2007 and 3990 tons in 2019. Cesar produced a total of 2180 tons in 2007 and 3660 tons in 2019, whilst Tolima 2007 had a production of 2740 tons and 1700 tons in 2019. As can be seen in the results, Arauca and Cesar increased the production of cocoa from 2007 to 2019; however, Norte de Santander and Tolima reduced the production by 4% and 38%, respectively.

Figure 3.

Regionalized cocoa production in post-conflict regions (ton). Source: own elaboration using information from Agronet (www.agronet.gov.co, accessed on 5 March 2025) [].

3.3. Amount of Residues Derived from Cocoa Industrialization in the Prioritized Regions

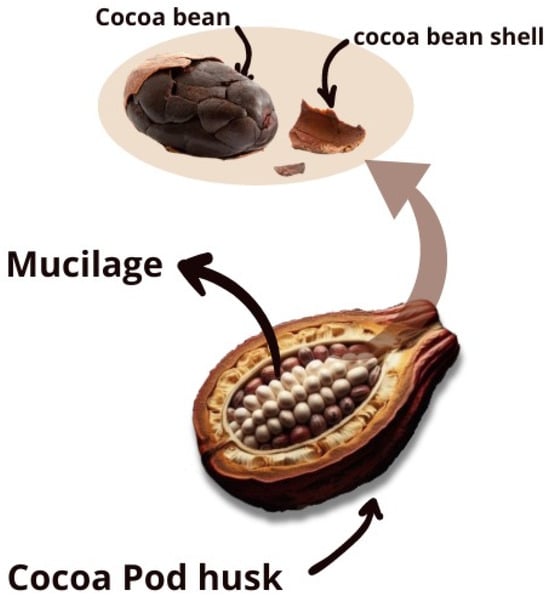

Residues generated during the industrialization process of cocoa are shown in Figure 4. Three types of waste are mainly produced:

Figure 4.

Industrialized cocoa residues. Source: adapted from [].

- Cocoa pod husks (CPHs) constitute the external part of the fruit and are composed of three layers (endocarp, mesocarp, and epicarp). It is the most abundant residue (i.e., between 67% and 76% of the mass of the cocoa fruit) and it has been the most studied by several authors [,,]. Among the studies stand those that have found the use of CPH as a precursor for the production of biofuels and fertilizers [], and the production of low added value products such as soaps or animal feed [].

- Mucilage (CM) is a residue of whitish appearance that constitutes a fraction of the pulping process. This is a controlled fermentation where biochemical reactions attempt the separation of the grain from the mucilage. The amount of this residue depends on the type of cocoa, the state of maturation, and its physical integrity [] and is usually between 3 and 5% of the weight of the total fruit [,].

- Cocoa bean shells (CBS) constitute around 2.8% of the weight of the fruit [,,] and represent around 10–17% of the total weight of cocoa beans [].

It is estimated that approximately 10 tons of residue is produced for each ton of industrialized product [,] and that the average of the moisture content of the different fractions of cocoa residues is 85, 82.5, and 71% for CBS, CM, and CPH, respectively [,,].

The total quantities of waste generated during cocoa industrialization in post-conflict areas in Colombia were calculated according to Equation (1), considering the cultivated quantities of cocoa between 2007 and 2019 (Figure 3) and the average production of the residue according to the references. The results are presented in Table 1, where it can be seen that during 2007, there was a total production of 18,260 tons of cocoa (on a wet basis) in the post-conflict regions, with an estimated 182,600 tons of residue produced, discriminated as 26,400 tons of CBS, 23,000 tons of CM, and 133,200 tons of CPH. In 2019, the production of cocoa (on a wet basis) was 40,740 tons, with 407,400 tons of residues, discriminated as 58,960 tons of CBS, 51,300 tons of CM, and 297,200 tons of CPH.

Table 1.

Potential of residues production from the industrialization of cacao in the post-conflict regions in Colombia.

To demonstrate the potential for waste production, the cacao variety used in the analysis must be considered. There are three genetic groups of cacao trees or varieties: Criollo (T. cacao spp. Criollo), Forastero (T. cacao spp. Sphaerocarpum), and Trinitario [].

Criollo cacao is currently grown in Colombia. This type is of higher quality and represents only 5% of the total cacao produced worldwide. In Ecuador, the so-called Forastero cacao is grown, which is of medium quality and accounts for 75% of global production. Trinitario cacao, a hybrid between Criollo and Forastero, accounts for 20% of the global total and is produced in the same areas where Criollo cacao is produced [].

Criollo cacao is considered a fine variety of so-called aromatic cacao, used to make much sweeter and less bitter chocolates. This variety represents 10% of global annual production. Forastero is the most widely cultivated variety, accounting for almost 90% of global production; it grows mainly in West Africa (Ivory Coast, Ghana, Cameroon, and Nigeria) and has little flavor or aroma.

Trinitario is a hybrid derived from a variety obtained on the island of Trinidad; derived from the crossing of the two previous varieties, it is more aromatic than the Forastero and more resistant than the Criollo [].

It is estimated that between 80% and 90% of total cocoa production is discarded as waste, and only between 10% and 20% is destined for the market (cocoa beans) [].

After harvesting the cocoa fruit, the first residue produced during pulping is the cob husk (CPH), the main residue generated in cocoa production, which represents between 52 and 75% of the weight of the fruit; other authors such as [] mention that they represent between 70 and 80% of the weight of the fruit, though this depends on the variety of cocoa and the way of processing it []. The authors also mention that it should be considered that these proportions depend on the climatic conditions—temperature and humidity—determined by the geographical location of the cocoa plantations. As observed, the variation in the amount of CPH generated ranges between 5% and 18%. If we compare the three varieties of cocoa, studies such as [] determine that, in general, the so-called Trinitario generates the greatest amount of waste, followed by the Criollo and finally the Forastero; however, this cannot be generalized because other factors influence the generation of waste, as mentioned above.

As will be seen later, the CM mucilage is obtained after cocoa processing by manipulation and pressure; it is obtained from the pulping of the fruit, after splitting the cocoa pod in half []. The amount of mucilage generated as a residue depends on the type of cocoa, the maturation, and the physical integrity of the fruits. The data show that the CM represents 8 and 13% [,] of the total weight of the fruit; a variation of 5% is verified, according to the author mentioned [,]. This percentage of variation depends on the factors already mentioned.

3.4. Biogas Production Potential from the Waste Studied, and the Production Yield of Each Type of Waste

In Colombia, Law 1715 of 2014 establishes regulations for the integration of non-conventional renewable energy, including biogas and biomethane, into the National Energy System, providing a solid legal framework and offering investment incentives []. This law incentivizes the development of renewable energy in Colombia to reduce dependence on a single technology, maintain a clean energy generation matrix, and reduce the risks associated with relying on energy imports. In Colombia, the biofuels policy is the strongest element of the country’s energy security strategy. Biofuels reduce the need to import diesel or gasoline by replacing a percentage of each gallon with ethanol or biodiesel []. The law mentions that in the case of individuals and the self-government structures of Indigenous peoples and communities and of peasant, Black, Afro-Colombian, Raizal, and Palenquera communities that are constituted as Energy Communities, they may be beneficiaries of public resources for the financing of investment, operation, and maintenance of theses infrastructures []. Additionally, Law 2099 of 2021, in addition to making numerous modifications and additions to Law 1715 of 2014, authorized the Ministry of Energy and Mines to promote the development and research of energy products of organic and renewable origin to issue the regulations that allow their inclusion within the national energy matrix [].

Biofuels for domestic consumption, as in South American countries, have also been promoted in some sub-Saharan African countries, especially in landlocked countries such as Malawi [].

Cocoa cultivation is of great socioeconomic importance in Latin America and the Caribbean (LAC) as it is one of the main export products, both as a raw material and as processed products. There are approximately 1.8 million hectares planted in Latin America and the Caribbean []. Cocoa is cultivated from Mexico to Brazil, the latter being the most important in terms of planted hectares, accounting for 40% of the region’s total. The countries that follow in terms of planted hectares are Ecuador (24%), Colombia (9%), the Dominican Republic (9%), Peru (6%), and Venezuela (4%) []. Nearly 90% of production is cultivated in family farming (FF). In the region, cocoa cultivation has a long history linked to millions of people, many of them linked to AF, so it is a source of economic income and favors the redistribution of the wealth of the countries [].This crop constitutes an alternative to face the effects of climate change and is currently key to carrying out peace processes, constituting a viable option to replace illicit crops and other less profitable crops in several countries such as Colombia. In Colombia, with the signing of the peace agreement between the FARC and the national government in November 2016, access to producing farms that were located in conflict zones was facilitated, as well as to new areas suitable for cocoa []. Regarding job creation, it is estimated that in Colombia, three hectares of cocoa generate one direct job and one and a half (1.5) indirect jobs. Between 2013 and 2018, direct jobs related to cocoa production activities increased from 51,000 to 62,000, and indirect jobs increased from 75,000 to 93,000 [].

In countries like Ecuador, cocoa production has a significant impact on the country’s economy, providing an important source of employment and generating income for farmers and their families. According to estimates by the Ministry of Agriculture and Livestock, cocoa cultivation in Ecuador generates approximately 500,000 direct and indirect jobs [].

The production of raw materials for biofuels has been associated with various socioeconomic and environmental impacts at the local level. Economically, it has been shown to boost rural development and increase population income []. In this regard, local results are positive due to the participation of rural communities in the production of raw materials, their transportation, processing, and final use in obtaining biogas [,]. These positive aspects are also related to household income, poverty alleviation, and increased food security [].

In these contexts, biofuels are perceived as a way to increase the energy security of countries and, at the same time, boost rural development and poverty reduction through the generation of income and rural employment [,]. Installing and operating biogas production plants not only allows for the proper use of waste from local agricultural products, but also generates employment because they require the collection and transportation of biomass, and once at the plant, personnel with different levels of education are required to monitor its operation [].

In addition to influencing the improvement in the quality of life of households, increased income can also have additional impacts on human well-being, for example, by facilitating better access to food. Access to mass consumption goods, such as clothing, food, and household items, is also improved [,].

Biogas technology offers a sustainable and environmentally friendly solution to meeting energy needs, especially in rural areas.

Although biogas technology has several advantages, the main problem hindering the technology’s penetration in rural areas is the high maintenance cost of digesters [,]. The lack of knowledge regarding the maintenance of biogas storage systems is the biggest challenge to biogas production in rural China. Other challenges include the lack of technical knowledge and the complexity of some biogas digester designs.

On the other hand, [] summarize the main challenges encountered in rural areas of Limpodio, South Africa, which can be extrapolated to the reality of rural areas in South America []. These challenges are summarized as the following: limited resources available, technical challenges (digesters do not work, biogas production is limited, access to technical personnel is limited), knowledge problems (lack of awareness, perceptions about biomass, mistrust about the operation of biodigesters), and socioeconomic factors (restrictions, high investment, little financial support from institutions). They also mention that most biogas users are unaware of the operating principle of the technology. This lack of knowledge makes the operation, maintenance, and even technical service of biogas digesters difficult. This also results in suboptimal production, since the biogas requirements for optimal production are not fully met. Despite the difficulties and challenges that determine the adoption of biogas technology in post-conflict areas of Colombia, it is possible to apply it because this technology responds to the needs of rural areas, especially when integrated with agricultural practices [].

Although biogas technology presents difficulties, comprehensive policies addressing the construction and operation of high-efficiency biogas systems could resolve the existing dilemmas in their operation [,]; furthermore, if rural households were subsidized for the operation and maintenance of high-efficiency biogas systems, this could increase their production [,,].

The main biofuels are bioethanol, biogas, and biodiesel. Bioethanol is a type of alcohol that is produced from materials rich in sugars and is mainly used for vehicles mixed with gasoline. In post-conflict regions, the presence of vehicles is limited or non-existent []. On the other hand, biodiesel is produced from vegetable oils and animal fats, which in post-conflict regions of Colombia are limited; biodiesel is used mixed with diesel to be used in engines []. Biogas is obtained from the decomposition of organic matter in the process of anaerobic digestion and is mainly used to generate heat and electricity and, unlike the previous two, it is more useful in rural areas because it is in these areas where conventional energy is limited [,].

Biogas is widely distributed in countries with developed agriculture (such as India, China, Brazil, etc.), which makes it an economically and ecologically viable option as a simultaneous solution to waste treatment problems and energy demand []. The main problems associated with the production of ethanol as a fuel are economic and environmental. The economic problems are related to the prices of cereals that compete with its use as food [], which is scarce in post-conflict areas of Colombia. A more attractive option in rural areas is the production and use of biogas because it is always related to the simultaneous processing of waste and energy production with the closing of the carbon cycle at the local level [,].

The potential for using cocoa residues to generate energy is promising [], and some experiences show that the yield values are good enough to consider these possibilities [,]. However, in the post-conflict regions of Colombia, there is no evidence that anaerobic digestion plants in can use cocoa residues as a substrate [,,].

Recent studies have reported the use of cocoa industrial wastes to produce solid, liquid, and gaseous biofuels []. Different types of biofuels can be obtained from cocoa residues: biogas, ethanol, methanol, biodiesel, etc. []. Cocoa pod husks (CPH) are one of the most studied; however, they are underexploited [,].

According to [,,] anaerobic digestion, compared to other biofuel production processes, is at a more advanced level of technological maturity and sectoral development, which allows the treatment of organic matter from different types of waste or materials of agricultural origin and also integrates the generation of renewable energy with the development of the circular economy and waste management in the same process. On the other hand, from a technical point of view, anaerobic digestion generates environmental and economic advantages derived from the integration of the recovery of different wastes in a single facility [,].

Table 2, Table 3 and Table 4 summarize studies on technologies to produce biogas from industrial cocoa residues. Biogas is one of the most versatile sources of renewable energy []. The obtainment and use of biogas has many advantages compared to bioethanol and biodiesel, the main one being that it is the only renewable energy that can be used for all energy applications, whether as fuel, or for thermal or electrical applications, according to M. K []. The processes of recovery of cocoa residues in anaerobic digestion produce digestate. In addition, mentions that for every ton of CPH, 0.89 tons of digestate are produced []. This can be used as high-quality fertilizer, which has not only economic but also environmental benefits [] because it can replace traditional fertilizers, which allows increased productivity in the fields of livestock and agriculture.

Table 2.

Potential production of biogas from CPH residues. CPH = cocoa pod husk. AD = anaerobic digestion.

Table 3.

Potential production of biogas from CBS residues. CBS = cocoa bean shell; VS = volatile solids.

Table 4.

Potential production of biogas from CM residues. CM = mucilage. COD = chemical oxygen demand.

An anaerobic digestion plant provides a wide range of environmental and social benefits for the actors in the system. The main product of the process is biogas. This is a high-quality, renewable fuel that can be used efficiently for electricity generation, thereby reducing greenhouse gas (GEI) emissions and dependence on imports [].

On the other hand, [] concluded that when using cocoa residues, the two most effective treatment technologies for the recovery of CPH are hydrothermal carbonization and anaerobic fermentation since their potential in the production of biogas has already been proven. Likewise, Rico et al. [] noted that cocoa shells (CPH) showed the highest methane yield compared to organic waste such as sludge and cow manure.

The use of cocoa residues for biogas production using anaerobic digestion (AD) is a relatively simple alternative that allows a reduction in the mass of such residues []. However, given their high content of lignocellulosic material, sometimes it is necessary to pre-treat them to increase the availability of organic material, therefore increasing the feasibility of the conversion via biofuel production. The pretreatment technologies used for cocoa and specifically for CPH are important issues in the application of biofuel generation processes (for example, biogas and ethanol) in small- and large-scale cocoa-producing countries. The high availability of waste from cocoa is essential []. According to DANE data, in 2019 in Colombia, 64,281 tons of cocoa were produced, which represents approximately 642,000 tons of waste; in Ecuador, according to ICCO, (2016) [], 234,000 metric tons of cocoa beans were produced per year and each ton of dry cocoa beans generated between 10 and 15 tons of wet cocoa residue, which consisted mainly of pods [], CBS, a lignocellulosic material obtained from the roasting process, has valuable nutritional compound content thanks to the migration of polysaccharides, phenols, methyl xanthines, and caffeine from the cocoa grains during the fermentation process [] Also, the potential for energy production using CBS lies in its high calorific value, which is slightly higher than that of wood. In the article by [], the authors present a review of the possibilities of applying the concept of biorefineries using the different types of residues generated during the industrial processing of cocoa []. For instance, direct combustion was studied, and a high potash content was found in the ashes; therefore, the use of this process needs more analysis []. In the case of AD, to ensure adequate stability of the process, the decisive factor is the C/N ratio, whose optimal range is from 25 to 32. The CPH has a C/N range of 28 to 34; therefore, it has been considered as a promising material for the application of AD [].

Research conducted by [] presents the results obtained from technical, economic, social, and environmental analyses of different alternatives for thermo- and biochemical conversion processes using cocoa residues for the production of heat and power in rural areas of the Côte d’Ivoire (i.e., direct combustion, gasification, pyrolysis, anaerobic digestion, and hydrothermal carbonization). This investigation concludes that CPH is a material that, in addition to being abundant and not competing for land, has a high calorific value, i.e., 17.9 MJ/kg vs. 18.6 MJ/kg for wood (dry basis) [].

The study concluded that from the examined alternatives, AD and hydrothermal carbonization are the most feasible due to six factors being considered, such as the efficiency in the coal conversion and in the electrical energy production, requirements for raw materials, products, use of products, and cost. In the case of AD, the reactor model analyzed was a continuous flow horizontal reactor operating under thermophilic conditions. Biogas production was calculated as 208.1 m3/ton of wet CPH, with a methane concentration of 53%.

The study by [] showed that CPH was effectively pretreated using a 7.5% (w/v) aqueous solution of hydrogen peroxide (H2O2) at a temperature of 30 °C, with 130 rpm for 75 min, before the co-AD process of a mixture CPH/chicken manure which produced a super habit of 134 kWh of heat from the biogas, a methane content between 63 and 66%, and therefore can be used for direct supply or converted to electrical energy.

The potential of biogas is calculated in relation to the obtained residues and taking into account the dry bases of the residues and the yield of biogas. Table 5 shows the obtained results.

Table 5.

Potential production of biogas and biofuels from cocoa residues.

The potential available electricity in the 170 municipalities of the prioritized areas in Colombia based on the biogas production from cocoa residues is shown in Table 6 and Table 7. The electricity production potential was calculated considering that every 20 m3 of methane can produce 250 KWh of electricity, the 56% methane of biogas, 12.5 KWh/m3 from the methane, and a daily average electricity consumption per capita in Colombia of 3.87 KWh [,,,]. According to the results, the daily electricity potential production will be 1393 MWh in 2007 (141 from CBS, 216 from CM, and 1036 from CPH) and 3109 MWh in 2019 (315 from CBS, 482 from CM, and 2312 from CPH). However, if we take into account the results of Macini et al. [], the daily electricity potential production will be 531 and 1186 MWh in 2007 and 2019, respectively, only taking into account the CPH residues.

Table 6.

Potential production of electricity and inhabitants in relation to the production of cocoa in 2007.

Table 7.

Potential production of electricity and inhabitants in relation to the production of cocoa in 2019.

4. Conclusions

This study determines the potential application of cocoa residues for biogas production in post-conflict areas in Colombia; a total of 170 municipalities from 16 subregions were prioritized, having 6.8 million inhabitants, with 56% living in rural areas.

The production of cocoa in the prioritized regions showed an increase from 18,260 tons in 2007 to 40,750 tons in 2019, highlighting the departments of Arauca, Antioquia, Norte de Santander, Cesar, and Tolima.

The studies reviewed highlighted several factors: (i) the need to combine or integrate technologies (anaerobic digestion, pyrolysis, and dark fermentation) among others to achieve higher yields; (ii) the need to make technologies energetically self-sustainable, which may involve coupling different technologies such as anaerobic digestion/slow pyrolysis to increase the possibility of biofuel/biochar/chemical production; and, (iii) depending on the specific market situation, the product portfolio produced can be high quality energy and/or other products.

In addition, there are still some challenges to make the recently developed technologies feasible for use in remote and deprived regions such as those prioritized in post-conflict Colombia. The main challenges are as follows: (i) distances between the cacao growths to optimize the trades off between fuel consumption during transportation and energy been produced; (ii) pretreatment required to make the residues, especially the cocoa pod husk, a suitable material for subsequent biogas production; (iii) market creation and price competitiveness; (iv) more environmental studies on the possibility of using biogas plants in these areas.

Although challenges are encountered in introducing biogas technology in post-conflict regions, there are government policies seeking to integrate biogas as a non-conventional renewable energy into the National Energy System. Investment in these technologies allows for the design, implementation, maintenance, and safe operation of future biogas production facilities.

The industrialization of cocoa produced 26,420 tons of cocoa bean shell in 2007 and 58,960 tons in 2019; 22,980 and 51,280 tons of mucilage in 2007 and 2019; and 133,200 and 297,200 tons of cocoa pod husk in 2007 and 2019, producing biogas for heating and cooking purposes or to supply electricity for 360,000 inhabitants in 2007 and 803,409 inhabitants in 2019.

The implementation of biogas production plants in post-conflict zones requires adequate coordination between the communities in post-conflict zones, the government, investors, and the technical and operational personnel who will introduce these technologies. It is recommended that the first plants be pilot plants with moderate production capacities, so that as their operations stabilize, they can grow in production capacity. This will require the involvement of other stakeholders, such as cocoa producers, the Colombian energy sector, government authorities, and academics, who will provide support and raise awareness among the population about the advantages and disadvantages of this technology and how to efficiently operate the facilities.

This study has limitations in terms of the amount of information presented on the so-called residue index (RPR); however, it is sufficient to guarantee a good approximation of the amount of biogas that can be generated in the areas studied. It is necessary to corroborate the RPR data with experimental data in different regions of South America and the world where cocoa is grown and industrialized.

Author Contributions

Conceptualization, R.F.C.-Q. and A.C.; methodology, R.F.C.-Q., C.B.-A. and T.L.; validation, R.F.C.-Q., J.C.C.-Q., T.L. and A.C.; investigation, C.B.-A. and D.M.C.-C.; data curation, C.B.-A. and D.M.C.-C.; writing—original draft preparation, C.B.-A., D.M.C.-C. and J.C.C.-Q.; writing—review and editing, R.F.C.-Q., A.C., T.L. and J.C.C.-Q.; visualization, R.F.C.-Q., D.M.C.-C. and C.B.-A.; supervision, R.F.C.-Q., A.C. and T.L.; project administration, R.F.C.-Q. and A.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the CELISE project “Sustainable production of Cellulose-based products and additives to be used in SMEs and rural areas”, funded by MSCA-RISE European Union’s Horizon 2020 research and innovation program, with grant agreement No 101007733.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors acknowledge the financial support of the research project H2020-MSCA-RISE CELISE (grant number 101007733) of the European Commission.

Conflicts of Interest

The authors declare no conflicts of interest.

Correction Statement

This article has been republished with a minor correction to an author’s ORCID. This change does not affect the scientific content of the article.

Abbreviations

The following abbreviations are used in this manuscript:

| AF | family farming |

| SDGs | Sustainable Development Goals |

| GDP | gross domestic product |

| VS | volatile solids |

| UNFCCC | United Nations Framework Convention on Climate Change |

| CPH | cacao pod husk |

| CM | mucilage |

| CBS | cocoa bean shell |

| AD | anerobic digestion |

| Agronet | Ministry of Agriculture of Colombia |

| ICA | Agricultural Institute |

| FAO | Food and Agriculture Organization of the United Nations |

| DANE | National Administrative Department of Statistics |

| PDET | Territorial Development Plan |

| RPR | residue index |

| MADR | Ministry of Agriculture and Rural Development |

| MS | systematic mapping |

| GEI | greenhouse gas emissions |

| SMP | specific methane production |

| C/N | carbon nitrogen |

| COD | total organic load |

| DF | dark fermentation |

| ASBR | anaerobic sequencing batch reactor |

References

- Solarte-Toro, J.C.; Cardona Alzate, C.A. Biorefineries as the Base for Accomplishing the Sustainable Development Goals (SDGs) and the Transition to Bioeconomy: Technical Aspects, Challenges and Perspectives. Bioresour. Technol. 2021, 340, 125626. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, A.; Pandit, R.K. Smart Cities in India: Linkages with Circular Economy. In Sustainability in the Built Environment in the 21st Century: Lessons Learned from India and the Region; Iyer-Raniga, U., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 185–200. [Google Scholar]

- Mukherjee, A.; Okolie, J.A.; Tyagi, R.; Dalai, A.K.; Niu, C. Pyrolysis Kinetics and Activation Thermodynamic Parameters of Exhausted Coffee Residue and Coffee Husk Using Thermogravimetric Analysis. Can. J. Chem. Eng. 2021, 99, 1683–1695. [Google Scholar] [CrossRef]

- De-Lucas, A.I.; Taranco, C.d.P.; Rodríguez-García, E.; Paniagua, P.P. Biomasa, Biocombustibles y Sostenibilidad; Centro Tecnológico Agrario y Agroalimentario: Palencia, Spain, 2012; Volume 13, ISBN 9788493189150. [Google Scholar]

- Naqvi, S.R.; Jamshaid, S.; Naqvi, M.; Farooq, W.; Niazi, M.B.K.; Aman, Z.; Zubair, M.; Ali, M.; Shahbaz, M.; Inayat, A.; et al. Potential of Biomass for Bioenergy in Pakistan Based on Present Case and Future Perspectives. Renew. Sustain. Energy Rev. 2018, 81, 1247–1258. [Google Scholar] [CrossRef]

- Bautista-Cespedes, O.V.; Willemen, L.; Castro-Nunez, A.; Groen, T.A. The Effects of Armed Conflict on Forest Cover Changes across Temporal and Spatial Scales in the Colombian Amazon. Reg. Environ. Change 2021, 21, 70. [Google Scholar] [CrossRef]

- Escallón, J.M.V. The Historical Relationship between Agrarian Reforms and Internal Armed Conflicts: Relevant Factors for the Colombian Post-Conflict Scenario. Land Use Policy 2021, 101, 105138. [Google Scholar] [CrossRef]

- Saavedra-Sanabria, O.L.; Durán, D.; Cabezas, J.; Hernández, I.; Blanco-Tirado, C.; Combariza, M.Y. Cellulose Biosynthesis Using Simple Sugars Available in Residual Cacao Mucilage Exudate. Carbohydr. Polym. 2021, 274, 118645. [Google Scholar] [CrossRef]

- Shahid, M.K.; Batool, A.; Kashif, A.; Nawaz, M.H.; Aslam, M.; Iqbal, N.; Choi, Y. Biofuels and Biorefineries: Development, Application and Future Perspectives Emphasizing the Environmental and Economic Aspects. J. Environ. Manag. 2021, 297, 113268. [Google Scholar] [CrossRef]

- Fernando, Y.; Tseng, M.L.; Aziz, N.; Ikhsan, R.B.; Wahyuni-TD, I.S. Waste-to-Energy Supply Chain Management on Circular Economy Capability: An Empirical Study. Sustain. Prod. Consum. 2022, 31, 26–38. [Google Scholar] [CrossRef]

- Saravanan, A.; Hemavathy, R.V.; Sundararaman, T.R.; Jeevanantham, S.; Kumar, P.S.; Yaashikaa, P.R. Solid Waste Biorefineries. In Refining Biomass Residues for Sustainable Energy and Bioproducts: Technology, Advances, Life Cycle Assessment, and Economics; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–17. [Google Scholar] [CrossRef]

- Gontard, N.; Sonesson, U.; Birkved, M.; Majone, M.; Bolzonella, D.; Celli, A.; Angellier-Coussy, H.; Jang, G.W.; Verniquet, A.; Broeze, J.; et al. A Research Challenge Vision Regarding Management of Agricultural Waste in a Circular Bio-Based Economy. Crit. Rev. Environ. Sci. Technol. 2018, 48, 614–654. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Sarsaiya, S.; Kumar, V.; Chaturvedi, P.; Sindhu, R.; Binod, P.; Zhang, Z.; Pandey, A.; Awasthi, M.K. Processing of Municipal Solid Waste Resources for a Circular Economy in China: An Overview. Fuel 2022, 317, 123478. [Google Scholar] [CrossRef]

- World Bank ESCAP: International Trade Costs | DataBank. Available online: https://databank.worldbank.org/source/escap-world-bank:-international-trade-costs (accessed on 25 March 2025).

- Corro, G.; Pal, U.; Bañuelos, F.; Rosas, M. Generation of Biogas from Coffee-Pulp and Cow-Dung Co-Digestion: Infrared Studies of Postcombustion Emissions. Energy Convers. Manag. 2013, 74, 471–481. [Google Scholar] [CrossRef]

- Oosterkamp, W.J. Chapter 13—Use of Volatile Solids from Biomass for Energy Production. In Bioenergy Research: Advances and Applications; Gupta, V.K., Tuohy, M.G., Kubicek, C.P., Saddler, J., Xu, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 203–217. ISBN 9780444595614. [Google Scholar]

- González Álvarez, J. Las Biorrefinerías: Aplicación a Materiales y Residuos Lignocelulósicos. Horizonte 2050. bie3 Boletín IEEE 2018, 11, 718–731. [Google Scholar]

- Presidente de la República. Decreto Ley 893 de 2017—Gestor Normativo—Función Pública. 2017; p. 11. Available online: https://www.funcionpublica.gov.co/eva/gestornormativo/norma.php?i=81856 (accessed on 12 March 2025).

- Álvarez Riascos, K.T. Desarrollo Local Como Herramienta de Postconflicto En Colombia. GeoGraphos. Rev. Digit. Estud. Geogr. Cienc. Soc. 2016, 7, 1–35. [Google Scholar] [CrossRef]

- Suarez, A.; Árias-Arévalo, P.A.; Martínez-Mera, E. Environmental Sustainability in Post-Conflict Countries: Insights for Rural Colombia. Environ. Dev. Sustain. 2018, 20, 997–1015. [Google Scholar] [CrossRef]

- Galván, M.; Degano, S.; Hilbert, J.; Montenegro, M.; Becker, A. CONICET | Buscador de Institutos y Recursos Humanos. In Proceedings of the Caracterización y Adaptación de Sustratos de Faena Porcina para la Producción de Biogás Mediante Digestión Anaeróbica, Córdova, Argentina, 14–16 June 2017; pp. 1–7. [Google Scholar]

- González Cuenca, D.; Molina, D.E.; María, A.; Ramírez, M. Paz Ambiental y Paz Territorial: Los Desafíos de Colombia Para El Postconflicto; Blanch, E.T.L., Ed.; Universidad Santo Tomás: Tolima, Colombia, 2020; pp. 24–39. [Google Scholar] [CrossRef]

- Suarez, A.; Arias-Arévalo, P.; Martinez-Mera, E.; Granobles-Torres, J.C.; Enríquez-Acevedo, T. Involving Victim Population in Environmentally Sustainable Strategies: An Analysis for Post-Conflict Colombia. Sci. Total Environ. 2018, 643, 1223–1231. [Google Scholar] [CrossRef]

- Slunge, D.; García, J.H.; Garcia, J.; Slunge, D. Environment and Climate Change Management: Perspectives for Post Conflict-Colombia. Policy Brief Swed. 2015, 2, 2–35. [Google Scholar]

- Banerjee, O.; Cicowiez, M.; Vargas, R.; Obst, C.; Cala, J.R.; Alvarez-Espinosa, A.C.; Melo, S.; Riveros, L.; Romero, G.; Meneses, D.S. Gross Domestic Product Alone Provides Misleading Policy Guidance for Post-Conflict Land Use Trajectories in Colombia. Ecol. Econ. 2021, 182, 106929. [Google Scholar] [CrossRef]

- Valverde García, D.; Pérez Esteve, É.; Barat Baviera, J.M. Changes in Cocoa Properties Induced by the Alkalization Process: A Review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2200–2221. [Google Scholar] [CrossRef]

- Badrie, N.; Bekele, F.; Sikora, E.; Sikora, M. Cocoa Agronomy, Quality, Nutritional, and Health Aspects. Crit. Rev. Food Sci. Nutr. 2015, 55, 620–659. [Google Scholar] [CrossRef]

- Mendoza-Meneses, C.J.; Feregrino-Pérez, A.A.; Gutiérrez-Antonio, C. Potential Use of Industrial Cocoa Waste in Biofuel Production. J. Chem. 2021, 2021, 3388067. [Google Scholar] [CrossRef]

- Escobar, D.; Juarez, M.; Martinez, B.; Romero, T.; Cuervo, J.; Tirado, J.; Utrilla, M.; Morales, M. Producción de Etanol a Partir de Jugo de Mucílago de Cacao (Theobroma cacao) Como Subproducto de La Fermentación. Ing. Química 2019, 95, 1–4. [Google Scholar]

- Mišević, P.; Volarević, H.; Perić, M. The Trend Analysis of Less Sugar Chocolate Confectionery Markets. In Book of Proceedings, Economic and Social Development, 52nd International Scientific Conference; Varazdin Development and Entrepreneurship Agency: Varazdin, Croatia, 2020; p. 654. [Google Scholar]

- Guirlanda, C.P.; da Silva, G.G.; Takahashi, J.A. Cocoa Honey: Agro-Industrial Waste or Underutilized Cocoa by-Product? Future Foods 2021, 4, 100061. [Google Scholar] [CrossRef]

- Beg, M.S.; Ahmad, S.; Jan, K.; Bashir, K. Status, Supply Chain and Processing of Cocoa—A Review. Trends Food Sci. Technol. 2017, 66, 108–116. [Google Scholar] [CrossRef]

- ISO 34101-1:2019; Sustainable and Traceable Cocoa—Part 1: Requirements for Cocoa Sustainability Management Systems. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/64765.html (accessed on 3 May 2025).

- Hii, C.L.; Law, C.L.; Cloke, M. Modeling Using a New Thin Layer Drying Model and Product Quality of Cocoa. J. Food Eng. 2009, 90, 191–198. [Google Scholar] [CrossRef]

- Ghysels, S.; Acosta, N.; Estrada, A.; Pala, M.; De Vrieze, J.; Ronsse, F.; Rabaey, K. Integrating Anaerobic Digestion and Slow Pyrolysis Improves the Product Portfolio of a Cocoa Waste Biorefinery. Sustain. Energy Fuels 2020, 4, 3712–3725. [Google Scholar] [CrossRef]

- Handojo, L.; Triharyogi, H.; Indarto, A. Cocoa Bean Shell Waste as Potential Raw Material for Dietary Fiber Powder. Int. J. Recycl. Org. Waste Agric. 2019, 8, 485–491. [Google Scholar] [CrossRef]

- European Forest Institute. Alisos. Climate Focus Diagnóstico de La Cadena de Valor Del Cacao, y Mapeo de Los Indicadores y Sistemas de Información Existentes. EUREDD Facil. 2021, 1, 30. [Google Scholar]

- Boletín Técnico Encuesta Nacional Agropecuaria (ENA) 2017 Encuesta Nacional Agropecuaria. Available online: https://www.dane.gov.co/files/investigaciones/agropecuario/enda/ena/2017/boletin_ena_2017.pdf (accessed on 5 April 2025).

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food Waste-to-Energy Conversion Technologies: Current Status and Future Directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef]

- Das, A.; Emele, L.; Meinke-Hubeny, F.; Moorkens, I.; Nissen, C.; Tomescu, M. Renewable Energy in Europe 2018: Recent Growth and Knock-on Effects; European Environment Agency: Copenhagen, Denmark, 2018; p. 76. [Google Scholar]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and Potential of the Anaerobic Digestion of Waste-Activated Sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Reinelt, T.; Delre, A.; Westerkamp, T.; Holmgren, M.A.; Liebetrau, J.; Scheutz, C. Comparative Use of Different Emission Measurement Approaches to Determine Methane Emissions from a Biogas Plant. Waste Manag. 2017, 68, 173–185. [Google Scholar] [CrossRef]

- Ding, H.; Xu, F. Chapter 20-Production of Phytochemicals, Dyes and Pigments as Coproducts in Bioenergy Processes. In Bioenergy Research: Advances and Applications; Elsevier: Amsterdam, The Netherlands, 2014; Volume 2, pp. 353–365. ISBN 9780444595614. [Google Scholar]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Castellanos, D.; Martínez, J.M.R.; Patiño, P.O.G.; Vargas, J.C.; Lozano, M.E.V.; González, C.S.D.; Montoya, O.Q.; Hernández, D.M.D.; Cortes, Y.P.M.; Lombana, L.F.Z.; et al. Estimación Del Potencial de Conversión a Biogás de La Biomasa En Colombia y Su Aprovechamiento; Universidad Nacional de Colombia: Bogotá, Colombia, 2017. [Google Scholar]

- Rodríguez, A.G.; Rodrigues, M.; Sotomayor, O. Hacia Una Bioeconomía Sostenible en América Latina y el Caribe Elementos Para Una Visión Regional; Recursos Naturales y Desarrollo 191; United Nations: New York, NY, USA, 2019. [Google Scholar]

- Ferrer, I.; Lansing, S.; Martí-Herrero, J. (Eds.) Biogas for Rural Areas; MDPI—Multidisciplinary Digital Publishing Institute: Basel, Switzerland, 2022. [Google Scholar]

- Hernando Herrera, H. Generación de Energía a Través de Biogás Em Colombia; Universidad Federal de Integración Latinoamericana: Foz do Iguaçu, Brazil, 2013. [Google Scholar]

- Vásquez, Z.S.; de Carvalho Neto, D.P.; Pereira, G.V.M.; Vandenberghe, L.P.S.; de Oliveira, P.Z.; Tiburcio, P.B.; Rogez, H.L.G.; Góes Neto, A.; Soccol, C.R. Biotechnological Approaches for Cocoa Waste Management: A Review. Waste Manag. 2019, 90, 72–83. [Google Scholar] [CrossRef] [PubMed]

- Da Cruz Ferraz Dutra, J.; Passos, M.F.; García, G.J.Y.; Gomes, R.F.; Magalhães, T.A.; dos Santos Freitas, A.; Laguna, J.G.; da Costa, F.M.R.; da Silva, T.F.; Rodrigues, L.S.; et al. Anaerobic Digestion Using Cocoa Residues as Substrate: Systematic Review and Meta-Analysis. Energy Sustain. Dev. 2023, 72, 265–277. [Google Scholar] [CrossRef]

- Avila, J.M.S.; Noboa, J.W.D.; Rivera, F.R.P.; Quezada, J.P.S. Estimación Del Potencial de Producción de Bioetanol a Partir de Los Residuos de La Corteza Del Cacao En Ecuador. Cienc. Tecnol. Agropecu. 2020, 21, 1–20. [Google Scholar] [CrossRef]

- McDonagh, M.S.; Kleijnen, J.; Whiting, P.F.; Wilson, P.M.; Sutton, A.J.; Chestnutt, I.; Cooper, J.; Misso, K.; Bradley, M.; Treasure, E. Systematic Review of Water Fluoridation. BMJ 2000, 321, 855–859. [Google Scholar] [CrossRef]

- Salcedo-Puerto, O.; Mendoza-Martinez, C.; Vakkilainen, E. Solid Residues from Cocoa Production Chain: Assessment of Thermochemical Valorization Routes. Renew. Sustain. Energy Rev. 2025, 208, 115048. [Google Scholar] [CrossRef]

- Yan, Y.; Yan, M.; Ravenni, G.; Angelidaki, I.; Fu, D.; Fotidis, I.A. Novel Bioaugmentation Strategy Boosted with Biochar to Alleviate Ammonia Toxicity in Continuous Biomethanation. Bioresour. Technol. 2022, 343, 126146. [Google Scholar] [CrossRef]

- Kitchenham, B.A.; Budgen, D.; Pearl Brereton, O. Using Mapping Studies as the Basis for Further Research—A Participant-Observer Case Study. Inf. Softw. Technol. 2011, 53, 638–651. [Google Scholar] [CrossRef]

- Arksey, H.; O’Malley, L. Scoping Studies: Towards a Methodological Framework. Int. J. Soc. Res. Methodol. 2005, 8, 19–32. [Google Scholar] [CrossRef]

- Corredor, Y.A.V.; Pérez, L.I.P. Aprovechamiento de residuos agroindustriales en el mejoramiento de la calidad del ambiente. Revista Facultad De Ciencias Básicas 2018, 14, 59–72. [Google Scholar] [CrossRef]

- Khan, K.S.; Kunz, R.; Kleijnen, J.; Antes, G. Five Steps to Conducting a Systematic Review. J. R. Soc. Med. 2003, 96, 118–121. [Google Scholar] [CrossRef]

- Petersen, K.; Feldt, R.; Mujtaba, S.; Mattsson, M. Systematic Mapping Studies in Software Engineering. In Proceedings of the 12th International Conference on Evaluation and Assessment in Software Engineering (EASE), Bari, Italy, 26–27 June 2008. [Google Scholar] [CrossRef]

- Presidencia de La Republica de Colombia. Decreto 2566 de 2003; p. 15. Available online: https://www.mineducacion.gov.co/1780/w3-article-104846.html (accessed on 4 June 2025).

- FAO. Residuos Agrícolas Y Residuos Ganaderos-Manual De Usuario; FAO: Rome, Italy, 2014; p. 35. Available online: https://www.fao.org/publications/card/es/c/20a4bb52-4d9b-4963-b8e5-73465c93cbdf/ (accessed on 4 June 2025).

- SIPRA. Available online: https://sipra.upra.gov.co/nacional (accessed on 2 April 2025).

- Biblioteca Agropecuaria de Colombia—BAC. Available online: https://www.agrosavia.co/biblioteca (accessed on 2 April 2025).

- Grajales, D.F.P. Agromapas, Geospatial Platform for Rural Affairs in Colombia. In Proceedings of the 3rd International Conference on Agro-Geoinformatics, Agro-Geoinformatics 2014, Beijing, China, 11–14 August 2014. [Google Scholar] [CrossRef]

- Ritchie, S.M.; Banyas, K.M.; Sevin, C. A Comparison of Selected Bibliographic Database Search Retrieval for Agricultural Information. Issues Sci. Technol. Librariansh. 2019, 2019, 1–24. [Google Scholar] [CrossRef]

- Deka, S.K.; Lahkar, N. Performance Evaluation and Comparison of the Five Most Used Search Engines in Retrieving Web Resources. Online Inf. Rev. 2010, 34, 757–771. [Google Scholar] [CrossRef]

- Voorhees, E.M. The Philosophy of Information Retrieval Evaluation. In Evaluation of Cross-Language Information Retrieval Systems; Springer: Cham, Switzerland, 2002; pp. 355–370. [Google Scholar] [CrossRef]

- Stokes, P.; Foster, A.; Urquhart, C. Beyond Relevance and Recall: Testing New User-Centred Measures of Database Performance. Health Inf. Libr. J. 2009, 26, 220–231. [Google Scholar] [CrossRef]

- Sewell, R.R. Comparing Four CAB Abstracts Platforms from a Veterinary Medicine Perspective. J. Electron. Resour. Med. Libr. 2011, 8, 134–149. [Google Scholar] [CrossRef]

- Quintero Osorno, C.A.; Quiroga Velasco, L.F. Estimación Del Potencial Energético a Partir de La Biomasa Primaria Agrícola En El Departamento de Cundinamarca. 2017. Available online: https://repository.udistrital.edu.co/bitstream/handle/11349/5703/QuirogaVelascoLuisFelipe2017.pdf?sequence=1&isAllowed=y (accessed on 15 May 2025).

- Mesa de Conversaciones, Acuerdo Final Para La Terminación Del Conflicto y La Construcción de Una Paz Estable y Duradera. Available online: https://www.jep.gov.co/Documents/Acuerdo%20Final/Acuerdo%20Final%20Firmado.pdf (accessed on 15 May 2025).

- McGreevey, W.P. Historia Económica de Colombia, 1845–1930; Universidad de Los Andes: Bogotá, Colombia, 2017; Available online: https://economia.uniandes.edu.co/publicaciones/libros/historia-economica-de-colombia-1845-1930 (accessed on 5 June 2025).

- Agronet Inicio. Available online: https://www.agronet.gov.co/Paginas/inicio.aspx (accessed on 2 April 2025).

- Campos-Vega, R.; Nieto-Figueroa, K.H.; Oomah, B.D. Cocoa (Theobroma cacao L.) Pod Husk: Renewable Source of Bioactive Compounds. Trends Food Sci. Technol. 2018, 81, 172–184. [Google Scholar] [CrossRef]

- Porto de Souza Vandenberghe, L.; Kley Valladares-Diestra, K.; Amaro Bittencourt, G.; Fátima Murawski de Mello, A.; Sarmiento Vásquez, Z.; Zwiercheczewski de Oliveira, P.; Vinícius de Melo Pereira, G.; Ricardo Soccol, C. Added-Value Biomolecules’ Production from Cocoa Pod Husks: A Review. Bioresour. Technol. 2022, 344, 126252. [Google Scholar] [CrossRef]

- Dahunsi, S.O. Mechanical Pretreatment of Lignocelluloses for Enhanced Biogas Production: Methane Yield Prediction from Biomass Structural Components. Bioresour. Technol. 2019, 280, 18–26. [Google Scholar] [CrossRef]

- Lu, F.; Rodriguez-Garcia, J.; Van Damme, I.; Westwood, N.J.; Shaw, L.; Robinson, J.S.; Warren, G.; Chatzifragkou, A.; McQueen Mason, S.; Gomez, L.; et al. Valorisation Strategies for Cocoa Pod Husk and Its Fractions. Curr. Opin. Green. Sustain. Chem. 2018, 14, 80–88. [Google Scholar] [CrossRef]

- Fernández Escobar, Á.O.; Erazo Solórzano, C.Y.; Torres Segarra, C.V.; Tuárez García, D.A.; Torres Navarrete, E.D.; Díaz Ocampo, R.G. Extracción de Mucílago de Cáscara de Theobroma cacao L. Para Uso En Clarificación de Jugos de Saccharum Officinarum. Cienc. Tecnol. 2022, 15, 25. [Google Scholar] [CrossRef]

- Grassia, M.; Messia, M.C.; Marconi, E.; Demirkol, Ş.; Erdoğdu, F.; Sarghini, F.; Cinquanta, L.; Corona, O.; Planeta, D. Microencapsulation of Phenolic Extracts from Cocoa Shells to Enrich Chocolate Bars. Plant Foods Hum. Nutr. 2021, 76, 449–457. [Google Scholar] [CrossRef]

- Rojo-Poveda, O.; Zeppa, G.; Ferrocino, I.; Stévigny, C.; Barbosa-Pereira, L. Chemometric Classification of Cocoa Bean Shells Based on Their Polyphenolic Profile Determined by Rp-Hplc-Pda Analysis and Spectrophotometric Assays. Antioxidants 2021, 10, 1533. [Google Scholar] [CrossRef] [PubMed]

- Antwi, E.; Engler, N.; Nelles, M.; Schüch, A. Anaerobic Digestion and the Effect of Hydrothermal Pretreatment on the Biogas Yield of Cocoa Pods Residues. Waste Manag. 2019, 88, 131–140. [Google Scholar] [CrossRef] [PubMed]

- Sánchez Quezada, J.P. Evaluación Energética De Cáscaras De Cacao Nacional Y CCN 51; Universidad de Cuenca: Cuenca, Ecuador, 2013; Available online: https://dspace.ucuenca.edu.ec/bitstream/123456789/4508/1/tesis.pdf (accessed on 2 April 2025).

- Wickramasuriya, A.M.; Dunwell, J.M. Cacao Biotechnology: Current Status and Future Prospects. Plant Biotechnol. J. 2018, 16, 4–17. [Google Scholar] [CrossRef] [PubMed]

- Cepeda, D.; Pound, B.; Nelson, V.; Kajman, G.; Cabascango, D.; Martin, A.; Chile, M.; Posthumus, H.; Caza, G.; Mejia, I.; et al. Assessing the Poverty Impact of Sustainability Standards: Ecuadorian Cocoa; ResearchGate: Berlin, Germany, 2013. [Google Scholar]

- Sánchez, V.H.; Zambrano, J.L.; Iglesias, C. La Cadena Del Valor Del Cacao En América Latina y El Caribe; INIAP, Estación Experimental Santa Catalina: Quito, Ecuador, 2019; ISBN 9789942364654. [Google Scholar]

- Mudombi, S.; Von Maltitz, G.P.; Gasparatos, A.; Romeu-Dalmau, C.; Johnson, F.X.; Jumbe, C.; Ochieng, C.; Luhanga, D.; Lopes, P.; Balde, B.S.; et al. Multi-Dimensional Poverty Effects around Operational Biofuel Projects in Malawi, Mozambique and Swaziland. Biomass Bioenergy 2018, 114, 41–54. [Google Scholar] [CrossRef]

- CONGRESO, D.E.C. Ley 1715 de 2014—Gestor Normativo—Función Pública 2014, 32. Available online: https://www.funcionpublica.gov.co/eva/gestornormativo/norma.php?i=57353 (accessed on 5 April 2025).

- Mesa Puyo, D. Transición Energética: Un Legado Para El Presente y El Futuro de Colombia Iván Duque Márquez Presidente de La República. 2021. Available online: https://www.minenergia.gov.co/documents/5856/TRANSICION_ENERGETICA_COLOMBIA_BID-MINENERGIA-2403.pdf (accessed on 5 April 2025).

- SANDRA. Producción de Cacao En Ecuador y Su Impacto Económico—Del Monte AG 2025. Available online: https://delmonteag.com.ec/produccion-de-cacao-en-ecuador-y-su-impacto-economico/ (accessed on 12 April 2025).

- Elias Velasquez, P.; Acevedo, P.; Santis, A.; Bardone, E.; Marzocchella, A.; Bravi, M.; Rojas, J.C.; Ramírez, K.G.; Velasquez, P.E. Evaluation of Bio-Hydrogen Production by Dark Fermentation from Cocoa Waste Mucilage. Chem. Eng. Trans. 2020, 79, 2020. [Google Scholar] [CrossRef]

- Rasimphi, T.; Kilonzo, B.; Tinarwo, D.; Nyamukondiwa, P. Challenges, Opportunities, and Possible Interventions in the Biogas Sector in Rural Areas of Limpopo, South Africa. Energy Strategy Rev. 2024, 56, 101562. [Google Scholar] [CrossRef]

- Johnson, F.X.; Matsika, E. Bio-Energy Trade and Regional Development: The Case of Bio-Ethanol in Southern Africa. Energy Sustain. Dev. 2006, 10, 42–53. [Google Scholar] [CrossRef]

- Achterbosch, T.; Gerdien, M.; Slingerland, M.; Smeets, E. Combining Bioenergy Production and Food Security; Netherlands, 2013; NL Agency. Available online: https://edepot.wur.nl/260061 (accessed on 12 April 2025).

- Johnson, F.X.; Silveira, S. Pioneer Countries in the Transition to Alternative Transport Fuels: Comparison of Ethanol Programmes and Policies in Brazil, Malawi and Sweden. Environ. Innov. Soc. Transit. 2014, 11, 1–24. [Google Scholar] [CrossRef]

- Jarzebski, M.P.; Ahmed, A.; Boafo, Y.A.; Balde, B.S.; Chinangwa, L.; Saito, O.; von Maltitz, G.; Gasparatos, A. Food Security Impacts of Industrial Crop Production in Sub-Saharan Africa: A Systematic Review of the Impact Mechanisms. Food Secur. 2020, 12, 105–135. [Google Scholar] [CrossRef]

- Huang, X.; Wang, S.; Shi, Z.; Fang, L.; Yin, C. Challenges and Strategies for Biogas Production in the Circular Agricultural Waste Utilization Model: A Case Study in Rural China. Energy 2022, 241, 122889. [Google Scholar] [CrossRef]

- Atmowidjojo, A.C.; Harun, R.; Setyabudi, F.M.C.S.; Utami, A.W.; Idrus, S. Anaerobic Digestion Potential of Cocoa Pod Husk and Cocoa Bean Shell: Case of Gunung Kidul, Indonesia. Adv. Biol. Sci. Res. 2023, 29, 560–576. [Google Scholar] [CrossRef]

- Mancini, G.; Papirio, S.; Lens, P.N.L.; Esposito, G. Anaerobic Digestion of Lignocellulosic Materials Using Ethanol-Organosolv Pretreatment. Environ. Eng. Sci. 2018, 35, 953–960. [Google Scholar] [CrossRef]

- Gonzalez-Cabra, A.; Suarez-Muñoz, F. Potencial de Producción de Biometano y Biohidrógeno a Partir de Residuos Agrícolas: Mucílago de Café Y Cacao Y Estiércol de Cerdo; Universidad Santo Tomás: Manila, Philippines, 2018; Available online: https://bibliotecadigital.oducal.com/Record/ir-11634-15305?sid=4469 (accessed on 12 April 2025).

- Cortes, T.R.; Cuervo-Parra, J.A.; Robles-Olvera, V.J.; Cortes, E.R.; Pérez, P.A.L. Experimental and Kinetic Production of Ethanol Using Mucilage Juice Residues from Cocoa Processing. Int. J. Chem. React. Eng. 2018, 16, 20170262. [Google Scholar] [CrossRef]

- Maleka, D. Assessment of the Implementation of Alternative Process Technologies for Rural Heat and Power Production from Cocoa Pod Husks. 2016. Available online: https://kth.diva-portal.org/smash/get/diva2:946287/FULLTEXT01.pdf; (accessed on 18 April 2025).

- Moreno, M.S.L. Utilización de Los Subproductos Del Beneficio Del Cacao: Una Revisión; Universidad de Bogotá Jorge Tadeo Lozano: Bogotá, Colombia, 2020; Available online: http://hdl.handle.net/20.500.12010/18805 (accessed on 5 April 2025).

- Jameel, M.K.; Mustafa, M.A.; Ahmed, H.S.; Jassim Mohammed, A.; Ghazy, H.; Shakir, M.N.; Lawas, A.M.; Khudhur Mohammed, S.; Idan, A.H.; Mahmoud, Z.H.; et al. Biogas: Production, Properties, Applications, Economic and Challenges: A Review. Results Chem. 2024, 7, 101549. [Google Scholar] [CrossRef]

- Naciones Unidas. Incentivos y Oportunidades En El Marco Regulatorio Para El Aprovechamiento Energético Del Biogás Producido En Plantas de Tratamiento de Aguas Residuales En Países Seleccionados de América Latina y El Caribe. 2024. Available online: https://www.cepal.org/es/publicaciones/80404-incentivos-oportunidades-marco-regulatorio-aprovechamiento-energetico-biogas (accessed on 5 June 2025).

- Mansur, D.; Tago, T.; Masuda, T.; Abimanyu, H. Conversion of Cacao Pod Husks by Pyrolysis and Catalytic Reaction to Produce Useful Chemicals. Biomass Bioenergy 2014, 66, 275–285. [Google Scholar] [CrossRef]

- Scheuer, P.M.; Southgate, A.N.N.; Martelli, M.F.; Dias, C.; da Silva, M.E.; Coelho, A.A.; de Francisco, A. Quality Properties of a Bread Made with Levain and Cocoa Waste. J. Culin. Sci. Technol. 2022, 20, 409–420. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).