Abstract

The adaptation of lignocellulosic materials such as Cannabis sativa L. as a new renewable energy source is linked to the fact that the technology must be developed to be able to adapt to local market conditions. Bioenergy consumers are faced with this problem because, when it comes to the selection of briquettes and pellets for energy production, there are only individual standards in place. This research is intended to provide a better understanding of hemp product potential as a new material that can be used in the production of pellets and briquettes for biofuel purpose. Nevertheless, the anisotropic raw material interferes with the compaction process and may expose a poor durability of the pellets and briquettes. The research that was conducted evaluated the conditions of the biofuels by measuring the physical and chemical parameters. The ash content, compressive strength, and durability of the samples were examined. The statistical data analysis was performed after the strength tests on the prepared samples.

1. Introduction

1.1. Classification of the Energy Sources

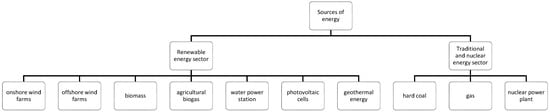

Traditional sources of energy such as coal, oil, and gas emit considerable amounts of greenhouse gases and particulates when burned. The use of renewable energy instead of fossil fuels facilitates the reduction of excessive environmental pollution. Globally, there is an ongoing trend of modernization and adaptation of technologies using renewable energy sources. There has been an increase in discussions about the use of waste materials in the energy production sector in recent years [1,2]. General energy sources classifications [3] presented in few doctoral thesis [4] allow for the identification of non-traditional power sectors (renewable sources of energy), traditional power sectors (gas, coal), and nuclear energy. Renewable energy sources also include wind power, waterpower, solar power, geothermal power, biogas, and biofuels. The classification of energy sources according to their origin and ability to be acquired is presented in Figure 1.

Figure 1.

Energy source classification in terms of origin.

The intensities of occurrence of non-traditional and traditional energy sources are more variable than expected. In Poland, it is possible to provide a high amount of biomass to the market [5], which is most often used as a feedstock for biofuel production [6,7]. Biomass is the most important source of renewable energy in the present day, and it is used in households, power plants, and heat plants throughout the world. Biomass is an important and widely used source of energy in Poland, where it accounts for between 18% and 22% of the country’s total energy production [4]. The evidence also shows that biomass is an important and significant source of carbon dioxide sequestration and contributes to the reduction of greenhouse gas emissions, as well [1], since it is a significant source of carbon dioxide sequestration and therefore contributes to the reduction of greenhouse gas emissions.

The management of biomass in the form of solid biofuels for heating purposes facilitates decreasing the demand for fossil fuels in heating and cogeneration systems. In this case, we refer to an effective material for producing cheap, eco-friendly renewable energy [8]. Despite many advantages, the use of solid biofuels is still inconsiderable. Solid biofuels have considerable potential for rural area developments, as they provide new opportunities for the local agricultural and forest entrepreneurs. The condition of using solid biomass at a greater scale requires specific physical and chemical material properties to be acquired, and so the bioenergy plant selection criteria [2] and the parameters of the biofuels made should be better investigated during the experimental studies.

1.2. Biomass of Agricultural Origin

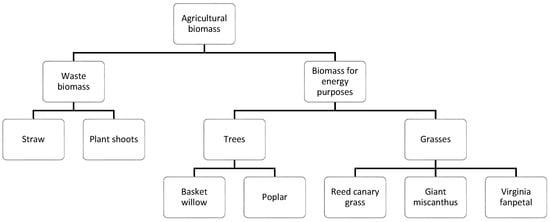

Solid biomass of agricultural origin is acquired in agricultural areas. Despite crops being grown for energy purposes, undoubtedly a larger proportion of solid biomass comes from agricultural waste, especially from the surpluses and the residue produced during agricultural production. Depending on the source of origin, biomass can be divided into agricultural waste (e.g., straw and shoots) or that grown for energy purposes. The classification is presented in Figure 2.

Figure 2.

Agricultural biomass division.

The most popular agricultural waste used in the Polish renewable energy sector is straw. In traditional animal farming, which still dominated up to the early 1980s, there was a high demand for that material which was, in vast amounts, used as bedding material. Currently, a decrease in the animal population and a change in the animal farming methods has resulted in an excess of straw and the problem of its adequate use. The chemical composition of straw is similar to that of wood [5,9]. Straw contains 75% high-quality components (cellulose and hemicellulose) and 25% low-value components (lignin, ash, protein, and incrusting substances) [10,11]. As compared to coal, straw contains much less sulfur and nitrogen, which, in the burning process, decreases the emissions of greenhouse gases to the atmosphere [12]. The straw also has a lower energy value compared to the commonly applied traditional fuels, despite its low heat output.

The eco energy sector also includes plants grown for energy purposes, with their specific calorific value. The biomass increases recorded over a short time are expressed with the ratio of the energy of the biomass accumulated to their production expenditure [2,5]. In Polish conditions, the highest energy yield is recorded for the perennial cultivation of basket willow (Salixs Sp.), poplar (Populus L.), giant miscanthus (Miscanthus sinensis giganteus), Virginia fanpetal (Sida hermaphrodita rusby), or some grasses, e.g., reed canary grass (Phalaris arundinacea). The average period of energy crop plantation functioning is 15–20 years [5].

Energy plantation profitability depends on the overall economic situation and the actions of energy companies. Recent years have shown a decreasing interest in that type of biomass from Polish planters and a growing interest in cheaper imported biofuels. Such actions result from limiting cofiring and suspending special payments. As a result, small energy plantations are liquidated. Their biomass can be replaced with available and relatively cheap forest biomass. Some literature sources inform of an increase in the production of perennial energy crops (2010—6 193 ha, 2011—7 619 ha, 2012—10 344 ha, 2013—11 509 ha) [2,4,5], which can be due to the launch of big private plantations by heat and electricity producers.

1.3. Possibilities of Hemp Based Biofuels

In recent years, hemp plants have gained popularity and attention because of their unique properties [8,13]. There are a variety of biofuels that can be produced using hemp in an industry with a wide variety of biofuels [14]. Hemp fibers can also be used to make lightweight concrete and hemp panels. The use of plant materials can lead to sustainable development, and it has many benefits. The biomass from hemp consists of both fast-growing fibers and oil-rich seeds. Hemp biomass yields range from 2 to 25 tons per hectare depending on climate, soil quality, and cultivation practices [15,16]. The yields of hemp biomass can be increased with further research and technological development, making it an even more promising and sustainable feedstock [17]. Many different fields can be applied to hemp, including both traditional and innovative fields. Innovations in the hemp processing industry can also influence the development of new biofuels. In order to determine whether hemp biofuels are biodegradable, studies have been conducted in order to assess their biodegradability. Biofuels therefore have a smaller impact on the environment and are thus an eco-friendlier choice than ordinary ones [8].

The ability of hemp to produce organic [18] and sustainable biofuels [14] has sparked growing interest in the plant in recent years because of its potential applications. The sustainable management of natural resources can be facilitated through the use of hemp as a lignocellulosic raw material [19]. The management of lignocellulosic materials can be improved in the future through innovative modifications. There are many uses for hemp stems because they are strong and versatile. There is a polymer complex called lignin embedded in the hemp cell wall, which provides strength and flexibility [10,20,21]. The presence of lignin in lignocellulosic materials affects their performance significantly [22,23]. They are perfect for producing biofuels due to their environmentally friendly properties. Furthermore, biofuels have been generated from this raw material in innovative ways. In addition to creating biodiesel from hemp oil, oil residues can also be converted into biomass for use as fuel.

Intensive scientific research on hemp continues to uncover new opportunities for industries and the environment. It is evident that hemp could revolutionize a number of industries and contribute to a greener future. Among the many studies conducted to improve hemp, scientists have also studied its chemistry [24,25]. According to the results of those studies, one of their biggest advantages is that they are lignocellulosic. The versatility of their use can also mean that they are suitable for different applications, like cellulose and lignin. The scientific literature suggests [18,26] that hemp (Cannabis sativa L.) biomass may be a promising biofuel source due to its rapid growth and lower pesticide requirements. There are several ways to use hemp for biofuels, including the production of bioethanol, biogas, and solid biofuels. Plant yields vary according to climatic conditions, soil quality, and hemp variety, and they can provide sugars for fermentation. Despite these findings, many factors must be considered to fully realize the potential of hemp as a biofuel source, including economic, technological, and regulatory factors.

2. Materials and Methods

2.1. Material

The samples to be used in this study were pellets and briquettes made from hemp stalks (Cannabis sativa L.). In a general sense, this demonstrates the potential of solid biomass in the development of sustainable biofuels as an alternative. There have been a wide range of applications for hemp in various types of industries to date. A number of physical and chemical parameters have been studied in order to determine the potential energy of raw material. Until recently, hemp stalks, also known as hemp straw, were considered to be a waste material. The stalk of hemp consists of a wooden core and fibers arranged on the stalk, called shives. It is possible to specify a wooden core with an unfilled space inside of a hemp stalk.

The raw material that the pellets and briquettes were made of for the test was supplied by a company called Cannabotanique. The samples were prepared using hemp stalks that were 1.5 to 2.5 m high. The hemp that was used in the research was grown in Poland, more specifically in the Mazowieckie Voivodeship, where it was grown on a plantation situated in the center of the community. In Poland, hemp (Cannabis sativa L.) grown on a plantation is regulated to include no more than 0.2% THC. Throughout its cultivation, this plant was subjected to temperate climate conditions. During the cultivation period, the average daytime temperature fluctuated in the range of 15–24 °C. The harvesting of the crops was carried out using agricultural machinery that was specially designed to harvest mature crops. The pellets and briquettes used in the research are presented in Figure 3.

Figure 3.

The samples used in the research: (a) pellets; (b) briquettes.

The principal part of hemp is the fibers, often several tens of centimeters long, forming a long and thin structure. The combination of cellulose, hemicellulose, and lignin determines a solid biofuel’s durability and elasticity through their interaction [19]. About 70–80% of a fiber’s cell wall consists of these compounds, which are the main structural components. Since cellulose is present in fibers, fibers are able to maintain their elasticity, strength and structural integrity. There is no doubt that lignin is essential for maintaining the structural integrity of cells. The strength of hemp fibers comes from microscopic strands of cellulose, called microfibrils, which are arranged along the fiber axis. Plant cells have water channels that contribute to the cell’s moisture balance. Fiber’s properties, such as adhesion and moisture resistance, are also influenced by pectin and wax [27,28,29,30].

2.2. Materials Moisture Content

In order to maintain the moisture content of the tested product, the part of the raw material that pellets and briquettes were made of was dried in a laboratory dryer at 105 °C until it became dry matter. In general, in the lignocellulosic material compaction process, to achieve the recommended moisture content of raw materials, the specifically designed cuvette should be used [31]. In the literature, it is recommended to repeat the treatment after two weeks in order to maintain a moisture content of 12% [32]. The calibration of a laboratory cuvette filled with medium is necessary before measuring the moisture content. It is important to note that different moisture parameters are required for the pelletizing and briquetting processes.

Among the factors that can affect these values are the temperature and humidity levels of the environment. To determine the weight of the samples, the moisture content of the samples should be verified by measuring their weight before each test is conducted. The test was applied to lignocellulosic samples in order to determine their moisture content [33]. Every sample of the material was again verified for moisture content before every test was performed. The Radwag MAC 50 scale (Radom, Poland) was used to determine the weight of the raw materials. These methods were applied in order to obtain accurate measurements of the moisture content of the lignocellulosic samples.

2.3. Bulk Density of Solid Biofuels

Bulk density is one of the parameters that can be used to determine the quality of pellets and briquettes. According to the accepted standards, the value should be between 1000 and 1400 kg·m3 [4]. Density can be calculated from the piston displacement and the briquette’s volume. Considering the bulk density of solid biofuels, we can determine how much mass is contained in each unit volume of the fuel. In addition to providing insights into solid biofuel efficiency, this also shows how the fuel is transported and used. The amount of space between particles and the presence of air are taken into account when measuring this density. Through a comprehensive assessment, the solid biofuel storage capacity can be gauged to make informed decisions. Solid biofuels have properties such as bulk density, which determine how much mass they can contain within a specified volume.

The measurement of bulk density can be carried out by calculating how much mass a space contains. Calculating the ratio of the mass of the tested substance to its volume was carried out by analyzing its bulk density. The measurement of mass per unit volume provides valuable insights into the properties and behavior of materials. The bulk density of a substance is calculated by comparing its mass to its volume. The process requires meticulous measurement and analysis, considering factors like the volume occupied by the product itself, the spaces between its particles, and the presence of air in the volume. In order to accurately assess bulk density, an empty, dust-free, and dry container must be used. The container was weighed prior to measurement to establish a baseline. For precision in weighing, an accuracy of ±10 g is typically maintained. In many applications, including product handling, transportation, and industrial processes, attentiveness to detail is essential in obtaining reliable data.

2.4. Ash Content

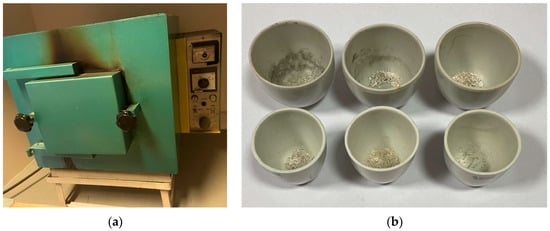

In order to determine the amount of ash in the raw material, the prepared samples were incinerated. It appears that the measurement of ash is an important step in determining the chemical composition of solids. The iron, silicon, aluminum, magnesium, calcium, sodium, and potassium content can all be measured in relation to mineral saturation [23]. Measurements of ash are carried out after samples have been burned, following a systematic process that involves several steps that must be repeated consistently and correctly. The first step in preparing an ash sample is to burn the substance in a controlled environment to remove any contaminants. In order to determine the weight of the ash produced, a scale should be used. The methodology also includes calibrating and controlling the apparatus used for analysis. The calibration of apparatus is necessary for accurate and precise measurements. Temperature and duration should be kept constant to ensure a standard operating environment. Controlling these parameters is essential for the repeatability and reliability of measurements. The muffle furnaces used for ash content measurements and samples created during the burning process are also presented in Figure 4.

Figure 4.

The measurement of ash content: (a) muffle furnaces; (b) ash samples.

To determine the degree of ash content, slow incineration and a muffle furnace were used. To measure the ash content, sample specimens were prepared, burned, weighed, inspected, and calibrated, and the apparatus used to measure the ash content was calibrated. In accordance with the literature, it was recommended that the samples be dried before use [34,35]. The next step was to weigh the samples and place them in the crucible, which was followed by the burning process. The weight of each prepared sample was around 2 g. Muffle furnaces preheated to 805 °C were used to burn the samples [33,36]. It took approximately two hours to determine the ash content. In order to cool down the burnt samples in the desiccator, the crucible-incinerated samples were placed in the desiccator. The next step was to determine the weight of the crucible along with the ash. Depending on the initial sample weight, the results are either given as a percentage share or as grams per unit. Several factors play an important role in determining the quality of the analysis results, including precision, accuracy, and repeatability.

In order to ensure their optimal quality and effective use, the ash content in pellets and briquettes must be determined for a proper evaluation of pellets and briquettes as solid biofuels. The combustion process will affect pellets and briquettes based on conditions such as duration and temperature. Considering the fact that pellets and briquettes contain materials that are similar to one another, the same incineration conditions were applied to them. There is a difference between the mechanical properties of these two types of solid biofuels because they are not of the same consistency and density in respect to their mechanical properties. The combustion process conditions require a set period of time, and it takes about 6 h to achieve the end result for a full combustion of the sample.

2.5. Solid Biofuel Quality Characteristic

The pressure generated during the operation of pellet and briquette pressing varies depending on the press’s technical parameters and the dimensions of the pellets and briquettes. The literature provides a wide range of pressure per unit area recommendations based on the data provided by various authors [4,31,37]. The range of pressures can range from a few kPa to more than 100 kPa. The pressure required to produce briquettes from wood waste should range from 45 to 60 MPa per unit area of the briquette [4]. Therefore, it is necessary to specify the correct pressure per unit area for the briquetting process, since it is a complex and troublesome task. During the process, this also depends on the amount of irregularity and the length of the fraction (how much the raw material has shrunk), along with other factors such as the type of biomass and the moisture content [32,34]. All parameters play an important role in the production of strong durability. In the literature, one can find data on the durability of briquettes produced from various raw materials [38,39]. However, information on the durability of pellets and briquettes made of shredded hemp is missing. A breakdown of the values of the coefficient of durability (Ψ) of the briquettes made of various raw materials described in the literature is provided in Table 1.

Table 1.

Values of the coefficient of durability for briquettes made of various kinds of raw materials.

The pellet and briquette quality is relevant for all the properties of the solid biofuel and its performance, including durability. Durability is a basic parameter defining the pellets and briquettes produced. In the past, the parameter used to be established with a three-degree quality scale (very good, satisfactory, and unsatisfactory). In the applicable literature, the pellets’ and briquettes’ durability are determined as a percentage mass loss [40] or its absolute equivalent marked with the coefficient of durability [4]. Compliant with the requirements of the European Committee for Standardization (CEN), durability is defined with the coefficient of durability. The standard describes the parameter as a measure of resistance of biodegradable energy carriers in a solid form to shock or wear resistance while transported or handled. The coefficient of pellets’ and briquettes’ durability can be calculated from Formula (1).

where mpbt is a mass of pellets or briquettes after the durability test, and mpb is a mass of pellets or briquettes before the durability test. A method of gravitational shedding and a compressive force that destroys the sample were used to determine the mechanical properties of pellets and briquettes. In order to assess a sample’s resistance to gravitational shedding, one uses the weight loss coefficient ψ [41]. In order to test the quality of a batch of solid biofuel, samples must be dropped from a height of two meters onto a steel plate at least three times. After each drop of sample solution, the samples were required to be sifted through a sieve after the procedure was completed. The mesh size of the sieve corresponded to the diameter of the pellet or briquette used for the screening process [41,42].

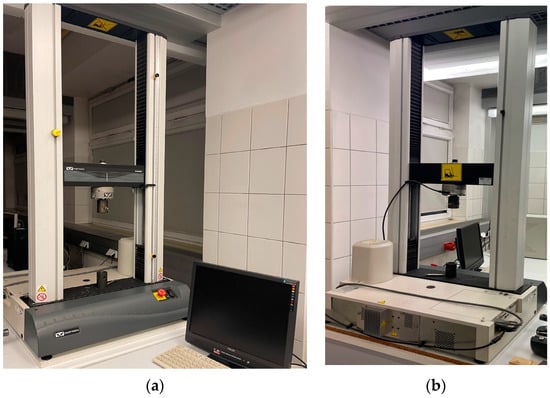

The value of the destroying force required by an Instron 3369 testing machine (Norwood, MA, USA) to destroy pellets and briquettes was determined experimentally. The testing machine was equipped with up to two flat planes, which allowed the pellet and briquette samples to be placed between them to be tested. Tests were carried out until either the structure of the sample was destroyed by splitting in half or the force was clearly diminished. The compressive strength of the samples was tested in longitudinal and vertical positions in order to determine the average for all tested samples. In the next step, statistical parameters were calculated based on data from the measurements. The Instron 3369 testing machine used for strength analysis is presented from front and back views in Figure 5.

Figure 5.

The Instron 3369 testing machine used for strength analysis: (a) front; (b) back.

2.6. Granulometric Composition Test

Based on the assumptions of the research, the pellets and briquettes analyzed in this study required fractionality tests at different stages of testing in order to prove their fractionality. Sieves are particularly useful in the case of weight loss in solid fuel quality characteristics where there is a need for sieving the solid biofuel. In order to determine fractional composition based on the test results of the pellets and briquettes, the standards were used in order to determine the fractional composition of pellets and briquettes after part of the tests. The separation process was conducted using sieves whose mesh sizes were predicted using the methodology [40]. The sieve separator with installed sieve baskets can be seen in Figure 6.

Figure 6.

The sieve separator.

Measurements were conducted by placing pellets or briquettes in sieve baskets based on the type of test. Screen separator shakes reflect the shock wave frequencies to which pellets or briquettes can be expected to be exposed during transportation. To simulate road transport conditions as closely as possible, the time (s) and amplitude of shaking (Hz) were chosen. The solid biofuel was tested on a sieve with a mesh size of 0 to 8 mm for pellets, and on a sieve with a mesh size of 0 to 16 mm for briquettes. It was decided to use sieves that were capable of handling the lower and upper fraction sizes in the tested biofuel. The fractions were weighed after they had been separated. In order to determine the mass of the i-th fraction (mfi), a Radwag electronic scale with an accuracy of 0.01 g was used. An equation for determining the quantitative proportion of the i-th fraction (αfi) is presented in Formula (2).

2.7. Statistical Analysis

The statistical analysis of the results was conducted using analysis of variance (ANOVA) as the chosen method. The methodology stipulates that statistical analysis must align with a specific statistical hypothesis [43]. To rigorously test hypotheses, it is crucial to gather data related to a particular parameter. ANOVA compares variance differences between two groups and within a group. The assumptions are validated through ANOVA, and the outcome is interpreted using the p-value, which indicates the probability. A p-value below 0.05 signifies a significant difference between the groups, leading to the rejection of the null hypothesis. To assess homogeneity, ANOVA with Duncan’s post hoc test can be applied to the samples [43,44].

3. Results

3.1. Material Characteristic

3.1.1. Physical Analysis

Among to the most important factors affecting hemp (Cannabis sativa L.), compaction process belongs the moisture content [13,14]. Natural lignin-cellulose materials have a high hygroscopicity, with influences all of their properties. A large amount of water is typically found in hemp after harvest, which needs to be dried under controlled temperature and ventilation conditions. The hemp’s low moisture level maintains its flexibility. In accordance with the methodology, compression is performed on a test machine which has a compression plane. The content of moisture samples was analyzed before all tests. Tests were performed at an approximately 6% moisture content of the pellets and briquettes. The results of the moisture content of samples are presented in Table 2.

Table 2.

The results of moisture content of samples.

The table presents moisture content percentages for biofuels in the form of pellets and briquettes. There was a wide range of moisture content percentages between pellets and briquettes, ranging from 5384% to 5757% for pellets and 6064% to 6441% for briquettes. Based on Duncan tests, the measured parameters of moisture content and biofuel type were analyzed. The statistical analysis and Duncan test support the conclusion that there was significant variation between the measured parameters and a correlation between them. It is estimated that the average moisture content is around 5.64% in pellets and 6.27% in briquettes. The amount of water contained in briquettes seems to be slightly higher than that in pellets. However, the moisture content of pellets and briquettes is highly variable between samples, thus suggesting that their production might differ in quality.

There was a significant effect on the correlations between the analyzed indicators, which was further confirmed by the statistical significance value of p = 0.018. The empirical value of F(1, 4) is 15.064. A correlation was found between the studied parameters by fitting them into homogeneous groups. In the course of the analyses, the magnitude α, characterizing the level of significance and expressing the probability of error in the selection of the confidence factor, was taken into account. Taking into account the verified residual hypotheses, the value of α was taken at a level equal to 0.05. The value represents the difference between unity and 0.95 for confidence factor F, and thus F = 1 − α. According to the calculated correlation coefficient of 0.018, there was a strong statistical correlation between the variables. Statistical analysis results were also affected by the nature of the problem and the accuracy of the average distribution. In addition, there was also the possibility of statistical analysis at an α level of 0.03 or 0.01 [8,14,18].

In order to accurately characterize the raw material, the dimensional method was used to determine the density. Methods for measuring density include preparing samples, calibrating measuring instruments, performing measurements, and analyzing results in order to obtain precise density values. An accurate determination of the density of a substance is extremely important not only for the quality control of the product, but also for conducting further research into the matter. In this analysis, the diameter and length of the pellets and briquettes were measured in order to determine their quality. The density of each solid biofuel was determined by the ratio between volume and weight. The summaries of the volume density values for each solid biofuel are presented in Table 3.

Table 3.

The measurement of density.

The densities of pellets range from 240,222 kg·m3 to 288,629 kg·m3. In contrast, briquette densities range from 126,068 kg·m3 to 184,570 kg·m3. Information on the geometric dimensions and weights of pellets and briquettes was provided. On the basis of previous measurements, this part calculates the volume and the volumetric density, as well. As a result of these data, the physical characteristics of each solid fuel could be analyzed and compared with one another more precisely and effectively. Additionally, the measured parameters showed significant variation based on the statistical analysis conducted. There was a strong correlation between them, as confirmed by the Duncan test. Based on the correlation between the analyzed indicators, it was evident that the correlations were significantly impacted, as indicated by the statistically significant value of p = 0.007, with the empirical value of F(1, 4) = 25.374.

3.1.2. Determination of Ash Content

The analysis conducted on various forms of solid biofuel highlighted notable variations in their dimensions. The discrepancy in dimensions can be attributed to several factors, including the source of the biofuel, the method of processing, or the composition. An ash procedure was used to determine the proportion of ash present in the raw materials examined. In a muffle furnace, raw materials were reduced to ash thoroughly at a consistent temperature of 805 degrees Celsius to ensure complete combustion. The procedure takes a designated amount of time to complete. The ash content within each sample could be accurately determined in this controlled environment. According to the literature [45], ash may contain mineral substances. It is possible to obtain biomass minerals either directly from biomass or indirectly from external sources. The mineral content of ash is key to determining its environmental impact, as well as its suitability for various applications. In light of this information, it is imperative to analyze solid biofuels holistically and consider all factors that affect their composition. The measured values of ash content are gathered and presented in Table 4.

Table 4.

The measured value of ash content.

The ash content of pellets ranges from 3.351% to 3.852%, while that of briquettes is between 3.414% and 3.738%. In order to determine the degree of significance of the parameter studied, the obtained results were statistically processed using an analysis of variance. Based on the ash content of the solid biofuels, the parameters determining homogeneous group assignment were determined. The Duncan test did not confirm significant differences between measured parameters based on the statistical analysis performed. The correlations among the studied indicators showed no significant influence, as evidenced by the p = 0.659, where F(1, 4) = 0.2265, corresponding to the empirical value of F(1, 4) = 0.227.

3.2. Physical Analysis of Pellets and Briquettes

3.2.1. Longitudinal and Vertical Compressive Strength

The compressive strength of the raw material is its resistance to forces that may result in deformation or destruction. In order to determine the extent of deformation of the samples during the strength tests, forces applied to them in special planes were measured to determine how much deformation occurred. It has been found that even if anisotropic materials crack during stiffness tests, they still maintain high stress values during those tests. Since the pellets and briquettes tested had an irregular fractional distribution, their blades were arranged in a random manner. The tests were performed using a machine with a compression speed of 5 mm per minute as a part of the testing process. Consequently, a yield stress was introduced, which was measured up to the first big crack on the surface. The results of the tests performed on prepared samples are presented in Table 5.

Table 5.

The results of tests performed on prepared samples.

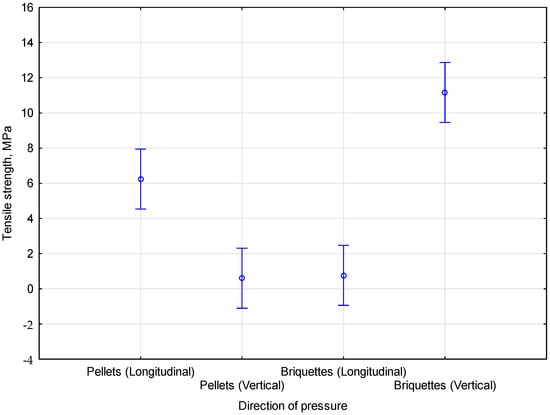

The compressive strength of pellets varies from 4.6 MPa to 8.4 MPa when applied longitudinally, while it varies from 0.2 MPa to 1.0 MPa when applied vertically. The compressive strength of briquettes varies between 0.6 MPa and 1.0 MPa under longitudinal pressure, whereas it varies between 9.4 MPa and 12.5 MPa under vertical pressure. Longitudinal and vertical tests were conducted to determine the compressive strength of each solid biofuel. There was a difference in compressive strength between briquettes and pellets based on the results. It was noted that pellets had stronger strength in the longitudinal direction. In practice, pellets were stacked between the clamping plates to achieve the desired strength of measurement. Although this was the natural extrusion direction of the pellets once the strength limit was exceeded, the single pellet tested broke. The briquettes had the opposite strength to their alignment during their strength test. A higher strength of briquettes in the vertical direction is certainly related to the briquette clamping direction. The briquettes in this direction reached 12.5 MPa in strength. The results of further statistical analysis revealed that they can be characterized according to the parameters. The average results of the compressive strength on the solid biofuel with different pressure directions are presented in Figure 7.

Figure 7.

The average results of the compressive strength on the solid biofuel with different pressure direction.

The average compressive strength of the solid biofuel when applied to different directions of pressure was further analyzed statistically. The distribution of stresses defining strength varied depending on the positioning of the solid biofuel. There were some cases where the decline was more pronounced than in others. Statistics showed that, in some cases, there was a significant variation in the measured parameters along with a correlation between them. It was found in most cases that there was a significant effect of correlation between the examined indicators on the correlations, which was further confirmed by a statistical significance value of p = 0.131. It has been found that the empirical value of F(3, 8) is 46,545.

3.2.2. Durability Tests

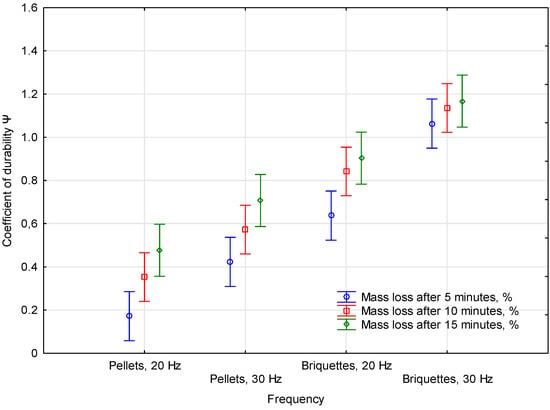

Durability tests of selected pellets and briquettes were conducted in order to determine the extent of mass loss. The samples that had been aggregated into compacted devices based on the pelleting and briquetting techniques were put through a durability test to determine their durability. In order to determine the durability of the solid biofuel, research was conducted in accordance with the literature [4,40,42]. In accordance with research methodology, durability tests were conducted in a shaking device at a given frequency and time. The frequency interval in which the test was conducted was 20 to 30 Hz. In order to measure the level of shattering, a measurement was taken every 5 min. In terms of its natural properties, the solid biofuel’s structure exhibited anisotropic properties. The results of durability testing on the solid biofuel samples are presented in Table 6.

Table 6.

The results of durability testing on the solid biofuel samples.

The strongest coefficient of durability, Ψ = 1, was recorded for pellets produced from hemp, which had the biggest quality factor. This meant that there was no shattering, or that only a small amount of shattering occurred in the solid biofuel during the durability test. Due to its size, the blend contained a significant amount of fine fractions, which probably positively affected the quality of the pellets. A coefficient of durability of 0.988 was obtained from briquettes produced with a higher proportion of fractions ranging from 0 to 10 mm. The statistical characteristics of mass loss after 5, 10, and 15 min at 20 and 30 Hz are presented in Figure 8.

Figure 8.

The statistical characteristics of mass loss after 5, 10, and 15 min at 20 and 30 Hz.

The study results were statistically analyzed, comparing the magnitude of the crumble of solid biofuels during durability tests over a given time span. The Duncan test was used as part of the statistical analysis, in order to separate the analyzed factors into homogeneous groups based on the factors that were analyzed. The statistical analysis of all cases showed differences between the measured parameters. The statistical significance value of the measurement was very low, with p = 0.00002, and the empirical value of the F(9, 14.753) statistic was 12.242.

4. Discussion

The energy industry today faces the challenge of producing high-quality solid biofuel from waste biomass. The literature review [4,37,38,39,42] concerns agricultural and forest raw materials and the possibilities of their transformation to the form of briquettes, as well as the properties describing the end-product solid biofuel. In order to provide biofuels in satisfactory conditions, it is necessary to characterize both physical and chemical properties. There is a wide range of literature [38,46] available on the characteristics of measuring the strength and durability of biofuel. Additionally, the topic of biomass densification is generating current interest due to research and interest from farmers and foresters. It was noted that different research centers were interested in the densification of the biomass made from agricultural waste (straw and plant shoots), dedicated crops (reed canary grass, giant miscanthus, Virginia fanpetals, basket willow, poplar), and waste of sawmill origin (chips, woodchips, and sawdust). The literature relentlessly emphasizes the benefits of using raw materials for sustainable community development [7,17,47]. In the available literature, however, no characteristics were found of the pressure densification of shredded residues. The physical and chemical properties of hemp are gaining importance for the development of solid biofuels and sustainable raw materials. Research on lignocellulosic materials allows the optimization of processing technologies for hemp and other biomaterials to improve biofuel yield and quality. Research into using hemp as a biofuel feedstock should be intensified in order for bioenergy to continue to advance.

The literature disregards briquetting studies, especially for lignocellulosic residues of non-homogenous materials [4,40,45]. There is also a possibility that innovations in the hemp processing industry could also affect the development of new biofuels. The products are therefore more environmentally friendly since they have less environmental impact. Due to their environmentally friendly properties, they are perfect for producing biofuels due to their excellent solid biofuel properties. Innovative modifications of lignocellulosic materials will improve the management of raw materials in the future. As part of the Section 3.1, the physical properties of hemp from which the solid biofuels were made were analyzed. The structure of hemp can exhibit multiple phases, similar to that of lignocellulosic materials. The moisture content of hemp (Cannabis sativa L.) raw material is an important factor in its processing. It has been observed that under natural conditions, hemp keeps a moisture content of approximately 0.09%, with a standard deviation of 0.04%. The size and granulometric composition of the analyzed biofuel forms differed significantly. Raw materials were burned at 805 °C for a fixed time in a muffle furnace to determine the ash content. In the literature, there is information that suggests that ash may contain minerals [45]. According to the p-value of 0.659, there were no significant correlations between measured indicators.

The compressive strength of solid biofuels was evaluated by stacking them vertically and longitudinally. It was found that briquettes and pellets differed in compressive strength. There was a significant strength difference between the pellets in the longitudinal direction. In practice, the solid biofuels were stacked between clamping plates in order to achieve the desired strength measurements. During the strength test, briquettes displayed the opposite alignment to pellets. The higher strength of the briquettes when crimped in the vertical direction is likely to be due to the way that they are compressed. Pellets had an average longitudinal strength of 6.2 MPa and a vertical strength of 0.6 MPa. For briquettes, the average strength was 0.7 MPa longitudinally and 11.2 MPa vertically. As a result of these results, we find that briquettes with higher pressures in the vertical direction are significantly stronger than pellets. Furthermore, a statistical analysis was conducted on the average strength of the solid biofuel in different clamping directions. According to statistics, some measurements showed a significant difference in parameters along with a correlation between them.

To determine weight loss, selected pellets and briquettes were tested for strength. A durability test was performed on the pelleted and briquetted samples using a shaking device at a fixed frequency and time. As with pellets, the durability coefficient remained high after 10 min of vibration at a screen size of 6 mm and frequency of 20 Hz. Using a 10 mm screen size and a frequency of 30 Hz, briquettes had a durability factor of 0.989 after 15 min. Briquettes were found to be less durable than pellets. The durability coefficient of 0.988 was assigned to briquettes that contained more fine fractions. The empirical F(9, 14.753) statistic of 12.242 and the very low p-value of 0.00002 provided evidence of differences between the measured parameters.

5. Conclusions

This article presents results that offer various interpretations. Hemp samples were discovered to contain approximately 0.09% moisture, with a standard deviation of 0.04%. Furthermore, a density analysis highlighted differences in size and weight between pellets and briquettes, crucial for quality control and further investigation. Optimal strength, tear resistance, and flexibility in hemp are contingent upon this moisture level, alongside density variations observed in pellets and briquettes, influencing quality control and subsequent research efforts. An assessment of ash content indicated disparities between pellets and briquettes, potentially containing mineral substances. Tightness tests revealed divergent strengths between the two solid biofuel forms, with pellets exhibiting greater longitudinal strength and briquettes showing higher vertical strength. Statistical analyses validated these discrepancies and unveiled correlations between strength parameters, emphasizing a noteworthy difference in durability favoring pellets.

Compression strength tests revealed differing strengths between pellets and briquettes, with pellets excelling longitudinally and briquettes vertically. Statistical analyses confirmed these disparities, highlighting pellets’ generally superior durability. Notably, briquettes with a higher fine fraction content exhibited lower durability coefficients, a significant finding according to statistical analysis. In conclusion, moisture control, density determination, and strength analysis emerge as pivotal aspects in assessing the physical and mechanical attributes of hemp biofuels. This article underscores the imperative for further research aimed at optimizing processing techniques to enhance the performance and quality of these solid biofuels.

Author Contributions

Conceptualization, K.R. and E.G.; methodology, K.R. and E.G.; software, K.R. and E.G.; validation, K.R. and E.G.; formal analysis, K.R. and E.G.; investigation, K.R. and E.G.; resources, K.R. and E.G.; data curation, K.R. and E.G.; writing—original draft preparation, K.R. and E.G.; writing—review and editing, K.R. and E.G.; visualization, K.R. and E.G.; supervision, K.R. and E.G.; project administration, K.R. and E.G.; funding acquisition, K.R. and E.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wisniewski, G.; Rogulska, M.; Grzybek, A.; Pietruszko, S.M. The Role of Renewable Energy in Carbon Dioxide Emission Reduction in Poland; Elsevier: Amsterdam, The Netherlands, 1995; Volume 52. [Google Scholar]

- Petryk, A.; Adamik, P. The Guarantees of Origin as a Market-Based Energy Transition Mechanism in Poland. J. Water Land Dev. 2023, 1, 11–16. [Google Scholar] [CrossRef]

- Rupesh, S.; Deepanraj, B. Hydrogen Energy Classification and Comparison with Other Energy Resources. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2023; ISBN 978-0-12-409548-9. [Google Scholar]

- Roman, K. Dobór Parametrów Technicznych Procesu Brykietowania Biomasy Leśnej; Warsaw University of Life Sciences: Warsaw, Poland, 2017. [Google Scholar]

- Raslavičius, L.; Grzybek, A.; Dubrovin, V. Bioenergy in Ukraine—Possibilities of Rural Development and Opportunities for Local Communities. Energy Policy 2011, 39, 3370–3379. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef]

- Ramesh, P.; Arul Mozhi Selvan, V.; Babu, D. Selection of Sustainable Lignocellulose Biomass for Second-Generation Bioethanol Production for Automobile Vehicles Using Lifecycle Indicators through Fuzzy Hybrid PyMCDM Approach. Fuel 2022, 322, 124240. [Google Scholar] [CrossRef]

- Song, H.; Liu, T.; Gauvin, F. Enhancing Mechanical Performance of Green Fiber Cement Composites: Role of Eco-Friendly Alkyl Ketene Dimer on Surfaces of Hemp Fibers. J. Mater. Res. Technol. 2024, 28, 3121–3132. [Google Scholar] [CrossRef]

- Roman, K.; Roman, M.; Szadkowska, D.; Szadkowski, J.; Grzegorzewska, E. Evaluation of Physical and Chemical Parameters According to Energetic Willow (Salix viminalis L.) Cultivation. Energies 2021, 14, 2968. [Google Scholar] [CrossRef]

- Chernova, T.E.; Mikshina, P.V.; Salnikov, V.V.; Ibragimova, N.N.; Sautkina, O.V.; Gorshkova, T.A. Development of Distinct Cell Wall Layers Both in Primary and Secondary Phloem Fibers of Hemp (Cannabis sativa L.). Ind. Crops Prod. 2018, 117, 97–109. [Google Scholar] [CrossRef]

- Sun, X.; Wu, Q.; Picha, D.H.; Ferguson, M.H.; Ndukwe, I.E.; Azadi, P. Comparative Performance of Bio-Based Coatings Formulated with Cellulose, Chitin, and Chitosan Nanomaterials Suitable for Fruit Preservation. Carbohydr. Polym. 2021, 259, 117764. [Google Scholar] [CrossRef]

- Madadi, M.; Bakr, M.M.; Song, G.; Sun, C.; Sun, F.; Hao, Z.; Abomohra, A. Co-Production of Levulinic Acid and Lignin Adsorbent from Aspen Wood with Combination of Liquid Hot Water and Green-Liquor Pretreatments. J. Clean. Prod. 2022, 366, 132817. [Google Scholar] [CrossRef]

- Altman, A.W.; Kent-Dennis, C.; Klotz, J.L.; McLeod, K.R.; Vanzant, E.S.; Harmon, D.L. Review: Utilizing Industrial Hemp (Cannabis sativa L.) by-Products in Livestock Rations. Anim. Feed. Sci. Technol. 2024, 307, 115850. [Google Scholar] [CrossRef]

- Nazmul, R.T.; Sainsbury, B.A.; Garcez, E.O.; Al-Deen, S.; Ashraf, M. Characterisation of the Effects of Hemp Shives for Internal Curing of Concrete. Constr. Build. Mater. 2023, 409, 133916. [Google Scholar] [CrossRef]

- Gulbis, B.; Ferster, A.; Vermylen, C.; Dresse, M.F.; Vanderfaeillie, A.; Delannoy, A.; Labarque, V.; Philippet, P.; Kentos, A.; Sztern, B.; et al. An Estimation of the Incidence and Demographic Picture of the Major Hemoglobinopathies in Belgium (From a Confidential Inquiry. Hemoglobin 2008, 32, 279–285. [Google Scholar] [CrossRef]

- Amaducci, S.; Venturi, G.; Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C.; Venturi, G.; Cromack, H.T.H. Agronomy of Fibre Hemp (Cannabis sativa L.) Agronomy of Fibre Hemp (Cannabis sativa L.) in Europe. Ind. Crops Prod. 2000, 11, 107–118. [Google Scholar]

- Werf, H.V.D.; Mathussen, E.W.J.M.; Haverkort, A.J. The Potential of Hemp (Cannabis sativa L.) for Sustainable Fibre Production: A Crop Physiological Appraisal. Ann. Appl. Biol. 1996, 129, 109–123. [Google Scholar] [CrossRef]

- Leszczyński, M.; Roman, K. Hot-Water Extraction (HWE) Method as Applied to Lignocellulosic Materials from Hemp Stalk. Energies 2023, 16, 4750. [Google Scholar] [CrossRef]

- Du, S.; Zhao, Z.; Li, B.; Li, Y.; Tong, N.; Che, Q.; Wang, J. Preparation of Natural Antibacterial Regenerated Cellulose Fiber from Seed-Type Hemp. Ind. Crops Prod. 2024, 208, 117873. [Google Scholar] [CrossRef]

- Luyckx, M.; Hausman, J.-F.; Isenborghs, A.; Guerriero, G.; Lutts, S. Impact of Cadmium and Zinc on Proteins and Cell Wall-Related Gene Expression in Young Stems of Hemp (Cannabis sativa L.) and Influence of Exogenous Silicon. Environ. Exp. Bot. 2021, 183, 104363. [Google Scholar] [CrossRef]

- Yimlamai, P.; Chitbanyong, K.; Wanitpinyo, K.; Puangsin, B.; Nanta, K.; Khantayanuwong, S.; Pisutpiched, S.; Chaisan, T.; Fei, B.; Hiziroglu, S. Properties of Mixture of Hemp Bast and Softwood Pulp for Filter Paper Manufacture. Heliyon 2024, 10, e25353. [Google Scholar] [CrossRef]

- Piątek, M.; Bartkowiak, A. Effectiveness of Using Physical Pretreatment of Lignocellulosic Biomass. J. Water Land Dev. 2023, 1, 62–69. [Google Scholar] [CrossRef]

- Roman, K.; Leszczyński, M.; Pycka, S.; Wardal, W.J. The Effects of Seawater Treatment on Selected Coniferous Wood Types. Materials 2023, 16, 5831. [Google Scholar] [CrossRef]

- Rachini, A.; Mougin, G.; Delalande, S.; Charmeau, J.-Y.; Barrès, C.; Fleury, E. Hemp Fibers/Polypropylene Composites by Reactive Compounding: Improvement of Physical Properties Promoted by Selective Coupling Chemistry. Polym. Degrad. Stab. 2012, 97, 1988–1995. [Google Scholar] [CrossRef]

- Khalifa, M.; Wuzella, G.; Lammer, H. The Green Catalyst: Role of Hemp Fibers in the Curing Reaction of Bio-Based Epoxy Composites. Mater. Today Commun. 2023, 37, 107052. [Google Scholar] [CrossRef]

- Zhao, J.; Griffin, J.; Roozeboom, K.; Lee, J.; Wang, D. Lignin, Sugar, and Furan Production of Industrial Hemp Biomass via an Integrated Process. Ind. Crops Prod. 2021, 172, 114049. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel Sustainable Hemp-Based Composites for Application in the Building Industry: Physical, Thermal and Mechanical Characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Aryal, K.; Maraseni, T.; Kretzschmar, T.; Chang, D.; Naebe, M.; Neary, L.; Ash, G. Knowledge Mapping for a Secure and Sustainable Hemp Industry: A Systematic Literature Review. Case Stud. Chem. Environ. Eng. 2024, 9, 100550. [Google Scholar] [CrossRef]

- Zarafshani, H.; Watjanatepin, P.; Lepelaar, M.; Verbruggen, J.; Ouagne, P.; De Luca, R.; Li, Q.; Scarpa, F.; Placet, V.; Van Acker, K. Environmental Assessment of Woven Hemp Fibre Reinforced Epoxy Composites and Potential Applications in Aerospace and Electric Scooter Industries. Results Mater. 2023, 20, 100474. [Google Scholar] [CrossRef]

- Kremensas, A.; Vaitkus, S.; Vėjelis, S.; Członka, S.; Kairytė, A. Hemp Shivs and Corn-Starch-Based Biocomposite Boards for Furniture Industry: Improvement of Water Resistance and Reaction to Fire. Ind. Crops Prod. 2021, 166, 113477. [Google Scholar] [CrossRef]

- Al-musawi, H.; Huber, C.; Gusenbauer, C.; Ungerer, B.; Grabner, M.; Ploszczanski, L.; Schönbauer, B.; Painer, J.; Krenke, T.; Müller, U. The Compressive Behaviour of Beech and Birch at Different Moisture and Temperature Conditions along the Grain. Eng. Fail. Anal. 2024, 159, 108017. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, R.; Kasal, B.; Wei, Y.; Yan, L. Moisture-Induced Stresses and Damage in Adhesively Bonded Timber-Concrete Composite Connection. Constr. Build. Mater. 2024, 416, 135184. [Google Scholar] [CrossRef]

- Roman, K.; Grzegorzewska, E.; Leszczyński, M.; Pycka, S.; Barwicki, J.; Golisz, E.; Zatoń, P. Effect of Seawater with Average Salinity on the Moisture Content, Ash Content and Tensile Strength of Some Coniferous Wood. Materials 2023, 16, 2984. [Google Scholar] [CrossRef]

- Östman, B.A.-L. Wood Tensile Strength at Temperatures and Moisture Contents Simulating Fire Conditions. Wood Sci. Technol. 1985, 19, 103–116. [Google Scholar] [CrossRef]

- Chen, W.; Chen, J.; Williams, K.; Wheeler, C. Investigation into the Ship Motion Induced Moisture Migration during Seaborne Coal Transport. Adv. Powder Technol. 2017, 28, 3004–3013. [Google Scholar] [CrossRef]

- Pukalchik, M.; Mercl, F.; Panova, M.; Břendová, K.; Terekhova, V.A.; Tlustoš, P. The Improvement of Multi-Contaminated Sandy Loam Soil Chemical and Biological Properties by the Biochar, Wood Ash, and Humic Substances Amendments. Environ. Pollut. 2017, 229, 516–524. [Google Scholar] [CrossRef]

- Fiszer, A. Influence of Straw Humidity and Temperature of Briquetting Process on the Quality of Agglomerate. J. Res. Appl. Agric. Eng. 2009, 54, 68–70. [Google Scholar]

- Fiszer, A. Methods for Measuring the Durability of Solid Biofuel. J. Res. Appl. Agric. Eng. 2010, 55, 68–70. [Google Scholar]

- Niedziółka, I.; Szymanek, M.; Zuchniarz, A. Ocena Trwałości Brykietów Wytworzonych Z Masy Roślinnej Kukurydzy Pastewnej. Inżynieria Rol. 2008, 9, 235–240. [Google Scholar]

- Hebda, T.; Złobecki, A. Wpływ Stopnia Rozdrobnienia Słomy Na Trwałość Kinetyczną Brykietów. Inżynieria Rol. 2011, 6, 45–52. [Google Scholar]

- Gruszczyński, D.; Szymanowski, K. Effect of Thermomechanical Modification of Scots Pine (Pinus sylvestris L.) Wood on Machine Sanding Efficiency. Ann. WULS For. Wood Technol. 2022, 118, 74–84. [Google Scholar] [CrossRef]

- Borowski, G. Badania Właściwości Mechanicznych Węgla z Biomasą. Postępy Nauk. I Tech. 2008, 2, 81–89. [Google Scholar]

- Başar, C.A.; Korkmaz, A.A.; Önal, Y.; Utku, T. Evaluation of Optimum Carbonization Conditions of the Blended Domestic Polymeric Waste, Biomass and Lignite in the Presence of Catalyst by Taguchi and ANOVA Optimization Analysis. J. Hazard. Mater. Adv. 2022, 8, 100164. [Google Scholar] [CrossRef]

- Fu, P.; Tan, Z. Block-Wise Primal-Dual Algorithms for Large-Scale Doubly Penalized ANOVA Modeling. Comput. Stat. Data Anal. 2024, 194, 107932. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K. Forest Residues as a Renewable Source of Energy: Elemental Composition and Physical Properties. BioResources 2019, 14, 6–20. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Patel, N.; Feofilovs, M.; Blumberga, D. Evaluation of Bioresource Value Models: Sustainable Development in the Agriculture Biorefinery Sector. J. Agric. Food Res. 2022, 10, 100367. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).