Abstract

The necessity to change systems generating electrical energy is evident. The best solution would be to use installations utilizing renewable energy sources, complemented by efficient electric energy storage. This process requires time and further development, as well as new achievements in this area. Improving the situation can also result from enhancing the efficiency of devices already in operation. For a coal-fired power block, an important aspect is the variability of loads and ensuring the highest efficiency of all devices that make up the technological chain of such a unit, especially in variable working conditions. The article presents a new solution for regulating the working parameters of a radial fan for use in power engineering, which has high efficiency over a wide range of loads. The proposed six-blade solution allows one to obtain 115 Pa higher total pressure compared to four-blade systems, and efficiencies higher by 4.6 percentage points. The process of selecting elements and design parameters of the fan and its control system is discussed. The performance characteristics of the device with the new control system are presented.

1. Introduction

Limiting the impact of energy on the climate amid rising energy demand is one of the most challenging issues of the 21st century [1]. In addition to constructing new units based on renewable or low-emission energy sources, modernizing existing facilities that burn fossil fuels is crucial, especially in countries with significant fossil fuel resources. Modernizations of professional power plants should aim to achieve maximum efficiency of production units, taking into account not only the efficiency of the boiler and turbine set, but also all machines that are part of the auxiliary equipment. Fans are significant elements in this last group in power plants, combined heat and power plants, and other large industrial plants. Among this numerous group of flow machines, flue gas fans consume from 0.4 to 1.4% of the energy generated by the power block [2]. Emission reduction installations, such as flue gas desulfurization installations, additionally increase the energy demand of these devices. The effective operation of fans requires these flow machines to work with the highest possible efficiency over a wide range of loads, resulting from the operation of power blocks in the range of large power changes [3].

The only way to achieve a wide range of fan operations is through their effective regulation, regardless of the fan design (axial, radial, diagonal, cross-flow). Fans can be regulated mechanically and electrically [4]. Aerodynamic regulation changes the shape or position of the fan’s elements, modifying its flow characteristics [5]. This is achieved by changing the angle of the impeller wheel blades, using sliding discs in the rotor, or pre-guide vanes. Electrical regulation, changing the rotational speed of the rotating assembly, uses an electric drive with a frequency converter [6,7]. Frequency converters for 6000 V voltage are characterized by significantly higher investment costs compared to mechanical solutions.

The fan control system is designed to influence its parameters in order to maximize their adjustment to the needs of the installation or receiver. This is particularly important in cases where the needs of the installation or receiver vary over time. Then, the efficiency of the device should be considered not only at the optimal operating point, where a properly selected or designed fan should achieve its maximum efficiency [6,8]. Rather, efficiency should be related to the entire range of loads, and then it may turn out that the most economical solution is not devices with the highest efficiency at a specific operating point, but devices with an efficient and high-performance control system that ensures high efficiency over a wide range of device operations [9]. In addition to methods based on changing the installation resistance curve and the method based on changing the rotor speed, there is another way to regulate fans, known as aerodynamic regulation. Aerodynamic regulation involves changing the shapes of or changing the connections between the fan’s structural elements [6,10]. The introduced changes cause a change in the machine’s flow characteristics. This effect can be achieved by the variable setting of the impeller wheel blade angle [11,12], the use of a sliding disc in the impeller [5,10,13], or by using inlet guide vanes [14,15].

A frequently used method of aerodynamic regulation of radial fans is the introduction of an additional element such as guide vanes into their design. Inlet guide vanes, or otherwise, prewhirl vanes, are installed at the inlet to the blade crown [11]. The task of the inlet guide vane is to introduce a twist: a preliminary swirl of the working medium, which should be transferred to the impeller [8,16,17]. The swirl created in the guide vane affects the work delivered to the medium according to Formula (1), resulting from Euler’s equation for flow machines:

where

Δe = ρ · (u2c2u − u1c1u)

Δe—an increase in unit work referred to 1 m3 of gas [J/m3];

ρ—gas density [kg/m3];

u2—velocity of transportation at the impeller outlet (commonly referred to as cross-section 2—external diameter of the impeller) [m/s];

u1—velocity of transportation at the impeller inlet (commonly referred to as cross-section 1—internal diameter of the impeller) [m/s];

c2u—transportation velocity component from the absolute velocity at the impeller outlet (commonly referred to as cross-section 2—external diameter of the impeller) [m/s];

c1u—transportation velocity component from the absolute velocity at the impeller inlet (commonly referred to as cross-section 1—internal diameter of the impeller) [m/s].

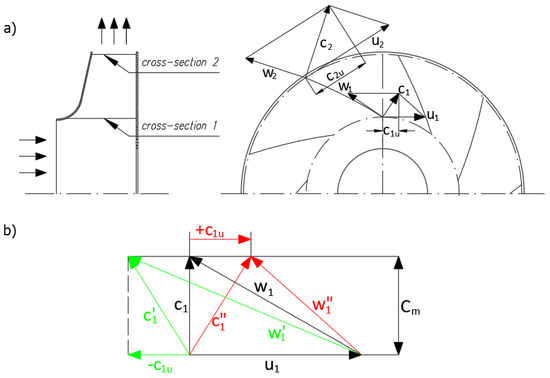

Introducing swirl at the impeller inlet affects the value of c1u. Figure 1a shows the flow diagram of the medium through the radial rotor. The flow velocities of the medium arranged in velocity triangles were also marked. Changes in the velocity triangles during regulation with inlet swirl are shown in Figure 1b. The preliminary swirl of the medium allows for the generation of both co-swirling and counter-swirling relative to the direction of rotation of the impeller [10]. A positive value of the transportation velocity component (red color in Figure 1b) indicates conformity of the swirl direction with the direction of rotation of the impeller, and reduces damming and flow losses [18]. Additionally, such co-swirling causes a shift of the pumping boundary towards lower outputs, which increases the range of stable fan operation.

Figure 1.

Speed triangles: (a) sketch of flow through a radial impeller with marked cross-section and classic system of velocity triangles is presented; (b) changes in speed triangles during regulation with swirl at the impeller inlet [18].

Design elements that allow for the generation of swirl are the inlet guide vanes. Depending on the type of construction, one can distinguish axial guide vanes, conical guide vanes, radial guide vanes, louvered guide vanes, and progressive louvered guide vanes [18]. The type of system used depends on many design factors, but also on economic ones. In the case of modernization, there may also be space limitations for constructing and installing the guide vane.

Fans for energy applications usually have high power and are designed individually for a specific application. In this case, the guide vane system is also constructed for a given fan design. Due to the complicated flow and space limitations for the guide vane installation, an attempt was made to use a louvered guide vane with different blade setting angles. The design process was carried out by using a simplified computational model and experimental studies of a fan model made to scale. The obtained results were developed for the actual flow machine using similarity criteria and Ackeret’s formulas [19,20,21].

2. Materials and Methods

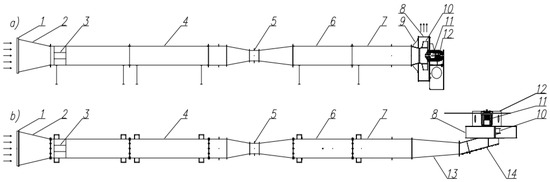

The design process supported by experimental research was carried out in two stages. The first one involved determining the geometry of the impeller and establishing its performance characteristics (system without inlet box; Figure 2a). In the second stage, the process of selecting the geometry of the inlet guide vane, as well as its position relative to the axis of the impeller (system with inlet box; Figure 2b), was conducted. The research in both stages was carried out using models of fan elements made on a 1:4 scale. Adapting the measurement station used to determine the characteristics of the tested centrifugal fans (Figure 2a) to the station testing various configurations of primary blades (Figure 2b) took 2 years. Initially, a design was prepared containing executive documentation of additional elements of the station. These elements were then made of steel and the site was rebuilt. The research itself lasted 6 months.

Figure 2.

Diagram of the research stand: (a) axisymmetric flow to the impeller wheel; (b) flow to the impeller wheel using an inlet box (1—inlet throttle, 2—confusor, 3—flow straightener, 4, 6, 7—suction channel, 5—Venturi nozzle, 8—spiral casing, 9—inlet funnel, 10—model impeller, 11—electric motor, 12—motor cradle, 13—reduction channel, 14—inlet box) [22].

Research on various systems of guide vanes regulating the operation of a radial fan was conducted on a test stand in accordance with the standard PN-ISO 5801:2008 [23] as a type “C” testing setup. It is used to test new geometries of rotor wheels. In these tests, the suction pipeline is positioned axially with respect to the impeller inlet. In order to enable one to test the system of the inlet box, steering apparatus and fan, it was necessary to expand the test stand with a reduction channel (13) and an inlet box (14) (see Figure 2b).

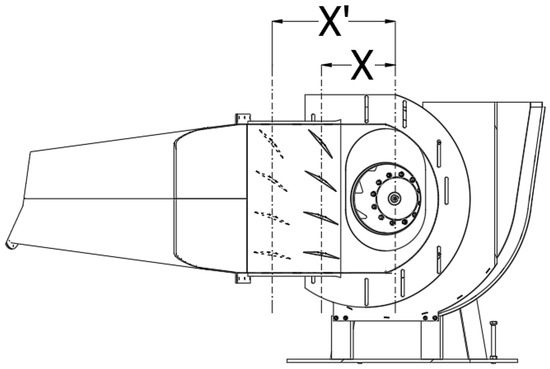

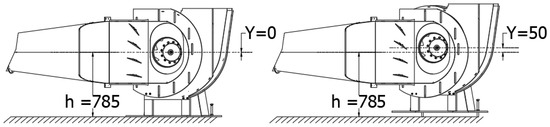

The designed inlet box allows for changing the distance between the axis of rotation of the impeller and the axis passing through the axes of rotation of the guide vane apparatus—parameter X (see Figure 3)—and for changing the setting of the symmetry plane of the inlet box relative to the axis of rotation of the impeller—parameter Y (see Figure 4) [8,16,24].

Figure 3.

Sketch showing the geometric parameters X selected for the study.

Figure 4.

Sketch showing the geometric parameters Y selected for the study.

The X parameter could be adjusted from 375 mm to 625 mm. The parameter Y = 0 means that the entire system (suction pipeline, inlet box, fan) is symmetrical. It can be adjusted in the range of 0–100 mm.

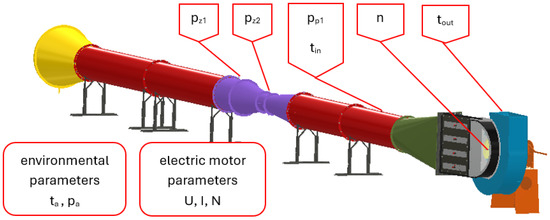

At the research stand (see Figure 5), temperature measurements in the pipeline were carried out using two Pt-100 resistance temperature sensors, and temperature measurements were made in two control cross-sections: at the impeller inlet (tin) and at the impeller outlet (tout). Ambient temperature (ta) and ambient pressure (pa) measurements were carried out using a COMET D thermo-hygro-barometer. Pressure measurements in the designated measurement planes were made using Aplisens PR28 sensors (Warsaw, Poland) and these pressures are as follows: (pz1), (pz2), and (pp1). Each measuring plane consists of four measuring stubs spaced every 90°. The measured pressure values are the values resulting from the average measurement, because the impulse holes are connected with cables to the collection and expansion tank, and then this tank is connected to the pressure sensor. Rotational velocity measurement (n) was carried out using a laser tachometer. Voltage measurement (U) was performed using a U-S2A voltage transducer. Current intensity measurement (I) was performed using the PPI1220 current transducer and the 50/5A current transformer. Power measurement (N) was performed using a three-phase active power transducer PPP740. In order to determine the fan’s operating characteristics at the research stand, measurements were made, and the following physical quantities were determined: —dynamic pressure in the Venturi nozzle [Pa]; pss—static pressure at the control cross-section downstream the fan [Pa]; and N—electrical power of the fan drive [W]. The measured physical quantities allowed one to calculate resulting quantities that enabled the plotting of the following characteristics describing performance of the considered fan:

Figure 5.

Research test stand: 3D model view with marked measurement points of individual physical quantities. pz1—pressure measured in the throat of a cylindrical Venturi with an internal diameter of 240 mm; pz2—pressure measured in the cylindrical section of the Venturi with an internal diameter of 450 mm; pp1—pressure measured in the pipe section before the reducing channel; tin—medium temperature in the inlet channel; n—rotor rotation speed; tout—medium temperature in the outlet channel; ta—ambient temperature; pa—ambient pressure; U—electric voltage of the drive motor; I—electric current of the drive motor; N—power of the electric motor.

Δpc = f()—head characteristic (head curve);

η = f()—efficiency characteristic (efficiency curve);

N = f()—power characteristic (power curve) [13].

All measurements were made after determining the flow conditions and the same physical quantities were measured for both configurations of the station. After setting the steering gear and the inlet box in the appropriate configuration, the engine driving the rotor wheel was started. Approximately 10 min after the flow had stabilized, measurements were taken. A single measurement performed on the measuring unit consisted of 2048 samples collected in 1 s. To plot the characteristics, 10 measurements were collected each time at various states of installation throttling. The data were then averaged and substituted into the formulas shown below.

For stationary conditions, these were constant values at a given measurement point. Circumferential-pressure-averaging was intended to take into account differences in static pressure around the channel periphery, and to obtain a value representative of the flow in the entire cross-section for a fluid velocity, relative to the channel wall, of zero.

The density of the medium was calculated using the Clapeyron Equation (2).

The density of the medium in the designated measurement cross-sections was calculated on the basis of the ambient pressure measured value and temperature measured in the designated measurement planes. The relationship was used to determine the density of the medium in the suction channel.

At the test stand, the value of the volume flow of the factor was determined on the basis of the relationship (4).

The flow coefficient α, which is a function of the Reynolds number, was calculated using the Formula (5):

The expansion coefficient ε was determined based on the relationship (6). In this mathematical formula, the isentropic coefficient k describes the ratio of specific heat at constant pressure to specific heat at constant volume and is equal to 1.4:

The relationship was used to calculate the dynamic pressure value (7)

By using the continuity Equation (8) and knowing the value of the volume flow in one of the measurement planes, it is possible to determine the volume flow in any cross-section of the test station

The fan efficiency was calculated based on the Equation (9)

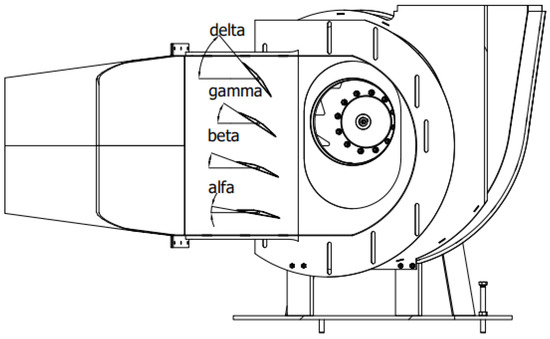

Thanks to the determined characteristics, it is possible to compare the influence of the selected geometrical parameters (X, Y) on the operating parameters of the guide vane fan system. The research aimed to find the position of the louvered guide vane inside the inlet box that is most advantageous in terms of the levels of efficiency and head values obtained. Both classic systems, in which each blade is set at the same angle, and progressive systems, in which the opening angles of individual blades change unevenly, were tested (see Figure 6).

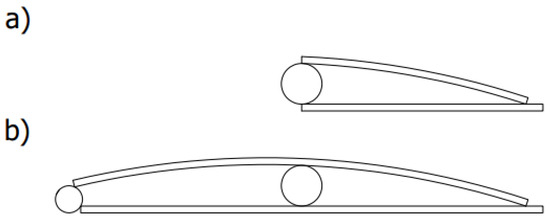

Figure 6.

Sketch explaining the angular settings of the progressive systems under investigation [22].

3. Results and Discussion

An important aspect of the modernization process was to select the appropriate design and geometry of the impeller, and then to determine its performance characteristics for axial flow (without guide apparatus). The characteristics obtained in this way formed the basis for analyzing the results obtained for the design solutions of the fan with the inlet guide vane. Geometric and design variants were tested to examine the impact of the displacement of the box axis relative to the axis of rotation, the inclination of the axis of rotation of the guide vanes relative to the symmetry plane, different angles of the guide vanes, and different numbers of guide vanes in the box.

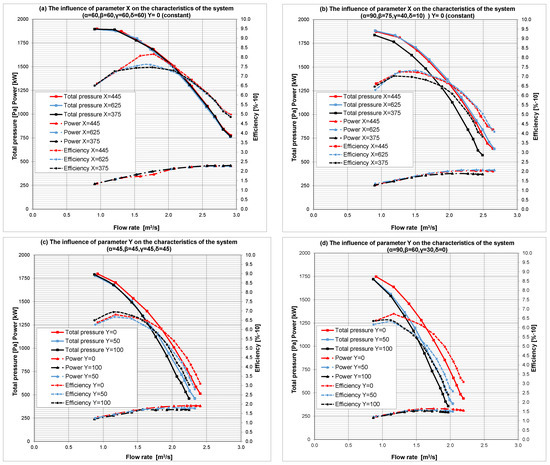

The blade settings (design angles of the blades) on the charts presented in Figure 7 were shaped in the manner presented in Table 1.

Figure 7.

Fan performance characteristics for different guide vane angle settings given in Table 1.

Table 1.

Angular settings of individual blades for the research results presented in Figure 7.

Conducting over 50 tests of different blade systems allowed for the observation of the following relationships. The obtained head characteristics relative to efficiency for classic systems (an example is presented in Figure 7a) are characterized by high insensitivity to parameter X. Discrepancies between the settings of parameter X in the range from 375 mm to 675 mm averaged ±0.4%, and the maximum changes did not exceed 2%. In the case of efficiency curves for classic systems, the most advantageous variant turned out to be parameter X, in which the ratio of the distance of the straight line passing through the axes of rotation of the blades to the inlet diameter of the impeller is 1.24.

Progressive systems have a significantly higher sensitivity to parameter X. Setting the progressive system at a distance of X = 375 mm causes a lowering of the head curve position relative to the system (X = 445 mm), which for the tested progressive systems turned out to be the most advantageous. The average pressure drop is about 150 Pa, and the maximum efficiencies are about 5% lower.

Initially, with four-blade systems, the Y parameter did not affect the results. It was concluded that this was caused by too low speeds in the inter-blade channels of the palisade, so the number of blades was increased from four to six. As a result, the distance between subsequent axes of rotation of the blades was reduced from 187.5 mm to 133.5 mm

The introduction of parameter Y in the tested systems proved to be unjustified. Both classic and progressive systems achieve the highest operating parameters in the variant Y = 0. However, the characteristics obtained for systems Y = 50 mm are shaped at higher levels than the results obtained for the variant Y = 100 mm. In four-blade systems, the swirl generated in the blade palisade is too low for the introduction of asymmetry resulting in an increase in operating parameters. Therefore, it was decided to increase the number of blades to obtain higher speed in the inter-blade channels.

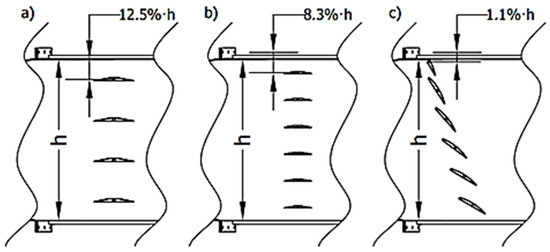

It has been observed that in louvered guide vanes with four blades, up to 12.5% of the flowing medium does not participate in the generated swirl, assuming an even distribution of flow throughout the cross-section (see Figure 8).

Figure 8.

(a) Presentation of the guide vane positions in a four-vane system, (b) presentation of the guide vane positions in a six-vane system, (c) proposed slanted six-vane system equipped with a half-vane.

The solution developed in this area is the half-vane (see Figure 9). The system using the half-vane is a six-vane system, which was additionally decided to be set obliquely relative to the medium flowing onto the guide vane apparatus (see Figure 8c). A comparison of the fan performance characteristics with a guide vane equipped with six and four vanes, for various design variants, is shown in Figure 10.

Figure 9.

Sketch of (a) half-vane L = 77 mm, (b) standard-vane L = 143.5 mm.

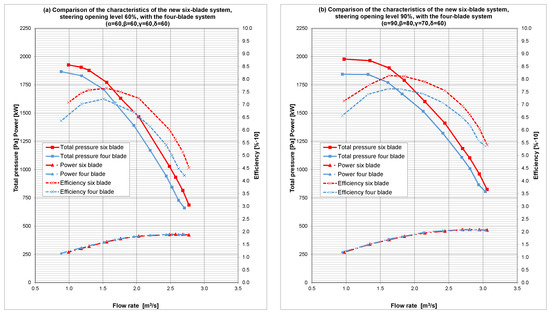

Figure 10.

Fan performance characteristics for systems with six and four vanes.

Comparing the proposed innovative solution at a 60% opening level with the classic four-vane system with blade angles equal to 60°, it can be noticed that the average difference in the obtained head values is 110 Pa in favor of the proposed solution. For an efficiency level of 2.5 m3/s, the proposed system has a head value of 1017 Pa, while the four-vane system has a value of only 878 Pa. The difference in the obtained head values is over 13.5%. For an efficiency level of 2 m3/s, the six-vane system has a head value of 1485 Pa, while the four-vane system has a value of only 1362 Pa. The difference in the obtained head values is over 8.2%. Analyzing the efficiency curves, a significant advantage of the proposed solution over the system in which the blades are set at the same angle can be noticed. The average difference in efficiency for the entire measurement range is close to 6 percentage points.

The skewed six-vane system with a half-vane compared to the progressive system (α = 90°, β = 80°, γ = 70°, δ = 60°), for X = 445 mm and Y = 0 mm, achieves higher values for both head value and efficiency across the full range of measured quantities. The head curve of the innovative system in the range from 1 to 3 m3/s is, on average, 115 Pa above the curve of the four-vane system. The head values achieved in this range are over 7% higher for the proposed solution. The efficiency curve of the innovative system is on average 4.6 percentage points higher than that of the four-vane system in the range from 1 to 3 m3/s.

The positive results of the proposed concept of the skewed louvered guide vane led to a re-examination of parameter Y. In the case of a guide vane apparatus designed to achieve the greatest possible preliminary swirl on the vane palisade, shifting the inlet box relative to the axis of rotation of the rotating assembly proved to be justified. The results of the fan tests for different values of asymmetry (Y = 0, 50, 100 mm) are shown in Figure 11.

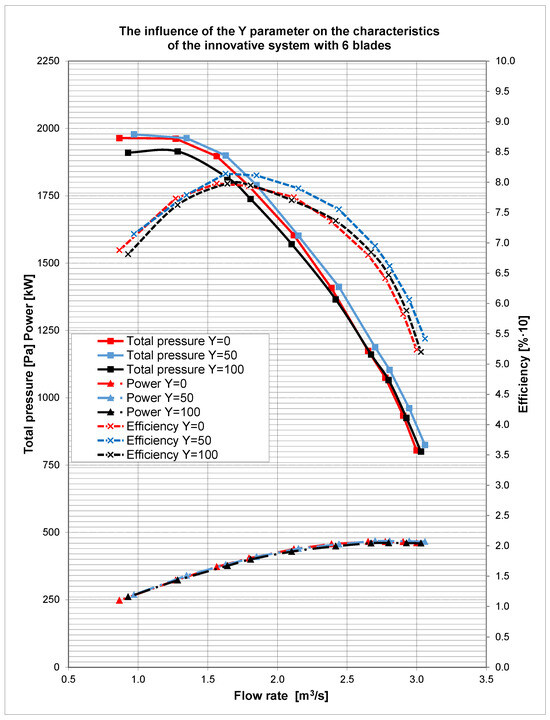

Figure 11.

Characteristics of fan operating parameters for systems with six blades for different asymmetries of the vane guide system.

Opening the guide vane apparatus to 90% allows for achieving maximum efficiencies at levels of 2.99 m3/s for the system where Y = 0 mm, 3.03 m3/s for Y = 100 mm, and 3.05 m3/s for Y = 50 mm. Introducing an asymmetry of Y = 50 mm allows for achieving the highest levels of head values as well as the highest efficiencies across the entire examined range of adjustability at a guide vane opening level of 90%.

4. Conclusions

Designing additional elements for the research stand enabled the planned studies to be carried out with the aim of determining the most favorable values for the selected parameters X (equal to 625 mm for the tested system) and Y (equal to 50 mm for the tested system). The conducted studies allowed for the development of a new type of progressive louvered guide vane.

The research showed that the introduction of a half-vane in a six-vane steering system significantly improves flow efficiency. The half-vane reduces the amount of medium that does not participate in the generated swirl, as observed in a conventional four-vane system, by as much as 12.5%. Setting the vanes obliquely relative to the incoming medium further improves the flow characteristics. The skew of the vanes favors a more even distribution of flow velocity, which leads to increased system efficiency and better transfer of preliminary swirl energy to the impeller wheel. Thanks to the design changes, the developed fan control system achieved better results on the test stand by the following: for 60% opening at a capacity of 2.5 m3/s, head value of 1485 Pa, compared to the four-blade system with a value of 1362 Pa; and for an opening of 90% efficiency of 2 m3/s, the head value was 1712 Pa, and for a four-blade was 1590 Pa. The proposed six-blade solution allows one to obtain 115 Pa higher total pressure compared to four-blade systems, and 4.6 percentage points higher efficiency.

Conducted tests, covering over 50 different systems, allowed for the determination of the best number of blades in the guide vane system. The six-vane system proved to be the most efficient. The proposed slanted six-vane system with a half-vane showed a significant advantage over traditional systems in terms of aerodynamic efficiency. The results of these studies can be used in industrial practice to modernize existing fan systems in power plants and in combined heat and power plants. The application of the proposed guide vane system allows for increased energy efficiency and reduction of operational costs. The research results provide valuable guidelines for further work on increasing the energy efficiency of ventilation systems in the power generation industry.

Author Contributions

Conceptualization, D.Z.; Methodology, D.Z.; Formal analysis, D.Z.; Investigation, D.Z.; Resources, D.Z.; Data curation, D.Z.; Writing—original draft, D.Z.; Writing—review & editing, K.J.; Supervision, K.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ministry of Climate and Environment. National Energy and Climate Plan until 2030; (update of NECP from 2019)—Draft from 29.02.2024; Ministry of Climate and Environment: Warsaw, Poland, 2024. (In Polish)

- Pawlik, M.; Strzelczyk, F. Power Plants, 7th revised edition—1st reprint PWN; WNT Publishing House: Warsaw, Poland, 2016. (In Polish) [Google Scholar]

- Bartnik, R.; Skomudek, W.; Buryn, Z.; Hnydiuk-Stefan, A. Modernization of Power Plants; Energy and Economic Efficiency; WNT Publishing House: Warsaw, Poland, 2020. (In Polish) [Google Scholar]

- Cory, W. Fans and Ventilation: A Practical Guide; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Eck, B. Ventilatoren. Entwurf und Betrieb der Radial, Axial und Querstromventilatoren; Springer: Berlin/Göttingen/Heidelberg, Germany, 1972. [Google Scholar]

- Walczak, J. Radial Compressors, Blowers, and Fans; Poznań University of Technology Publishing House: Poznań, Poland, 2013. (In Polish) [Google Scholar]

- Markiewicz, H. Electrical Installations; WNT Publishing House: Warsaw, Poland, 2018. (In Polish) [Google Scholar]

- Beczkowski, J. Optimization of Parameters of an Energy Centrifugal Fan with Special Consideration of the Regulation System under Real Constraints; Institute of Flow Machines, Łódź University of Technology: Łódź, Poland, 2011. (In Polish) [Google Scholar]

- Kaya, D.; Çanka Kılıç, F.; Öztürk, H.H. Energy Efficiency in Fans. In Energy Management and Energy Efficiency in Industry. Green Energy and Technology; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Fortuna, S. Fans—Theoretical Basics, Design and Operational Issues, and Applications; Techwent S.C. Publishing House: Kraków, Poland, 1999. (In Polish) [Google Scholar]

- Kosowski, K.; Masiukiewicz, M. Axial and Centrifugal Fans; Scientific and Technical Publishing House: Warsaw, Poland, 2009. (In Polish) [Google Scholar]

- Marciniak, E. Design and Testing of a New Type of Regulation for a Centrifugal Fan with Additional Adjustable Rotor Blades; Institute of Flow Machines, Łódź University of Technology: Łódź, Poland, 2018. (In Polish) [Google Scholar]

- Jankowski, F. Pumps and Fans in Sanitary Engineering; Arkady Publishing House: Warsaw, Poland, 1975. (In Polish) [Google Scholar]

- Rydlewicz, J. Flow Fans and Pumps; Łódź University of Technology Publishing House: Łódź, Poland, 1989. (In Polish) [Google Scholar]

- Tuliszka, E. Compressors, Blowers, and Fans; Scientific and Technical Publishing House: Warsaw, Poland, 1976. (In Polish) [Google Scholar]

- Tan, L.; Zhu, B. A review of prewhirl regulation by inlet guide vanes for compressor and pump. Renew. Sustain. Energy Rev. 2018, 97, 133–145. [Google Scholar]

- Zhang, Y.; Zhou, Y.; Wang, X. Aerodynamic performance of a centrifugal fan with inlet guide vanes. Energy Convers. Manag. 2020, 203, 112252. [Google Scholar]

- Kuczewski, S. Fans: Theory, Design, Investigations; Scientific Publishing House PWN: Warsaw, Poland, 2000. (In Polish) [Google Scholar]

- Frąckowiak, W. Fan Louver Guide Vanes with Blades Sequentially Adjusted to Decreasing Angles; Works of the Institute of Thermal Technology; ITC: Łódź, Poland, 1969; Issue 39. (In Polish) [Google Scholar]

- Jeżowiecka-Kabsch, K.; Szewczyk, H. Fluid Mechanics; Wrocław University of Technology Publishing House: Wrocław, Poland, 2001. (In Polish) [Google Scholar]

- Zarzycki, R.; Prywer, J. Process Engineering. Fluid Mechanics; PWN Scientific Publishing House: Warsaw, Poland, 2020. (In Polish) [Google Scholar]

- Zarębski, D. The Influence of Various Design Solutions of Progressive Guide Vanes on the Efficiency of a Radial Fan; Interdisciplinary Doctoral School of Łódź University of Technology: Łódź, Poland, 2024. (In Polish) [Google Scholar]

- PN-ISO 5801:2008; Fans—Methods of Performance Testing (ISO 5801:2007, IDT). ISO: Geneva, Switzerland, 2007.

- Beczkowski, J.; Sobczak, K.; Jóźwik, K. Model Investigations of the Radial Fan with Guide Vanes—Part 2—Numerical Investigations. Łódź Univ. Technol. Sci. J. Therm. Flow Mach.—Turbomach. 2008, 133, 317–326. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).