Abstract

This paper introduces a novel approach for rapidly balancing lithium-ion batteries using a single DC–DC converter, enabling direct energy transfer between high- and low-voltage cells. Utilizing relays for cell pair selection ensures cost-effectiveness in the switch network. The control system integrates a battery-monitoring IC and an MCU to oversee cell voltage and ensure battery protection. A prototype circuit with twelve lithium-ion batteries demonstrates the method’s efficacy, achieving a remarkable balancing time of 48 min during charging with a maximum efficiency of 89.85%. Comparative analysis with other methods underscores the superior performance of the proposed balancing circuit in terms of balancing time and implementation cost. Furthermore, this paper delves into hardware aspects of battery management systems (BMSs) for electric vehicles and stationary applications. It offers an overview of prevailing concepts in state-of-the-art systems, aiding readers in assessing considerations essential for BMS design in various applications. The discussion includes examples of battery packs sourced from commercially available electric vehicles. Subsequently, the manuscript addresses implementation aspects concerning the measurement of critical physical variables such as voltage, current, and temperature, alongside balancing strategies.

1. Introduction

In contemporary times, the prevalence of lithium-ion batteries in the automotive sector is on the rise. To cater to applications demanding substantial power and voltage, such as electric vehicles (EVs), hybrid electric vehicles (HEVs), and energy storage systems (ESSs), it is imperative to assemble battery arrays comprising a multitude of cells interconnected both in series and parallel [1]. For instance, the Tesla Roadster’s battery comprises a staggering 6831 Li-ion cells organized into 69 strings, with each string housing 99 cells [2]. Subtle disparities arising from the manufacturing process and operating conditions can lead to variations in the characteristics of cells within the same string. These disparities manifest as discrepancies in cell voltages, which tend to amplify with each charge and discharge cycle. Since the cells in a string are interconnected in series, the performance of the entire string is contingent on the weakest cell, ultimately limiting the capacity of the battery string. During regular operation, the weakest cell undergoes over-discharge and undercharge, ultimately resulting in its failure. Meanwhile, the healthy cells may experience overcharge as the charging process continues until the string voltage reaches its nominal value. In this scenario, the voltage of the healthy cell may surpass the maximum allowable charge voltage, hastening its degradation and potential failure [1]. Consequently, the implementation of a cell-balancing circuit is indispensable for battery strings or modules [3].

To date, numerous cell balancing techniques and configurations have been proposed and developed. These methods can be categorized into active and passive approaches [4]. Passive methods, which employ resistors to discharge overcharged cells, are suitable for lead-acid and NiMH batteries but have the drawback of increasing system temperature due to power dissipation as heat.

Active cell-balancing techniques can be classified into four distinct categories based on their charge-transfer methods: the pack-to-cell method, cell-to-pack method, cell-to-cell method, and cell-to-pack-to-cell method.

The implementation of the cell-to-pack method can be achieved either using a single transformer [5] or multiple transformers [6]. However, this approach entails a high cost, due to the substantial requirement of MOSFETs and gate drivers, resulting in a relatively slow balancing process. Conversely, the pack-to-cell method can be realized with a multi-output transformer [7] or multiple transformers [8], which involve fewer switches compared to the cell-to-pack method. However, it necessitates a greater number of transformers, rendering its design complex and costly. A combination of both methods, known as the cell-to-pack-to-cell method [9], offers faster balancing speeds but is generally less preferred. This approach demands a significant number of photo-couplers to drive bidirectional switches and requires the use of two DC–DC converters, making it complex and expensive to implement.

In contrast, cell-to-cell methods emerge as a favorable choice in terms of cost, complexity, and balancing speed. Several topologies have been developed based on the cell-to-cell balancing method [10,11,12], including the adjacent cell-to-cell method and the direct cell-to-cell method. The adjacent cell-to-cell method transfers charge between two neighboring cells through capacitors [13,14], inductors [15,16,17], or a combination of both [18], as a resonant tank. However, this method relies on pulse transformers or photo-couplers to drive bidirectional switches, resulting in higher costs and implementation complexity. The direct cell-to-cell method is designed to achieve high efficiency by transferring charge directly from any cell to any other cell. In this approach, a single-switched capacitor [19] or a single-switched inductor [20,21] serves as the medium for charge transfer, making it easier to implement but with a longer balancing time. While the cell-to-cell LC resonant topology [22] offers higher efficiency due to soft-switching operation, it does not provide fast balancing speeds and requires a substantial number of switches and gate drivers. Similarly, the coupled inductor topology [23] and the multi-winding transformer topology [24], which use only one core and one transformer for charge transfer, are cost-effective but intricate to implement.

To address these challenges, a direct cell-to-cell method using a DC–DC converter is proposed in [25,26]. A cost-effective balancing circuit is presented in [25] utilizing relays, while [26] achieves superior performance at a higher cost. In this research, a new cell-to-cell balancing circuit for lithium-ion battery groups is introduced to overcome the drawbacks of conventional cell-balancing methods. This proposed topology facilitates direct charge transfer from a high-voltage cell to a low-voltage cell through a DC–DC converter. The control of this method is straightforward to implement. By employing relays, which can be driven by a transistor array, as cell selection switches, the cost of the balancing circuit can be significantly reduced. Furthermore, the balancing speed can be enhanced by appropriately designing the voltage gain of the push–pull converter, ensuring that the balancing current remains substantial even as the voltage difference between the two cells diminishes. Section 2 introduces BMS requirements and features. In Section 3, the battery management testing structure includes the hardware and software. In Section 4, an overview of the portable electronic components used in the design is explained. In Section 5, the experimental setup and some measurements are provided. In Section 6, results to show the superiority of the proposed method are presented. In Section 7, the conclusion is given.

2. Battery Management System

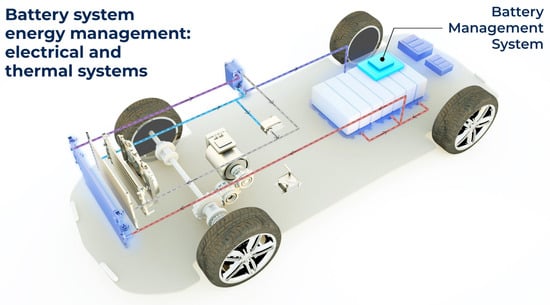

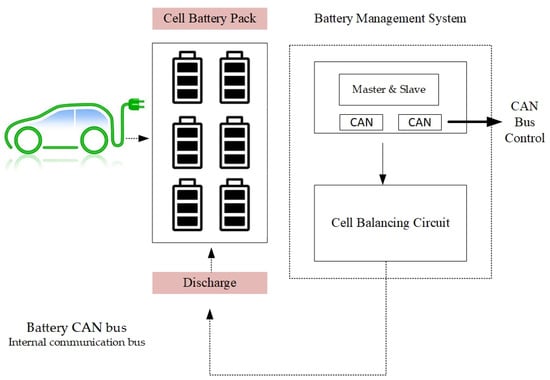

Figure 1 shows the battery management system integration and its requirements referring to the set of specifications, features, and functions that are necessary for the proper management, control, and maintenance of batteries. These requirements are particularly important in various applications such as consumer electronics, electric vehicles, renewable energy systems, and more. Effective battery management helps ensure optimal performance, safety, and longevity of battery systems. Here are some common battery management requirements:

Figure 1.

Battery Management System (BMS) integrations.

2.1. State of Charge (SoC) and State of Health (SoH) Monitoring

The BMS should accurately measure the remaining capacity of the battery. This can be achieved through voltage, current integration, and/or coulomb counting methods. The BMS should track capacity degradation over time by comparing the battery’s current performance to its initial performance. This helps to predict the battery’s remaining useful life.

2.2. Voltage and Current Monitoring

The BMS continuously measures cell and pack voltages to prevent overcharging or over-discharging. It ensures that no cell or pack exceeds its safe voltage limits. Monitoring the current flowing into and out of the battery helps prevent overcurrent situations, which can damage the battery or surrounding components.

2.3. Temperature Monitoring

The BMS should measure the temperature of individual cells or the overall pack. If temperatures approach dangerous levels, the BMS should take action to cool down the battery or limit charging/discharging rates.

2.4. Cell Balancing

The BMS should monitor individual cell voltages and, if necessary, apply balancing techniques to equalize the charge among cells. This prevents overcharging of some cells while others remain undercharged.

2.5. Overcurrent and Overvoltage Protection

The BMS should have circuitry to quickly disconnect the battery in the event of overcurrent or overvoltage, preventing damage to the battery or connected devices.

2.6. Under Voltage Protection

Similar to overvoltage protection, the BMS should disconnect the battery when its voltage drops to a level that could lead to deep discharge.

2.7. Over Temperature Protection

The BMS should monitor temperature sensors and respond to overheating conditions by reducing charging/discharging rates or even disconnecting the battery.

2.8. Communication Interface

The BMS should provide a communication interface, such as a Controller Area Network (CAN) bus or UART, for interacting with other system components and external devices. This enables real-time monitoring and control.

2.9. Safety Mechanisms

The BMS should have fail-safe mechanisms that, in the event of a fault, isolate the battery from the rest of the system to prevent potential hazards.

Several key safety strategies were integral to these vehicles’ HV systems.

Firstly, rigorous insulation techniques and materials effectively isolate HV components from the vehicle’s chassis and low-voltage systems, thereby preventing unintended electrical contact and leakage. Continuous monitoring systems actively supervise the HV network for abnormalities, such as short circuits or insulation breaches, enabling swift detection and response. Rapid shutdown mechanisms, including high-speed relays or contactors, promptly disconnect the HV system in case of detected faults, minimizing risks of electric shock or fire. Additionally, strategically placed circuit breakers or fuses safeguard against overcurrent conditions, averting thermal incidents. This design emphasizes adherence to stringent safety standards and extensive testing protocols to ensure these protective measures meet regulatory requirements and exceed safety benchmarks. Collectively, these integrated safety measures uphold the reliability and safety of electric and hybrid vehicles’ HV systems across various operational scenarios.

These safety measures collectively contribute to minimizing the risk of hazardous situations in electric and hybrid vehicles, ensuring the protection of occupants, emergency responders, and bystanders.

2.10. Fault Detection and Diagnostics

The BMS should use algorithms to detect faults, such as cell imbalances, low capacity, or communication errors. These diagnostics help pinpoint issues and facilitate maintenance.

2.11. User Interface and Indicators

For consumer devices or vehicles, the BMS might have LED indicators, display screens, or notifications to inform users of battery status, warnings, and critical alerts.

2.12. Energy Management

In electric vehicles or renewable energy systems, the BMS might control charging and discharging rates to optimize energy usage for efficiency and to extend battery life.

2.13. Data Logging and Analysis

Some BMS designs include data logging capabilities to record voltage, current, temperature, and other parameters over time. These data aid in identifying trends, optimizing usage, and diagnosing issues.

2.14. Redundancy and Fail-Safe Design

Critical systems require redundant BMS components to ensure reliable operation even if one part fails. Fail-safe mechanisms could involve automatic system shutdown in case of critical failures.

2.15. Signal Acquisition and Filtering

Front-end ICs, particularly Battery Management System Slaves (BMS-Slaves), play a crucial role in modern battery management systems (BMSs) by facilitating signal acquisition and filtering.

2.15.1. Signal Acquisition

BMS-Slaves are responsible for directly interfacing with individual cells or groups of cells within the battery pack. They acquire critical signals such as cell voltage, temperature, and sometimes current, depending on the specific configuration and requirements of the BMS. These ICs typically include high-precision analog-to-digital converters (ADCs) that sample the analog signals from the cells at regular intervals. The ADCs convert these analog measurements into digital data, which are then processed by the BMS for monitoring and control purposes.

2.15.2. Signal Filtering

Effective signal filtering is essential to ensure accurate and reliable data acquisition from the battery cells. BMS-Slaves incorporate various filtering techniques to eliminate noise and interference that can affect the integrity of the acquired signals. This includes both hardware-based filtering within the analog front-end circuitry and software-based digital filtering algorithms implemented in the microcontroller or digital signal processor (DSP) cores within the ICs.

- (i)

- Hardware Filtering: This involves the use of capacitors, resistors, and inductors to attenuate unwanted frequencies and reduce noise in the analog signal path. Bandwidth limiting and anti-aliasing filters are commonly employed to ensure that only the relevant signal components are passed on to the ADCs.

- (ii)

- Digital Filtering: Once the signals are digitized by the ADCs, digital filtering algorithms are applied to further enhance signal quality. These algorithms can include moving average filters, low-pass filters, or more sophisticated algorithms such as Kalman filters to extract accurate measurements from the noisy input signals.

2.15.3. Integration with BMS Architecture

BMS-Slaves are integrated into the broader BMS architecture, typically communicating with a central control unit (BMS Master) or distributed data acquisition system. They transmit the processed digital data, including filtered signals, to the master unit via communication protocols such as SPI (Serial Peripheral Interface), I2C (Inter-Integrated Circuit), or CAN (Controller Area Network). This integration allows the BMS to monitor the health and status of individual cells or modules in real-time, enabling timely diagnosis and management of the battery pack.

3. Proposed Circuit for Cell Balancing

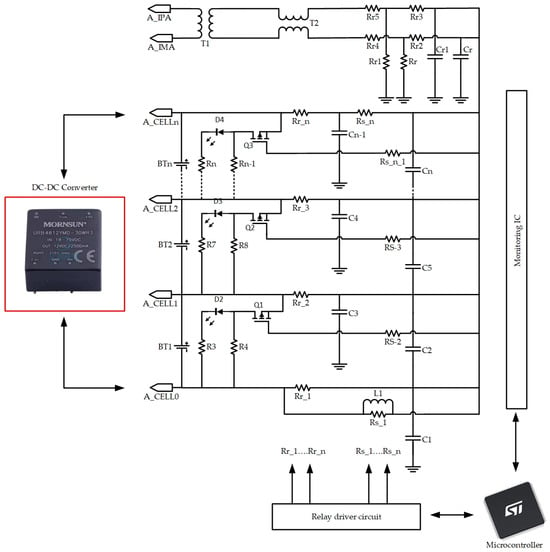

Figure 2 illustrates the cell-to-cell balancing circuit. Firstly, there are battery cells connected to each terminal of the converter to facilitate charger transfer. Secondly, there is a DC–DC converter (Mornsun, Guangzhou, China) tasked with transferring charge from a high-voltage cell to a low-voltage one. Lastly, there is a control circuit for monitoring IC for updating cell voltage and an STMicrocontroller responsible for managing converter and cell balancing.

Figure 2.

Cell-balancing circuit.

The cell-balancing circuit utilizes two groups of relays. The first group, R3 to Rn-1, facilitates connection between the battery cell and the primary side of the converter. The second group from R5 to Rn-4, enables connection between the battery cell and the secondary side of the converter. So, this allows the transfer of charge between any cell to any other cell in a group.

The DC–DC converter is chosen for its straightforward design, ease of control, and high efficiency in charge transfer. Assuming ideal components, the transformer’s turns ratio was initially set at 1:1, reflecting the typical voltage deviation within a battery group of less than 0.2 V. However, for practical design considerations accounting for voltage drops across components, the transformer turns ratio was adjusted to 1:1.2 in this study. To minimize ripple voltage and current within strict limits for lithium-ion batteries during charge/discharge cycles, a duty cycle of 0.5 was employed to achieve minimal input/output ripple.

The voltage monitoring IC measures the cell voltages within the group and communicates them to the STMicrocontroller via I2C serial communication. The balancing current is determined using a current sense resistor on the primary side. The current on the secondary side can be computed using the transformer turns ratio and the converter efficiency. The internal impedance impacts both the balancing current and battery terminal voltage, necessitating consideration during system design.

Working Principle of Cell-Balancing Circuit

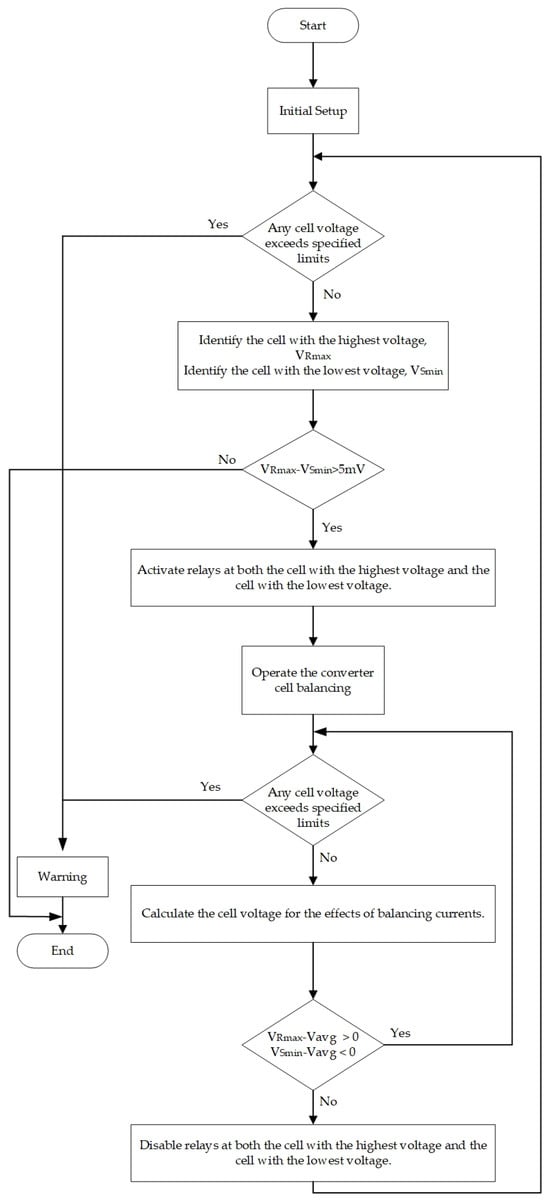

Figure 3 shows the algorithm method of cell balancing. Initially, the controller reads the voltages of all cells within the allowable range, VSmin, and the cell with the highest voltage, VSmax. Subsequently, the relay Rr_max, on the input side, is closed to connect the cell with VSmax to the converter’s input. While relay Rs_min, on the output side, is closed to connect the cell with VSmin to the converter’s output. This initiates the balancing process between these two cells immediately.

Figure 3.

Algorithm method of cell balancing.

When these selected cells are balanced, the controller continuously monitors all voltages and the balancing current. It recalculates the average voltage of all cells. When one of the balanced cells reaches the average voltage, both relays, Rr_max and Rs_min, are turned off. The controller then identifies the next pair of cells with the highest and lowest voltages and repeats the balancing process.

During the cell balancing, a specific pair of cells, where BTn represents the cell with the highest voltage and BT1 represents the cell with the lowest voltage, is connected to the converter. Relay Rs_1 connects cell BT1 to the converter’s output, and relay Rr_n connects cell BTn to the converter’s input, with all other relays remaining inactive. The DC–DC converter immediately begins balancing these two cells.

4. Battery Management Testing Structure

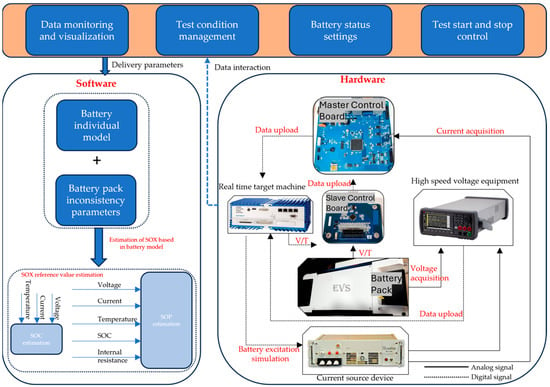

The testing structure for a battery management system achieves rapid switching of testing conditions and high-test repeatability by incorporating a virtual battery and high-precision current sources to emulate the analog signals of actual battery packs. Utilizing a real-time simulation system enables the development of a closed-loop BMS testing system, with Figure 4 illustrating the framework of the testing platform, comprising both hardware and software components.

Figure 4.

The framework of the testing platform (hardware and software).

The hardware section encompasses the master board, slave board, battery pack, high-speed voltage equipment, current source device, and the real-time target machine. On the software side, there is a high-precision battery pack and SOX reference value estimation. Furthermore, the upper computer management software facilitates machine–researcher interaction, managing data monitoring, visualizing each module of the platform, overseeing test conditions, configuring the initial state of the battery pack model, and controlling the test start–stop functions.

4.1. Hardware Section

The hardware components of the testing platform comprise a master board, a slave board, a battery pack, a current source device, high-speed voltage equipment, and a real-time target machine. The battery pack is primarily responsible for generating analog signals, such as voltage and temperature. In the context of temperature sensing, most BMSs employ thermistors, measuring the voltage at a specific port and determining the sensor’s resistance to ascertain the battery temperature.

The current source functions as a unidirectional output source, simulating the total current signal of the battery system. A signal conditioning module, utilizing a full-bridge circuit, converts the unidirectional current to bidirectional, allowing the combined current source and conditioner to produce charging and discharging analog signals for the battery system. The real-time target machine serves as the software implementation center and controls each hardware component. It facilitates output control for the virtual object and facilitates communication interactions among the various hardware elements.

The primary role of the high-precision data collection equipment is to gather analog signals emitted by the virtual object and transmit the collected signal data to the upper computer. The virtual battery in this study integrates a high-precision voltage acquisition system, with its output directly employed as the high-precision acquisition result. Similarly, the current source incorporates a high-precision current acquisition system. When combined with the reported values, the BMS undergoes evaluation after obtaining the reference value through data transmitted from the high-precision collection equipment.

4.2. Software Section

The software is segmented into seven modules: launch control, battery model, virtual battery control, current source control, BMS data interaction, signal update, and port configuration. The battery model serves as the pivotal element, primarily tasked with regulating analog signal outputs, including battery cell voltage, battery cell temperature, and total current. The virtual battery control module’s function is to convert model calculation results into data recognizable by the hardware component, adhering to a specified communication protocol. The current source control module ensures the continuous maintenance of the current path during unidirectional current source signal tuning.

The BMS software (vSTM32CubeMonitor) architecture is structured around a modular design paradigm, where different functional units, such as cell monitoring, thermal management, state estimation, and communication interfaces, operate as distinct modules. These modules are interconnected through well-defined communication channels that enable seamless data exchange and coordination.

- (i)

- Modularity and Interfacing: Each module within the BMS, such as the cell monitoring module responsible for voltage and current measurements or the thermal management module for temperature monitoring, operates independently but communicates with other modules through standardized interfaces. This modularity not only enhances flexibility in system design but also facilitates easier integration of new functionalities or upgrades.

- (ii)

- Communication Protocols: The architecture employs robust communication protocols such as CAN to ensure reliable data transmission between modules. These protocols define the message structure, error-handling mechanisms, and timing constraints, thereby ensuring the integrity of data across the system.

- (iii)

- Centralized Control and Monitoring: A centralized control unit or master module oversees the operation of the entire BMS. It collects data from individual modules, processes information using algorithms for state estimation and fault detection, and provides commands back to the modules for corrective actions. This centralized approach optimizes system performance and ensures consistent operation under varying conditions.

- (iv)

- Fault Tolerance and Redundancy: The incorporation of fault-tolerant mechanisms and redundancy into the architecture was critical. This ensures that the BMS can continue operating even in the event of module failure or communication errors, thereby enhancing system reliability and safety.

5. Modularization

In applications requiring higher power and/or greater energy demand, the battery pack necessitates the integration of multiple cells. Specifically designed integrated circuits (ICs) cater to such systems, offering simultaneous monitoring and balancing capabilities, the latter being unnecessary in single-cell systems. A central module, commonly referred to as the Battery Management System Master (BMS-Master) or Electronic Control Unit (ECU), typically houses advanced functions. This includes intricate state-of-charge estimation and power prediction algorithms, demanding substantial processing power. The system structure, exemplified in Figure 5, illustrates a typical configuration.

Figure 5.

Structure of BMS for EV applications.

The modules housing the front-end ICs are commonly known as Battery Management System Slaves (BMS-Slaves). These modules perform fundamental tasks, such as signal acquisition and filtering, managed by the monitoring ICs. Examples of such ICs include Texas Instruments’ Linear Technology’s Maxim Integrated. The TI offers passive balancing, while the AMS device supports both passive and active balancing with an external transformer. Additional details on balancing can be found in Section 5.

Redundancy in voltage monitoring, as per requirements, is often desired for enhanced safety. Consequently, secondary protection ICs may be employed in conjunction with the ICs or integrated within the same package to provide an additional layer of security. Alternatively, one may consider implementing a completely redundant BMS, although this approach would significantly escalate costs, as discussed in Section 2.

Batteries from various commercially available electric vehicles were dismantled to analyze cell aging following a period of usage, which also allowed the authors to examine and compare different systems.

Typically, the high-voltage system in electric or hybrid vehicles is designed as an IT network. This setup ensures that there is no intentional connection between the vehicle chassis and the high-voltage system. In this configuration, if one fault occurs, it does not immediately pose a danger. However, if a second fault occurs, it could lead to a potentially hazardous situation. Therefore, it is crucial to detect the first fault promptly so that the system can respond appropriately.

It is crucial to recognize that, while implementing safety measures is essential, they can inadvertently introduce new hazards. Consider the scenario of a system triggering the main contactors to open while a battery–electric vehicle is in motion. Depending on the driving conditions at that moment, the sudden loss of power could pose a greater risk than the initial reason for the contractor’s opening. This dilemma is not unique to automotive systems, it applies to aircraft and other critical applications where any sudden loss of power is unacceptable.

Functions and Features for Advanced Battery Monitoring and Balancing

The Battery Management System Master (BMS-Master) or Electronic Control Unit (ECU) plays a pivotal role in ensuring the optimal performance, safety, and longevity of battery packs in various applications. Below is a comprehensive overview of the specific functions and features integrated into these systems for advanced battery monitoring and balancing:

Cell Voltage Monitoring: The BMS-Master/ECU continuously monitors the voltage of individual cells within the battery pack. This is crucial for identifying any cell imbalances that could lead to performance degradation or safety issues.

State of Charge (SoC) Estimation: Utilizing sophisticated algorithms, the BMS-Master/ECU estimates the State of Charge (SoC) of the battery pack. This estimation is essential for providing accurate information to users about remaining battery capacity.

State of Health (SoH) Monitoring: Monitoring the State of Health (SoH) allows the BMS-Master/ECU to assess the overall health and degradation of the battery pack over its lifespan. This information helps in predicting battery life and planning maintenance schedules.

Temperature Monitoring and Control: The BMS-Master/ECU monitors the temperature of individual cells and the overall battery pack. It ensures that the battery operates within safe temperature limits by implementing thermal management strategies such as cooling or heating.

Current Monitoring: Monitoring the current flowing into and out of the battery pack is essential for assessing its instantaneous power output and managing charging/discharging rates to prevent overcurrent conditions.

Balancing and Equalization: To prevent cell imbalances that can reduce battery efficiency and lifespan, the BMS-Master/ECU implements balancing techniques. This involves redistributing charge among cells through active or passive balancing methods.

Fault Diagnosis and Management: The system detects faults such as overvoltage, undervoltage, overcurrent, and overheating. It responds by implementing appropriate safety protocols, such as disconnecting the battery pack or limiting power output.

Data Logging and Communication: The BMS-Master/ECU records operational data such as voltage, current, temperature, and SoC over time. These data are crucial for performance analysis, diagnostics, and optimizing battery usage. Communication interfaces (e.g., CAN bus, Ethernet) allow real-time monitoring and remote diagnostics.

Safety and Compliance: Ensuring compliance with safety standards and implementing safety features such as cell-level monitoring, redundant circuitry, and fault-tolerant design are integral functions of the BMS-Master/ECU.

User Interface and Control: Providing a user interface for operators or system integrators to configure parameters, monitor battery status, and receive alerts or warnings enhances usability and safety.

6. Experimental Setup

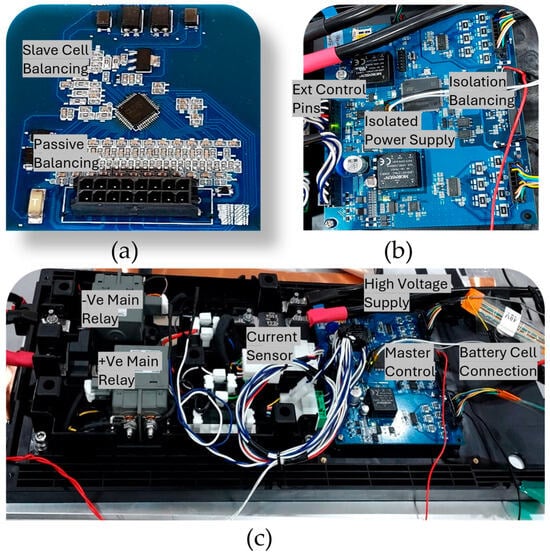

A prototype circuit was implemented for twelve lithium-ion batteries to prove the validity of the proposed balancing method, as shown in Figure 6a. A STMicrocontroller was used for the control and a monitoring IC, which can measure from 9 to 15 cells, was used to monitor the voltages of the twelve battery cells. The transistor array and the relays were implemented on the PCB to connect a pair of cells to the DC–DC converter.

Figure 6.

Circuit of (a) proposed balancing circuit (slave board), (b) master board, and (c) experimental setup.

The control system utilized an SPC584B70E7FMCOX, as shown in Figure 6b, which is a highly advanced integrated circuit that belongs to the automotive-grade microcontroller family and has been specifically designed to meet the stringent requirements of modern automotive applications. Developed by STMicroelectronics, this IC integrates powerful processing capabilities with a rich set of peripherals tailored for automotive use cases. At its core lies a robust ARM Cortex-R5F processor (Arm Developer, Cambridge, UK), providing high-performance and real-time processing capabilities crucial for automotive safety and control systems. The SPC584B70E7FMCOX boasts a comprehensive set of peripherals including analog-to-digital converters (ADCs), digital-to-analog converters (DACs), and communication interfaces such as CAN (Controller Area Network) and LIN (Local Interconnect Network), as well as timers, PWM controllers, and GPIOs, enabling seamless integration into various automotive control modules like engine management systems, body control modules, and advanced driver assistance systems (ADASs). Furthermore, its automotive-grade qualification ensures reliability under harsh environmental conditions, making it suitable for use in vehicles where durability and safety are paramount. With its combination of processing power, peripheral features, and automotive-grade reliability, the SPC584B70E7FMCOX stands as a cornerstone for innovation in the automotive electronics industry, empowering the development of safer, more efficient, and smarter vehicles.

On the PCB, a transistor array and relays were incorporated to facilitate the connection of a pair of cells to the DC–DC converter. Figure 6c depicts the experimental setup designed for testing. The component details of the system are outlined in Table 1.

Table 1.

Components list of the proposed BMS circuit.

The cell-balancing circuit comprises two modules with seven cells, it consists of a total of 14 cells interconnected serially using screwed contacts. Each module features a PCB mounted on top, housing an LTC6804HG-1TRPBF IC designed for monitoring up to 12 lithium-ion cells connected in series.

Beyond the cell modules, the battery housing incorporates contactors (dedicated to inverter and DC charging), fuses, a service plug, an LEM current transducer, an insulation monitor, and a cooling fan. Removal of the service plug divides the pack into two sections, located below the left-hand seat in the car. The main fuse also divides the pack midway. Cooling air, sourced from the vehicle’s air conditioning system, is channeled through short plastic pipes and expelled outside by the fan.

Not housed within the battery casing is the Battery Management Unit (BMU), also known as the BMS master, responsible for communication with the rest of the vehicle. Positioned beneath the rear bench seat, the BMU connects directly to contactors, the current transducer, and the insulation monitor. The microcontroller atop the cell modules interconnects and communicates with the BMU through an internal CAN bus. Some signals from the battery’s internal CAN bus are also accessible on the vehicle’s main CAN bus at a lower resolution.

The DC–DC converter in our battery system fulfills two critical functions: voltage regulation and charge transfer facilitation. Voltage regulation is achieved through sophisticated control mechanisms, such as pulse-width modulation (PWM), which adjusts the duty cycle of switching transistors to convert the battery’s varying input voltage into a stable output voltage suitable for the load or charging system. This process ensures efficient power delivery and protects sensitive components from voltage fluctuations. Moreover, the converter plays a pivotal role in facilitating charge transfer between individual cells within the battery pack. In series-connected cells, the converter manages charge balancing by redistributing energy among cells to maintain uniform voltage levels and prevent cell overcharging or undercharging. This capability not only optimizes the battery pack’s performance but also extends its lifespan by mitigating the impact of cell degradation.

The DC–DC converter is designed to efficiently regulate voltage levels in various electronic systems. Operating on a wide input voltage range, typically from 4.5 V to 36 V, it provides a stable output voltage, often around 12 V, which is common in many applications. This converter employs synchronous rectification, a technique that enhances efficiency by reducing power losses during the conversion process. Its advanced control circuitry ensures precise regulation of the output voltage, even under varying load conditions and input voltage fluctuations. Additionally, the converter features overcurrent protection, thermal shutdown, and input under voltage lockout, safeguarding both the converter itself and the connected devices from potential damage. With its compact size and high efficiency, this converter is suitable for a wide range of industrial, automotive, and telecommunications applications where reliable and efficient voltage regulation is essential.

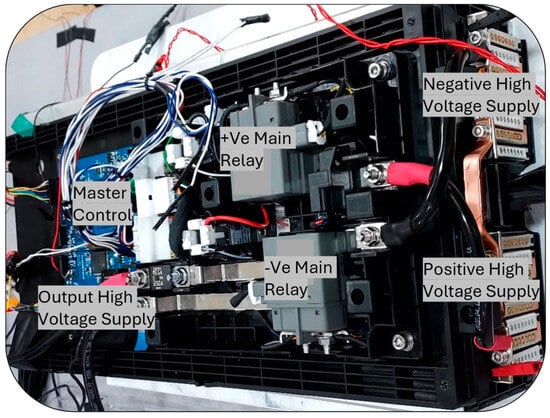

The battery module for electric vehicles is shown in Figure 7. Each module is equipped with a PCB housing an LTC6804 IC, designed for monitoring up to 12 lithium-ion cells connected in series. The PCB design is standardized for versions accommodating four and eight cells. In the four-cell module, half of the PCB’s channels remain unutilized, while the eight-cell module employs an additional PCB to interface with the remaining channels. In addition to voltage measurement, each PCB also integrates three temperature sensors linked to a nearby controller alongside the Linear Technology BMS IC.

Figure 7.

Battery pack module of BMS for electric vehicles.

The battery housing includes essential components such as contactors, fuses, a service plug, a current transducer, an insulation monitor, and a cooling fan. Removal of the service plug divides the pack into two sections, conveniently located beneath the vehicle’s left-hand seat. Cooling air is drawn from the vehicle’s air conditioning system, directed through short plastic conduits, and expelled by the aforementioned fan.

The BMS master unit, located beneath the rear bench seat, manages communication with other vehicle systems. Direct connections link contactors, current transducer, and insulation monitor to the BMS master. Signals from the battery’s internal CAN bus are also accessible at a lower resolution on the vehicle’s main CAN bus. The battery housing exhibits ample free space, possibly attributable to the air-cooling system’s design.

7. Results

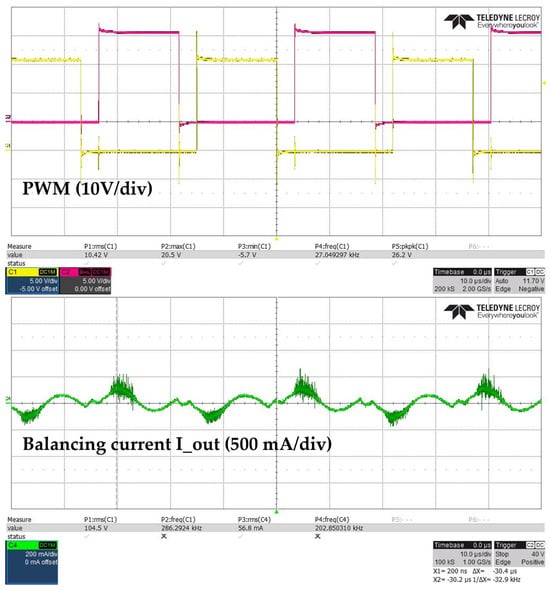

The DC–DC converter utilized a 50% duty cycle to facilitate the transfer of charge from a cell with a higher voltage to another cell with a lower voltage. Figure 8 illustrates the waveforms of the DC–DC converter under conditions where the input cell voltage was 3.8 V and the output cell voltage was 3.65 V.

Figure 8.

Waveform of DC–DC converter (PWM waveforms and cell balancing current).

The converter was designed for operation at 270 kHz. MOSFETs operate with a 50% duty cycle to transfer the charge from a cell with a higher voltage to one with a lower voltage. Waveforms of the converter, under input cell voltage of 3.8 V and output cell voltage of 3.65 V, are depicted in Figure 8.

The efficiency of the converter, as determined through measurement, fell within the span of from 86.3% to 89.7%. The adoption of the proposed circuit, facilitating direct energy transfer between two cells, led to an enhanced efficiency level.

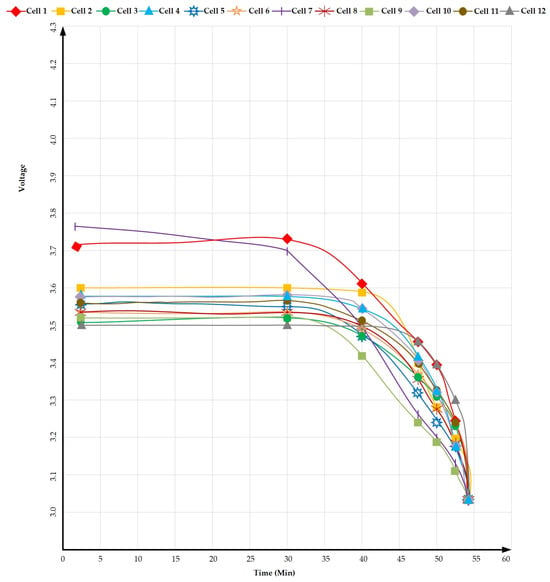

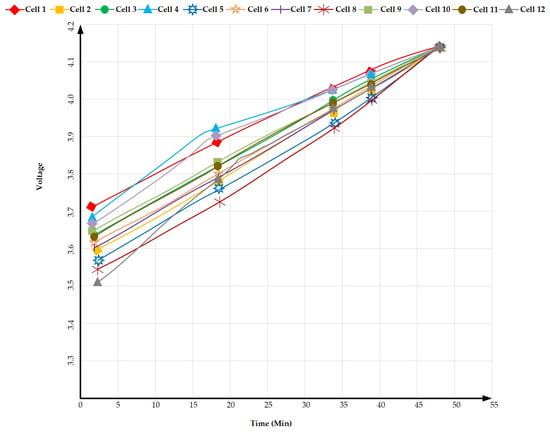

The effectiveness of the proposed cell-to-cell balancing method was also evaluated during both charging and discharging modes, as depicted in Figure 9 and Figure 10.

Figure 9.

Cell voltages during charging as regulated by the proposed cell-balancing circuit.

Figure 10.

Cell voltages during discharging as regulated by the proposed cell-balancing circuit.

During the relaxation mode, the prototype circuit was tested with twelve cells in a battery string. Initially, the circuit detected that cell number 7 had the highest voltage at 3.78 V, while cell number 4 had the lowest at 3.6 V. Consequently, these two cells were prioritized for balancing. After 19 min, cell number 7 reached an average voltage of 3.705 V. Subsequently, the system identified cell number 6 as the new highest-voltage cell and cell number 8 as the lowest, initiating another round of balancing. This process continued until all cells reached an equilibrium voltage of 3.705 V, with a slight deviation of only 12 mV, achieved within 54 min.

The proposed circuit and control method presented in our manuscript significantly enhances the efficiency of charge transfer between individual cells within a battery string through several innovative strategies. This converter effectively manages both charging and discharging processes between cells, thereby optimizing the overall battery pack performance. Specifically, during charging, the converter intelligently balances the charge distribution among cells by dynamically adjusting the charging currents based on real-time monitoring of individual cell voltages. This ensures that each cell within the string reaches its optimal state of charge without overcharging or undercharging, thereby maximizing the battery’s capacity utilization and longevity. Moreover, during discharging, the converter facilitates smooth power delivery by maintaining balanced voltage levels across cells, which minimizes voltage sag and enhances system reliability. Furthermore, our control method incorporates predictive algorithms that anticipate potential cell imbalances and pre-emptively adjust the converter’s operation to prevent detrimental effects on battery health. By integrating these advancements, our proposed circuit and control method not only enhance the efficiency of charge transfer but also contribute to prolonging battery life and improving overall system efficiency. These aspects have been elaborated upon in the revised manuscript to provide a comprehensive understanding of the innovative contributions and practical implications of our approach.

8. Limitations

Battery Management Systems (BMSs) are pivotal for optimizing the performance, safety, and longevity of batteries, yet they face several inherent limitations. Chief among these is the challenge of accurately estimating the State of Charge (SOC), complicated by factors like temperature fluctuations, battery aging, and varying discharge rates. Achieving precise SOC estimation remains a critical research area.

Moreover, advanced BMSs incorporating features such as cell balancing and fault detection are complex and costly, potentially limiting their adoption in cost-sensitive applications. Additionally, scalability across different battery chemistries and configurations poses a hurdle, necessitating customized solutions. Reliability concerns also loom large, as BMS failures can lead to detrimental outcomes such as overcharging or undercharging, compromising battery lifespan and safety.

9. Conclusions and Future Work

In this study, we introduced a novel approach to cell-to-cell balancing in battery systems that is both cost-effective and rapid. Our proposed circuit and control method facilitates the efficient transfer of charges between individual cells within a battery string using a DC–DC converter. Through a straightforward control strategy, we demonstrated the effective balancing of twelve lithium-ion batteries in just 48 min during the charging process, showcasing remarkable performance in terms of balancing time. Moreover, our experimental results revealed an impressive efficiency of up to 89.85%, as energy is directly transferred from high-voltage cells to low-voltage cells. This highlights the practicality and efficacy of our method, making it suitable for integration into battery management systems for electric vehicle applications.

Future research should prioritize enhancing SOC estimation algorithms to account for aging, temperature, and dynamic operational conditions. Advancements in fault detection and diagnosis methodologies can bolster BMS reliability by swiftly identifying issues like cell degradation or abnormal temperature spikes. Efficient cell balancing techniques that minimize energy losses and optimize battery longevity also warrant exploration. Standardizing BMS interfaces and communication protocols across industries would facilitate seamless integration and interoperability. Moreover, developing intelligent energy management strategies based on real-time data and user preferences could significantly enhance overall system efficiency. Innovations in sensing technologies for temperature, voltage, and current measurements promise more precise monitoring and control of battery conditions. Ultimately, advancing towards cost-effective BMS solutions suitable for mass production and deployment in diverse applications from consumer electronics to electric vehicles and renewable energy systems remains a crucial goal for realizing the full potential of Battery Management Systems.

Author Contributions

T.N.V.K. and L.C. proposed the idea of this paper. The formal analysis was performed by T.N.V.K. and S.V.S.V.P.D.K.; the design was by T.N.V.K.; resources by L.C. and S.S.R. Experiment by all authors. Review by L.C. and S.S.R. Manuscript writing by T.N.V.K. and L.C. Moreover, this work was supervised by L.C. All authors have read and agreed to the published version of the manuscript.

Funding

The New Brunswick Innovation Foundation through its Climate Impact Research Fund.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Affanni, A.; Bellini, A.; Franceschini, G.; Guglielmi, P.; Tassoni, C. Battery Choice and Management for New-Generation Electric Vehicles. IEEE Trans. Power Electron. 2005, 52, 1343–1349. [Google Scholar] [CrossRef]

- Tesla Roadster. Available online: https://en.wikipedia.org/wiki/Tesla_Roadster#Battery_system (accessed on 19 December 2007).

- Lukic, S.M.; Cao, J.; Bansal, R.C.; Rodriguez, F.; Emadi, A. Energy Storage Systems for Automotive Applications. IEEE Trans. Ind. Electron. 2008, 55, 2258–2267. [Google Scholar] [CrossRef]

- Daowd, M.; Omar, N.; Van Den Bossche, P.; Van Mierlo, J. Passive and Active Battery Balancing Comparison Based on Matlab Simulation. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–7. [Google Scholar]

- Imtiaz, A.M.; Khan, F.H. Time Shared Flyback Converter Based Regenerative Cell Balancing Technique for Series Connected Li-Ion Battery Strings. IEEE Trans. Power Electron. 2013, 28, 5960–5975. [Google Scholar] [CrossRef]

- Park, H.S.; Kim, C.E.; Moon, G.W.; Lee, J.H.; Oh, J.K. Two-Stage Cell Balancing Scheme for Hybrid Electric Vehicle Lithium-Ion Battery Strings. In Proceedings of the 2007 IEEE Power Electronics Specialists Conference, Orlando, FL, USA, 17–21 June 2007; pp. 273–279. [Google Scholar]

- Lim, C.S.; Lee, K.J.; Ku, N.J.; Hyun, D.S.; Kim, R.Y. A Modularized Equalization Method Based on Magnetizing Energy for a Series-Connected Lithium-Ion Battery String. IEEE Trans. Power Electron. 2014, 29, 1791–1799. [Google Scholar] [CrossRef]

- Park, H.S.; Kim, C.E.; Kim, C.H.; Moon, G.W.; Lee, J.H. A Modularized Charge Equalizer for an Hev Lithium-Ion Battery String. IEEE Trans. Ind. Electron. 2009, 56, 1464–1476. [Google Scholar] [CrossRef]

- Kim, C.H.; Kim, M.Y.; Moon, G.W. A Modularized Charge Equalizer Using a Battery Monitoring Ic for Series-Connected Li-Ion Battery Strings in Electric Vehicles. IEEE Trans. Power Electron. 2013, 28, 3779–3787. [Google Scholar] [CrossRef]

- Ye, Y.; Cheng, K.W. Modeling and Analysis of Series–Parallel Switched-Capacitor Voltage Equalizer for Battery/Super capacitor Strings. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 977–983. [Google Scholar] [CrossRef]

- Henry, J.M.; Kimball, J.W. Practical Performance Analysis of Complex Switched-Capacitor Converters. IEEE Trans. Power Electron. 2011, 26, 127–136. [Google Scholar] [CrossRef]

- Kim, M.Y.; Kim, C.H.; Kim, J.H.; Moon, G.W. A Chain Structure of Switched Capacitor for Improved Cell Balancing Speed of Lithium-Ion Batteries. IEEE Trans. Ind. Electron. 2014, 61, 3989–3999. [Google Scholar] [CrossRef]

- Baughman, A.C.; Ferdowsi, M. Double-Tiered Switched-Capacitor Battery Charge Equalization Technique. IEEE Trans. Power Electron. 2008, 55, 2277–2285. [Google Scholar] [CrossRef]

- Uno, M.; Tanaka, K. Influence of High-Frequency Charge–Discharge Cycling Induced by Cell Voltage Equalizers on the Life Performance of Lithium-Ion Cells. IEEE Trans. Power Electron. 2011, 60, 1505–1515. [Google Scholar] [CrossRef]

- Dong, B.; Li, Y.; Han, Y. Parallel Architecture for Battery Charge Equalization. IEEE Trans. Power Electron. 2015, 30, 4906–4913. [Google Scholar] [CrossRef]

- Kutkut, N.H. A modular nondissipative current diverger for EV battery charge equalization. In Proceedings of the APEC ‘98 Thirteenth Annual Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 15–19 February 1998; Volume 2, pp. 686–690. [Google Scholar]

- Mestrallet, F.; Kerachev, L.; Crebier, J.C.; Collet, A. Multiphase Interleaved Converter for Lithium Battery Active Balancing. IEEE Trans. Power Electron. 2014, 29, 2874–2881. [Google Scholar] [CrossRef]

- Lee, Y.S.; Cheng, G.T. Quasi-Resonant Zero-Current-Switching Bidirectional Converter for Battery Equalization Applications. IEEE Trans. Power Electron. 2006, 21, 1213–1224. [Google Scholar] [CrossRef]

- Speltino, C.; Stefanopoulou, A.; Fiengo, G. Cell Equalization in Battery Stacks through State of Charge Estimation Polling. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 5050–5055. [Google Scholar]

- Park, S.H.; Kim, T.S.; Park, J.S.; Moon, G.W.; Yoon, M.J. A New Buck-Boost Type Battery Equalizer. In Proceedings of the 2009 Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 1246–1250. [Google Scholar]

- Villa, L.F.L.; Pichon, X.; Sarrafin-Ardelibi, F.; Raison, B.; Crebier, J.C.; Labonne, A. Toward the Design of Control Algorithms for a Photovoltaic Equalizer: Choosing the Optimal Switching Strategy and the Duty Cycle. IEEE Trans. Ind. Electron. 2014, 29, 1447–1460. [Google Scholar] [CrossRef]

- Lee, K.M.; Chung, Y.C.; Sung, C.H.; Kang, B. Active Cell Balancing of Li-Ion Batteries Using LC Series Resonant Circuit. IEEE Trans. Ind. Electron. 2015, 62, 5491–5501. [Google Scholar] [CrossRef]

- Park, S.H.; Park, K.B.; Kim, H.S.; Moon, G.W.; Youn, M.J. Single-Magnetic Cell-to-Cell Charge Equalization Converter with Reduced Number of Transformer Windings. IEEE Trans. Power Electron. 2012, 27, 2900–2911. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, X.; Cui, Y.; Zou, J.; Yang, S. A MultiWinding Transformer Cell-to-Cell Active Equalization Method for Lithium-Ion Batteries with Reduced Number of Driving Circuits. IEEE Trans. Power Electron. 2016, 31, 4916–4929. [Google Scholar]

- Pham, V.L.; Khan, A.B.; Nguyen, T.T.; Choi, W. A low cost, small ripple, and fast balancing circuit for lithium-ion battery strings. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Busan, Republic of Korea, 1–4 June 2016; pp. 861–865. [Google Scholar]

- Pham, V.L.; Nguyen, T.T.; Tran, D.H.; Vu, V.B.; Choi, W. Anew cell-to-cell fast balancing circuit for Lithium-ion batteries in Electric Vehicle and Energy Storage System. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 2461–2465. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).