Abstract

The transport sector is tackling the challenge of reducing vehicle pollutant emissions and carbon footprints by means of a shift to electrified powertrains, i.e., battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs). However, electrified vehicles pose new issues associated with the design and energy management for the efficient use of onboard energy storage systems (ESSs). Thus, strong attention should be devoted to ensuring the safety and efficient operation of the ESSs. In this framework, a dedicated battery management system (BMS) is required to contemporaneously optimize the battery’s state of charge (SoC) and to increase the battery’s lifespan through tight control of its state of health (SoH). Despite the advancements in the modern onboard BMS, more detailed data-driven algorithms for SoC, SoH, and fault diagnosis cannot be implemented due to limited computing capabilities. To overcome such limitations, the conceptualization and/or implementation of BMS in-cloud applications are under investigation. The present study hence aims to produce a new and comprehensive review of the advancements in battery management solutions in terms of functionality, usability, and drawbacks, with specific attention to cloud-based BMS solutions as well as SoC and SoH prediction and estimation. Current gaps and challenges are addressed considering V2X connectivity to fully exploit the latest cloud-based solutions.

1. Introduction

In 2021, according to the International Energy Agency (IEA), global carbon dioxide (CO2) emissions from the transport sector had rebounded, growing by 8% to nearly 7.7 Gt CO2 because of the pandemic restrictions lifting [1]. Furthermore, the worldwide carbon neutrality goals dictated by national and international regulations have been leading the transport sector to face new challenges because of carbon footprint reduction [2]. Within this framework, the European Commission (EC) proposed the “Fit for 55”, a series of regulatory proposals intended to achieve climate neutrality in the European Union by 2050, including the intermediate target of at least 55% net reduction in greenhouse gas emissions by 2030 [3]. In particular, the EC proposal strengthens the 2030 CO2 targets, from −37.5% to −55% for new passenger cars and from −31% to −50% for new vans, both relative to a 2021 baseline. In addition, the proposal introduces the target to meet zero tailpipe CO2 emissions from 2035 onwards [4]. Thereby, the incoming stricter regulations and the mid-term European Commission policies have compelled academia, research institutions, and OEMs to study and extensively invest in advanced technologies and solutions toward the full electrification of the light-duty road transport sector. BEVs and PHEVs retain a high potential for penetrating the market and contributing to reducing pollutants and greenhouse gas emissions in the following years. To sustain a wide diffusion of electrified vehicles (EVs), battery performance and durability are key factors. For this purpose, an optimized battery management system (BMS) can prevent degradation phenomena and extend the battery lifetime [5], avoiding battery replacement which can negatively affect the EVs’ life cycle analysis. A proper BMS ensures the monitoring and control of the batteries. It is comprised of different types of sensors, actuators, and controllers managed with logic or algorithms [6], aimed at making the batteries operate within the proper voltage and temperature interval, guaranteeing the safety requirements and prolonging their service life. In particular, the BMS includes functions such as cell balancing, thermal management and state management [7]. A key role of the BMS is to provide an accurate battery state estimation. Commonly, the battery state mainly includes the state of charge (SoC), state of health (SoH), and state of power (SoP) [8,9]. In the case of electrochemical energy storage systems, internal battery states cannot be directly measured [10]. They can be estimated and predicted indirectly through voltage, current and temperature measurements [11]. Owing to the intricate electrochemical processes within the battery, the internal states display a markedly nonlinear correlation with measurable parameters. This concern increases in severe working conditions [10]. In addition, the rate of aging and wear phenomena increase according to the severity of the battery operating conditions, and in terms of discharge depth, number of charges and discharge cycles and temperature [12,13]. Moreover, battery degradation during the cycle affects the state estimation reliability [14]. Hence, precise estimation of the battery state remains a technical challenge, particularly given the potential variations in battery performance over time due to aging. Achieving a stable and accurate estimation is crucial for the entire lifespan of the battery.

SoC represents a main concern related to BMS design in EVs due to its importance in providing some important information, such as the remaining energy and/or remaining useable time [15] to prevent the battery from over-charging/ discharging [16]. As a result, the estimation of battery SoC has been extensively studied. Many techniques have been developed and can be grouped into direct, model-based, and data-based methods. Direct methods are only suitable for laboratory purposes, whereas model- and data-based methods have gained interest for online implementation. Model-based estimation methods have more potential to be employed in real applications due to their rational tradeoff between complexity and prediction accuracy [17]; nevertheless, a battery model definition is necessary introducing potential errors. On the contrary, the data-based approach does not need a sophisticated battery model, but a huge amount of data is necessary to train the model becoming challenging for online applications [18]. Similarly, the SoH-estimation method includes direct, model-based, and data-driven methods, the strengths and shortcomings of which are like the SoC-estimation methods [19]. It is worth dwelling on the fact that in the SoH model-based approach, the functional relationship between battery parameters and battery aging state is usually established under certain battery-operating conditions; thus, its feasibility and estimation accuracy still need to be further verified with various current rates, ambient temperatures and even types of lithium-ion batteries [11]. SoH data-driven methods have the potential to overcome these limitations at the cost of expensive training datasets [18]. Therefore, with the increasingly functional demand for BMS [20], despite the advancements in the modern onboard BMS, more detailed data-driven algorithms for SoC, SoH and fault diagnosis cannot be implemented due to limited computing capabilities. To overcome these limitations, the conceptualization and/or implementation of BMS in-cloud applications are under investigation [21,22]. The development is in an early stage of progress. The advantages expected by adopting cloud-based solutions are related to a simplification of local computing and more accurate and reliable prognostics and diagnostics of the battery system [23].

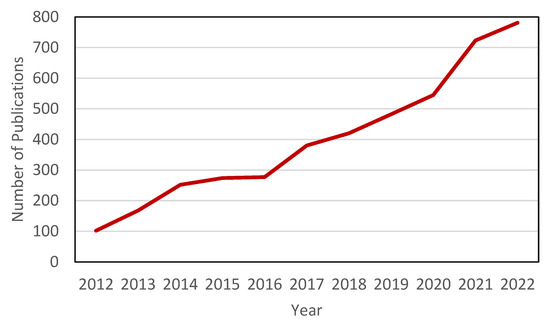

Presently, researchers are actively engaged in exploring SoC and SoH estimation, as well as advancements in BMS. Over the past decade, a diverse range of estimation techniques and developments in BMS has been documented. Figure 1 illustrates the evolving trend of research articles dedicated to the subjects of SoC and SoH estimations, as well as BMS.

Figure 1.

SoC and SoH estimation and BMS published articles per year over the last decade.

These published research articles were identified using the Web of Science database. The search criteria were based on the combination of logic operators (AND, OR) and some keywords inside titles and abstracts. In particular, the following key words were used: “state of charge” OR “state of health” AND “battery management system”. Figure 1 shows the increasing interest in these matters within the last decade. For a fair comparison, 2023 is not considered as being ongoing.

Since the list of existing methods in terms of SoC and SoH estimation provided in the technical literature is extensive, several review papers have been proposed pointing out their advantages and their weaknesses. Compared with the other literature reviews, this article summarizes comprehensively and exhaustively the main SoC and SoH estimation approaches. A further step is to address the current gaps and challenges to drive the readers toward the potential use of cloud-based BMS solutions for future connected vehicles.

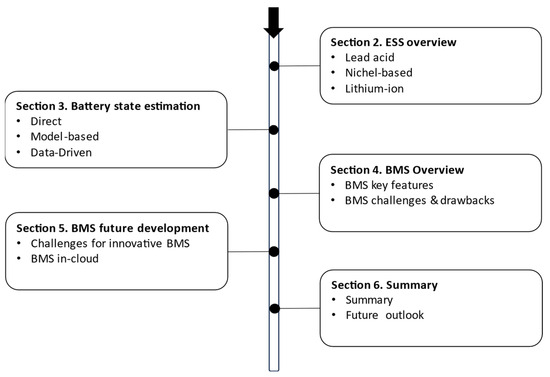

The remainder of this paper is organized as follows. Section 2 provides a brief overview of the main ESSs used in battery-powered vehicles. Section 3 describes the battery parameter estimation approaches mainly referring to SoC and SoH estimation methodologies. An overview of battery management systems is reported in Section 4, with a particular focus on BMS key features. Details on innovative BMS in-cloud applications are provided in Section 5. Finally, Section 6 reports a summary and a discussion on future development. Figure 2 shows an illustration of the present review paper structure.

Figure 2.

Various steps of investigation.

2. Energy Storage Systems for Electrified Vehicles

The ESSs, commonly referred to as batteries, serve as the predominant means for storing electrical energy. Typically, a battery comprises two electrodes, namely the anode (negative electrode) and cathode (positive electrode), along with an electrolyte. Electrical energy is stored as electrochemical energy through redox reactions between the two electrodes, facilitated by charges of opposite signs moving within the electrolyte toward the opposing electrode. The specific battery technologies are differentiated via the materials used for the electrodes and the type of electrolyte. A brief overview is proposed as follows.

Lead acid battery uses lead oxide (PbO2) as the positive electrode, lead (Pb) as the negative electrode and about 37% sulfuric acid (H2SO4) as electrolyte. The electrolyte can be liquid, or it can be absorbed in a glass-fiber mat. The overall chemical reaction for the lead acid battery is [24]:

Lead acid batteries stand out as the most economical energy storage technology owing to the utilization of low-cost materials. Because of their lower energy density, lead acid batteries become the preferred choice in scenarios where the stored energy is less critical, and cost-effectiveness is crucial. This is particularly evident for auxiliary vehicle systems (starters, pumps, etc.), micro-hybrid vehicles or electric scooters. The success of lead acid batteries in these contexts is attributed to their inherent safety features and notable recycling rates (up to 95%) [25].

Nickel-based batteries employ nickel hydroxide as the positive electrode alongside various negative electrode materials. The categorization of nickel-based batteries depends on the negative materials, leading to distinctions such as Ni-Fe, Ni-Cd, Ni-Zn, Ni-MH, and Ni-H2. Typically, the electrolyte utilized is a potassium hydroxide solution. Nickel-iron and zinc are less attractive in electric hybrid and electric vehicles due to their low specific energy, high cost, reduced life cycle and heightened maintenance requirements. Conversely, Ni-Cd and Ni-MH have been widely used in battery-powered vehicles due to their extended life cycles (2000 cycles or more) and higher energy density. The overall electrochemical reactions are shown as follows [24]:

Nevertheless, Ni-Cd suffers a high memory effect, and the use of cadmium poses critical concerns regarding its environmental compatibility. On the other hand, Ni-MH batteries exhibit a low memory effect, negligible environmental effect, and a wide operating temperature range [26]. In addition, their high power density and adequate lifetime have qualified them as the world market leader for use in hybrid electric vehicles [25]. Nonetheless, Ni-MH battery technology can be considered a mature technology that has reached its best potential in terms of cost reduction and characteristics. Therefore, this type of battery does not seem to be competitive with lithium technology batteries [27].

Nowadays, Li-ion-based batteries are most suitable and applicable in powered-battery vehicles due to their characteristics and performance compared with other cell chemistry technologies [28]. Lithium batteries exhibit high specific energy and power values, are lightweight, boast extended lifespans and do not suffer from memory effects or the harmful impacts seen in lead or cadmium batteries. Nevertheless, lithium batteries are comparatively more expensive than other battery technologies, requiring protective measures for safe operation and a cell balancing system to ensure uniform battery performance at consistent voltage and charge levels [27]. However, notwithstanding the price reduction in the Li-ion-based batteries, the increasing demand for raw materials poses significant environmental and health concerns [29]. Depending on the positive cathode materials, lithium batteries can be classified into lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel–manganese–cobalt oxide (LiNiMnCoO2), lithium nickel cobalt aluminum oxide (LiNiCoAlO2), and lithium titanate (Li4Ti5O12) batteries. The overall electrochemical reaction in a Li-ion-based battery is described as follows [24]:

The LiCoO2 lithium-ion batteries were the first to be developed. Due to the higher costs associated with cobalt oxide, subsequent advances introduced nickel and manganese oxide batteries, with the latter proving to be more economical and cost-effective [26]. Among lithium-ion batteries, the LiFePO4 battery is recognized for its superior power density, substantial discharge current, and comparatively lower cost. Furthermore, the LiFePO4 battery exhibits stability in both thermal and chemical operations and has 30% more lifecycles than the lithium manganese oxide battery [30]. The LiNiMnCoO2 chemistry retains a small amount of the world market-share despite its energy and power densities, safety and cost [31]. Li4Ti5O12 batteries are presently used in battery-powered applications because of their faster charging behavior compared with other lithium batteries due to elevated stability in charging/discharging operations. Despite these batteries being able to be operated safely at cold temperatures, a proper thermal management strategy is mandatory [29]. The main characteristics of the batteries mentioned are outlined in Table 1. However, this list is far from being exhaustive, and other batteries with different cell chemistries can be evaluated.

Table 1.

Characteristics of different batteries [26,30,31].

The continuous growth in energy required by different applications, such as electric hybrid vehicles and electric vehicles, pushes researchers to find new materials or new solutions for cell chemistry. The use of lithium–sulfur (Li-S) can be considered a promising candidate for next generation power supplies due to its potentially high specific energy value (about 500 Wh/kg), which is two to three times higher than that of current commercial lithium batteries [32].

With the rise in use of lithium batteries, a BMS is essential to ensure safe and optimized operations of the ESSs. To achieve this goal, correct battery state estimation is mandatory.

3. Key Battery Parameters Estimation

Fundamentals for the BMS and supervisory control of battery-powered vehicles are the accurate estimation of SoC and SoH. Knowledge of these is a prerequisite for effective charging and the thermal and health management of the battery. In the following sections, the main SoC and SoH estimation techniques are reported and discussed. For each category listed, when available, the estimation errors are also reported.

3.1. State of Charge Estimation Methodologies

Commonly, the battery cell SoC can be defined as the ratio between the current cell capacity, QC, and its nominal one, QN, provided by the manufacturer. The equation to calculate SoC is provided as follows:

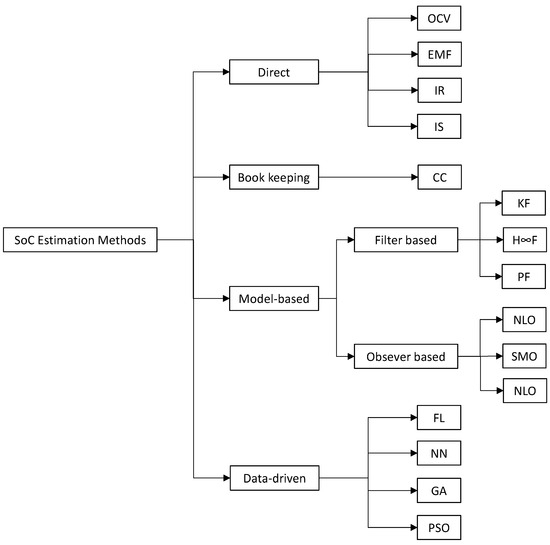

SoC is usually expressed in percentage value, where 100% represents a fully charged cell whereas 0% means a fully discharged condition. In the technical literature, several techniques are suitable for SoC estimation. Figure 3 summarizes the estimation approaches grouping them into three main categories: direct, model-based, and data-driven methods. As can be seen in Figure 3, in this work, the Coulomb– counting (CC) method is listed in the direct methods category, because it is related to the direct current measurements. It is worth highlighting that several authors in the technical literature refer to CC and modified CC as book-keeping methods [33,34], because in this method, the SoC estimation is established by keeping track of the charging or discharging current.

Figure 3.

SoC estimation methods.

3.1.1. Direct Estimation Methods

The direct SoC estimation approaches can be classified into the following five categories: open-circuit voltage (OCV), internal resistance (IR), impedance spectroscopy (IS), electromotive force (EMF) and CC. In the following sub-sections, a brief explanation of each method is given.

- (1)

- Open Circuit Voltage

OCV is a conventional approach to evaluate the SoC by measuring the circuit voltage in an open circuit state and using SoC–OCV relationships. The SoC–OCV relationships are not the same for different batteries, they are influenced by battery capacity and electrode materials. For example, a lead-acid battery has a linear SoC and OCV relationship [35]. Conversely, the LFP battery shows a quasi-flat SoC–OCV relationship region. Within this region, OCV variation is very small compared to SoC variation. Thus, misleading estimation of SoC might occur [36] Although the SoC–OCV curve of lithium–ion batteries is relatively stable, it will change according to the charging/discharging rate, battery temperature, cell variation, and cycle life of the battery [37]. To consider the aging mechanism, several adjustments to the OCV modeling curve are necessary, such as incremental capacity or differential voltage analysis [38]. While this method demonstrates simplicity and high accuracy, it necessitates an extended resting period to attain the battery’s equilibrium state, a duration influenced by environmental conditions. Additionally, precise voltage measurements are essential due to the battery’s hysteresis characteristics.

- (2)

- Internal Resistance

The IR method is based on the relationship between the internal resistance of the battery and SoC. This estimation approach evaluates the internal resistance measuring the charging/discharging current and the terminal voltage in the same short period [39]. IR is computed as the ratio of the battery voltage and charging/discharging current following Ohm’s Law:

It is named Direct Current (DC) internal resistance [40]. It is worth emphasizing that if the sampling period is shorter than 10 ms, only the ohmic internal resistance can be detected; for a longer time, the internal resistance assessment becomes more complicated [41]. In general, the IR value is in the order of milliohms and its measure is also challenging due to the temperature and number of cycles’ influence. Furthermore, internal resistance changes slowly and is hard to observe for SoC estimation; thus, this approach is not suitable for online SoC estimation [42].

- (3)

- Impedance spectroscopy

IS is an experimental method to characterize electrochemical systems, such as batteries, and supercapacitors. During the measurement of an IS, a small alternate current (AC) flows through the battery, and the voltage, the response concerning amplitude and phase, is measured. The impedance of the system is determined by the complex division of AC voltage by AC. This sequence is repeated for a certain range of different frequencies, and the full range of frequency properties of the battery can be obtained. IS gives a precise impedance measurement in a wide band of frequencies, thus providing a unique tool for analysis of the dynamical behavior of batteries, which directly measures the nonlinearities as well as very slow dynamics [20]. The IS method exhibits exceptional accuracy, quickly and non-destructively capturing the dynamic characteristics of batteries. Nonetheless, this method comes with a high cost, significant susceptibility to battery life and temperature sensitivity. Furthermore, an accuracy loss in SoC estimation is observed if the battery temperature changes greatly [41]. Therefore, the impedance-based method is not sufficiently accurate to be implemented for vehicle applications [42].

- (4)

- Electromotive force

The electromotive force (EMF) voltage of a battery is the OCV or equilibrium voltage when a battery is in equilibrium or in an open circuit state for a long period [43]. Therefore, EMF is useful to describe the relationship between the battery terminal voltage under equilibrium conditions and several parameters such as temperature and SoC [44]. Through the OCV relaxation technique, the EMF can be calculated when the battery is charged or discharged and the current is subsequently interrupted. After a significant time has elapsed since the current interruption, the change in OCV is negligible and the EMF can be assessed as the OCV of the battery in its equilibrium condition (OCV = EMF) [45]. The OCV relaxation process may take a lengthy time, especially if the battery is completely depleted in cold conditions or with an excessive charge/discharge current rate [46]. Thus, this method is not suitable for online applications.

- (5)

- Coulomb Counting

In the CC method, the charging or discharging current of the battery is considered by integrating the time to find the SoC. This method permits the inclusion of some internal battery effects such as self-discharge, capacity-loss, and discharging efficiency [47]. The mathematical formulation [48] of this approach is as follows:

where SoC(t0) is the initial SoC value; T is the sampling period; CN is the nominal battery capacity; η is the Coulomb efficiency; i(t) is the charging/discharging current; Sd is the self-discharge rate. The initial SoC value is the main concern because it will cause errors in the accuracy of the SoC estimation. When the initial SoC value is known, this method works more efficiently considering a short time-period. Although this method has been widely used in recent years, CC is not actually used as a sole tool for estimating SoC but rather is used in combination with other techniques, e.g., in [49], the CC method is coupled with OCV to enhance the initial SoC estimation considering the effect of the internal resistance of the battery. Nonetheless, the easy implementation of the CC approach is not suitable for online SoC estimation [50]. Table 2 summarizes the estimation errors via direct methods for further comparison.

Table 2.

SoC estimation errors via direct methods.

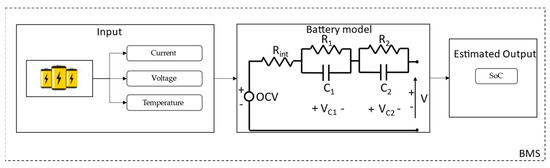

3.1.2. Model-Based Estimation Methods

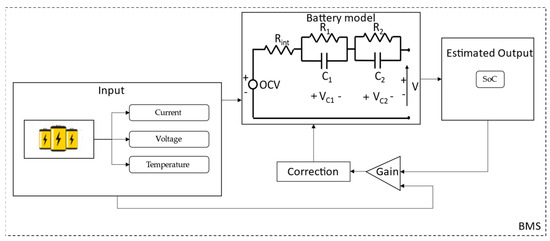

To address the direct methods’ limitations, in view of online battery parameter estimations, model-based techniques have been introduced. These methods connect through a battery model the measured battery signals (voltage, current and temperature) with the battery SoC. A high-fidelity battery model is required to capture the characteristics of the real-life battery and predict its dynamic behavior under varying operating conditions. In a BMS algorithm, the model uses signals as inputs to calculate the SoC and other battery states. The schematic battery state estimation diagram process is depicted in Figure 4.

Figure 4.

Schematic battery state estimation diagram process.

The most common battery models proposed are the electrochemical (EChM) and the equivalent circuit (ECM).

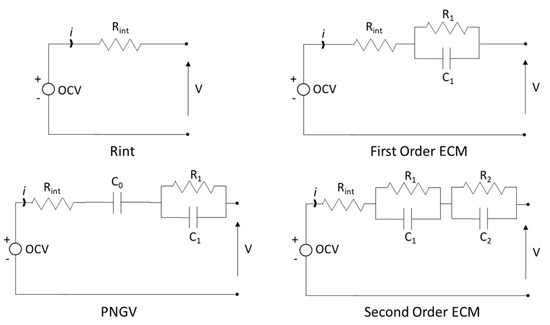

The ECM model is composed of an open-circuit voltage source connected with a combination of electric elements such as resistors, and capacitors to describe the battery behavior under a certain load [55]. The simplest ECM, also known as the Rint model, is an ideal OCV voltage source connected in series with an internal ohmic resistance, both functions of SoC, SoH, and temperature [56]. The internal resistance Rint value represents the voltage drop in the cell when it supplies/absorbs current under a certain load. This parameter defines battery performance and its SoH [57]. Improved versions of this basic model are obtained by adding different resistor–capacitor (RC) branches to capture different time constants inherent in the battery system. In the Thevenin ECM or first-order ECM, a RC group is added to represent the voltage relaxation dynamics and describe the transient response during charging/discharging phases [58]. A further improvement in the first-order ECM consists of adding a capacitor in series to the internal ohmic resistance to describe the OCV changing with the SoC value. This battery model is called Partnership for a New Generation of Vehicles (PNGV) [59]. The PNGV model is an accurate nonlinear equivalent circuit model for transient response process simulation. It can be used with high currents and in charging/discharging severe conditions [41]. Nevertheless, the relatively high complexity leads to an increase in computational effort and consequently lower real-time performance. The so-called second-order ECM is composed of two RC branches to take into account the slow and fast transient response caused by charge transfer and ion diffusion phenomena [60]. The second-order ECM is widely used for online battery SoC estimation since it is computationally efficient and accurate. The increase in RC branches improves the model accuracy, however the computational effort increases as well [61]. Figure 5 illustrates the typical representations of the aforementioned models.

Figure 5.

ECM model schematizations.

The EChM models adopt differential equations to model battery physicochemical phenomena such as diffusion and electrochemical kinetics. Hence, the definition of the equations involves a specialized knowledge of electrochemistry [62]. The most accurate EChM model is the pseudo two dimension (P2D). The key assumption for the P2D model is the one-dimensional dynamics of chemical reaction, neglecting the variations over the other two directions. Furthermore, to consider the intercalation/deintercalation of lithium on the solid matrix and the ion diffusion over a single direction the existence of small particles inside the electrolyte is assumed. As the main direction, the pseudo-radius of such particles is superimposed [63]. The overall complexity of the model due to the high numbers of partial differential equations and the computational time-consuming process to solve them make the P2D not suitable for SoC online estimation [60]. Several simplifications have been proposed for the P2D model for real-time application [64,65] at the cost of penalties in SoC estimation accuracy. In comparison, EChMs offer a key advantage by inherently incorporating the dependency of battery behavior on SoC and temperature. In contrast, electrical models necessitate the storage of their parameters as look-up tables across diverse SoC and temperature combinations to derive reliable SoC-OCV curves [42]. Nevertheless, the merits of the ECM-based approach, such as low complexity and high accuracy, make it favorable for online SoC estimation.

Even though several approaches have been proposed to estimate directly SoC using a battery model [9,66], this section just reviews electrical and electrochemical models because they represent a prerequisite for battery state estimation approaches. Further advancements in SoC estimation via model-based approaches are obtained by coupling a battery model, generally first or second-order ECM, with an adaptive filter algorithm. Reducing the noise influence on the battery model by the filter can improve the accuracy and robustness of the battery SoC estimation [40].

- (1)

- Kalman Filter-based algorithms

The essence of the Kalman filter (KF) algorithm is to use a recursive formula to calculate the current state starting from a prior estimated state and current measurement signals to minimize the mean of the squared error [60]. The filter then feeds back and recursively uses prior prediction to determine the new best guess at each time step [67]. The self-correcting nature of the KF algorithm makes it suitable for SoC online estimation. A Kalman filter computes the states of the system by utilizing a process model, a measurement model, and a set of noisy measurements of the inputs and outputs of the system. While the process model contains all the information about the system dynamics, the measurement model relates the outputs of the system to its inputs and states. The process and measurement models predict the present state and correct the raw state estimation obtained from the process model [68].

Depending on the equations’ linearization process, the KF algorithms can be grouped into two main categories: linear KF (LKF) and non-linear KF. Among the nonlinear KF algorithms, extended KF (EKF), sigma-point KF (SPKF) and cubature KF (CKF) can be mentioned. SPKF is further divided into central difference KF (CDKF) and unscented KF (UKF) [60].

LKF is commonly used as a data fusion algorithm in several technical applications due to its robustness and acceptable computational cost to filter parameters from inaccurate observation [69]. The basic idea of KF is to compare the measured terminal voltage with the modeling one, and the difference is fed back to update the predicted SoC through a gain matrix, as schematically depicted in Figure 6. The algorithm works as an optimal state estimator with a self-correcting nature for real-time SoC estimation of the battery. It employs a recursive process estimating the unknown SoC by exploiting previous knowledge, system predictions and noisy measurement [70]. LKF is composed of two equations: a process Equation (4), which is used to predict the current state xk from the prior state xk−1; a measurement Equation (5) useful for updating the current state to converge to the real value [70]:

where x represents the system state; u is the control input; w is process noise to capture the uncertainties in the model; y is measurement input; v is measurement noise to capture the measurement error; meanwhile, A, B, C and D are the time-varying covariance matrixes that describe the dynamics of the system. Both measurement noise and process noise are defined as Gaussian errors. Yatsui and Bai [67] presented a LKF-based SoC estimation method for lithium-ion batteries. Experimental results validate the effectiveness of KF during the online application reporting and also a low estimation of SoC errors. Dong et al. [71] have developed a simplified linearized ECM to simulate the dynamic characteristics of a battery when the OCV is not linear to apply LKF for SoC estimation. Despite LKF being an efficient filtering algorithm proposed for tracking the state of linear systems in Gaussian noise environments, its performance is limited when it is applied to systems which exhibit hysteresis effects and strong nonlinearities during charging/discharging events [72]. Thus, improved methods have been put forward to tackle this issue.

Figure 6.

Kalman filter schematization for SoC estimation.

A widely used method for battery parameter/state estimation for non-linear systems is the extended Kalman filter (EKF) [73]. To deal with the non-linear characteristics of battery models, EKF employs partial derivates and a first-order Taylor series to linearize the battery model. The linearization process occurs at each step. In particular, Equations (4) and (5) are modified as follows [74]:

At each time step, matrices of f(xk,uk) and g(xk,uk) are linearized close to the operation point by the first order in the Taylor series and the remainder of the series are truncated. In the technical literature, several applications of EKF or an improved version of it have been proposed for SoC estimation. Jiang et al. [75] proposed a battery SoC estimation approach via EKF. The experimental results reported showed an average SoC estimation error of 1% [75]. In [76], a comparison between a standard EKF and an improved EKF algorithm was proposed. Although the experimental findings demonstrated that both filters have good performance, the improved EKF showed a slightly better SoC estimation accuracy. Similarly, Sepasi et al. [74] proposed an improved EKF variant including aging effects in the battery electrical model. The novel approach reported has shown a low computational burden with a good SoC estimation accuracy making it suitable for online implementation. In several works, EKF has also been used with DD algorithms to enhance the SoC estimation accuracy. For example, in [77] EKF has been adopted with a neural network. In particular, NNs have been used to model the non-linear battery behavior, whereas the EKF has been adopted for SoC estimation. Similarly, an EKF data-driven approach was proposed in [78]. The novel approach has produced an accurate SoC estimation within the 2% error.

Since the linearization process in EKF uses the first-order Taylor series, a linearization error may occur under highly non-linear conditions due to a lower accuracy of the first-order Taylor series. Furthermore, the accuracy of the EKF algorithm depends on battery model parameters and the prior knowledge of the system noise signals. The assumption of fixed measurement and process noise covariance matrices in EKF reduces the overall performance of SoC estimation [79]. Thus, in practice, inappropriate initial noise information will make the approach fail in ensuring its performance. To overcome this issue, the adaptive updating of these matrices has been introduced through the adaptive EKF (AEKF) [80]. As stated previously, misleading SoC estimation may occur for highly nonlinear models adopting EKF. To mitigate this problem, an improved version of KF has been proposed named SPKF. This algorithm is capable of linearizing the process up to the third order of a Taylor series expansion [81]. Rather than using Taylor-series expansions to approximate the required covariance matrices, SPKF performs several functional evaluations whose results are used to compute an estimated covariance matrix [82]. The algorithm selects a set of sigma points with weighted mean and covariance values exactly like the values of the mean and covariance of the model being developed [35]. This approach presents comparable computer complexity compared with EKF. In addition, the original functions do not need to be differentiable and no derivate calculation is needed [82]. Based on the weighing factor, the SPKF algorithm is classified into two categories: unscented Kalman filter (UKF) and central difference Kalman filter (CDFK) [83]. The UKF estimates covariance with statistical methods rather than with a Taylor series. In particular, UKF applies an unscented transformation, which is a method for calculating the statistics of a random variable propagating through a nonlinear system [81]. In CDKF, a Sterling interpolation formula is used to avoid derivative computing through polynomial approximation. This approach uses central difference instead of a first or second-order Taylor series expansion [83].

- (2)

- H∞ Filter

The H∞ filter (HIF) represents another viable solution to overcome the noise influence on the accuracy of the traditional EKF algorithm. This algorithm considers the time-varying element of battery parameters and does not require the details of process noise and measurement noise [84]. HIF can restrict the effects of the uncertainty and perturbation of the system model and no specifications of the disturbances and model uncertainties are necessary. Accordingly, the battery SoC may be determined without needing the exact statistical features of the system and measurement errors. Despite its robustness and easy implementation, ageing, hysteresis and temperature effects could influence the accuracy of the model [70]. In [85], the HIF algorithm was used to estimate the SoC of lithium-ion batteries. The method was validated through real-time experimental battery data. Zhang et al. [86] proposed a robust HIF to estimate the SoC of a lithium battery pack. The proposed method takes into account battery time-varying parameters with no prior knowledge of the process and measurement noise, respectively. Several UDD cycles have been performed to test the algorithm’s performance. In order to enhance the SoC estimation accuracy, HIF has been combined with DD techniques [87,88] and filter-based methods [89].

- (3)

- Particle Filter

A particle filter (PF) is a probability-based estimator that uses the Monte Carlo simulation technique to approximate the probability density function of a non-linear system with a set of random weighted particles without any explicit assumption about the form of the distribution [90]. The weight represents the chance of the particles to be selected in the probability density function [91]. When designing a particle filter, the main difficulty is to select the proper proposal distributions that can approximate the posterior distributions [50]. Because PF is suitable for estimation for non-linear systems, such as battery models, it can be adopted as a SoC estimator algorithm. In [91], a PF-based approach is proposed for estimating simultaneously in real-time the state of charge and internal temperature of a prismatic lithium-ion battery using a first-order ECM model. The PF-based solution was compared with the traditional EKF algorithm in terms of SoC and temperature estimation showing a faster convergence to the real values of SoC and internal temperature when compared to the EKF solution. A similar result is reported by Gao et al. [92]. To deal with the computational cost limitations of the PF, it is necessary to select a number of particles that provide a good trade-off between the accuracy and reliability of the results [91]. In several works [93,94], PF was implemented with other techniques to improve its efficiency at a cost of more complexity. Table 3 summarizes the estimation errors for further comparison.

Table 3.

Filter-based SoC estimation errors.

- (4)

- Observer-based methods

An observer-based method is realized to provide state feedback on the estimated values of the state variables of a system based on external measurements [95]. Several observer-based methods have been proposed for battery state estimation.

Sliding-mode observer (SMO) is an observer algorithm with the advantage of compensating the modelling errors caused by variation in the parameters of the circuit model and can help overcome some of the drawbacks that other model-based methods present [55]. With respect of SoC estimation, Ning et al. [96] used SMO to estimate the battery SoC based on a parameter adaptive battery model to reduce systematic errors. The proposed approach shows good estimation accuracy. In [97], based on a second-order ECM, a novel SMO was proposed for SoC estimation. Different test cycles were performed to assess the robustness and estimation accuracy of the proposed algorithm.

The proportional integral observer (PIO) is an efficient algorithm to estimate the state of a system with unknown input disturbance [95]. It has been observed that this approach has lower computational complexity but high precision without matrix operation, even though the original SoC is uncertain [50]. Xu et al. proposed a PIO approach for SoC estimation based on a first-order ECM. To validate the proposed algorithm, a UDDS cycle is performed experimentally [98]. In [36], a dual-circuit observer based was proposed to estimate SoC. A PIO circuit path was used to deal with capacity error and initial error. Even though the initial SoC was unknown, the proposed approach yielded reasonable SoC accuracy.

Another observer approach is that of the non-linear observer (NLO). This approach is used to deal with linear systems and non-linear observation equations. An advantage of this method is that it does not need complicated matrix operations, thus the computation cost can be reduced [99]. In [100], an NLO is tuned through an optimization algorithm to enhance the observer robustness and SoC estimation accuracy. In [99], a novel method for SoC estimation using a NLO is presented. The proposed approach is then compared with EKF and SMO showing a faster convergence and an improved SoC accuracy, respectively. Table 4 summarizes observer-based SoC estimation errors.

Table 4.

Observer-based SoC estimation errors.

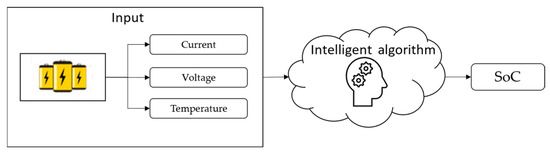

3.1.3. Data-Driven

Data-driven (DD) approaches consider the battery as a black-box model. In this case, the battery is presumed to be an unknown system and the internal dynamics have been learned through a vast quantity of data [50]. Specifically, the model considers online measurable parameters such as battery current, voltage and temperature as inputs and battery state of charge (SoC) as the output. The model utilizes intelligent algorithms to train on input and output data, establishing the relationship between them [41]. Figure 7 schematically depicts the process. The main DD approaches exploited for SoC estimation, as shown in Figure 3, include fuzzy logic (FL), neural network (NN), genetic algorithm (GA), and particle swarm optimization (PSO). These approaches, being free of capturing any physico-chemical mechanisms, have potential advantages such as flexibility and strong adaptability and being highly nonlinearly matching [101]. However, the main disadvantage of these algorithms is their sensitivity to the quality of the training dataset and that they may easily encounter overfitting or underfitting problems. In addition, the on-board implementation of DD methods for online SoC estimation is currently challenging.

Figure 7.

Data-driven schematization approach.

In the following sub-sections, the DD approaches previously listed are presented and discussed.

- (1)

- Fuzzy logic

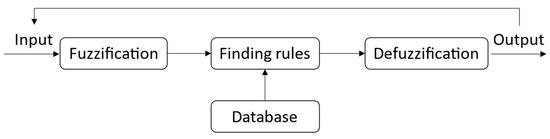

The FL method provides a powerful means of modeling nonlinear and complex systems [47]. This methodology is regarded as a problem-solving approach that simplifies all input data, characterized by noise, vagueness, ambiguity and imprecision, through the application of objective rules to determine the real value of the input [102]. In addition, FL does not require a precise mathematical model of the system, as it only uses the input data and identifies the parameters using the fuzzy rule base. Fuzzy methods are robust and tolerant to imprecise measurements and component variations with rules that are easily tunable. The basic idea of a fuzzy algorithm is to formulate human knowledge and reasoning as a collection of “If–Then–Else” rules tractable by a computer [103]. The FL process can be divided into the following steps [104]: First, the inputs are fuzzified, or otherwise are converted into fuzzy language and grouped into membership functions. In the rule step, the relationship between input and output variables is described and a database defines the membership functions for the input and output variables. Finally, the fuzzy output value is defuzzied and translated into a real analogue value output. Figure 8 shows the basic steps of the FL approach.

Figure 8.

Basic step of the fuzzy logic approach.

At present, few studies use only FL to assess battery SoC [105,106]. Commonly, fuzzy algorithms are combined with other intelligent algorithms to enhance SoC estimation accuracy. For example, Burgos et al. [107] proposed a novel fuzzy logic algorithm to predict the battery SoC. In particular, the fuzzy model characterized the relationship between the battery OCV, SoC and the discharge current. It was used in combination with an EKF to predict the battery ScC. In [108], the authors proposed a method to estimate battery SoC involving fuzzy algorithms to process data obtained by IS and CC with an estimation error of about 5%. Similarly, Malkhandi et al. [109] proposed a model for SoC estimation adopting CC and a learning system based on FL. Despite a reasonable accuracy in SoC estimation, the FL approach is expensive in terms of storage and computational effort requirements to determine the parameters of a complex and nonlinear system. Thus, this approach is not suitable for online SoC estimation.

- (2)

- Neural network

NN is a mathematical tool with adaptability and self-learning skills able to form a complex nonlinear system. Commonly, a NN is formed from three layers [102]: the input layer, the hidden layer and the output layer. The input layer transfers the data to the hidden layer. Generally, as input data discharge current, the terminal voltage and temperature are considered [35]. The hidden layer provides the mathematical junction between input and output through its neurons [62]. In the third layer, SoC is addressed as output. The NN main advantage is that it can be utilized without knowledge of the cell’s internal structure. Thus, NN is suitable for the SoC estimation of all kinds of batteries. Nevertheless, to ensure a reliable SoC estimation, a large quantity of training data and storage are required. In addition, non-negligible computational effort is necessary to manage the whole training process [33]. Therefore, the NN estimation approach is challenging to implement on board. Chen et al. [110] combined a NN with an EKF-based algorithm for the estimation of SoC. This hybrid approach provides an estimation of SoC accuracy within 1%. In [111], an OCV-based method for SoC estimation using the dual neural network fusion battery model was proposed. A first NN is used to estimate battery parameters of first- and second-order models. A second NN is employed to assess SoC via OCV-based methods for both ECMs.

- (3)

- Genetic algorithm

A genetic algorithm (GA) is an optimization technique where the variables of interest of the system to be optimized are characterized in the form of strings called chromosomes. GA simulates natural biological evolution according to the “fitness level” of the individuals which provides a large set of possible solutions to a given problem. Through the genetic operators (selection, crossover and mutation) and natural selection, improved generations are bred. By selection operator, parent solutions that have better fitness levels are more likely to reproduce which means better genes are more likely to dominate the next generation. Crossover combines the features of two parents at a certain crossover fraction to form new solutions by swapping corresponding segments of parent chromosomes. By randomly changing one or more genes at a low mutation rate, mutation introduces variability into the next generation that will stop GA converging at a local minimum [112]. A GA can be used both for single and multi-objective optimization, with the search strategy that, through iterations, maximizes or minimizes a given function of a properly formulated problem [113]. The idea of coupling a numerical model of a given engineering unit with an algorithm for decision-making has been proven to be an effective and cost-saving option to achieve the desired results, even without resorting to real counterparts and spending time in heavy experimental tests [114]. Practically, in SoC estimation applications, the chromosome is a string containing battery parameters such as SoC. The algorithm after the creation of a random set of chromosomes, via an iterative process, finds the optimal solution. It is necessary to obtain the definition of a stop criterion via an objective function in order to select the best population in each iteration [62]. Xu et al. [115] combined CC and a first-order ECM to estimate the battery SoC. Their proposed approach used GA to optimize battery parameters. Similarly, in [112], the GA was used to find the optimum parameters of an equivalent model of a LiFePO4 battery pack to estimate battery SoC via UKF.

- (4)

- Particle swarm optimization

PSO is a nature-inspired optimization technique. The inspiration came from the social behavior of groups of animals, such as schools of fish or flocks of birds. It was first presented by Kennedy and Eberhart [116]. The algorithm first generates a random population, then the next population is generated based on an objective function to be optimized [62]. PSO is simpler than the GA approach and has several advantages such as fewer parameters to be tuned, lower computational effort and higher degree of convergence. Nevertheless, it is time-consuming to properly tune the parameters [117]. PSO is used in a wide range of industry applications [118,119,120], and has been extensively used in battery parameter estimations [121,122]. Sun et al. [123] adopted PSO to tune up a Thevenin ECM to identify the critical parameters useful to SoC estimation. The proposed algorithm can estimate battery SoC with negligible errors. Similarly, Ye et al. [124] combined PSO and an adaptive algorithm to estimate battery parameters and SoC. DD-based algorithms’ SoC estimation errors are summarized in Table 5 for further comparison.

Table 5.

SoC estimation errors via DD approaches.

3.2. State of Health Estimation Methodologies

Battery aging is a long-term gradual process which influences the battery health status. The increasing internal battery resistance with battery aging is one of the critical aspects limiting the lifetime of batteries. It is well-known that battery internal resistance changes with temperature and SoC [125]. In particular, high temperatures will also accelerate some irreversible chemical reactions. As a result, the reduction in the active material of the battery causes the aging and fade in capacity [5]. Increasing the number of battery charging/discharging cycles leads to a battery health status degradation and consequently an attenuation of its power and capacity. Furthermore, while the capacity decreases, the internal resistance increases [19]. In general, as the battery ages and its chemical reactions such as the growth of the solid electrolyte interface disrupt the migration of ions, the internal resistance or capacitance irreversibly changes [126]. Because a battery can be represented as an ECM, both capacity and internal resistance are commonly adopted for the SoH definition. Concerning the internal resistance [127], SoH is defined as follows:

where REND is internal resistance at the end of battery life; R is the resistance at the current state; and Ri is the initial resistance when the battery is new.

As mentioned, capacity loss is another phenomenon occurring with battery aging. Thus, concerning the capacity [126], SoH is defined as follows:

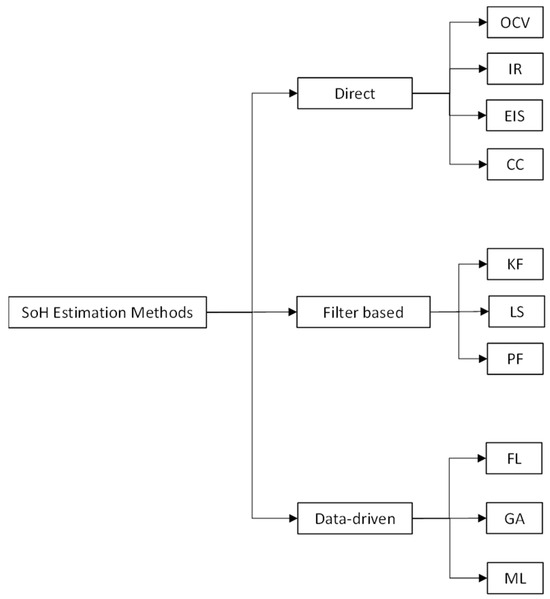

where C0 is the rated capacity whereas Ci is the current available capacity of the battery. Several methods have been developed over the years for estimating battery SoH. In general, the estimation methodologies can be divided into direct, filter-based and data-driven. Figure 9 summarizes the different approaches for SoH estimation.

Figure 9.

SOH estimation techniques’ classification.

Since SoC and SoH are closely related, the estimation methods are also quite similar, thus, in the following sub-sections, a brief description and the most relevant findings regarding the SoH estimation are reported.

3.2.1. Direct Estimation Methods

In this section, the most important common direct methods are reported and briefly disseminated. These methods are carried out in laboratories to collect data and measurements that may be utilized over time to better understand and analyze the aging behavior of the battery.

Internal battery resistance is considered a health status indicator which defines the voltage drop when a current is applied to the battery. This parameter is influenced by battery aging and degradation and its value increases as SoH decreases. Thus, internal resistance is considered a SoH indicator [8]. To ascertain IR, pulse discharge and IS are the most common methods [128]. In the pulse discharge method, a high-rate pulse current is applied to the test battery, and the internal resistance is calculated using Ohm’s law following Equation (1). It is worth highlighting that in this case, the pulse voltage change and pulse current variation are utilized to assess the resistance. Chen et al. [129] proposed a method to estimate SoH through the established linear relationship between ohmic internal resistance and capacity fade. An online estimator is also proposed for SoH evaluation.

Electrochemical impedance spectroscopy (EIS) provides a non-destructive measurement of battery internal resistance over a wide range of frequencies under low current loads [130]. Since battery impedance increases with aging and different battery dynamics tend to affect different frequency ranges on the EIS measurement, IS can be used as a diagnostic tool to monitor battery SoH [131]. Nonetheless, the definition of an EChM, unique for each battery, and the expensive instruments required ensure that EIS methods are only for lab purposes [33]. Eddahech et al. have proposed an EChM model for data and SoH estimation through EIS. In the same work, adopting a NN, the authors extended the SoH monitoring to different battery types [132]. Similarly, in [133], a novel approach based on EIS for SoH assessment was proposed with a good estimation accuracy.

The CC method is also used to estimate SoH [134]. The transferred amount of ampere-hours is continuously tracked during a full charge–discharge cycle to assess the remaining capacity [135]. SoH is computed through relation (7) as the ratio of the computed capacity and the rated one. This method is time-consuming due to the continuous tracking of ampere-hours. Furthermore, a high storage capacity is required. Despite its simple implementation, frequent recalibration is needed to avoid errors in charge integrations [131]. In [135], an enhanced CC method was proposed to estimate SoH. The evaluation was performed via adoption of the maximum releasable capacity.

The OCV-based SoH estimation method can be performed in both online and offline states. However, establishing a correlation between SoH and OCV requires thorough and time-consuming laboratory testing [134]. In [136], the charging curves were monitored at different lifespans of the battery to assess the capacity fade and model parameters based on an EChM to estimate SoH. It is reported that a SoH estimation error is under 3% in all aging conditions of the battery. Weng et al. [137] used the OCV model and incremental capacity analysis to evaluate battery aging characteristics at different operating temperatures for predicting SoH.

Direct methods are simple and easy to implement, with a low computational burden. Nevertheless, these methods are constrained by test conditions and are not suitable for real-time applications. The estimation errors of the listed approaches are provided in Table 6.

Table 6.

SoH direct estimation errors.

3.2.2. Filter-Based Method

As introduced in Section 3.1.2, KF algorithms use a series of measurements taken over time (i.e., voltage, current and temperature), to estimate the output variable that tends to be more precise through a recursive update of the estimated variable. As a result, KF and its extensions can be adopted as the SoH estimator [131]. In contrast, batteries degrade in a nonlinear manner, consequently, the overall noise does not always exhibit Gaussian behavior. Thus, instead of using LKF which could not converge, its extensions can address this problem [8]. Kim et al. [138] applied a dual-extended Kalman filter (DEKF) for SoH prediction. Furthermore, NN is used to identify typical battery patterns to enhance SoH estimation. The proposed method addresses good estimation accuracy, mitigating the issue of high complexity and computational requirements. Similarly, Azis et al. [139] proposed a DEKF approach to simultaneously estimate SoC and SoH. The first EKF is used to predict SoC, whereas the second is used to estimate Rint and actual capacity to determine SoH.

As mentioned in Section 3.1.3, PF is suitable for nonlinear systems with non-Gaussian noise. Beyond SoC estimation, PF can also be utilized for predicting battery lifespan and health prognosis. Zhu et al. [140] proposed a novel combination of PF and UKF to predict battery SoH based on a second-order ECM of a commercial cell. During the charging and discharging phases, the proposed algorithm showed a maximum estimation error of up to 0.38% and 0.62%, respectively. An improved PF algorithm is presented in [141]. The proposed algorithm achieves a high accuracy by settling the SoH estimation error at a very low level.

Another widely used algorithm is the least square (LS)-based algorithm. This algorithm identifies the best-fit function that minimizes the sum of the quadratic errors between the measured output and system response [55]. It provides an accurate estimation of battery parameters that are directly related to battery states such as internal resistance for battery SoH [8]. For instance, in [142], a LS-based algorithm was proposed to estimate SoH. The proposed method can estimate battery SoC and SoH based on terminal voltage and current, without a priori knowledge of battery parameters. The effectiveness and accuracy of the proposed method are confirmed via simulation. Wu et al. [143] proposed a novel LS-based algorithm to estimate SoH for LiFePO4 batteries. A temperature correction method was also proposed to avoid ambient temperature influence on SoH accuracy. Experimental tests have demonstrated the accuracy of the proposed method.

In Table 7, filter-based SoH estimation errors are listed. Although these methods are characterized by a high degree of accuracy, they are burdened by the definition of a degradation model of the system to properly consider battery aging [130].

Table 7.

Filter-based SoH estimation errors.

3.2.3. Data-Driven Methods

The growing interest in DD methods for estimating battery SoH, as an alternative to traditional SoH estimation methods, is related to their ability to operate without a comprehensive understanding of implicit changes in battery chemical parameters or working principles. Nonetheless, to achieve a high SoH estimation accuracy through DD methods, a large quantity of battery data and considerable computational effort are required [144]. These methods can be grouped into FL, GA and ML methods.

The FL method is a powerful method, but it requires a large quantity of testing data, relatively large computations, and a good understanding of the batteries themselves to be proven accurate for SoH prediction [131]. Kim et al. [145] used a fuzzy logic-controlled methodology to predict the battery SoH. First, the cell resistance and maximum capacity were determined based on voltage, current, temperature, and time, and then a fuzzy logic approach was applied to estimate the battery SoH using the resistance and the maximum capacity values. In ref. [146], a FL was proposed for SoH prediction to avoid battery failure.

The GA technique is also suitable to estimate SoH. Several works are proposed in the technical literature employing a GA algorithm coupled with a battery model to estimate battery parameters. For instance, in ref. [147], SoH is estimated online by using a second-order ECM coupled with a GA.

With the rapid development of processing capability, data storage and communication technologies, SoH prediction based on ML algorithms has received widespread attention [128]. Traditional ML algorithms treat raw data, including voltage, current and temperature, as direct inputs. Nevertheless, the nonlinear matching capability is heavily contingent on aging data, due to the significant influence of health indicators on the SoH estimation performance [148]. Therefore, extracting effective features correlated to health mechanisms is a crucial step for effective and reliable SoH estimation. Currently, various advanced methods combined with life-related feature extraction have been proposed and widely used for SoH monitoring [149]. Neural networks are one of the most popular algorithms used to process training data and measured data in machine learning. For instance, Song et al. [150] have implemented a feedforward neural network (FFNN) trained on a huge amount of data collected from big data platforms to predict SoH. In [151], the authors proposed a back propagation neural network (BPNN) to estimate SoH. The reliability and effectiveness of the proposed approach were tested experimentally. LSTM, as a variant of a recurrent NN, has also attracted extensive attention for SoH estimation to capture and update the degradation data due to its ability to learn both on short-term and long-term scales [149]. Hong et al. [152] proposed an LSTM-based SoH estimation by fitting the relationships between aging factors and operating conditions. The evaluation was oriented to real driving conditions. Similarly, Falai et al. [153], based on a LSTM framework, proposed a novel approach for online SoH estimation to reduce computational time. For further comparison, DD-based SoH estimation errors are summarized in Table 8.

Table 8.

Data-driven-based SoH estimation errors.

In this section, the most common ML approaches for SoH estimation are provided in brief overview. For a more exhaustive and comprehensive overview of all of the ML methods for SoH estimation, it is suggested to consult refs. [119,129].

4. Battery Management System Overview

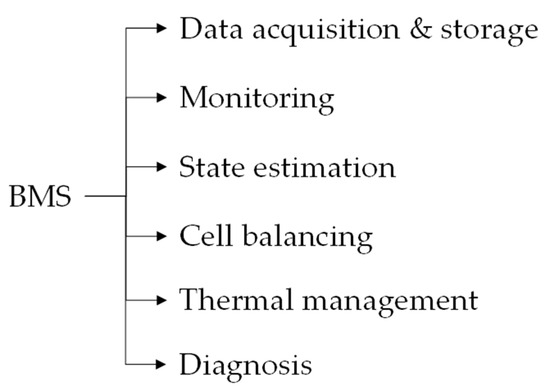

As stated previously, battery-powered vehicles could represent a promising solution for a more sustainable form of transportation. A reliable and cost-effective management of on-board ESSs is a key point for the development of vehicles, ensuring proper performance as well as the safe operation of the on-board ESSs. Figure 10 shows a schematic overview of the key features of a modern BMS.

Figure 10.

BMS main functions.

As can be seen, the main functions can be grouped mainly into the following categories: data acquisition and storage, monitoring, state estimation, cell balancing, thermal management and diagnosis. Each category will be briefly discussed in the following sections.

- a.

- Data acquisition and storage

The BMS data acquisition system is composed of sensors, measurement hardware, the processor and software [6]. Temperature, terminal voltage, current and other information of each cell in the battery pack are collected in real-time to obtain an accurate overview of ESS working conditions. The requirement for voltage and current measurements vary according to the type of battery technology employed [154]. The acquired data are processed and then stored by BMS for equalization of the battery cells, thermal management, fault diagnosis and control of the other functional parts via the BMS controller [31].

- b.

- Monitoring

In real working conditions, battery behavior changes dynamically. Thus, continuous monitoring is required to obtain information about the battery operating conditions. This function, involving the acquired data, indicates the necessity of the charge and discharge control, avoiding overcharging or undercharging conditions, etc. During operation, an abnormal variation in the battery current and voltage values may cause system failure or system burnout [31]. Accordingly, it is crucial to monitor the current and voltage of the battery to prevent over-current/voltage and undercurrent/voltage operations [155]. The performance and durability of the battery are primarily contingent on its charging and discharging processes. An efficient control of these processes can mitigate the memory effect, thus extending the battery lifespan.

- c.

- State estimation

In real-time operating conditions, the battery state changes due to complex, time-varying and nonlinear battery characteristics [156]. Battery state estimation enhances the battery operability and increases the durability of the designed system [157]. State estimation is mainly referred to SoC and SoH estimation. An accurate estimation of the battery SoC is necessary to prevent battery failure, provide efficient cell balancing, and accurate SoH estimation. SoH estimation is crucial in selected energy management strategies to prolong battery life and appropriately arrange for the replacement of the battery [22]. Despite the importance of state estimation, the SoC and SoH values cannot be measured directly from the battery. As a result, using embedded algorithms, the BMS must estimate the current state of the battery from collected real-time battery data [156]. As thoroughly reviewed in this work, several methods are suitable for SoC estimation. According to [60], KF family algorithms represent the right trade-off between complexity and accuracy due to their self-correcting nature and acceptable computational burden for online implementation. Conversely, SoH estimation is more challenging due to the complex nonlinear aging mechanism of the battery. As reviewed in Section 2, more complex intelligent algorithms have been proposed to enhance SoH estimation accuracy. Nevertheless, their online implementation is currently challenging owing to BMS limited computer capability and data storage [158]. Estimation of the battery state not only helps to determine whether the operational environment is safe and reliable but also provides information about the charge–discharge operation, which is especially important for cell balancing [159].

- d.

- Cell balancing

The concept of cell balancing is related to the consecutive charge–discharge cycle that may cause unequal voltage ranges in individual cells due to changes in their physical characteristics [160]. Imbalanced voltage and charge may reduce the overall performance and durability of ESSs [80]. Thus, cell balancing is necessary and can be provided by active and passive balancing techniques. In passive cell balancing, the charge in excess is dissipated as heat through a resistor. In active cell balancing, the charge is effectively transferred from a highly charged cell to a low one via a capacitor or an inductor [161].

- e.

- Thermal management

A thermal management system (TMS) is responsible for controlling the heating/cooling apparatus to maintain the battery temperature within a specific temperature range and reduce the temperature gradients and temperature inhomogeneity across the pack. Conventionally, the TMS is implemented onboard. Nonetheless, due to the computational limits of a local BMS, the thermal model is the most common model used for battery TMS [23]. Currently, thermal management represents a challenge for future BMS.

- f.

- Diagnosis

The BMS is essential for evaluating and diagnosing faults. The fault diagnosis technology is composed of a system database and records, an intelligent control program, communication networks and other technical measures [31].

5. Towards the Future: BMS in the Cloud Applications

As outlined in the literature studies [158], the conventional BMS is constrained by limited data logging and computational capability. Currently, as the number of batteries increases, the amount of computing and data storage required by BMS grows exponentially, and the state estimation methods exhibit inadequate adaptability under extreme conditions, making battery safety concerns more prominent [162]. Therefore, the development of more advanced and intelligent BMS is ongoing [10].

A promising solution to tackle such limitations in local BMS could be represented by the adoption of BMS in-cloud solutions. The advantages of adopting a cloud-based BMS could be related to simplifying local computing and implementing more accurate and complex algorithms in the cloud for battery system diagnostics [163]. Locally, BMSs should address their own functions; meanwhile new features, such as data-based lifetime prediction, system optimization and advanced battery state estimation, which are hard to implement in onboard BMSs, can be implemented in the cloud [21]. The cell monitoring function can be improved significantly with the help of the cloud platform, due to the use of more historical data and a better user interface [22]. As seen in the previous section, an efficient battery thermal management system is crucial to maintain battery temperatures within the proper range and to decrease the temperature variance between cells. Cloud-based BMSs can provide computing power support for the identification of these parameters, so a precise and more accurate thermal management will be realized in the future [23]. The restricted local data storage capacity of the BMS could be overcome with the adoption of a cloud-based solution that potentially offers an unlimited data storage capacity [164]. With the cloud platform, the use of big data and machine learning algorithms could potentially analyze large quantities of data and identify patterns that can be used to predict battery states, health status and degradation. The efficiency of such an approach is related to the amount and consistency of the training dataset [165].

Several research studies have investigated cloud-based solutions for state estimation. For instance, Li et al. [21] have proposed a cloud-based BMS application for SoC and SoH estimation using an adaptive extended HIF and PSO, respectively. Similarly, in ref. [166], a cloud-based SoC and SoH estimation was carried out by adopting different ML techniques. In ref. [167], a cloud-based SoH estimation method for lithium-ion batteries using sparse charging data was proposed. A health status indicator was extracted from an ECM model. By using the experimental data deployed on the cloud computing system, the correlation of battery health with the health status indicator was verified and SoH was estimated through data-driven algorithms. In Table 9, estimation errors are reported for further comparisons.

Table 9.

In-cloud battery state estimation errors.

It is worth dwelling on several drawbacks that need to be addressed to fully exploit BMS in the cloud. A fast and reliable internet connection is a prerequisite to guarantee seamless battery system operations [163]. With this regard, a continuous data exchange is provided from the onboard BMS to the cloud. Thus, a concern may be related to the communication channel between local and in-cloud systems that can be compromised and manipulated by adversaries leading to misleading battery control. Security gaps and potential damage should be addressed for an appropriate cloud-BMS implementation [168]. To ensure secure and private data transmission, including V2X communication, proper protocols can be used [33]. Complexity and cost of implementation are other two aspects to take into account that need to be assessed extensively. The costs of operating and maintaining the cloud platform depend largely on the amount of data and algorithms used on the cloud [22]. Lastly, a non-negligible aspect is the lack of dedicated legislation and standardization for this specific field [168].

6. Summary and Future Outlook

This paper discusses the SoC and SoH estimation approach including their merits, limitations and estimation errors from the literature. For SoC and SoH, the estimation methods can be mainly grouped into three categories: direct, model-based, and data-driven methods.

Since direct methods are only for laboratory purposes, these methods are not suitable to be implemented online.

SoC model-based estimation approach, in particular, KF and its extensions, represent the right trade-off between complexity and estimation accuracy due to their self-correcting nature and acceptable computational burden for online implementation. Conversely, model-based SoH estimation is more challenging due to the complex nonlinear aging mechanism of the battery. Consequently, it is crucial to strike a balance between the accuracy of the SoH estimation and the complexity of the model. Because of the variability in operating conditions, EchM- and ECM-based models may not be completely accurate. Accordingly, accurate model-based SoH estimation remains a challenge.

Data-driven methods have gained increasing attention for estimating battery SoC and SoH because they do not require an understanding of implicit changes in battery chemical parameters or working principles. In particular, for the SoH estimation approach, a growing trend is represented using ML techniques. The main advantage is represented by the SoH prediction based on previous aging data at the cost of time-consuming experiments to collect them. With this regard, the consistency and reliability of the training dataset for the intelligent algorithm is the main concern. Notwithstanding, the computational effort is another non-negligible aspect to consider. Table 10 summarizes the pros and cons of the discussed estimation approaches.

Table 10.

Summary of the state estimation approaches.

As pointed out, the conventional BMS is constrained by limited data logging and computational capability. Furthermore, as the number of batteries increases, the amount of computing and data storage required by BMS grows exponentially. Thus, an improvement is expected. A promising solution could be represented by bridging the more demanding features of the local BMS into the cloud. The advantages of adopting a cloud-based BMS could be related to simplifying local computing and implementing more accurate and complex algorithms in the cloud for battery state estimation and diagnostics.

In conclusion, the development of the V2X technology and faster connection will allow an enhancement of BMS bandwidth requirements. Therefore data-driven battery management schemes based on big data and cloud platform computing will become potentially the future trend.

7. Conclusions

This study deals with a comprehensive and novel overview with particular reference to the research status regarding the SoC and SoH estimation methods. The specificity of this study relies on the fact that it provides an overview of the current BMS key features and is also provided in terms of functionality and usability highlighting the main drawbacks. Finally, an assessment of the potential use of a cloud BMS solution is carried out with an outlook on future perspectives. The main outcomes are summarized as follows.

A battery model is essential to capture battery dynamic behavior and represents a prerequisite for state estimation.

The physics-based electrochemical models require the definition of proper differential equations to model battery physics. Despite their accuracy, the overall complexity of the models and the computational effort requirements make these kinds of models less attractive for online battery state estimation.

The ECM-based approach is widely used for online implementation due to its low complexity and good accuracy.

Direct methods are suitable for lab purposes, therefore model-based approaches, especially KF family algorithms, represent the right trade-off between complexity and accuracy due to their self-correcting nature and acceptable computational burden for online implementation.

Model-based SoH estimation is more challenging due to the complex nonlinear aging mechanism of the battery. Thus, more complex intelligent algorithms have received increasing attention to enhance battery state estimation accuracy. Nevertheless, their online implementation is currently challenging.

The traditional BMS is restricted by insufficient data logging and computational power. Thus, computationally demanding applications such as thermal management and real-time SoH estimation remain still a research challenge.

The use of BMS in-cloud applications has the potential to overcome the major challenges related to local BMS. With the cloud platform, the use of big data and machine learning algorithms could potentially analyze large amounts of data identifying patterns capable of predicting battery and health status, and degradation. On the other hand, complexity, maintenance, operating costs, lack of dedicated legislation and standardization, and reliable and secure connection infrastructure are non-negligible factors to consider for the use of in-cloud BMS solutions.

Future research activities will be devoted to addressing these concerns to fully exploit the potential of in-cloud BMS solutions.

Author Contributions

Conceptualization, G.D.L., G.D.B., A.G. and D.A.M.; methodology, G.D.L., G.D.B., A.G. and D.A.M.; formal analysis, G.D.L.; investigation, G.D.L.; data curation, G.D.L.; writing—original draft preparation, G.D.L.; writing—review and editing, D.A.M. and G.D.B.; supervision, A.G. and D.A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Italian National Recovery and Resilience Plan (PNRR).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| AEKF | Adaptive Extended Kalman Filter |

| AC | Alternate Current |

| BEVs | Battery Electric Vehicles |

| BMS | Battery Management System |

| BPNN | Back Propagation Neural Network |

| CC | Coulomb Counting |

| CO2 | Carbon Dioxide |

| DC | Direct Current |

| DD | Data-Driven |

| DEKF | Dual Extended Kalman Filter |

| ECM | Equivalent circuit model |

| EChM | Electrochemical model |

| EMF | Electromotive Force |

| ESS | Energy Storage System |

| EU | European Commission |

| EKF | Extended Kalman Filter |

| FL | Fuzzy Logic |

| FNN | Feedforward Neural Network |

| GA | Genetic Algorithm |

| HIF | H∞(Infinity) Filter |

| IEA | International Energy Agency |

| IR | Internal Resistance |

| IS | Impedance Spectroscopy |

| LKF | Linear Kalman Filter |

| LS | Least Square |

| LSTM | Long Short-Term Memory |

| KF | Kalman Filter |

| ML | Machine Learning |

| NLO | Non Linear Observer |

| NN | Neural Network |

| OCV | Open Circuit Voltage |

| P2D | Pseudo Two Dimension |

| PF | Particle Filter |

| PIO | Proportional Integral Observer |

| PSO | Particle Swarm Optimization |

| PNGV | Partnership for New Generation of Vehicles |

| RC | Resistor–Capacitor |

| SMO | Sliding Mode Observer |

| SoC | State of Charge |

| SoH | State of Health |

| SoP | State of Power |

| TMS | Thermal Management System |

| UKF | Unscented Kalman Filter |

References