Abstract

Agrivoltaics (APV), the co-location of agriculture and photovoltaics (PV), addresses an inherent competition for land usage. Taking the same dual-use concept to the urban landscape, rooftop APV can provide locally grown food in areas of need while providing distributed energy generation. In this multi-year investigation, different APV plots in northern Colorado, USA, were studied for crop metrics, light transmission, air temperature, soil/substrate temperature and moisture. Crops were grown under different solar panel types including opaque silicon and opaque and semi-transparent (ST) thin-film CdTe technologies. Growth conditions were characterized showing generally improved conditions and moderated temperatures under the panels. The ST-CdTe panels had increased photosynthetically active radiation (PAR) compared to both opaque panel types without a significant corresponding increase in temperature.

1. Introduction

1.1. Solar Photovoltaics (PV)

Climate change is the most urgent problem facing humanity. Estimates from the Natural Resources Defense Council (NRDC) [1] indicate that, unaddressed, climate change could cost the US economy USD 615 B per year by 2050. This represents 1.47% of the US GDP. Many countries, including the United States, are committed to net-zero carbon emissions by 2050. The European Green Deal is the European Union’s long-term framework to achieve climate neutrality by 2050. It relies on solar PV to help achieve economic development, future prosperity, and resilience [2]. Based on economic modeling, achieving 100% with more than 60% solar power is the most cost-effective approach to reach climate neutrality by 2050 [3].

According to the US Energy Information Administration (EIA) [4], solar PV electricity accounted for 2.8% of the electricity generated in the US in 2021. To achieve 60% capacity, approximately 500 gigawatts (GW) of new residential solar installations and 1500 GW of new utility scale solar will need to be constructed by 2050 in the US alone. Economics drives the increase in PV deployment—the lower the cost, the greater the uptake. Solar PV costs have dropped dramatically over the last five years and now cost less than other power-generation technologies. In the US, subsidy-free power is now produced at the utility scale below USD 30/megawatt Hour (MWh) [5], well below the cost of coal generation. Even with today’s significant growth rate for PV deployment, it will take several decades to achieve carbon-free energy for the majority of the world. The significant increase in demand for PV electricity will require different approaches to deployment and integration.

1.2. Agrivoltaics

The term agrivoltaics (APV) is a contraction of the two words agriculture and photovoltaics. As demand for renewable solar energy surges in the US and across the world, so will the demand for food. The United Nations Food and Agriculture Organization (FAO) has projected that while global energy consumption will grow by up to 50% by 2035, food production must rise 60% in order to feed the world population by 2050 [6]. The energy consumption from agriculture is a significant contributor to overall energy use [7]. The APV model provides a framework to address these challenges within the food–energy–water nexus.

APV is a land-use model with the means to provide decarbonized energy while keeping agricultural land productive. APV’s multi-land-use strategy maximizes the use of the sun’s energy by capturing some of it for PV energy production while allowing the rest to be utilized for agricultural food production. The APV model has existed across the globe for several decades, but scalable adoption has been sporadic [8]. Agrivoltaics have been shown to provide overall economic benefits [9,10].

As the costs of PV technology drop, and the demands increase to convert agricultural lands to solar farms, the potential for APV is on the rise. The improved understanding of the crop growth environment is beneficial to increasing implementation and designing optimized farms [11]. Specifically, there is a need to understand the crop growth environment created in an agrivoltaics system in a particular geographic area, and its potential impacts on crops that are important to that region (e.g., vegetables). Studies have shown favorable results for APV systems [12], particularly when deployed in warmer regions [13,14].

In APVs, the shadow effect from the high coverage of opaque panels has been shown to have negative impacts on plants [15]. Semi-transparent solar panels are beginning to be investigated for APV [16,17,18]. Silicon ST panels use gaps between the opaque cells for light to pass. Thin-film ST panels are a newer technology with potential benefits for APV. The ST thin-film APVs are uniformly transparent [18] and use relatively less semiconductor absorber films than the opaque counterparts. The amount of light passing through the panel (and subsequently available for crop growth) can be tailored during manufacturing. Cadmium telluride (CdTe) solar is the most successful thin-film technology and has demonstrated very low energy costs for utility scale applications [19]. ST CdTe panels are being investigated for building integration for windows [20,21]; however, little research has been reported for semi-transparent CdTe used for APV [16].

1.3. Rooftop Agrivoltaics (RAPV)

APV can be deployed in an open field space or integrated onto rooftop settings forming rooftop agrivoltaics (RAPV). Rooftops are a primary frontier in the search for urban food security [22]. Urban areas have limited space available for traditional food production to occur. Paradoxically, there is often a significant amount of unused space on the rooftops of buildings. RAPV could provide a fully integrated solution on underused space beneath the panels and address issues at the food–water–energy nexus.

Studies demonstrate the feasibility of growing food on low-slope rooftops in urban areas. As of the publication of the paper by [23], there were about 17.5 hectares of rooftop farms in the world, with the majority (about 15 hectares) in North America. There is an opportunity to combine rooftop farms with PV energy production. In these synergistic RAPV installations, plants evaporatively cool solar panels, and solar panels partially shade plants in the high temperature, water-limiting space on green roofs. The protection from solar panels slows the water-use rate of the plants below them, reducing the drought stress of food crops.

1.4. Agrivoltaic Deployment

APV deployment addresses a key concern for PV land-use allocation by opening up agricultural areas to PV deployment [13]. Most APV installations involve installing standard PV systems, perhaps on modified or elevated racking, in standard agricultural environments. This would allow agricultural laborers and machinery access to the crops under the panels. Although this simple co-location can be beneficial, there are tradeoffs between the agricultural and PV production. For example, panel rows are typically spaced farther apart than in non-agricultural PV installations. This is to enable sufficient sunlight to reach the crops. This approach has demonstrated benefits including reduced plant drought stress, greater food production for regionally important vegetable crops, and reduced PV panel heat stress [13].

There is an active tradeoff between energy production (high PV panel density with significant crop shading) and high photosynthetically active radiation (PAR) or low panel density with minimal shading. To achieve 80% of the open sky photosynthetically active radiation (PAR), only ~50% of panel coverage can be implemented in traditional APV deployments [24]. The use of newly developed semi-transparent PV could potentially mitigate these issues and is studied here. These tradeoffs require increased system design costs and an understanding of crop PAR requirements to balance the capital expense costs, power production, and crop yield to maintain the overall economics.

In this work, we investigate the crop growth environment under four types of APV installations in two separate sites. Semi-transparent thin-film CdTe panels are compared with similar opaque CdTe and crystalline silicon. Spectroradiometer readings, air temperature above the crops, and soil temperature data are reported for each panel type.

2. APV Experiments

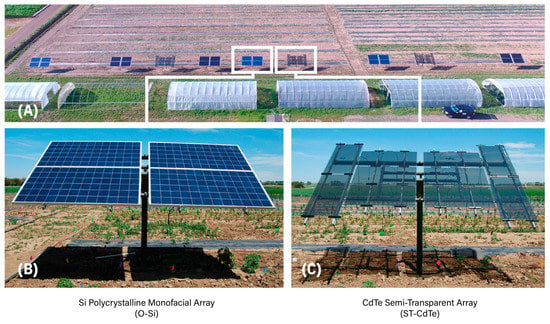

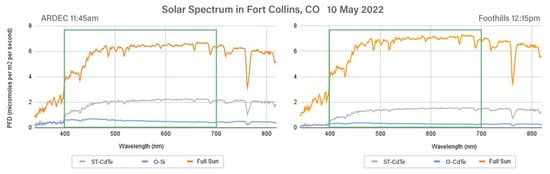

These experiments investigate APV growing environments under experimental PV arrays using different panel types, installation configurations, and orientations. Three different PV panel types deployed at two separate APV sites were studied. Both sites are located on land owned by Colorado State University (CSU), approximately 14 km from each other. The first, ARDEC South, which will be referred to as “ARDEC”, has nine pole-mounted PV arrays (Figure 1 and Figure 2). The second, Foothills Campus, which will be referred to as “Foothills”, has a simulated RAPV growing system under a ground-mounted PV array (Figure 3). Three types of panels were investigated: opaque polycrystalline silicon (O-Si), opaque thin-film cadmium telluride (O-CdTe), and thin-film semi-transparent cadmium telluride (ST-CdTe) with 40% transparency (Figure 1).

Figure 1.

Experimental APV system with semi-transparent CdTe panels. Panels have 40% transparency.

Figure 2.

ARDEC site overview (A) Replicated AV test plots at CSU’s ARDEC South location. (B) Opaque silicon (O-Si). (C) Semi-transparent CdTe (ST-CdTe).

Figure 3.

Foothills Campus site overview. (A) Construction emulates a RAPV installation. (B) Growing environment under the O-CdTe panels at Foothills. (C) Growing environment under the 40% ST-CdTe solar panels at Foothills.

2.1. ARDEC South (ARDEC)

This study was conducted on a permanent experimental installation of pole-mounted PV arrays on certified organic land at the CSU Agricultural Research, Development, and Education Center, South (ARDEC) (40.610012, −104.993979; altitude: 1523 m), in 2020 and 2021. CSU in Fort Collins, CO, has 3.4 ha of certified organic field space dedicated to vegetable cropping systems research and demonstrations. The soil at ARDEC is classified as a Nunn clay loam [25]. Soil samples were collected to a depth of 20–30 cm each year before planting and were tested at the CSU Soil, Water, and Plant Testing Laboratory. Soil was analyzed for pH, electrical conductivity, lime, texture, organic matter, and nutrient content to determine recommended fertilizer rates during the growing season.

The PV plots were installed as a randomized complete block design (RCBD) with three panel transparency types and one full sun control in three replications in an open field environment (Figure 2A). Two types of panels at ARDEC were included in this study. The first type was the thin-film telluride CdTe (ST-CdTe) with 40% transparency (Figure 2C), manufactured by Advanced Solar Power in Hangzhou, China. These are smaller than most commercially available panels designed for utility scale installations and have a rated output of 57 W. Their dimensions were 1200 mm long × 600 mm wide × 7 mm thick. The second type was polycrystalline silicon (Opaque Si), model JKM325PP-72, with 0% transparency (Figure 2B), manufactured by Jinko Solar in Shanghai, China. These have a rated output of 325 W; their dimensions were 1956 mm long × 992 mm wide × 41 mm thick.

The O-Si panel type is commercially available; however, the ST-CdTe panels are not yet UL-listed for grid connection in the US, and therefore, are being researched on an experimental basis. Similar opaque panels are listed and are routinely installed in grid-connected sites. The ST-CdTe panels consist of small, alternating regions of fully opaque solar cells and fully transparent areas (no solar cell material). The panels are fabricated as fully opaque, and laser ablation is used to selectively remove the solar absorber materials [26]. After ablation, the panels are laminated on the back with glass. According to the manufacturer, the PV transparency can be tuned at the factory between 0% and 90% light transmission. The spacing is narrow, and from a meter away the panel appears as uniform diffused light (Figure 2C). The ability to control this type of transmission by selective ablation is a specific attribute to the thin-film technology.

Each of the six PV arrays was mounted on the Montana Solar Top-4 racking system (Figure 2). The ST-CdTe arrays had six landscape-oriented and four portrait-oriented panels (Figure 2C). This provides a similar surface area to the silicon arrays. The racking system of each array was attached to a 152.5 mm diameter steel pole that was installed into a 600 mm-wide × 1830 mm-deep concrete pad. The angle of the arrays could be adjusted manually from vertical (0 degrees) to near horizontal (~90 degrees), parallel with the soil. Throughout the growing season, the arrays were set to 35 degrees to the south. When the panels were angled at 35 degrees, the bottom edge of the panel was 1220 mm above the ground and the back edge of the panels was 2360 mm above the ground. Each of the 12 subplots (both PV and control) was 4.3 m wide, and the subplots were spaced 4.3 m apart. The arrays were designed to simulate replicated field conditions for open field APV operations.

Drip irrigation was installed across all plots. The crop species tested in 2020 and 2021 included peppers (cultivars: Ace F1 bell, Jalapeño Early), summer squash (cultivar: Early Prolific Straightneck), and lettuce (cultivar: Butterhead). The tomato cultivars tested in 2021 included Red Racer and Tasmanian Chocolate. These vegetable crop species are important to small- and medium-sized growers who represent some early agrivoltaics adopters in northern Colorado.

2.2. Foothills Campus (Foothills)

A simulated RAPV study was conducted under existing solar panel arrays at the CSU Foothills campus west of Fort Collins, Colorado (40.586318–105.147377). During the 2020 growing season, a pilot study was initiated in 600 mm long × 1200 mm wide × 100 mm deep modular green roof trays, the same ones used in [27]. The green roof substrate was the RoofliteTM intensive agricultural blend (Landenberg, PA, USA). In the study, treatments were located in full sun, in the shade of the ST-CdTe panels, and in the shade of O-CdTe panels. Selected crops included lettuce, bush beans, and cilantro. The solar panels were an O-CdTe type with 1200 mm × 600 mm dimension and mounted in a configuration with approximately a 20–30 mm gap between the panels. The configuration is shown on the left side of Figure 3. Table 1 shows the locations, array configurations and panel types at both sites.

Table 1.

Location, array configuration, and panel types for both sites.

During the 2021 growing season, the site was expanded to include a 17 m × 8.7 m × 15 cm deep green roof system underneath and between two existing solar panel arrays. In the green roof system, the 20 mm root barrier and Extenduct drainage/water retention layer were supplied by Green Roof Solutions (Glenview, IL, USA). The growing substrate was a custom green roof agricultural blend of 60% expanded shale aggregate, 20% compost, 10% vermiculite, and 10% peat moss by volume. One treatment was located in full sun, one treatment in deep shade under O-CdTe, and one in the shade of 40% ST-CdTe frameless solar panels (Figure 3). These panels were the same as the ST-CdTe panels used in the ARDEC site. The panels were mounted to a standard ground-mounted racking system angled at approximately 35 degrees to the south. The front edge of the panels was 350 mm above the substrate and the back edge was 1220 mm above the substrate. Irrigation was supplied by 1.5 lph Netafim drip emitters spaced at 150 mm intervals and lines were spaced 300 mm apart. Two pepper (Ace, jalapeño) and two tomato (Red Racer, Tasmanian Chocolate) cultivars were grown in addition to lettuce and yellow summer squash.

2.3. Data Collected

Growing conditions at ARDEC and Foothills in both full sun and under solar panels were continuously monitored using HOBO H21-USB micro station data loggers (Onset Computer Corporation; Bourne, MA, USA). An Apogee Spectroradiometer (Model SS-110, 340–820 nm; Logan, UT, USA) was used to quantify the light conditions in terms of Photon Flux Density (PFD) and Photosynthetic Photon Flux Density (PPFD). PFD is the measure of micromoles of light that land in one square meter in one second (μmol·m−2·s−1). PPFD is a similar metric but only accounts for photons of light within the PAR range (400–700 nm), that land in one square meter in one second. At each site, three spectroradiometer readings were taken at 5 min intervals and then averaged. Data parameters collected at both research sites included PPFD, air temperatures at 30 cm above the soil/substrate, and soil/substrate temperatures at 2.5 cm deep. Data collection varied over the years at both sites. The variation is attributed to different construction dates.

3. Results and Discussion

To demonstrate the differences in the growing conditions under the PV arrays compared to full sun, we show data from one example date (14 August) for each 2020–2021 growing season at the ARDEC site and the 2020–2021 growing season at the Foothills site. We selected this date as representative of peak vegetable harvest where the plant canopy is established, thus optimally providing evapotranspiration benefits for the PV panels. The spectroradiometer readings are from 2022 at ARDEC and Foothills. We collected and analyzed light and temperature data as they are both key indicators of crop success in a specific growing environment.

3.1. Spectroradiometer

The spectroradiometer was used to analyze the differences in quantity and quality of light through measures of PPFD (PAR μmol·m−2·s−1 ) under each of the PV panel types compared to full sun conditions. The measures of PPFD are commonly used by agriculturalists to define light conditions and requirements for various crops in controlled agricultural environments.

3.2. Spectroradiometer Results

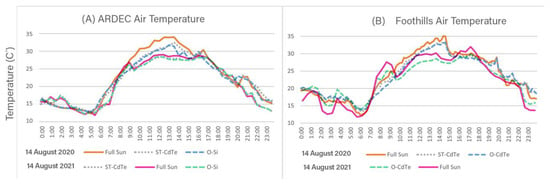

Solar photon flux varies depending on the time of year, the time of day, and cloud cover or atmospheric moisture content. We show PPFD in full sun, under ST-CdTe, and under O-Si panels at each location to compare the impact on light conditions in each individual PV array configuration (Figure 4). The orange line symbolizes the wavelengths of the full sun, the grey line symbolizes the wavelengths reaching the canopy level under ST-CdTe panels, and the blue line symbolizes the wavelengths reaching the canopy level under O-Si or O-CdTe panels, respectively.

Figure 4.

Spectroradiometer readings (ARDEC, 2022/Foothills, 2022).

In Figure 4, the green rectangle delineates light in the PAR range (PPFD) from other wavelengths of light. The spectroradiometer readings from ARDEC and Foothills show similar patterns of PPFD between the full sun and under-PV panel types. Both types of PV panels allowed all light wavelengths through, but with varying intensity. At ARDEC at 11:45 pm on 10 May 2022, the average PPFD in full sun was 1816, while it was 601 under ST-CdTe and 163 under O-Si. At Foothills at 12:15 on 10 May 2022, the average PPFD in full sun was 1970, while it was 405 under ST-CdTe and 92 under O-CdTe. Ultraviolet (UV) light in the 10–400 nm wavelengths was also notably absorbed by the PV panels.

At both locations, the opaque panels had the greatest impact on the amount of light reaching the plant canopy. The ST-CdTe panels allowed significantly less light than full sun, but more than three times the amount of light under the opaque panels at each respective site. The PV panels influenced the quantity of light at the soil/substrate surface but did not disproportionately impact any specific wavelength or quality of light. The reduction in the quantity of PPFD under the panels has the potential to impact plant physiology, stress, and yield in various ways depending on the climate and other crop system factors.

In regions with a short growing season or low light intensity, the sustained reduction in PPFD may impact plant growth negatively, while controlled light reduction in regions with a long growing season or high light intensity is likely to benefit plant growth.

The mitigation of UV radiation in the plant-growing environment is important to note because UV radiation is known to damage physiological and reproductive plant processes [28]. The negative impacts of UV exposure can be exacerbated in regions of high elevation and greater solar radiation, like Colorado. In these settings, plants are often overexposed to sunlight and, as a result, cannot utilize all the sunlight that reaches their canopies. Light beyond the needs of photosynthesis becomes a stressor and is managed as excess heat to be dissipated via transpiration and other mechanisms. When water is limited, plants close their pore-like openings, called stomata, which effectively stops transpiration. Temperatures inside the plant increase and trigger photoinhibition, resulting in inefficient carbon use and additional plant stress. Providing shade and air temperature moderation when the sun is at its zenith can alleviate the damage caused by these plant stressors. In fact, many specialty crop growers in high solar radiation locations use shade cloths in their operation to prevent plant stress and sun scalding [29]. Our results show moderated light conditions designed to shade plants and improve growing conditions for crops under the shade or partial shade from PV panels.

The ST-CdTe panels were specifically included in this investigation to evaluate the relative impact of light transmission for crops because the mitigation of light reduction is amongst the top priorities in agrivoltaic research [16,30]. The relatively higher light transmission under ST-CdTe panels compared to that of opaque PV panels can enable a higher panel density compared to other APV configurations. An increased and uniform panel density provides economic benefit through decreased PV installation costs. Because uniform panel density is the standard in the PV industry, this type of array allows for the same economic models, installation techniques, and operations and maintenance protocols that are already used. Increasing the uniform panel density without compromising light transmission increases economic viability for PV installation and an opportunity for plant growth.

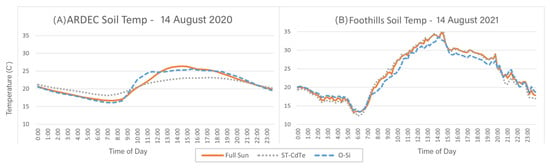

3.3. Air Temperatures

Ambient air temperatures at both ARDEC and Foothills recorded at the plant canopy level (30 cm above the soil) indicate that the shade from the PV arrays resulted in cooler ambient air temperature by an average of 1.3 °C during the hottest hours of the day (Figure 5). Most notably, the air temperature under the ST-CdTe did not differ from the air temperature below O-Si or O-CdTe. This is consistent with data provided by others [13,27], which showed similar differences between the substrate surface temperature in full sun compared to under opaque PV panels. Considering the higher light level under the ST-CdTe compared to either opaque panel type, without a corresponding higher air temperature, we suggest that the growing conditions under semi-transparent panels are more suitable for plant growth.

Figure 5.

Air temperatures across both sites at 30 cm of height. (A) ARDEC 2020 and 2021 and (B) Foothills 2020 and 2021.

3.4. Soil Temperature

It has been documented that soil temperature is closely associated with plant growth, plant stress (particularly at the initial root zone), and soil microbial diversity [31]. When soil temperatures rise above the optimum threshold, it can impede physiological processes such as plant water and nutrient uptake, plant growth regulator (PGR) signaling, and metabolite production, causing damage to plants. Extreme high temperatures can significantly impact crop growth and cause damage to plants [32]. Maintaining moderated soil temperatures through additional shade provided by APV systems can benefit temperate crops.

3.4.1. ARDEC South Soil Temperature

Soil temperatures at ARDEC show a much-attenuated temperature fluctuation in comparison to the air temperature results (Figure 6A). Shading from the PV panels, especially the ST-CdTe, generated lower temperatures midday. More specifically, in 2020, the soil temperature was 3 °C cooler under ST-CdTe panels in the afternoon. Overall, the solar panels provide moderated soil temperatures resulting in cooler daytime temperatures and lower nighttime temperatures, especially in the shade of PV panels.

Figure 6.

Soil Temperature at 2.5 cm depth (ARDEC, 2020, and Foothills, 2021).

3.4.2. Foothills Soil Temperature

The green roof substrate temperature among both panel types aligned closely with air temperatures (Figure 6B). This is likely due to the green roof substrate water-holding capacity, which is much lower than field soils, especially the clay-rich soils at ARDEC. Green roof substrate’s lower water-holding capacity results in less soil moisture and subsequently higher substrate temperatures when compared to growing conditions at-grade.

4. Conclusions

In this study, we compared the effects of three types of PV panels on light and temperature compared to an open field agricultural growing environment and a green roof environment. Overall, our findings demonstrate that the agrivoltaic concept holds promise for plant growth in conjunction with PV land-use across various scales. The benefits of partial shade [23] from PV arrays produces a growing environment that could allow for the expansion of PV integration in combination with agriculturally productive rural and urban regions across the globe [13,27].

Compared to the opaque panels, the semi-transparent panels allowed for greater light intensity to the plants while not increasing the soil/substrate or air temperatures, which can be beneficial to plants [32]. This finding warrants further exploration of semi-transparent panels for RAPV and building integrated photovoltaics (BIPV) with indoor climate-controlled crop operations. While the microclimate in small scale agrivoltaic systems with semi-transparent panels should not be considered a controlled environment [12], it can be considered a semi-controlled growing environment for crop systems due to the moderated temperature and light conditions, not unlike the shade cloth described earlier.

Semi-transparent PV panels offer a solution that caters to specific agricultural applications depending on the crop type and climate. The integration of PV with agricultural operations enables the expansion of renewable energy development while maintaining productive agricultural operations [12,13]. Future studies are needed to analyze soil moisture, crop yield impact across diverse climates [22], and panel temperatures with relative efficiencies for responsible agrivoltaic deployment at scale.

Author Contributions

M.U., T.H., J.B. and K.L.B. made significant contributions to this paper from the conception of the study through the identification and selection of the research methodology and its conduct, the writing of the paper, and its editorial side. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

This work was partially supported under the US National Science Foundation’s Industry University Cooperative Research Center program NSF 2052735. Sandbox Solar LLC, Fort Collins CO—Funding ARDEC Agrivoltaic site through USDA NIFA SBIR Phase 1, 2019. Matt Staver—Drone Photographer.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Natural Resources Defense Council (NRDC). The Cost of Climate Change: What We’ll Pay If Global Warming Continues Unchecked. May 2008. Available online: https://www.nrdc.org/sites/default/files/cost.pdf (accessed on 12 August 2021).

- European Commission. The European Green Deal. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 1 December 2022).

- Solar Power Europe. 100% Renewable Europe. 2020. Available online: https://www.solarpowereurope.org/100-renewable-europe/ (accessed on 20 September 2022).

- US Energy Information Administration (EIA). Electric Power Monthly Preliminary Data. February 2022. Available online: https://www.eia.gov/energyexplained/electricity/ (accessed on 1 December 2022).

- Lazard 2021: Lazard’s Levelized Cost of Energy Analysis—Version 15.0. October 2021. Available online: https://www.lazard.com/media/451881/lazards-levelized-cost-of-energy-version-150-vf.pdf (accessed on 12 January 2023).

- Food and Agricultural Organization. 2014. Available online: https://www.fao.org/fileadmin/templates/wsfs/docs/expert_paper/How_to_Feed_the_World_in_2050.pdf (accessed on 12 January 2023).

- Fu, X.; Niu, H. Key technologies and applications of agricultural energy internet for agricultural planting and fisheries industry. Inf. Process. Agric. 2022; in press, corrected proof. [Google Scholar] [CrossRef]

- Al Mamun, M.A.; Dargusch, P.; Wadley, D.; Zulkarnain, N.A.; Aziz, A.A. A review of research on agrivoltaic systems. Renew. Sustain. Energy Rev. 2022, 161, 112351. [Google Scholar] [CrossRef]

- Neupane Bhandari, S.; Schlüter, S.; Kuckshinrichs, W.; Schlör, H.; Adamou, R.; Bhandari, R. Economic feasibility of agrivoltaic systems in food-energy nexus context: Modelling and a case study in Niger. Agronomy 2021, 11, 1906. [Google Scholar] [CrossRef]

- Agostini, A.; Colauzzi, M.; Amaducci, S. Innovative agrivoltaic systems to produce sustainable energy: An economic and environmental assessment. Appl. Energy 2021, 281, 116102. [Google Scholar] [CrossRef]

- Williams, H.J.; Hashad, K.; Wang, H.; Zhang, K.M. The potential for agrivoltaics to enhance solar farm cooling. Appl. Energy 2023, 332, 120478. [Google Scholar] [CrossRef]

- Marrou, H.; Guilioni, L.; Dufour, L.; Dupraz, C.; Wéry, J. Microclimate under agrivoltaic systems: Is crop growth rate affected in the partial shade of solar panels? Agric. For. Meteorol. 2013, 177, 117–132. [Google Scholar] [CrossRef]

- Barron-Gafford, G.; Pavao-Zuckerman, M.; Minor, R.; Sutter, L.; Barnett-Moreno, I.; Blackett, D.; Thompson, M.; Dimond, Y.; Gerlak, A.; Nabhan, G.; et al. Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725. [Google Scholar] [CrossRef]

- Marrou, H.; Dufour, L.; Guglioni, L.; Salles, J.-M.; Loisel, P.; Nogier, A.; Wery, J. Designing farming system combining food and electricity production. In Proceedings of the 4th International Symposium for Farming Systems Design, Lanzhou, China, 19–22 August 2013. [Google Scholar]

- Gorjian, S.; Bousi, E.; Özdemir, Ö.E.; Trommsdorff, M.; Mustapha, A.; Anand, A.; Kant, K.; Chopra, S.S. Progress and challenges of crop production and electricity generation in agrivoltaic systems using semi-transparent photovoltaic technology. Renew. Sustain. Energy Rev. 2022, 158, 112126. [Google Scholar] [CrossRef]

- Cossu, M.; Cossu, A.; Paola, A.D.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and comparison of the solar radiation distribution inside the main commercial photovoltaic greenhouse types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834. [Google Scholar] [CrossRef]

- Barichello, J.; Vesce, L.; Mariani, P.; Leonardi, E.; Braglia, R.; Di Carlo, A.; Canini, A.; Reale, A. Stable semi-transparent dye-sensitized solar modules and panels for greenhouse application. Energies 2021, 14, 6393. [Google Scholar] [CrossRef]

- Munshi, A.H.; Sasidharan, N.; Pinkayan, S.; Barth, K.L.; Sampath, W.S.; Ongsakul, W. Thin-film CdTe photovoltaics–The technology for utility scale sustainable energy generation. Sol. Energy 2018, 173, 511–516. [Google Scholar] [CrossRef]

- Sun, Y.; Shanks, K.; Baig, H.; Zhang, W.; Hao, X.; Li, Y.; He, B.; Wilson, R.; Liu, H.; Sundaram, S.; et al. Integrated semi-transparent cadmium telluride photovoltaic glazing into windows: Energy and daylight performance for different architecture designs. Appl. Energy 2018, 231, 972–984. [Google Scholar] [CrossRef]

- Alrashidi, H.; Issa, W.; Sellami, N.; Ghosh, A.; Mallick, T.K.; Sundaram, S. Performance assessment of cadmium telluride-based semi-transparent glazing for power saving in façade buildings. Energy Build. 2020, 215, 109585. [Google Scholar] [CrossRef]

- Bousselot, J.; Russell, V.; Tolderlund, L.; Celik, S.; Retzlaff, B.; Morgan, S.; Buffam, I.; Coffman, R.; Williams, J.; Mitchell, M. Green roof research in North America: A recent history and future strategies. J. Living Archit. 2020, 7, 27–64. [Google Scholar] [CrossRef]

- Buehler, D.; Junge, R. Global trends and current status of commercial urban rooftop farming. Sustainability 2016, 8, 1108. [Google Scholar] [CrossRef]

- Riaz, M.H.; Imran, H.; Younas, R.; Alam, M.A.; Butt, N.Z. Module technology for agrivoltaics: Vertical bifacial versus tilted monofacial farms. IEEE J. Photovolt. 2021, 11, 469–477. [Google Scholar] [CrossRef]

- Soil Survey Staff; Natural Resources Conservation Service; U.S. Department of Agriculture. Soil 2018: 2018 Web Soil Survey. 24 February 2018. Available online: https://websoilsurvey.sc.egov.usda.gov/ (accessed on 20 September 2022).

- Wu, X.; (Chairman of Advanced Solar Power (ASP), 801 Lingyun St, Jianggan District, Hangzhou, Zhejiang, China, 310018). In conversation with author, December 2017.

- Bousselot, J.; Slabe, T.; Klett, J.; Koski, R. Photovoltaic array influences the growth of green roof plants. J. Living Archit. 2017, 4, 9–18. [Google Scholar] [CrossRef]

- Stapleton, A.E. Ultraviolet radiation and plants: Burning questions. Plant Cell 1992, 4, 1353–1358. [Google Scholar] [CrossRef]

- Maughan, T.; Drost, D.; Black, B.; Day, S. Using Shade for Fruit and Vegetable Production. 2017. Available online: https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=2673&context=extension_curall (accessed on 12 January 2023).

- Stallknecht, E.J.; Herrera, C.K.; Yang, C.; King, I.; Sharkey, T.D.; Lunt, R.R. Designing plant–transparent agrivoltaics. Sci. Rep. 2023, 13, 1903. [Google Scholar] [CrossRef]

- Sabri, N.S.A.; Zakaria, Z.; Mohamad, S.E.; Jaafar, A.B.; Hara, H. Importance of soil temperature for the growth of temperate crops under a tropical climate and functional role of soil microbial diversity. Microbes Environ. 2018, 33, 144–150. [Google Scholar] [CrossRef]

- Wahid, A.; Gelani, S.; Ashraf, M.; Foolad, M.R. Heat tolerance in plants: An overview. Environ. Exp. Bot. 2007, 61, 199–223. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).