1. Introduction

Since ancient times, people have used various sources to heat their homes or prepare their food. Nowadays, there are various devices that allow us to heat or cook very comfortably. These devices include boilers, thermal plants, generators and stoves. These devices use solid (wood, pellets), liquid (diesel) or gaseous (methane, propane, butane or LPG) fuels. A disadvantage of using liquid or gaseous fuels is that they have a high explosive potential; therefore, they must be handled with care to avoid devastating accidents. To avoid this critical situation, knowledge of fire- and explosion-related properties of fuels is necessary to ensure the safety of the processes that involve their use.

Among gaseous fuels, methane and butane are very often used. Butane is an easily liquefied and colorless gas obtained from different sources, such as oil, natural gas wells and cracking processes. It is commonly used as a fuel source (for portable stoves, lighters and torches), as propellant for aerosols, as refrigerant or as raw material for manufacturing of some products (e.g., butadiene—a widely used monomer). Compared to higher hydrocarbons (e.g., diesel oil), butane is considered a clean-burning energy source due to the fact that during its combustion, the carbon monoxide and particulate matter concentrations in exhaust gases are lower [

1]. Along with propane, butane is a main constituent of liquefied petroleum gas (LPG), which is a gaseous fuel used currently to power car engines.

Despite its advantages and widespread use, butane is a highly flammable gas, the accidental escape of which can lead to unwanted fires or even explosions. Therefore, to avoid these hazardous situations, a thorough study of its combustion is necessary. For this purpose, the present research aims to investigate the propagation speed of n-butane–air flames via experimental measurements in two different small-scale enclosures (a sphere and a cylinder) and computation using a dedicated computing package.

The propagation speed (

Ss), which is also known as space velocity or flame speed, is defined as the velocity of the flame front relative to a fixed coordinate system (e.g., explosion enclosure) [

2,

3]. Most experimental or modeling studies [

4,

5,

6,

7,

8] examine the normal burning velocity (

Su)—a major feature of flammable mixtures, being necessary to validate reaction mechanisms or compute the heat release rate under various conditions [

9]. Together with the normal burning velocity, the propagation speed is a substantial property of a flammable mixture and a significant parameter in respect to the rates of fuel oxidation in products and heat generation. Understanding the propagation speed of a flame is necessary to predict the flame blow-off and flash-back, as well as to evaluate the risk factors that may arise in mine galleries or operating chemical reactors in which flammable blends may be formed. Moreover, the propagation speed of a flame is an important parameter in the design of vents and explosion proof vessels and mitigation of the damaging effects of explosions [

3]. Thus, many previous studies focused on the propagation velocities of methane [

8,

10,

11,

12], ethane [

13] or propane-air [

14,

15] mixtures by running experiments and numerical models under various initial conditions.

The steady or unsteady fuel–air flames can be characterized using experimental or computation results of Ss and/or Su. Such studies, which can be performed using a variety of fuel–air blends, allow better control of the complex combustion process in terms of both safety and its use as an energy source.

Despite their practical importance, the propagation speed of

n-butane–air mixtures have been less thoroughly investigated compared with normal burning velocity. Jiang et al. [

16] investigated the flame propagation characteristics of rich

n-butane–air mixtures at ambient initial conditions in a micro-constant volume vessel. They observed that the propagation speed was slightly lower in this micro-enclosure than that obtained using a vessel of conventional size. The propagation speeds of a stoichiometric

n-butane–air blend obtained via experiments using a spherical vessel under various initial temperatures and pressures were also reported [

17]. The authors found that a pressure increase resulted in a decrease in the propagation speed, while an increase in temperature led to an increase in the propagation speed.

Given that the literature data regarding this combustion parameter are of poor quality, the present study has a great practical interest in understanding the propagation of explosions when n-butane–air mixture burns in enclosures. The main objective of this study is to provide experimental data regarding the effect of the initial pressure, initial temperature and equivalence ratio on the flame propagation of n-butane–air. The study is significant, as it reveals the essential characteristics of the explosion process of n-butane–air mixture under different initial conditions, and the results would help to deepen understanding of this fuel explosion and improve assessment of the explosion hazardousness. Additionally, the present paper serves not only the specialists in the combustion field, but also people who seek general information about this domain, as the importance of n-butane combustion extends from its burning in internal combustion engines to its use as an energy source.

4. Results and Discussion

The propagation speed (

Ss) is correlated with the normal burning velocity (

Su) using the following equation [

2,

3]:

In this equation, Sg (the gas velocity) represents the velocity of the flame front determined based on the expansion of the burned gas behind the flame front and the compression of the unburned gas ahead of it.

The normal burning velocity represents the component of the displacement velocity of the flame front to the surface of its front.

Ss is also related to

Su through the following equation [

3,

26]:

In Equation (2),

E0 represents the expansion coefficient of the unburned gas of constant-pressure combustion that is specific to the initial (early) stage of explosion propagation. Its value is given as the ratio between the burnt and unburnt gas densities:

Here, ρu is the unburnt gas density, ρb is the burnt gas density, Tf,p is adiabatic flame temperature of isobaric combustion, n0 is the initial mole number and ne is the final (end) mole number obtained via equilibrium computations on flames.

The adiabatic flame temperature (of either isobaric or isochoric combustion) represents an important parameter that is necessary for the examination of combustion processes that take place in closed or open vessels. It is related to other combustion parameters, such as flammability limits, propagation speeds, extinction of the flame, etc. In addition, the adiabatic flame temperature of isobaric combustion can be used to predict the limiting oxygen concentration of inert–diluted fuel–oxidizer mixtures and the flammability limits of the complex multifuel–oxidizer mixtures. Therefore, knowledge of the adiabatic flame temperature represents a necessity.

Representative values of the adiabatic flame temperatures of isobaric combustion (

Tf,p) of

n-butane–air blends computed at an initial pressure of 1 bar are given in

Figure 1. Very close values were obtained using the ECHIMAD and COSILAB computer packages, which was in accordance with the different sets of input data. Moreover, the presented results agree with results reported by Ren et al. [

27], as can be seen in

Figure 3.

As shown in

Figure 3, the adiabatic flame temperature of the isobaric combustion varies with

n-butane concentration. The

Tf,p values increase from the

n-butane concentration that corresponds to the lower explosion limit to a maximum value that is greater than that of the stoichiometric mixture, while still being close to it. After this maximum value, the

Tf,p values decrease until the

n-butane concentration that corresponds to the upper explosion limit is attained. Such behavior was reported by many authors who studied fuel–air mixtures [

2,

6,

27], as well as by Sankar et al. [

28], who investigated the effect of hydrogen addition on the normal burning velocity of LPG–air blends. The authors of paper [

28] mentioned that the normal burning velocity follows the same trend as the adiabatic flame temperature and the normal burning velocity increases in tandem with the increase in adiabatic flame temperature. Indeed, an increase in normal burning velocity in tandem with an increase in adiabatic flame temperature was also reported by Hu et al.’s [

29] study of the effects of inerts on the normal burning velocity of methane–air blends.

In

Figure 4, the expansion coefficients of systems at an initial pressure of 1 bar, which were obtained via the equilibrium calculation that used the ECHIMAD and COSILAB programs, are plotted against the

n-butane concentration. Close values were obtained using both programs in the lean and stoichiometric ranges of mixture compositions. In the range of rich mixtures, some differences appear between the data derived from the ECHIMAD and COSILAB programs.

It is observed that the expansion coefficients of

n-butane–air mixtures have the same trend as the adiabatic flame temperatures, with the maximum value set at a slightly richer concentration than that of the stoichiometric mixture. The same behavior was obtained for methane–air mixtures with different fuel concentrations [

6,

30].

Alternative equations used to calculate the expansion coefficients have been proposed by some researchers [

2,

31,

32,

33]. These equations give approximate values of the expansion coefficient when no equilibrium calculations are realizable (e.g., flammable gas with a complex composition). The calculations are based on a parameter characteristic of the isochoric combustion of studied flammable mixtures (e.g., the maximum explosion (end) pressure

pe, which is obtained during explosions at initial pressure

p0) [

18]. In this study, several alternative equations, which are summarized in

Table 1, were tested to obtain the expansion coefficients.

It was observed that the parameters

A and

B from the equation proposed by Babkin et al. [

31] presented a low dependence on the state of the blend and its composition; therefore, this equation was simplified [

32,

33]. On the other hand, as noted by Agrawal [

33], this simplified equation could be used to examine the explosions that occurred in enclosures, regardless of the state and nature of the studied mixtures, a fact that provides an overview on the normal burning velocities of these mixtures.

In

Figure 5, a comparison of data obtained using these alternative equations is given. The data were obtained using the adiabatic explosion pressures delivered by running the ECHIMAD program instead of experimental peak explosion pressures. From

Figure 5, we can observe that the expansion coefficients obtained via the simplified equation proposed by Babkin et al. [

32] and Agrawal [

33] match the results delivered by the equilibrium computation, especially for those mixtures with 2.0 to 3.6 vol%

n-butane. The values computed using the equation proposed in [

2] are higher for all studied compositions. Therefore, in this study, only expansion coefficients delivered from equilibrium computations were used.

In this study, the propagation speeds

Ss of

n-butane–air blends were obtained based on normal burning velocities

Su and expansion factors

E0 using Equation (2), which is described above. The experimental normal burning velocities characteristic of the

n-butane–air explosions were obtained using pressure-time records registered during experiments performed via either spherical or cylindrical enclosures. After pressure recording, the obtained curves were processed using the cubic law method [

34], which is a method based on the examination of the early stage of flame propagation (Δ

p ≤

p0). Another set of normal burning velocities were obtained via the kinetic modeling, as described in the

Section 3.

A set of representative results of propagation speeds

Ss obtained after processing the experimental

p(

t) curves recorded in both spherical and cylindrical enclosures, which referred to variation in this parameter with fuel concentration, is given in

Figure 6. In the same figure, the propagation speeds obtained using computed normal burning velocities are plotted. Lower propagation speeds were obtained using measurements in the cylindrical enclosure compared to those obtained via experiments performed in the spherical enclosure. This result could have occurred due to the fact that while using cylindrical enclosures, the flame spherically propagates until a specific moment at which it comes into contact with the vessel’s walls; after this moment, the flame undergoes deformations that affect the process of spherical propagation of the flame and, thus, the propagation speed.

The propagation speeds obtained via modeling with INSFLA program using the modified Warnatz mechanism, which occurred at ambient initial temperature and pressure, are lower than the experimental speeds recorded in the range of lean- and rich-

n-butane/air mixtures, as revealed in

Figure 6. The kinetic modeling involves a mechanism that has a significant impact on the accuracy of the computed normal burning velocities and, hence, the propagation speeds. Even if the kinetic mechanisms used by scholars consider a large number of elementary reactions and chemical species, it appears that combustion is a more complex and not fully understood process. Therefore, inconsistencies appear between measurements and computations. On the other hand, computations can be made via dedicated programs for flames that adiabatically propagate and do not take heat losses into account, as occurred in the present case. Therefore, detailed research and close collaboration between researchers from different fields are still needed to improve the reaction mechanisms to ensure that the calculations provide results as close to reality as possible. However, the results agree around the stoichiometric composition ([C

4H

10] = 3.13 vol%).

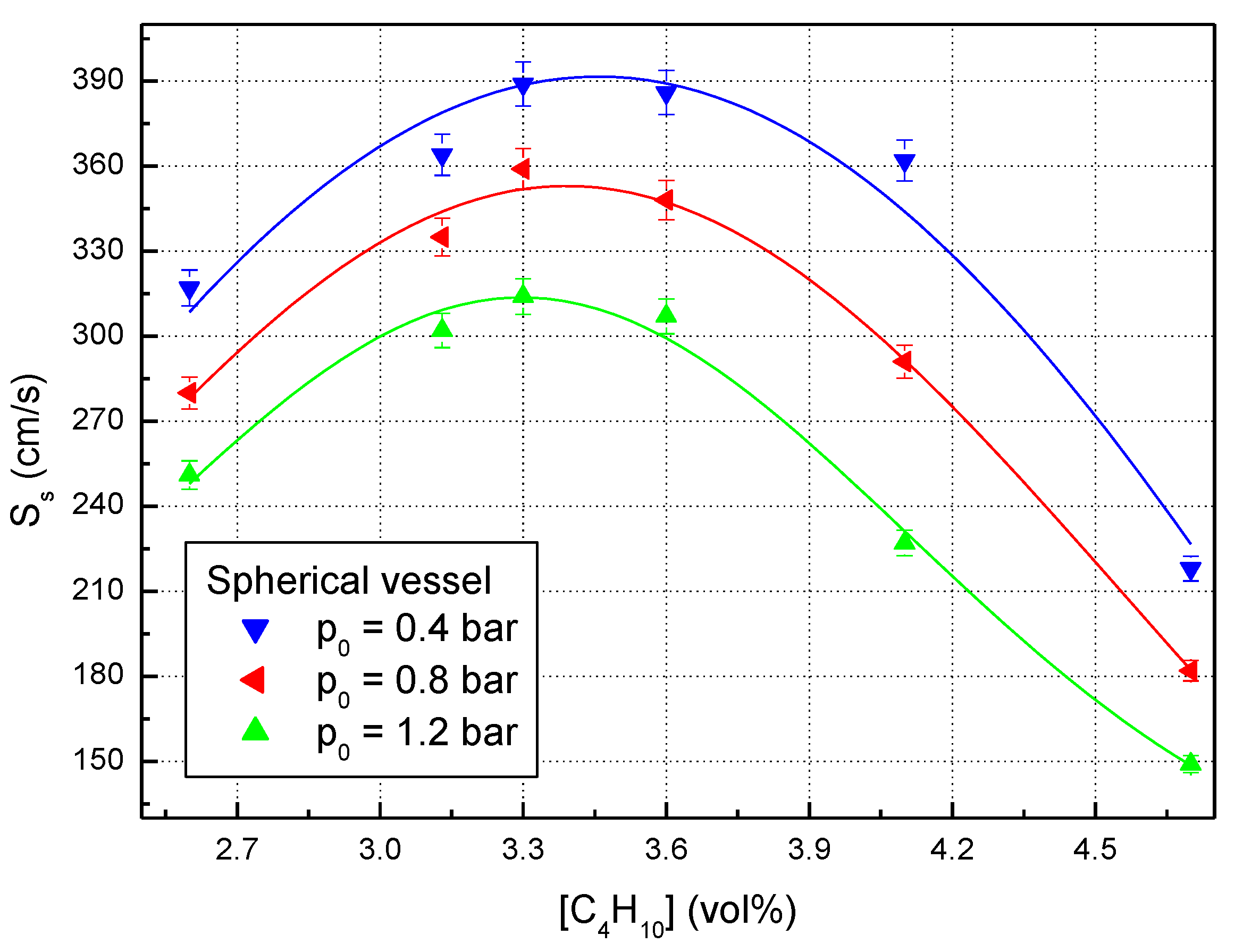

Other sets of representative results are given in

Figure 7 and

Figure 8, where data obtained at different initial pressures are plotted. Data presented in

Figure 7 were obtained via tests using the spherical vessel, while data presented in

Figure 8 were obtained using data collected via experiments performed using a cylindrical enclosure.

As seen in

Figure 7 and

Figure 8, another parameter that affects the propagation speed is the initial pressure. The influence of this physical parameter on the propagation speed can be better observed in

Figure 9, where a representative graphic referring to a 3.60 vol%

n-butane mixture is given. Here, data obtained using both cylindrical and spherical enclosures are presented. We can observe that the pressure increases determine a decrease in the propagation speed. This behavior is valid for the propagation speeds of any fuel–air mixture. The propagation speeds obtained via computation are higher than those obtained via experiments. This result occurs due to the fact that the calculations do not take into account thermal losses that occur in experiments, thus overestimating the values of these parameters of interest.

The dependence of propagation speed

Ss on the initial pressure

p0 can be examined using the following empirical power law:

In this equation, Ss,ref represents the reference value of the propagation speed obtained when p0 = pref. Usually, pref = 1 bar. Thus, the baric coefficients of propagation speed β can be obtained using a non-linear regression analysis of the results.

Equation (4) is similar to that used to describe the dependence of normal burning velocity on initial pressure.

A representative set of data regarding the baric coefficients of propagation speeds of some

n-butane–air mixtures is presented in

Table 2.

The baric coefficients of propagation speeds at ambient initial temperature are smaller than the baric coefficients obtained using normal burning velocities. For example, for the stoichiometric mixture, the present values of the baric coefficients of propagation speeds are

β = −0.220 when calculated using data obtained via the spherical enclosure and

β = −0.386 when calculated using data recorded via the cylindrical enclosure. In comparison, the baric coefficient of normal burning velocity of the stoichiometric mixture obtained in the same initial conditions, as reported in [

17], was

β = −0.171. These discrepancies occur due to the fact that the expansion coefficients themselves to some extent depend on the initial pressure. This behavior was previously reported for other alkane–air mixtures, such as inert propane–air mixtures [

14].

Another factor of interest that affects the propagation speed examined in the present research is the initial temperature.

Figure 10 presents the variation in the propagation speed based on the initial composition and temperature. By keeping the initial composition and pressure constant, an increase in propagation speed occurs when the initial temperature increases, as long as the pre-heating stage does not lead to self-ignition or slow oxidation reactions. This increase can be better observed in

Figure 11, where data computed for two lean mixtures at various initial temperatures are plotted. The increase in the propagation speed when the initial temperature increases is explained based on increase in adiabatic flame temperature, expansion coefficients and normal burning velocity, as well as, hence, of the propagation speed, as the initial temperature of the fuel–air blend increases.

Similar to the variation of the normal burning velocity with the initial temperature, an empirical equation describes the variation of the propagation speed with the initial temperature when the initial composition and pressure are constant:

In Equation (5), Ss,ref represents the reference value of the propagation speed when T = Tref, and α represents the thermal coefficient of the propagation speed, which was calculated using a non-linear regression analysis of the results. Usually, Tref is considered to be the ambient temperature (298 K).

If the baric coefficients of the propagation speeds present an insignificant variation with the initial composition of the studied mixture, the thermal coefficients present a significant variation, which is similar to that of the propagation speed. This result can be observed in

Figure 12, where the thermal coefficients of the propagation speeds of the studied range of fuel compositions at an initial pressure of 1 bar are plotted. It is observed that the thermal coefficients of the propagation speed, which have constant initial pressure, strongly depend on mixture composition, reaching smaller values at a concentration slightly higher than that of the stoichiometric mixture.

Compared to the thermal coefficients of the normal burning velocities of an alkane–air mixture, which usually have values between 1.30 and 2.30 at an initial pressure of 1 bar [

35,

36], the thermal coefficients of the propagation speeds of

n-butane–air mixtures are lower. This result is due to the fact that initial temperature affects both the normal burning velocity and expansion coefficients, which are two parameters that influence the propagation speed.