Hydrogen or Electric Drive—Inconvenient (Omitted) Aspects

Abstract

1. Introduction

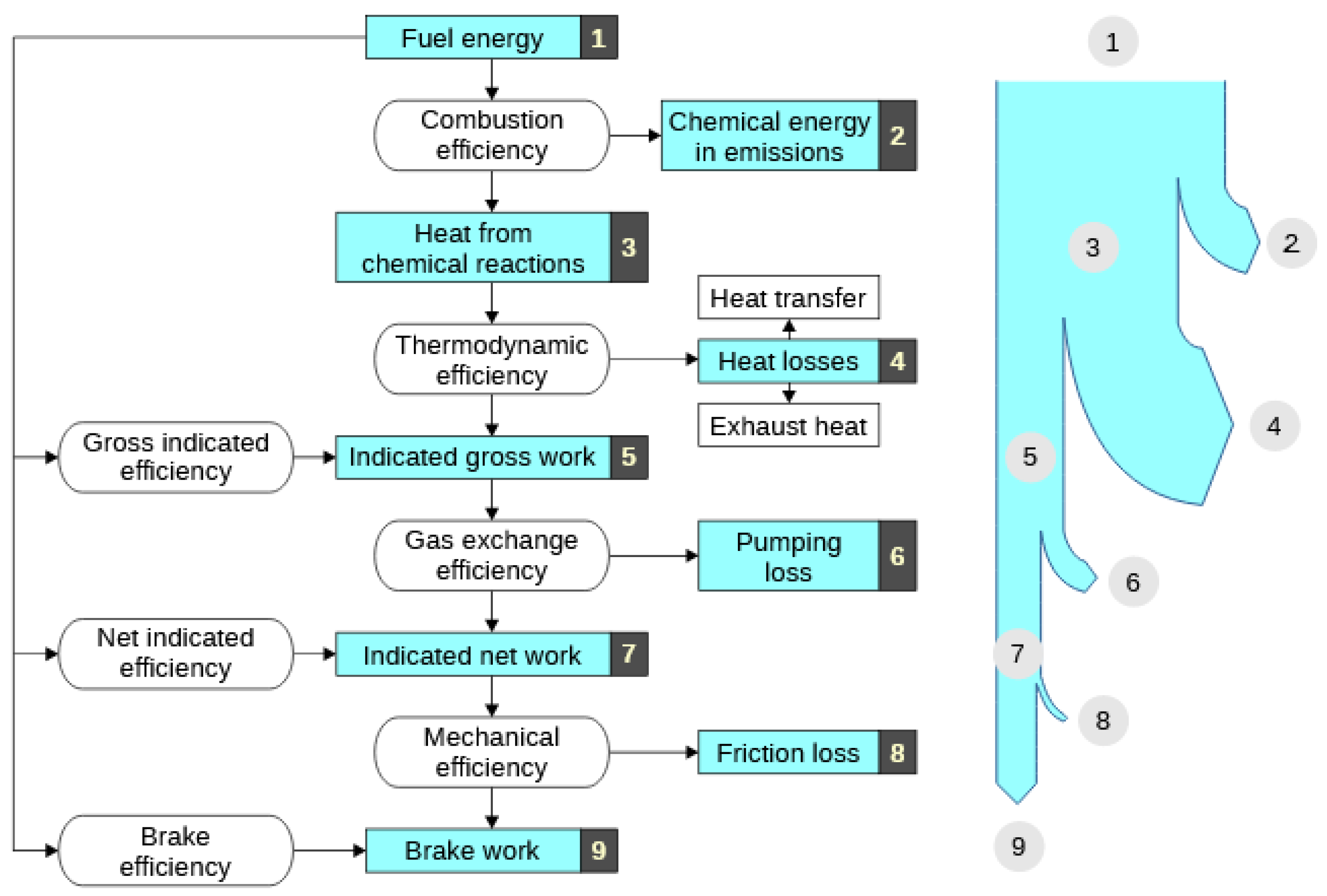

Drive Efficiency

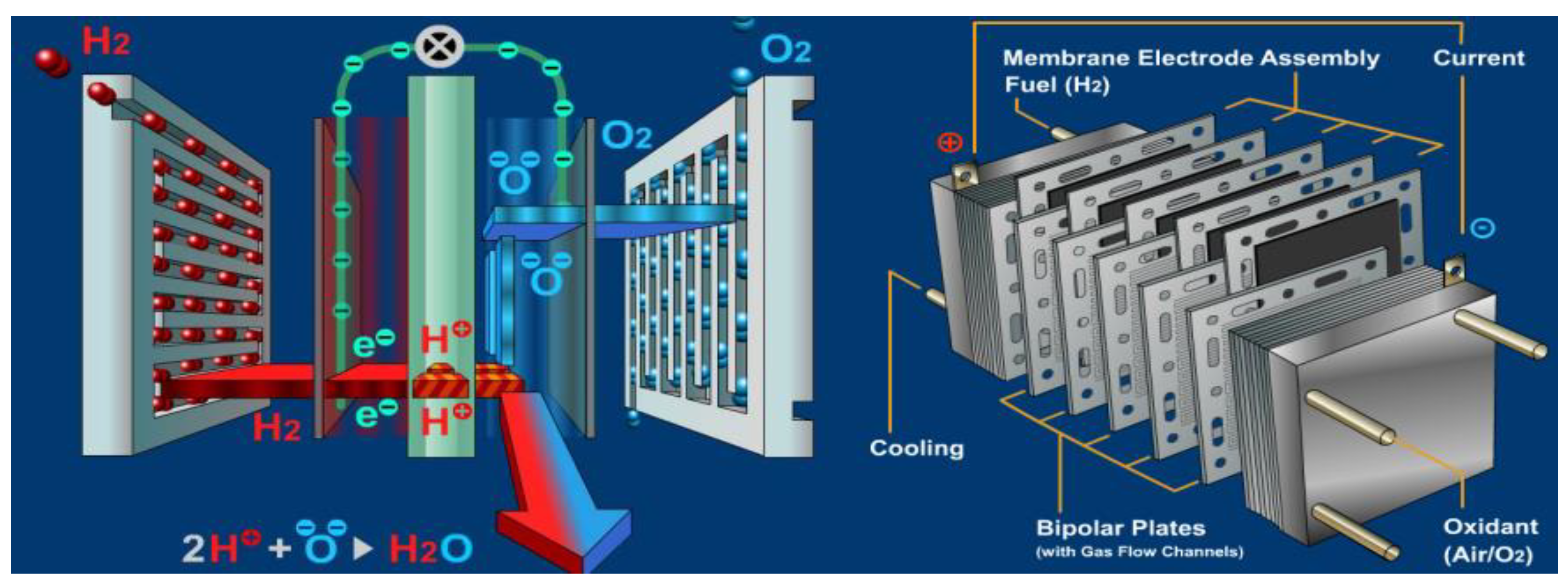

- unlike engines operating on the basis of the Carnot cycle, the maximum efficiency of energy conversion in fuel cells is at non-zero power;

- pure water is the product of conversion of chemical energy of hydrogen into electricity;

- electricity generation in applications with power ranging from milliwatts [mW] to megawatts [MW] is continuous, as long as substrates for electrochemical reactions are supplied.

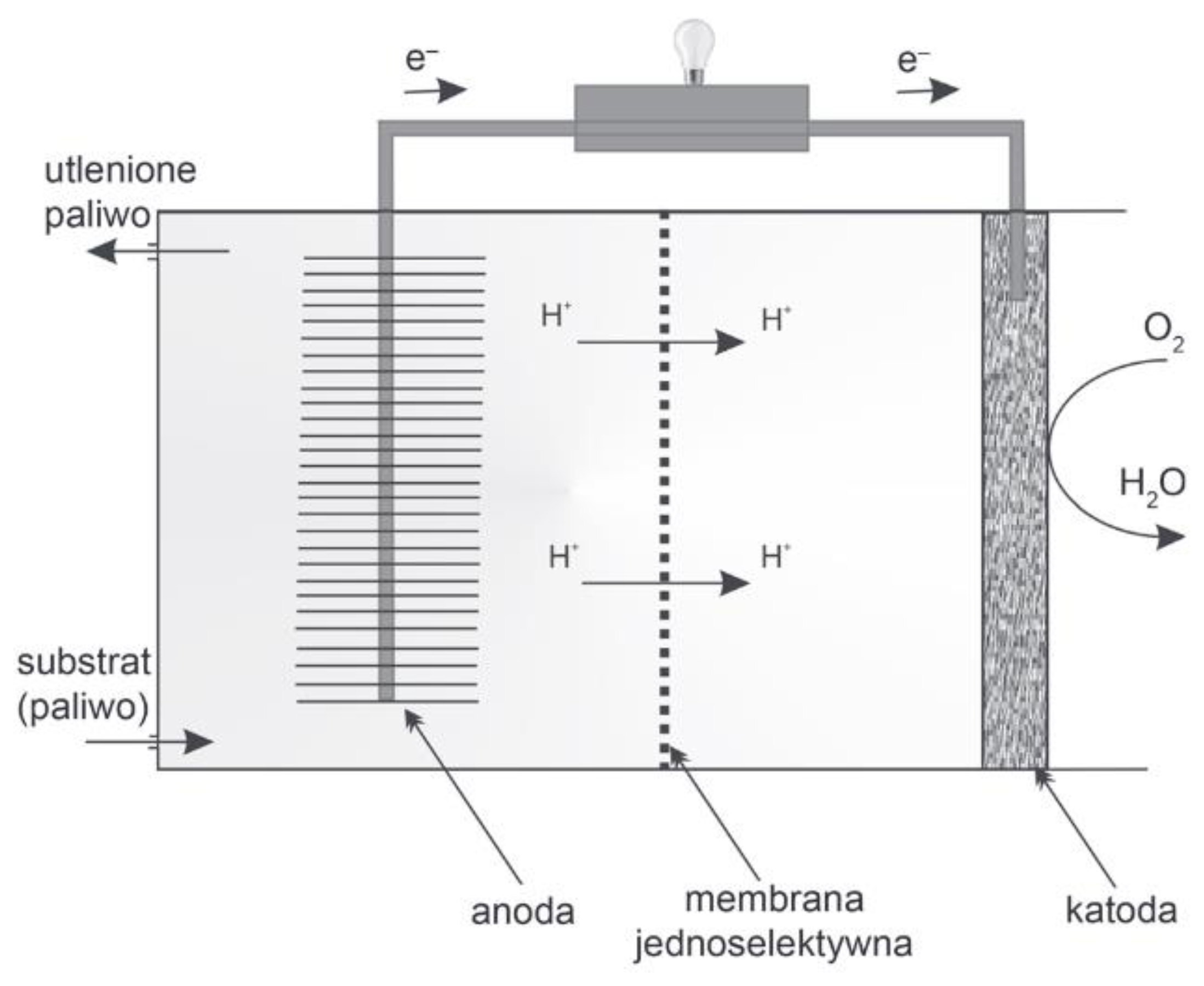

2. The Principle of Fuel Cell Operation

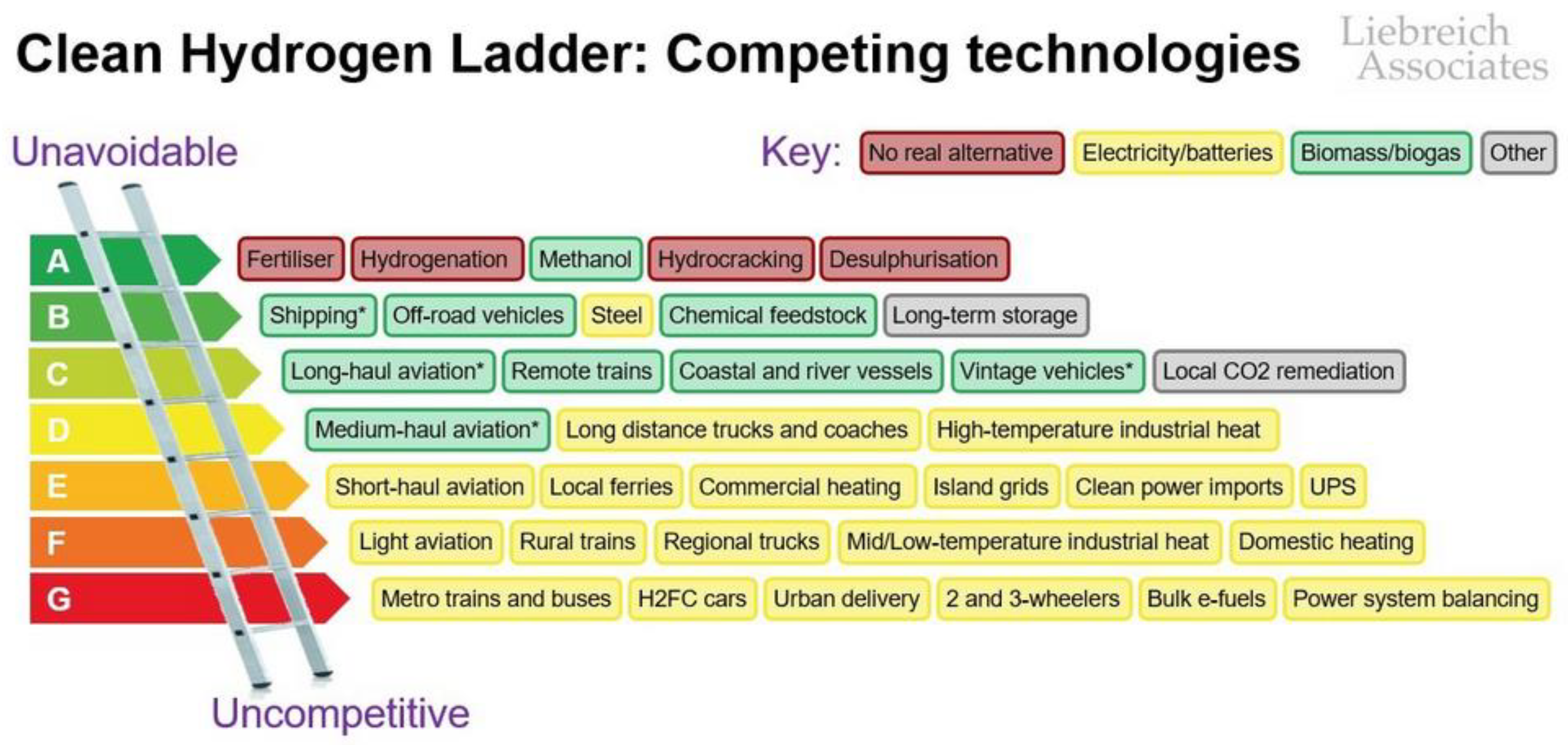

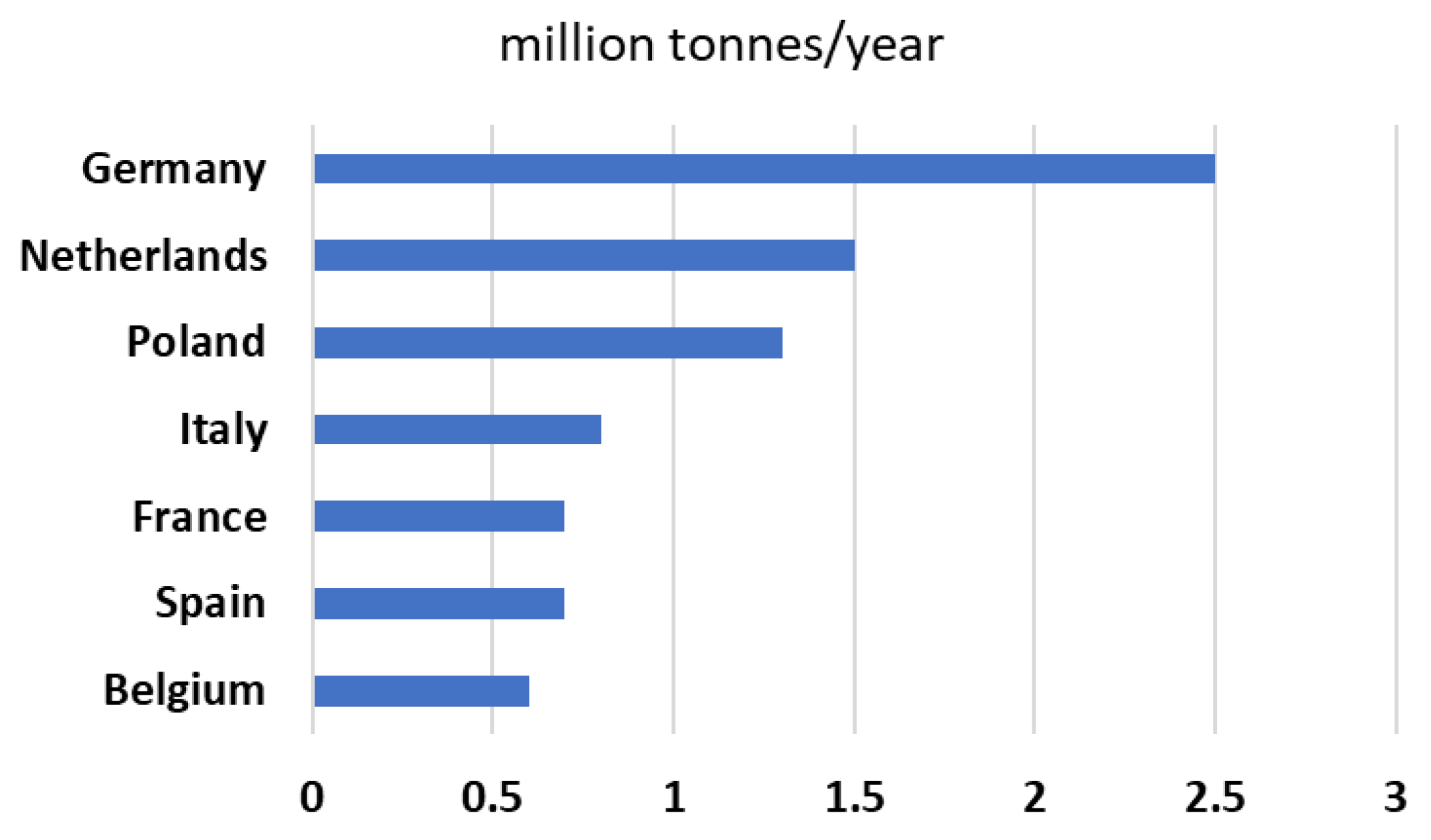

3. Application of Hydrogen Fuel

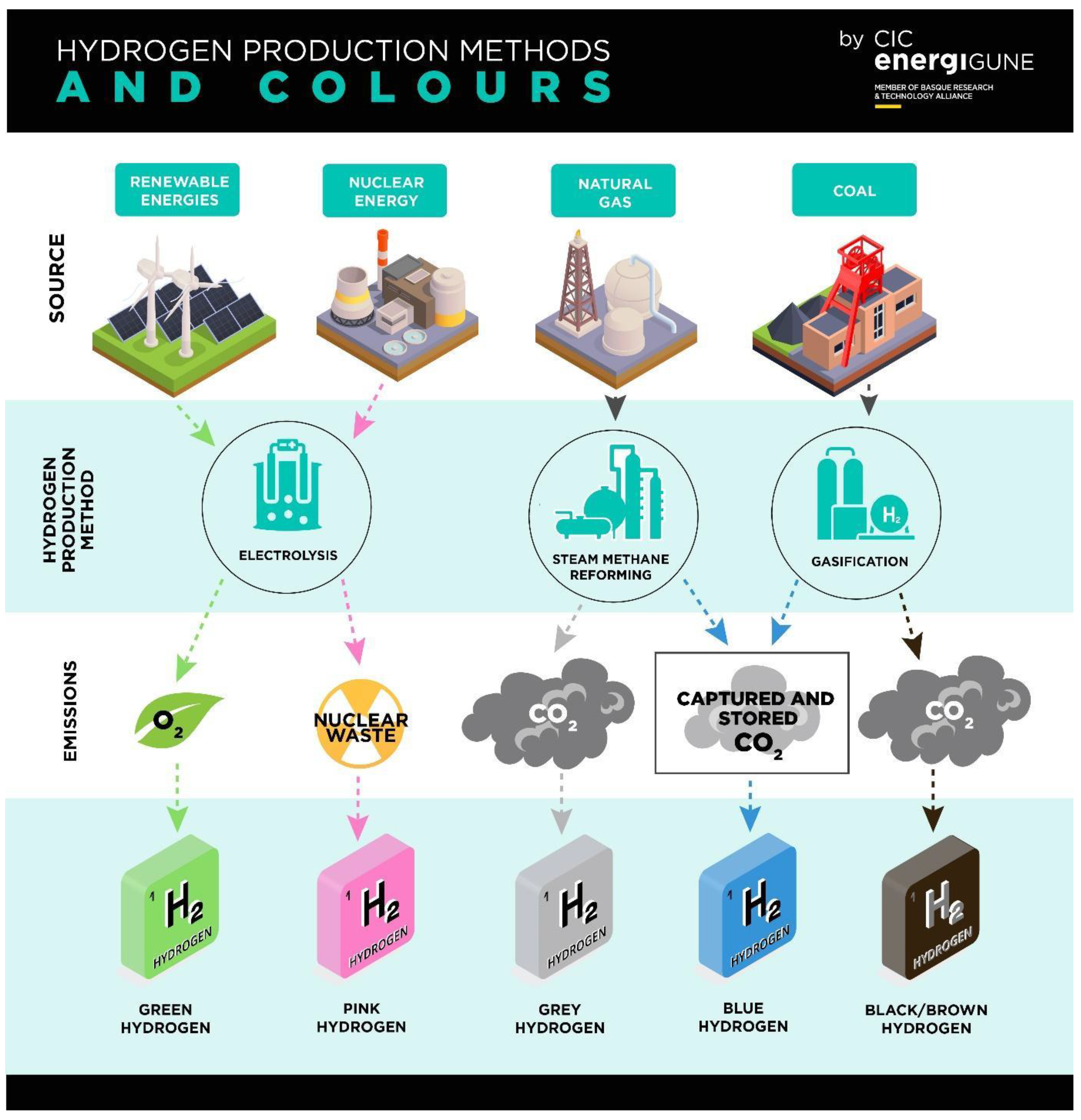

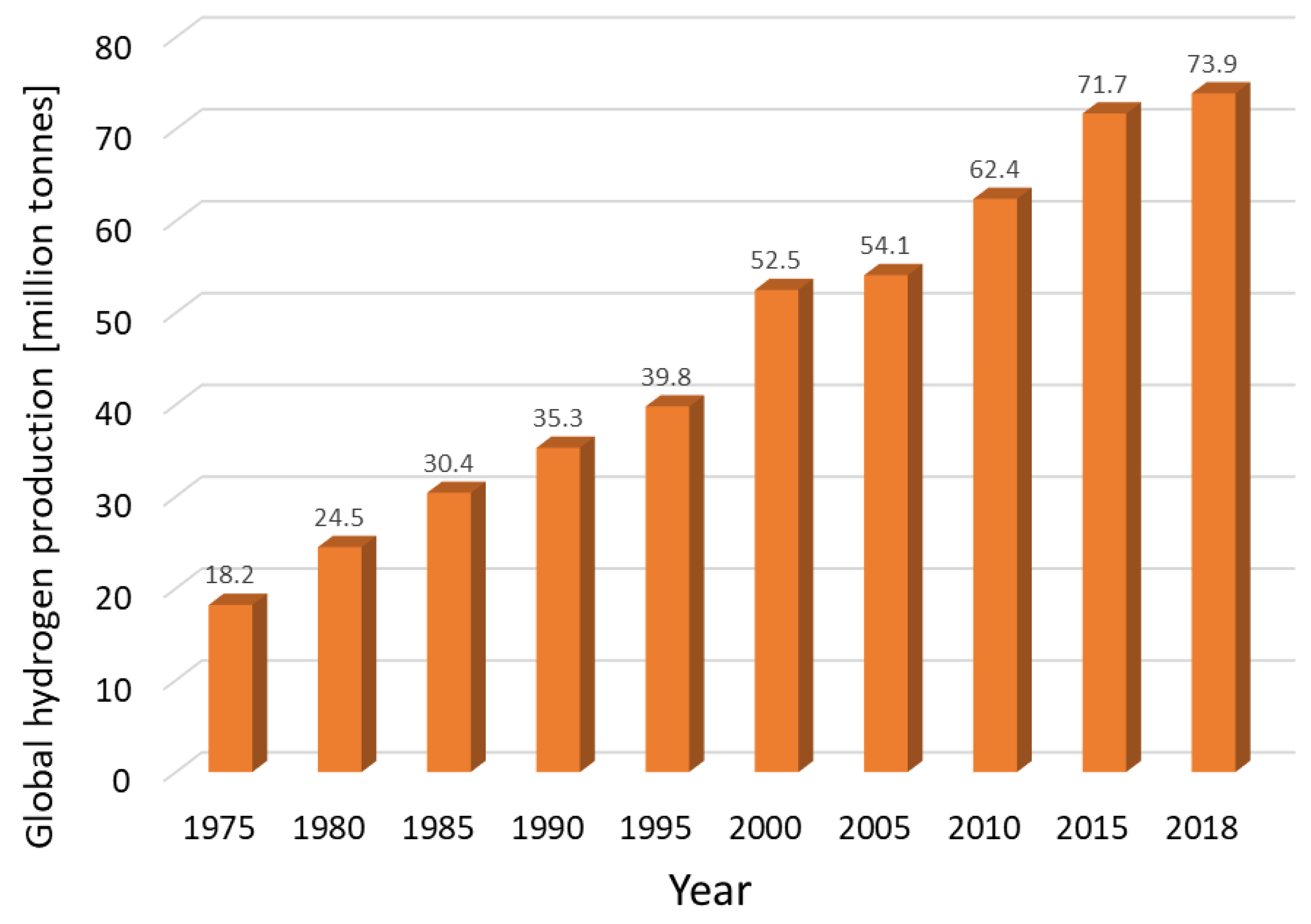

4. The Question, the Answer to Which Is the Foundation of Further Analysis: How Is Hydrogen Obtained?

4.1. Fundamentals of Hydrogen Technologies

- steam reforming (SR);

- partial oxidation (POX);

- auto thermal reforming (ATR).

4.2. Direct Solar Water Splitting Processes

4.3. Biological Processes

4.4. Is Blue Hydrogen a Threat to the Climate? No One Listens to Scientists!

5. The Concept of a Modern Hydrogen Drive

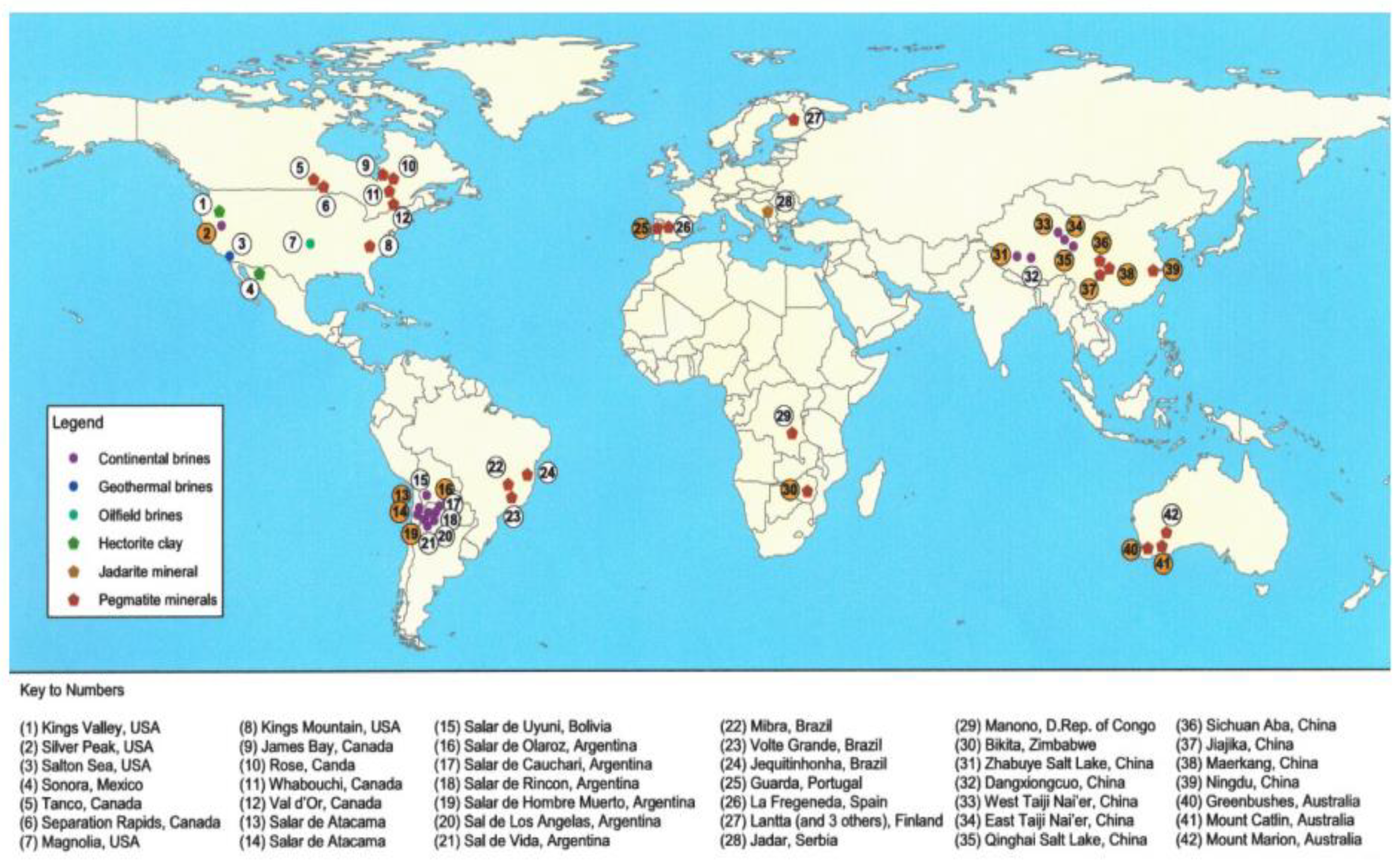

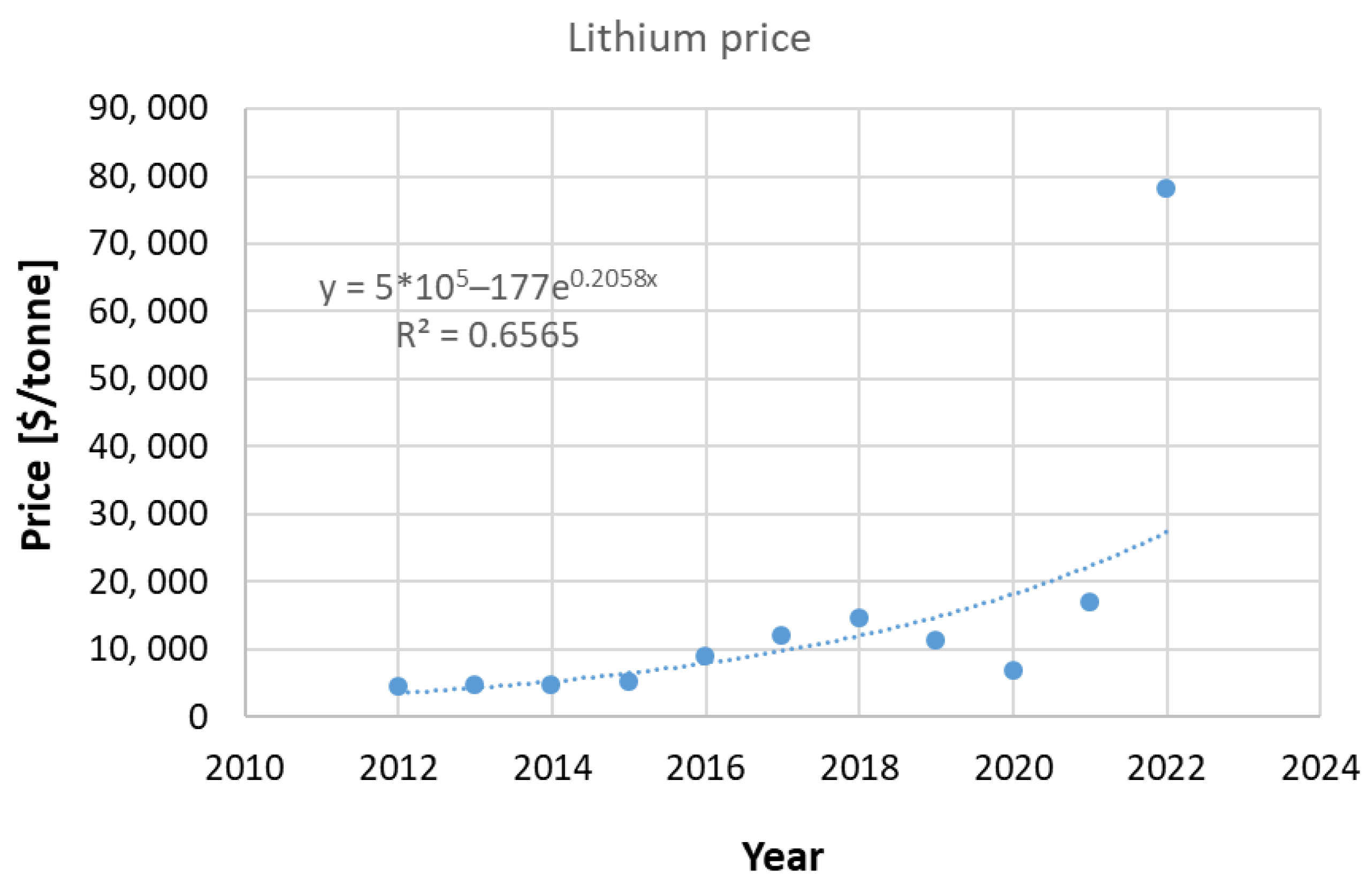

6. Lithium Production

- engine noise;

- rolling noise;

- aerodynamic noise.

7. Economical Aspects

- the shape of the Earth’s orbit, especially its eccentricity, because the Earth’s orbit around the Sun does not follow a perfect circle;

- angle of inclination of the Earth’s axis relative to the plane of the Earth’s orbit around the sun;

- the change in the angle of inclination of the axis of rotation in which the Earth’s axis is pointing is known as precession.

- ∘

- companies provide incorrect information about the features relating to its environmental impact [69]—lithium-ion batteries (acquisition of lithium related to environmental degradation—open-cast mining);

- ∘

- companies distort the actual impact of the product on the environment [70]—the ecological aspect is emphasised (electric cars do not emit exhaust fumes), but they do not mention that 80% of electricity in the EU is generated from burning fossil fuels, and no one can answer what will be done with used batteries in a few years;

- ∘

- companies omit certain information, the disclosure of which could undermine the “ecological” nature of the product (nonecological aspects of the production of lithium-ion batteries, excessive wear of car tyres and releases into the natural environment).

8. Conclusions

- Huge water consumption for the extraction of lithium from the ore, estimated at about 1890 litres per metric ton.

- Danger of toxic chemicals entering post-mining excavations and groundwater (lithium mining and extraction).

- Lithium mining (open-pit mining) can impact the environment, including fish that are human food up to 150 miles downstream.

- Possible contamination of crops in the lithium mining area.

- If hydrogen-based transportation should be applied globally, then it should be in the form of hydrogen internal combustion engine vehicles or using fuel cells. Pure hydrogen does not contain carbon; there are no carbon-based pollutants, such as carbon monoxide (CO), carbon dioxide (CO2) and hydrocarbons (HC), in the exhaust, as well as no problems with batteries.

9. Advantages and Disadvantages of Hydrogen Trains

9.1. Benefits

- No emission of substances other than water vapour;

- Hydrogen is plentiful and can be produced from renewable energy;

- Short refuelling times;

- Their potential as a two-mode train, which means that they can run on both electrified and conventional lines;

- Better fuel consumption, more efficient? It is probably about engine efficiency;

- No engine noise or visual pollution;

- There are no disturbances in the entire network due to the lack of infrastructure for electricity transmission.

9.2. Disadvantages

- The technology is currently expensive (investments required);

- Most of the energy used in the hydrogen extraction process currently comes from non-renewable sources;

- It requires storage of hydrogen under very high pressure on board (danger?);

- There are few places for refuelling, the need to expand the network;

- The hydrogen installation, which is currently located, for example, in the EMU, limits the number of people who can board the car;

- Currently, hydrogen trains are still dependent on virgin hydrogen and infrastructure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wahid, M.R.; Budiman, B.A.; Joelianto, E.; Aziz, M. A Review on Drive Train Technologies for Passenger Electric Vehicles. Energies 2021, 14, 6742. [Google Scholar] [CrossRef]

- Hurtová, I.; Sejkorová, M.; Verner, J.; Šarkan, B. Comparison of electricity and fossil fuel consumption in trolleybuses and bus. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018. [Google Scholar] [CrossRef]

- Hata, H. What Drives Electric Multiple Units? Railway Technology Today 4; Wako, K., Ed.; Japan Railway & Transport Review 17; EJRCF: Tokyo, Japan, 1998; pp. 40–47. [Google Scholar]

- Chinguwaa, S.; Nyembaa, W.R.; Ngondob, E.; Mbohwac, C. Development of an electric drive train for cycles as a sustainablemeans of transportation for a green environment. Procedia Manuf. 2019, 33, 91–98. [Google Scholar] [CrossRef]

- Pornet, C. Electric drives for propulsion system of transport aircraft, Chapter 5 in New application of electric drives. New Appl. Electr. Drives 2015, 9, 115–141. [Google Scholar]

- Favorsky, O.N. Thermal to Mechanical Energy Conversion: Engines and Requirements; Encyclopedia of Life Support Systems (EOLSS): Paris, France, 2009; ISBN 978-1-84826-021-4. Available online: http://www.eolss.net/sample-chapters/c08/e3-11.pdf (accessed on 5 April 2023).

- Mauro, S.; Şener, R.; Gül, M.Z.; Lanzafame, R.; Messina, M.; Brusca, S. Internal combustion engine heat release calculation using single-zone and CFD 3D numerical models. Int. J. Energy Environ. Eng. 2018, 9, 215–226. [Google Scholar] [CrossRef]

- Spitsov, O. Heat Transfer inside Internal Combustion Engine: Modelling and Comparison with Experimental Data. Master’s Thesis, Faculty of Technology, Lappeenranta University of Technology, Lappeenranta, Finland, 2013. [Google Scholar]

- Johansson, B. Path to High Efficiency Gasoline Engine. In Proceedings of the 2010 Directions in Engine-Efficiency and Emission Research (DEER), Detroit, Michigan, 27–30 September 2010. [Google Scholar]

- Hannu Jääskeläinen, Engine Efficiency. Available online: https://dieselnet.com/tech/engine_efficiency.php (accessed on 4 October 2022).

- Barbir, F. Pem Fuel Cells. In Theory And Practice, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Malinowski, A.M.; Iwan, G. Paściak, Właściwości elektryczne polimerowych ogniw paliwowych na bazie modyfikowanych elektrolitów. Przegląd Elektrotechniczny 2014, 90, 73–76. [Google Scholar]

- Odenweller, A.; Ueckerdt, F.; Nemet, G.F.; Jensterle, M.; Luderer, G. Probabilistic feasibility space of scaling up green hydrogen supply. Nat. Energy 2022, 7, 854–865. [Google Scholar] [CrossRef]

- Available online: https://www.ndr.de/der_ndr/presse/mitteilungen/Franzoesischer-Wirtschaftsminister-verbittet-sich-Kritik-an-franzoesischer-Atompolitik,pressemeldungndr23834.html (accessed on 5 April 2023).

- Fan, L.; Tu, Z.; Chan, S.H. Siew Hwa Chan, Recent development of hydrogen and fuel cell technologies: A review. Energy Rep. 2021, 7, 8421–8446. [Google Scholar] [CrossRef]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen Fuel Cell Vehicles; Current Status and Future Prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Ryan, P. O’Hayre, Fuel cells for electrochemical energy conversion. EPJ Web Conf. 2017, 148, 00013. [Google Scholar] [CrossRef]

- Sopena, D. Feve Hydrogen Tram. Presentation on I st Rail Technological Forum for Internationalization, 28 June 2011, Madrid, Spain. Available online: https://www.vialibre-ffe.com/pdf/Tranvia_hidrogeno_Feve.pdf (accessed on 5 April 2023).

- Khotseng, L. Fuel Cell Thermodynamics, Chapter in Thermodynamics and Energy Engineering; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Available online: https://www.heise.de/hintergrund/Gruener-Wasserstoff-in-der-Energiewende-Fokussierter-Einsatz-unverzichtbar-6193503.html?seite=all (accessed on 5 April 2023).

- Michael Liebreich, Liebreich Associates, Clean Hydrogen Ladder, Version 4.1, Concept Credit: Adrian Hiel, Energy Cities, 15 August 2021. Available online: https://www.linkedin.com/pulse/clean-hydrogen-ladder-v40-michael-liebreich/ (accessed on 5 April 2023).

- Wiącek, D. Wodór jako paliwo przyszłości. Autobusy 2011, 10, 446–452. [Google Scholar]

- Kalamaras, C.M.; Efstathiou, A.M. Hydrogen Production Technologies: Current State and Future Developments; Hindawi Publishing Corporation: London, UK, 2013. [Google Scholar] [CrossRef]

- Kozdra, D. Czy Polska ma Potencjał Wodorowy? Polskie Towarzystwo Studiów nad Przyszłością. Available online: https://ptsp.pl/czy-polska-ma-potencjal-wodorowy/ (accessed on 5 April 2023).

- Holladay, J.D.; Hu, J.; King, D.L.; Wang, Y. An overview of hydrogen production technologies. Catal. Today 2009, 139, 244–260. [Google Scholar] [CrossRef]

- Markowska, K.; Grudniak, A.M.; Wolska, K.I. Mikrobiologiczne ogniwa paliwowe: Podstawy technologii, jej ograniczenia i potencjalne zastosowania, POST. Mikrobiol 2013, 52, 29–40. [Google Scholar]

- Davis, J.B.; Yarbrough, H.F., Jr. Preliminary experiments on a microbial fuel cell. Science 1962, 137, 615–616. [Google Scholar] [CrossRef]

- Lovley, D.R. Microbial fuel cells: Novel microbial physiologies and engineering approaches. Curr. Opin. Biotechnol. 2006, 17, 327–332. [Google Scholar] [CrossRef]

- Skłodowska, M. Europa chce mieć swoją „zieloną bombę wodorową”, Wysokie Napięcie 21 May 2020. Available online: https://wysokienapiecie.pl/29265-czy-tania-zielona-energia-przyblizy-nam-zielony-wodor/ (accessed on 5 April 2023).

- Available online: https://www.tuev-nord.de (accessed on 5 April 2023).

- Spiegel, C.S. Designing and Building Fuel Cells, 1st ed.; McGraw-Hill: New York, NY, USA, 2007. [Google Scholar]

- Rajeshwar, K.; McConnell, R.; Licht, S. Solar Hydrogen Generation: Toward a Renewable Energy Future, 1st ed.; Springer: New York, NY, USA, 2008. [Google Scholar]

- Muradov, N.Z.; Veziroǧlu, T.N. From hydrocarbon to hydrogen-carbon to hydrogen economy. Int. J. Hydrogen Energy 2005, 30, 225–237. [Google Scholar] [CrossRef]

- Gimpel, J.A.; Specht, E.A.; Georgianna, D.R.; Mayfield, S.P. Advances in microalgae engineering and synthetic biology applications for biofuel production. Curr. Opin. Chem. Biol. 2013, 17, 489–495. [Google Scholar] [CrossRef]

- Hemschemeier, A.; Melis, A.; Happ, T. Analytical approaches to photobiological hydrogen production in unicellular green algae. Photosynth. Res. 2009, 102, 23–540. [Google Scholar] [CrossRef]

- Dudek, M.; Dębowski, M.; Grala, A.; Zieliński, M.; Rokicka, M.; Kupczyk, K. Produkcja wodoru w procesach biologicznych prowadzonych przez glony. Interdyscyplinarne Zagadnienia W Inżynierii I Ochrronie Sr. 2014, 4, 199–211. [Google Scholar]

- Kilner, J. Hydrogen Production Methods and its Colours. Available online: https://cicenergigune.com/en/blog/hydrogen-production-methods-colours (accessed on 5 April 2023).

- Howarth, R.W.; Jacobson, M.Z. How green is blue hydrogen? Energy Sci. Eng. 2021, 9, 1676–1687. [Google Scholar] [CrossRef]

- Szypulski, P. Wodór “Brudniejszy” od Węgla? Alarmujący Raport Naukowców! 17 February 2022. Available online: https://www.auto-swiat.pl/wiadomosci/aktualnosci/wodor-brudniejszy-od-wegla-alarmujacy-raport-naukowcow/fpy3n3h (accessed on 5 April 2023).

- Burridge, T. All Aboard Britain’s First Hydrogen Train. BBC News. Available online: https://www.bbc.com/news/business-48698532 (accessed on 5 April 2023).

- Ritter, M. Hydrogen for Regio Trains. Available online: https://www.fch.europa.eu/sites/default/files/default_images/8.%20Michael%20Ritter_170515_hydrogen%20for%20regio%20trains_v01%20%28ID%202902215%29.pdf (accessed on 5 April 2023).

- Dąbrowski, K.M.; Zając, M.; Kozieł, K.A. Koncepcja Pozyskania Litu ze Złóż wód Termalnych z Wykorzystaniem Technologii Membranowych, Nauka-Technika-Technologia, 2nd ed.; Seria wydawnicza AGH: Kraków, Poland, 2021; pp. 31–44. [Google Scholar]

- Flexer, V.; Baspineiro, C.F.; Galli, C. Lithium recovery from brines: A vital raw material for green energies with a potential environmental impact in its mining and processing. Sci. Total Environ. 2018, 639, 1188–1204. [Google Scholar] [CrossRef]

- Szlugaj, J.; Radwanek-Bąk, B. Lithium sources and their current use. Gospod. Surowcami Miner. 2022, 38, 61–88. [Google Scholar]

- Coburn, K. The True Costs of Lithium Extraction: A Grim Reality for EV Owners. Available online: https://www.industrial-innovation.com/true-costs-lithium-extraction-grim-reality-ev-owners/ (accessed on 23 November 2022).

- Vertruyen, B.; Eshraghi, N.; Piffet, C.; Bodart, J.; Mahmoud, A.; Boschini, F. Spray-Drying of Electrode Materials for Lithium- and Sodium-Ion Batteries. Materials 2018, 11, 1076. [Google Scholar] [CrossRef] [PubMed]

- Palagonia, M.S.; Brogioli, D.; La Mantia, F. Lithium recovery from diluted brine by means of electrochemical ion exchange in a flow-through-electrodes cell. Desalination 2020, 475, 114192. [Google Scholar] [CrossRef]

- Malinowski, D. Wojna o Ten Metal już Trwa. Jego Ceny Biją Rekordy. Available online: https://www.wnp.pl/hutnictwo/wojna-o-ten-metal-juz-trwa-jego-ceny-bija-rekordy,621755.html (accessed on 9 November 2022).

- Available online: https://twitter.com/stats_feed/status/1512445210097160195?ref_src=twsrc%5Etfw%7Ctwcamp%5Etweetembed%7Ctwterm%5E1512445210097160195%7Ctwgr%5E9c6df844da3c10467c1df29e5a05f0fa7df57cfa%7Ctwcon%5Es1_&ref_url=https%3A%2F%2Fpulsembed.eu%2Fp2em%2FYqFQGm5LO%2F (accessed on 15 November 2022).

- Brown, T.; Walters, A.; Idoine, N.; Gunn, G.; Shaw, R.A. Lithium Profile. British Geol. Survey. 2016. Available online: https://www.bgs.ac.uk/news/mineral-profile-lithium/ (accessed on 12 November 2011).

- Świderek, T. Electric Cars Drive the Price of Lithium. Available online: https://www.obserwatorfinansowy.pl/in-english/business/electric-cars-drive-the-price-of-lithium/ (accessed on 23 November 2022).

- PolsatNews: Dzieci Wydobywają Kobalt Gołymi Rękami. Zarabiają Dolara Dziennie. 26 December 2020. Available online: https://www.polsatnews.pl/wiadomosc/2020-12-26/dzieci-wydobywaja-kobalt-golymi-rekami-zarabiaja-dolara-dziennie/ (accessed on 5 April 2023).

- Gdzie Piękna TESLA, a Gdzie Ponura Katanga. Available online: https://mlodytechnik.pl/technika/29278-gdzie-piekna-tesla-a-gdzie-ponura-katanga (accessed on 5 April 2023).

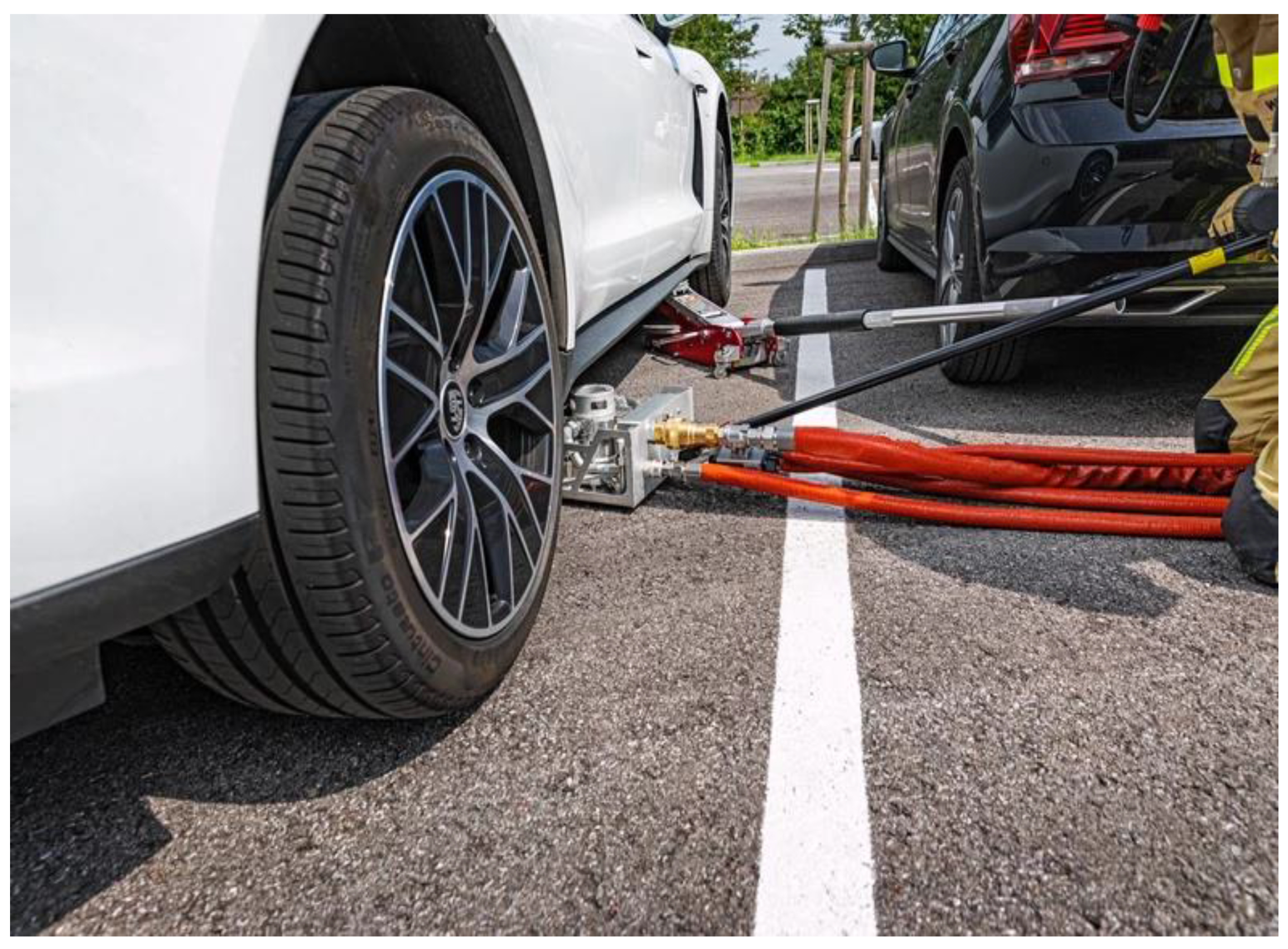

- Szypulski, P. Pożary aut Elektrycznych: Żeby Powstrzymać Ogień, Potrzeba Tysięcy Litrów Wody! Available online: https://www.auto-swiat.pl/ev/porady/pozary-aut-elektrycznych-jak-czesto-pala-sie-samochody-elektryczne-jak-ugasic-plonacy/t30mw5w (accessed on 24 November 2022).

- Buliński, F. Pożar Elektryka to Spory Problem. Francuzi Mają Patent, jak go Ugasić w 5 Minut. Available online: https://e.autokult.pl/pozar-elektryka-to-spory-problem-francuzi-maja-patent-jak-go-ugasic-w-5-min,6807673940682369a (accessed on 24 November 2022).

- Kamiński, M. Jak Ugasić Palące się auto Elektryczne? Nowe Sposoby Gaszenia Akumulatorów. Available online: https://www.auto-swiat.pl/ev/wiadomosci/jak-ugasic-palace-sie-auto-elektryczne-nowe-sposoby-gaszenia-akumulatorow/44x0dh6#slajd-1 (accessed on 24 November 2022).

- Urbańska, W.; Osial, M. Możliwości Odzyskiwania litu i Kobaltu Zawartych w Proszku Elektrodowym ze Zużytych Akumulatorów litowo-Jonowych MEtodą Kwaśnego Ługowania–stan Aktualny i Kierunki Rozwoju, Innowacyjna Zielona Gospodarka; Główny Instytut Górnictwa: Katowice, Poland, 2021; p. 36. [Google Scholar]

- Available online: https://elektrowoz.pl/auta/ile-wazy-bateria-tesla-roadster-2-okolo-08-12-tons-and-that's why-the-car-accelerates-in-19-seconds-to-60-mph/ (accessed on 5 April 2023).

- Masset, T.; Ferrari, B.J.D.; Oldham, D.; Dudefoi, W.; Minghetti, M.; Schirmer, K.; Bergmann, A.; Vermeirssen, E.; Breider, F. In Vitro Digestion of Tire Particles in a Fish Model (Oncorhynchus mykiss): Solubilization Kinetics of Heavy Metals and Effects of Food Coingestion. Environ. Sci. Technol. 2021, 55, 15788–15796. [Google Scholar] [CrossRef]

- Parker, B.W.; Beckingham, B.A.; Ingram, B.C.; Ballenger, J.C.; Weinstein, J.E.; Sancho, G. Microplastic and Tire Wear Particle Occurrence in Fishes from an Urban Estuary: Influence of Feeding Characteristics on Exposure Risk. Mar. Pollut. Bull. 2020, 160, 111539. [Google Scholar] [CrossRef] [PubMed]

- Clausen, U.; Doll, C.; Franklin, F.J.; Franklin, G.V.; Heinrichmeyer, H.; Kochsiek, J.; Rothengatter, W.; Siebero, N. Graniczenie Hałasu Kolejowego; Dyrekcja Generalna Ds. Polityk Wewnętrznych Unii; PE 2012. Available online: https://www.europarl.europa.eu/RegData/etudes/etudes/join/2012/474533/IPOL-TRAN_ET(2012)474533(SUM01)_PL.pdf (accessed on 5 April 2023).

- Polak, K. Sposoby minimalizacji emisji hałasu kolejowego w aglomeracji miejskiej. Autobusy 2018, 6, 221–225. [Google Scholar]

- Bethoux, O. Hydrogen Fuel Cell Road Vehicles: State of the Art and Perspectives. Energies 2020, 13, 5843. [Google Scholar] [CrossRef]

- Available online: https://www.aktien.investoren-wissen.de/megatrend-wasserstoff/?af=SEM_I_TD_GAW_OA_Megatrend-Wasserstoff_X-Suche-1&gclid=CjwKCAiA85efBhBbEiwAD7oLQMAJjaYU6N0DcwNjou8-RaBiC94ZMPmRTCl-MEQl4uTKUWGmZLjEixoCGFMQAvD_BwE (accessed on 5 April 2023).

- Available online: https://www.freiepresse.de/erfahrungen/trading/aktien/wasserstoff/ (accessed on 5 April 2023).

- Buis, A. Milankovitch (Orbital) Cycles and Their Role in Earth’s Climate, 27 February 2020. Available online: https://climate.nasa.gov/news/2948/milankovitch-orbital-cycles-and-their-role-in-earths-climate/ (accessed on 5 April 2023).

- Campis, C.J. Milankovitch Cycles, Paleoclimatic Change, and Hominin Evolution. Nat. Educ. Knowl. 2012, 4, 5. [Google Scholar]

- Available online: https://dictionary.cambridge.org/dictionary/english/greenwashing (accessed on 5 April 2023).

- Udrycka, K. Greenwashing. Zielone Pranie Mózgu. Available online: https://magazynpismo.pl/idee/katarzyna-udrycka-greenwashing-zielone-pranie-mozgu/?seo=pw; 6.12.2022 (accessed on 23 March 2023).

- Białas, K. Ekościema” w Marketingu, Czyli Czym jest Greenwashing. Available online: https://kaizenads.pl/marketing/ekosciema-w-marketingu-czyli-czym-jest-greenwashing/ 30.01.2023 (accessed on 23 March 2023).

- Innowacyjne Technologie dla Ekologicznego Transport; Company Information Brochure Medcom Electrify; MEDCOM: Warszawa, Poland, 2022.

- Updated: Electric Car Battery Replacement Costs. Available online: https://www.recurrentauto.com/research/costs-ev-battery-replacement (accessed on 26 March 2023).

- National Transportation Safety Board. Safety Risks to Emergency Responders from Lithium-Ion Battery Fires in Electric Vehicles; Safety Report NTSB/SR-20/01; National Transportation Safety Board: Washington, DC, USA, 2020. Available online: https://www.ntsb.gov/safety/safety-studies/Documents/SR2001.pdf (accessed on 5 April 2023).

- Szypulski, P. Elektrykiem i Hybrydą nie Wjedziesz na Prom? Pierwszy Armator Podjął Decyzję, Auta Świat, 19 January 2023. Available online: https://www.auto-swiat.pl/wiadomosci/aktualnosci/zakaz-wjazdu-autami-elektrycznymi-i-hybrydowymi-na-promy-pierwszy-przewoznik-zakazuje/y0dzqdg (accessed on 5 April 2023).

- Michałowski, I. Wprowadzono Zakaz Parkowania dla Samochodów Elektrycznych w Garażu Podziemnym, 29 April 2023. Available online: https://legaartis.pl/blog/2023/04/29/wprowadzono-zakaz-parkowania-dla-samochodow-elektrycznych-w-garazu-podziemnym/ (accessed on 5 April 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konieczny, J.; Labisz, K.; Surma, S.; Młyńczak, J.; Łukasik, J.; Boris, R.; Grzybowski, M. Hydrogen or Electric Drive—Inconvenient (Omitted) Aspects. Energies 2023, 16, 4400. https://doi.org/10.3390/en16114400

Konieczny J, Labisz K, Surma S, Młyńczak J, Łukasik J, Boris R, Grzybowski M. Hydrogen or Electric Drive—Inconvenient (Omitted) Aspects. Energies. 2023; 16(11):4400. https://doi.org/10.3390/en16114400

Chicago/Turabian StyleKonieczny, Jarosław, Krzysztof Labisz, Szymon Surma, Jakub Młyńczak, Jerzy Łukasik, Renata Boris, and Michał Grzybowski. 2023. "Hydrogen or Electric Drive—Inconvenient (Omitted) Aspects" Energies 16, no. 11: 4400. https://doi.org/10.3390/en16114400

APA StyleKonieczny, J., Labisz, K., Surma, S., Młyńczak, J., Łukasik, J., Boris, R., & Grzybowski, M. (2023). Hydrogen or Electric Drive—Inconvenient (Omitted) Aspects. Energies, 16(11), 4400. https://doi.org/10.3390/en16114400